Electromagnetic Pulse Welding of Tubular Products: Influence of Process Parameters and Workpiece Geometry on the Joint Characteristics and Investigation of Suitable Support Systems for the Target Tube

Abstract

:1. Introduction

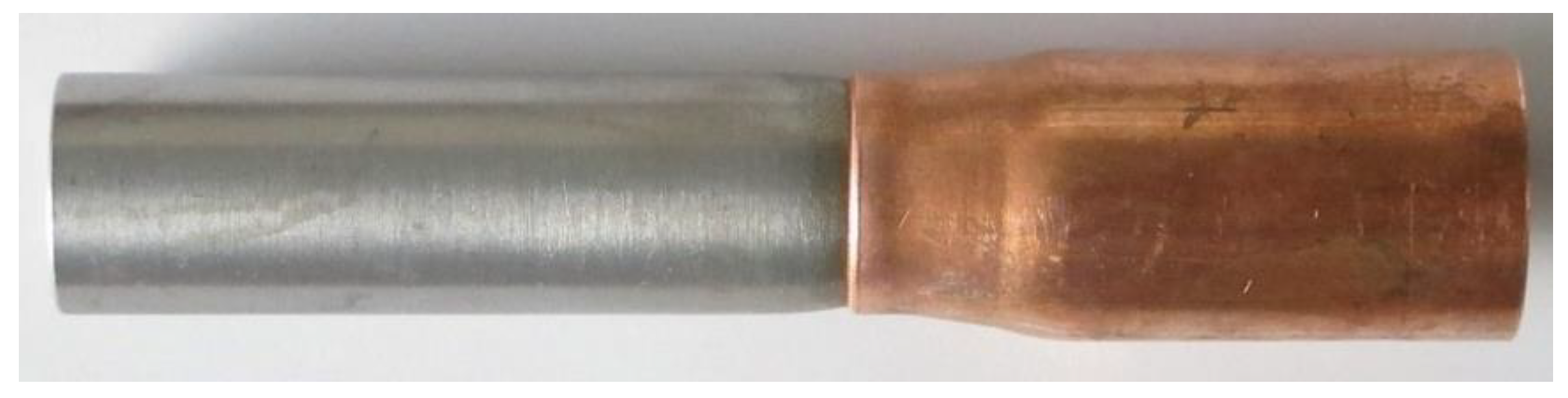

2. Materials and Methods

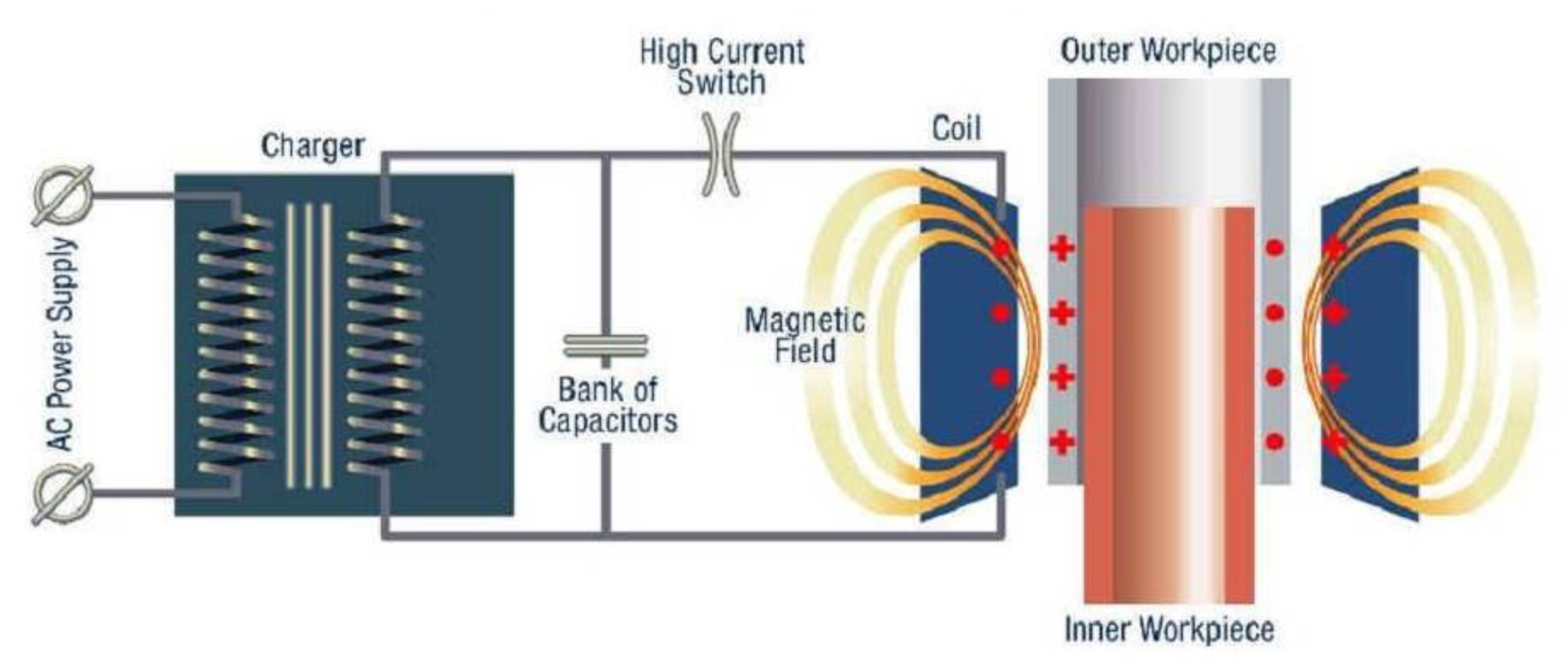

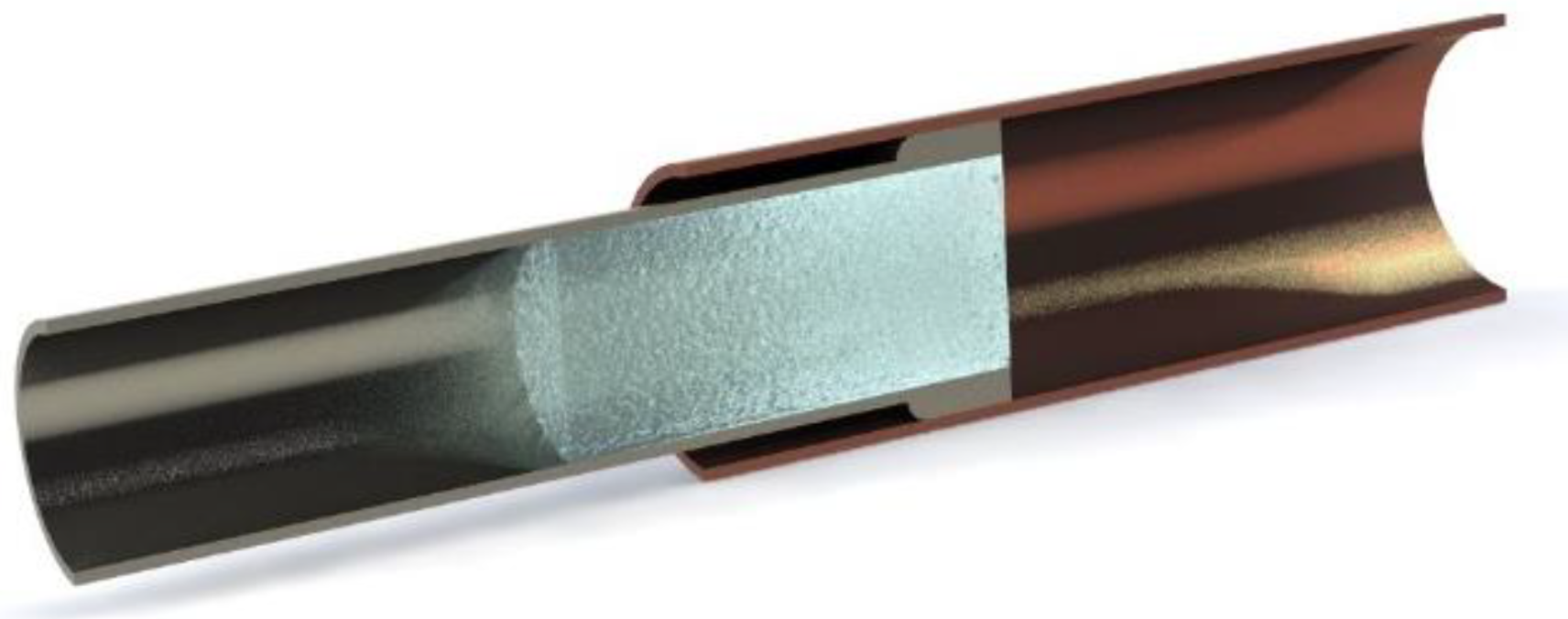

2.1. Working Principle of Electromagnetic Pulse Welding

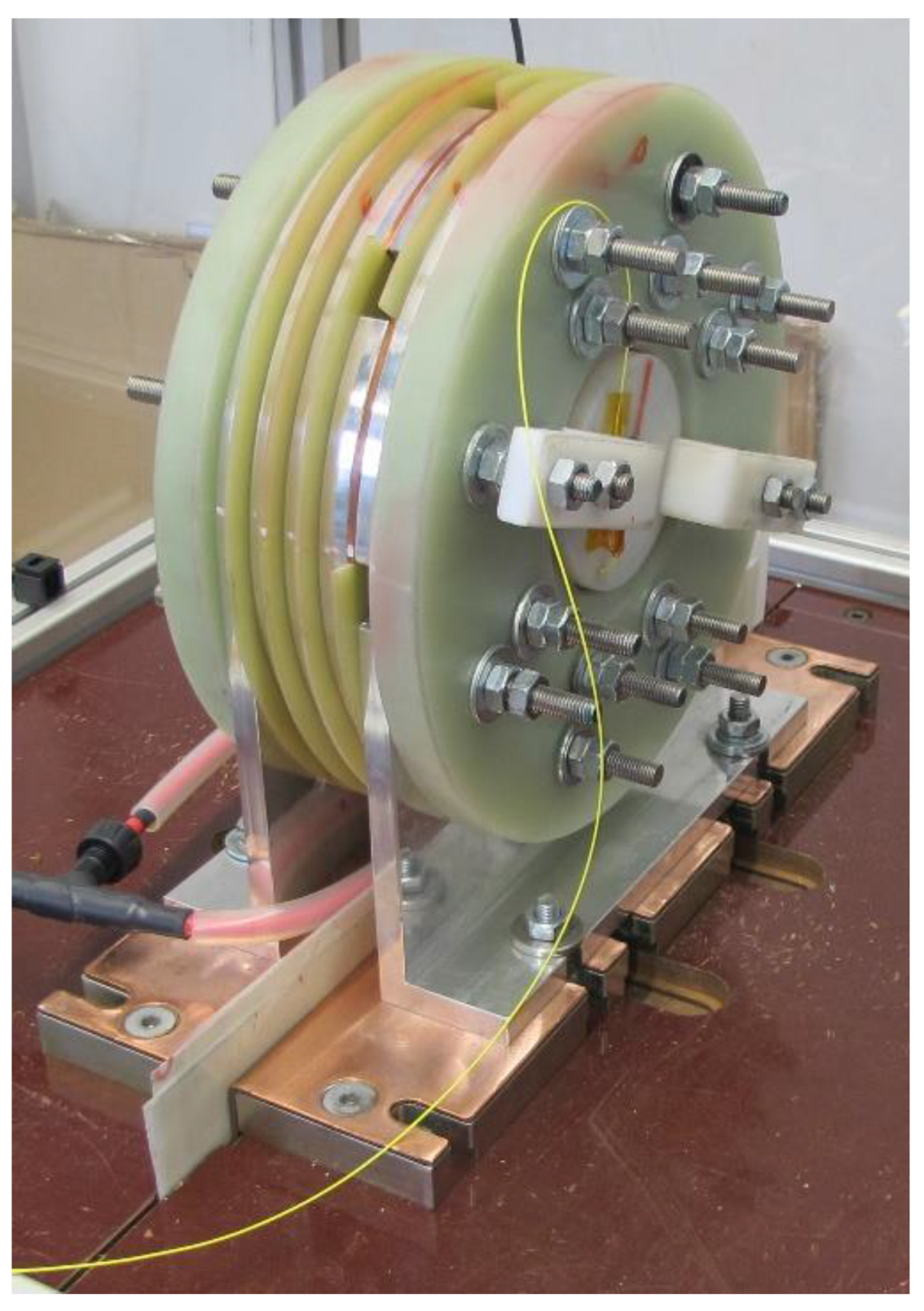

2.2. Set-Up of the Electromagnetic Pulse Welding System

