Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process

Abstract

1. Introduction

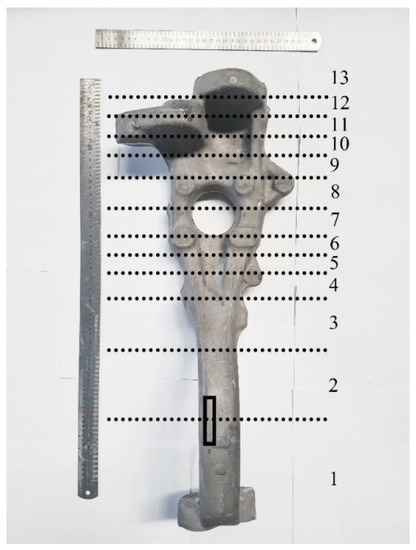

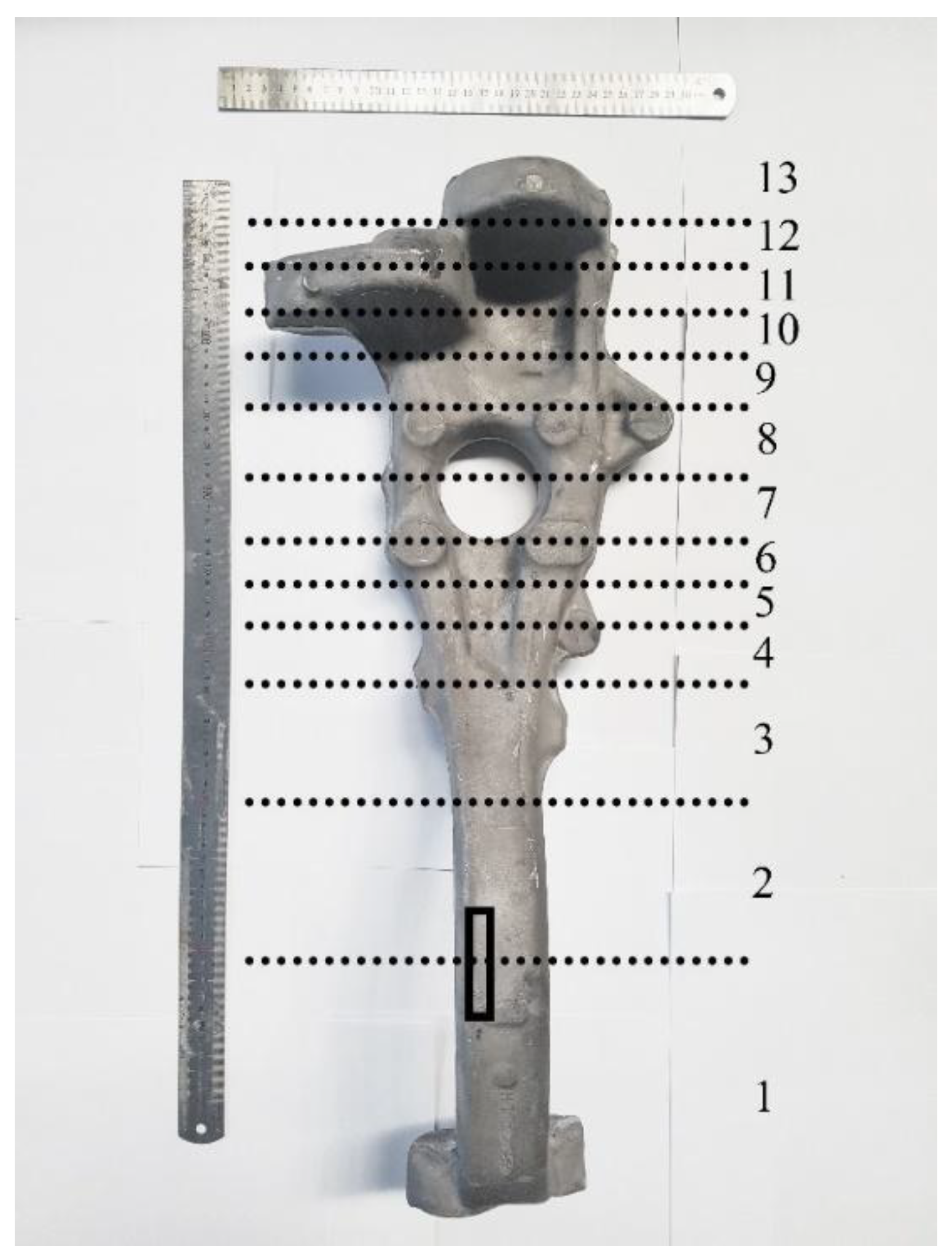

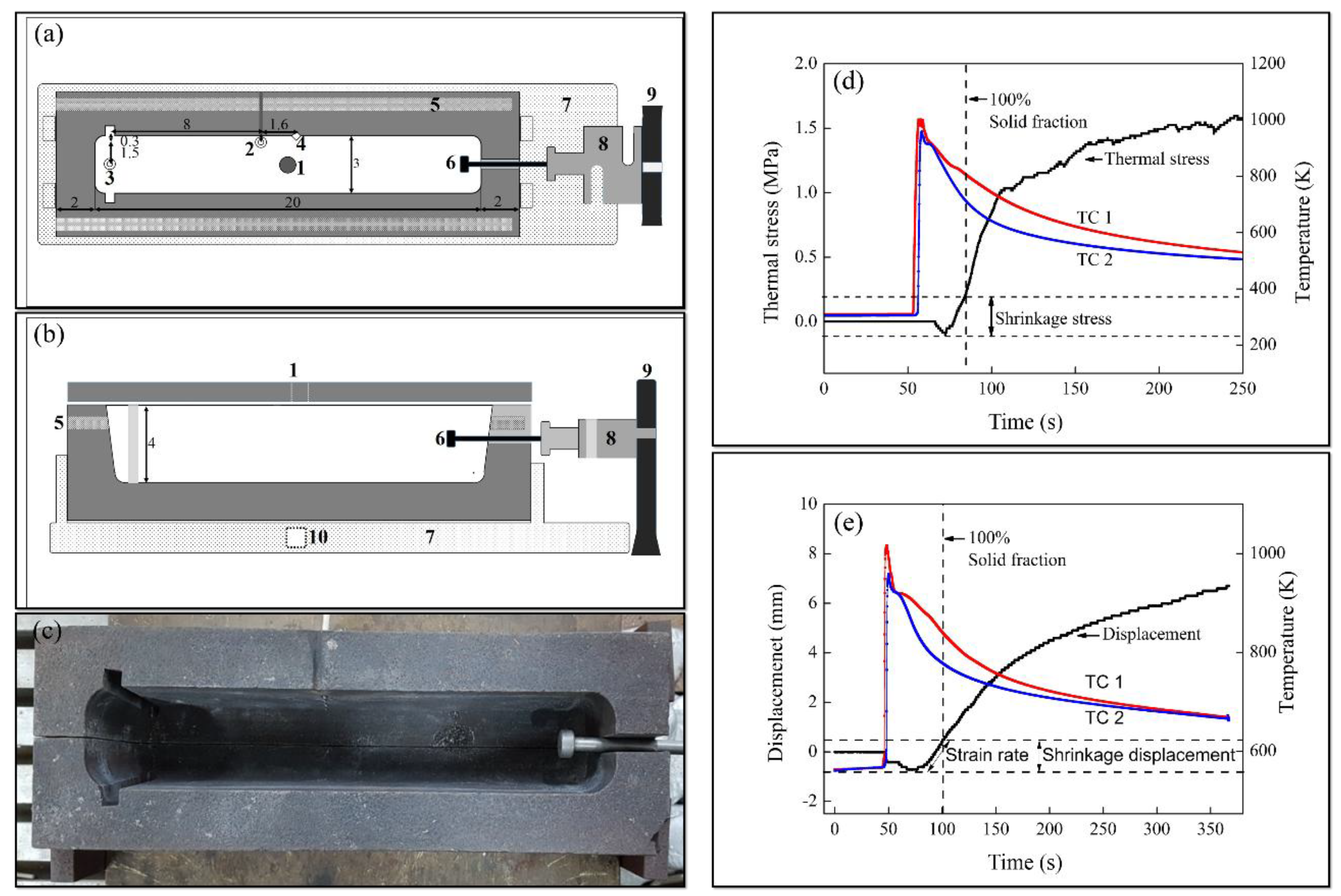

