Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters

Abstract

:1. Introduction

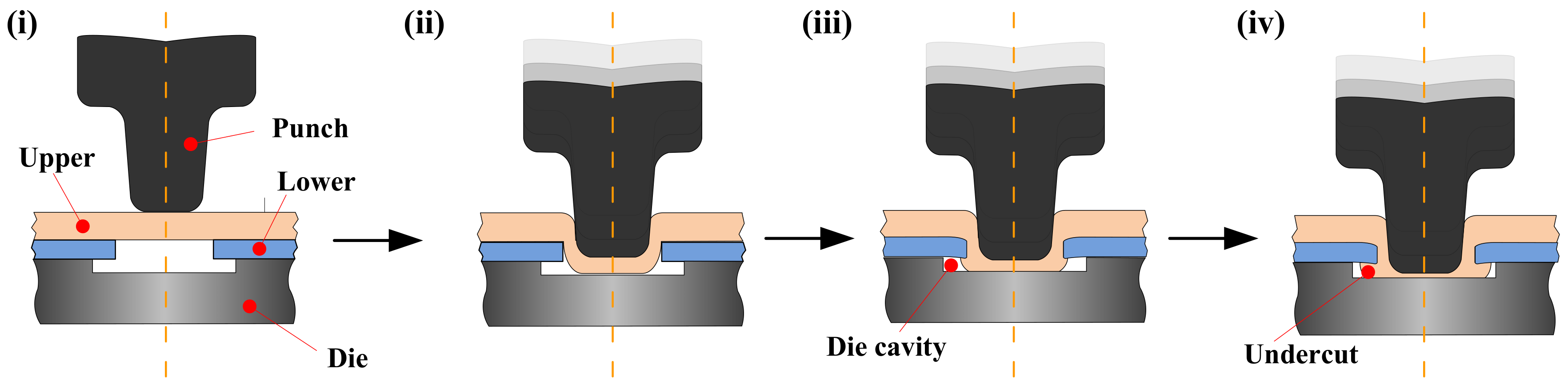

2. Failure Mode Dependent Joint Strength in Hole-Clinching

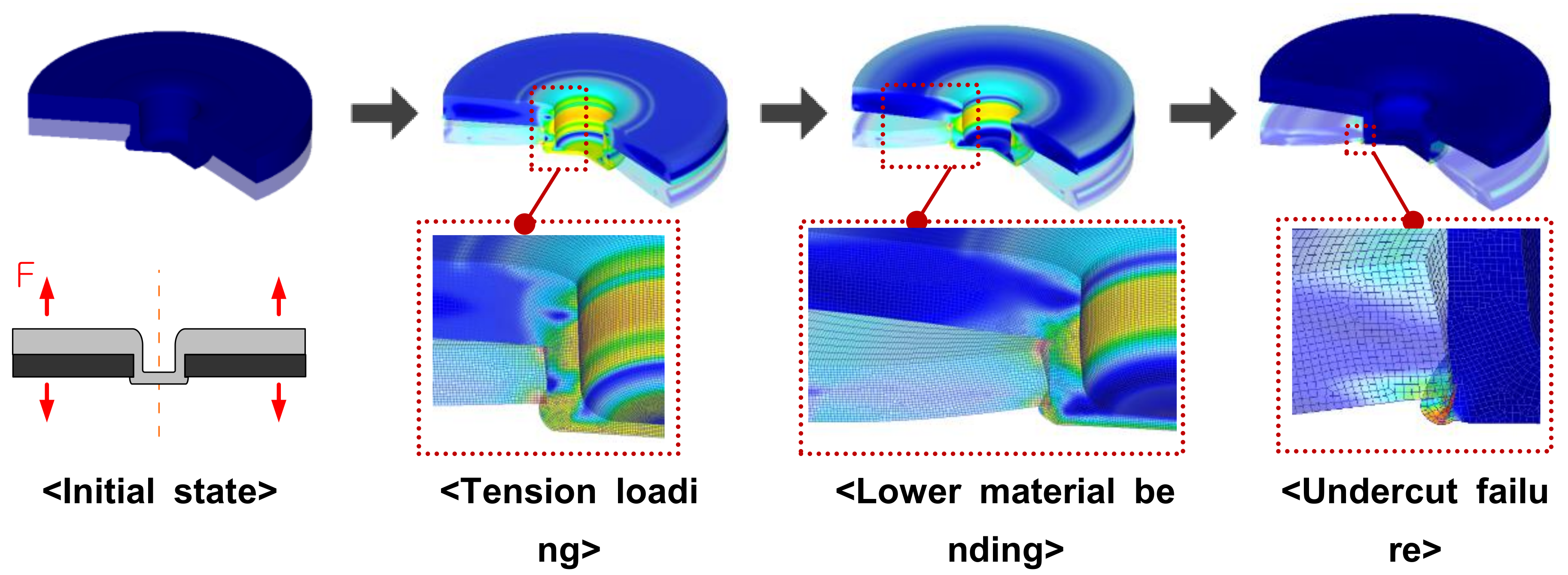

2.1. The Failure Mechanisms of Hole-Clinched Joints