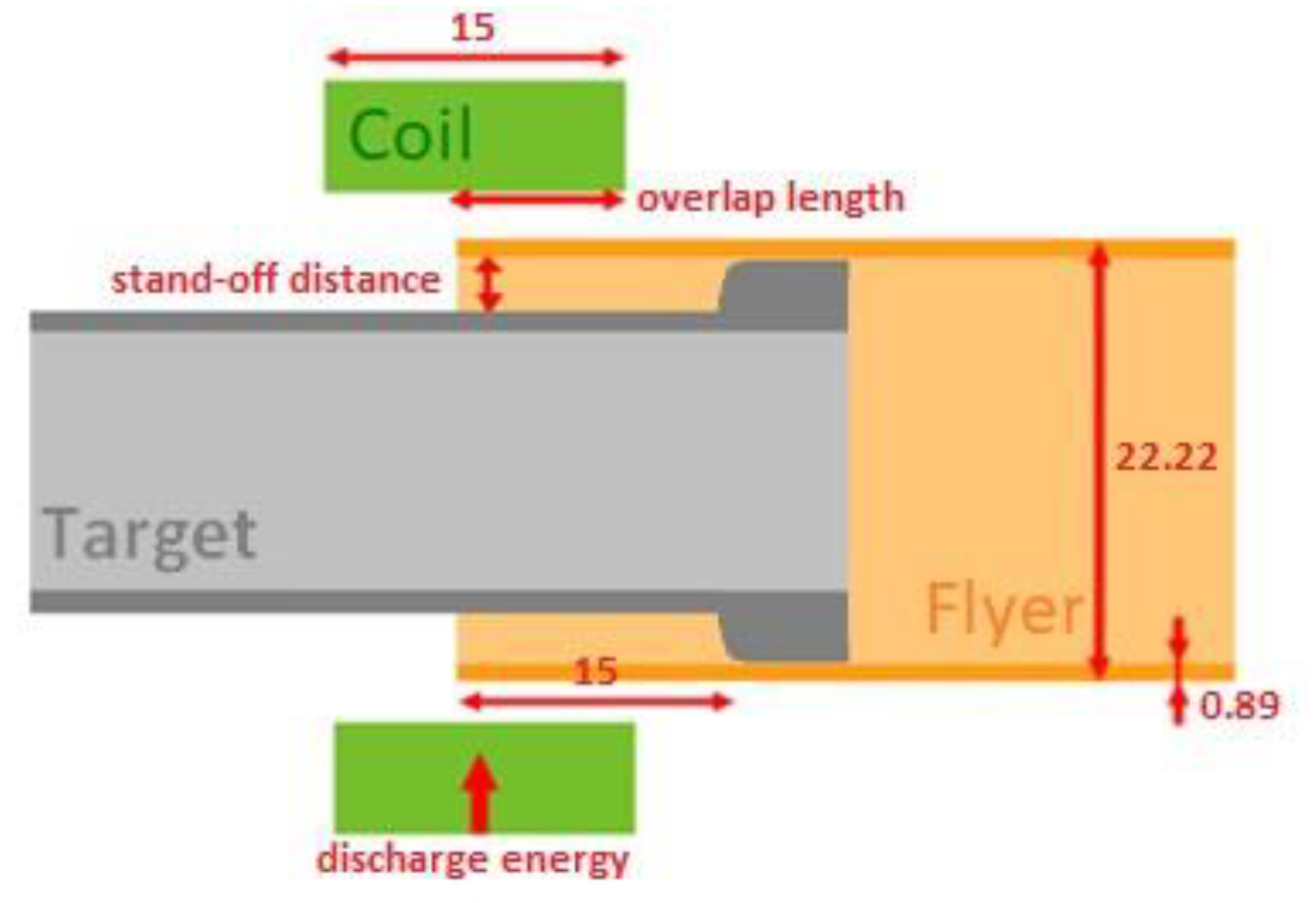

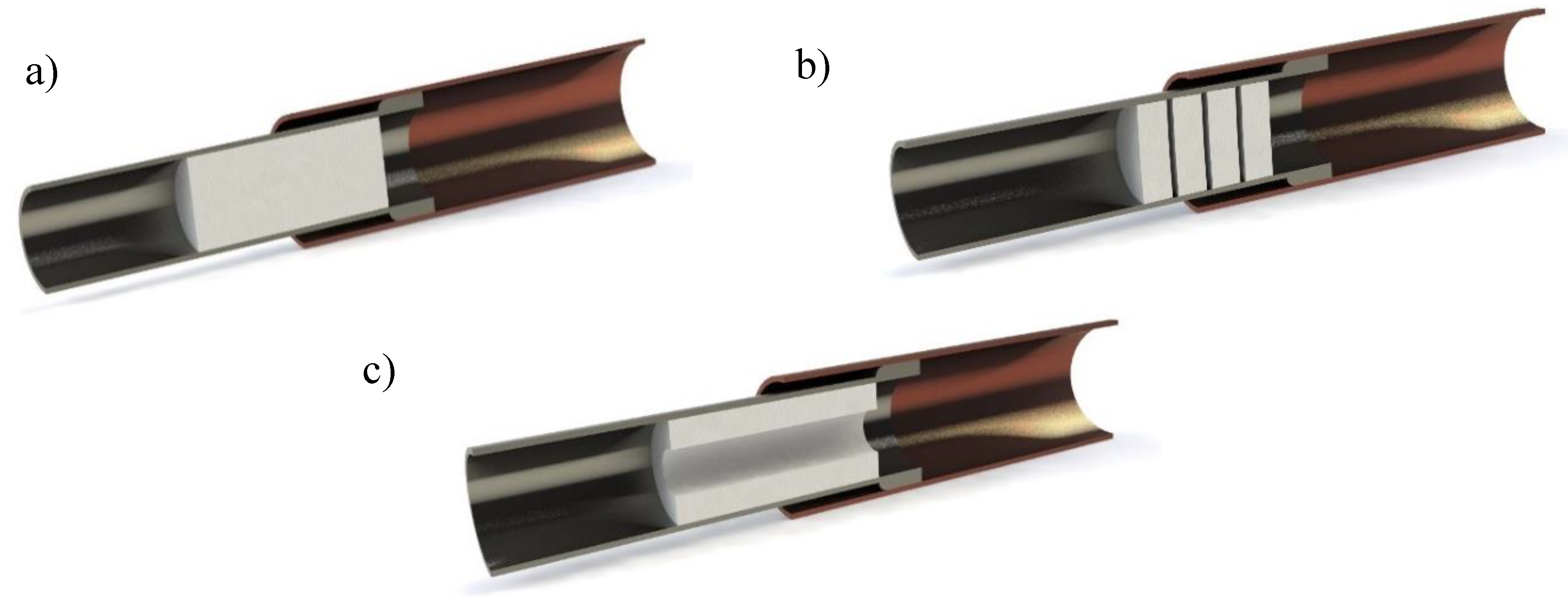

2.3. Materials and Dimensions

2.4. Weld Characterisation Methods

2.4.1. Leak Test with Air

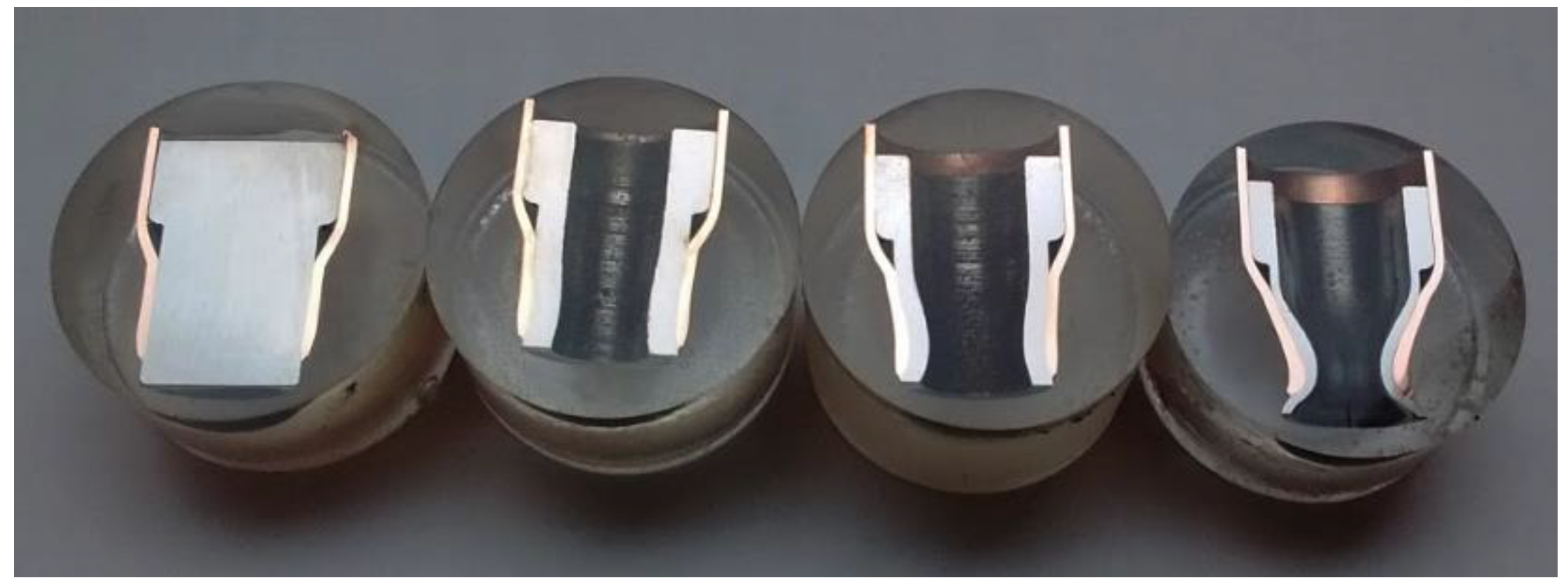

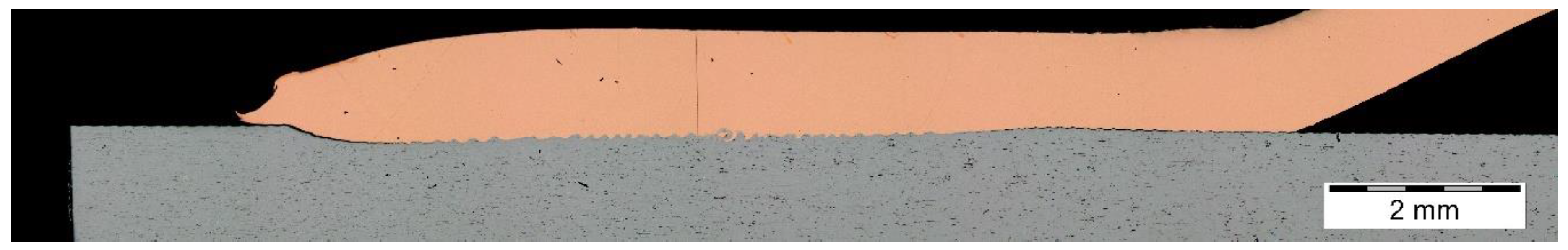

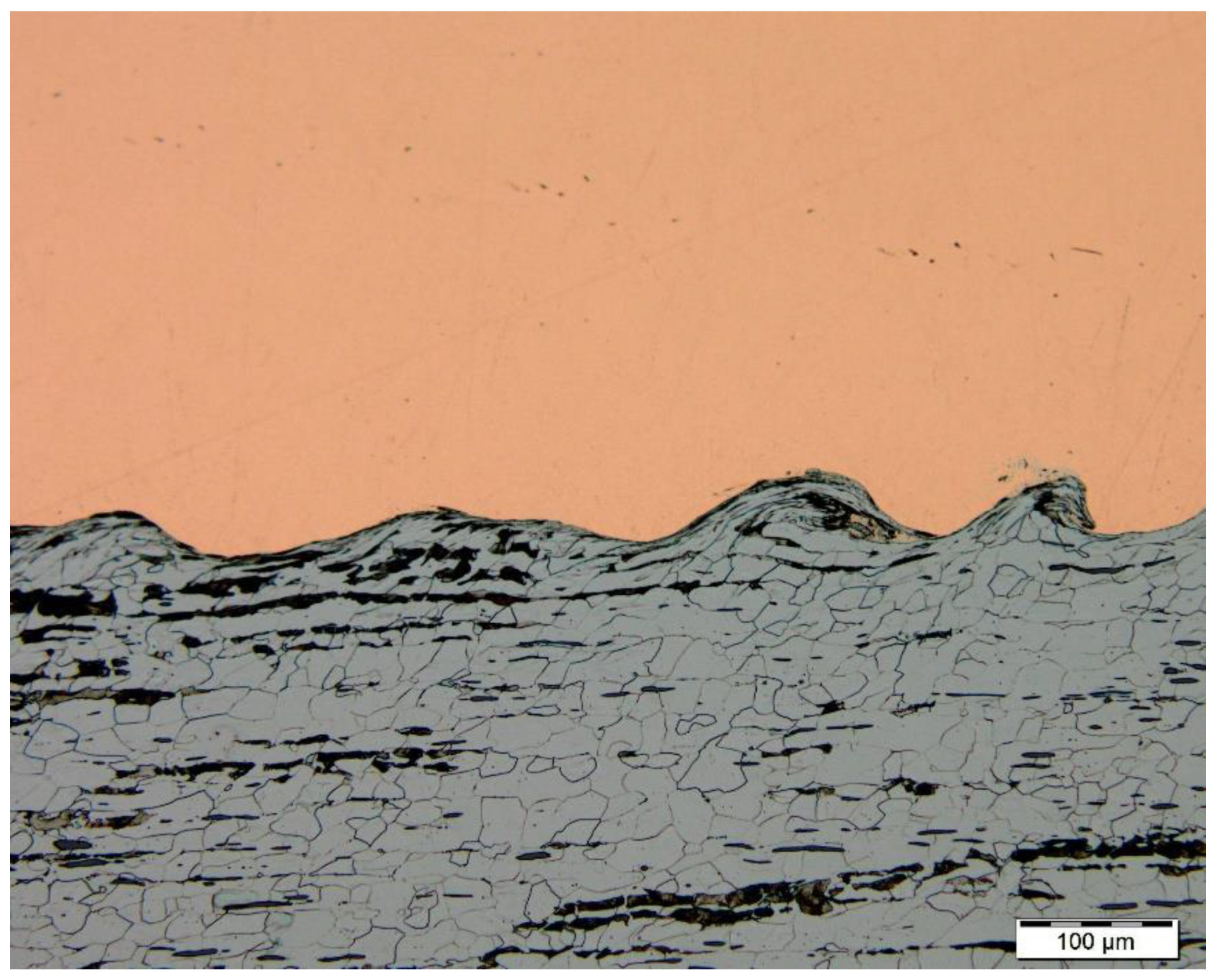

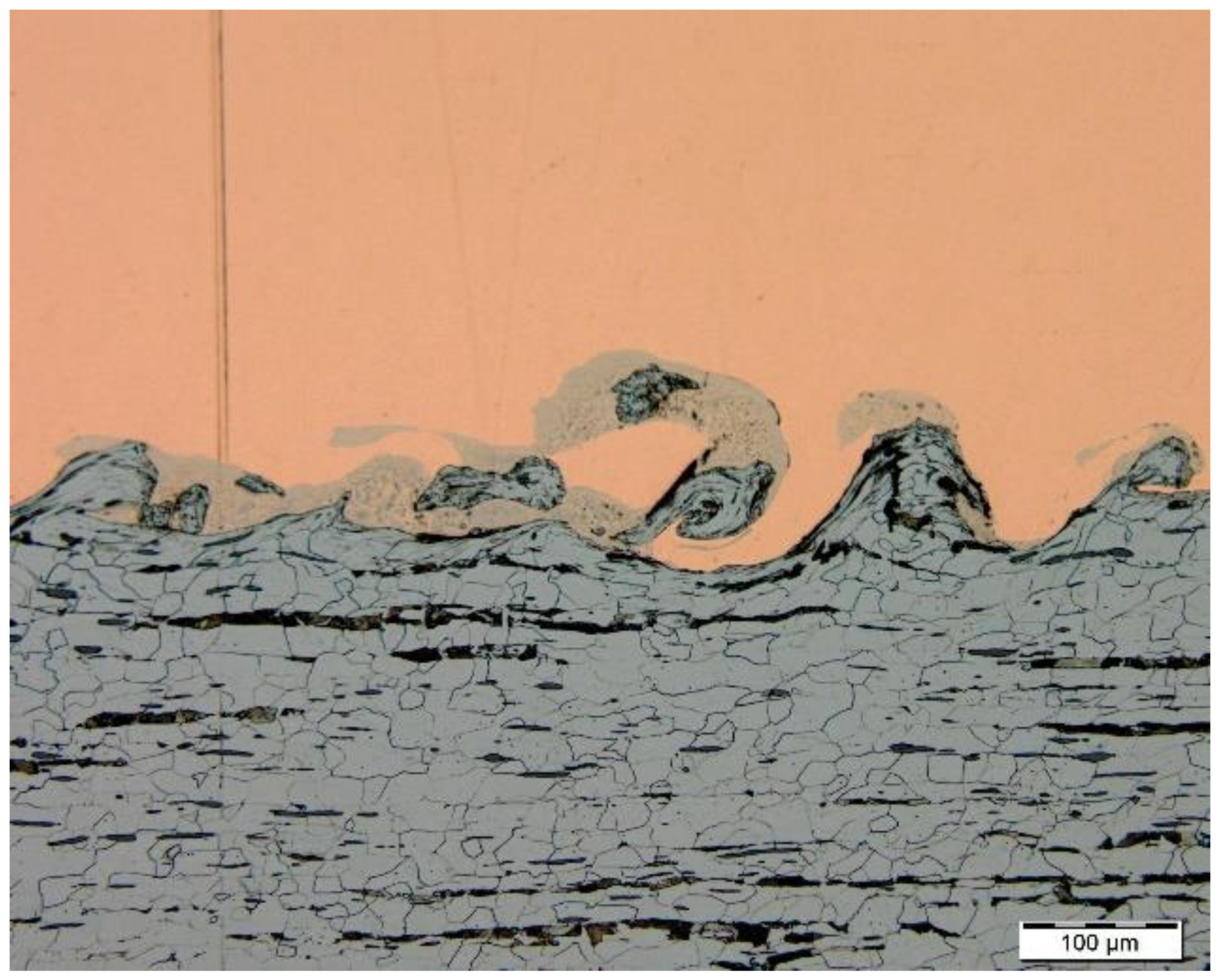

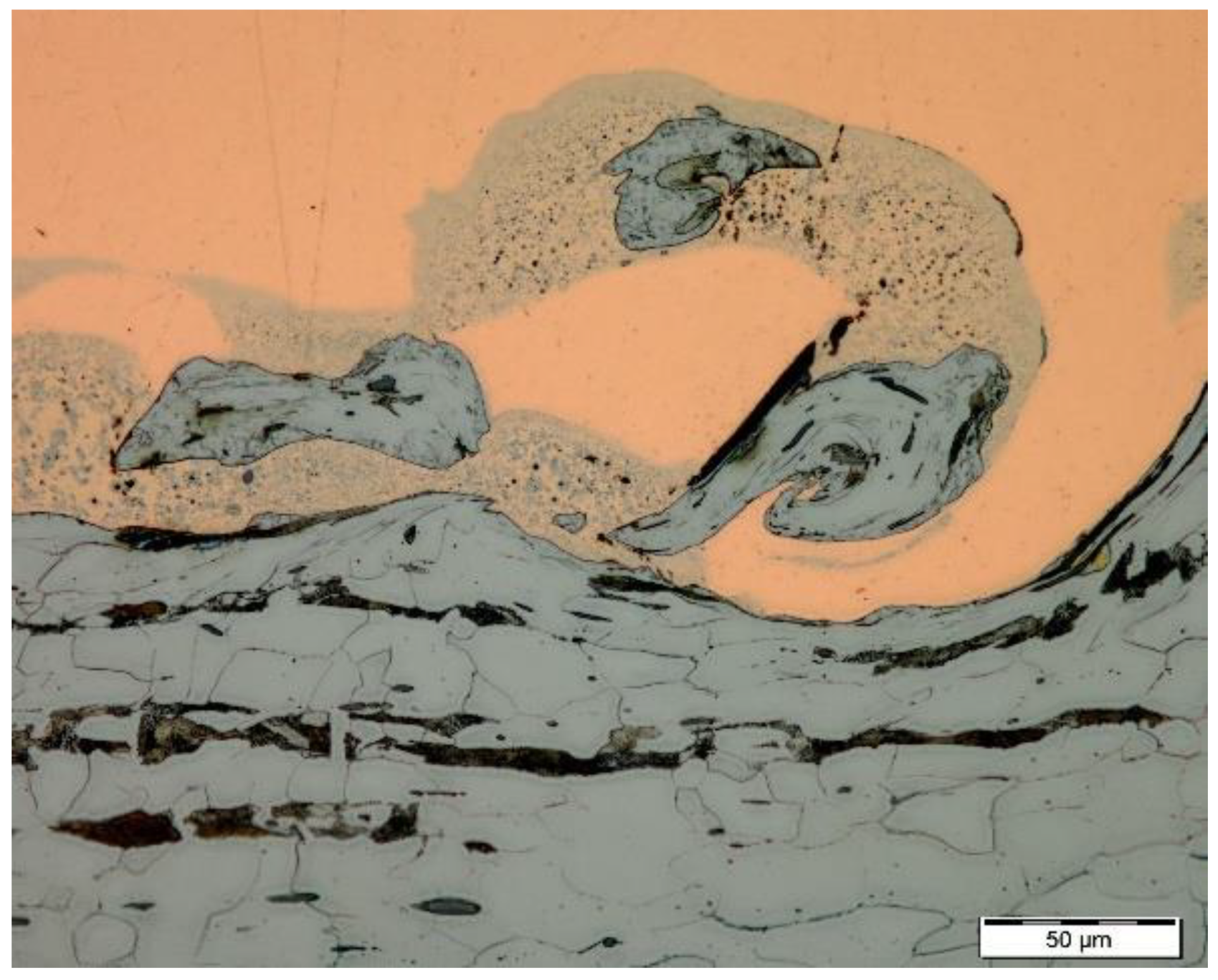

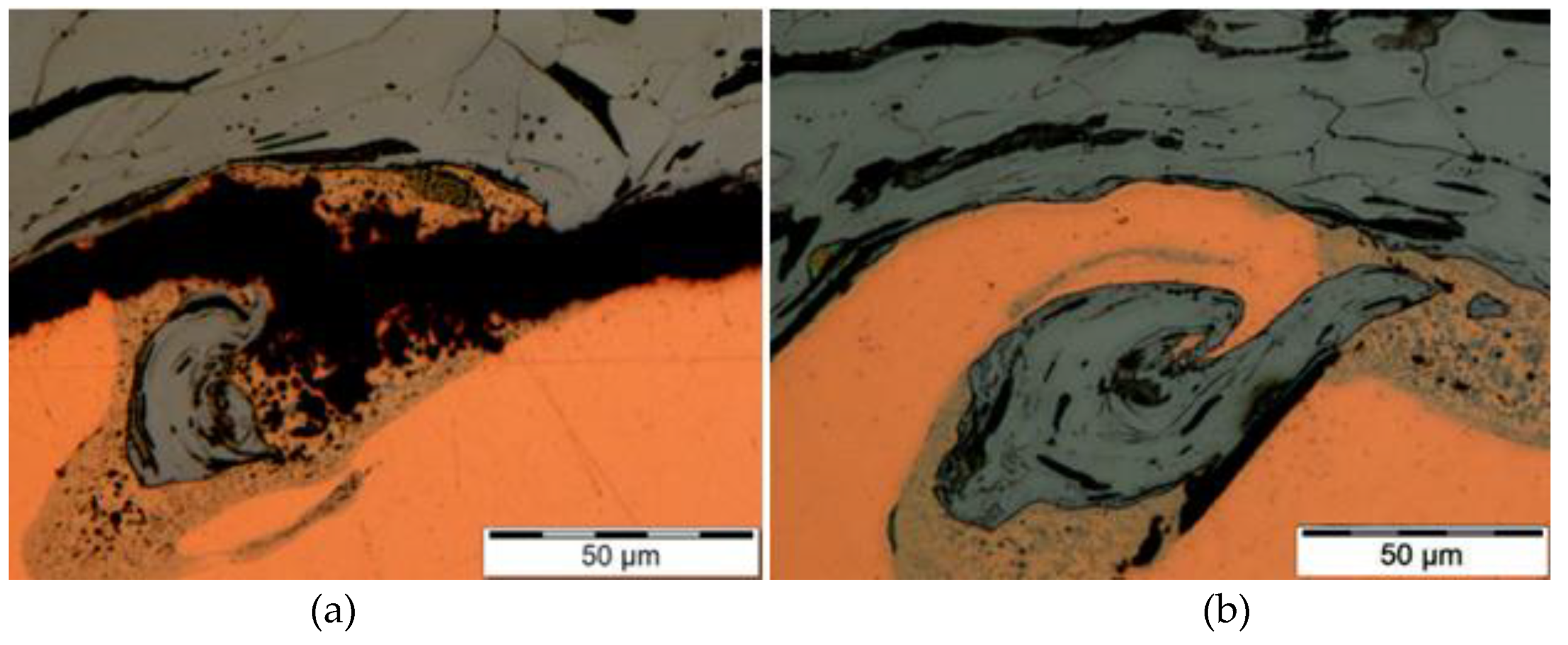

2.4.2. Metallographic Examination

- ●

- L1: the measured weld length near the field shaper cut,

- ●

- L2: the weld length at 180° relative to the field shaper cut,

