Resistance of Thermally Aged DSS 2304 against Localized Corrosion Attack

Abstract

1. Introduction

2. Materials and Methods

2.1. Electrochemical Measurements

2.2. Slow Strain Rate Test in NACE TM-0177 Solution in the Presence of S2O32−

3. Results

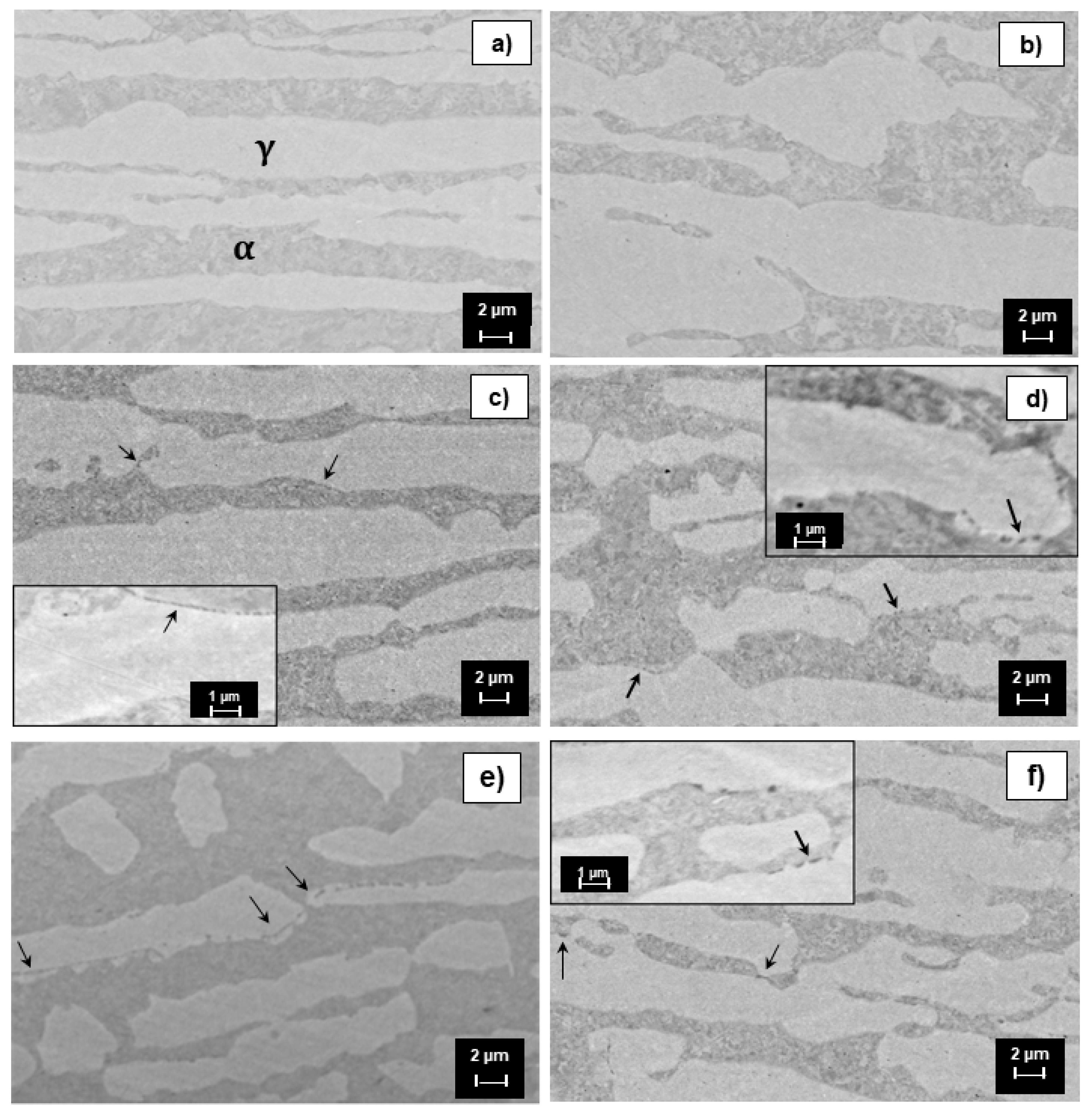

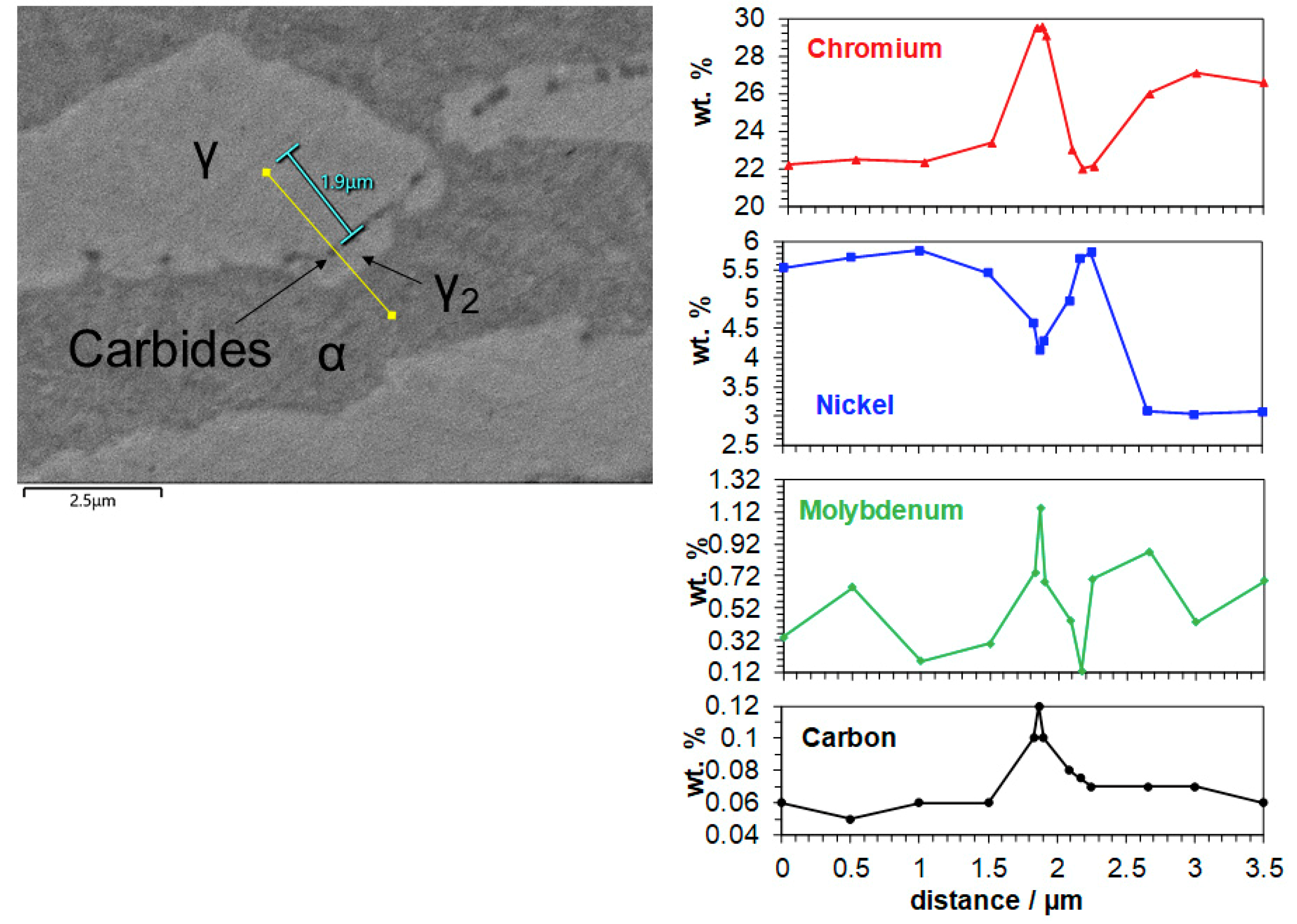

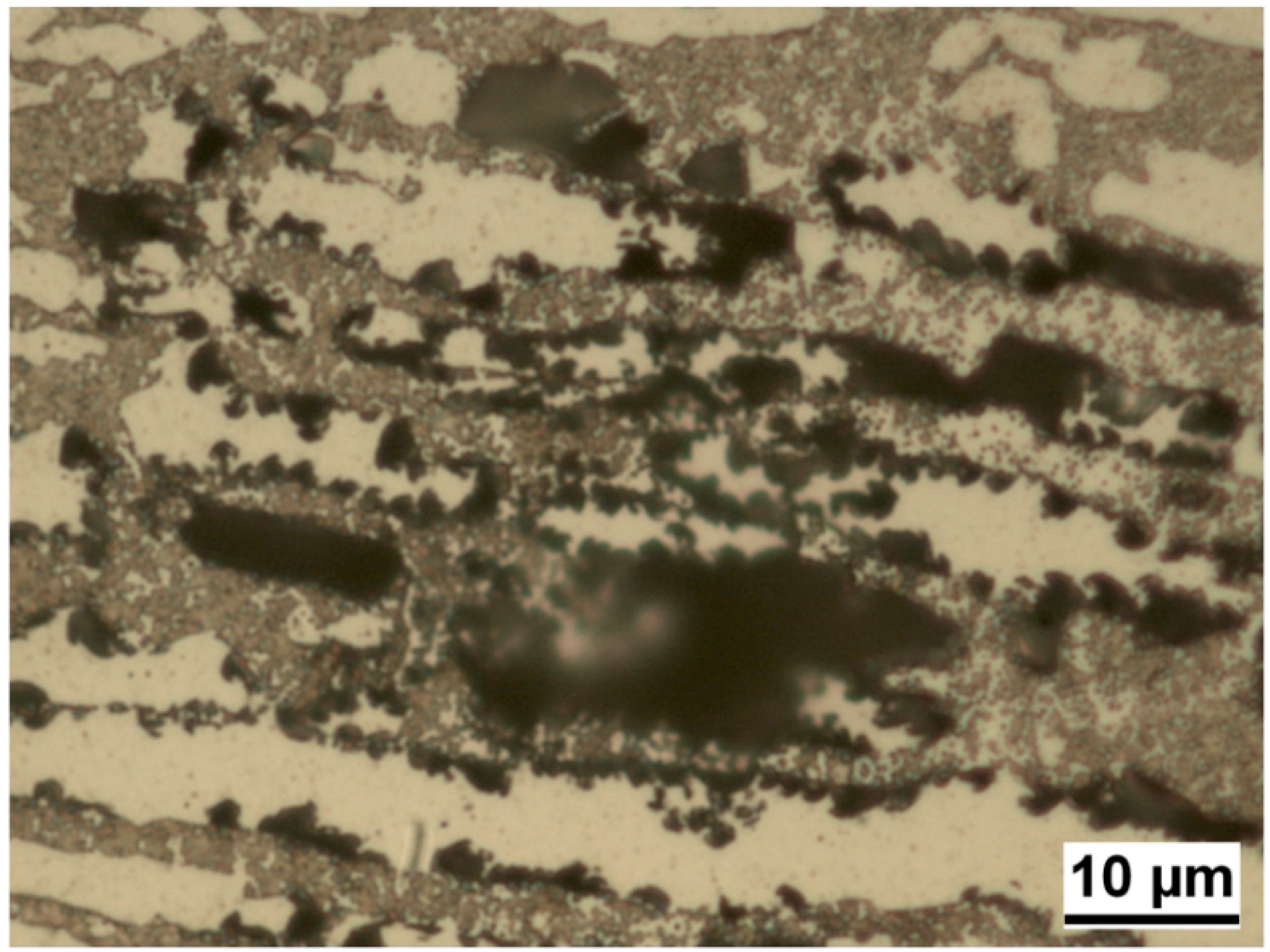