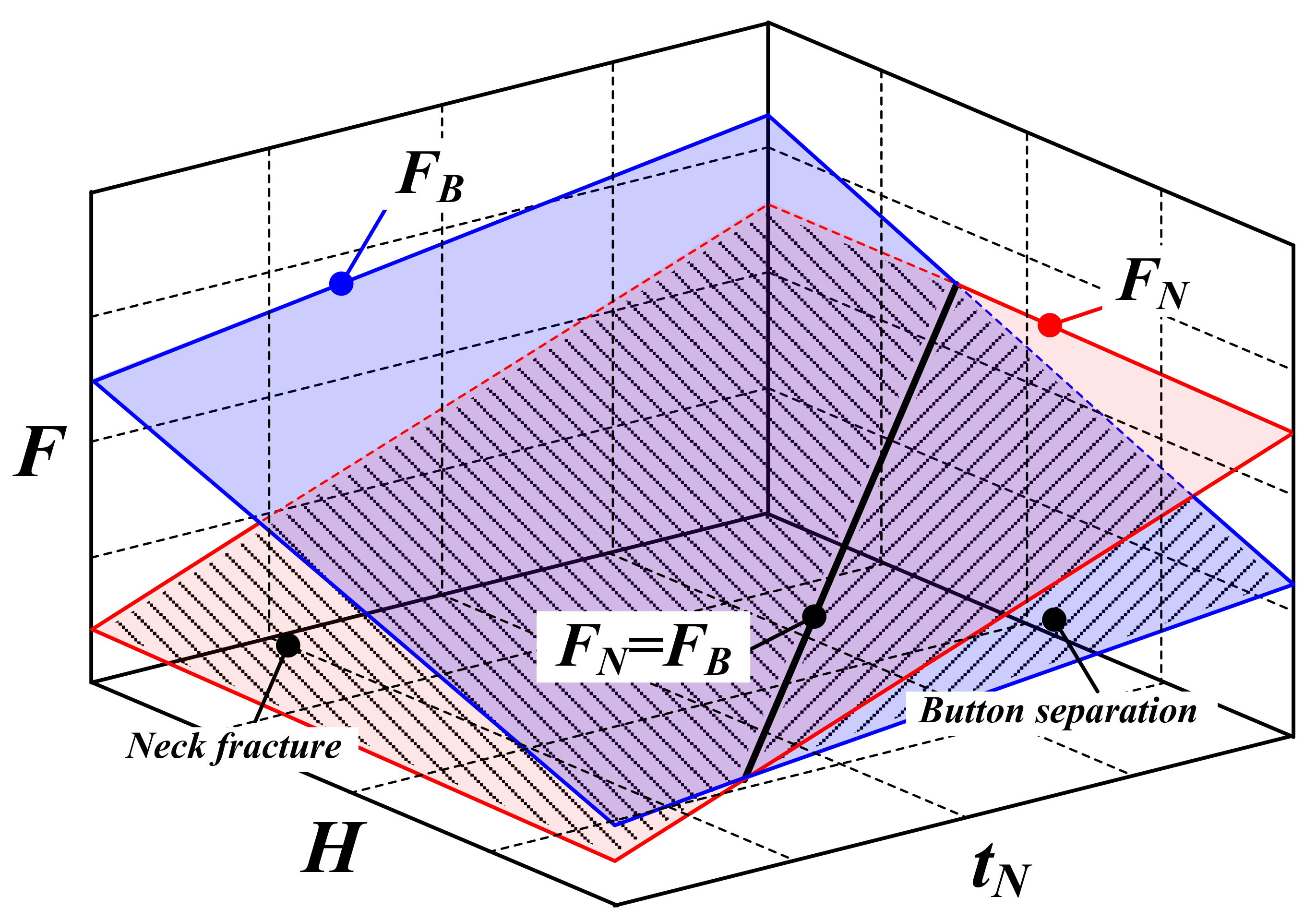

2.2. Joint Strength for Neck-Fracture and Button Separation Mode

2.3. Identification of Failure Mode

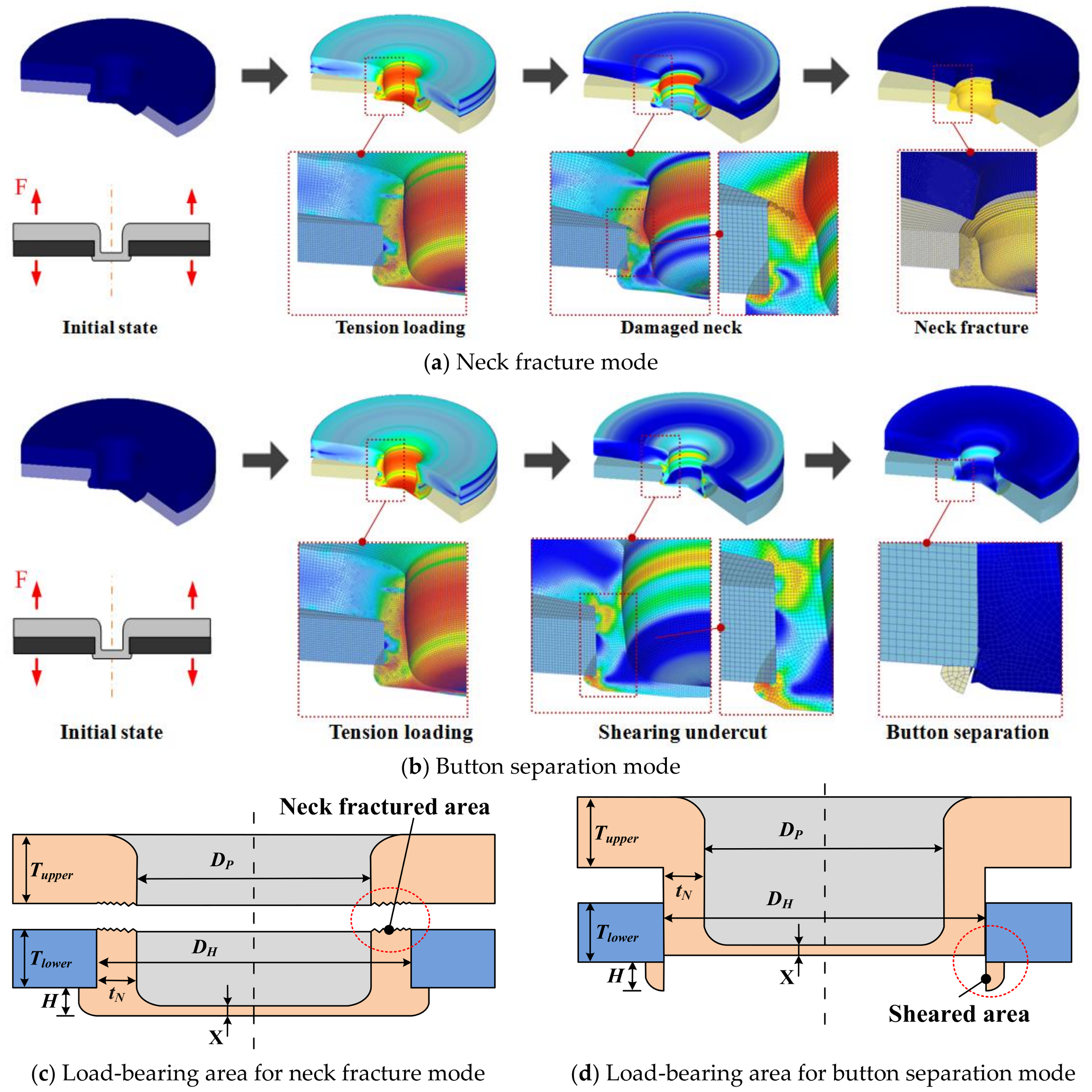

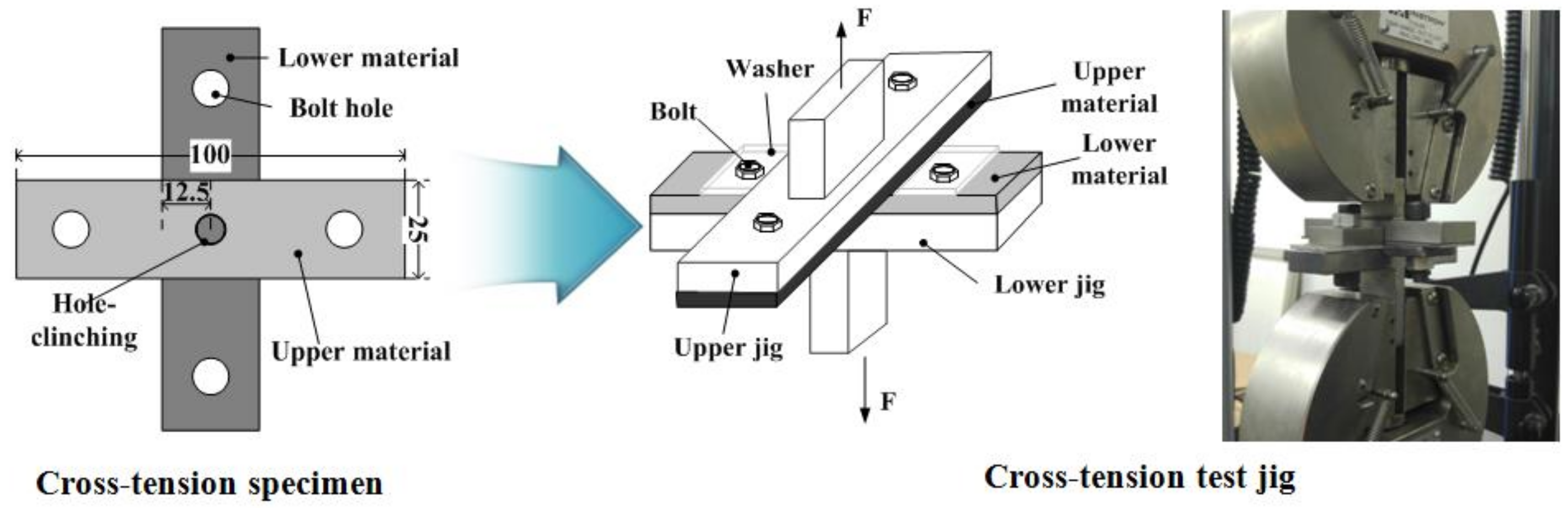

3. Experimental Verification of the Failure-Mode Dependent Joint Strength