- ●

- A: a parameter that is equal to:

- ○

- 0: if both locations contain a welded interface,

- ○

- 1: if only one location contains a welded interface (other location is for example cracked),

- ○

- 2: if at both locations no weld formation is observed.

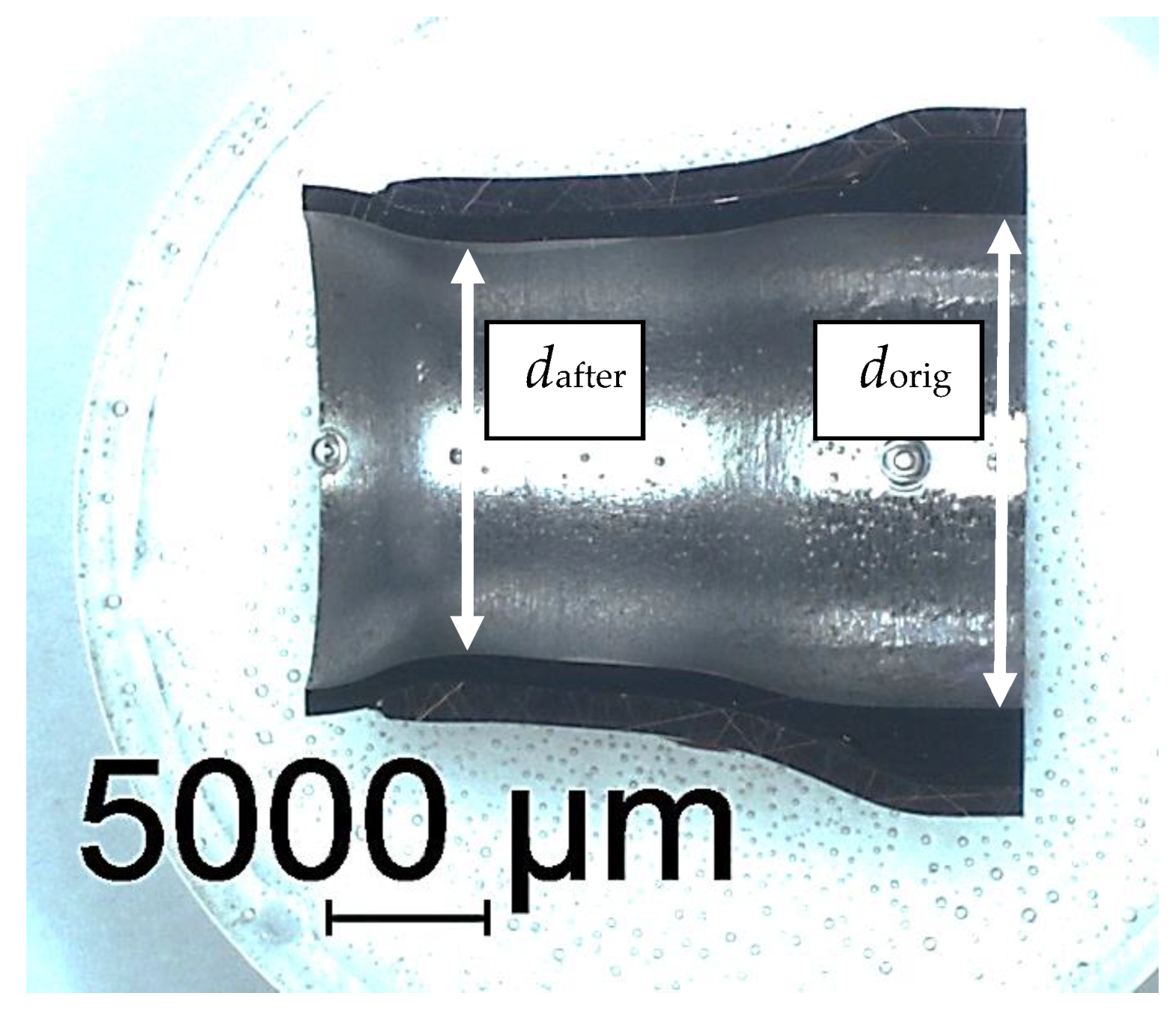

2.4.3. Reduction of the Internal Diameter of the Target Tube

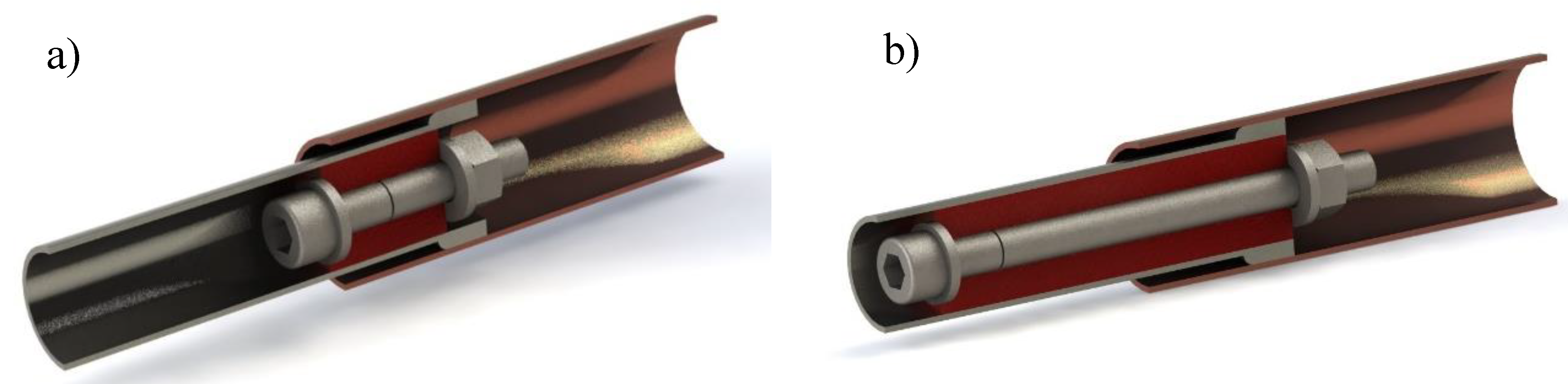

2.5. Internal Supports for the Target Tubes

3. Results

3.1. Overview of Experimental Work

- First phase: Influence of the process parameters and the workpiece geometry on the weld formation and joint characteristics. For this purpose, experiments were performed using target rods as a reference and target tubes with wall thicknesses of 1, 2 and 3 mm, without internal support. The purpose was to investigate the effect of the target tube wall thickness on the joint characteristics and the deformation of the target tube during welding. Also, tube-to-tube joints with a target tube with a wall thickness of 1 mm were manufactured using an internal PU-support for comparison.

