Hot Workability of 300M Steel Investigated by In Situ and Ex Situ Compression Tests

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Hot Compression Tests

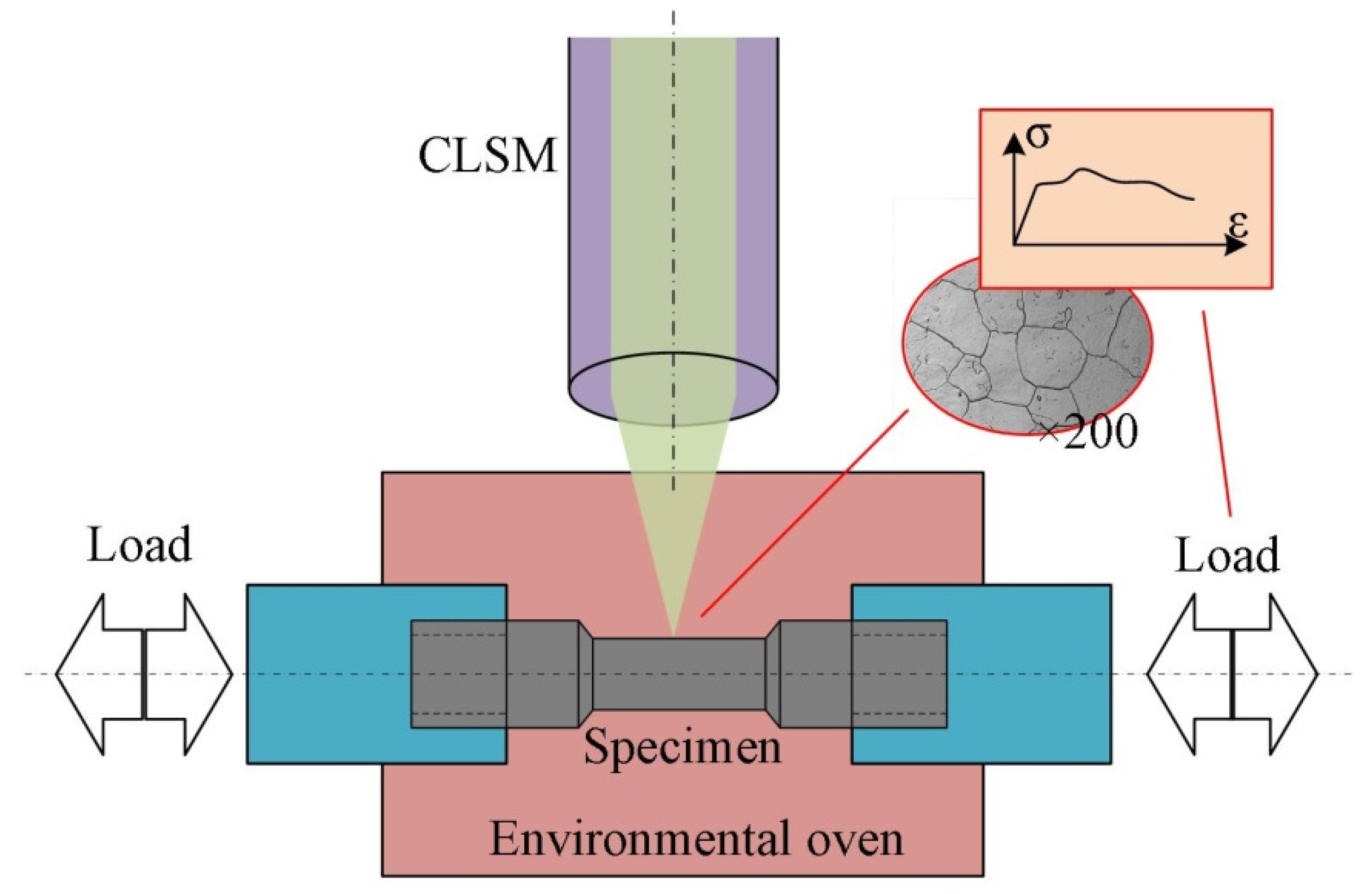

2.3. In Situ Compression Tests

3. Results and Discussion

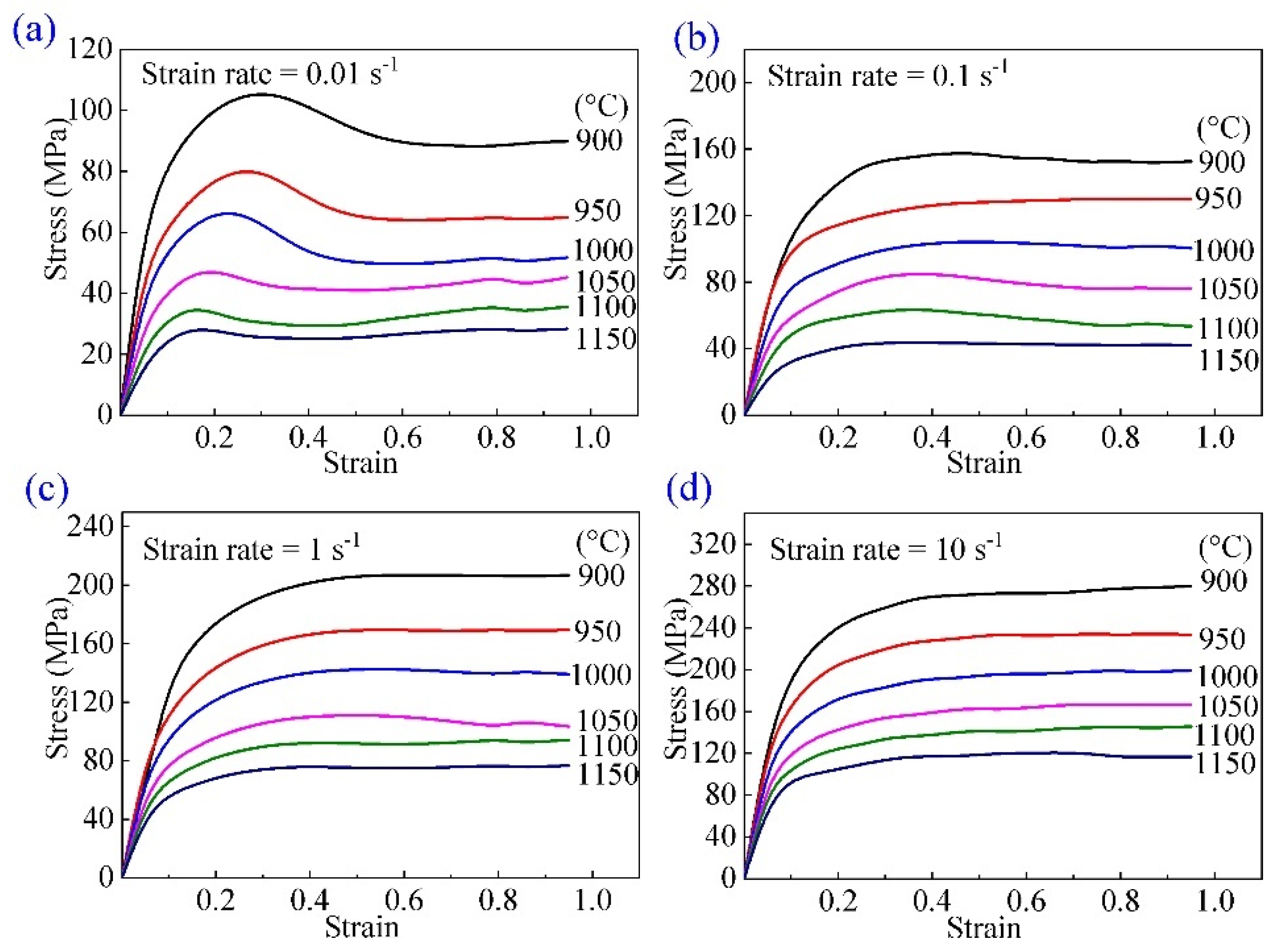