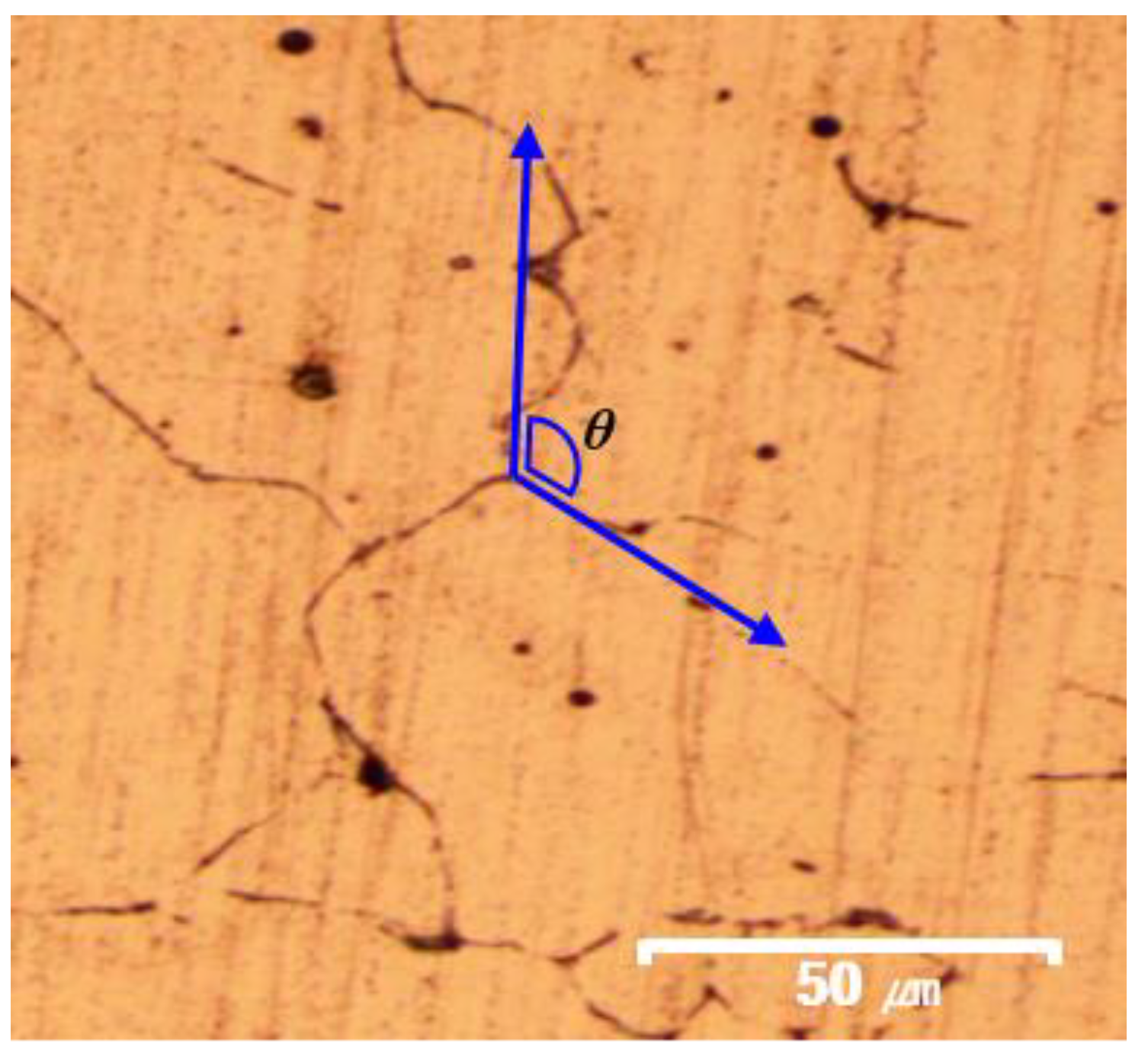

2. Material and Methods

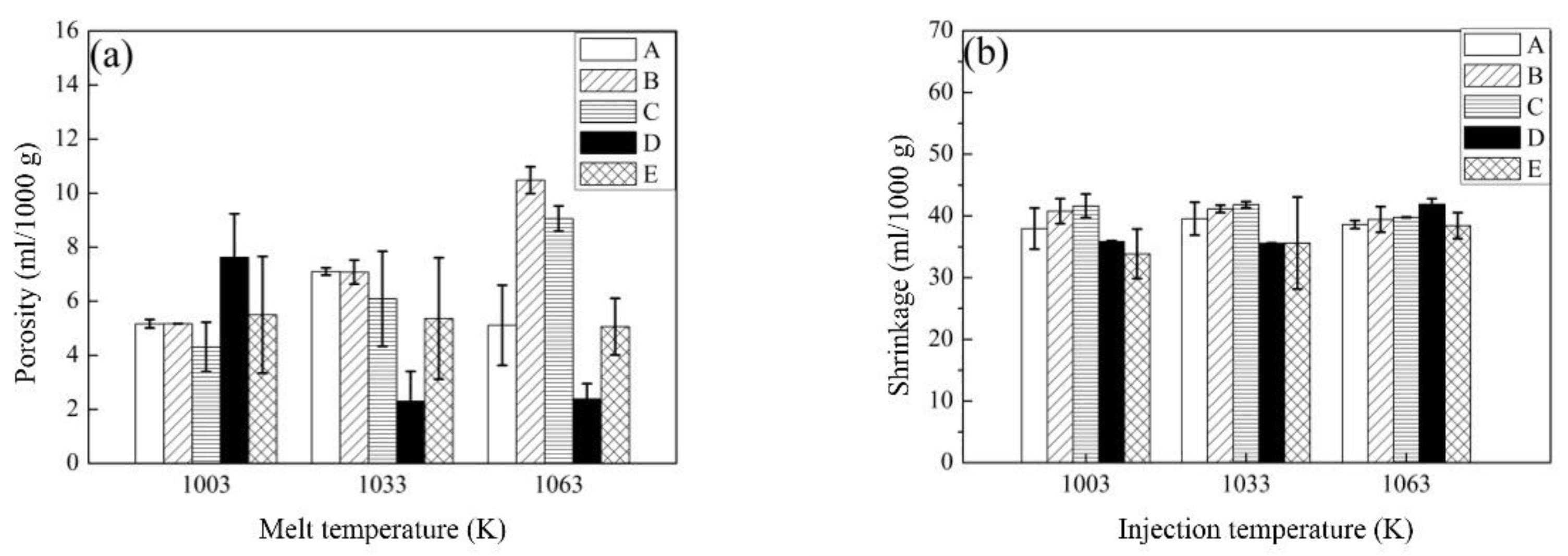