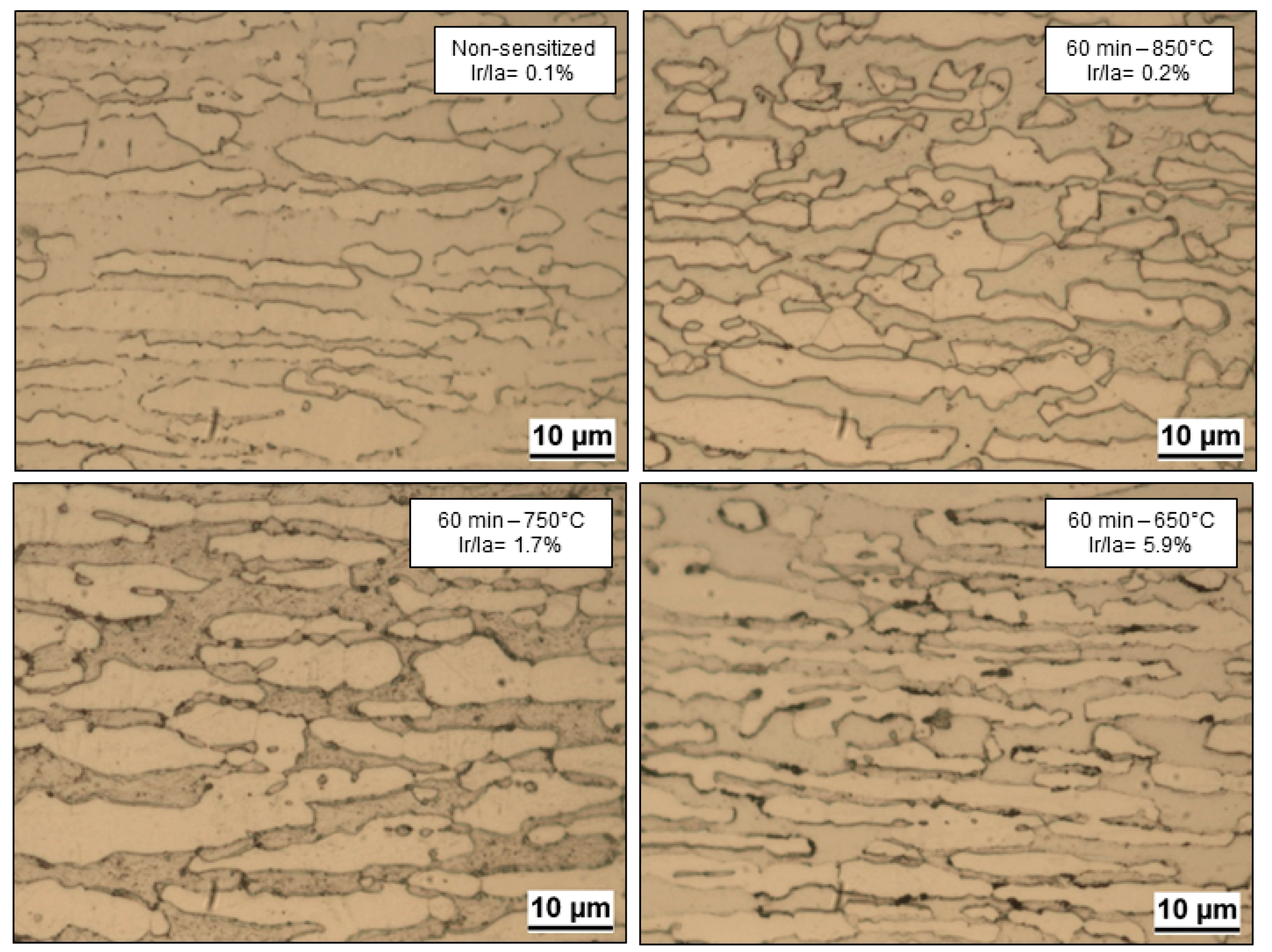

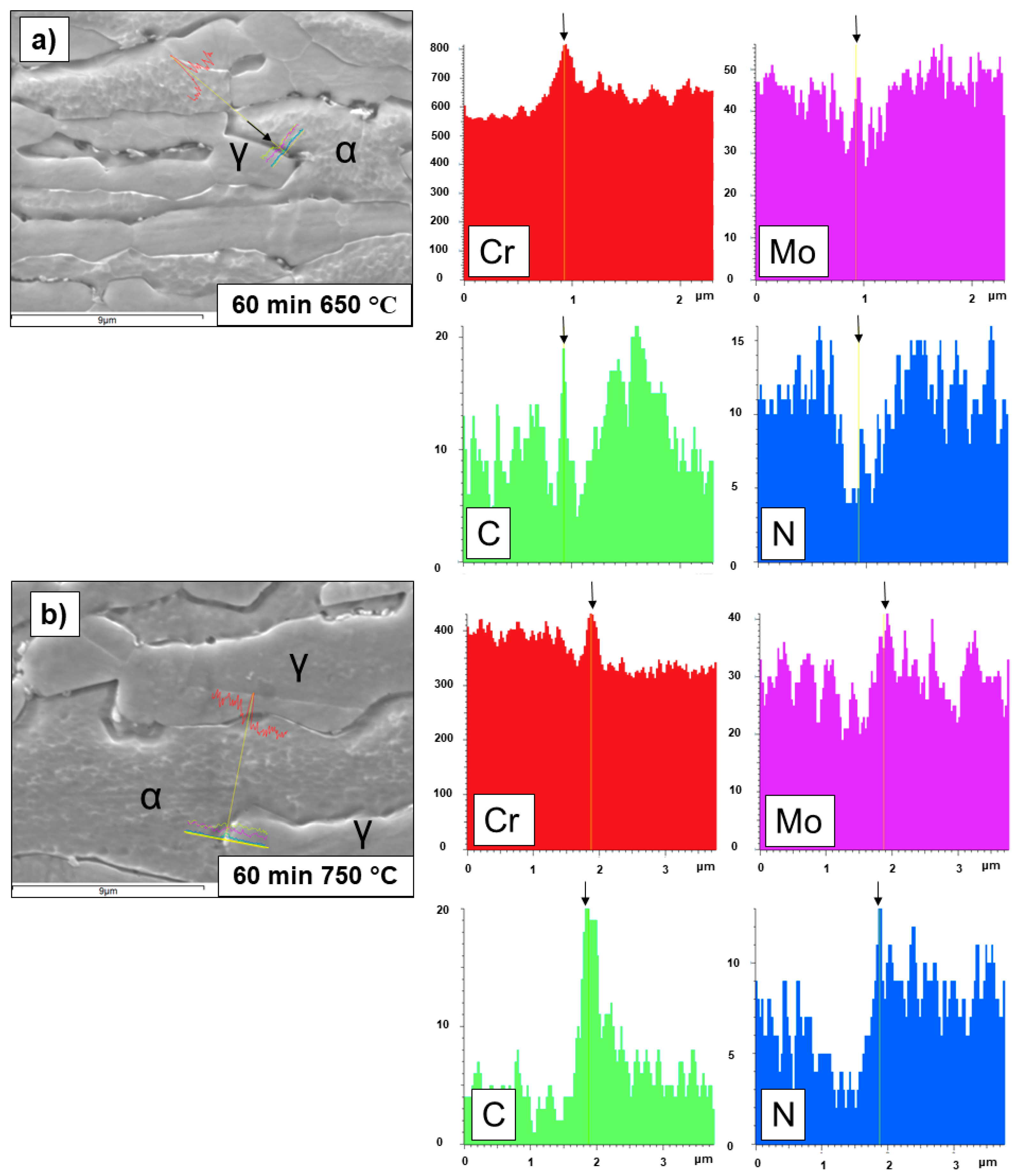

3.1. Microstructure

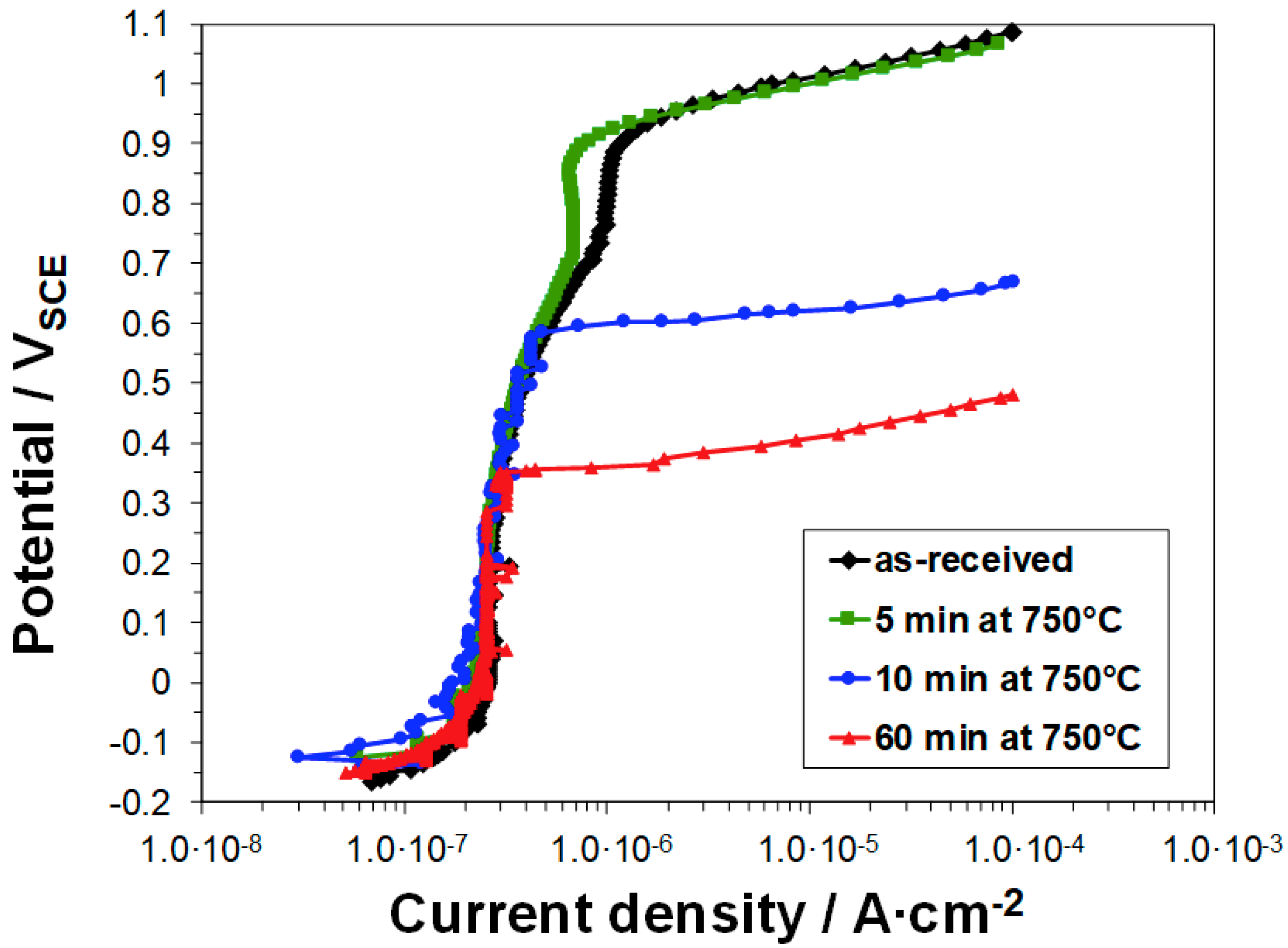

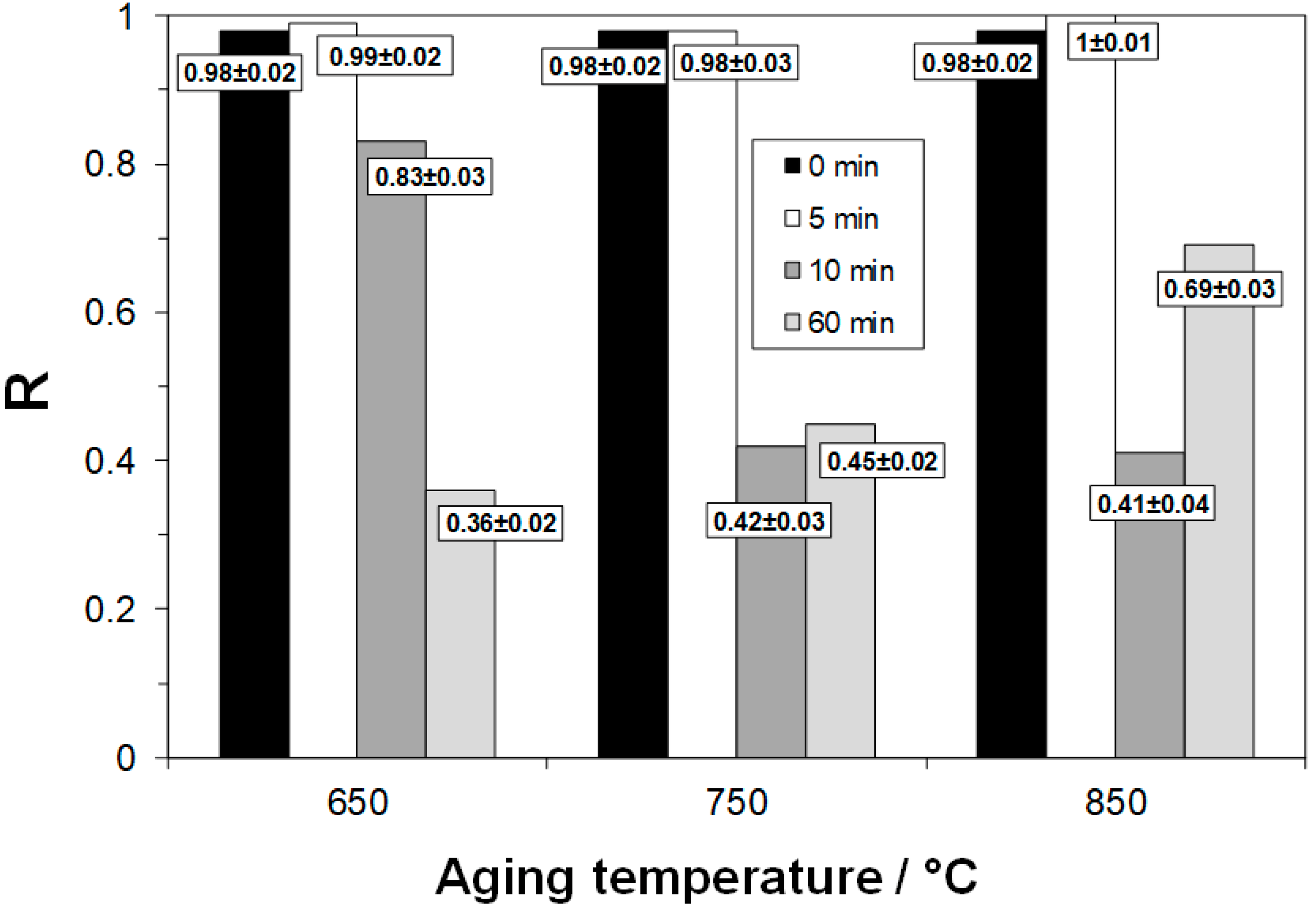

3.2. Pitting Potential Measurements

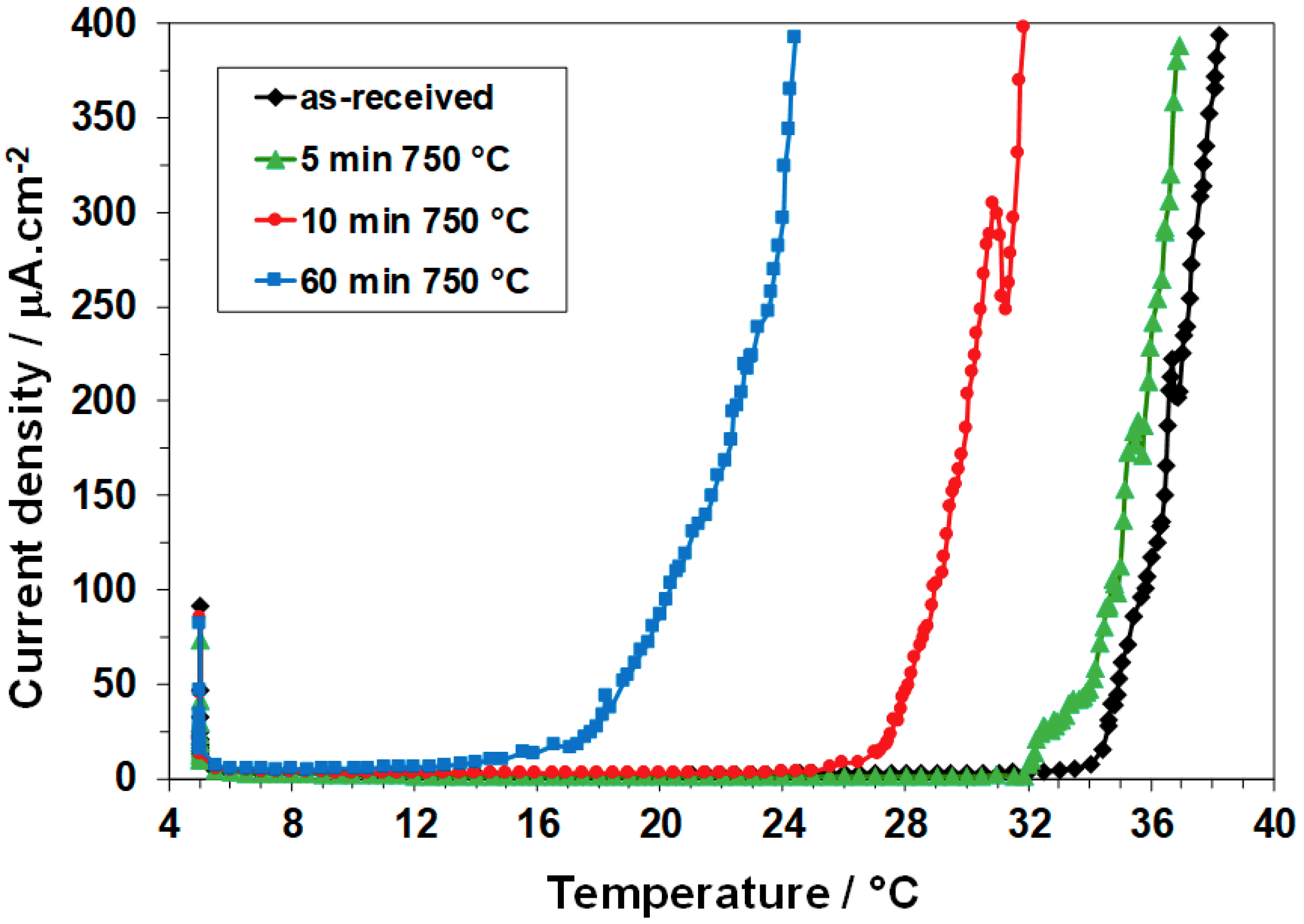

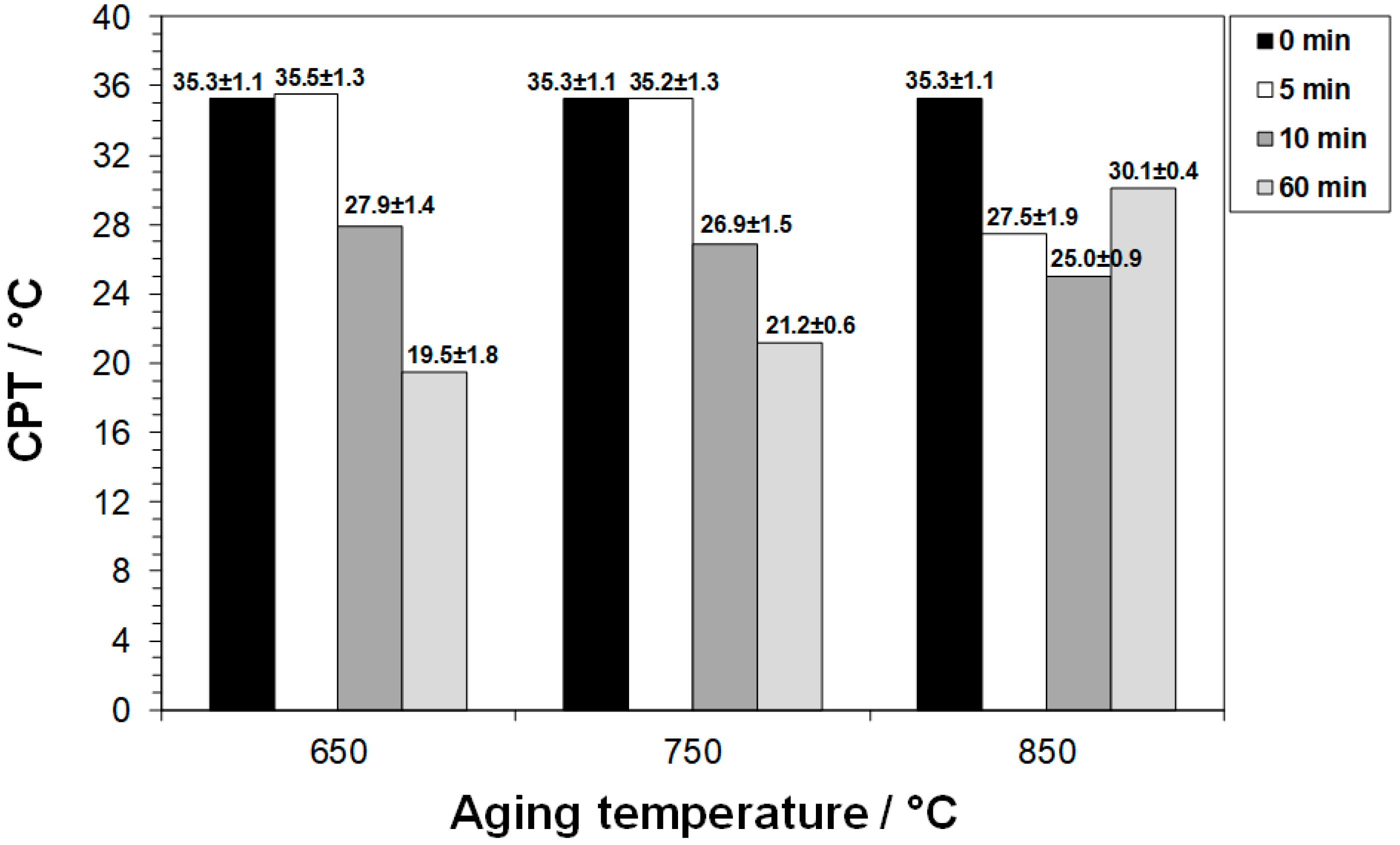

3.3. CPT Test

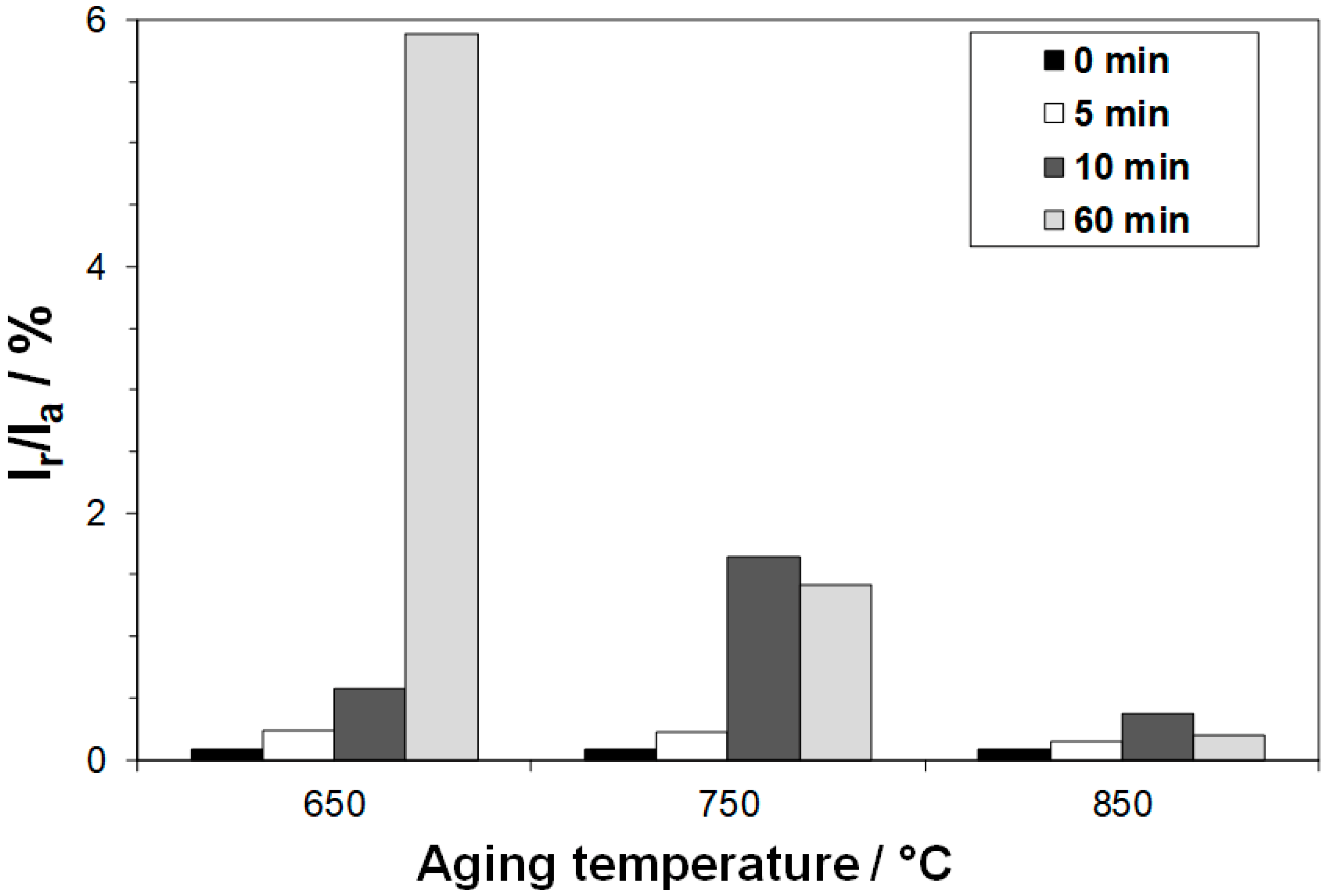

3.4. DL-EPR Test

