Prediction of Static Recrystallization Nucleation Sites in Tensile Deformed Single Crystal Pure Iron through a Combination of In-Situ EBSD and CP-FEM

Abstract

1. Introduction

2. Methodology

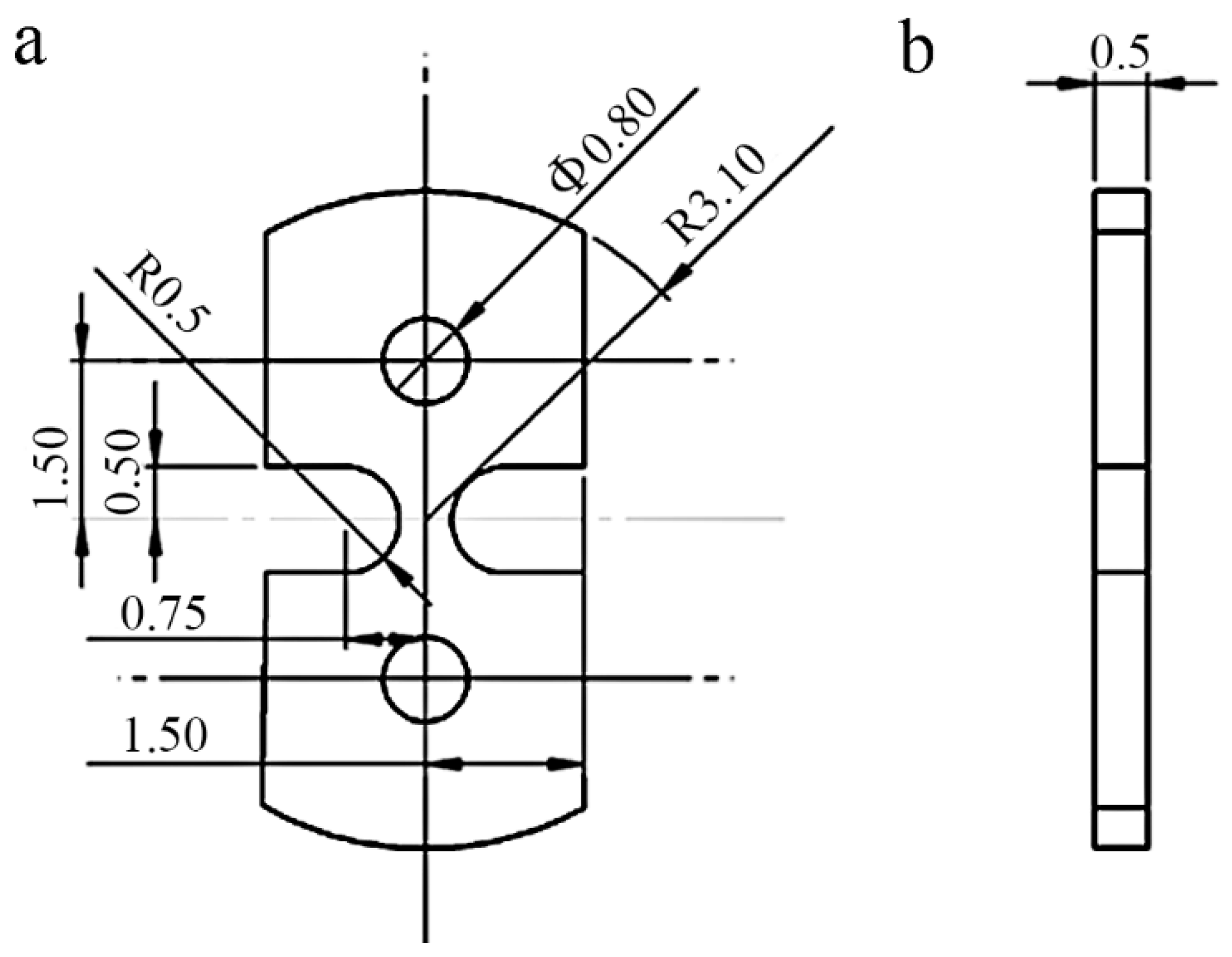