- Second phase: Investigation of suitable support systems for the target tube with a wall thickness of 1 mm

3.2. Influence of the Process Parameters and the Workpiece Geometry on the Joint Characteristics

3.2.1. Range of Weld Lengths and Reduction of the Inner Diameter of Leak Tight Welds

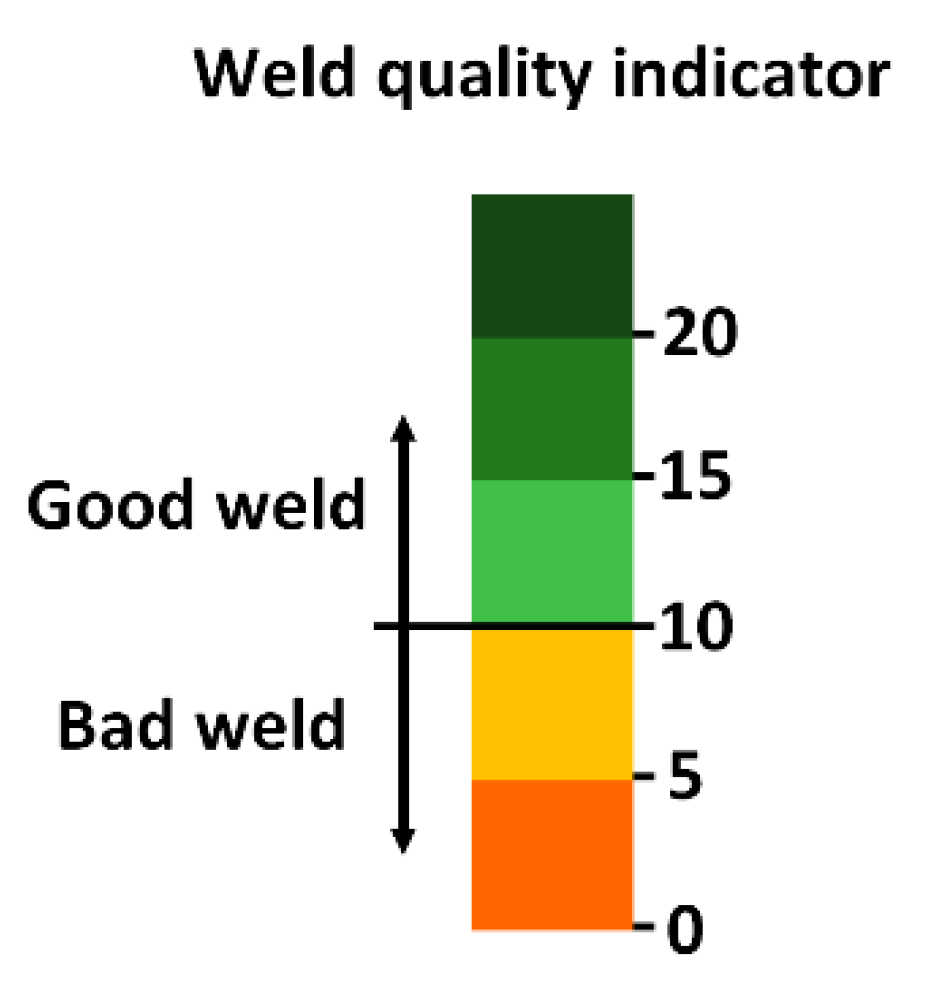

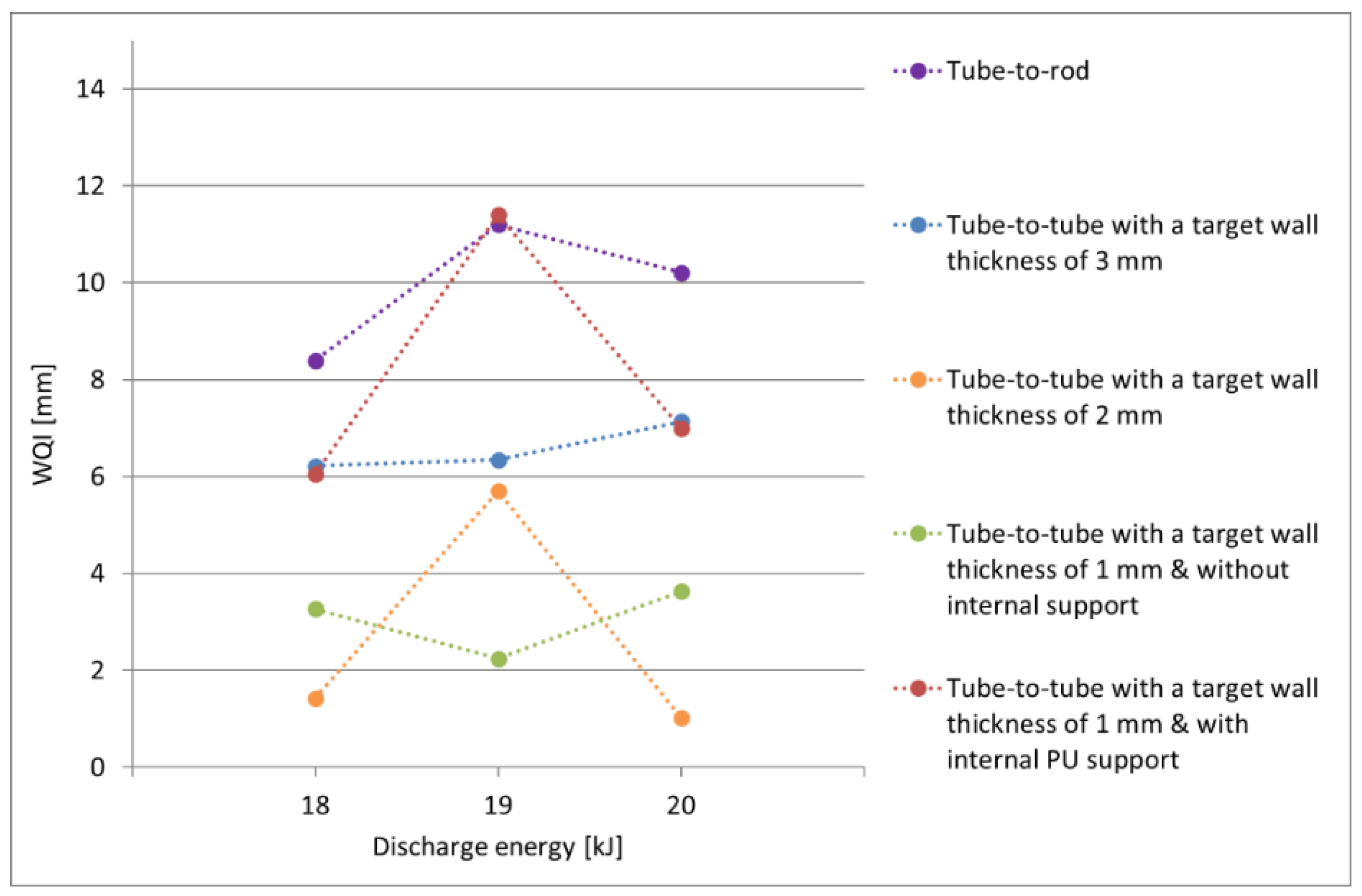

3.2.2. Influence of the Welding Parameters and the Wall Thickness of the Target Tube on the WQI

3.2.3. Influence of the Welding Parameters and the Wall Thickness of the Target Tube on the Deformation of the Target Tube

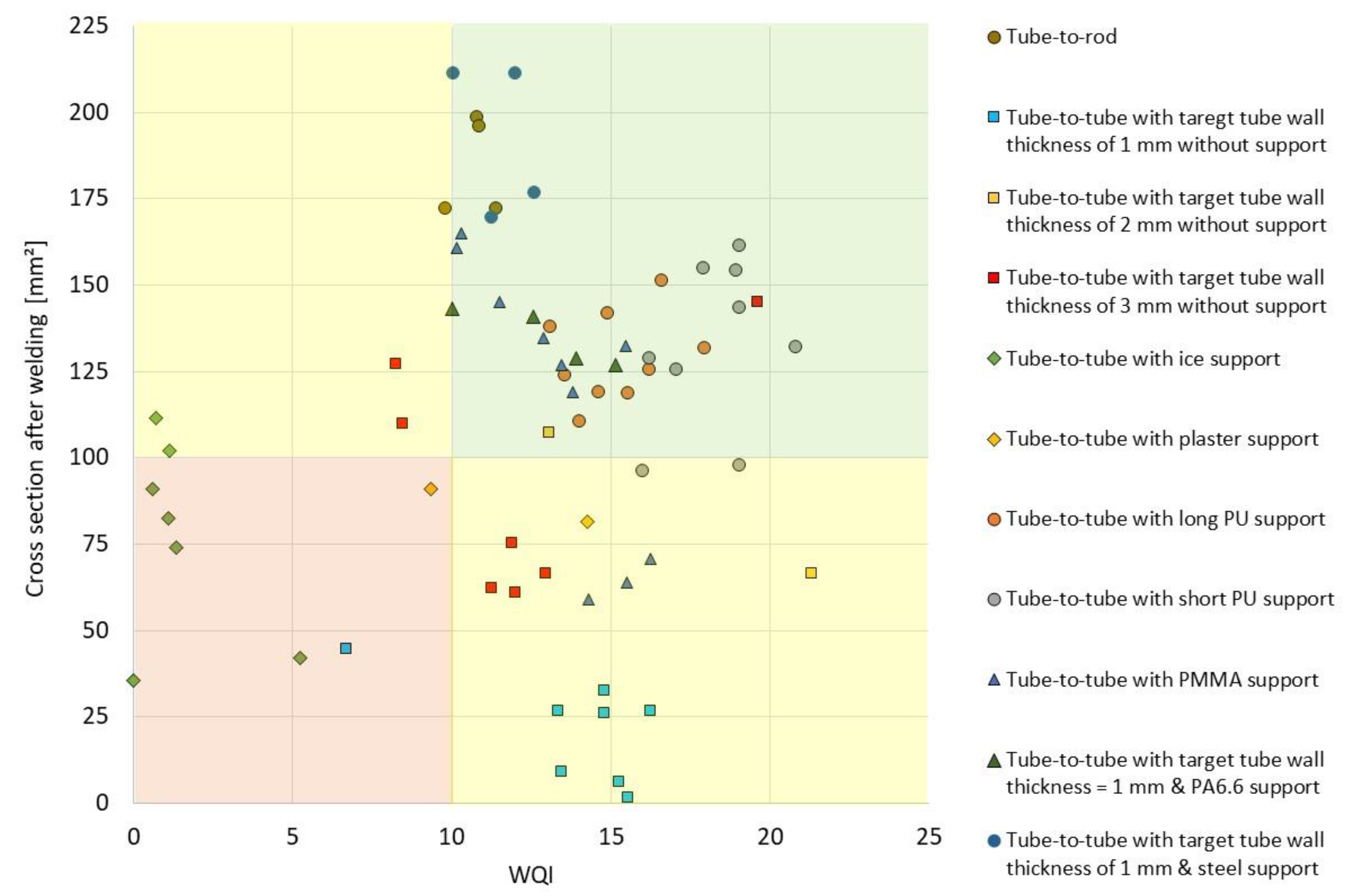

3.3. Investigation of Suitable Support Systems for the Target Tubes

- Leak tight

- Interfacial morphology with no or limited porosities and cracks and a sufficiently long welded interface at either side of the specimen. This corresponds with a WQI value of at least 10.

- Smallest possible reduction of the internal diameter of the target tube, such that a large cross-sectional area is maintained after welding. A qualitative support gives rise to a cross-sectional area after impact of at least 100 mm². This value was defined based on the application.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Faes, K.; Zaitov, O.; De Waele, W. Joining of Dissimilar Materials using the Electromagnetic Pulse Technology. In Proceedings of the ASM conference Trends in Welding Research, Chicago, IL, USA, 4–8 June 2012. [Google Scholar]

- Kwee, I.; Psyk, V.; Faes, K. Effect of the Welding Parameters on the Structural and Mechanical Properties of Aluminium and Copper Sheet Joints by Electromagnetic Pulse Welding. World J. Eng. Technol. 2016, 4, 538–561. [Google Scholar] [CrossRef]

- Sapanathan, T.; Raoelison, R.N.; Buiron, N.; Rachik, M. Magnetic Pulse Welding: An Innovative Joining Technology for Similar and Dissimilar Metal Pairs. In Joining Technologies; Ishak, M., Ed.; IntechOpen: London, UK, 2016. [Google Scholar]

- Faes, K.; Kwee, I. Morphological and mechanical characteristics of aluminium-copper sheet joints by electromagnetic pulse welding. In Proceedings of the International Conference of High Speed Forming (ICHSF), Dortmund, Germany, 27–28 April 2016; pp. 299–308. [Google Scholar]

- Verstraete, J.; De Waele, W.; Faes, K. Magnetic pulse welding: lessons to be learned from explosive welding. In Proceedings of the conference Sustainable Construction and Design 2011, Department of Mechanical Construction and Production, Ghent University, Ghent, Belgium, 16–17 February 2011. [Google Scholar]

- Join’EM project objectives. Available online: http://www.join-em.eu/objectives.html (accessed on 2 April 2019).

