1. Introduction

Metals are polycrystalline aggregates composed of numerous grains that can be considered perfect crystals if the materials are fully recrystallized. In order to predict the behavior of polycrystalline materials subjected to macroscopic load, the relationship between microstructures and properties should be known, and therefore, physically based modeling is of key importance. The understanding of microstructural changes is particularly important in setting up the thermomechanical processing (TMP) route. In TMP, the as-cast microstructure is subjected to continuous microstructural transformation. In the case of flat-rolled products, such as Al sheets, this transformation is conditioned by both deformation and recrystallization phenomena, since after casting, the material is subjected to hot rolling, which is followed by cold rolling, and finally the sheet is recrystallized during the final annealing process.

Various modeling approaches that employ diverse length scales (

Figure 1) have been developed to reveal the behavior of materials during TMP [

1]. It is a common practice to employ phenomenological models for the optimization of properties in groups of metals that do not reveal substantial varieties in chemical composition [

1,

2]. This strategy likewise works for tailoring a certain metal grade for a particular application. The main disadvantage of phenomenological approximations is that the model parameters need to be recalibrated in the case of a metal grade change or if the TMP quantitative indicators are varied in a wider range of processing windows. In more advanced numerical formulations, such as finite element modeling (FEM), materials are considered as continua, and thus, the mesoscopic phenomena, occurring on the grain levels, are not accounted for in this engineering length scale (

Figure 1). Nevertheless, FEM is successfully employed in many fields, especially when there is a need to simulate the response of a system subjected to mechanical load. On the other end of the length-scale spectrum, macroscopic properties are derived from interatomic potentials and by engaging basic principles of molecular thermodynamics, which ensures generic information about the relationships between atomic arrangements and macroscopic properties; however, this formulation is applicable only for ideal systems. The application of atomistic length-scale simulations to metals is restricted due to limitations in computational resources and also because of the fact that polycrystalline structures contain too many crystal defects even in a fully recrystallized state (typically 10

8 m

−2).

Since a 1-mm-thick metallic sheet (A4 size (21 cm × 29.7 cm)) contains approximately 4 billion grains of various crystal orientations, assuming that the average grain size is 25 μm, it becomes clear that neither engineering (continuum) nor atomistic scales are capable of revealing the true nature of mesoscopic transformation involved in TMP. To capture the essence of microstructural changes in industrially produced materials, both mean-field and full-field crystal plasticity (CP) models are employed [

1,

3,

4,

5,

6,

7,

8,

9]. Either approach implements a certain homogenization scheme insofar as performing calculations for the above-mentioned 4 billion crystals, consisting of even smaller entities, would require enormous computational power. In CP, homogenization implies a characteristic length scale (mesoscopic) represented by grains of polycrystalline aggregate, and these entities are treated as perfect crystals (the in-grain heterogeneities are usually not taken into account). The mesoscopic scale tends to fall between two ends of the characteristic length spectrum, and this level of order is important from a practical perspective, as many of the known properties are controlled by the grain size and crystallographic texture. CP approaches treat the polycrystalline material as a continuum at the level of the crystal because the grain size is order of magnitudes larger compared to the size of molecular domains.

Full-field models [

1,

3,

4] allow for analyzing not only the microscopic and macroscopic responses of material but also account for the evolution of heterogeneities at both levels. Although these methods give rise to a more comprehensive representation of a microstructure and provide detailed information on the deformation flow on meso- and macrolength scales, their practical implementation is limited because of extensive computational time. In contrast, the mean-field models are more computationally efficient, but they have fewer degrees of freedom compared to the full-field methods. For instance, in mean-field approximations [

5,

6,

7,

8,

9], among other things, each grain interacts with a neighboring one in a way defined by the homogenization scheme, and the misorientation in the grain developed during deformation cannot be captured. Even though some microstructural features are ignored in Taylor-type homogenization CP formulations (such as “visco-plastic self-consistent (VPSC) [

7], advanced Lamel (Alamel) [

5,

6], Cluster V [

8], etc.), simulations on a mesoscopic scale are still capable of providing generic knowledge on the relationship between the structure, properties, and performance of a polycrystalline aggregate. Polycrystal models have been successfully employed in simulating the evolution of texture in metals (subjected to diverse strain modes), calculating the plastic strain ratio as well as predicting the cup-earing [

5,

6,

7,

8,

9,

10,

11].