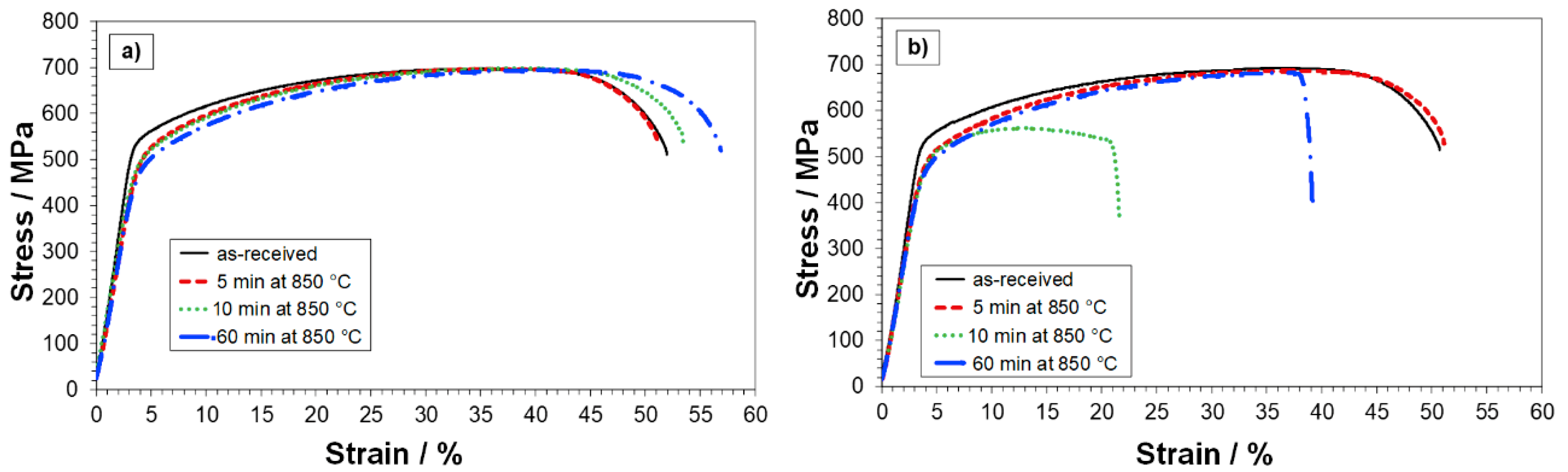

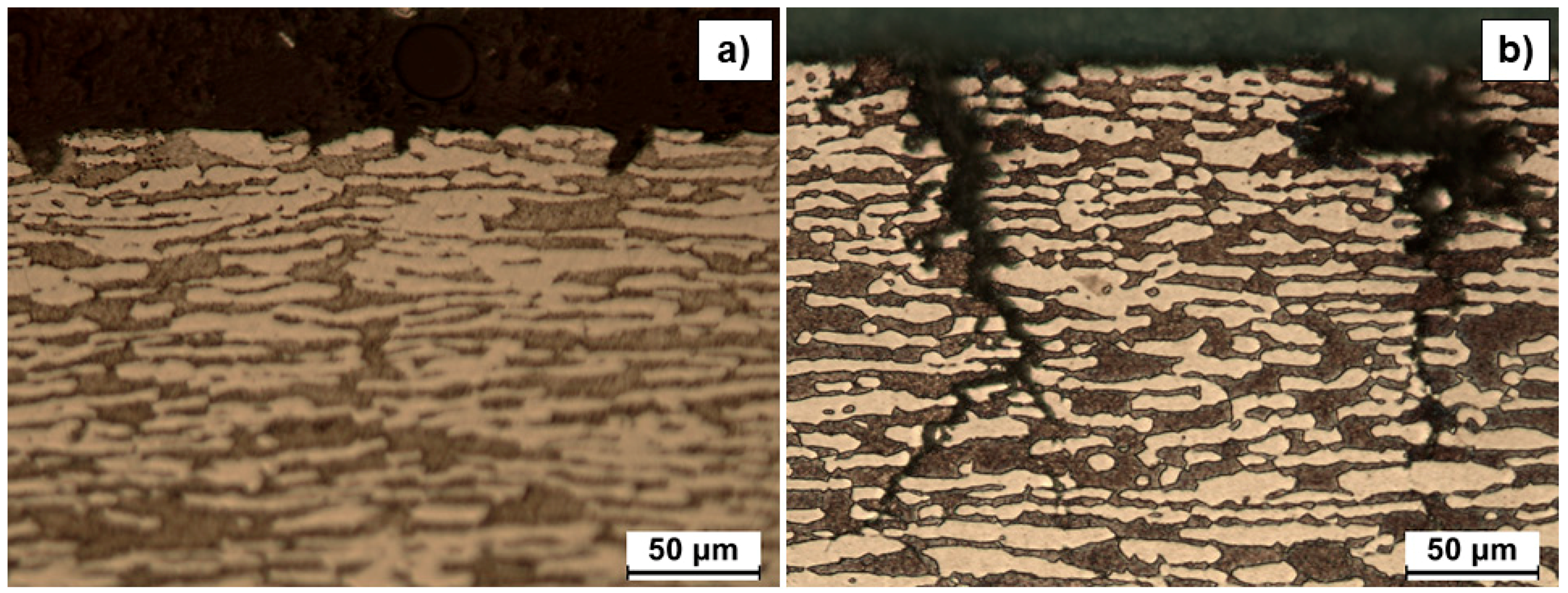

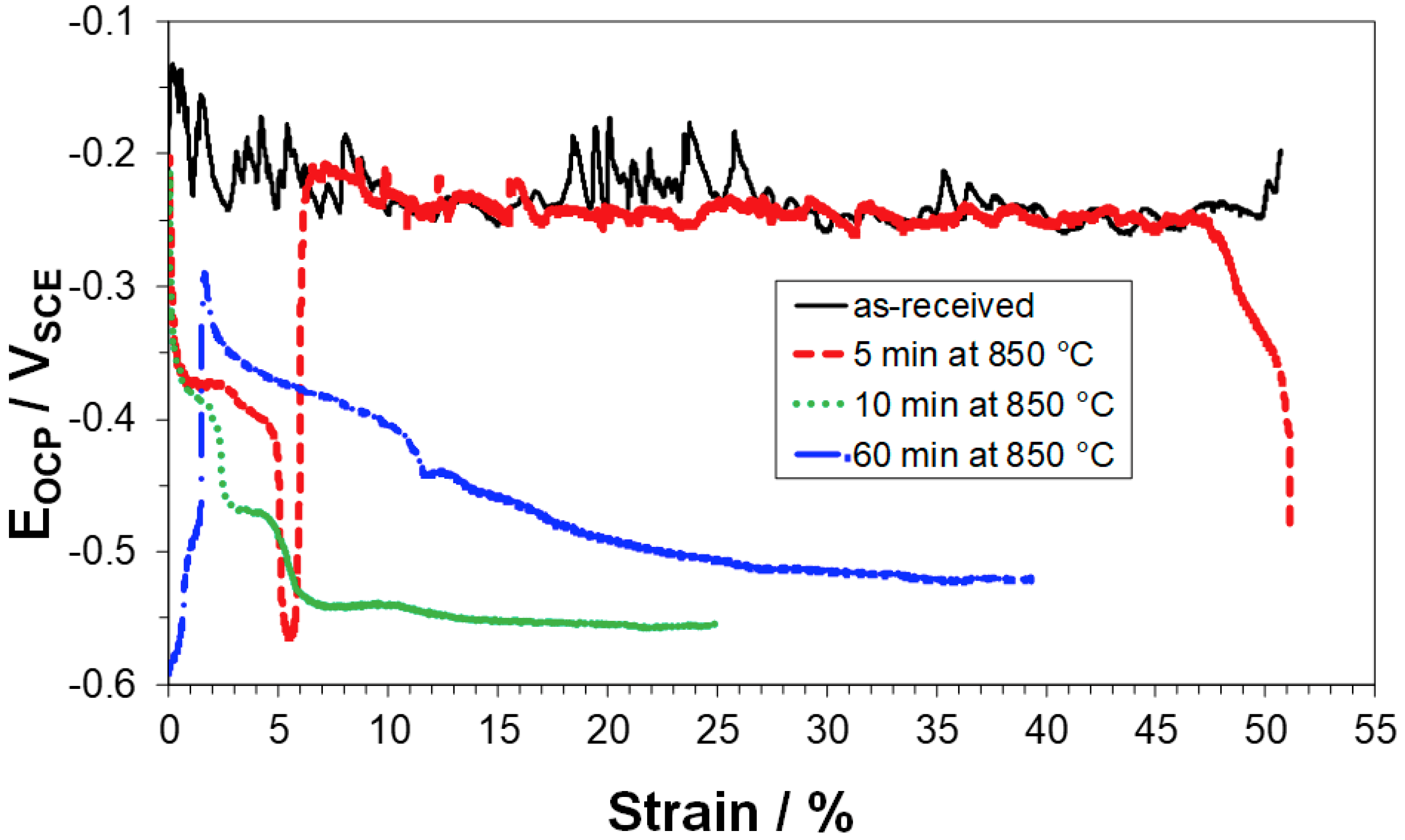

3.5. SSRT

4. Discussion

5. Conclusions

- The heat treatment in the 650–850 °C range on DSS 2304 determined the formation of chromium carbides at α/γ interphase and, under some conditions, the growth of Cr- and Mo-depleted γ2 phase.

- These microstructural modifications affected the localized corrosion performances of this alloy. Pitting and IGC mainly initiated in Cr- and Mo-depleted regions near to precipitates inside the γ2 and likely also the γ phases, then propagated in the ferrite matrix.

- Epitt and CPT values indicated a decrease in pitting resistance of DSS 2304 after 10 min aging at 650 and 750 °C, and the pitting behaviour worsened after longer aging time at these temperatures. At 850 °C, a 5-min aging was sufficient to markedly decrease the pitting resistance, but a recovery was observed after 60 min of aging.

- Similarly, DL-EPR results evidenced a significant IGC sensitization of DSS 2304 after 10 min at 750 °C and 60-min aging at both 650 and 750 °C but no aging treatment at 850 °C was detrimental to the alloy IGC resistance.

- As for pitting corrosion, SCC susceptibility in NACE solution containing 10−3 M S2O32− was also detected after 10 min aging at 650 and 750 °C and increased after longer aging time. SCC also occurred on the sample aged for 10 min at 850 °C. A longer heat treatment at this high temperature ensured a recovery of SCC resistance.

