Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior

Abstract

:1. Introduction

2. Materials and Methods

Microstructural Characterization

3. Experimental Results

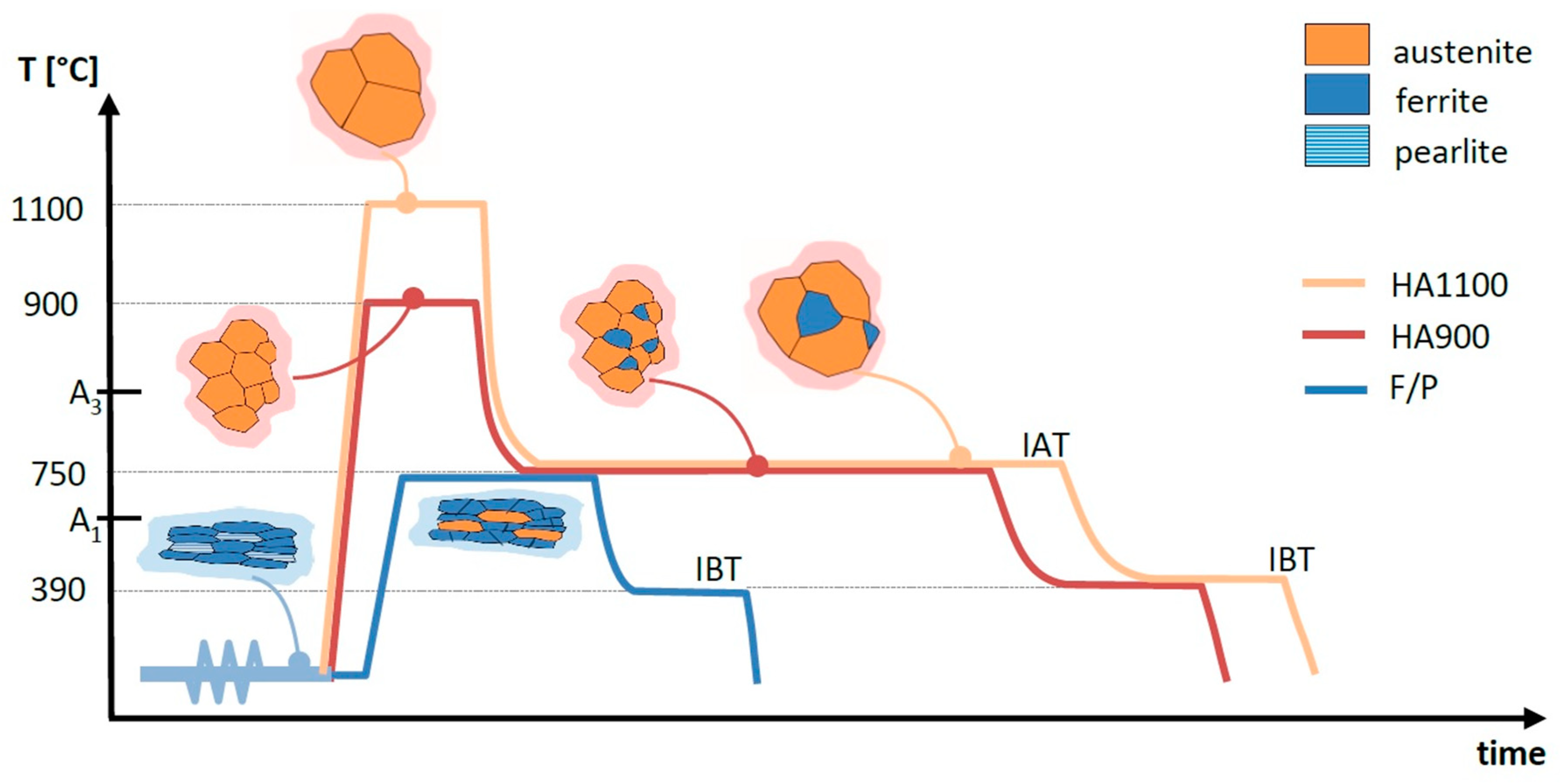