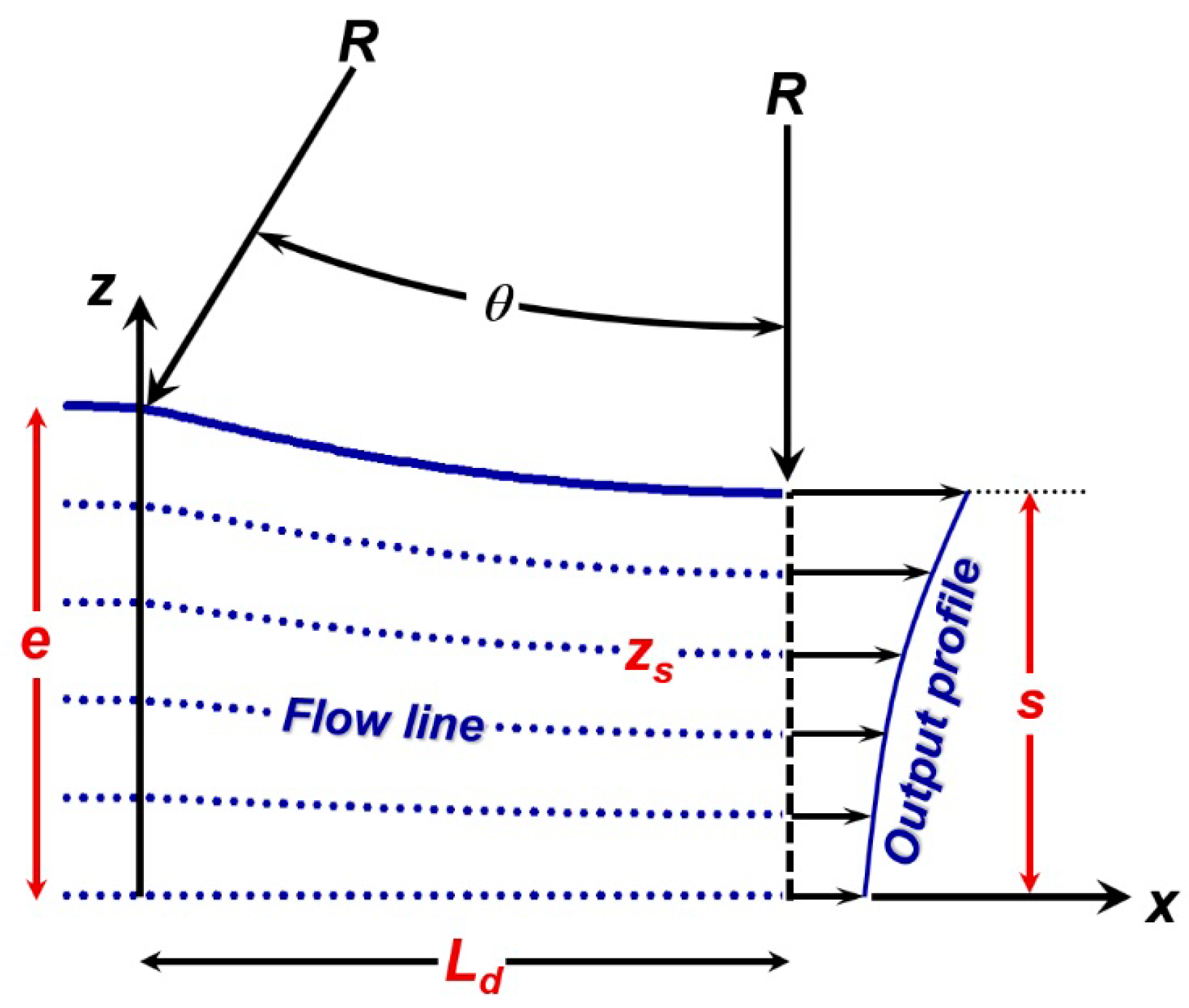

Among the many homogenization theories, Alamel [

5,

6] was employed in this study to simulate the texture evolution in an Al alloy. In this mean-field approach, the grain assembly is subdivided into a number of clusters consisting of two grains, whereas the interaction inside the cluster is governed by the randomly chosen grain boundary orientation. For a given pair of grains, the equilibrium of stresses is accomplished via the strain compatibility. Similarly to the above-listed Taylor-type models [

5,

6,

7,

8,

9], the grain pair is subjected to a strain mode identical to the macroscopic one. In crystal plasticity formulations (including Alamel), the evolution of texture in face centered cubic (FCC) metals during cold deformation is related to the crystallographic slip on octahedral slip systems, whereas the macroscopic strain mode is approximated by various models. In order to make the application of crystal plasticity modeling practically attainable, the CP should be coupled with the computationally effective approach, which is capable of accurate prediction of deformation flow in a material. When it comes to rolling, the simplest approximation is the plane strain compression, which disregards many aspects of the process. Because of its simplicity, this strain mode is often used in simulations and tends to provide a reasonable estimate of overall (bulk) texture evolution [

5,

6,

8,

10]. In FEM, the effect of many technological parameters on the deformation flow can be taken into account, while the displacement history is accurately calculated for various materials at diverse temperatures; however, the model set-up and the calculation procedure are time-consuming. In view of this, deformation is often approximated by analytical solutions [

12,

13,

14,

15,

16,

17,

18] such as flow-line models, which are capable of capturing many aspects of the process; however, the practical implementations of these computationally effective approaches are limited by fitting parameters, which have to be derived from the experimental data for each particular case.

Modeling the evolution of deformation texture in Al alloys by combining the basic principles of CP theories and models that are capable of predicting deformation flow is vital, since many crystallographic features evolved in deformation are directly linked to the evolution of recrystallization texture [

19,

20,

21]. The latter determines plastic anisotropy and limits the forming characteristics of a material.

Even though many efforts have been made to model texture development during cold rolling, there are nevertheless many aspects of texture evolution that are still not explained by existing models. The goal of this contribution was to employ computationally efficient and accurate numerical approaches that could ensure quantitatively reasonable texture simulations for the cold rolling process. For this, a well-established CP model (Alamel) [