- Kallee, S.; Schäfer, R.; Pasquale, P. Automotive Applications of Electromagnetic Pulse Technology (EMPT). Available online: http://www.english.pstproducts.com/Automotive%20Applications%20of%20EMPT.pdf (accessed on 2 April 2019).

- Vinitha, G.; Gupta, P.; Kulkarni, M.R.; Saroj, P.C.; Mittal, R.K. Estimation of charging voltage for electromagnetic welding. In Proceedings of the Annual International Conference on Emerging Research Areas: Magnetics, Machines and Drives (AICERA/iCMMD), Kottayam, India, 24–26 July 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Kudiyarasan, S.; Vendan, S.A. Magnetic Pulse Welding of Two Dissimilar Materials with Various Combinations Adopted in Nuclear Applications. Indian J. Sci. Technol. 2015, 8. [Google Scholar] [CrossRef]

- Kudiyarasan, S.; Arungalai Vendan, S. Joining of Two Dissimilar Materials in Various Combinations by Using Magnetic Pulse Welding. Int. J. Interdisciplin. Res. Innovations 2016, 4, 89–100. [Google Scholar]

- Verstraete, J. Magnetic pulse welding. Master’s Thesis, Department of Mechanical Construction and Production, Faculty of Engineering, Ghent University, Ghent, Belgium, 1 June 2011. [Google Scholar]

- Yu, H.; Fan, Z.; Zhao, Y.; Li, C. Research on magnetic pulse welding interface of copper-carbon steel. Mater. Sci. Technol. 2015, 23, 1–6. [Google Scholar]

- Patra, S.; Singh Aroraa, K.; Shome, M.; Bysakh, S. Interface Characteristics and Performance of Magnetic Pulse Welded Copper-Steel Tubes. J. Mater. Process. Technol. 2017, 245, 278–286. [Google Scholar] [CrossRef]

- Lueg-Althoff, J.; Gies, S.; Tekkaya, A.E.; Bellmann, J.; Beyer, E.; Schulze, S. Magnetic pulse welding of dissimilar metals in tube-to-tube configuration. In Proceedings of the 9th International Welding Symposium of Japan Welding Society, Tokyo, Japan, 11–14 October 2016; pp. 87–90. [Google Scholar]

- Xu, Z.; Cui, J.; Yu, H.; Li, C. Research on the impact velocity of magnetic impulse welding of pipe fitting. Mater. Des. 2013, 49, 736–745. [Google Scholar] [CrossRef]

- Cui, J.; Sun, G.; Xu, J.; Xu, Z.; Huang, X.; Li, G. A study on the critical wall thickness of the inner tube for magnetic pulse welding of tubular Al-Fe parts. J. Mater. Process. Technol. 2016, 227, 138–146. [Google Scholar] [CrossRef]

- Lueg-Althoff, J.; Schilling, B.; Bellmann, J.; Gies, S.; Schulze, S.; Tekkaya, A.E.; Beyer, E. Influence of the wall thicknesses on the joint quality during magnetic pulse welding in tube-to-tube configuration. In Proceedings of the 7th International Conference on High Speed Forming, Dortmund, Germany, 27–28 April 2016; pp. 259–268. [Google Scholar]

- Kwee, I.; Faes, K. Interfacial Morphology and Mechanical Properties of Aluminium to Copper Sheet Joints by Electromagnetic Pulse Welding. Key Eng. Mater. 2016, 710, 109–114. [Google Scholar] [CrossRef]

- Stern, A.; Shribman, V.; Ben-Artzy, A.; Aizenshtein, M. Interface phenomena and bonding mechanism in magnetic pulse welding. J. Mater. Eng. Perform. 2014, 23, 3449–3458. [Google Scholar] [CrossRef]

- Kore, S.D.; Date, P.P.; Kulkarni, S.V. Effect of process parameters on electromagnetic impact welding of aluminum sheets. Int. J. Impact Eng. 2007, 34, 1327–1341. [Google Scholar] [CrossRef]

- Cui, J.; Sun, G.; Li, G.; Xu, Z.; Chu, P.K. Specific wave interface and its formation during magnetic pulse welding. Appl. Phys. Lett. 2014, 105, 221901. [Google Scholar] [CrossRef]

- Simoen, S. Investigation of the weldability of dissimilar metals using the electromagnetic welding process. Master’s Thesis, Department of Electrical Energy, Metals, Mechanical Constructions & Systems, Ghent University, Ghent, Belgium, 1 June 2017. [Google Scholar]

- Roeygens, L.; De Waele, W. Faes, Experimental investigation of the weldability of tubular dissimilar materials using the electromagnetic welding process. In Proceedings of the conference Sustainable Construction and Design, Department of Mechanical Construction and Production, Ghent University, Ghent, Belgium, 1 June 2017. [Google Scholar]

- Lueg-Althoff, J.; Bellmann, J.; Gies, S.; Schulze, S.; Tekkaya, A.E.; Beyer, E. Magnetic Pulse Welding of Tubes: Ensuring the Stability of the Inner Diameter. In Proceedings of the 6th Euro-Asian Pulsed Power Conference, EAPPC 2016: Held with the 21st International Conference on High-Power Particle Beams (BEAMS 2016) and the 15th International Conference on Megagauss Magnetic Field Generation (MG-XV); Estoril, Portugal, 18–22 September 2016; pp. 504–507, ISBN 978-1-5108-4607-4. [Google Scholar]

- Lueg-Althoff, J.; Bellmann, J.; Gies, S.; Schulze, S.; Tekkaya, A.E.; Beyer, E. Magnetic Pulse Welding of Dissimilar Metals in Tube-to-Tube Configuration. In Proceedings of the 10th International Conference on Trends in Welding Research and 9th International Welding Symposium of Japan Welding Society, Tokyo, Japan, 11–14 October 2016; Volume 1, pp. 87–90, ISBN 978-1-5108-4403-2. [Google Scholar]

- Bertelsbeck, S.; Geyer, M.; Böhm, S. Magnetic impulse welding of flexible tubes. IIW document SC-Auto-56-12. Available online: www.iiwelding.org (accessed on 30 April 2019).

- JOINing of copper to aluminium by ElectroMagnetic fields (Join’EM). Project with funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. H2020-FoF-2014-677660 - JOIN-EM. Available online: http://www.join-em.eu/ (accessed on 2 April 2019).

- Ben-Artzy, A.; Stern, A.; Frage, N.; Shribman, V.; Sadot, O. Wave formation mechanism in magnetic pulse welding. Int. J. Impact Eng. 2010, 37, 397–404. [Google Scholar] [CrossRef]

| Category | Material Requirement | Support Material | Support Type | Izod Impact Strength | Inner Diameter | Outer Diameter | Length | Figure |

|---|---|---|---|---|---|---|---|---|

| Re-usable support | High fracture toughness | PU | Tube + M8 bolt | 69.9 J/m | 8 mm | 14/15/15.45 mm | 30 mm 50 mm | Figure 7 |

| PA6.6 | Rod | 160 J/m | not applicable | 15.4/16.4 mm | 35 mm | - | ||

| Steel | Rod | NA | not applicable | 15.1 mm 16.4 mm | 30 mm | - | ||

| Non re-usable support | Low melting point | Ice | Rod | NA | not applicable | - | 50 mm | Figure 8 |

| High solubility | Plaster | Rod | NA | not applicable | - | 100 mm | Figure 9 | |

| Low fracture toughness | PMMA | Rod | 16 J/m | not applicable | 15.4/16.4 mm | 35 mm 20 mm 15 mm 10 mm | Figure 10 | |

| Disks | not applicable | 15.4 mm | 4 × 5 mm2 | |||||

| Tube | 7 mm 9 mm | 15.4 mm | 35 mm 35 mm |

| Measurement | Wall Thickness of the Target Tube | ||||

|---|---|---|---|---|---|

| - (Rod) | 3 mm | 2 mm | 1 mm | 1 mm + Support | |

| Range of weld lengths (mm) | 2.3–6.7 | 1.5–5.6 | 1.4–4.9 | 1.1–2.9 | 3.6–4.0 |

| Range of the reduction of the inner diameter of the target tube (mm) | - | 0.9–1.3 | 2.4–3.0 | 5.7–7.7 | 2.0–2.4 |