3.1. Heat Treatment Study

3.2. Microstructural Characterization

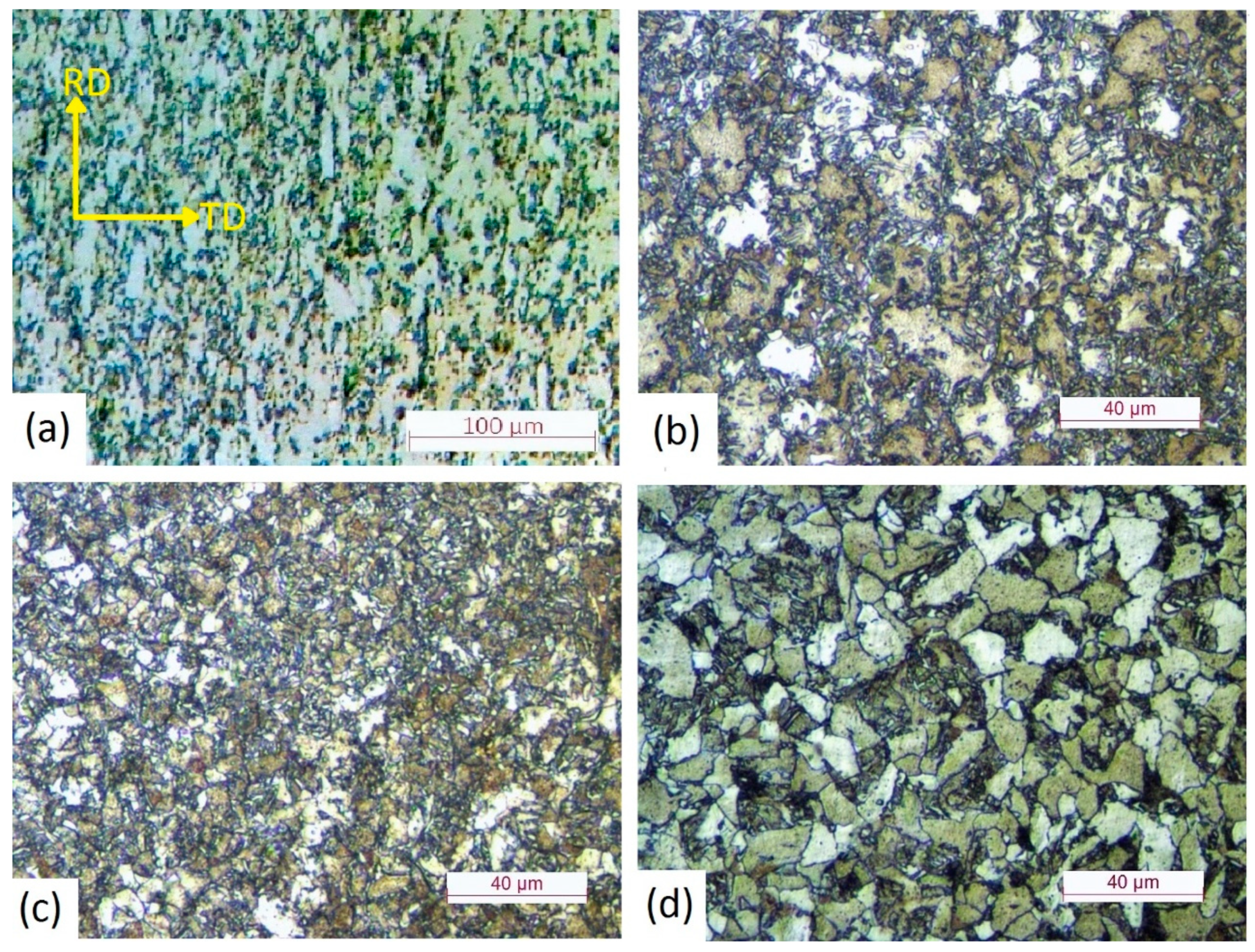

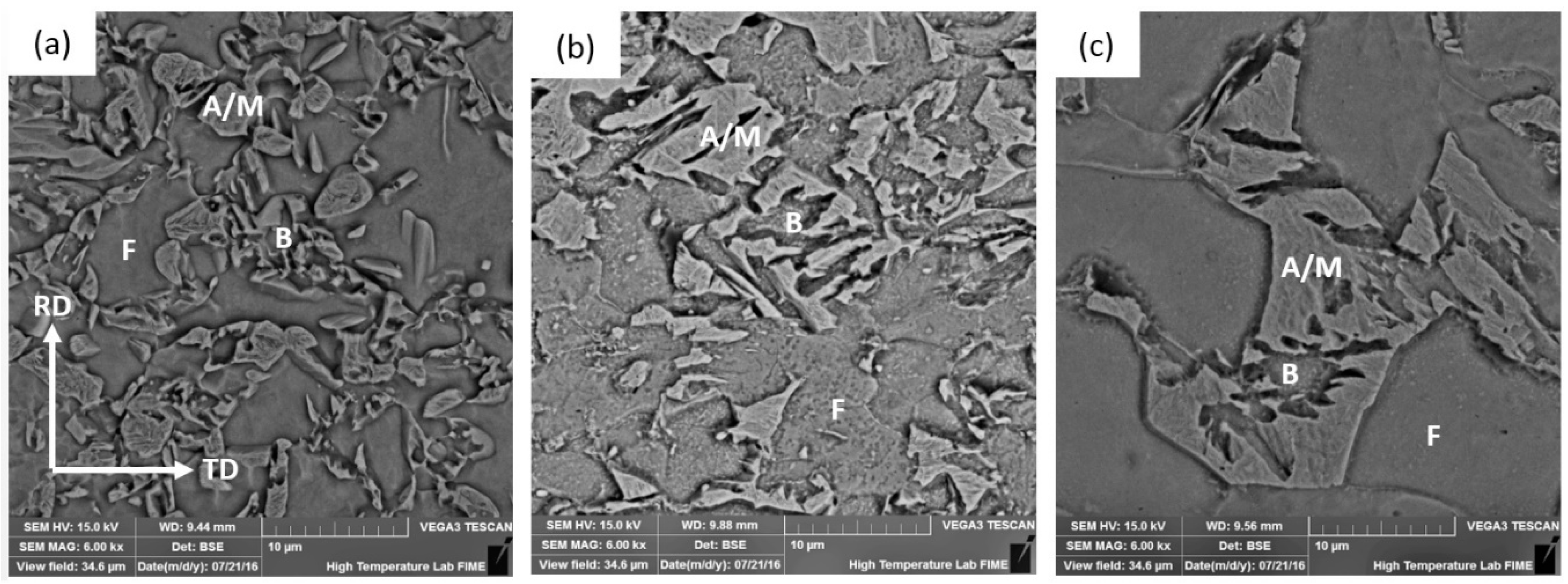

3.2.1. Characterization by Optical Microscopy, SEM, and X-Ray