5,

6] was coupled with the recently developed FLM [

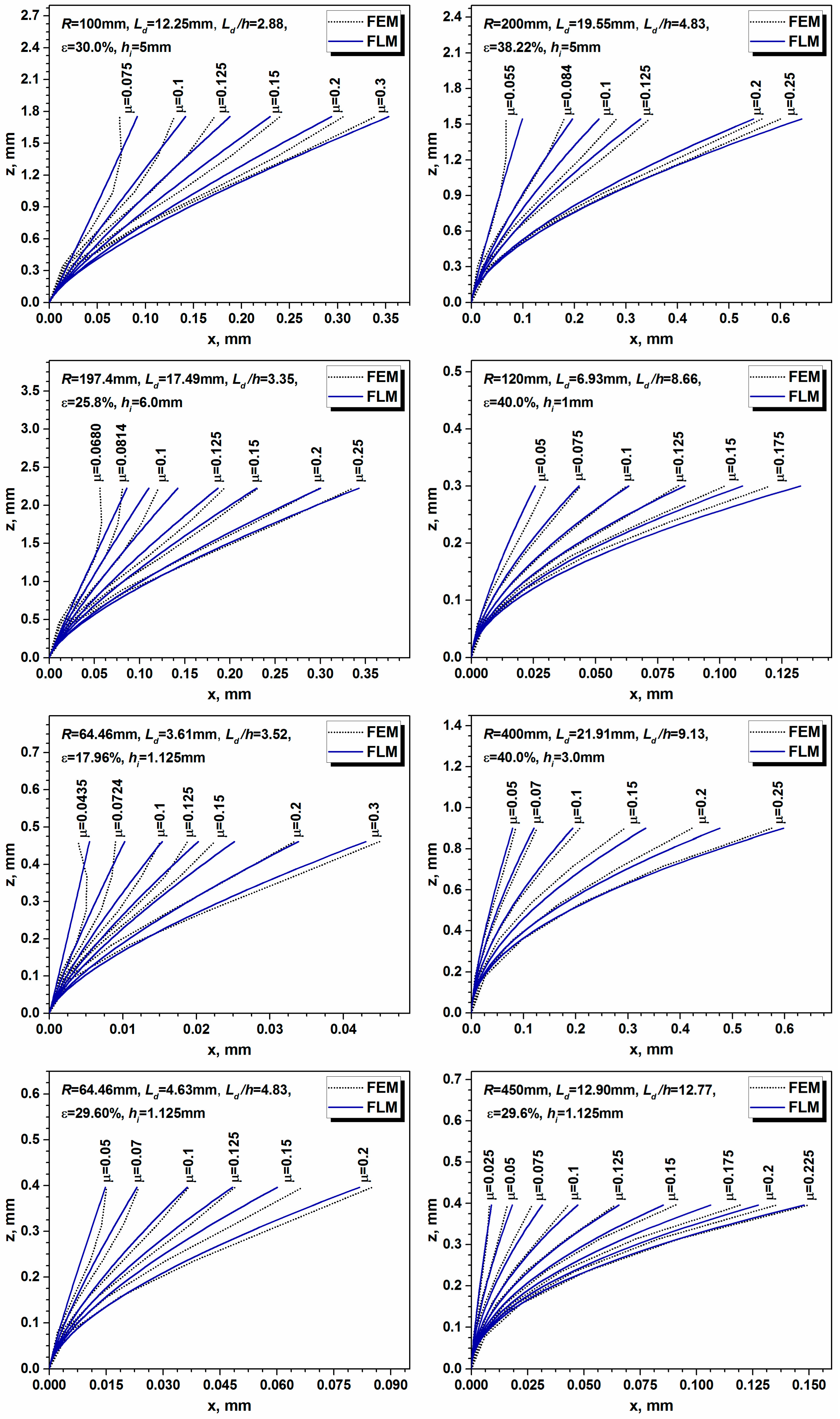

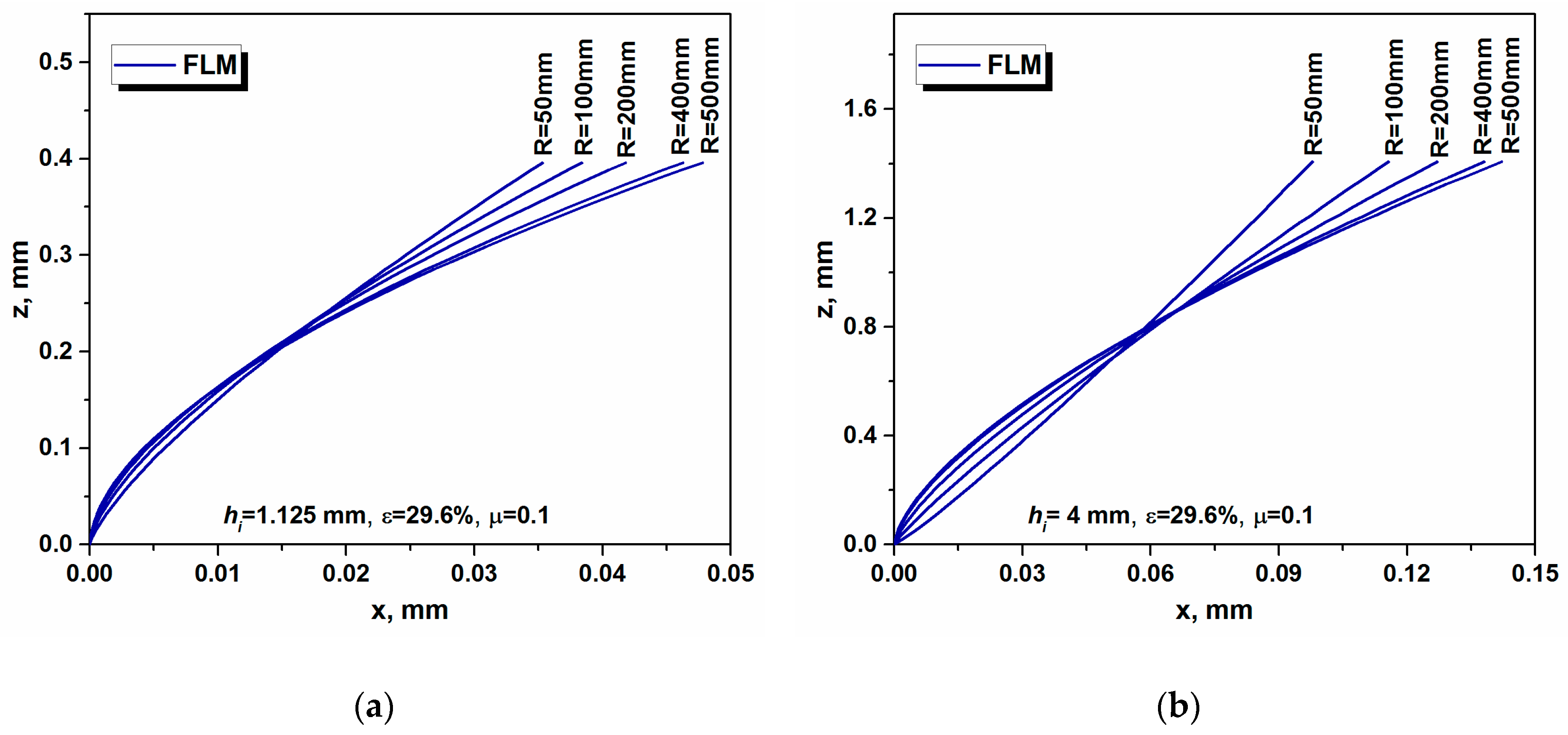

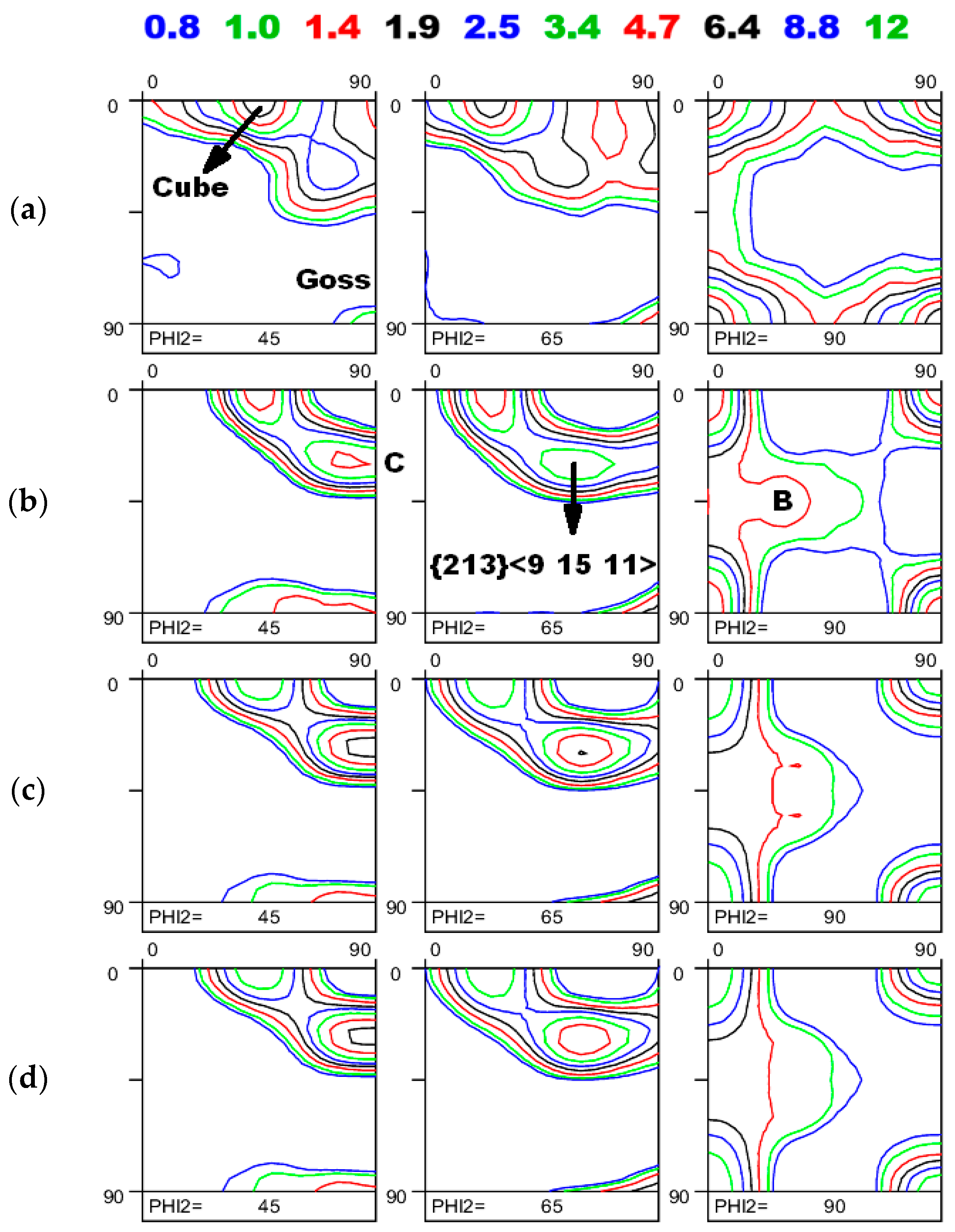

14]. To make the CP simulations practically applicable, a correlation was defined between the FLM model parameters, the roll gap geometry, and the friction coefficient. This implies that combined Alamel–FLM-based modeling can be performed without a fitting procedure, allowing for analyses of the effect of technological quantitative indicators on texture evolution in cold rolling. It is shown that the Alamel–FLM texture simulations revealed both qualitative and quantitative resemblance to the counterparts calculated with the deformation history obtained by means of finite element modeling. The quality of the texture simulations was estimated by comparing the simulated textures to the experimentally measured ones.

4. Application of Deformation History to Texture Simulation

Al alloys are generally cold-rolled with thickness reductions up to ~85% in several passes; however, in some cases, intermediate annealing can be employed to avoid texture banding, which leads to a roping phenomenon [

24,

27]. In the current case, the material was subjected to a 29.6% reduction along one path. Preceding the rolling, the annealing process ensured a recrystallization texture in the investigated material. The bulk (overall) texture of the sheet (

Figure 9a) measured across the thickness was mainly composed of recrystallization texture components such as Cube ({001}〈100〉), Goss ({001}〈100〉), and ~ {113}〈121〉 orientation (

φ1 = 75°, Φ = 25°,

φ2 = 45°). As revealed in

Figure 9b, the deformation process induced qualitative texture transformation, where the recrystallization texture components rotated to both α (〈001〉//ND) and β-fiber orientations, which is analytically described by the following expression:

The reference components of the β-fiber calculated by means of Equation (13) enable the tracing of the texture evolution involved in cold rolling. The deformation texture orientations showed an unequal distribution along the β-fiber (

Figure 9b). The intensity along this fiber tended to decline with an increase in

h (Equation (13)), i.e., the texture intensity followed a downward trend while moving from Copper (

h = 1) via {213}〈9 15 11〉 (

h = 2) to Brass (

h is an infinitely large number). In

Figure 9b, a 29.6% rolling reduction did not cause a severe drop in the intensity of the Cube orientation.

