Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels using in situ Neutron Diffraction and Crystal Plasticity Modeling

Abstract

1. Introduction

2. Materials and Methods

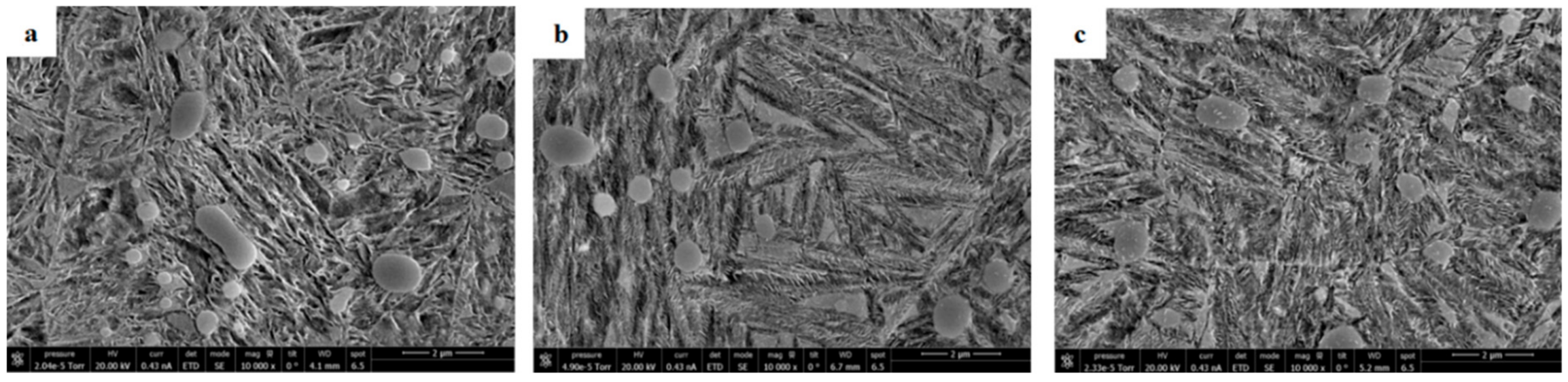

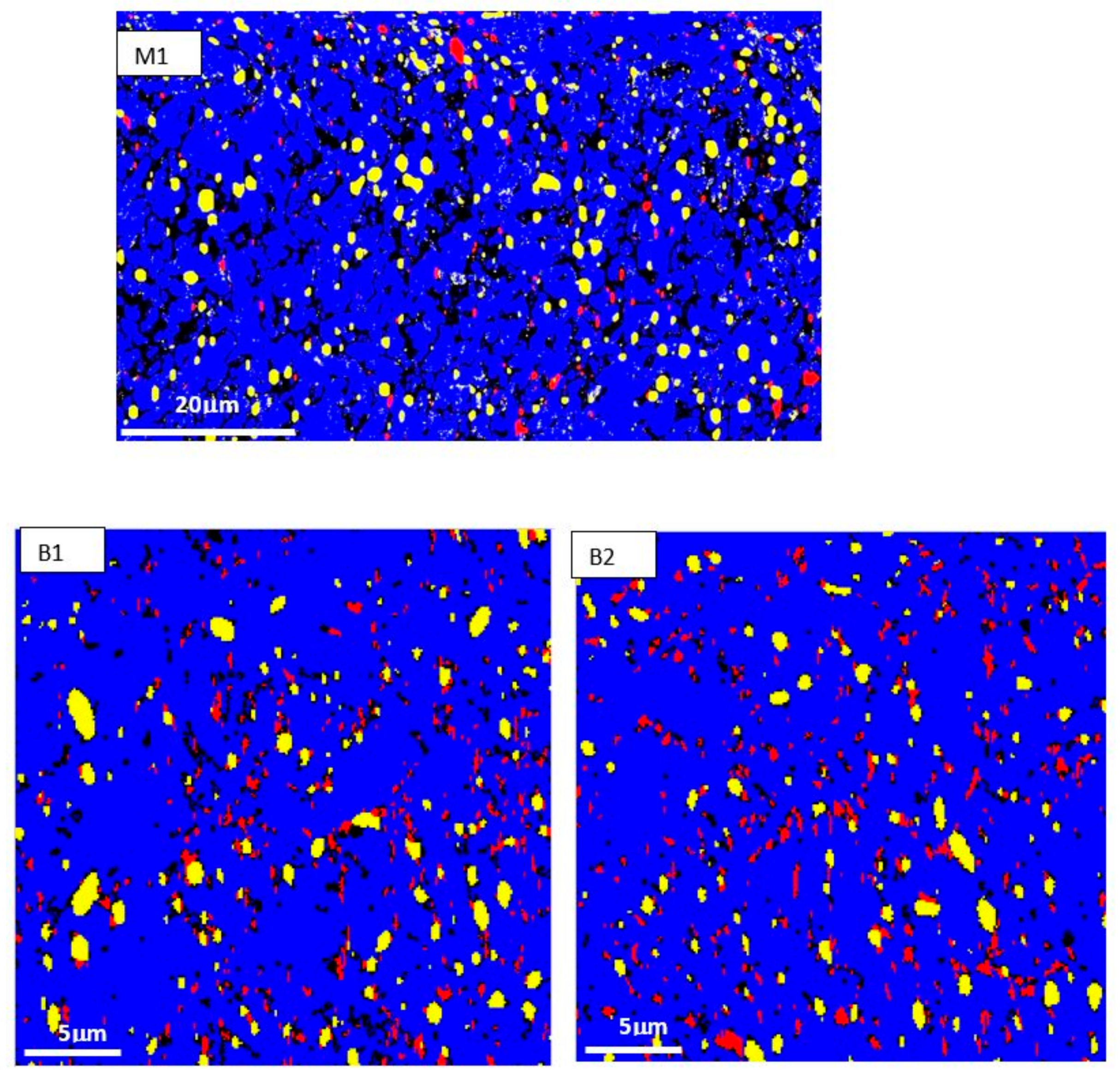

2.1. Material Characterization and Sample Preparation

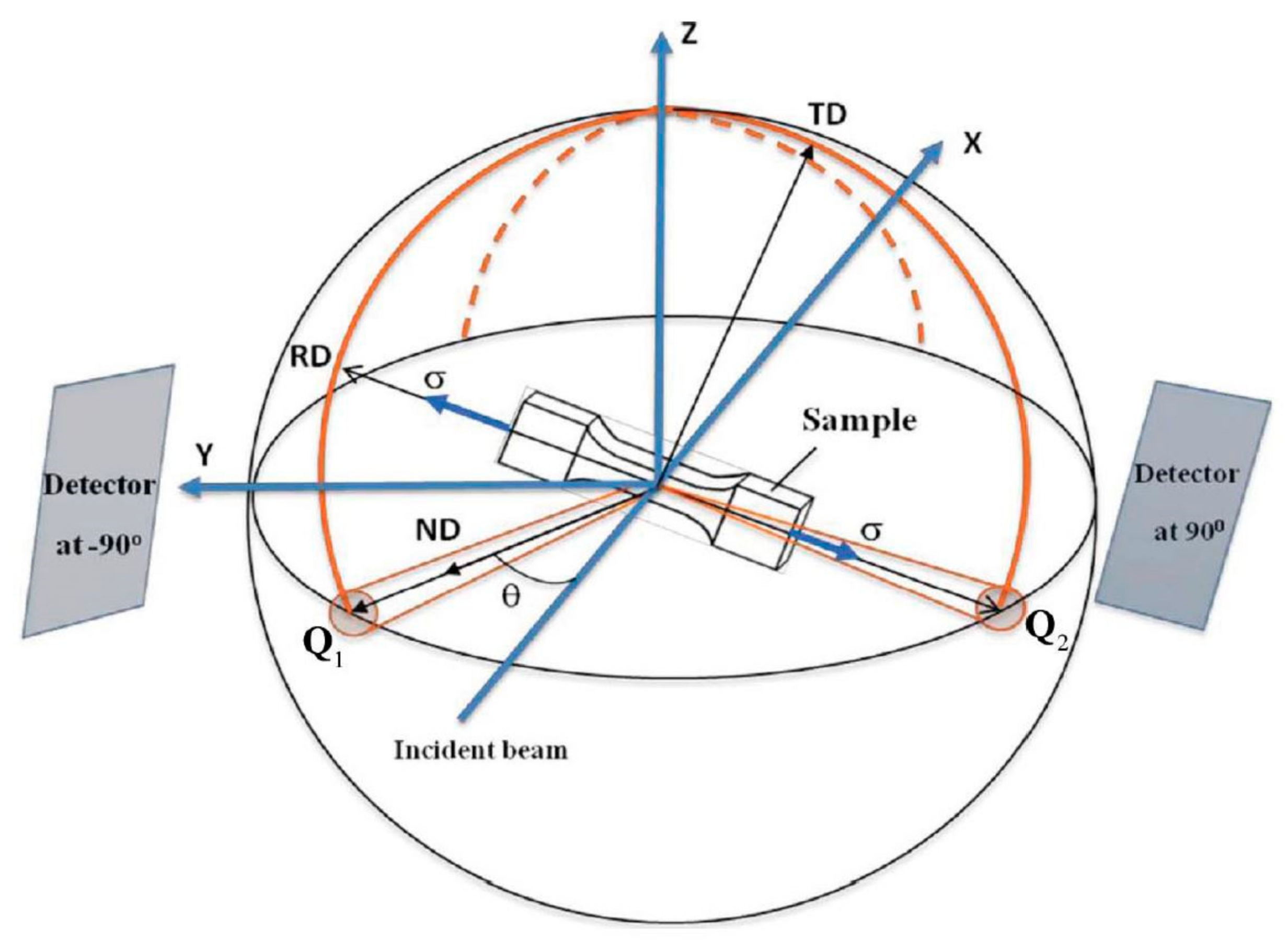

2.2. In situ Neutron Diffraction

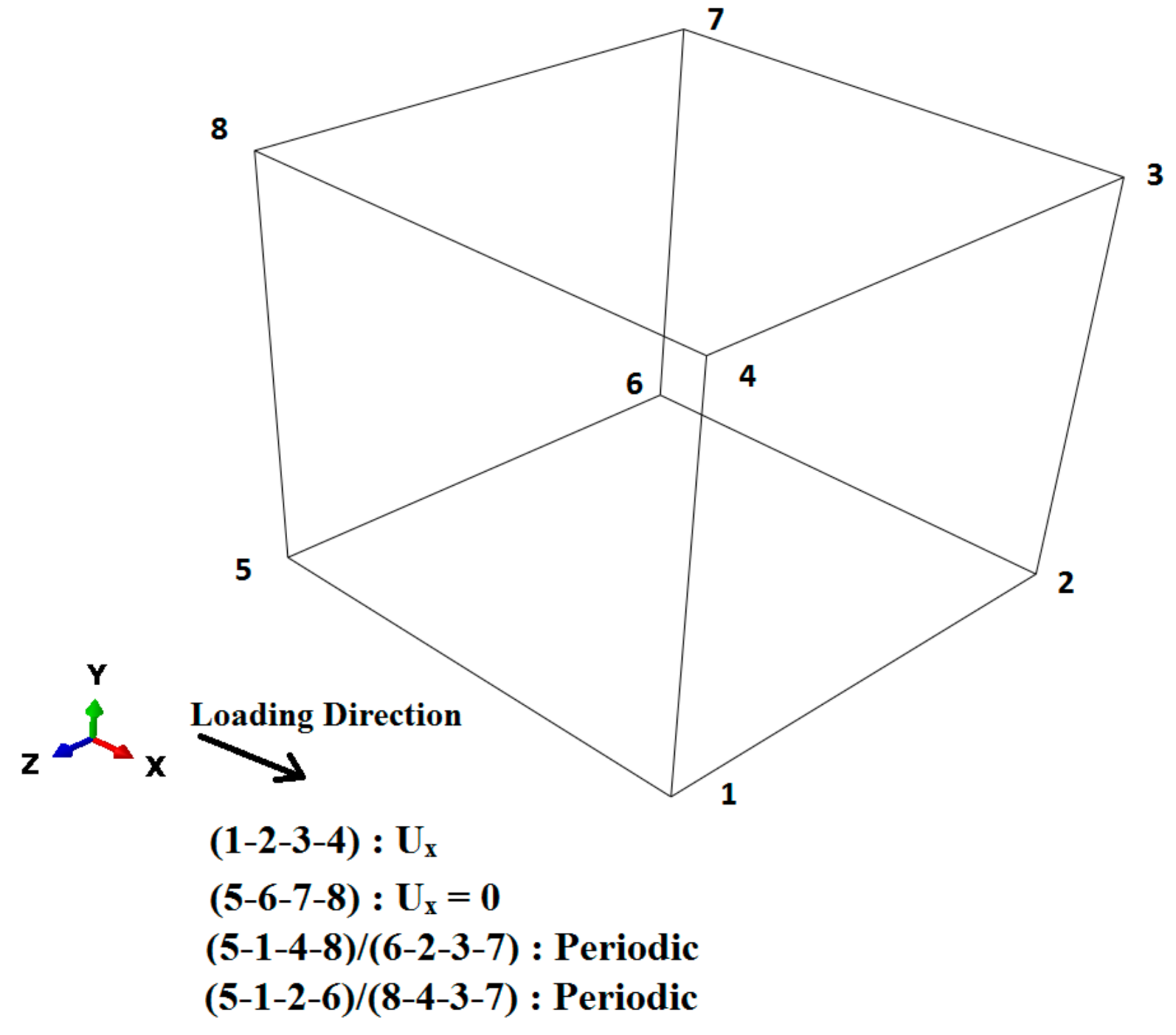

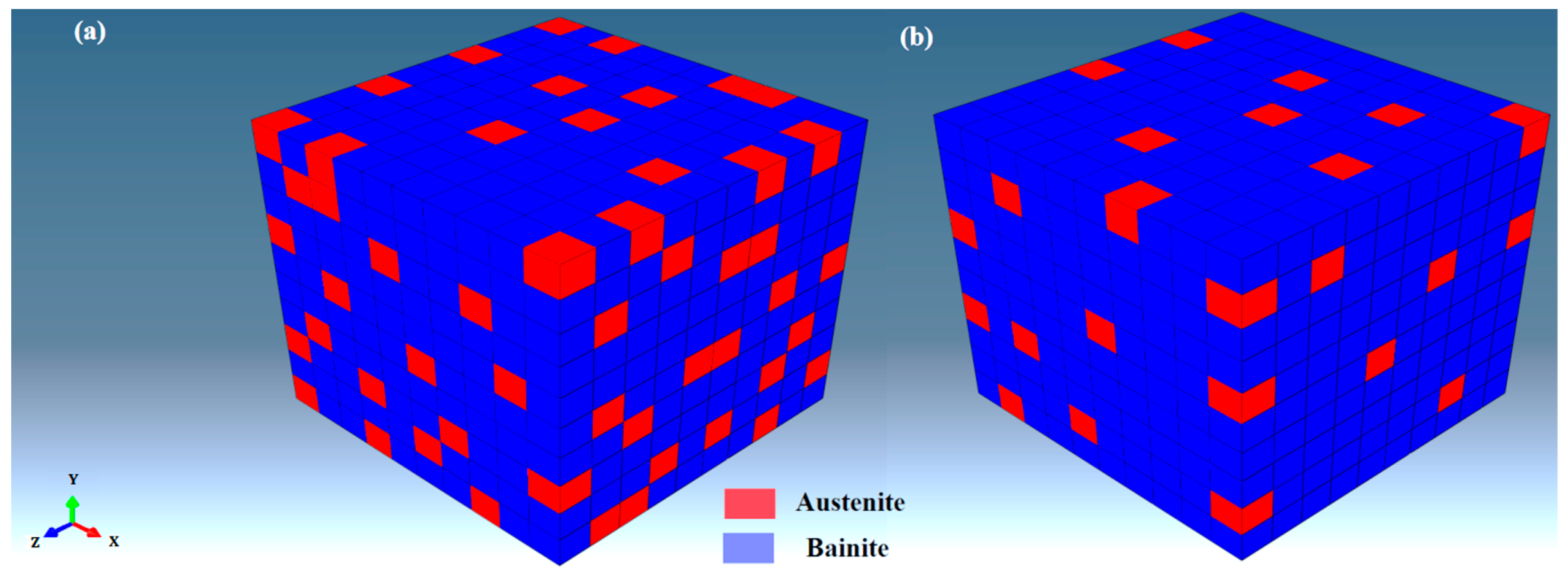

3. Constitutive Model

4. Results

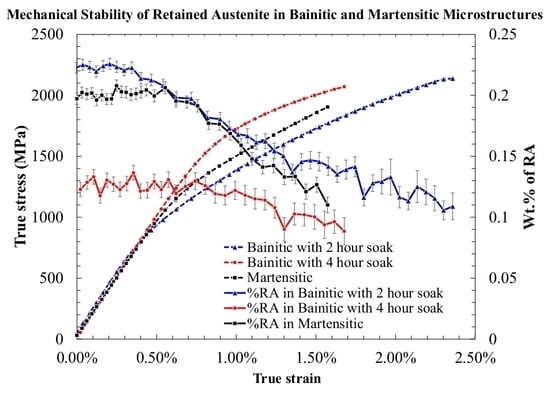

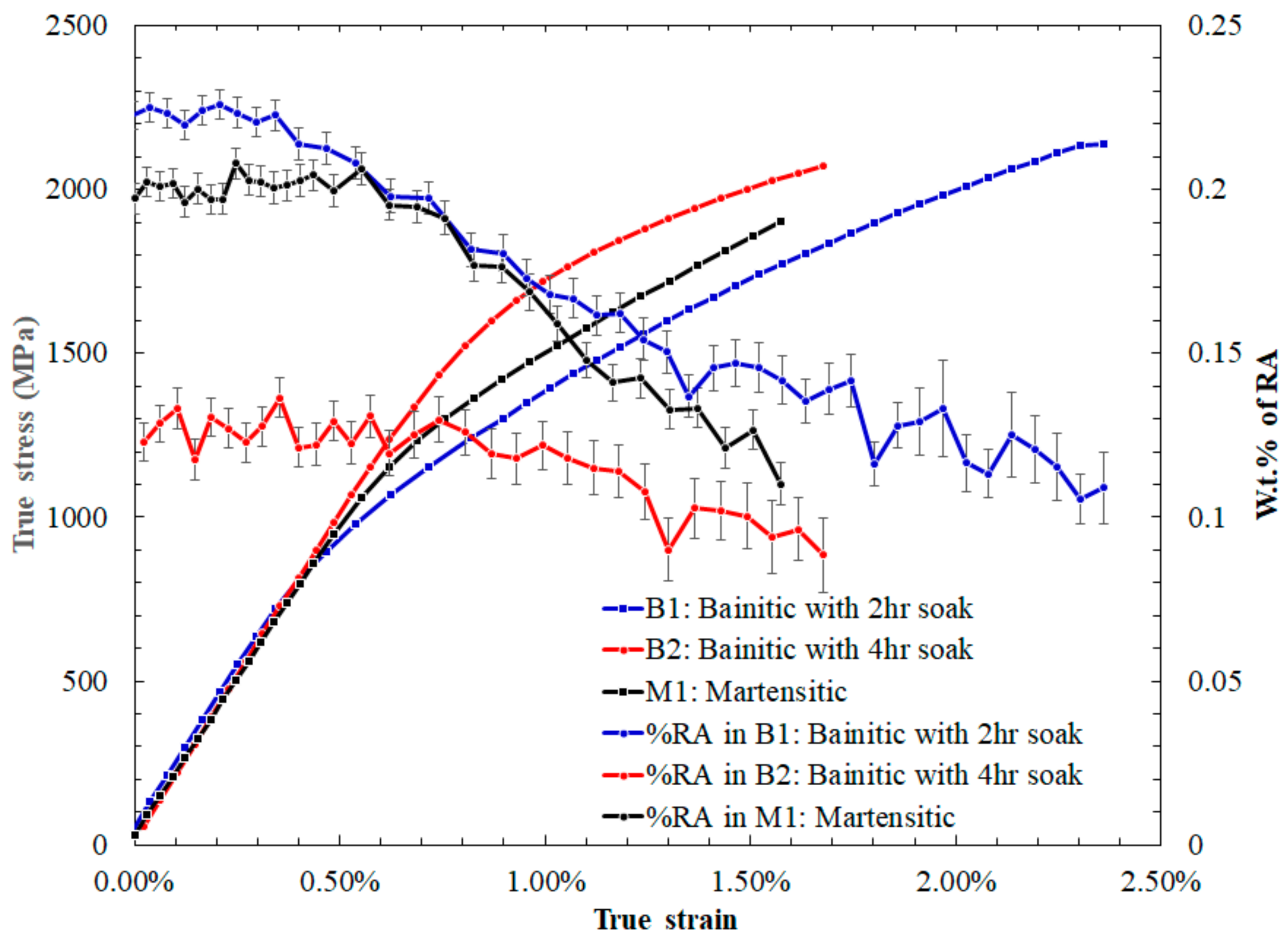

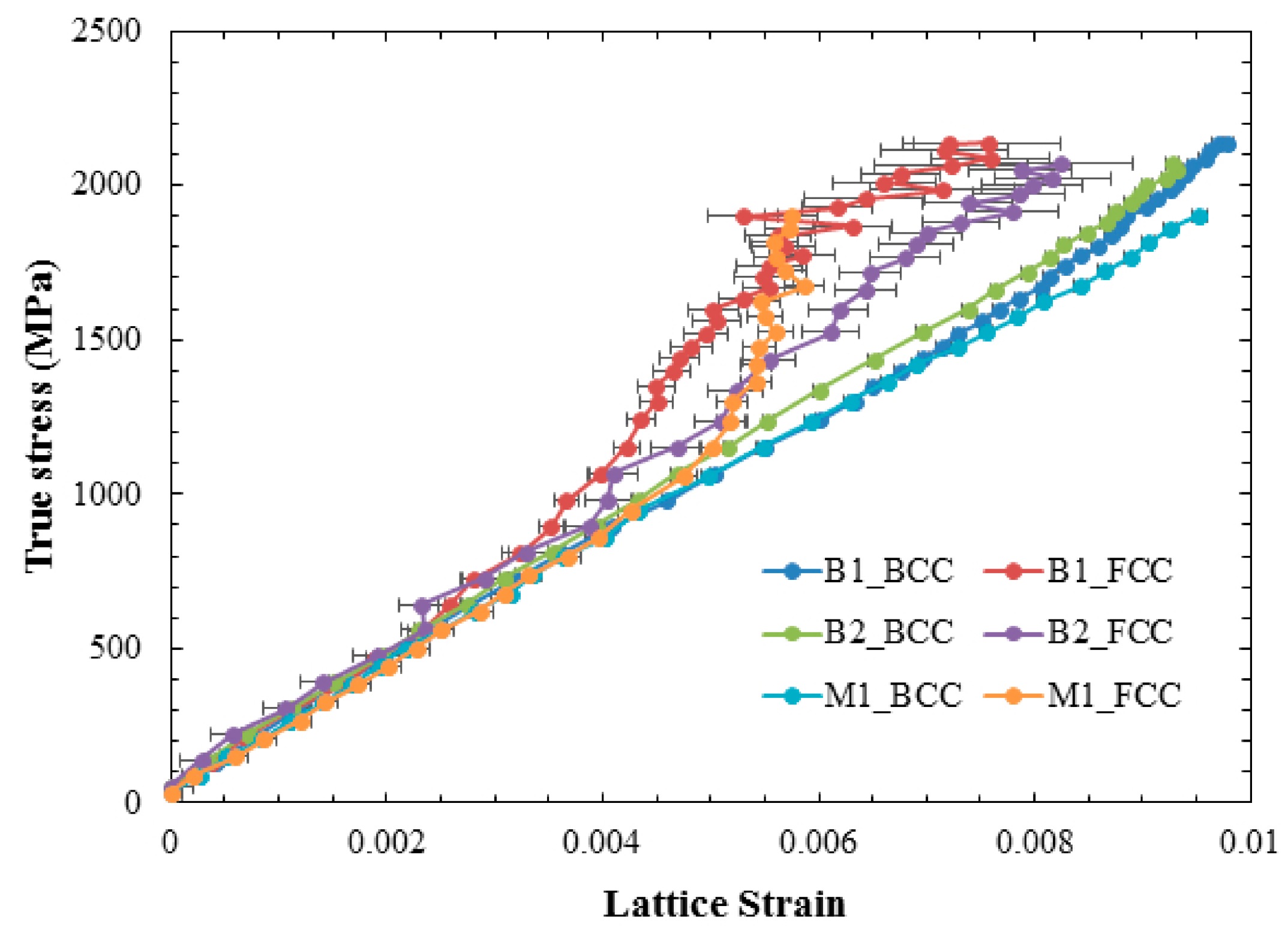

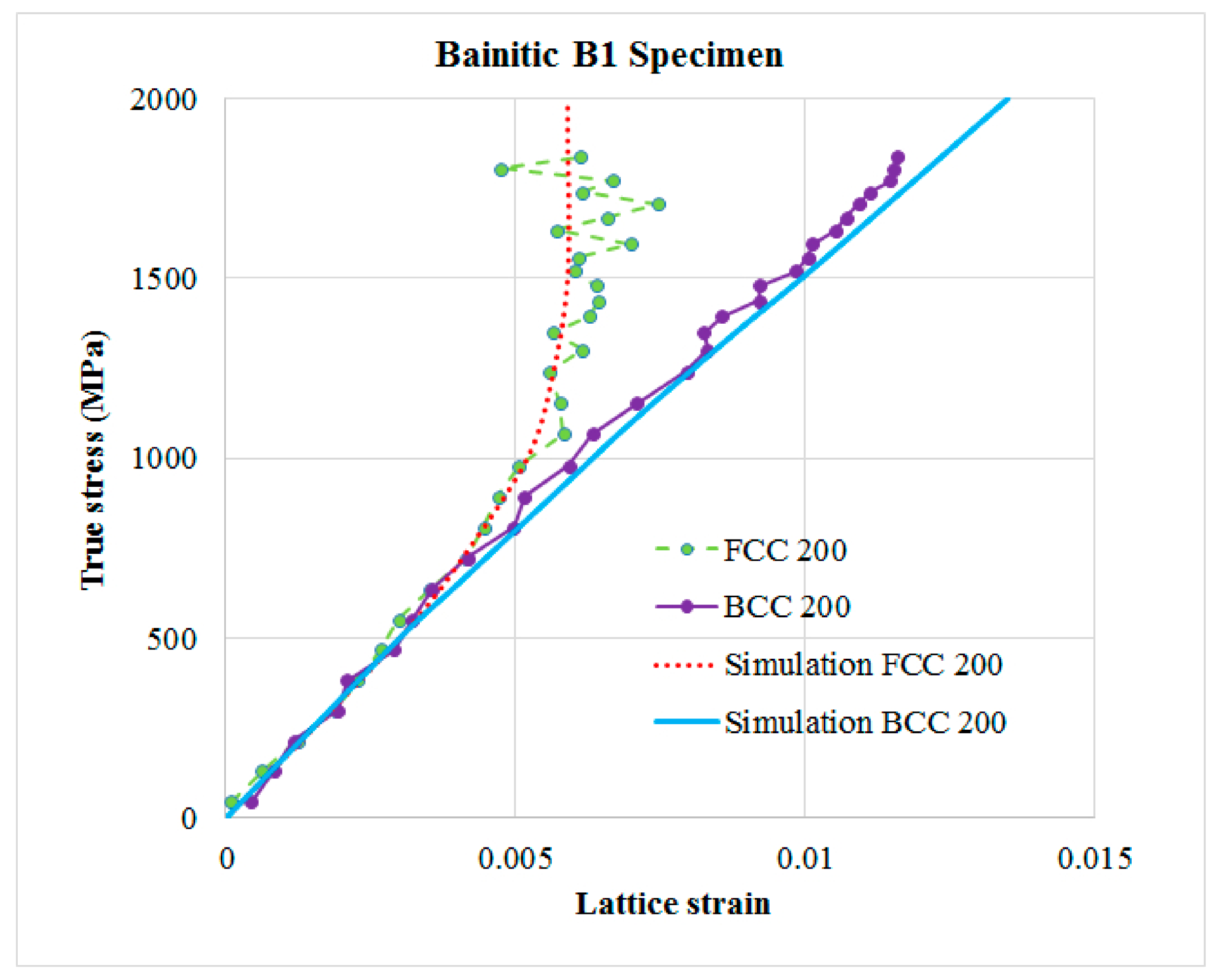

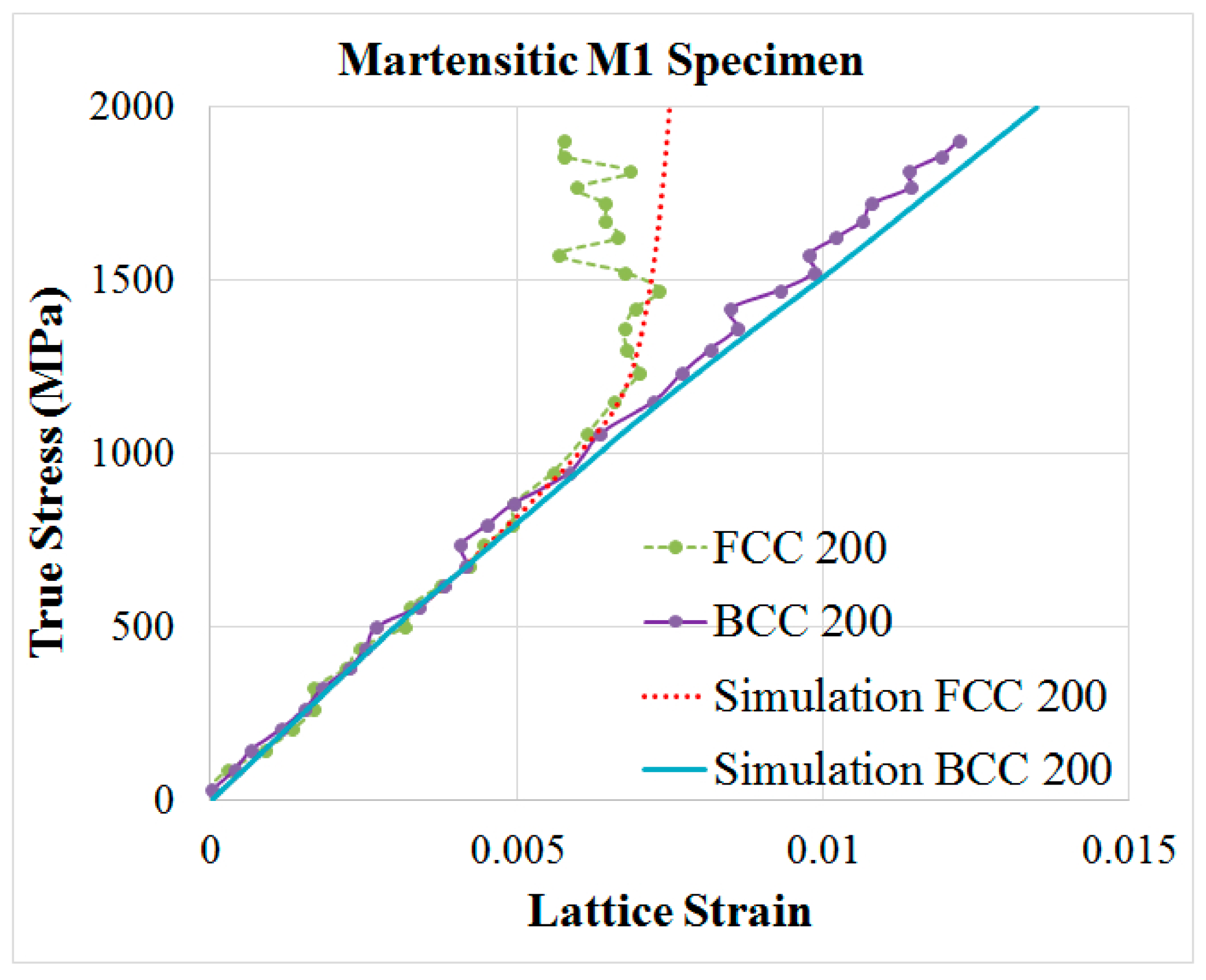

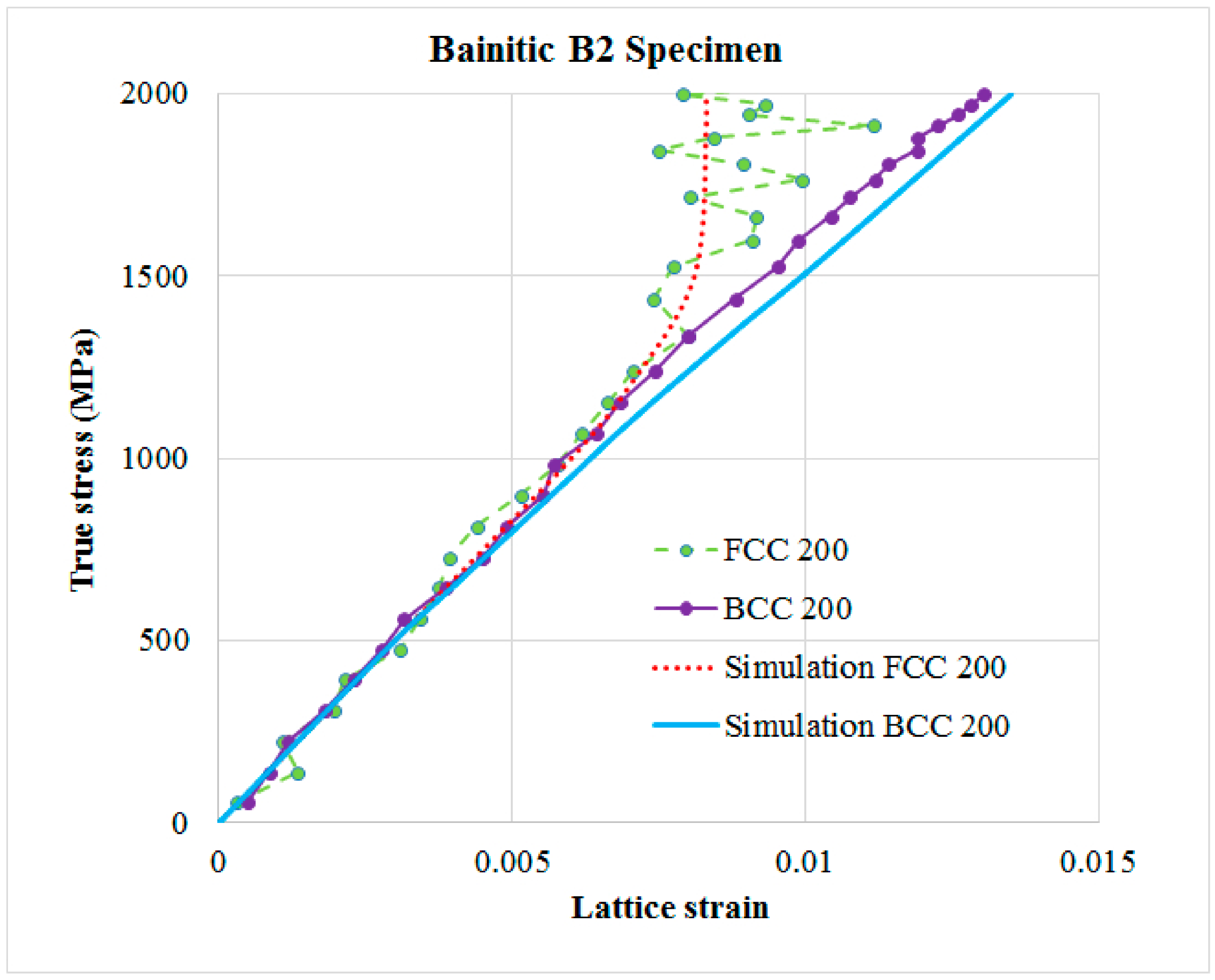

4.1. Experiment Results