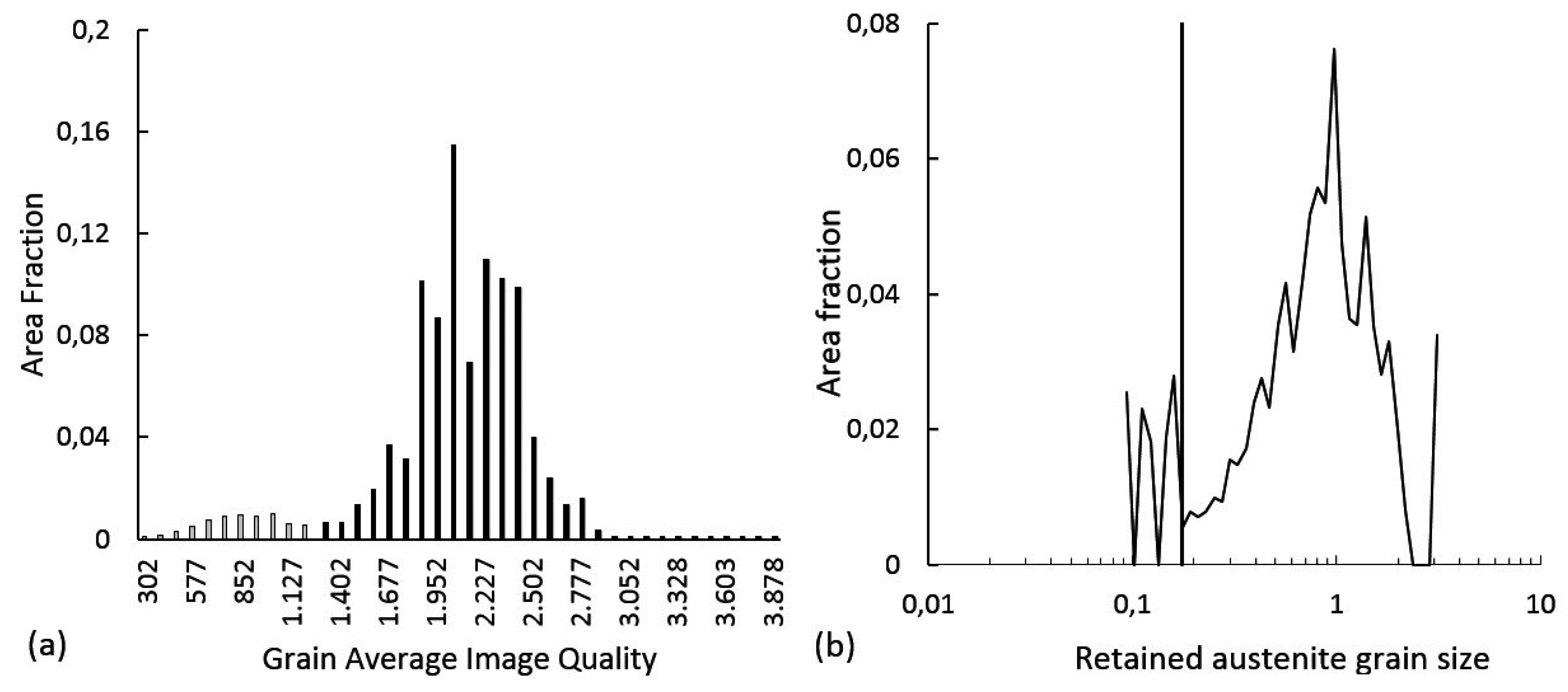

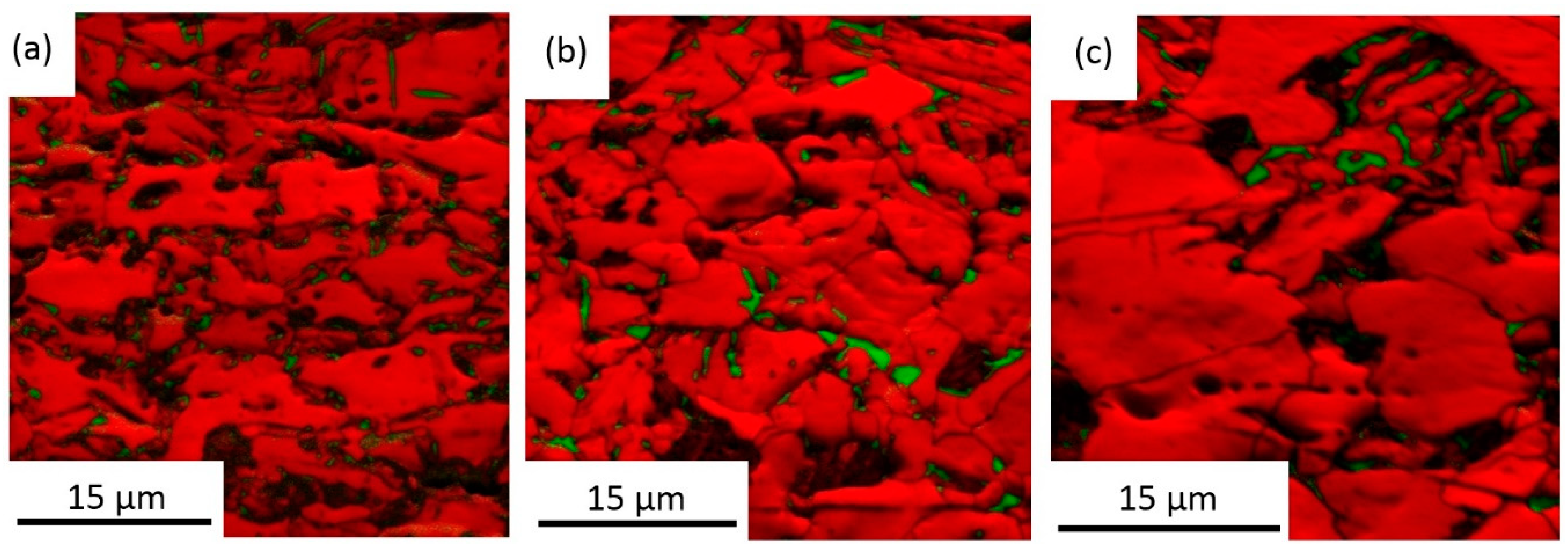

3.2.2. Retained Austenite and Martensite Characterization by EBSD

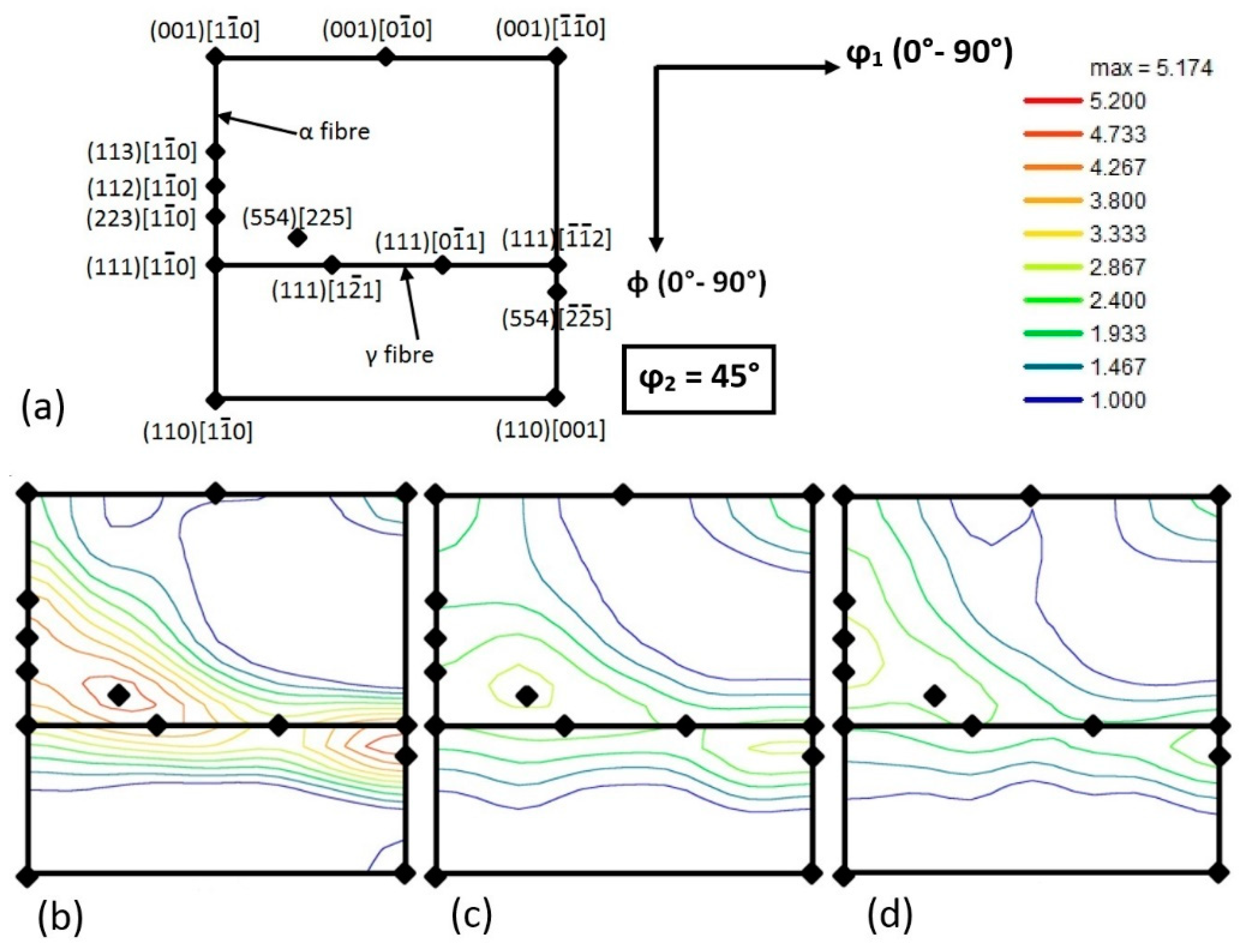

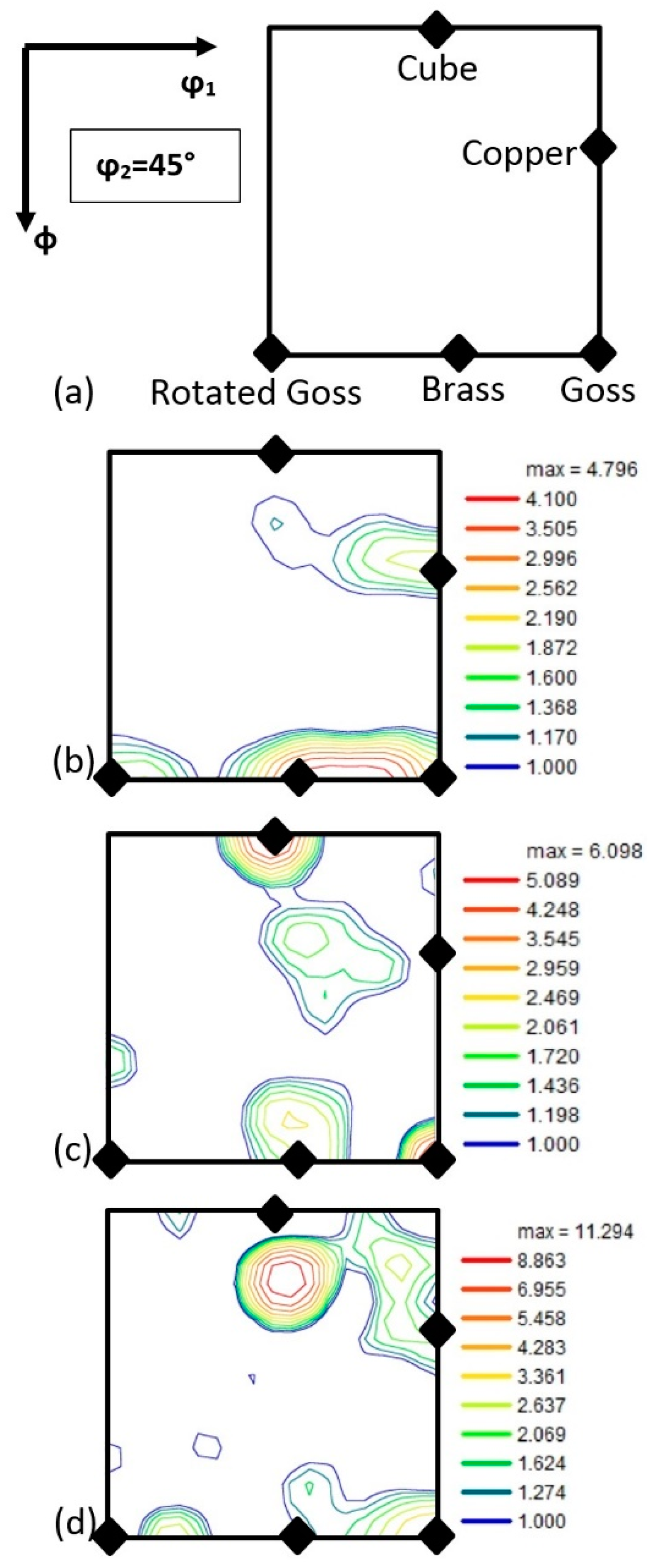