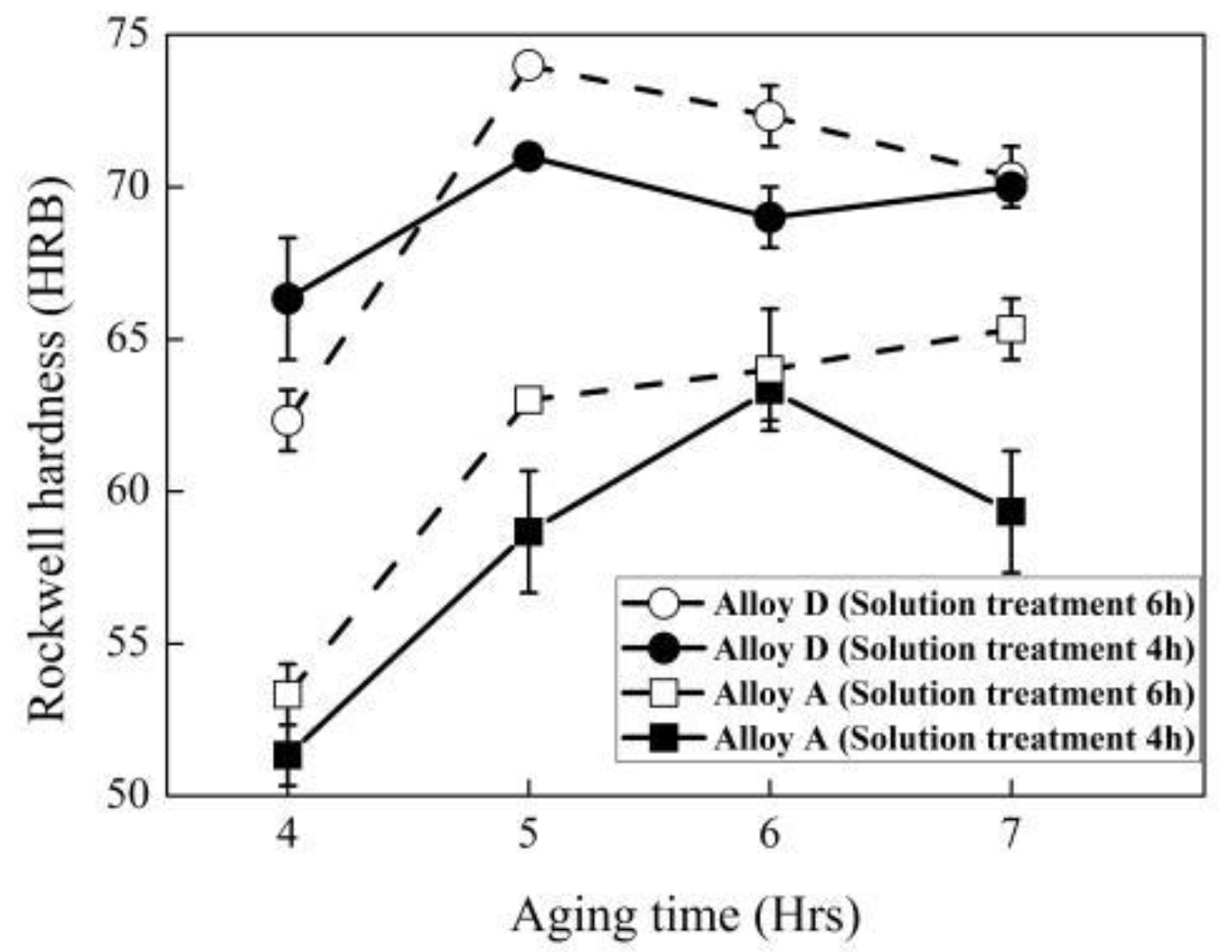

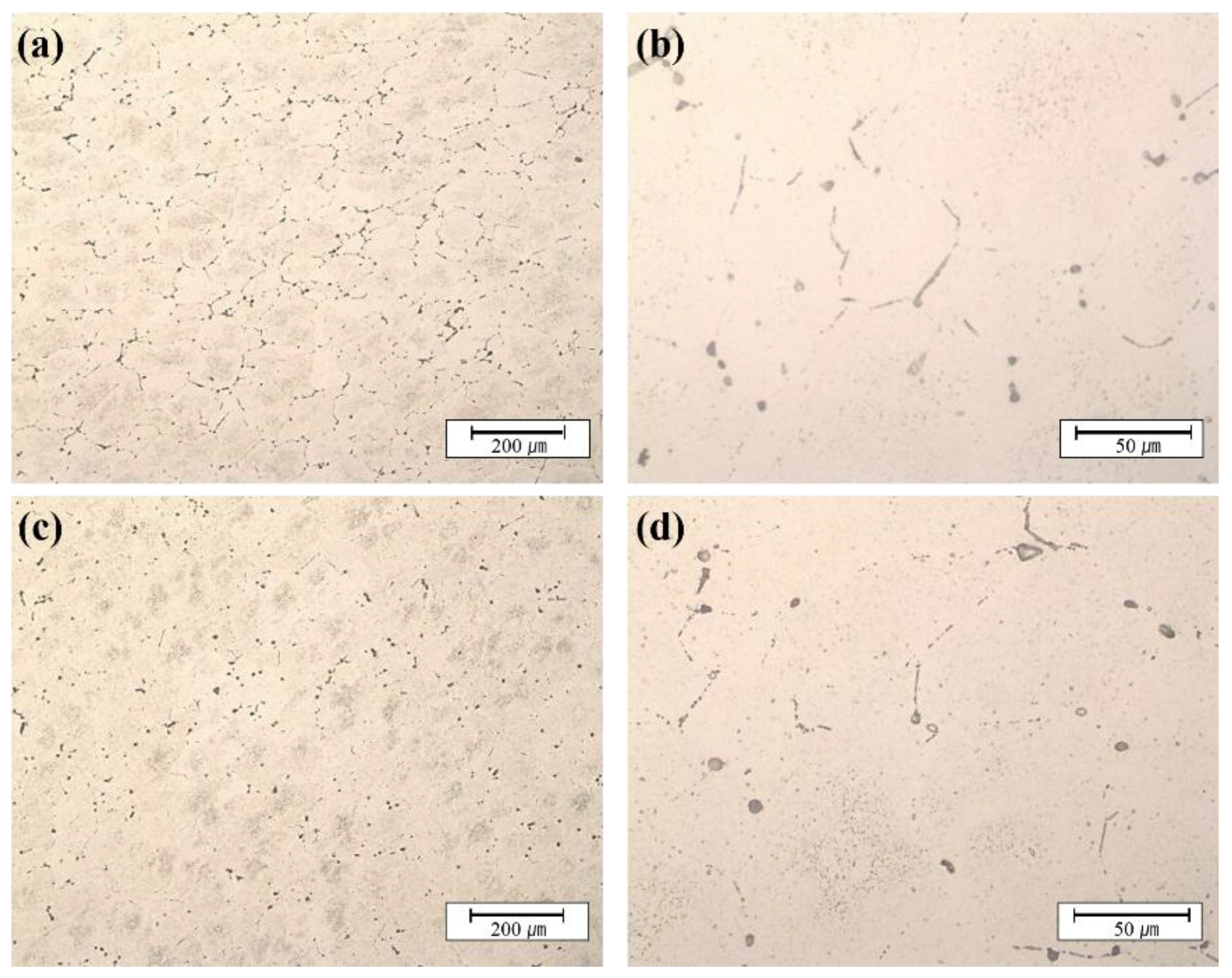