4.2. Crystal Plasticity Model Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Luzginova, N.; Zhao, L.; Sietsma, J. Evolution and thermal stability of retained austenite in SAE 52100 bainitic steel. Mater. Sci. Eng. A 2007, 448, 104–110. [Google Scholar] [CrossRef]

- Hossain, R.; Pahlevani, F.; Quadir, M.Z.; Sahajwalla, V. Stability of retained austenite in high carbon steel under compressive stress: an investigation from macro to nano scale. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef]

- Zaretsky, E.V. Rolling bearing steels–a technical and historical perspective. Mater. Sci. Technol. 2012, 28, 58–69. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. The bainite transformation in a silicon steel. Metall. Trans. A 1979, 10, 895–907. [Google Scholar] [CrossRef]

- Bhadeshia, H. Martensite and Bainite in Steels: Transformation Mechanism & Mechanical Properties. J. Phys. IV Colloq. 1997, 07, C5-367–C5-376. [Google Scholar]

- Podder, A.S.; Lonardelli, I.; Molinari, A.; Bhadeshia, H.K.D.H. Thermal stability of retained austenite in bainitic steel: an in situ study. Proc R Soc A 2011, 467, 3141–3156. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. High Performance Bainitic Steels. Mater. Sci. Forum 2005, 500–501, 63–74. [Google Scholar] [CrossRef]

- De Cooman, B.C. Structure–properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Jacques, P.J. Transformation-induced plasticity for high strength formable steels. Curr. Opin. Solid State Mater. Sci. 2004, 8, 259–265. [Google Scholar] [CrossRef]