3.1. Flow Behavior

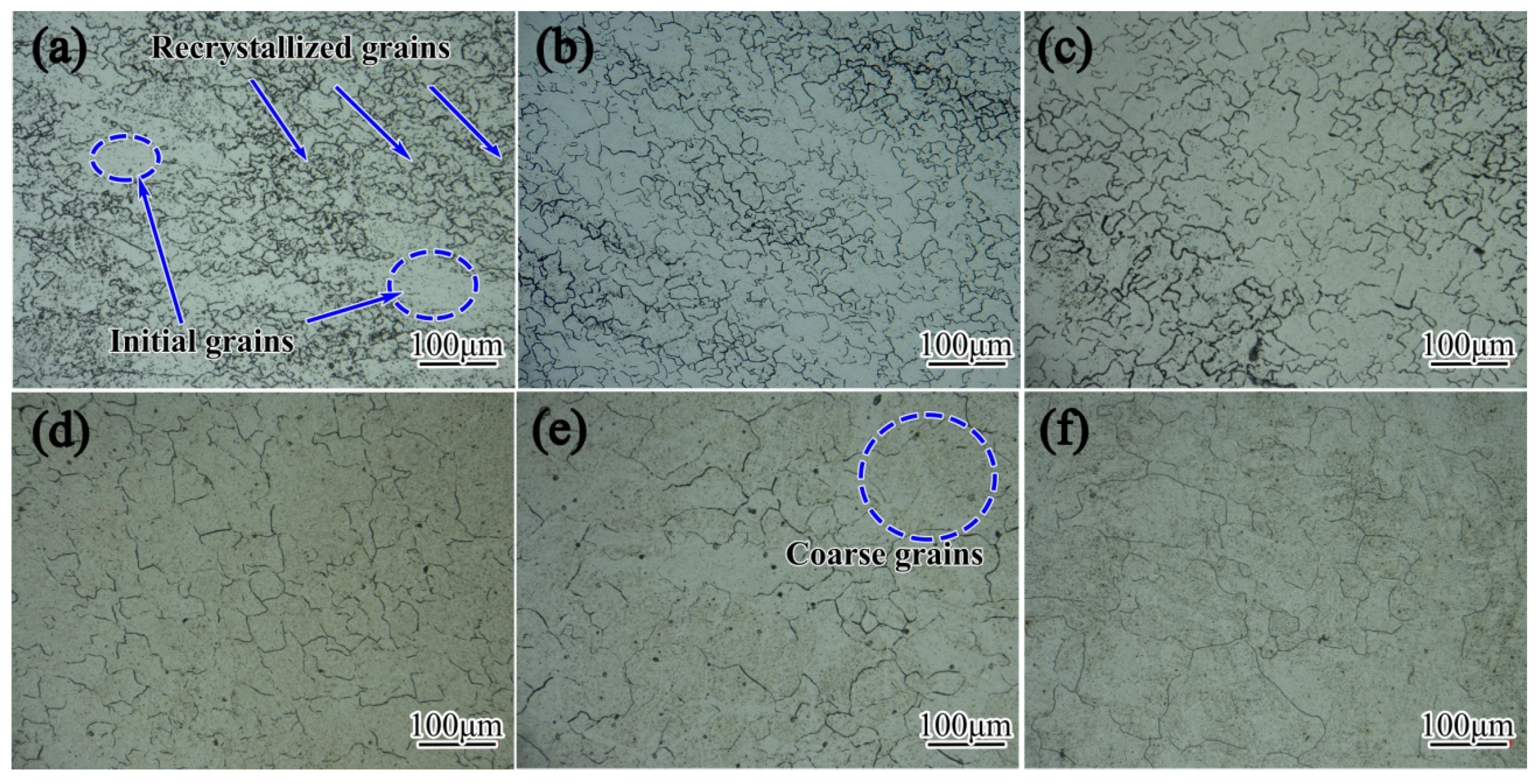

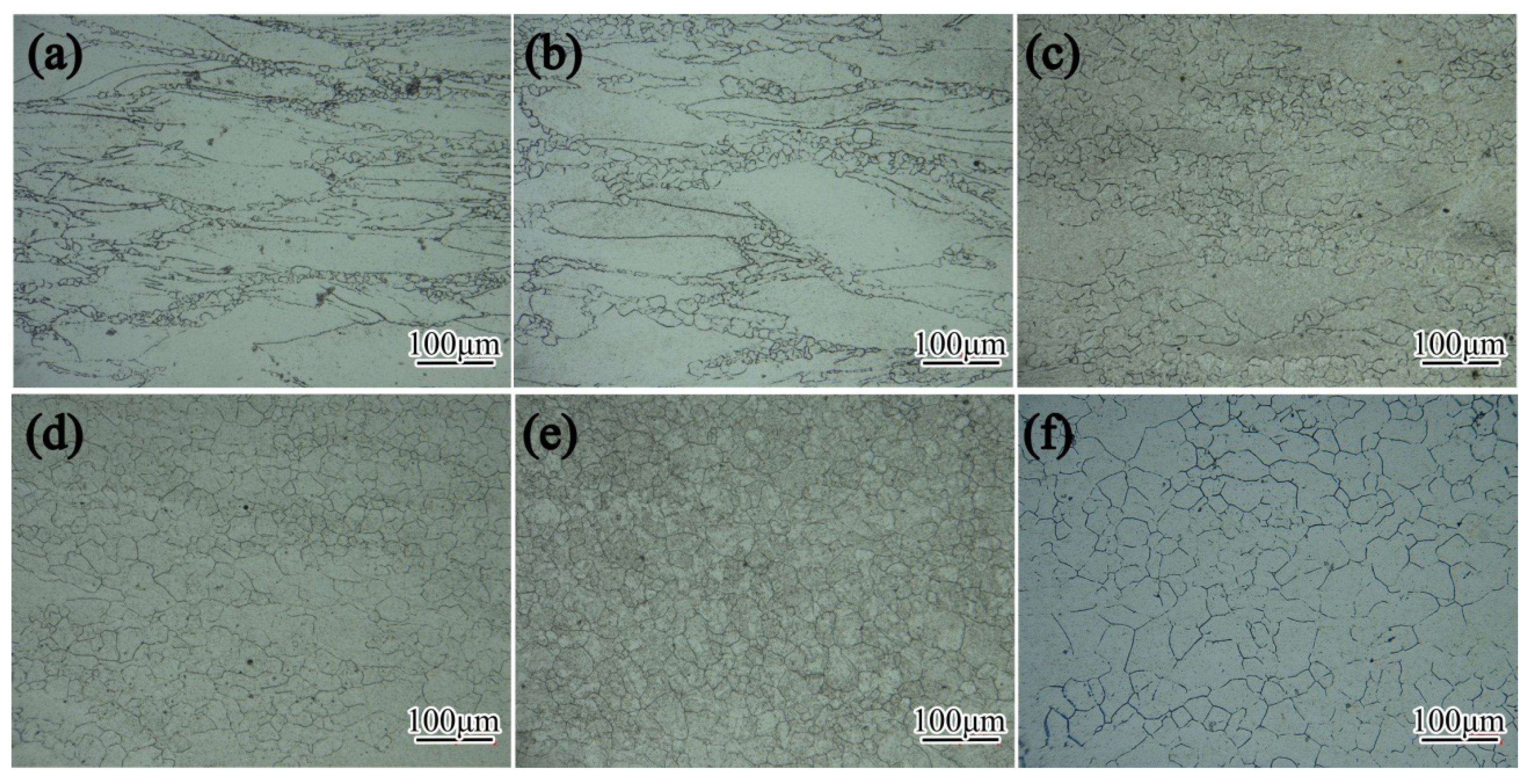

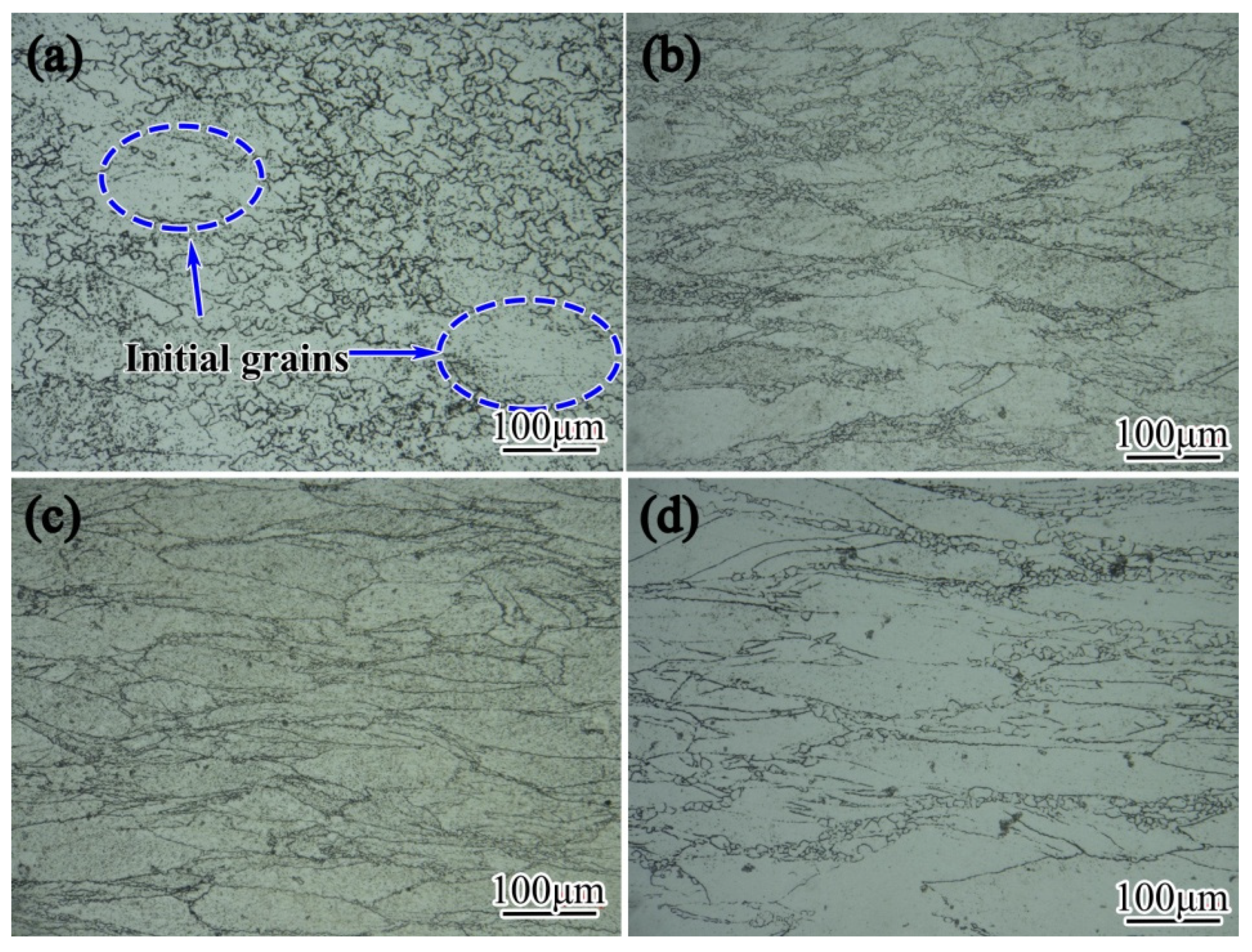

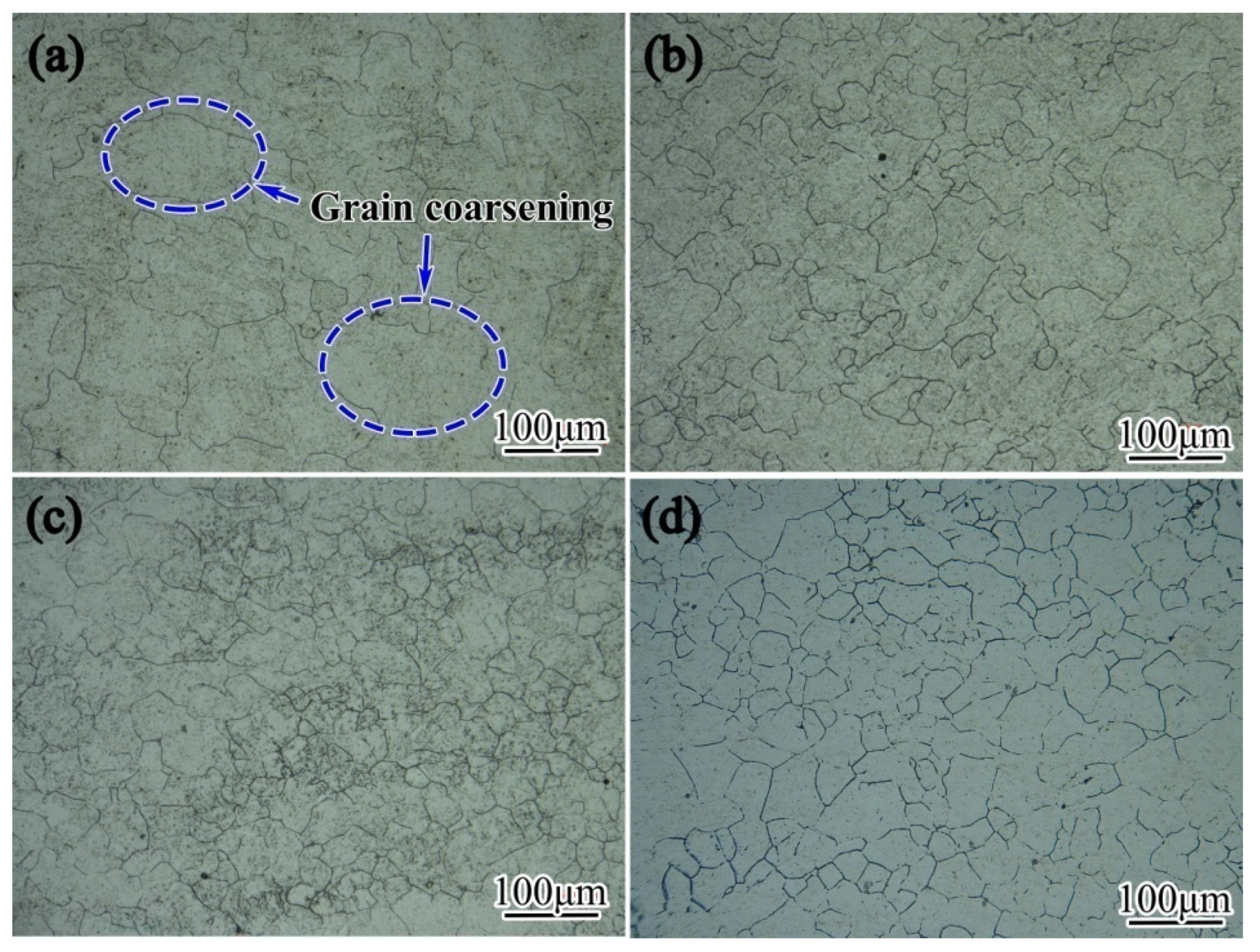

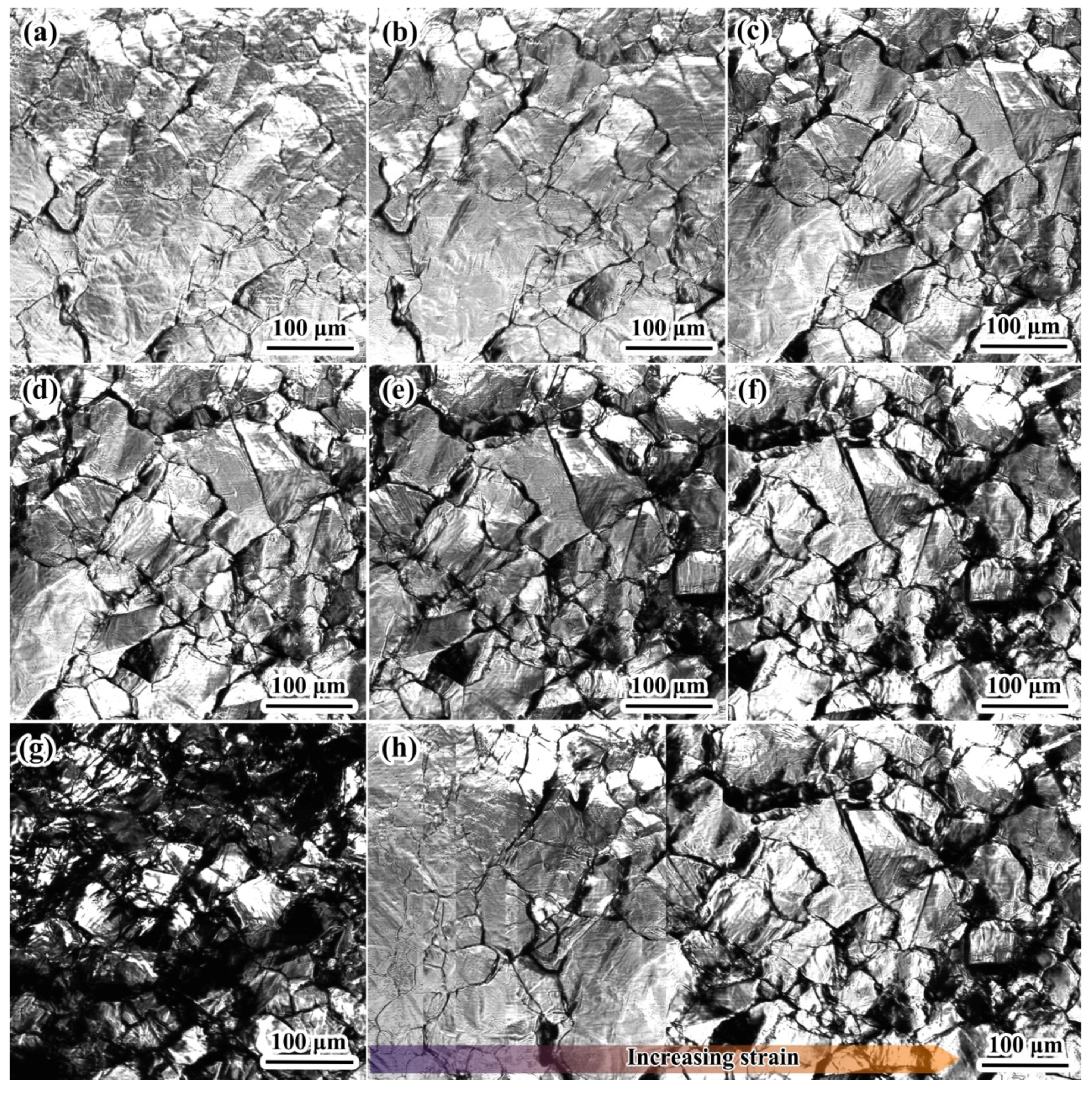

3.2. Microstructure Evolution

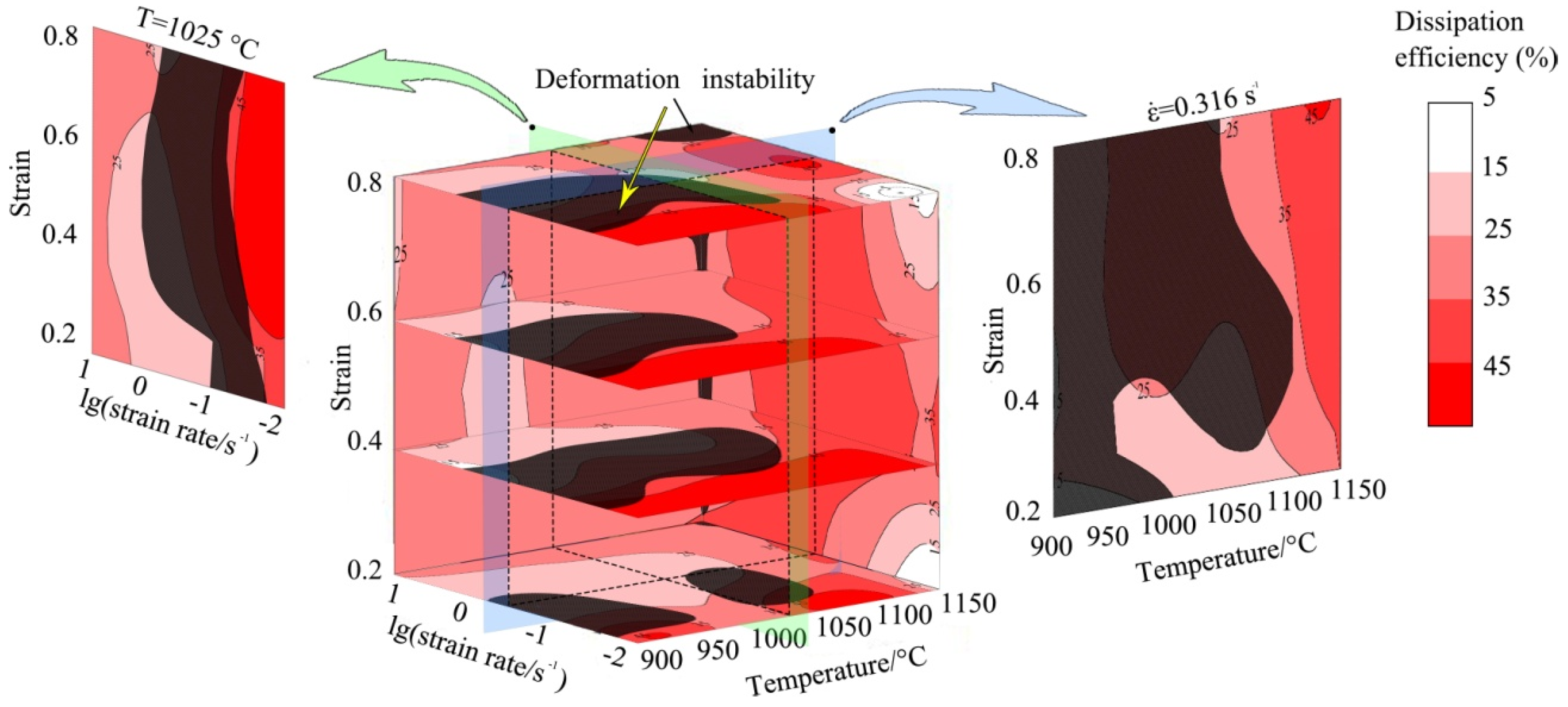