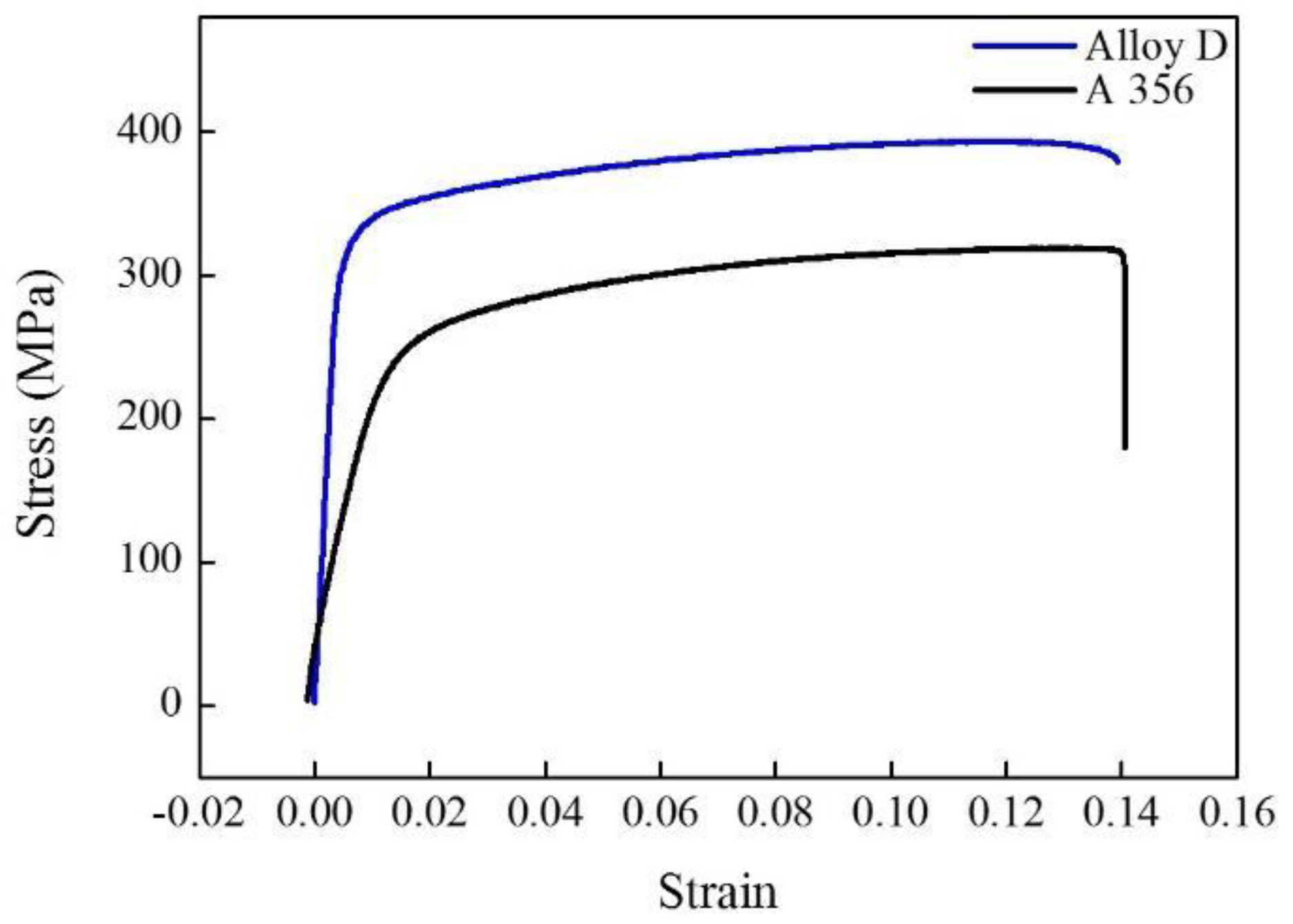

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campbell, J. Castings, 2nd ed.; Elsevier Butterworth-Heinemann: Burlington, MA, USA, 2003; p. 1. [Google Scholar]