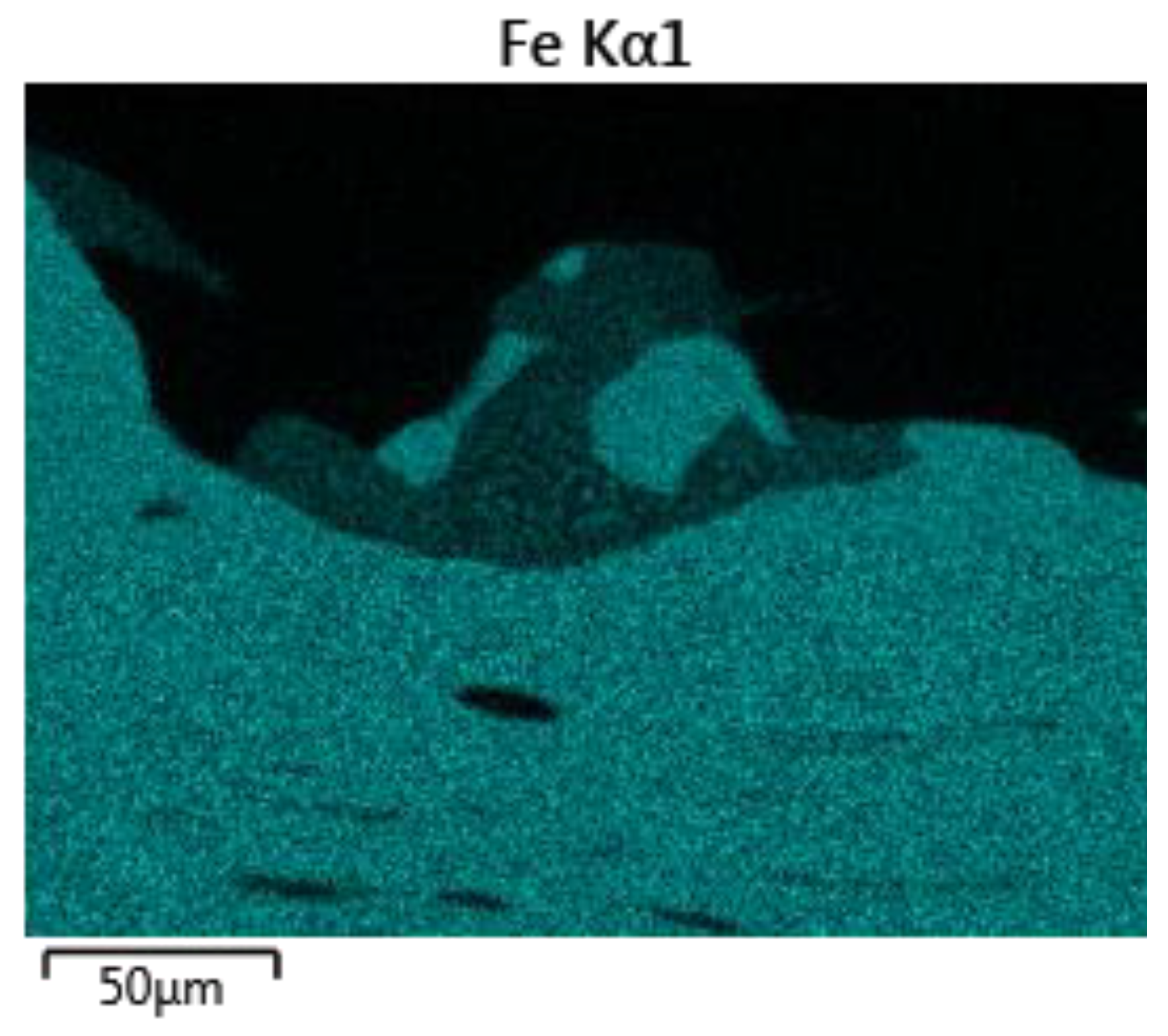

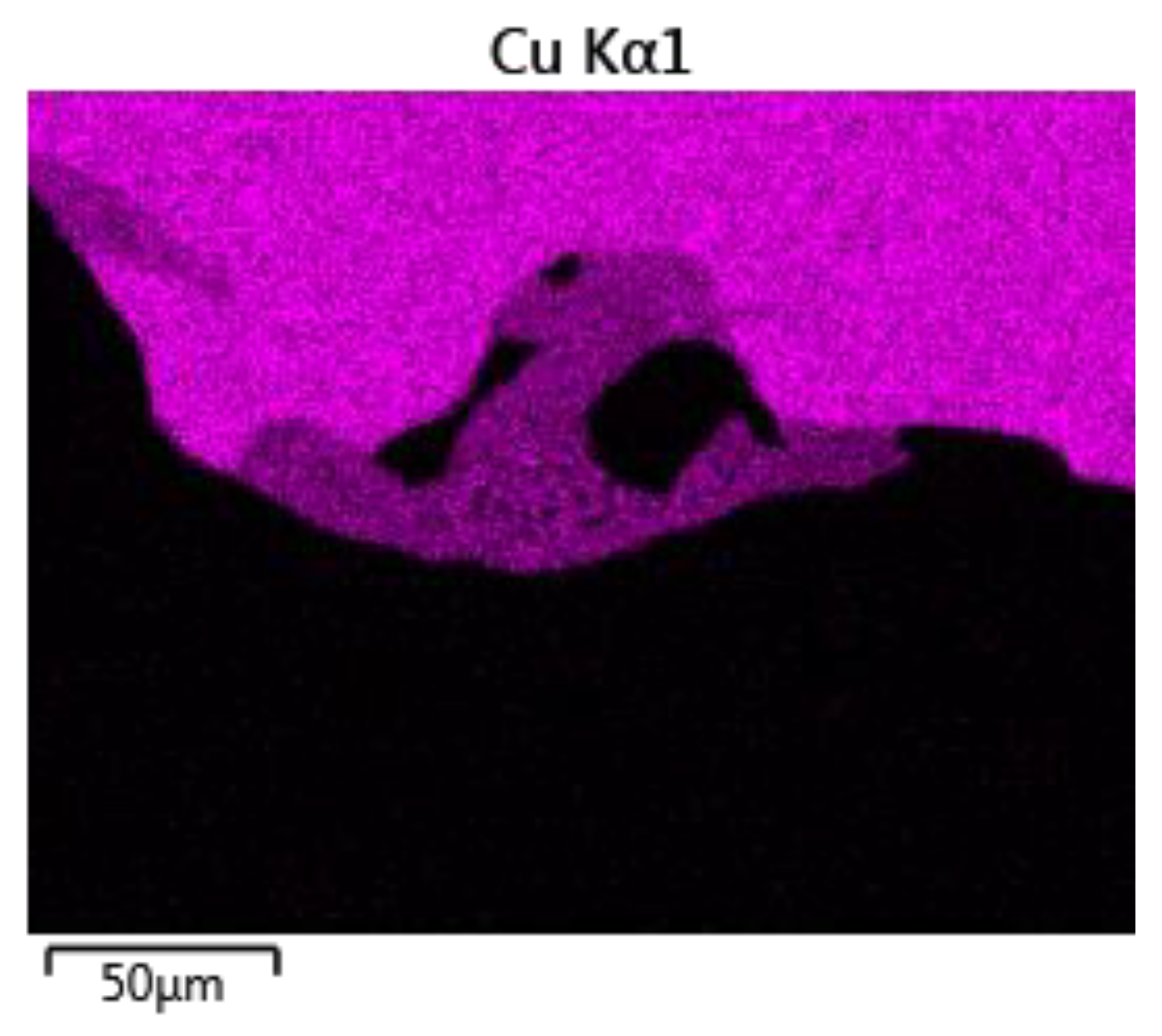

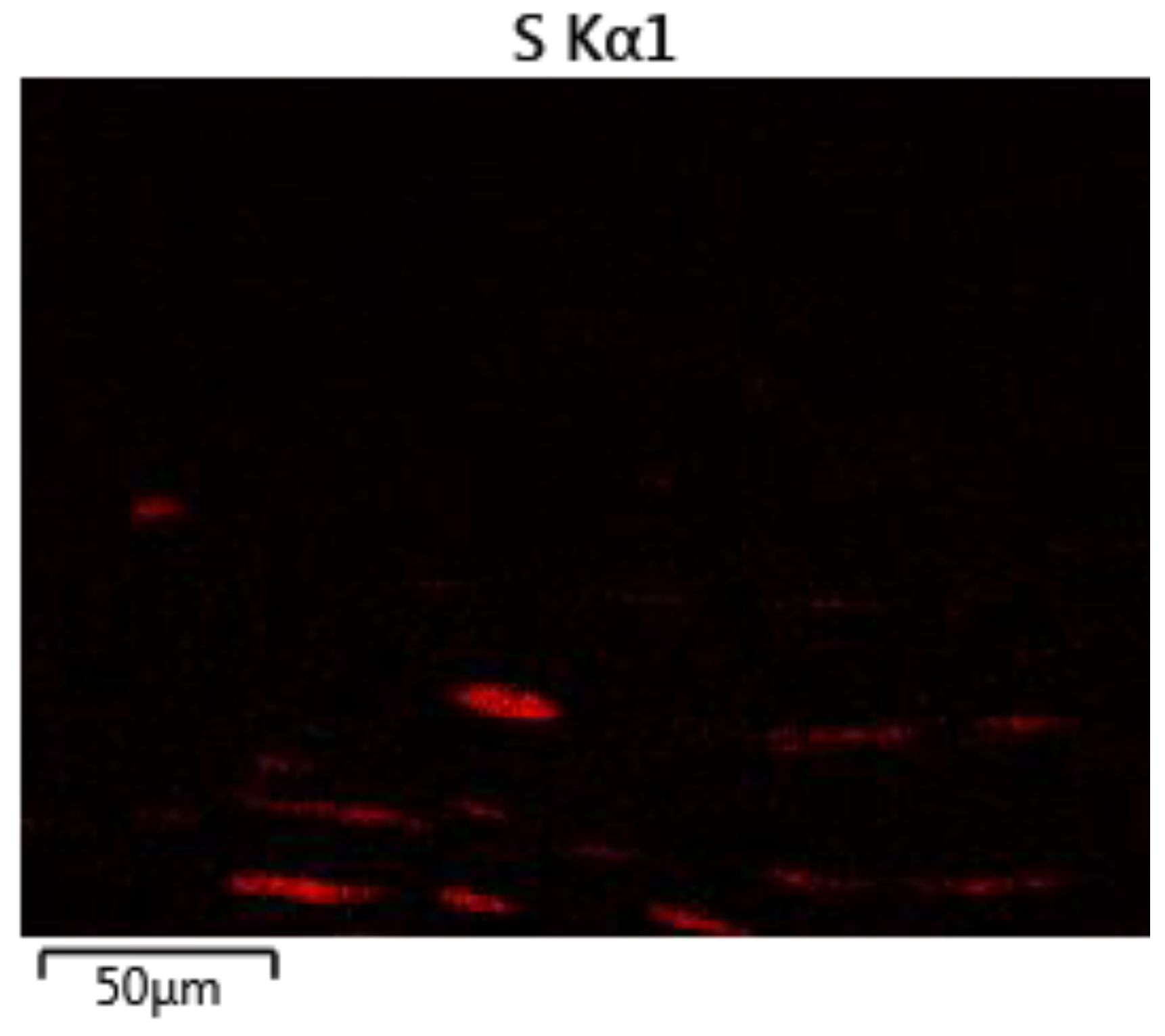

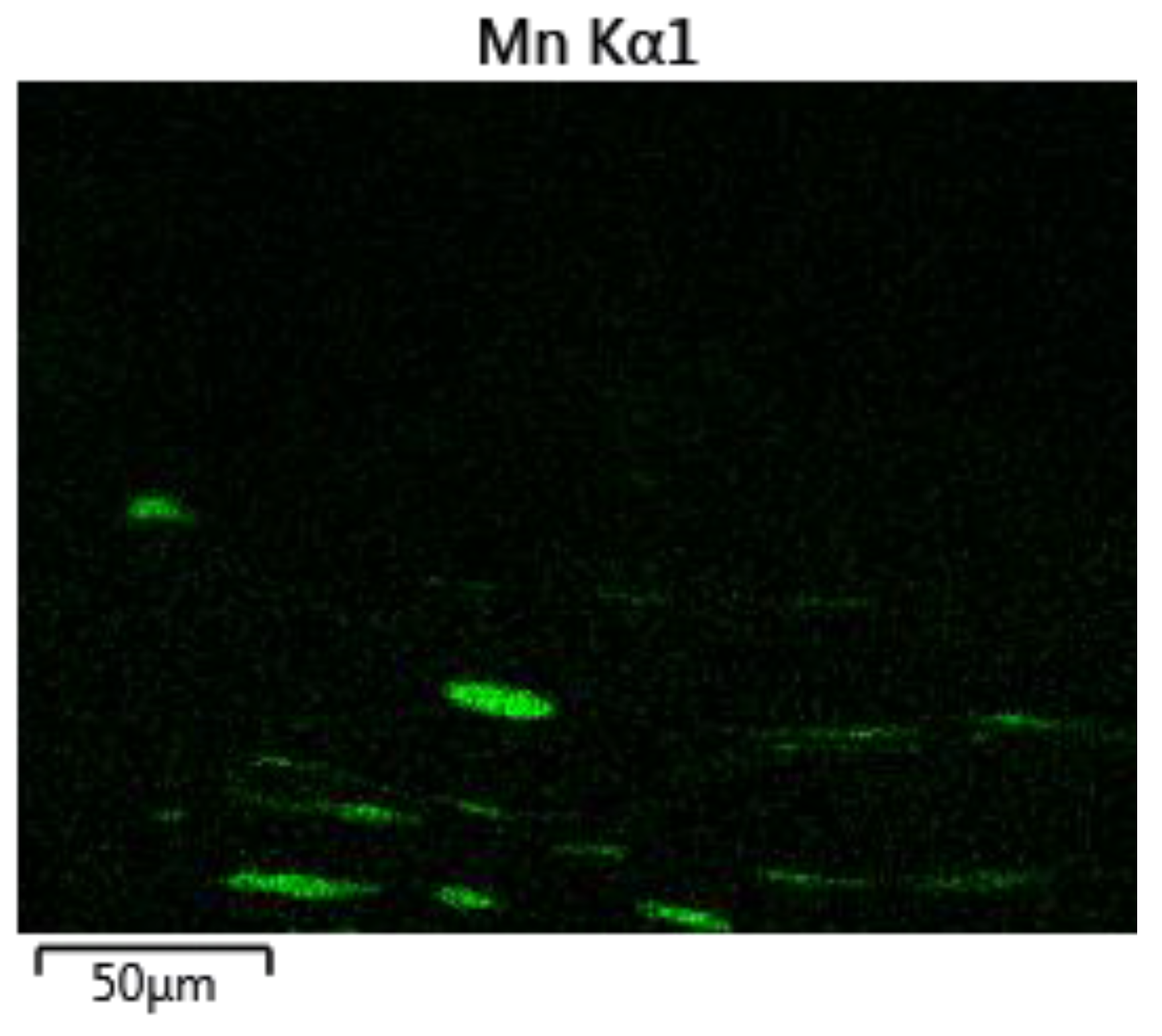

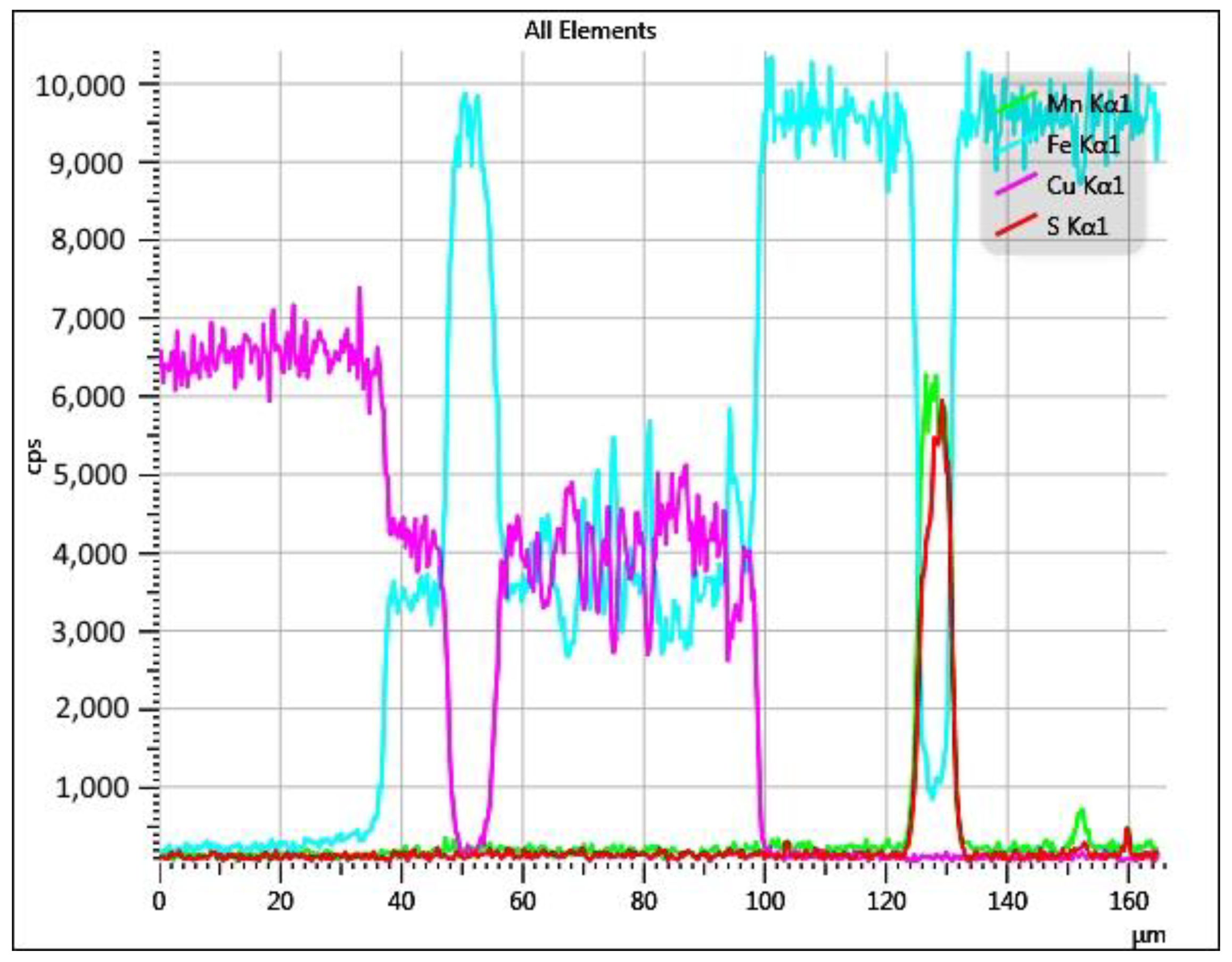

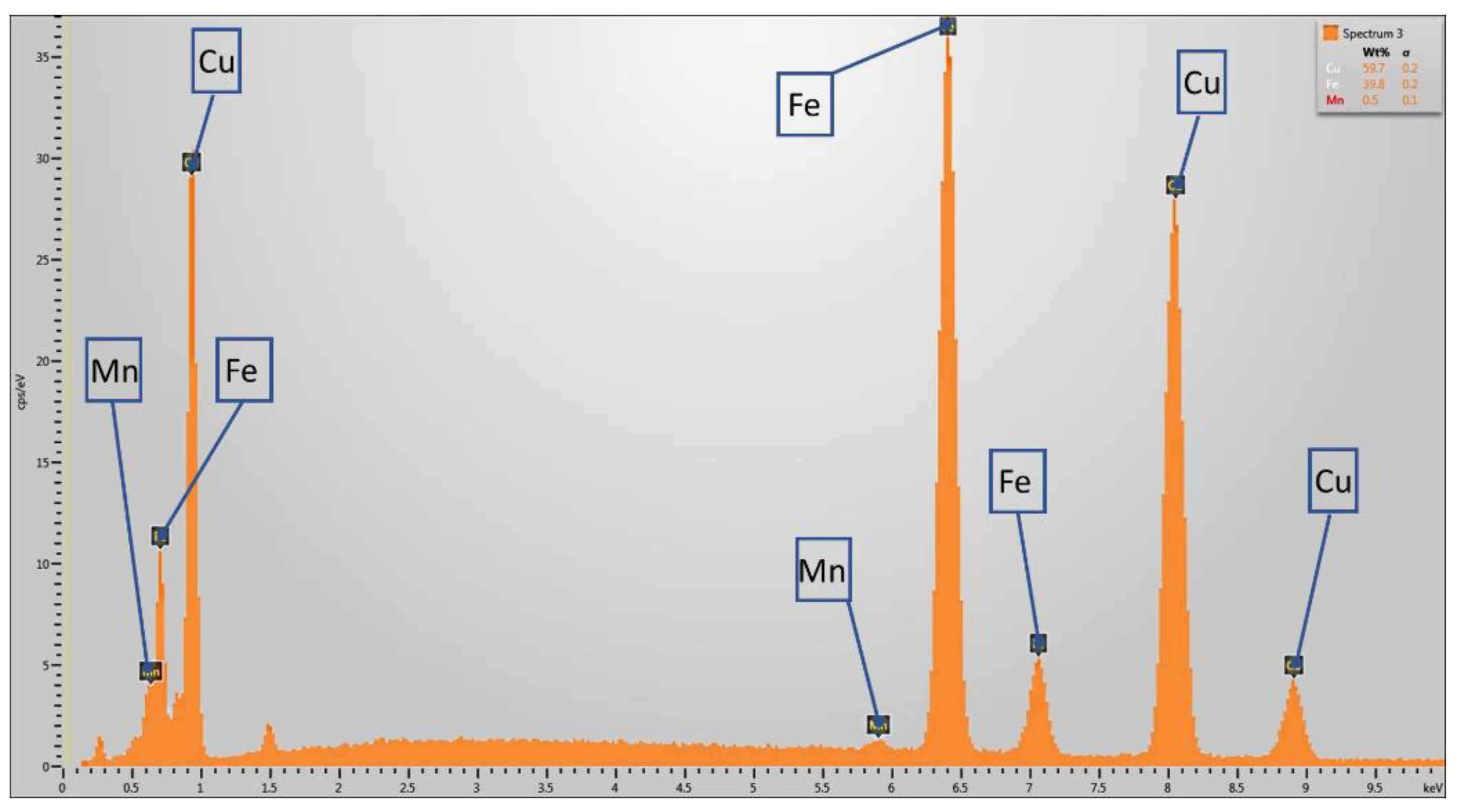

| Position | Cu (wt% ± σ) | Fe (wt% ± σ) | Mn (wt% ± σ) |

|---|---|---|---|

| 1 | 99.1 ± 0.1 | 0.9 ± 0.1 | - |

| 2 | 59.7 ± 0.2 | 39.8 ± 0.2 | 0.5 ± 0.1 |

| 3 | 0.6 ± 0.1 | 98.4 ± 0.1 | 0.9 ± 0.1 |

| Internal Support | Weld Quality: (WQI & Weld Length at 0°/180° from Field Shaper Cut | Remaining Internal Cross-Section after Welding (mm2) | Number of Process Steps | Cost | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Polyurethane (PU) | ++ WQI: 19.1 9.5/9.6 mm) | ++ 161.5 | - | + |

|

|

| Polymethyl-methacrylate (PMMA) | ++ WQI: 12.9 6.4/6.6 mm | + 134.8 | + | - |

|

|

| Ice | - WQI: 0.7 0.0/2.9 mm | - 111.5 | - | ++ |

|

|

| Plaster | ++ WQI: 14.3 7.1/7.2 mm | - 81.6 | - | + |

|

|

| Solid steel target workpiece + machining afterwards | + WQI: 10.8 5.4/5.4 mm | ++ 251.6 | - | + |

|

|

| Steel rod | ++ WQI: 12.6 mm 6.2/6.6 mm | ++ 176.7 | + | + |

|

|

| Polyamide (PA6.6) | ++ WQI: 15.5 7.2/8.7 mm | + 126.7 | + | - |

|