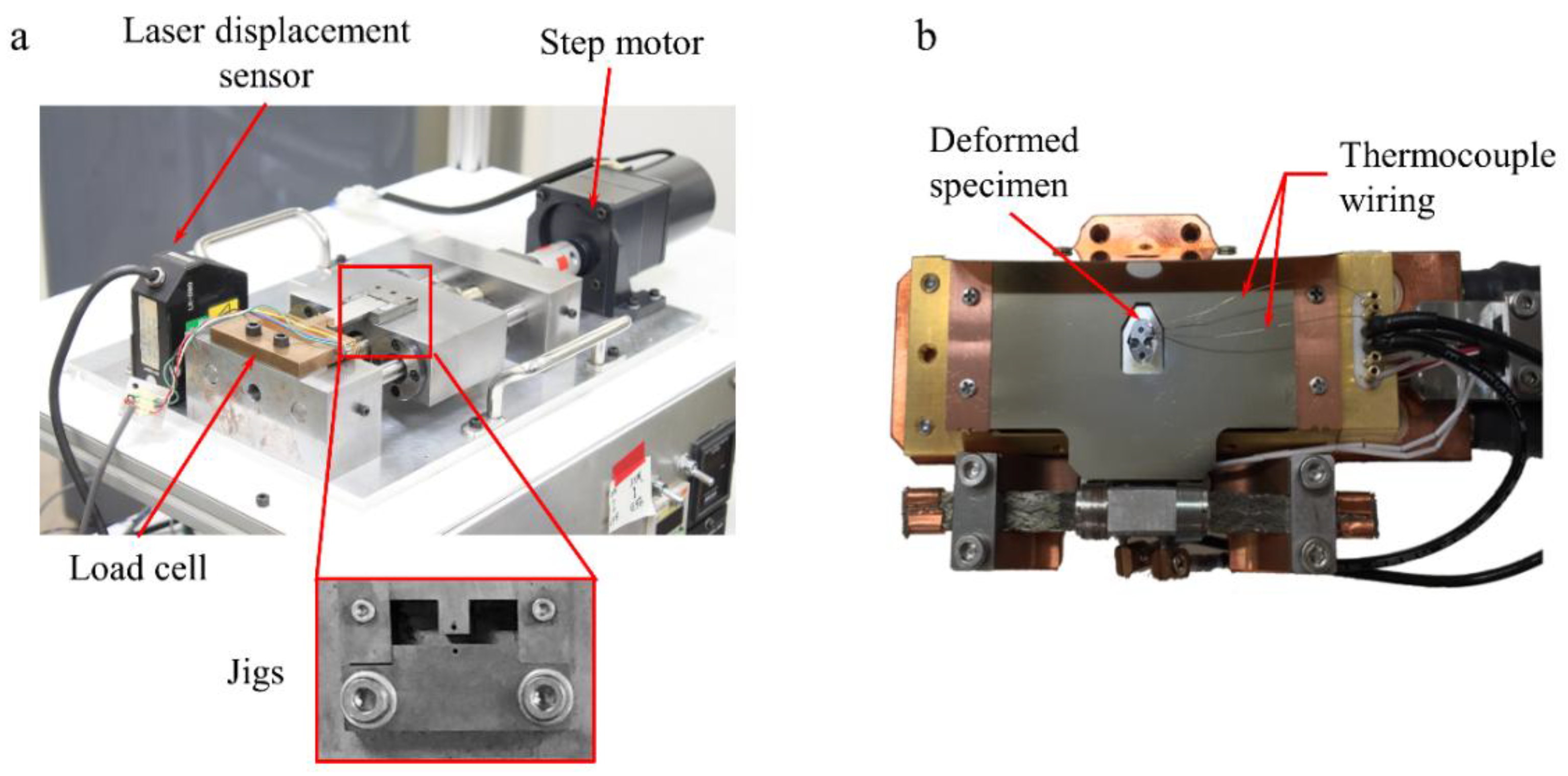

2.1. Experimental Setting

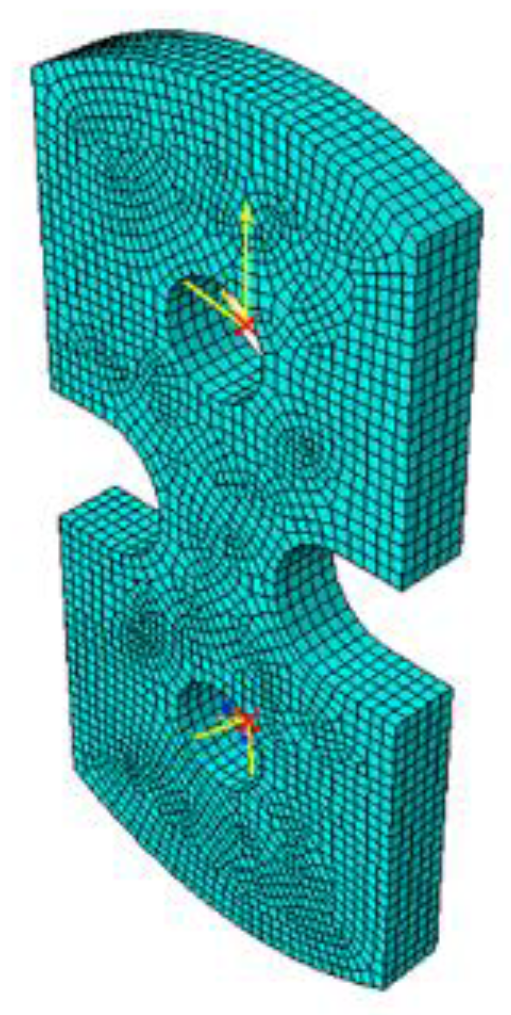