- Thomas, G. Retained austenite and tempered martensite embrittlement. Metall. Trans. A 1978, 9, 439–450. [Google Scholar] [CrossRef]

- Abudaia, F.B.; Evans, J.T.; Shaw, B. Characterization of retained austenite in case carburized gears and its influence on fatigue performance. Gear Technol. 2003, 20, 12–16. [Google Scholar]

- Rivero, I.V.; Ruud, C.O. Deviation of residual stress patterns in 52100 bearing steel due to inherent microstructural transformations after rolling contact. Mater. Charact. 2004, 53, 381–393. [Google Scholar] [CrossRef]

- Stickels, C.A. Plastic deformation of quenched and tempered 52100 bearing steel in compression. Metall. Trans. A 1977, 8, 63–70. [Google Scholar] [CrossRef]

- Voskamp, A.P. Material Response to Rolling Contact Loading. J. Tribol. 1985, 107, 359–364. [Google Scholar] [CrossRef]

- Voskamp, A.P.; Österlund, R.; Becker, P.C.; Vingsbo, O. Gradual changes in residual stress and microstructure during contact fatigue in ball bearings. Met. Technol. 1980, 7, 14–21. [Google Scholar] [CrossRef]

- Jacques, P.J.; Delannay, F.; Ladrière, J. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A 2001, 32, 2759–2768. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, D.-I.; Kim, H.S.; Bhadeshia, H.K.D.H.; Suh, D.-W. Strain partitioning and mechanical stability of retained austenite. Scr. Mater. 2010, 63, 297–299. [Google Scholar] [CrossRef]

- Xie, Z.J.; Ren, Y.Q.; Zhou, W.H.; Yang, J.R.; Shang, C.J.; Misra, R.D.K. Stability of retained austenite in multi-phase microstructure during austempering