3.1. Geometrical Interlocking Parameter

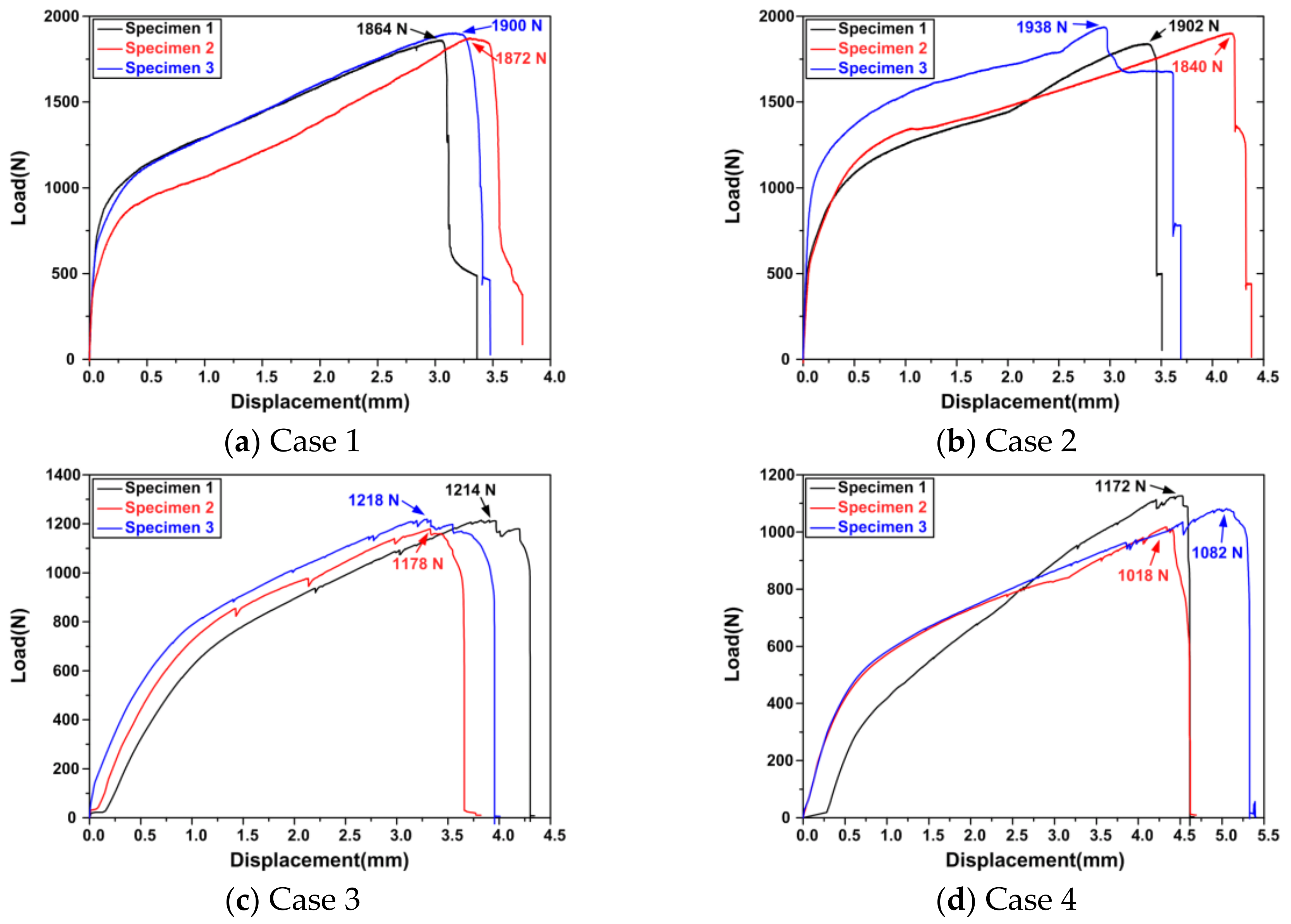

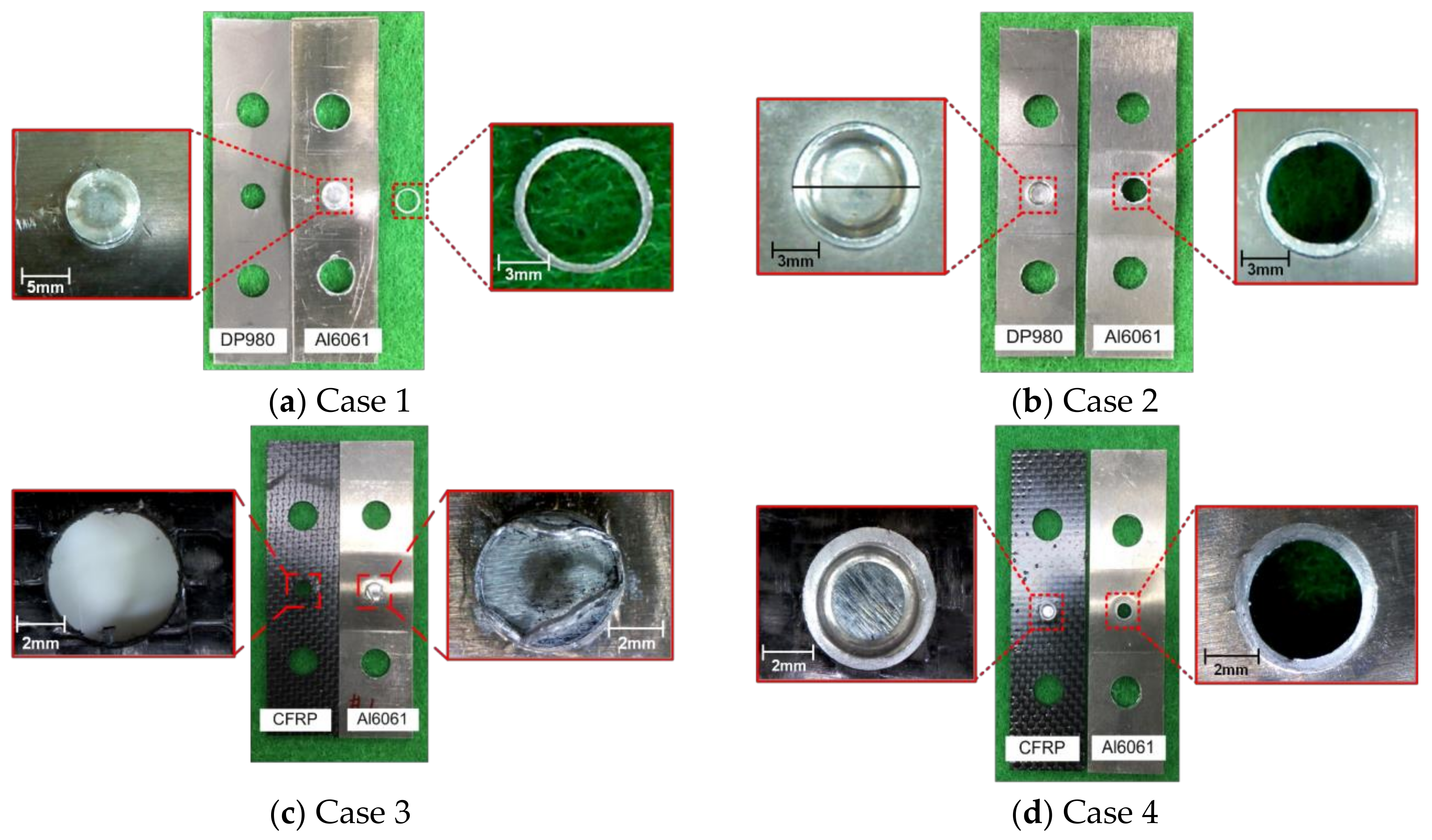

3.2. Evaluation of Joint Strength

4. Discussions

4.1. Relationship between the Geometrical Interlocking Parameters and Joint Strength

4.2. Lower Material

5. Conclusions

- 1.

- Under pull-out loading conditions, the analytical expressions for joint strength were derived for each failure mode of the hole-clinched joint and the validity of these expressions was verified through the hole-clinching experiments. Accordingly, it was found that it was possible to predict the failure-mode dependent joint strength within a maximum error of 7.8%. Similarly, all specimens in the experiments exactly exhibited the failure modes predicted by the analytical approach.

- 2.

