Properties of Components with Incrementally Formed Gears

Abstract

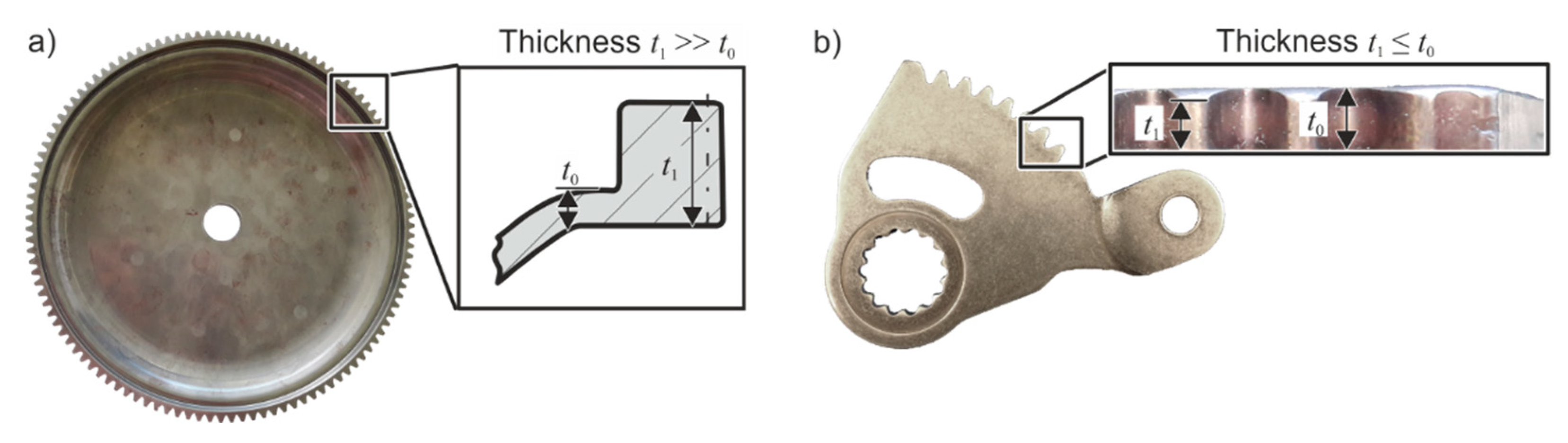

:1. Introduction

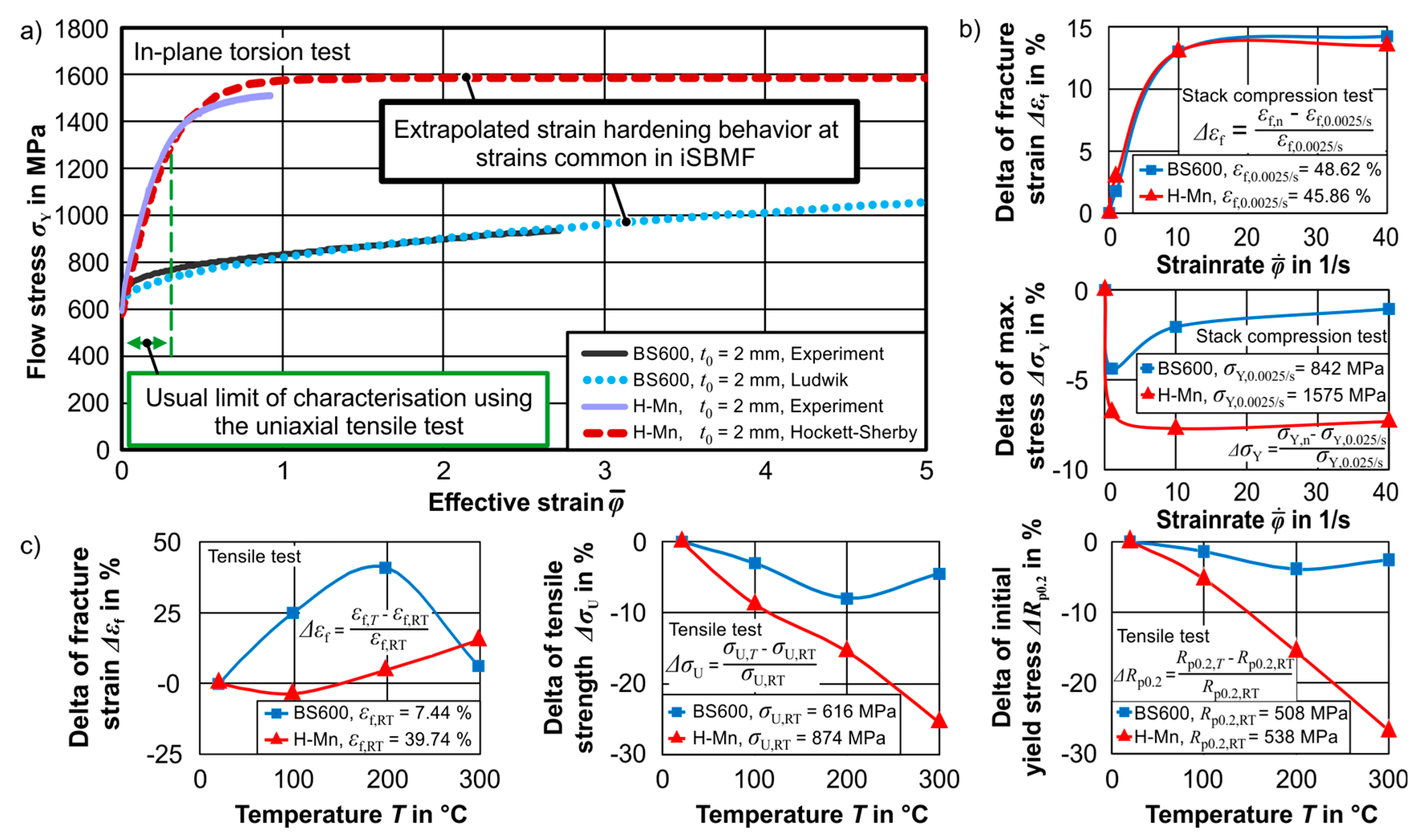

2. Mechanical Characterization

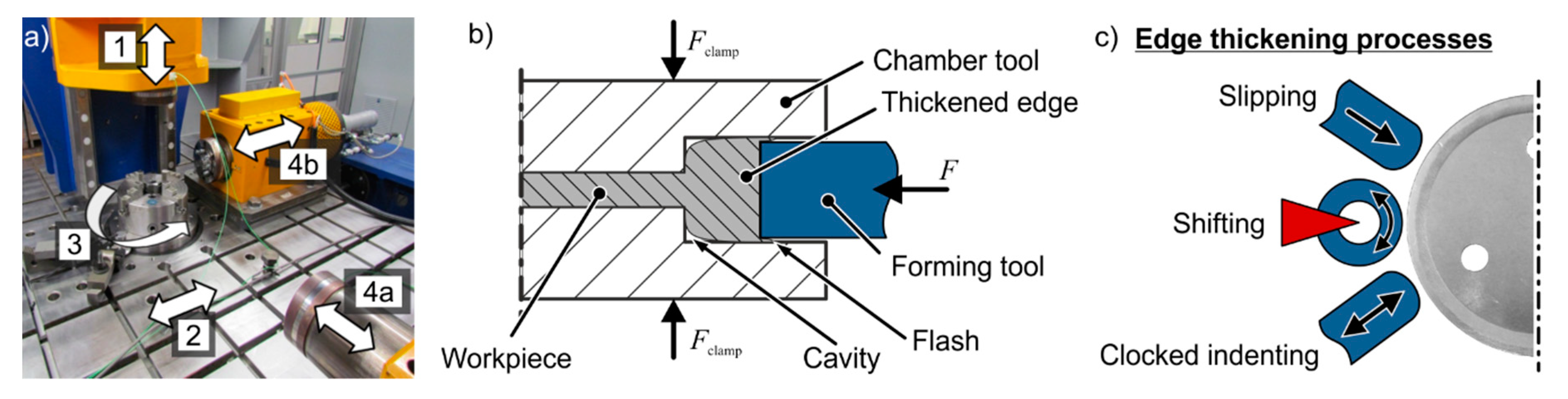

3. Experimental Procedure and Results

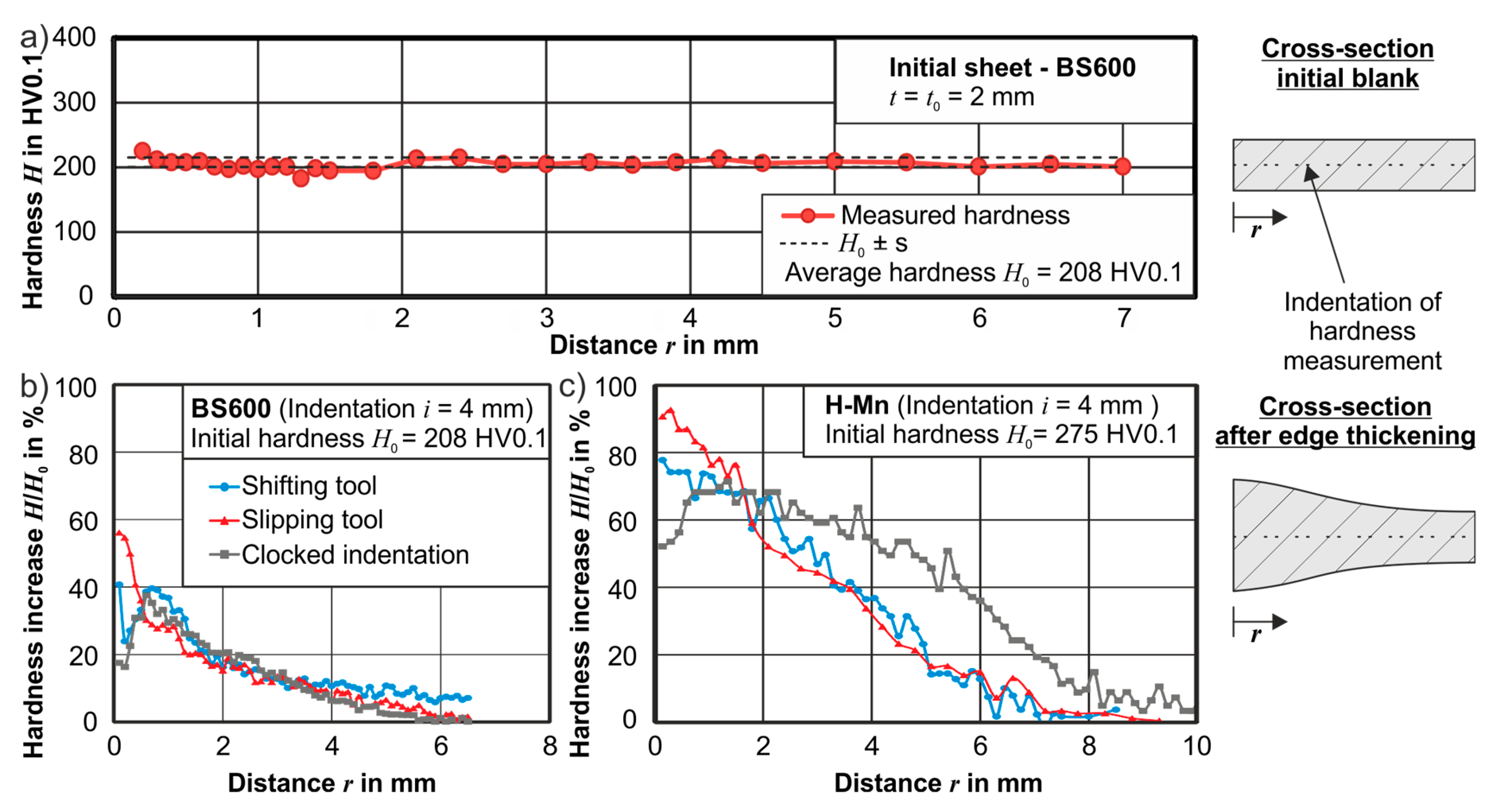

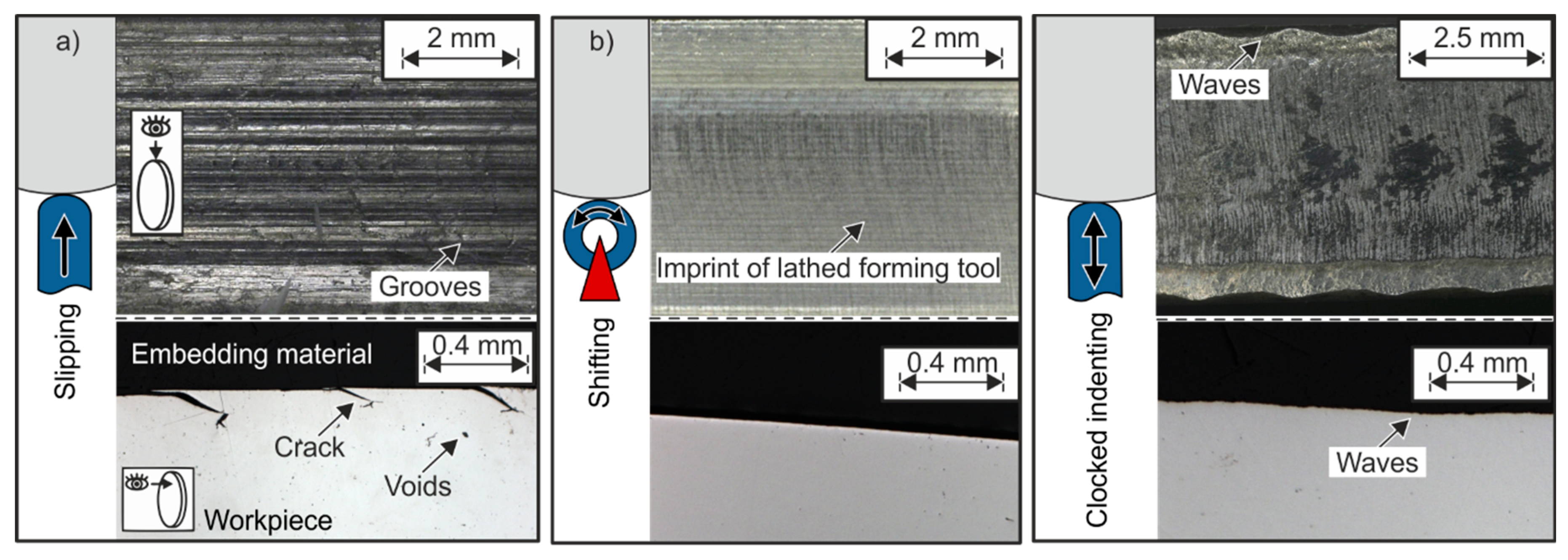

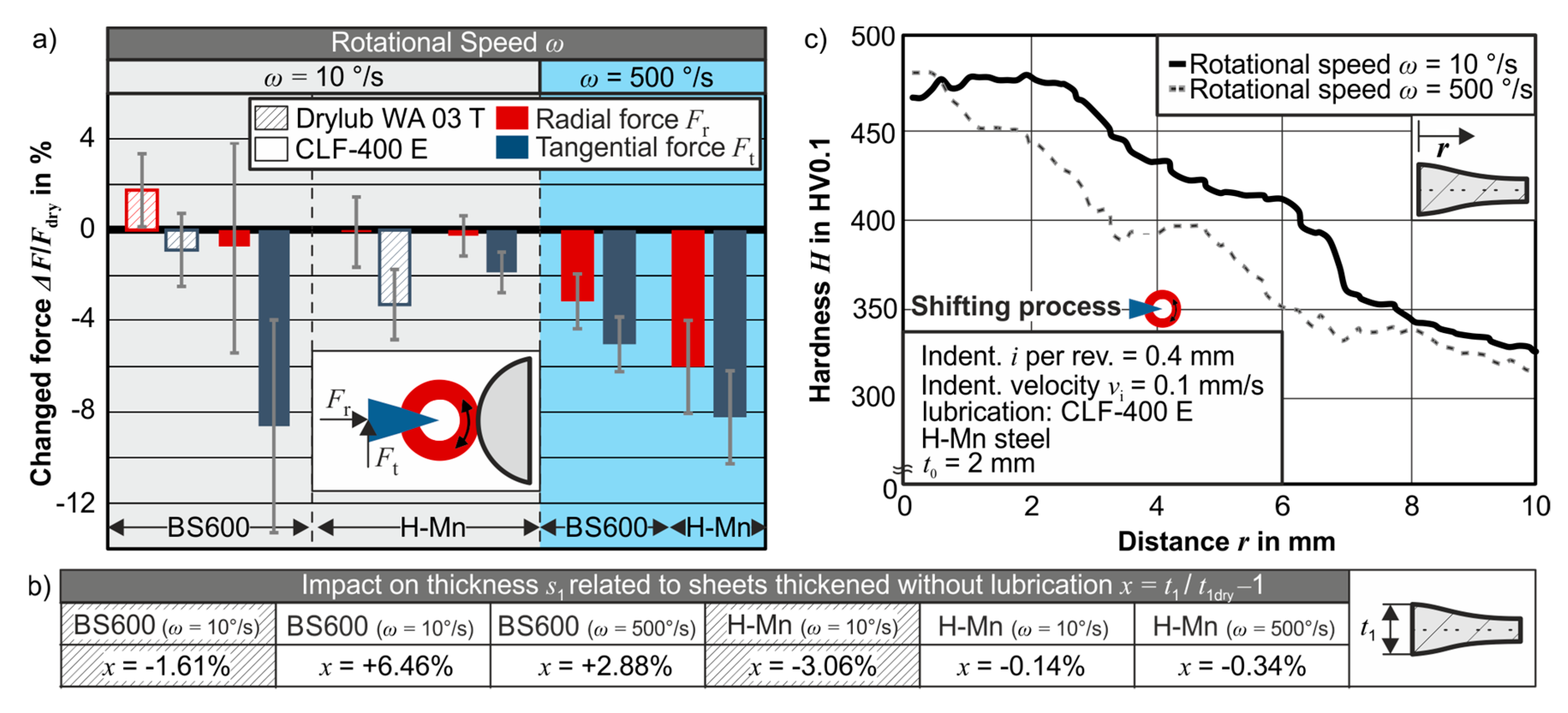