3.3. Texture Analyses

3.4. Retained Austenite Stabilization

3.4.1. Mechanical Stability

3.4.2. Chemical Stability

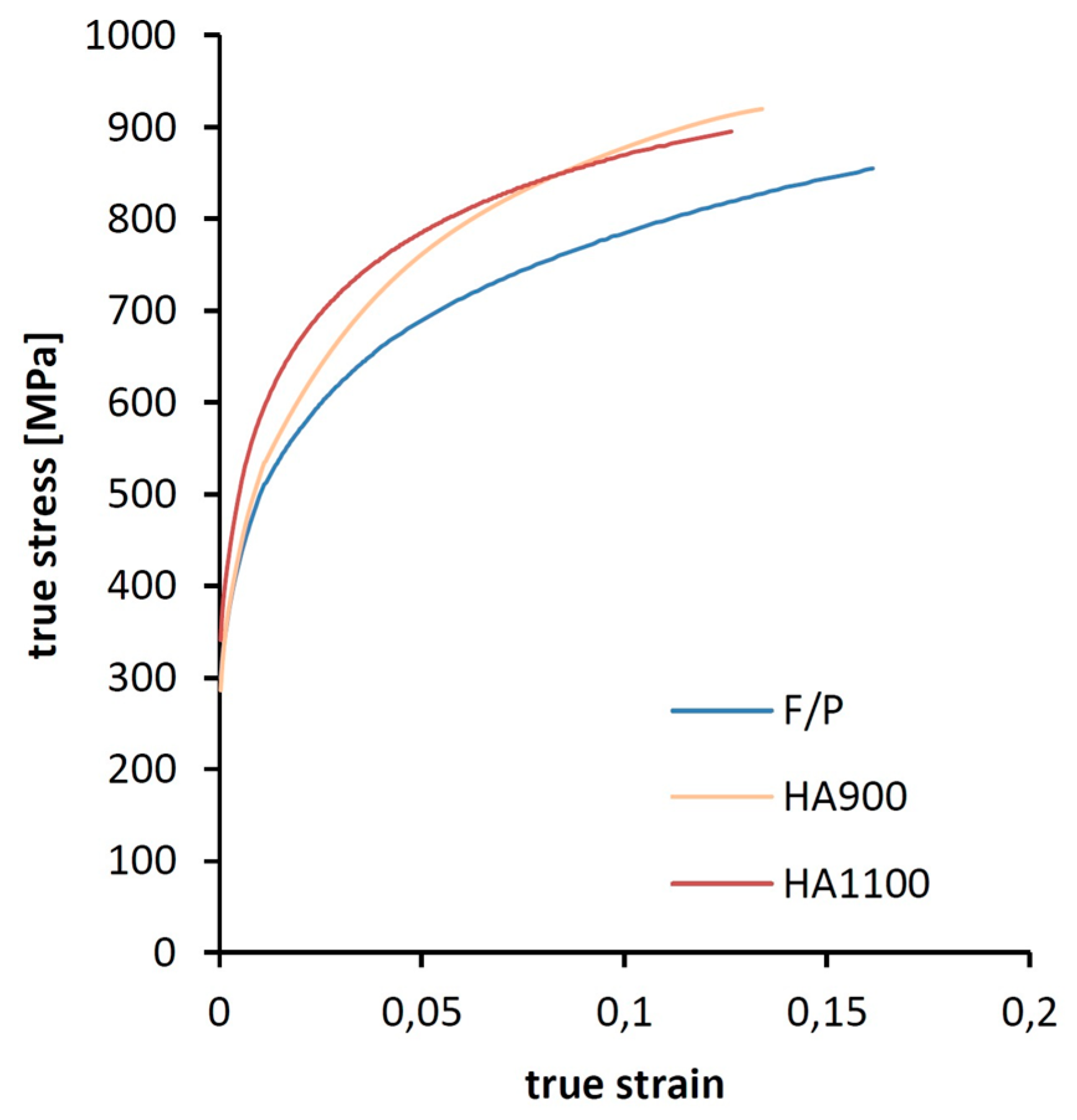

3.5. Mechanical Properties

4. Conclusions

- A change from 900 to 1100 °C in the homogenization temperature of austenite does not exert an effect on the retained austenite grain size, but it does affect the prior austenite grain size and the austenite chemical stability. At a homogenization temperature of 1100 °C, the chemical stability is lower (higher MS) than after homogenization at 900 °C, and a higher amount of austenite transforms into martensite after cooling from the austempering treatment.