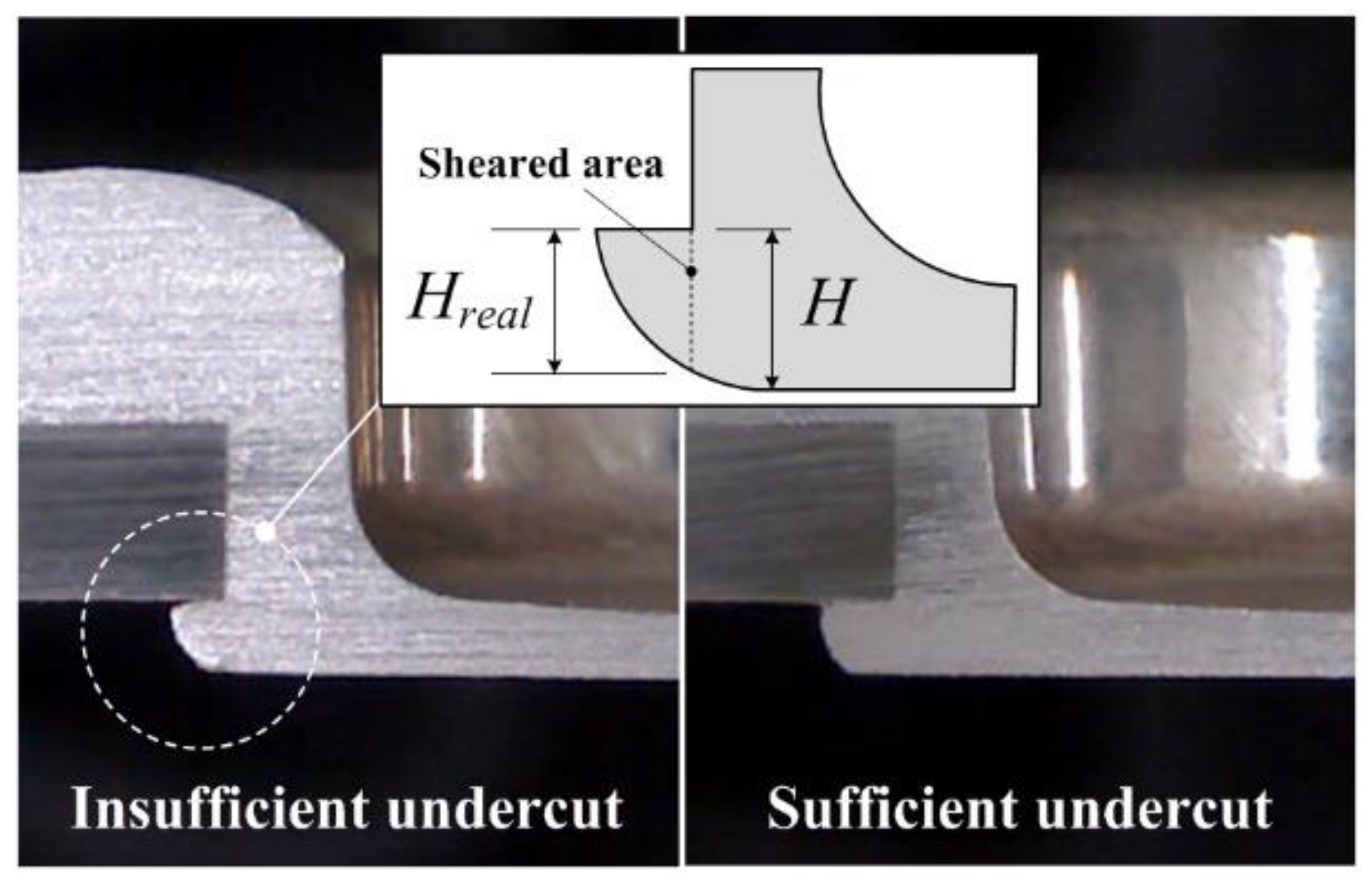

- The hole-clinched joint failed at the load-bearing region, which provided the joint strength in each failure mode. For a given punch diameter, the load-bearing region for the neck fracture and button separation mode were determined by the geometrical interlocking parameters, such as the neck thickness and undercut height.

- 3.

- The relationship between the analytical expressions for each failure mode clearly indicated the direction of the initial design and design modification for the hole-clinching process. In this regard, further research is needed to apply the proposed analytical expressions in hole-clinched joint design.

Author Contributions

Funding

Conflicts of Interest

References

- Mayyas, A.T.; Qattawi, A.; Mayyas, A.R.; Omar, M.A. Life cycle assessment-based selection for a sustainable light-weight body-in-white. Energy 2012, 39, 412–425. [Google Scholar] [CrossRef]

- Messler, R.W. Trends in key joining technologies for the twenty-first century. Assem. Autom. 2000, 20, 118–128. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, J.M.; Lee, K.H.; Ryu, H.Y.; Kim, B.M. Development of hybrid clinched structure by using multi-cohesive zone models. Int. J. Precis. Eng. Manuf. 2014, 15, 1015–1022. [Google Scholar] [CrossRef]

- Gomez, S.; Onoro, J.; Pecharroman, J. A simple mechanical model of a structural hybrid adhesive/riveted single lap joint. Int. J. Adhes. 2007, 27, 263–267. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic metal welding of aluminum sheets to carbon reinforced thermoplastic composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Arena, J.M.; Alía, C.; Narbón, J.J.; Ocaña, R.; González, C. Consideration for the industrial application of structural adhesive joints in the aluminium-composite material bonding. Compos. Part. B Eng. 2013, 44, 417–423. [Google Scholar] [CrossRef]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly (pheylene sulfide) composite single lap joints: Microstructure and mechanical performance. Mater. Design. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Yoshida, S.; Tsuchiya, A.; Nakata, K. Direct joining of carbon-fiber-reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B Eng. 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Dean, A.; Sahraee, S.; Reinoso, J.; Rolfes, R. Finite deformation model for short fiber reinforced composites: Application to hybrid metal-composite clinching joints. Comp. Struct. 2015, 151, 162–171. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Brenneis, M.; Pabst, C.; Resch, F. Joining by forming—A review on joint mechanisms, applications and future trends. J. Mater. Process. Technol. 2014, 214, 1972–1994. [Google Scholar] [CrossRef]

- Meschut, G.; Janzen, V.; Olfermann, T. Innovative and highly productive joining technologies for multi-material lightweight car body structures. J. Mater. Eng. Perform. 2014, 23, 1515–1523. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, S.H.; Lee, J.M.; Kim, B.H.; Kim, B.M.; Ko, D.C. Design of hole clinching process for joining CFRP and aluminum alloy sheet. Int. J. Precis. Eng. Manuf. 2014, 15, 1151–1157. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, J.M.; Ryu, H.Y.; Lee, K.H.; Kim, B.M.; Ko, D.C. Design of hole-clinching process for joining of dissimilar materials-Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J. Mater. Process. Technol. 2014, 214, 2169–2178. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, C.J.; Lee, K.H.; Lee, J.M.; Kim, B.M.; Ko, D.C. Influence of tool shape on hole clinching for carbon fiber-reinforced plastic and SPRC440. Adv. Mecha. Eng. 2014, 6, 810–864. [Google Scholar] [CrossRef]