and its effect on the ductility of a low carbon steel. Mater. Sci. Eng. A 2014, 603, 69–75. [Google Scholar] [CrossRef]

- Cui, W.; San-Martín, D.; Rivera-Díaz-del-Castillo, P.E.J. Stability of retained austenite in martensitic high carbon steels. Part I: Thermal stability. Mater. Sci. Eng. A 2018, 711, 683–695. [Google Scholar] [CrossRef]

- Cui, W.; Gintalas, M.; Rivera-Diaz-del-Castillo, P.E.J. Stability of retained austenite in martensitic high carbon steels. Part II: Mechanical stability. Mater. Sci. Eng. A 2018, 711, 696–703. [Google Scholar] [CrossRef]

- Xiong, X.C.; Chen, B.; Huang, M.X.; Wang, J.F.; Wang, L. The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scr. Mater. 2013, 68, 321–324. [Google Scholar] [CrossRef]

- Cakmak, E.; Choo, H.; An, K.; Ren, Y. A synchrotron X-ray diffraction study on the phase transformation kinetics and texture evolution of a TRIP steel subjected to torsional loading. Acta Mater. 2012, 60, 6703–6713. [Google Scholar] [CrossRef]

- Lani, F.; Furnémont, Q.; Van Rompaey, T.; Delannay, F.; Jacques, P.J.; Pardoen, T. Multiscale mechanics of TRIP-assisted multiphase steels: II. Micromechanical modelling. Acta Mater. 2007, 55, 3695–3705. [Google Scholar] [CrossRef]

- Kim, E.-Y.; Woo, W.; Heo, Y.-U.; Seong, B.; Choi, J.; Choi, S.-H. Effect of kinematic stability of the austenite phase on phase transformation behavior and deformation heterogeneity in duplex stainless steel using the crystal plasticity finite element method. Int. J. Plast. 2016, 79, 48–67. [Google Scholar] [CrossRef]