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faes, K.; Kwee, I.; De Waele, W. Electromagnetic Pulse Welding of Tubular Products: Influence of Process Parameters and Workpiece Geometry on the Joint Characteristics and Investigation of Suitable Support Systems for the Target Tube. Metals 2019, 9, 514. https://doi.org/10.3390/met9050514

Faes K, Kwee I, De Waele W. Electromagnetic Pulse Welding of Tubular Products: Influence of Process Parameters and Workpiece Geometry on the Joint Characteristics and Investigation of Suitable Support Systems for the Target Tube. Metals. 2019; 9(5):514. https://doi.org/10.3390/met9050514

Chicago/Turabian StyleFaes, Koen, Irene Kwee, and Wim De Waele. 2019. "Electromagnetic Pulse Welding of Tubular Products: Influence of Process Parameters and Workpiece Geometry on the Joint Characteristics and Investigation of Suitable Support Systems for the Target Tube" Metals 9, no. 5: 514. https://doi.org/10.3390/met9050514

APA StyleFaes, K., Kwee, I., & De Waele, W. (2019). Electromagnetic Pulse Welding of Tubular Products: Influence of Process Parameters and Workpiece Geometry on the Joint Characteristics and Investigation of Suitable Support Systems for the Target Tube. Metals, 9(5), 514. https://doi.org/10.3390/met9050514