- Skallerud, B.; Iveland, T.; Härkegård, G. Fatigue life assessment of aluminum alloys with casting defects. Eng. Fract. Mech. 1993, 44, 857–874. [Google Scholar] [CrossRef]

- Suyitno; Kool, W.H.; Katgerman, L. Micro-mechanical model of hot tearing at triple junctions in dc casting. 2002, 396–402, 179–184. [Google Scholar]

- Liu, Y.; Jie, W.; Gao, Z.; Zheng, Y. Investigation on the formation of microporosity in aluminum alloys. J. Alloys Compd. 2015, 629, 221–229. [Google Scholar] [CrossRef]

- Seo, K.H.; Jeon, J.B.; Youn, J.W.; Kim, S.J.; Kim, K.Y. Recycling of al-si die casting scraps for solar si feedstock. J. Cryst. Growth 2016, 442, 1–7. [Google Scholar] [CrossRef]

- Hanko, G.; Antrekowitsch, H.; Ebner, P. Recycling automotive magnesium scrap. JOM 2002, 54, 51–54. [Google Scholar] [CrossRef]

- Arafune, K.; Ohishi, E.; Sai, H.; Ohshita, Y.; Yamaguchi, M. Directional solidification of polycrystalline silicon ingots by successive relaxation of supercooling method. J. Cryst. Growth 2007, 308, 5–9. [Google Scholar] [CrossRef]

- Vijayarangan, S.; Rajamanickam, N.; Sivananth, V. Evaluation of metal matrix composite to replace spheroidal graphite iron for a critical component, steering knuckle. Mater. Des. 2013, 43, 532–541. [Google Scholar] [CrossRef]

- Sharma, M.M.; Ziemian, C.W.; Eden, T.J. Fatigue behavior of sic particulate reinforced spray-formed 7xxx series al-alloys. Mater. Des. 2011, 32, 4304–4309. [Google Scholar] [CrossRef]

- Sivananth, V.; Vijayarangan, S.; Rajamanickam, N. Evaluation of fatigue and impact behavior of titanium carbide reinforced metal matrix composites. Mater. Sci. Eng. A 2014, 597, 304–313. [Google Scholar] [CrossRef]

- Morri, A.; Ceschini, L.; Messieri, S.; Cerri, E.; Toschi, S. Mo addition to the a354 (al–si–cu–mg) casting alloy: Effects on microstructure and mechanical properties at room and high temperature. Metals 2018, 8. [Google Scholar] [CrossRef]

- Kernebeck, S.; Weber, S. Influence of short-term heat treatment on the mechanical properties of al–mg–si profiles. Metals 2018, 8. [Google Scholar] [CrossRef]

- Liu, K.; Mirza, F.A.; Chen, X.G. Effect of overaging on the cyclic deformation behavior of an aa6061 aluminum alloy. Metals 2018, 8. [Google Scholar] [CrossRef]

- Stangeland, A.; MO, A.; Nielsen, Ø.; M’Hamdi, M.; Eskin, D. Development of thermal strain in the coherent mushy zone during solidification of aluminum alloys. Metall. Mater. Trans. A 2004, 35, 2903–2915. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Liu, B.C.; Kang, J.W.; Xiong, S.M. A study on the numerical simulation of thermal stress during the solidification of shaped castings. Sci. Technol. Adv. Mater. 2001, 2, 157–164. [Google Scholar] [CrossRef]

- Eskin, D.G.; Suyitno; Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Dahle, A.K.; Arnberg, L. Development of strength in solidifying aluminium alloys. Acta Mater. 1997, 45, 547–559. [Google Scholar] [CrossRef]

- Metz, S.A.; Flemings, M.C. Fundamental study of hot tearing. AFS Trans. 1970, 78, 453–460. [Google Scholar]

- Kamguo Kamga, H.; Larouche, D.; Bournane, M.; Rahem, A. Hot tearing of aluminum-copper b206 alloys with iron and silicon additions. Mater. Sci. Eng. A 2010, 527, 7413–7423. [Google Scholar] [CrossRef]

- Li, X.M.; Starink, M.J. Effect of compositional variations on characteristics of coarse intermetallic particles in overaged 7000 aluminium alloys. Mater. Sci. Technol. 2001, 17, 1324–1328. [Google Scholar]

- Li, X.M.; Starink, M.J. Identification and analysis of intermetallic phases in overaged zr-containing and cr-containing al-zn-mg-cu alloys. J. Alloys Compd. 2011, 509, 471–476. [Google Scholar] [CrossRef]