- The steels homogenized at 1100 and 900 °C exhibit the highest UTS value. This is related to the austenite martensite transformation which induces an extra dislocation increment and, consequently, a high strength.

- This extra dislocation increment also decreases the strain ability, so the homogenized steels exhibit lower elongation than the ferrite–pearlite steel.

- The global mechanical response is also related to the surrounding phases. Thus, the steel homogenized at 900 °C exhibits the highest strain hardening index, due to its finest microstructure.

- An austenization treatment at an elevated temperature increases the yield strength. The steel homogenized at 1100 °C exhibits the highest YS despite its coarsest microstructure.

- A cold-rolled ferrite–pearlite initial microstructure promotes better texture components for deep drawing processes than a homogenized austenite initial microstructure. For the HA initial microstructure, a lower homogenization temperature promotes γ fiber components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petrov, R.; Kestens, L.; Houbaert, Y. Recrystallization of a cold rolled trip-assisted steel during reheating for intercritical annealing. ISIJ Int. 2001, 41, 883–890. [Google Scholar] [CrossRef]

- Jacques, P.J.; Furnémont, Q.; Lani, F.; Pardoen, T.; Delannay, F. Multiscale mechanics of TRIP-assisted multiphase steels: I. Characterization and mechanical testing. Acta Mater. 2007, 55, 3684–3693. [Google Scholar] [CrossRef]

- Van Dijk, N.H.; Butt, A.M.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; Van der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Zrník, J.; Muránsky, O.; Lukáš, P.; Nový, Z.; Sittner, P.; Horňak, P. Retained austenite stability investigation in TRIP steel using neutron diffraction. Mater. Sci. Eng. A 2006, 437, 114–119. [Google Scholar] [CrossRef]

- Van Der Zwaag, S.; Zhao, L.; Kruijver, S.O.; Sietsma, J. Thermal and mechanical stability of retained austenite in aluminum-containing multiphase TRIP steels. ISIJ Int. 2002, 42, 1565–1570. [Google Scholar] [CrossRef]

- Basuki, A.; Aernoudt, E. Influence of rolling of TRIP steel in the intercritical region on the stability of retained austenite. J. Mater. Process. Technol. 1999, 89–90, 37–43. [Google Scholar] [CrossRef]

- Wang, X.D.; Huang, B.X.; Rong, Y.H.; Wang, L. Microstructures and stability of retained austenite in TRIP steels. Mater. Sci. Eng. A 2006, 438–440, 300–305. [Google Scholar] [CrossRef]

- Chatterjee, S. Transformations in TRIP-assisted Steels: Microstructure and Properties. Ph.D. Thesis, Cambridge University, Cambridge, UK, November 2006. [Google Scholar]

- Sugimoto, K.; Usui, N.; Kobayashi, M.; Hashimoto, S. Effects of volume fraction and stability of retained austenite on ductility of TRIP-aided dual-phase steels. ISIJ Int. 1992, 32, 1311–1318. [Google Scholar] [CrossRef]

- Pereloma, E.V.; Timokhina, I.B.; Miller, M.K.; Hodgson, P.D. Three-dimensional atom probe analysis of solute distribution in thermomechanically processed TRIP steels. Acta Mater. 2007, 55, 2587–2598. [Google Scholar] [CrossRef]

- De Cooman, B.C. Structure–properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Guzmán, A. Obtención y estudio de las propiedades mecánicas y microestructurales de un acero con comportamiento TRIP (0,21%C, 0,82%Si, 1,87%Mn y 0,43%Al). Ph.D. Thesis, Universidad de Santiago de Chile, Santiago, Chile, May 2013. [Google Scholar]

- Matsumara, O.; Sakuma, Y.; Takechi, H. Enhancement of elongation by retained austenite in intercritical annealed 0.4C-1.5Si-0.8Mn steel. Trans. ISIJ 1987, 27, 570–579. [Google Scholar] [CrossRef]

- Roberts, C.S. Effect of carbon on the volume fractions and lattice parameters of retained austenite and martensite. JOM 1953, 197, 203–204. [Google Scholar] [CrossRef]

- Ryde, L. Application of EBSD to analysis of microstructures in commercial steels. Mater. Sci. Technol. 2006, 22, 1297–1306. [Google Scholar] [CrossRef]