- SCC failure initiated at the bottom of pits and was likely stimulated by hydrogen penetration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pohl, M.; Storz, O.; Glogowski, T. Effect of intermetallic precipitations on the properties of duplex stainless steel. Mat. Charact. 2007, 58, 65–71. [Google Scholar] [CrossRef]

- Badji, R.; Kherrouba, N.; Mehdi, B.; Cheniti, B.; Bouabdallah, M.; Kahloun, C.; Bacroix, B. Precipitation kinetics and mechanical behavior in a solution treated and aged dual phase stainless steel. Mater. Chem. Phys. 2014, 148, 664–672. [Google Scholar] [CrossRef]

- Wang Chan, K.; Chin Tjong, S. Effect of secondary phase precipitation on the corrosion behavior of Duplex Stainless Steels. Materials 2014, 7, 5268–5304. [Google Scholar] [CrossRef] [PubMed]

- Escriba, D.M.; Materna-Morris, E.; Plaut, R.L.; Padilha, A.F. Chi-phase precipitation in a duplex stainless steel. Mater. Charact. 2009, 60, 1214–1219. [Google Scholar] [CrossRef]

- Knyazeva, M.; Pohl, M. Duplex Steels. Part II: Carbides and Nitrides. Metallogr. Microstruct. Anal. 2013, 2, 343–351. [Google Scholar] [CrossRef]

- Moura, V.S.; Lima, L.D.; Pardal, J.M.; Kina, A.Y.; Corte, R.R.A.; Tavares, S.S.M. Influence of microstructure on the corrosion resistance of the duplex stainless steel UNS S31803. Mat. Charact. 2008, 59, 1127–1132. [Google Scholar] [CrossRef]

- Lopez, N.; Cid, M.; Puigalli, M. Infuence of σ-phase on mechanical properties and corrosion resistance of duplex stainless steels. Corros. Sci. 1999, 41, 1615–1631. [Google Scholar] [CrossRef]

- Lopez, N.; Cid, M.; Puigalli, M.; Azkarate, I.; Pelayo, A. Application of double loop electrochemical potentiodynamic reactivation test to austenitic and duplex stainless steels. Mater. Sci. Eng. A 1997, A229, 123–128. [Google Scholar] [CrossRef]

- Chen, T.H.; Yang, J.R. Effect of solution treatment and continuous cooling on σ-phase precipitation in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2001, A311, 28–41. [Google Scholar] [CrossRef]

- Kashiwar, A.; Phani Vennela, N.; Kamath, S.L.; Khatirkar, R.K. Effect of solution annealing temperature on precipitation in 2205 duplex stainless steel. Mat. Charact. 2012, 74, 55–63. [Google Scholar] [CrossRef]

- Sathirachinda, N.; Petterson, R.; Wessman, S.; Pan, J. Study of nobility of chromium nitrides in isothermally aged duplex stainless steels by using SKPFM and SEM/EDS. Corros. Sci. 2010, 52, 179–186. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Deng, B.; Zhang, W.; Xu, J.; Li, J. Effect of aging on the corrosion of 2101 lean duplex stainless steel. Mat. Charact. 2009, 60, 1522–1528. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C.; Brandi, S.D. The relationship between Chromium Nitride and Secondary Austenite precipitation in Duplex Stainless Steels. Metallurg. Mater. Trans. A 2003, 34A, 1575–1596. [Google Scholar] [CrossRef]

- Charles, J.; Chemelle, P. The history of duplex developments, nowadays DSS properties and duplex market future trends. In Proceedings of the 8th Duplex Stainless Steels Conference, Beaune, France, 13–15 October 2010. [Google Scholar]

- Zanotto, F.; Grassi, V.; Merlin, M.; Balbo, A.; Zucchi, F. Effect of brief heat treatments performer between 650 and 850 °C on corrosion behaviour of a lean duplex stainless steel. Corros. Sci. 2015, 94, 38–47. [Google Scholar] [CrossRef]

- Berner, M.; Liu, H.P.; Olsson, C.O.A. Estimating localized corrosion resistance of low alloy stainless steels: comparison of pitting potentials and critical pitting temperatures measured on lean duplex stainless steel LDX 2101 after sensitization. Corros. Eng. Sci. Techn. 2008, 43, 111–116. [Google Scholar] [CrossRef]

- Liu, H.; Johansson, P.; Liljas, M. Structural evolution of LDX 2101® (EN 1.4162) during isothermal ageing at 600–850°C. In Proceedings of the 6th European Stainless Steel Conference, Science and Market, Helsinki, Finland, 10–13 June 2008; pp. 555–560. [Google Scholar]

- Sun, K.; Zeng, M.; Shi, Y.; Hu, Y.; Shen, X. Microstructure and corrosion behavior of S32101 stainless steel underwater dry and wet welded joints. J. Mater. Process. Tech. 2018, 256, 190–201. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, H.; Zhang, H.; Yu, Z.; Hu, J.; He, L.; Li, J. Effect of isothermal aging on the pitting corrosion resistance of UNS S82441 duplex stainless steel based on electrochemical detection. Corros. Sci. 2015, 93, 120–125. [Google Scholar] [CrossRef]

- Tan, H.; Wang, Z.; Jiang, Y.; Yang, Y.; Deng, B.; Song, H.; Li, J. Influence of welding thermal cycles on microstructure and pitting corrosion resistance of 2304 duplex stainless steels. Corros. Sci. 2012, 55, 368–377. [Google Scholar] [CrossRef]

- Chen, L.; Tan, H.; Wang, Z.; Li, J.; Jiang, Y. Influence of cooling rate on microstructure evolution and pitting corrosion resistance in the simulated heat-affected zone of 2304 duplex stainless steels. Corros. Sci. 2012, 58, 168–174. [Google Scholar] [CrossRef]

- Jiang, Y.; Tan, H.; Wang, Z.; Hong, J.; Jiang, L.; Li, J. Influence of Creq/Nieq on pitting corrosion resistance and mechanical properties of UNS S32304 duplex stainless steel welded joints. Corros. Sci. 2013, 70, 252–259. [Google Scholar] [CrossRef]

- Pezzato, L.; Lago, M.; Brunelli, K.; Breda, M.; Piva, E.; Calliari, I. Effect of Secondary Phases Precipitation on Corrosion Resistance of Duplex Stainless Steels. Mater. Sci. Forum 2016, 879, 1495–1500. [Google Scholar] [CrossRef]

- Guo, L.; Li, X.; Sun, T.; Xu, J.; Li, J.; Jiang, Y. The influence of sensitive temperature on the localized corrosion resistance of duplex stainless steel SAF2304. Acta Metall. Sin. 2012, 48, 1503–1509. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, D.; Jiang, Y.; Shi, C.; Li, J. Microstructural evolution and pitting resistance of annealed lean duplex stainless steel UNS S32304. Nuclear Eng. Design 2012, 243, 56–62. [Google Scholar] [CrossRef]

- Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Zucchi, F. Stress corrosion cracking of LDX 2101® duplex stainless steel in chloride solutions in the presence of thiosulphate. Corros. Sci. 2014, 80, 205–212. [Google Scholar] [CrossRef]

- Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Zucchi, F. Stress-Corrosion Cracking Behaviour of Lean-Duplex Stainless Steels in Chloride/Thiosulphate Environments. Metals 2018, 8, 237. [Google Scholar] [CrossRef]

- Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Melandri, C.; Zucchi, F. Effect of brief thermal aging on stress corrosion cracking susceptibility of LDSS 2101 in the presence of chloride and thiosulphate ions. Corros. Sci. 2018, 130, 22–30. [Google Scholar] [CrossRef]

- Tsujikawa, S.; Miyasaka, A.; Ueda, M.; Ando, S.; Shibata, T.; Haruna, T.; Katahira, M.; Yamane, Y.; Aoki, T.; Yamada, T. Alternative for evaluating sour gas resistance of low-alloy steels and corrosion-resistant alloys. Corrosion 1993, 49, 409–419. [Google Scholar] [CrossRef]

- He, L.; Guo, Y.-J.; Wu, X.-Y.; Jiang, Y.-M.; Li, J. Effect of Solution Annealing Temperature on Pitting Behavior of Duplex Stainless Steel 2204 in Chloride Solutions. J. Iron Steel Res. Int. 2016, 23, 357–363. [Google Scholar] [CrossRef]

- International Organization for Standardization. UNI EN ISO 17864:2005: Corrosion of Metals and Alloys—Determination of the Critical Pitting Temperature under Potientiostatic Control; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- ASTM International. ASTM A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steel; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- International Organization for Standardization. ISO 12732:2006 Corrosion of Metals and Alloys—Electrochemical Potentiokinetic Reactivation Measurement Using the Double Loop Method (Based on Cihal’s Method); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Hong, J.; Han, D.; Tan, H.; Li, J.; Jiang, Y. Evaluation of aged duplex stainless steel UNS S32750 susceptibility to intergranular corrosion by optimized double loop electrochemical potentiokinetic reactivation method. Corros. Sci. 2013, 68, 249–255. [Google Scholar] [CrossRef]

- Wasnik, D.N.; Kain, V.; Samajdar, I.; Verlinden, B.; De, P.K. Resistance to sensitization and intergranular corrosion through extreme randomization of grain boundaries. Acta Mater. 2002, 50, 4587–4601. [Google Scholar] [CrossRef]

- NACE standard TM-0177-90 Standard Test Method Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking in H2S Environments; NACE International: Huston, TX, USA, 1990.