- Senkov, O.N.; Shagiev, M.R.; Senkova, S.V.; Miracle, D.B. Precipitation of al3(sc,zr) particles in an al-zn-mg-cu-sc-zr alloy during conventional solution heat treatment and its effect on tensile properties. Acta Mater. 2008, 56, 3723–3738. [Google Scholar] [CrossRef]

- Morimoto, K.; Takamiya, H.; Awano, Y.; Nakamura, M. Effects of si content and gas dissolution on shrinkage morphology of hypoeutectic al-si alloys. J. Jpn. Inst. Light Met. 1988, 38, 216–221. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Luo, J.; Zhu, J.; Zhang, J.; Zhuang, L. Effect of zn on microstructure, texture and mechanical properties of al-mg-si-cu alloys with a medium number of fe-rich phase particles. Mater. Charact. 2017, 134, 123–133. [Google Scholar] [CrossRef]

- Anyalebechi, P.N. Effect of process route on the structure, tensile, and fatigue properties of aluminium alloy automotive steering knuckles. Foundry Trade J. Int. 2012, 186, 189–196. [Google Scholar]

- Ruff, G.; Prucha, T.E.; Barry, J.; Patterson, D. Pressure counter pressure casting (pcpc) for automotive aluminum structural components. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

| Samples | Al | Si | Mg | Cu | Cr | Mn | Fe | Zn | Ti | Zr | SST (K) | ET (K) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300 K | 673 K | ||||||||||||

| A | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0 | 591.74 ± 8.47 | 615.28 ± 8.47 | 580.0 |

| B | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0.01 | 602.73 ± 6.46 | 624.12 ± 2.87 | 576.5 |

| C | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.001 | 0.139 | 0.02 | 610.09 ± 8.39 | 623.82 ± 8.70 | 576.5 |

| D | Bal. | 0.975 | 0.678 | 0.308 | 0.136 | 0.0958 | 0.0831 | 0.700 | 0.139 | 0 | 613.29 ± 10.73 | 630.33 ± 6.73 | 576.2 |

| E | Bal. | 0.975 | 0.678 | 0.500 | 0.136 | 0.0958 | 0.0831 | 1.500 | 0.139 | 0 | 600.94 ± 11.44 | 630.17 ± 2.91 | 573.7 |

| Samples | Strain Rate (×10−3, s−1) | Grain Boundary Angle (θ) | Value of δ | |||

|---|---|---|---|---|---|---|

| 300 K | 673 K | 300 K | 673 K | 300 K | 673 K | |

| A | 1.48 | 0.99 | 108.85 ± 12.25 | 104.57 ± 14.50 | 0.88 ± 0.14 | 0.84 ± 0.14 |

| B | 1.03 | 0.76 | 109.63 ± 13.71 | 101.83 ± 14.85 | 0.89 ± 0.14 | 0.81 ± 0.13 |

| C | 2.12 | 0.27 | 108.17 ± 15.82 | 98.64 ± 15.61 | 0.89 ± 0.18 | 0.79 ± 0.15 |

| D | 0.76 | 0.45 | 102.06 ± 11.68 | 93.91 ± 16.85 | 0.81 ± 0.11 | 0.75 ± 0.11 |

| E | 0.57 | 0.30 | 104.21 ± 13.11 | 87.83 ± 15.32 | 0.84 ± 0.15 | 0.71 ± 0.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, G.T.; Kim, K.Y.; Moon, J.-H.; Lee, C.; Kim, W.-J.; Kim, S.J. Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals 2018, 8, 857. https://doi.org/10.3390/met8100857

Jeon GT, Kim KY, Moon J-H, Lee C, Kim W-J, Kim SJ. Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals. 2018; 8(10):857. https://doi.org/10.3390/met8100857

Chicago/Turabian StyleJeon, Gyu Tae, Ki Young Kim, Jung-Hwa Moon, Chul Lee, Whi-Jun Kim, and Suk Jun Kim. 2018. "Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process" Metals 8, no. 10: 857. https://doi.org/10.3390/met8100857

APA StyleJeon, G. T., Kim, K. Y., Moon, J.-H., Lee, C., Kim, W.-J., & Kim, S. J. (2018). Effect of Al 6061 Alloy Compositions on Mechanical Properties of the Automotive Steering Knuckle Made by Novel Casting Process. Metals, 8(10), 857. https://doi.org/10.3390/met8100857