- Coppieters, S.; Lava, P.; Baes, S.; Sol, H.; Van Houtte, P.; Debruyne, D. Analytical method to predict the pull-out strength of clinched connections. Thin. Wall. Struct. 2012, 52, 42–52. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, J.Y.; Lee, S.K.; Ko, D.C.; Kim, B.M. Design of mechanical clinching tools for joining of aluminium alloy sheets. Mater. Design. 2010, 31, 1854–1861. [Google Scholar] [CrossRef]

- He, X.C.; Gao, A.F.; Yang, H.Y.; Xing, B.Y. Mechanical behavior of clinched sheet material joints and strength design procedure. Acta. Phys. Pol. A 2016, 120, 698–700. [Google Scholar] [CrossRef]

- Shen, G.; Lee, C.J.; Lee, J.M.; Kang, G.S.; Park, J.H.; Kim, B.M.; Ko, D.C. Prediction of failure mode in hole clinching of Al alloy and advanced high-strength steel. Key Eng. Mater. 2016, 716, 481–486. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, B.M.; Kang, B.S.; Song, W.J.; Ko, D.C. Improvement of joinability in a hole clinching process with aluminum alloy and carbon fiber reinforced plastic using a spring die. Compos. Struct. 2017, 173, 58–69. [Google Scholar] [CrossRef]

- EN ISO 14272. Resistance welding—Destructive testing of welds—Specimen dimensions and procedure for cross tension testing of resistance spot and embossed projection welds; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

| Materials | Elastic Modulus (GPa) | Yield Stress (MPa) | UTS (MPa) | Flow Stress (MPa) | Thickness (mm) |

|---|---|---|---|---|---|

| Al6061 | 70.1 | 55.0 | 125.2 | 2.0 | |

| DP980 | 197.4 | 781.2 | 987.3 | 1.4 | |

| CFRP (45°) | 31.2 | 318.0 | 962.7 | - | 1.4 |

| Case | Materials | Punch Diameter, DP | Pilot Hole Diameter, DH | Die Depth, H |

|---|---|---|---|---|

| 1 | Al6061-DP980 | 5.4 | 7.6 | 0.6 |

| 2 | Al6061-DP980 | 6.8 | 8.1 | 0.6 |

| 3 | Al6061-CFRP | 4.0 | 5.2 | 0.5 |

| 4 | Al6061-CFRP | 4.2 | 5.2 | 0.7 |

| Case | tN (mm) | X (mm) | Failure Load (N) | Failure Mode | |||

|---|---|---|---|---|---|---|---|

| FN | FB | ||||||

| 1 | 1.1 | 0.6 | 125.2 | 135.36 | 2808 | 1939 | Button separation |

| 2 | 0.62 | 1.0 | 125.2 | 118.82 | 1807 | 1814 | Neck fracture |

| 3 | 0.73 | 0.25 | 125.2 | 153.99 | 1356 | 1257 | Button separation |

| 4 | 0.58 | 0.4 | 125.2 | 144.96 | 1085 | 1657 | Neck fracture |

| Case | Failure Load | Failure Mode | |||

|---|---|---|---|---|---|

| Prediction (N) | Experiment (N) | Error (%) | Prediction | Experiment | |

| 1 | 1939 | 1880 | ‒3.0 ± 1.4 | Button separation | Button separation |

| 2 | 1807 | 1885 | 4.3 ± 3.5 | Neck fracture | Neck fracture |

| 3 | 1229 | 1203 | 2.8 ± 4.0 | Button separation | Button separation |

| 4 | 1085 | 1076 | 0.6 ± 4.1 | Neck fracture | Neck fracture |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-J.; Shen, G.; Kim, B.-M.; Lambiase, F.; Ko, D.-C. Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters. Metals 2018, 8, 1020. https://doi.org/10.3390/met8121020

Lee C-J, Shen G, Kim B-M, Lambiase F, Ko D-C. Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters. Metals. 2018; 8(12):1020. https://doi.org/10.3390/met8121020

Chicago/Turabian StyleLee, Chan-Joo, Guo Shen, Byung-Min Kim, Francesco Lambiase, and Dae-Cheol Ko. 2018. "Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters" Metals 8, no. 12: 1020. https://doi.org/10.3390/met8121020

APA StyleLee, C.-J., Shen, G., Kim, B.-M., Lambiase, F., & Ko, D.-C. (2018). Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters. Metals, 8(12), 1020. https://doi.org/10.3390/met8121020