- Petrov, R.; Kestens, L. Advanced high-strength steels: Electron Backscatter diffraction (EBSD). In Encyclopedia of Iron, Steel and Their Alloys; Colás, R., Totten, G.E., Eds.; CRC Press: Boca Ratón, FL, USA, 2016; pp. 46–69. [Google Scholar] [CrossRef]

- Roberts, G.A.; Mehl, R.F. The mechanism and the rate of formation of austenite from ferrite-cementite aggregates. Trans. ASM 1943, 31, 613–650. [Google Scholar]

- Ray, R.K.; Jonas, J.J. Transformation textures in steels. Int. Mater. Rev. 1990, 35, 1–36. [Google Scholar] [CrossRef]

- Butrón-Guillén, M.P.; Jonas, J.J.; Ray, R.K. Effect of austenite pancaking on texture formation in a plain carbon and a Nb microalloyed steel. Acta Metall. Mater. 1994, 42, 3615–3627. [Google Scholar] [CrossRef]

- Hutchinson, B. Deformation microstructures and textures in steels. Philos. Trans. R. Soc. A 1999, 357, 1471–1485. [Google Scholar] [CrossRef]

- Greenwood, G.W.; Johnson, R.H. The deformation of metals under small stresses during phase transformations. Proc. R. Soc. A 1965, 283, 403–422. [Google Scholar] [CrossRef]

| Steel ID | Aust. * | IAT ** | IBT *** | PAGS **** | |||

|---|---|---|---|---|---|---|---|

| [°C] | [min] | [°C] | [min] | [°C] | [min] | [μm] | |

| F/P | -- | -- | 750 | 10 | 390 | 7 | -- |

| HA900 | 900 | 10 | 750 | 90 | 390 | 7 | 10.3 ± 0.8 |

| HA1100 | 1100 | 10 | 750 | 135 | 390 | 7 | 18.9 ± 3.5 |

| Steel ID | F/P | HA900 | HA1100 |

|---|---|---|---|

| Ferrite grain size [µm] | 9 ± 4 | 8 ± 3 | 11 ± 2 |

| Vferrite [%] | 44 | 45 | 46 |

| Steel ID | % Aust. BTT * | % Aust. ATT ** | Transf. Aust. | Transf. Aust. % *** | % C Ret. Aust. **** |

|---|---|---|---|---|---|

| F/P | 5.7 | 2.2 | 3.5 | 62 | 1.11 |

| HA900 | 5.0 | 0.5 | 4.5 | 89 | 0.97 |

| HA1100 | 3.7 | 0.4 | 3.3 | 90 | 1.07 |

| Steel ID | F/P | HA900 | HA1100 |

|---|---|---|---|

| grain size [μm] | 0.7 ± 0.3 | 1.0 ± 0.6 | 1.0 ± 0.5 |

| aspect ratio | 2.7 ± 1.6 | 2.6 ± 1.3 | 2.9 ± 1.6 |

| RA vol. fraction % | 5.9 | 5,3 | 3.5 |

| martensite vol. fraction % | 2.5 | 4.1 | 4.8 |

| aust. after IB treatment % | 8.4 | 9.4 | 8.3 |

| aust. transf. to martensite by cooling from IB % | 30.0 | 43.6 | 57.8 |

| Steel ID | UTS [MPa] | YS [MPa] | Elongation [%] | Hardening Index n |

|---|---|---|---|---|

| F/P | 385 ± 27 | 732 ± 13 | 22.7 ± 2.0 | 0.19 ± 0.00 |

| HA900 | 401 ± 39 | 787 ± 23 | 16.8 ± 0.7 | 0.22 ± 0.01 |

| HA1100 | 438 ± 16 | 796 ± 8 | 16.3 ± 1.7 | 0.20 ± 0.00 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salinas, A.; Artigas, A.; Perez-Ipiña, J.; Castro-Cerda, F.; Garza-Montes-de-Oca, N.; Colás, R.; Petrov, R.; Monsalve, A. Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior. Metals 2018, 8, 1021. https://doi.org/10.3390/met8121021

Salinas A, Artigas A, Perez-Ipiña J, Castro-Cerda F, Garza-Montes-de-Oca N, Colás R, Petrov R, Monsalve A. Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior. Metals. 2018; 8(12):1021. https://doi.org/10.3390/met8121021

Chicago/Turabian StyleSalinas, Alvaro, Alfredo Artigas, Juan Perez-Ipiña, Felipe Castro-Cerda, Nelson Garza-Montes-de-Oca, Rafael Colás, Roumen Petrov, and Alberto Monsalve. 2018. "Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior" Metals 8, no. 12: 1021. https://doi.org/10.3390/met8121021

APA StyleSalinas, A., Artigas, A., Perez-Ipiña, J., Castro-Cerda, F., Garza-Montes-de-Oca, N., Colás, R., Petrov, R., & Monsalve, A. (2018). Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior. Metals, 8(12), 1021. https://doi.org/10.3390/met8121021