Figure 9c,d reveals the evolution of the rolling textures modeled with the Alamel model [

5,

6] by employing the deformation history in

Figure 10. The CP calculations were performed for six equidistant layers (the surface, four subsurface layers, and midthickness plane), and subsequently, the average bulk texture was calculated by merging the individual ODFs. When comparing

Figure 9b–d, it becomes apparent that both the experimental and modeled textures followed an identical evolutionary pattern. Similarly to the experimentally measured ODF of

Figure 9b, the β-fiber orientations of the modeled counterparts (

Figure 9c,d) were well distinguished in the first part of the skeleton line (between {112}〈111〉 and {213}〈9 15 11〉), while toward the tail of the fiber (running from {213}〈9 15 11〉 to {101}〈121〉), the individual components tended to vanish.

Inasmuch as the rolling was performed on well-lubricated surfaces on both the sheet and rolling cylinders, the FEM simulation was performed with the

μ slightly exceeding the minimum value necessary for rolling (

μ = 1.5

μmin), while the corresponding FLM model parameters (α and

n) were approximated by Equations (10)–(12). As

Figure 9 shows, an approximation of rolling by both the FEM and FLM employed [

14] provided a meaningful texture prediction; however, employing various deformation histories accounted for diverse texture development. The quality of the texture simulation was assessed by analyzing qualitative texture indicators (TIDs) such as the ODF maximum value (

ODFmax), texture index (

TI = ∫[

f(

g)]

2dg), and normalized index difference

ID. The

ID, observed between the experimental

fexp(

g) and the simulated

fsim(

g) textures, tended to rise with an increase in diversity between the compared ODFs:

An examination of the TIDs calculated for

Figure 9c,d clearly indicates that the FLM coupled with the CP model was capable of carrying out a texture simulation close to the one performed with the deformation history obtained by means of the finite element model. The employment of both FEM and FLM in the texture simulation led to a slight overestimation of the

ODFmax value compared to the experimental counterpart, whereas the calculated

TIs revealed a close resemblance to the experimentally measured one. Furthermore, the low

ID numbers obtained by FEM and FLM (

ID(FEM) = 0.085 and

ID(FEM) = 0.076) suggest that the FLM employed can be considered to be a potential approach for the computation of strain history in rolling. Although the time necessary for crystal plasticity simulation is hardly affected by the strain mode, the same cannot be said about the calculation of strain history by FEM and FLM, which gives credit to the practical implementation of the latter. The FLM calculation can be performed within a fraction of a second, while FEM requires hours for computation.