3.1. Edge Thickening

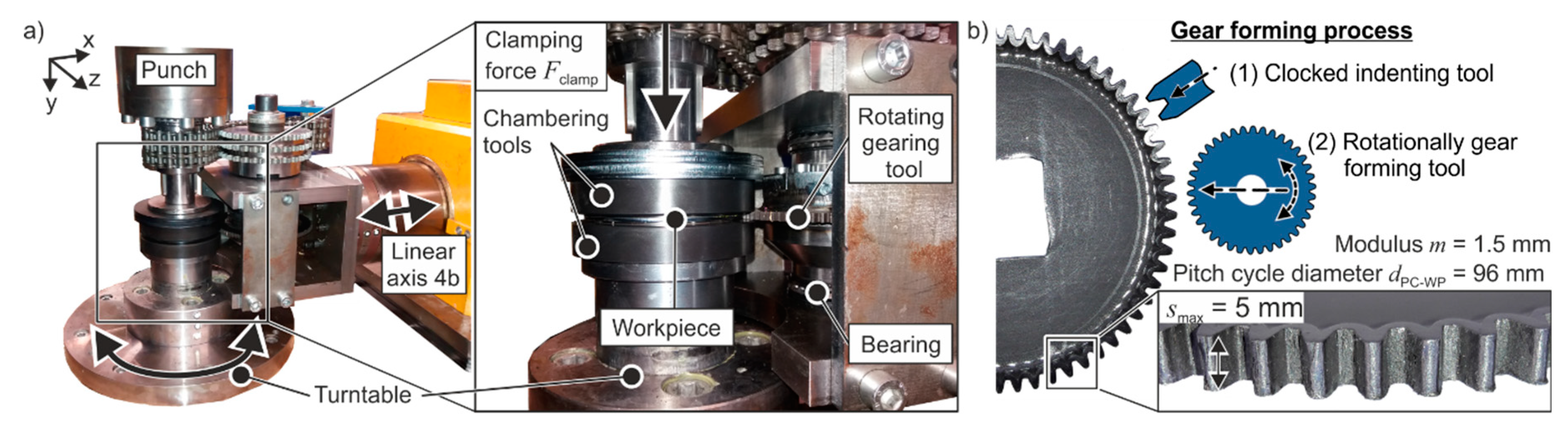

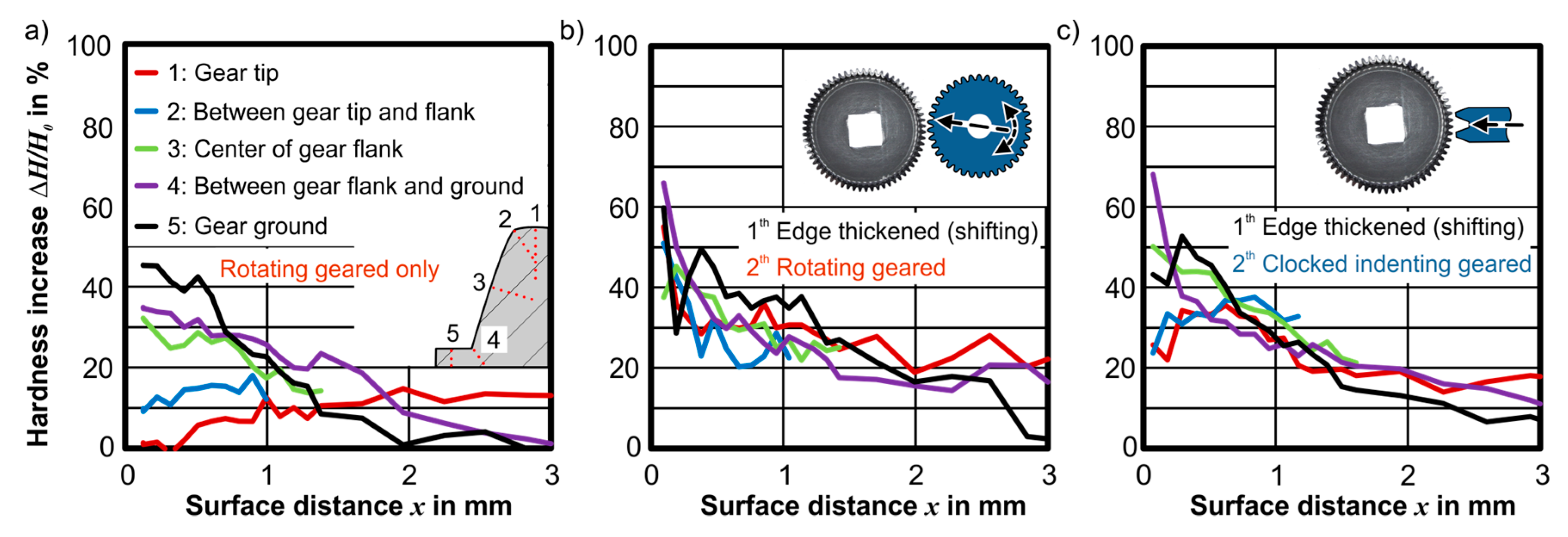

3.2. Gear Forming

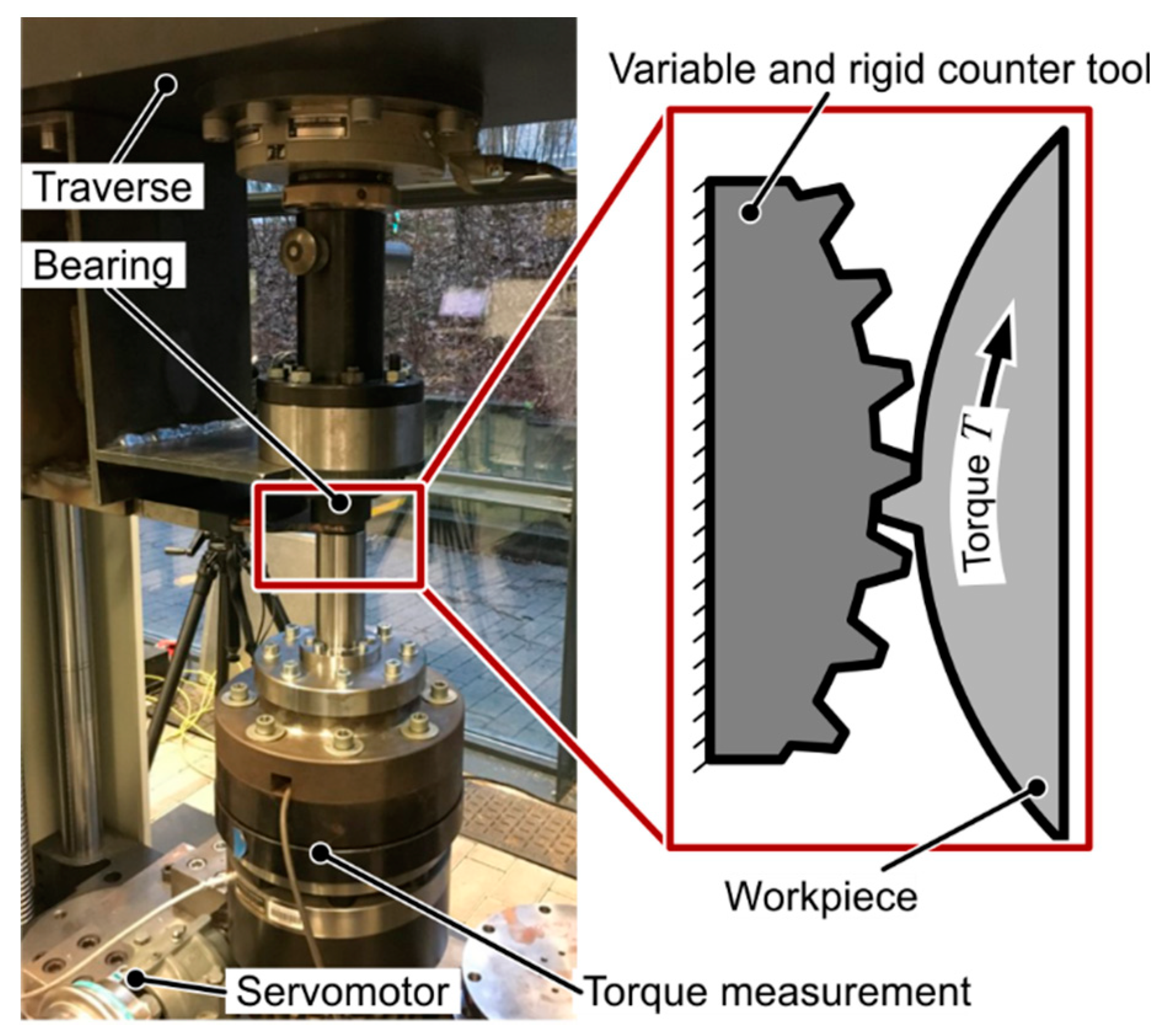

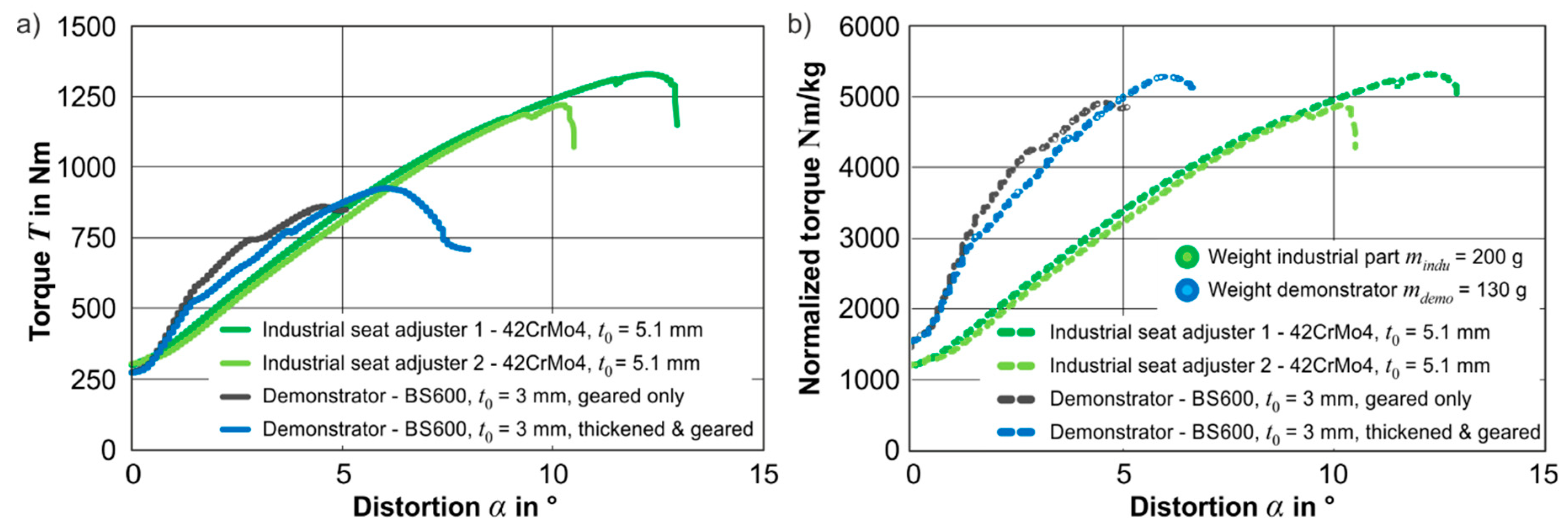

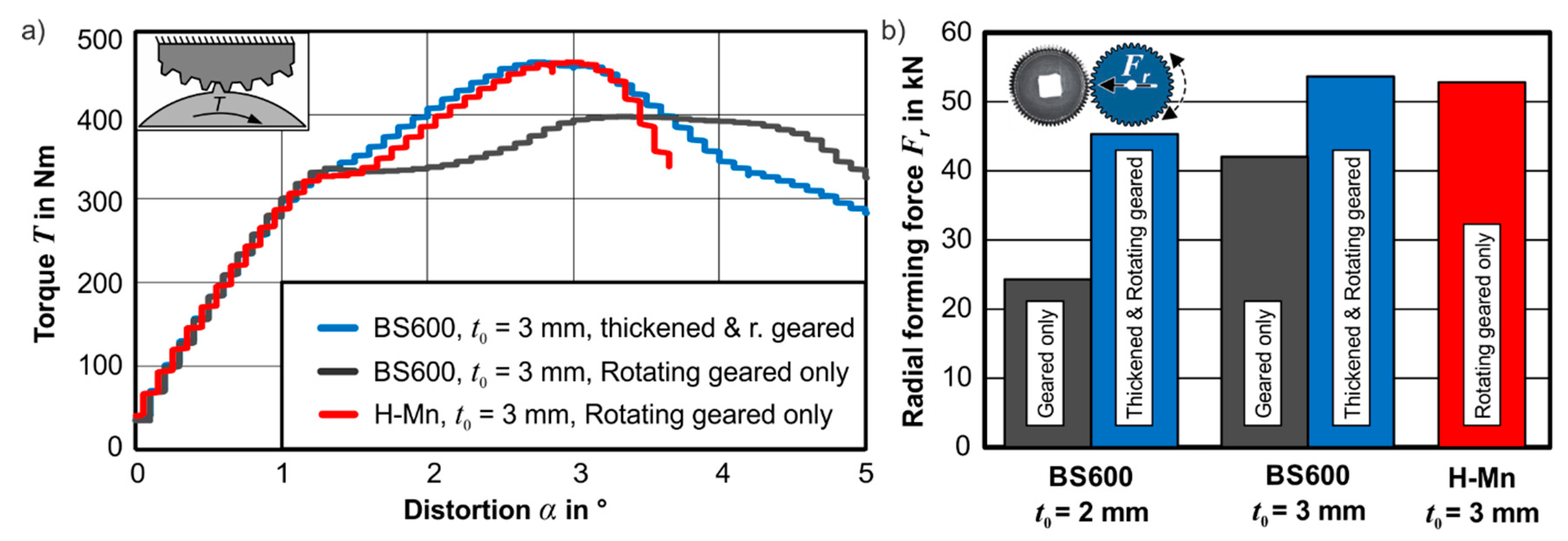

3.3. Benchmark-Test

4. Conclusion and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of lightweight components by metal forming. CIRP Annals 