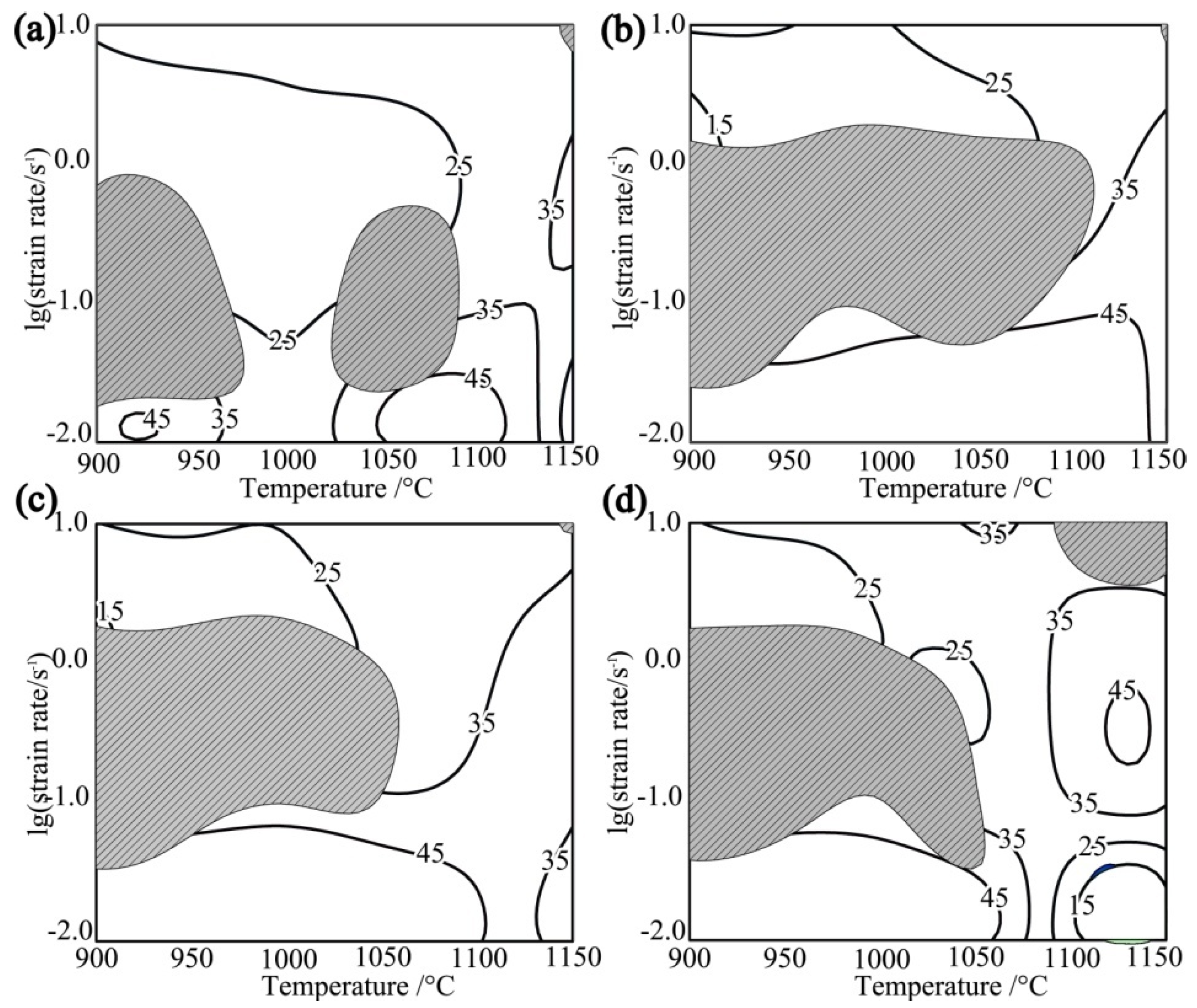

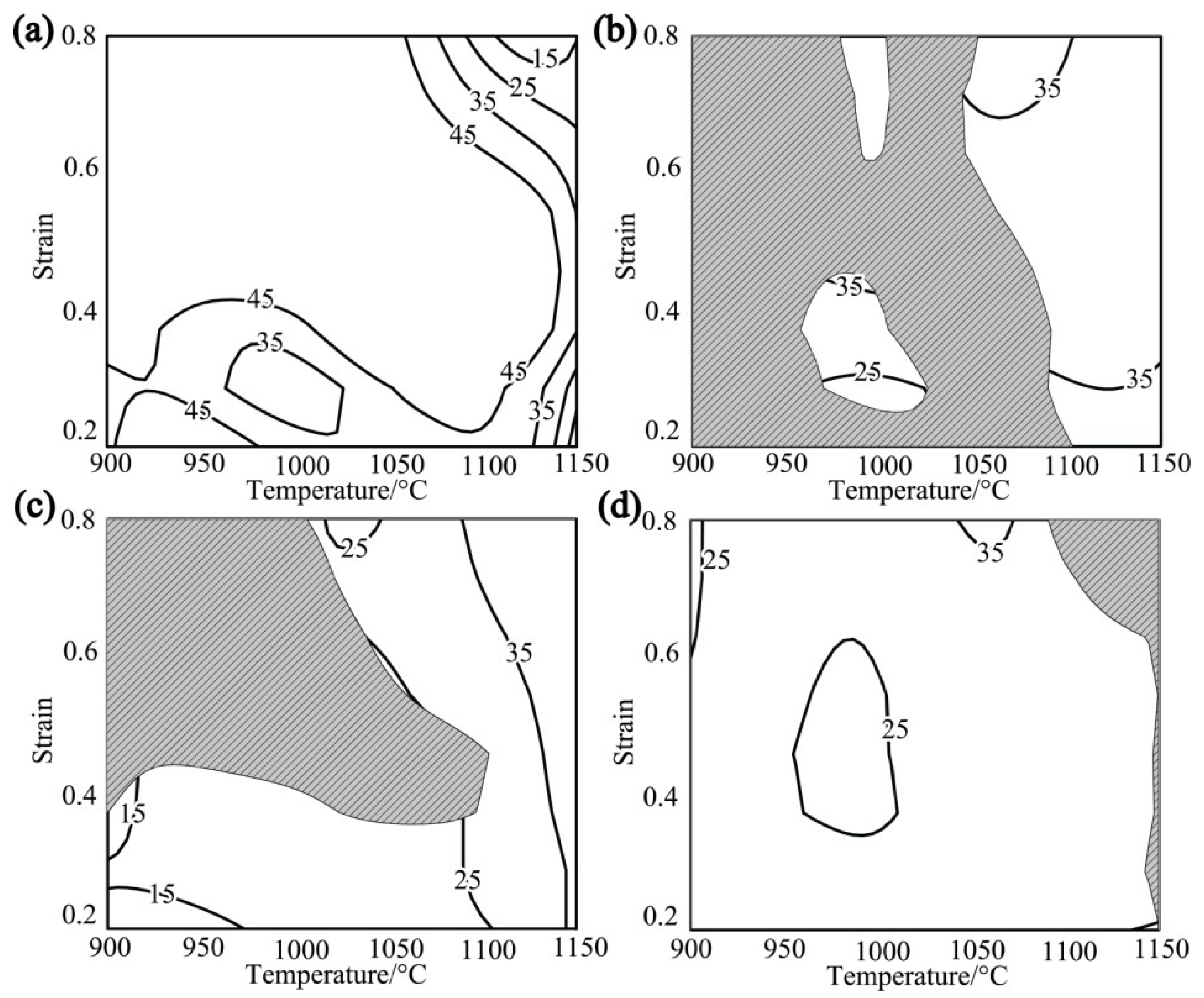

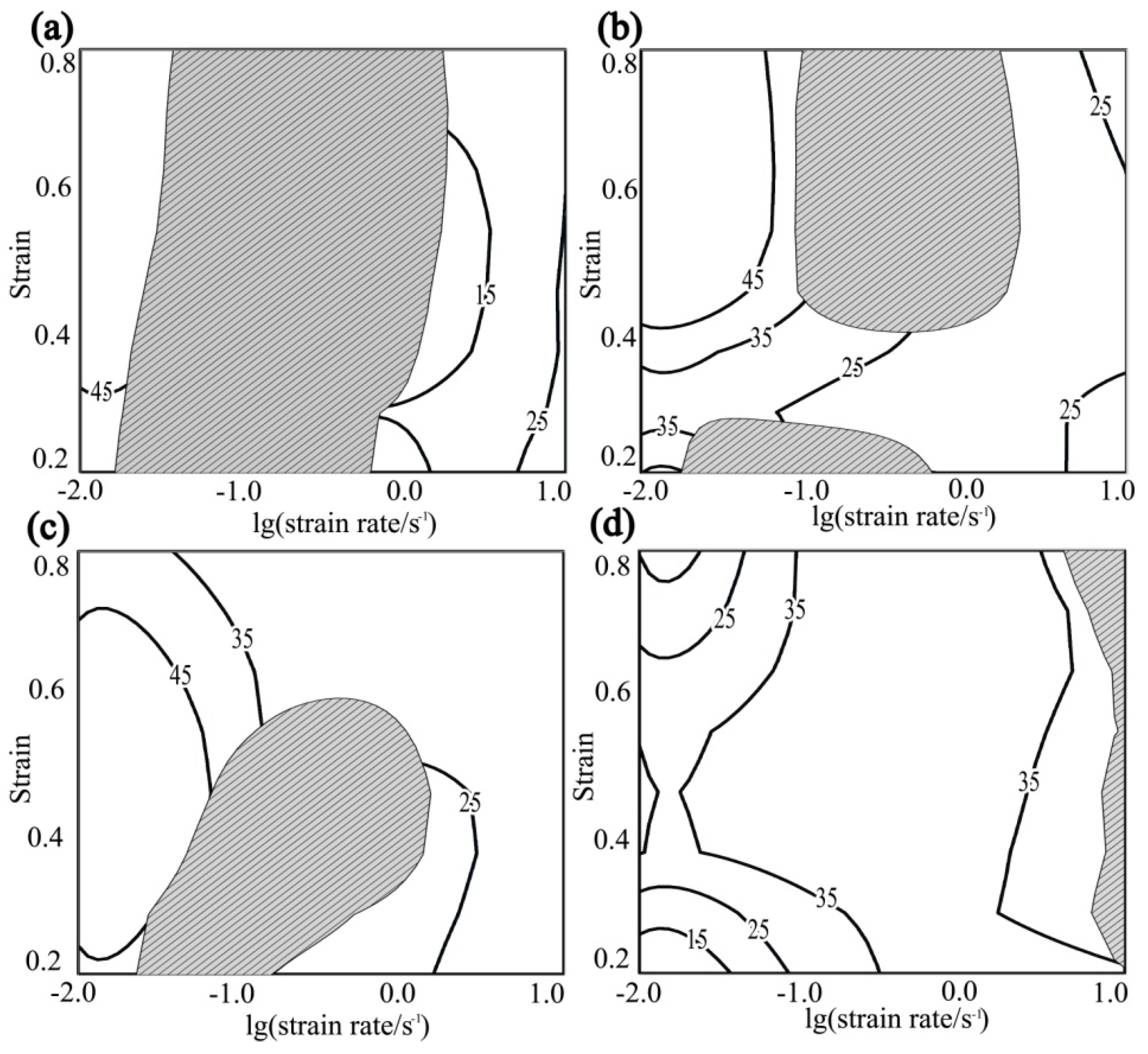

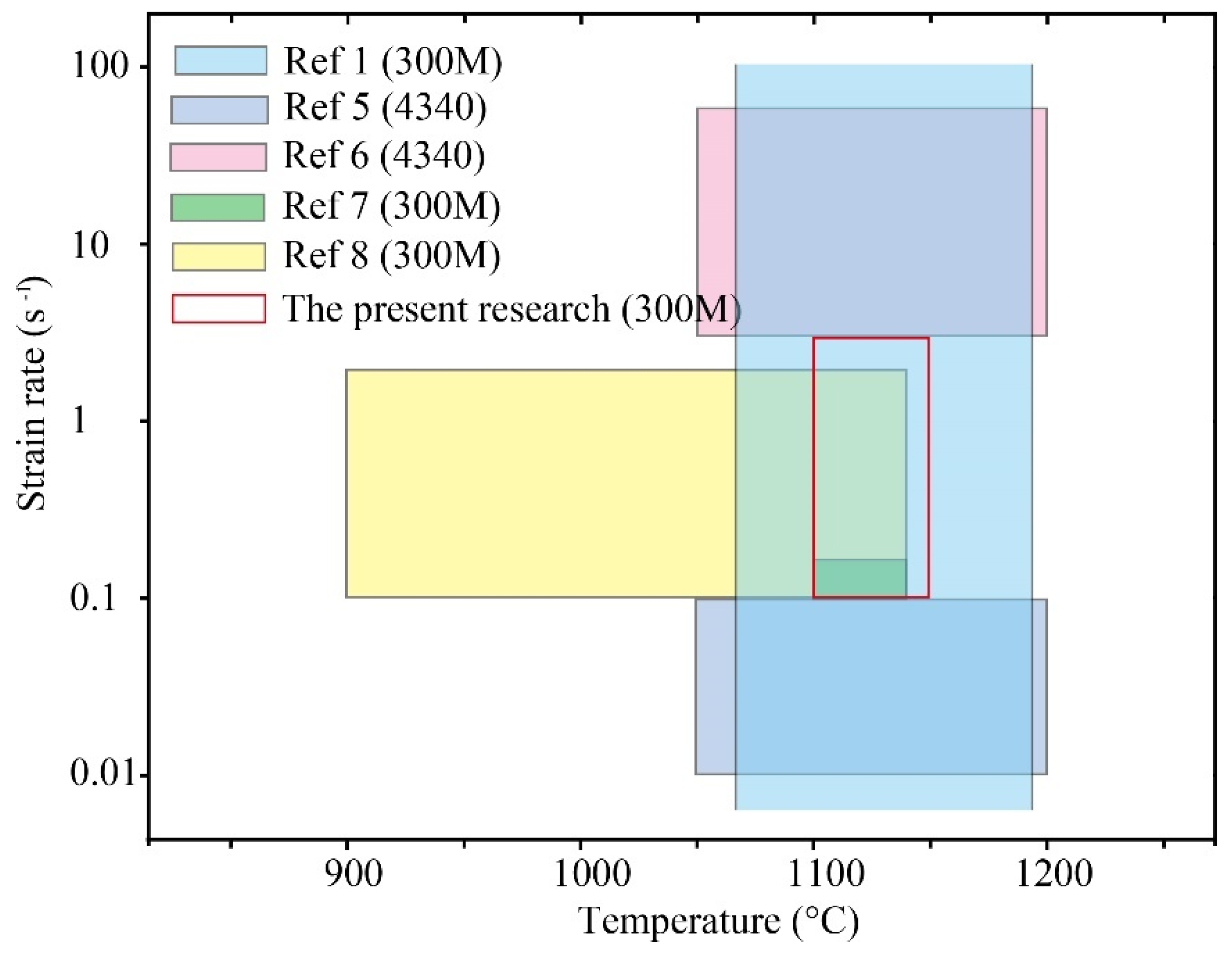

3.3. Hot Working Map

4. Conclusions

- (1)

- Different shapes of flow stress curves were obtained at different strain rates, and the shape change was explained by microstructure observations. At 10 s−1, the overall volume fraction of recrystallized grains was not high. Dynamic recovery dominated, and therefore, it showed monotonically increasing dynamic recovery type stress–strain curves. While at 0.01 s−1, the dynamic recrystallization was completed, and dynamic recrystallization dominated. Thus, it showed single-peaked dynamic recrystallization type stress–strain curves.

- (2)

- In situ compression results showed with increasing strain, the grains became finer and finer due to crushing of initial grains and dynamic recrystallization. This investigation is one of the few attempts that has succeeded in observing the grain evolution of steel during high temperature compression in recent years.

- (3)

- The hot processing maps were not only related to the recrystallized grain size, but also related to the volume fraction of recrystallized grains. The dissipation coefficients were comparatively higher at higher temperatures and slower strain rates, which was usually due to complete dynamic recrystallization and severe grain growth. While at lower temperatures and higher strain rates, the dissipation coefficients were low, incomplete recrystallization and mixed grain defect occurred.