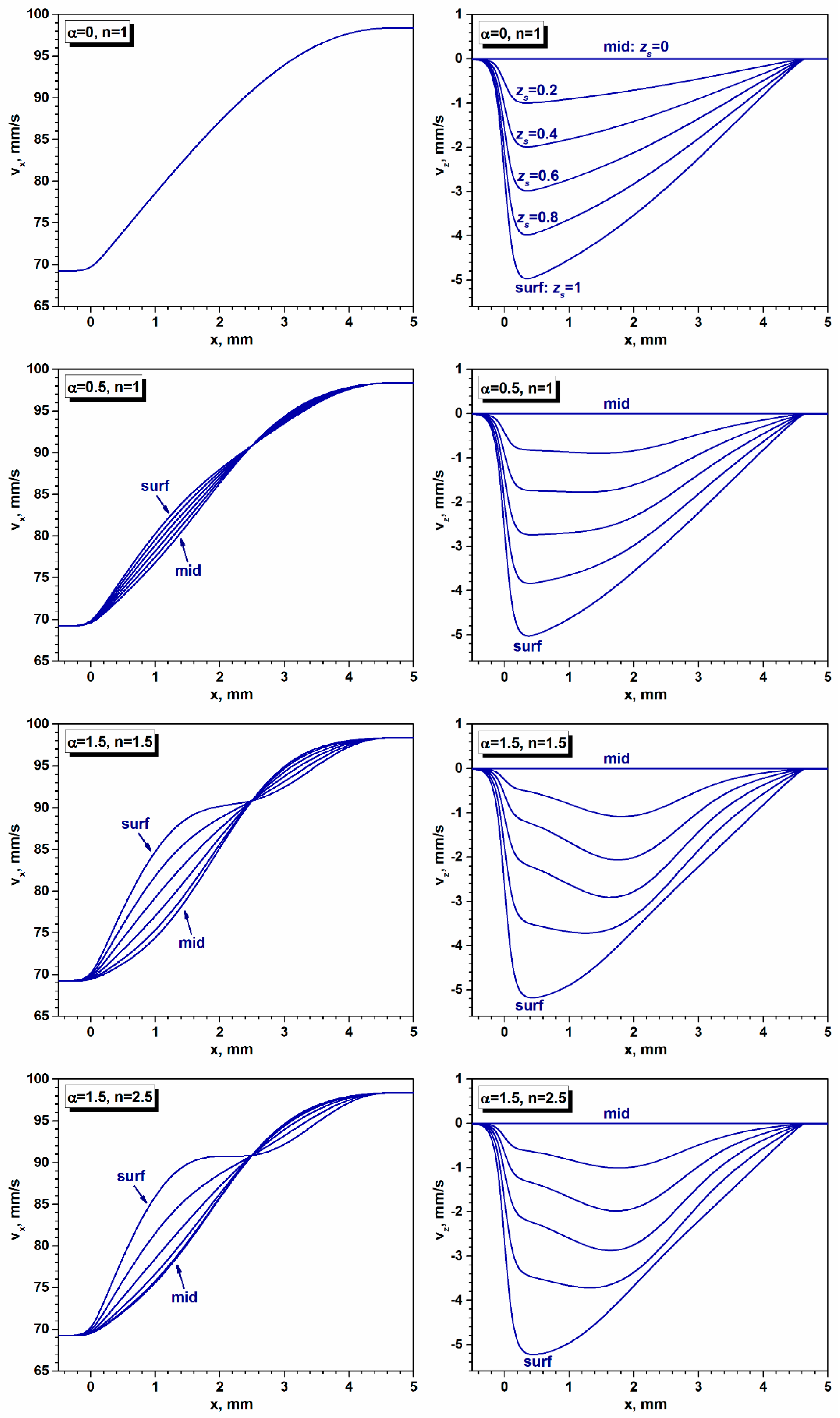

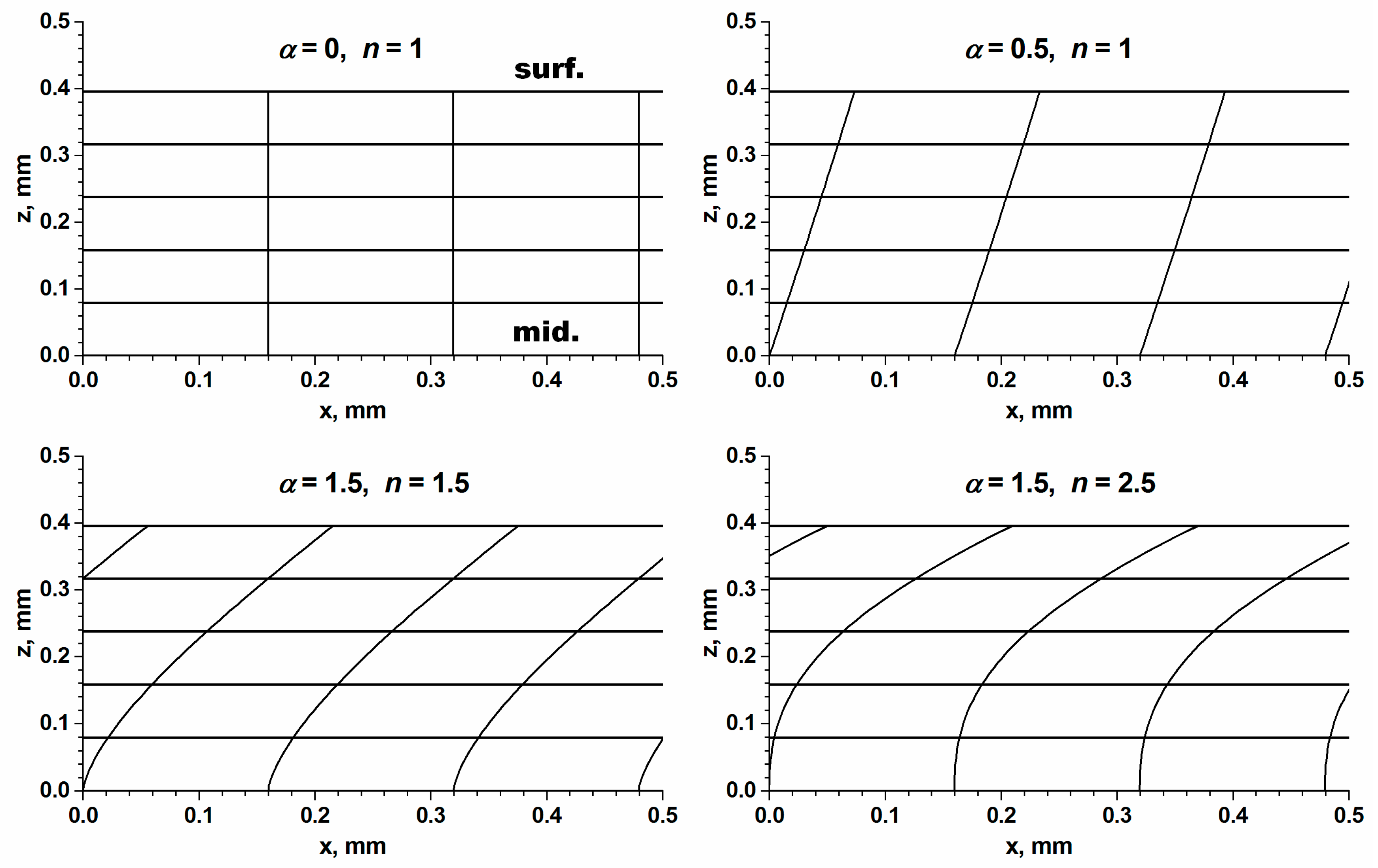

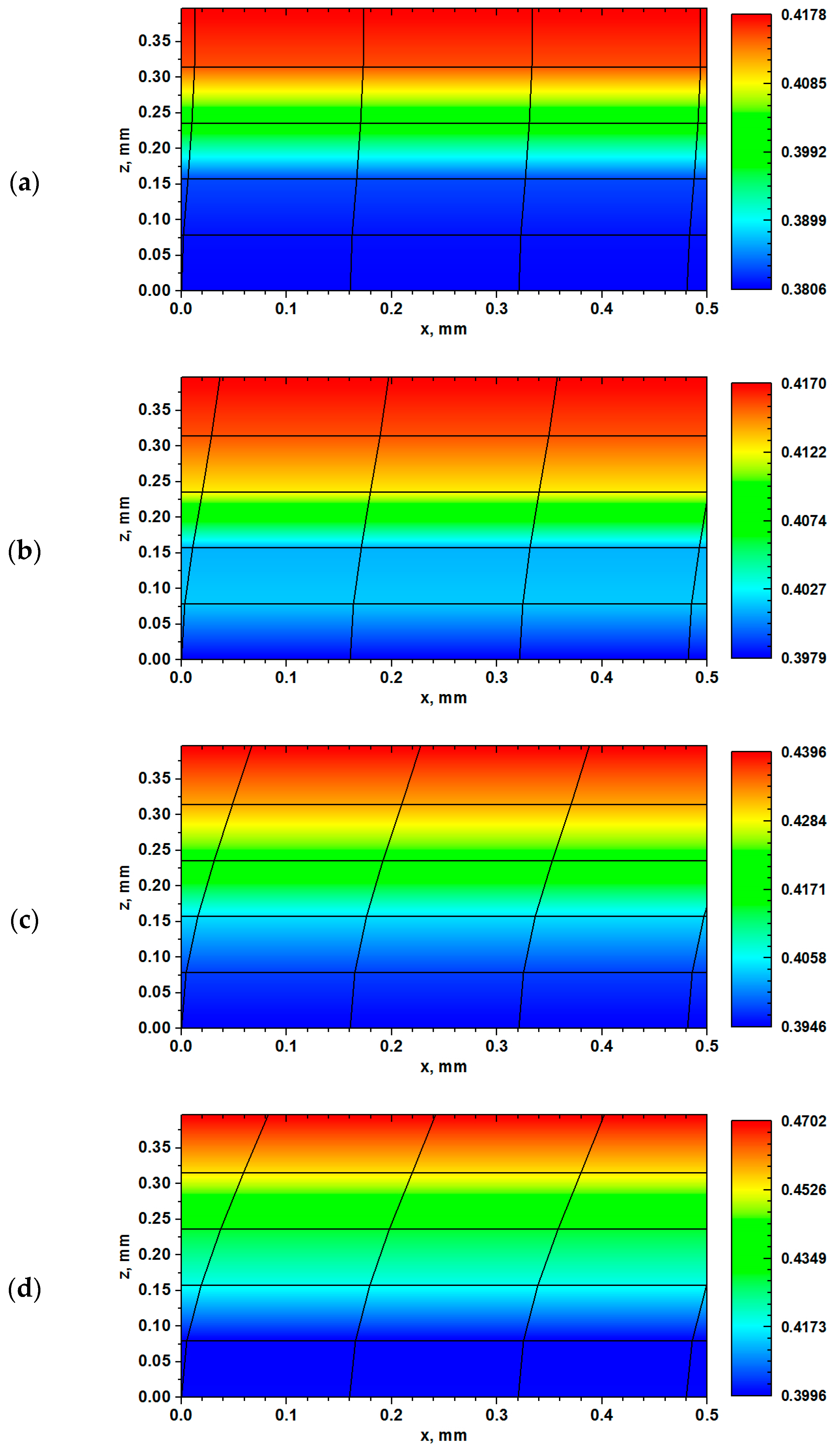

The heterogeneity of texture evolution across the thickness of a rolled sheet was accounted for by considering the heterogeneous nature of the strain path evolution in each individual layer (see

Figure 10). The through-thickness strain inhomogeneities tended to evolve due to unequal shear distribution. In cold-rolling trials, the sense of balance between the geometric and friction-induced shear components is governed by friction conditions. As seen in

Figure 10, first the resulting shear rate

was of a negative sense and after that became positive. This implied that initially

was tilted toward the roll gap geometry-induced shear components, while later the friction-induced shear tended to prevail [

2]. Apart from the quantitative diversity (

Figure 10), the major difference between the strain rate patterns calculated by FEM and FLM was that the flow-line model predicted a more gradual change of

components with time, while the corresponding counterparts computed by FEM revealed more oscillating behavior.

Figure 11 reveals both an experimentally measured and simulated evolution of texture in various thickness layers. The ODF of the first layer covered the area between the surface and 3/10 of the half-thickness, the second layer extended from the 3/10 to 3/5 of the half-thickness, and the third layer ranged between 3/5 and the midplane of the sheet. The ODFs of these layers, displayed in

Figure 11a, reveal a close qualitative resemblance, while some quantitative diversities can be observed between the individual textures. In order to access the degree of texture heterogeneity (

IDH) between the two layers (

i and

j), the index difference was expressed as

where

f0exp(

g) refers to experimentally measured overall (bulk) texture.

Prior to cold rolling (

Figure 11a), the recrystallization process ensured a minimal degree of heterogeneity in the investigated material (see

Table 1 for details). The values of

IDH tended to enhance after cold rolling, pointing toward the evolution of texture diversities in various layers (

IDH(

L1–2) = 6.43 × 10

−2 and

IDH(

L2–3) = 2.40 × 10