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Tsuchiya, M.; Nanya, T. Inclusion of hot stamping operations in progressive-die plateforging of tailored high strength gear part. Int. J. Adv. Manuf. Technol. 2017, 90, 3585–3594. [Google Scholar] [CrossRef]

- Birzer, F. Feinschneiden und Verfahrenskombinationen auf Feinschneidpressen. In Neuere Entwicklungen in der Massivumformung; MAT-INFO Werkstoff-Informationsgesellschaft: Fellbach, Germany, 2013; pp. 105–117. [Google Scholar]

- Behrens, B.-A.; Bistron, M.; Schäfer, F. Optimierung der Prozesskette beim Präzisionsschmieden von Zahnrädern durch Verschleißreduzierung. In Neuere Entwicklungen in der Massivumformung; MAT-INFO Werkstoff-Informationsgesellschaft: Fellbach, Germany, 2007; pp. 185–204. [Google Scholar]

- Gu, H.; Yin, G.; Shulkin, B. Laser beam welding of nitride steel components. Phys. Proc. 2011, 12, 40–45. [Google Scholar] [CrossRef]

- Bamberg, M.; Sviridov, A.; Weisheit, A.; Schleifenbaum, J.H. Case studies on local reinforcement of sheet metal components by laser additive manufacturing. Metals 2017, 7, 113. [Google Scholar]

- Merklein, M.; Allwood, J.M.; Behrens, B.-A.; Brosius, A.; Hagenah, H.; Kuzman, K.; Mori, K.; Tekkaya, A.E.; Weckenmann, A. Bulk forming of sheet metal. CIRP Annals 2012, 61, 725–745. [Google Scholar] [CrossRef]

- Mori, K.; Nakano, T. State-of-the-art of plate forging in Japan. Prod. Eng. Res. Dev. 2016, 10, 81–91. [Google Scholar] [CrossRef]

- Oyachi, Y.; Allwood, J.M. Characterizing the class of local metal sheet thickening processes. In Proceedings of the Steel Research International, 10th International Conference on Technology of plasticity (ICTP), Aachen, Germany, 25–30 September 2011; pp. 1025–1030. [Google Scholar]

- Friese, U. Vorrichtung zur Herstellung eines außen verzahnten Getriebeteiles. German Patent DE 43 35 505 C1, 19 October 1993. [Google Scholar]

- Jin, J.-S.; Wang, X.-Y.; Li, L. A sheet blank rotary forging process for disk-like parts with thickened rims. J. Mech. Sci. Technol. 2016, 30, 2723–2729. [Google Scholar] [CrossRef]