- (4)

- The optimal working parameters were suggested at 0.1–3 s−1 and 1100–1150 °C. When the deformation temperature and the pre-forging shape were restrained, the punch speed curves could be continuously adjusted to ensure that the average dissipation coefficient was between 35% and 40%.

Author Contributions

Funding

Conflicts of Interest

References

- Speich, G.R. Properties and Selection Irons and Steels, Ultrahigh-Strength Steels section. In Metals Handbook; ASM International: Materials Park, OH, USA, 2005; Volume 1, pp. 1118–1170. [Google Scholar]

- Dong, H.; Zhang, S.H.; Yong, Q.L. Steel and iron materials engineering. In China Materials Engineering Canon; Chemical Industry Press: Beijing, China, 2006; Volume 3, pp. 1048–1049. [Google Scholar]

- Skubisz, P.; Sinczak, J. Properties of direct-quenched aircraft forged component made of ultrahigh-strength steel 300M. Aircr. Eng. Aerosp. Technol. 2018, 90, 713–719. [Google Scholar] [CrossRef]

- Gong, B.; Duan, X.W.; Liu, J.S.; Liu, J.J. A physically based constitutive model of as-forged 34CrNiMo6 steel and processing maps for hot working. Vacuum 2018, 155, 345–357. [Google Scholar] [CrossRef]

- Sanrutsadakorn, A.; Uthaisangsuk, V.; Suranuntchai, S.; Thossatheppitak, B. Investigation of hot deformation characteristics of AISI 4340 steel using processing maps. Adv. Mater. Res. 2013, 683, 301–306. [Google Scholar] [CrossRef]

- Łukaszek-Sołek, A.; Krawczyk, J.; Sleboda, T.; Grelowski, J. Optimization of the hot forging parameters for 4340 steel by processing maps. J. Mater. Res. Technol. 2019, 8, 3281–3290. [Google Scholar] [CrossRef]

- Luo, J.; Li, M.Q.; Liu, Y.G.; Sun, H.M. The deformation behavior in isothermal compression of 300M ultrahigh-strength steel. Mater. Sci. Eng. A 2012, 534, 314–322. [Google Scholar] [CrossRef]

- Sun, H.M.; Li, M.Q.; Liu, Y.G. Development of processing map coupling grain size for the isothermal compression of 300M steel. Mater. Sci. Eng. A 2014, 595, 77–85. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Chen, R.; Guo, P.; Zheng, Z.; Li, J.; Feng, F. Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials 2018, 11, 972. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, N.; Li, J.; Feng, F. In-situ investigation of phase transformation behaviors of 300M steel in continuous cooling process. Mater. Charact. 2018, 144, 400–410. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, J.; Li, N.; Feng, F. In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials 2018, 11, 1862. [Google Scholar] [CrossRef]

- Chen, R.; Hong, C.; Li, J.; Zheng, Z.; Li, P.C. Austenite grain growth and grain size distribution in isothermal heat-treatment of 300M steel. Procedia Eng. 2017, 207, 663–668. [Google Scholar] [CrossRef]

- Liu, Y.G.; Li, M.Q.; Luo, J. The modelling of dynamic recrystallization in the isothermal compression of 300M steel. Mater. Sci. Eng. A 2013, 574, 1–8. [Google Scholar] [CrossRef]

- Zeng, R.; Huang, L.; Li, J.; Li, H.; Zhu, H.; Zhang, X. Quantification of multiple softening processes occurring during multi-stage thermoforming of high-strength steel. Int. J. Plast. 2019, 120, 64–87. [Google Scholar] [CrossRef]

- Semiatin, S.L. Forming and Forging. In ASM Handbook; ASM International: Almere, The Netherlands, 2005; Volume 14, pp. 584–585. [Google Scholar]

- Xi, T.; Yang, C.; Shahzad, M.; Yang, K. Study of the processing map and hot deformation behavior of a Cu-bearing 317LN austenitic stainless steel. Mater. Des. 2015, 87, 303–312. [Google Scholar] [CrossRef]

- Chen, R. A Specimen for the in situ Compression Test on the High Temperature Confocal Laser Scanning Microscope. Chinese Patent 201910327549.4, 23 April 2019. [Google Scholar]

- Babu, K.A.; Mandal, S.; Athreya, C.N.; Shakthipriya, B.; Sarma, V.S. Hot deformation characteristics and processing map of a phosphorous modified super austenitic stainless steel. Mater. Des. 2017, 115, 262–275. [Google Scholar] [CrossRef]

- Mohamadizadeh, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Mehtonen, S.; Porter, D. Hot deformation characterization of duplex low-density steel through 3D processing map development. Mater. Charact. 2015, 107, 293–301. [Google Scholar] [CrossRef]

- Chen, L.; Ma, X.; Liu, X.; Wang, L. Processing map for hot working characteristics of a wrought 2205 duplex stainless steel. Mater. Des. 2011, 32, 1292–1297. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Nolze, G. Irrational orientation relationship derived from rational orientation relationships using EBSD data. Cryst. Res. Technol. 2010, 43, 61–73. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Ueda, M.; Tsuji, N.; Minamino, Y. Crystallographic analysis of plate martensite in Fe–28.5 at.% Ni by FE-SEM/EBSD. Mater. Charact. 2005, 54, 378–386. [Google Scholar] [CrossRef]

- Chen, G.; Fu, G.; Cheng, C.; Yan, W.; Zou, Z.; Lin, S. Effects of strain rate on dynamic recrystallization microstructure of 3003 aluminum alloy in process of hot deformation. Trans. Mater. Heat. Treat. 2012, 33, 26–31. [Google Scholar]

- Chen, R.; Zheng, Z.; Li, J.; Fei, F. Constitutive Modeling and Hot Workability Analysis by Microstructure Examination of GH4169 Alloy. Crystals 2018, 8, 282. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Xiao, H.; Wang, M.; Li, J. Hot Workability of 300M Steel Investigated by In Situ and Ex Situ Compression Tests. Metals 2019, 9, 880. https://doi.org/10.3390/met9080880

Chen R, Xiao H, Wang M, Li J. Hot Workability of 300M Steel Investigated by In Situ and Ex Situ Compression Tests. Metals. 2019; 9(8):880. https://doi.org/10.3390/met9080880

Chicago/Turabian StyleChen, Rongchuang, Haifeng Xiao, Min Wang, and Jianjun Li. 2019. "Hot Workability of 300M Steel Investigated by In Situ and Ex Situ Compression Tests" Metals 9, no. 8: 880. https://doi.org/10.3390/met9080880

APA StyleChen, R., Xiao, H., Wang, M., & Li, J. (2019). Hot Workability of 300M Steel Investigated by In Situ and Ex Situ Compression Tests. Metals, 9(8), 880. https://doi.org/10.3390/met9080880