−2). This evolutionary pattern was likewise captured by the crystal plasticity calculations, which predicted more homogeneous textures for layers 2 and 3, whereas the extent of heterogeneity rose when the

IDH values for layers 1 and 2 were computed (FLM-CP:

IDH(

L1–2) = 4.59 × 10

−2 and

IDH(

L2–3) = 5.60 × 10

−3; FEM-CP:

IDH(

L1–2) = 4.41 × 10

−2 and

IDH(

L2–3) = 5.33 × 10

−3).

In the rolled material (

Figure 11b), the intensity of the {001}〈100〉 orientation was enhanced from the surface to the midthickness, and this tendency was equally captured by the CP simulations of

Figure 11c,d. The same evolutionary trend was observed for the {112}〈111〉 component, while the tail of the β-fiber (particularly the {101}〈121〉 orientation) tended to weaken from the surface to the middle. This phenomenon was also captured by both the FEM-CP and FLM-CP simulations. The quantitative texture indicators, which allowed for comparisons between the experimentally evolved deformation texture patterns (

Figure 11b) and the modeled counterparts (

Figure 1c,d), are summarized in

Table 2. It is obvious that the results of the simulations showed a close resemblance between the calculated and experimentally measured counterparts. Furthermore, a minimal discrepancy was observed between the FLM- and FEM-based CP predictions.

In addition to previously published works [

3,

4,

5,

6,

7,

8,

9,

10,

11,

28], this investigation reveals how the quality of the texture simulation is affected by the choice of strain history approximation. Examining the results of the CP computations shown in

Figure 9 and

Figure 11, it can be noticed that the Taylor-type homogenization model (Alamel) [

5,

6] provided both a qualitatively and quantitatively reasonable texture prediction upon the condition that the technique employed for the computation of the strain history was capable of capturing the strain heterogeneity across the thickness. As was shown in recent work [

28], the application of other homogenization schemes (VPSC [

7] or Cluster V [

8]) likewise tends to provide meaningful texture evolutionary patterns with quantitative texture characteristics comparable to the Alamel model. Therefore, the FLM employed [

14] can be successfully coupled with an arbitrary CP model.