- Wernicke, S.; Sieczkarek, P.; Grodotzki, J.; Gies, S.; Ben Khalifa, N.; Tekkaya, A.E. Material flow analysis for the incremental sheet-bulk gearing by rotating tools. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing, Los Angeles, CA, USA, 4–8 June 2017. [Google Scholar] [CrossRef]

- Gröbel, D.; Schulte, R.; Hildenbrand, P.; Lechner, M.; Engel, U.; Sieczkarek, P.; Wernicke, S.; Gies, S.; Tekkaya, A.E.; Behrens, B.A.; et al. Manufacturing of functional elements by sheet-bulk metal forming processes. Prod. Eng. Res. Devel. 2016, 10, 63–80. [Google Scholar] [CrossRef]

- Traphöner, H.; Heibel, S.; Clausmeyer, T.; Tekkaya, A.E. Influence of manufacturing processes on material characterization with the grooved in-plane torsion test. Int. J. Mech. Sci. 2018, 146, 544–555. [Google Scholar] [CrossRef]

- Sieczkarek, P.; Isik, K.; Ben Khalifa, N.; Martins, P.A.F.; Tekkaya, A.E. Mechanics of sheet-bulk indentation. J. Mat. Proc. Technol. 2014, 214, 2387–2394. [Google Scholar] [CrossRef]

| Material Parameter | BS600 | H-Mn | ||||

|---|---|---|---|---|---|---|

| 0° | 45° | 90° | 0° | 45° | 90° | |

| E-Modulus E (GPa) | 219.67 | 199.00 | 223.33 | 199.33 | 195.33 | 207.50 |

| Tensile strength Rm (MPa) | 613.00 | 587.33 | 613.67 | 883.67 | 866.00 | 896.50 |

| Yield strength Rp0,2 (MPa) | 502.67 | 531.00 | 559.33 | 510.67 | 510.00 | 512.50 |

| Fracture strain εf (%) | 6.35 | 5.86 | 6.19 | 44.33 | 44.83 | 39.57 |

| Hardening exponent n (-) | 0.08 | 0.06 | 0.05 | 0.07 | 0.08 | 0.09 |

| Lankford coefficient r (-) | 0.54 | 0.96 | 0.75 | 0.57 | 0.92 | 1.02 |

| Process Strategy | BS600 | H-Mn | ||

|---|---|---|---|---|

| ΔHmax/H0 | Influenced Radius ri/Total Indentation i | ΔHmax/H0 | Influenced Radius ri/Total Indentation i | |

| Slipping | +60% | ca. 6 mm/4 mm = 1.5 | +90% | ca. 8 mm/4 mm = 2 |

| Shifting | +40% | +79% | ||

| Clocked indenting | +19% | +50% | ||

| Process Strategy | Increase of Indent./Rev. | Increase of Rotational Speed | Addition of Lubricant |

|---|---|---|---|

| Slipping | ↓ | ↓ | ↑ |

| Shifting | ↓ | - | ↑ |

| Clocked | ↘ | - | - |

| ↑—Improvement; ↓—Worsening; -—No influence | |||

| Parameter | Gear Forming Strategy | |||||

|---|---|---|---|---|---|---|

| Clocked Indenting | Rotating (Continuously) | Rotating (Stepwise) | ||||

| Without Thickening | With Thickening | Without Thickening | With Thickening | Without Thickening | With Thickening | |

| ΔHmax /H0—Tip | +18% | +48% | +54% | +56% | +57% | +57% |

| ΔHmax /H0—Flank | +23% | +38% | +39% | +40% | +31% | +37% |

| ΔHmax /H0—Ground | +47% | +53% | +34% | +55% | +38% | +53% |

| Incr. indent. velocity vi | ↑ | ↑ | → | → | → | → |

| Incr. rot. speed ω | - | - | ↓ | ↓ | ↓ | ↓ |

| Addition of Lubricant | ↑ | ↑ | → | ↑↑ | → | → |

| Incr. of indent./rev. | - | - | ↑ | ↑↑↑ | ↓↓ | ↑↑↑ |

| ↑—Improvement; ↓—Worsening; -—No influence | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wernicke, S.; Sieczkarek, P.; Gies, S.; Tekkaya, A.E. Properties of Components with Incrementally Formed Gears. Metals 2019, 9, 515. https://doi.org/10.3390/met9050515

Wernicke S, Sieczkarek P, Gies S, Tekkaya AE. Properties of Components with Incrementally Formed Gears. Metals. 2019; 9(5):515. https://doi.org/10.3390/met9050515

Chicago/Turabian StyleWernicke, Sebastian, Peter Sieczkarek, Soeren Gies, and A. Erman Tekkaya. 2019. "Properties of Components with Incrementally Formed Gears" Metals 9, no. 5: 515. https://doi.org/10.3390/met9050515

APA StyleWernicke, S., Sieczkarek, P., Gies, S., & Tekkaya, A. E. (2019). Properties of Components with Incrementally Formed Gears. Metals, 9(5), 515. https://doi.org/10.3390/met9050515