- Woo, W.; Em, V.T.; Kim, E.-Y.; Han, S.H.; Han, Y.S.; Choi, S.-H. Stress–strain relationship between ferrite and martensite in a dual-phase steel studied by in situ neutron diffraction and crystal plasticity theories. Acta Mater. 2012, 60, 6972–6981. [Google Scholar] [CrossRef]

- Hidalgo, J.; Findley, K.O.; Santofimia, M.J. Thermal and mechanical stability of retained austenite surrounded by martensite with different degrees of tempering. Mater. Sci. Eng. A 2017, 690, 337–347. [Google Scholar] [CrossRef]

- Voothaluru, R.; Bedekar, V.; Xie, Q.; Stoica, A.D.; Hyde, R.S.; An, K. In-situ neutron diffraction and crystal plasticity finite element modeling to study the kinematic stability of retained austenite in bearing steels. Mater. Sci. Eng. A 2018, 711, 579–587. [Google Scholar] [CrossRef]

- Bedekar, V.; Voothaluru, R.; Xie, Q.; Stoica, A.; Hyde, R.S.; An, K. In-situ neutron diffraction analysis of crystal plasticity of retained austenite in bearing steel. Procedia Eng. 2017, 207, 1958–1963. [Google Scholar] [CrossRef]

- Jatczak, C.F.; Larson, J.A.; Shin, S.W. Retained Austenite and Its Measurements by X-ray Diffraction: An Information Manual; Society of Automotive Engineers: Warrendale, PA, USA, 1980; ISBN 0-89883-224-1. [Google Scholar]

- An, K. VDRIVE-Data reduction and interactive visualization software for event mode neutron diffraction. ORNL Rep. Oak Ridge Natl. Lab. Oak Ridge TN 2012. No ORNL-TM-2012-621. [Google Scholar]

- Stoica, G.M.; Stoica, A.D.; An, K.; Ma, D.; Vogel, S.C.; Carpenter, J.S.; Wang, X.-L. Extracting grain-orientation-dependent data from in situ time-of-flight neutron diffraction. I. Inverse pole figures. J. Appl. Crystallogr. 2014, 47, 2019–2029. [Google Scholar] [CrossRef]

- Turteltaub, S.; Suiker, A.S.J. A multiscale thermomechanical model for cubic to tetragonal martensitic phase transformations. Int. J. Solids Struct. 2006, 43, 4509–4545. [Google Scholar] [CrossRef]

- Voothaluru, R.; Liu, C.R. A crystal plasticity based methodology for fatigue crack initiation life prediction in polycrystalline copper. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 671–681. [Google Scholar] [CrossRef]

- Tjahjanto, D.D.; Turteltaub, S.; Suiker, A.S.J. Crystallographically based model for transformation-induced plasticity in multiphase carbon steels. Contin. Mech. Thermodyn. 2008, 19, 399–422. [Google Scholar] [CrossRef]

- Alley, E.S.; Neu, R.W. Microstructure-sensitive modeling of rolling contact fatigue. Int. J. Fatigue 2010, 32, 841–850. [Google Scholar] [CrossRef]

- Alley, E.S.; Neu, R.W. A hybrid crystal plasticity and phase transformation model for high carbon steel. Comput. Mech. 2013, 52, 237–255. [Google Scholar] [CrossRef]

- Voothaluru, R. A crystal plasticity based methodology for modeling fatigue crack initiation and estimating material coefficients to predict fatigue crack initiation life at micro, nano and macro scales. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Olson, G.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Mater. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Smit, R.J.M.; Brekelmans, W.A.M.; Meijer, H.E.H. Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput. Methods Appl. Mech. Eng. 1998, 155, 181–192. [Google Scholar] [CrossRef]

- Voothaluru, R.; Richard Liu, C. Determination of lattice level energy efficiency for fatigue crack initiation. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 670–678. [Google Scholar] [CrossRef]

- Turteltaub, S.; Suiker, A.S.J. Transformation-induced plasticity in ferrous alloys. J. Mech. Phys. Solids 2005, 53, 1747–1788. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|

| 1% | 1.09% | 0.6% | 1.06% | 0.11% | 0.013% | 0.012% | Bal |

| Sample ID | Hardness (HRc) | % RA | % C in RA |

|---|---|---|---|

| B1 | 58.6 | 17.7 | 0.98 |

| B2 | 58.8 | 9.1 | 1.09 |

| M1 | 61.0 | 18.0 | 0.9 |

| Martensite/Bainite | Austenite | ||||

|---|---|---|---|---|---|

| C11 | C12 | C44 | C11 | C12 | C14 |

| 278.7 | 114.2 | 90.2 | 229.1 | 101.2 | 85.4 |

| Specimen | Q (MPa) | |||

|---|---|---|---|---|

| B1 | 690 | 18% | 80.3 | 640 |

| B2 | 690 | 9% | 145 | 670 |

| M1 | 840 | 18% | 97.1 | 549 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voothaluru, R.; Bedekar, V.; Yu, D.; Xie, Q.; An, K.; Pauskar, P.; Hyde, R.S. Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels using in situ Neutron Diffraction and Crystal Plasticity Modeling. Metals 2019, 9, 482. https://doi.org/10.3390/met9050482

Voothaluru R, Bedekar V, Yu D, Xie Q, An K, Pauskar P, Hyde RS. Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels using in situ Neutron Diffraction and Crystal Plasticity Modeling. Metals. 2019; 9(5):482. https://doi.org/10.3390/met9050482

Chicago/Turabian StyleVoothaluru, Rohit, Vikram Bedekar, Dunji Yu, Qingge Xie, Ke An, Praveen Pauskar, and R. Scott Hyde. 2019. "Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels using in situ Neutron Diffraction and Crystal Plasticity Modeling" Metals 9, no. 5: 482. https://doi.org/10.3390/met9050482

APA StyleVoothaluru, R., Bedekar, V., Yu, D., Xie, Q., An, K., Pauskar, P., & Hyde, R. S. (2019). Investigating the Difference in Mechanical Stability of Retained Austenite in Bainitic and Martensitic High-Carbon Bearing Steels using in situ Neutron Diffraction and Crystal Plasticity Modeling. Metals, 9(5), 482. https://doi.org/10.3390/met9050482