Although FLM neglected the strain hardening phenomena, while the materials experienced hardening during deformation in the FEM, the result of the CP simulations performed with both FEM and FLM outputs revealed minor differences (

Figure 9 and

Figure 11). This implies that strain hardening parameters have a slight effect on the quality of texture prediction. Furthermore, approximating the rolling process with plane strain compression or geometric models [

10,

28] equally provides a reasonable estimate of texture evolution. Even though Taylor-type homogenization models employ strain hardening, varying the values of hardening model parameters for metallic systems, in which the deformation is governed by a single mode (such as a slip), has a negligible effect on the quality of texture prediction. It should be pointed out that this scenario is not applicable to polycrystals, which tend to deform in two diverse modes. In metals deformed by sleep and twinning, the deformation occurs by means of the first mechanism up to a certain strain level, whereas exceeding this straining degree induces another mechanism of deformation (twinning). In this case, the choice of correct hardening parameters is of critical importance. It should be likewise stressed here that when materials experience extensive strain hardening or are subjected to severe plastic deformation, the evolution of local phenomena (such as shear bands) cannot be neglected, since they affect texture development. In contrast to homogenization CP theories, crystal plasticity finite element approaches or CP formulations based on fast-Fourier transforms [

4] are capable of predicting macroscopic strain heterogeneities such as through-thickness strain gradients and also providing information on local phenomena (such as the strain/stress evolution on grain boundaries or the development of shear bands). These numerical approaches are computationally demanding and are not discussed in the frame of this study.

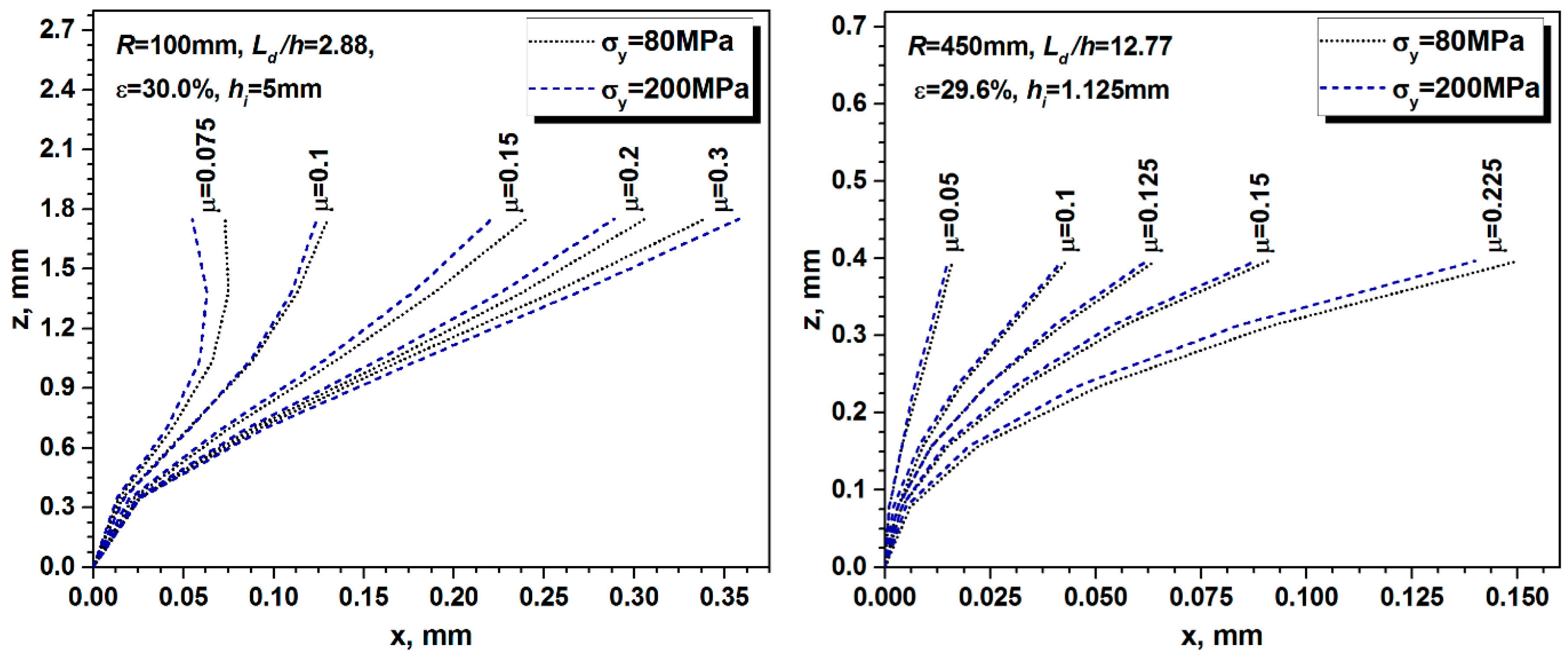

In addition to the above-mentioned issues, there are many pros and cons regarding the implementation of analytical models; however, to make the application of FLM approaches more practically attainable, both the upper and lower bounds of implementation should be determined. This investigation predominantly focused on Al alloys with a yield point comparable to 80 MPa; however, even in the frame of a particular series, the yield stress may vary around ~100 MPa. This change in the flow stress will significantly affect the stress state of materials during rolling, which is not accounted for in FLM [

14]. In order to determine the applicability limits of the FLM employed, the deformation flow was analyzed at the two ends of the

Ld/

h spectrum (

Ld/

h = 2.88 and

Ld/

h = 12.77) in materials with σ (σ

y = 80 MPa and σ

y = 200 MPa).The results of the FEM simulations presented in

Figure 12 suggest that an increase in yield stress from 80 MPa to 200 MPa triggers some variety in the displacement across the thickness at low values of the contact length-to-mean thickness ratio (

Ld/

h = 2.88), whereas this deviation tends to vanish when rolling is performed with large draughts (

Ld/

h = 12.77). Analyzing

Figure 5,

Figure 6 and

Figure 7 and 12, it turns out that the deformation flow in materials, as predicted by both the FEM and FLM simulations, was majorly controlled by roll gap geometry and friction conditions, while the hardening phenomena seemed to have a smaller effect on the corresponding displacement profiles. The inconsistencies shown in

Figure 12 did not cause significant qualitative and quantitative texture changes, since minor strain path variations do not affect the evolution of texture drastically (see

Figure 9 and

Figure 11). This implies that FLM [

14] can be employed for texture simulations in Al alloys from diverse series; nevertheless, it should be pointed out that if material properties or processing limits significantly deviate from the above-mentioned bounds, the results should be treated with particular care.