- Barteri, M.; De Cristofaro, N.; Scoppio, L.; Cumino, G.; Della Pina, G. Corrosion resistance of martensitic stainless steels in moderately sour oilfield environments. In Proceedings of the Corrosion ’95, NACE, Houston, TX, USA, 26–31 March 1995; p. 76. [Google Scholar]

- Garzon, C.M.; Ramirez, A.J. Growth kinetics of secondary austenite in the welding microstructure of a UNS S32304 duplex stainless steel. Acta Mater. 2006, 54, 3321–3331. [Google Scholar] [CrossRef]

- Calliari, I.; Pellizzari, M.; Baldo, S.; Zanellato, M.; Ramous, E. Analysis of phase stability in Cr-Ni and Cr-Mn DSS. In Proceedings of the 8th Duplex Stainless Steels Conference, Beaune, France, 10–13 June 2008. [Google Scholar]

- Maetz, J.-Y.; Douillard, T.; Cazottes, S.; Verdu, C.; Kléber, X. M23C6 carbides and Cr2N nitrides in aged duplex stainless steel: A SEM, TEM and FIB tomography investigation. Micron 2016, 84, 43–53. [Google Scholar] [CrossRef]

- Gong, J.; Jiang, Y.M.; Deng, B.; Xu, J.L.; Hu, J.P.; Li, J. Evaluation of intergranular corrosion susceptibility of UNS S31803 duplex stainless steel with an optimized double loop electrochemical potentiokinetic reactivation method. Electrochem. Acta 2010, 55, 5077–5083. [Google Scholar] [CrossRef]

- Amadou, T.; Braham, C.; Sidhom, H. Double Loop Electrochemical Potentiokinetic Reactivation Test Optimization in Checking of Duplex Stainless Steel Intergranular Corrosion Susceptibility. Metall. Mater. Tran. A 2004, 35A, 3499–3513. [Google Scholar] [CrossRef]

- Fang, Y.L.; Liu, Z.Y.; Xue, W.Y.; Song, H.M.; Jiang, L.Z. Precipitation of secondary phases in lean duplex stainless steel 2101 during isothermal ageing. ISIJ Int. 2010, 50, 286–293. [Google Scholar] [CrossRef]

- Marcus, P.; Oudar, J. Corrosion Mechanism in Theory and Practice, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 1995; pp. 240–248. ISBN 0-8247-0666-8. [Google Scholar]

- Choudhary, L.; Macdonald, D.D.; Alfantazi, A.A. Role of thiosulfate in the corrosion of steels: A review. Corrosion 2015, 71, 1147–1168. [Google Scholar] [CrossRef]

- Marcus, P.; Protopopoff, E. Thermodynamics of thiosulphate reduction on surfaces of iron, nickel and chromium in water at 25 and 300 °C. Corros. Sci. 1997, 39, 1741–1752. [Google Scholar] [CrossRef]

- Lee, K.M.; Cho, H.S.; Choi, D.C. Effect of isothermal treatment of SAF 2205 duplex stainless steel on migration of interface boundary and growth of austenite. J. Comp. 1999, 285, 156–161. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, Y.; Lia, X.; Dong, C. Interaction between austein-ferrite phases on passive performance of 2205 duplex stainless steel. J. Mater. Sci. Technol. 2018, 34, 2140–2148. [Google Scholar] [CrossRef]

- Devine, T.M. Kinetics of Sensitization and De-Sensitization on Duplex 308 Steinless Steel. Acta Metall. 1988, 36, 1491–1501. [Google Scholar] [CrossRef]

- Aydoğdu, G.H.; Aydinol, M.K. Determination of susceptibility to intergranular corrosion and electrochemical reactivation behaviour of AISI 316L type stainless steel. Corros. Sci. 2006, 48, 3565–3583. [Google Scholar]

- Mehrer, H. Diffusion in Solids Fundamentals, Methods, Materials, Diffusion-Controlled Processes; Springer: Berlin, Germany, 2007; pp. 127–130. [Google Scholar]

- Deng, B.; Jiang, Y.; Gong, J.; Zhong, C.; Gao, J.; Li, J. Critical pitting and repassivation temperatures for duplex stainless steel in chloride solutions. Electrochim. Acta 2008, 53, 5220–5225. [Google Scholar] [CrossRef]

- Bettini, E.; Kivisäkk, U.; Leygraf, C.; Pan, J. Study of corrosion behavior of a 22% Cr duplex stainless steel: Influence of nano-sized chromium nitrides and exposure temperature. Electrochim. Acta 2013, 113, 280–289. [Google Scholar] [CrossRef]

- Newman, R.C.; Isaacs, H.S.; Alman, B. Effect of sulfur compounds on the pitting behavior of type 304 stainless steel in near-neutral chloride solutions. Corrosion 1982, 38, 261–264. [Google Scholar] [CrossRef]

- Rhodes, P.R.; Welch, G.A.; Abrego, L. Stress corrosion cracking susceptibility of duplex stainless steels in sour gas environments. J. Mater. Energy Syst. 1983, 5, 3–18. [Google Scholar] [CrossRef]

| DSS | C | Mn | Cr | Ni | Mo | N | Si | Cu | V | S | P | Fe | PREN * |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DSS 2304 | 0.03 | 1.34 | 23.55 | 4.88 | 0.38 | 0.1 | 0.41 | 0.25 | 0.1 | 0.012 | 0.021 | Bal. | 26 |

| Epitt (VSCE) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| As-Received | 650 °C | 750 °C | 850 °C | ||||||

| 0 min | 5 min | 10 min | 60 min | 5 min | 10 min | 60 min | 5 min | 10 min | 60 min |

| 0.918 * ± 0.03 | 0.884 * ± 0.05 | 0.750 ± 0.08 | 0.481 ± 0.04 | 0.890 * ± 0.01 | 0.615 ± 0.01 | 0.336 ± 0.03 | 0.635 ± 0.06 | 0.640 ± 0.07 | 0.813 ± 0.04 |

| HCl Concentration (%) | Ir/Ia% | |||

|---|---|---|---|---|

| As-Received | 60 min 650 °C | 60 min 750 °C | 60 min 850 °C | |

| 0.3 | 0.02 ± 0.002 | 4.4 ± 0.05 | 0.2 ± 0.01 | 0.03 ± 0.003 |

| 0.45 | 0.08 ± 0.003 | 5.9 ± 0.07 | 1.4 ± 0.04 | 0.2 ± 0.02 |

| 0.6 | 1.7 ± 0.02 | 9.2 ± 0.11 | 5.2 ± 0.08 | 3.0 ± 0.05 |

| εf% | As Received | 650 °C | 750 °C | 850 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 5 min | 10 min | 60 min | 5 min | 10 min | 60 min | 5 min | 10 min | 60 min | ||

| Air at 25 °C | 52 ± 1 | 52 ± 3 | 52 ± 2 | 50 ± 1 | 51 ± 2 | 52 ± 3 | 56 ± 2 | 51 ± 1 | 53 ± 2 | 57 ± 1 |

| NACE TM-0177 with 10−3 M S2O32− | 51 ± 2 | 51 ± 1 | 43 ± 1 | 18 ± 3 | 50 ± 3 | 22 ± 1 | 25 ± 3 | 51 ± 3 | 22 ± 2 | 39 ± 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Zucchi, F. Resistance of Thermally Aged DSS 2304 against Localized Corrosion Attack. Metals 2018, 8, 1022. https://doi.org/10.3390/met8121022

Zanotto F, Grassi V, Balbo A, Monticelli C, Zucchi F. Resistance of Thermally Aged DSS 2304 against Localized Corrosion Attack. Metals. 2018; 8(12):1022. https://doi.org/10.3390/met8121022

Chicago/Turabian StyleZanotto, Federica, Vincenzo Grassi, Andrea Balbo, Cecilia Monticelli, and Fabrizio Zucchi. 2018. "Resistance of Thermally Aged DSS 2304 against Localized Corrosion Attack" Metals 8, no. 12: 1022. https://doi.org/10.3390/met8121022

APA StyleZanotto, F., Grassi, V., Balbo, A., Monticelli, C., & Zucchi, F. (2018). Resistance of Thermally Aged DSS 2304 against Localized Corrosion Attack. Metals, 8(12), 1022. https://doi.org/10.3390/met8121022