2.2. CP-FEM Simulation Setting

3. Results and Discussions

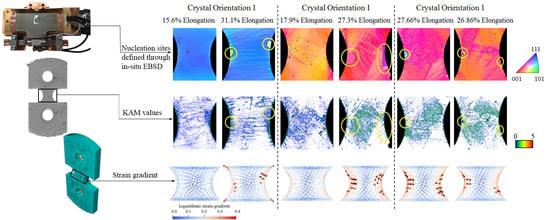

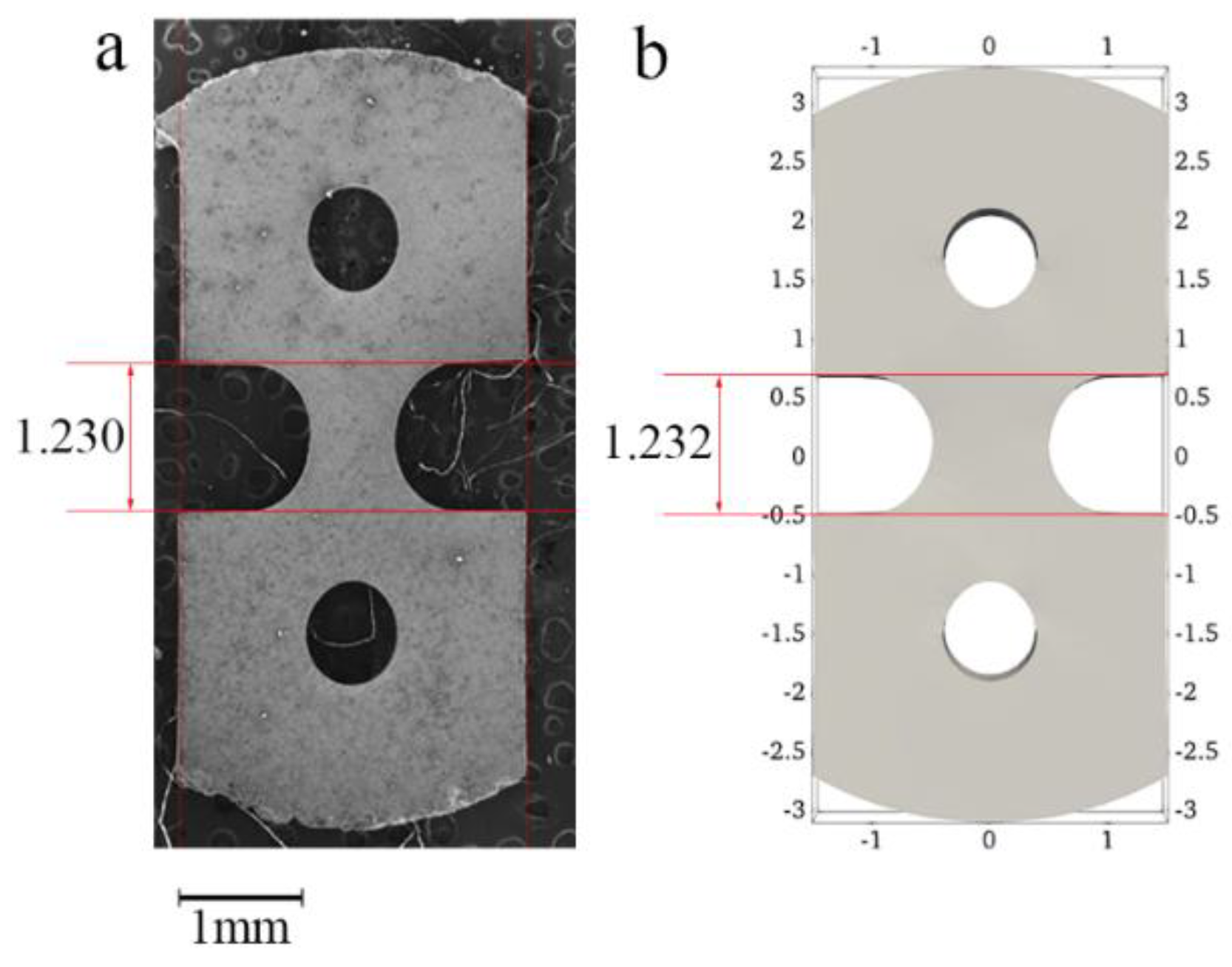

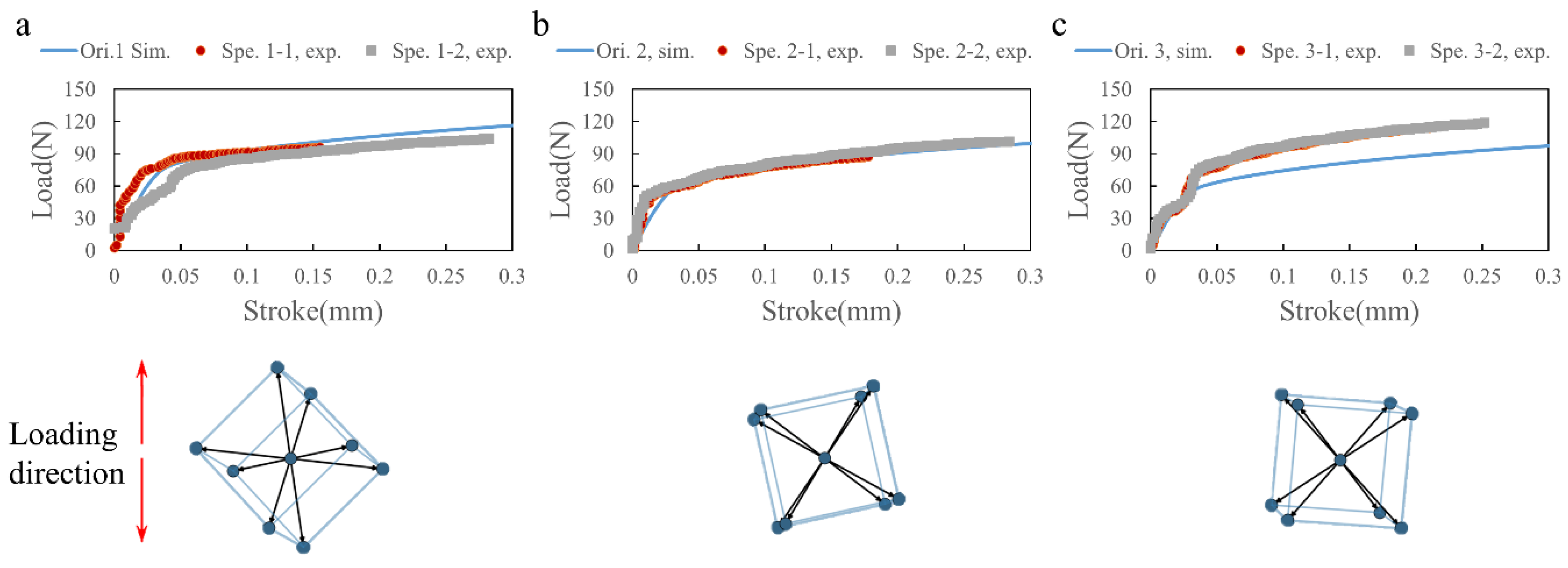

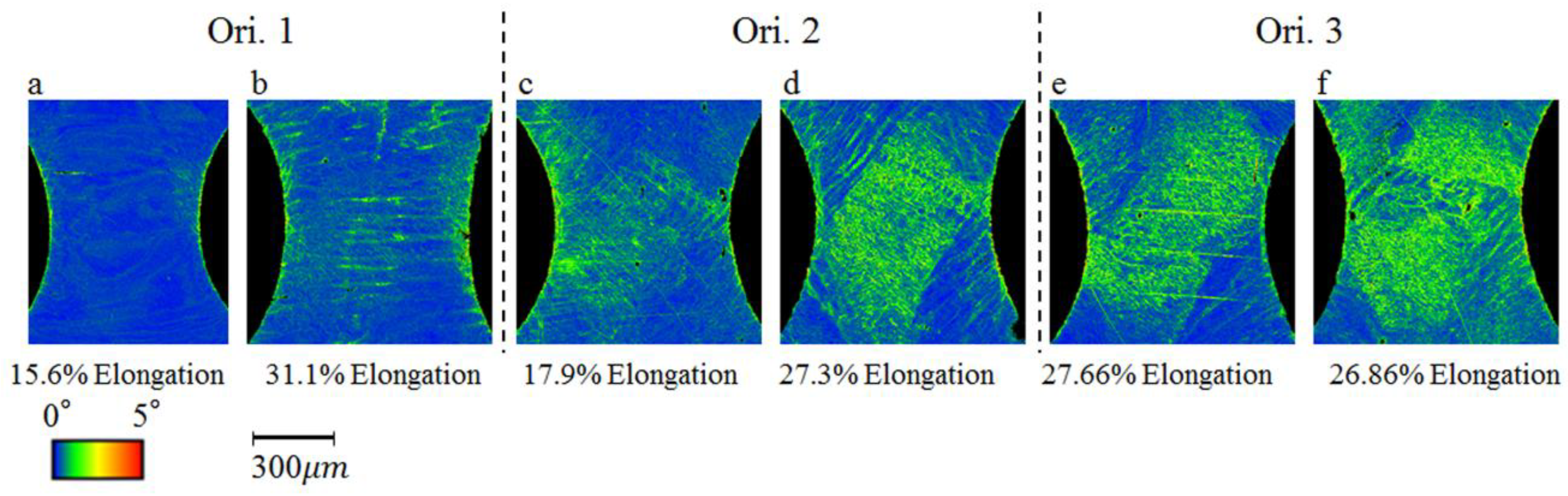

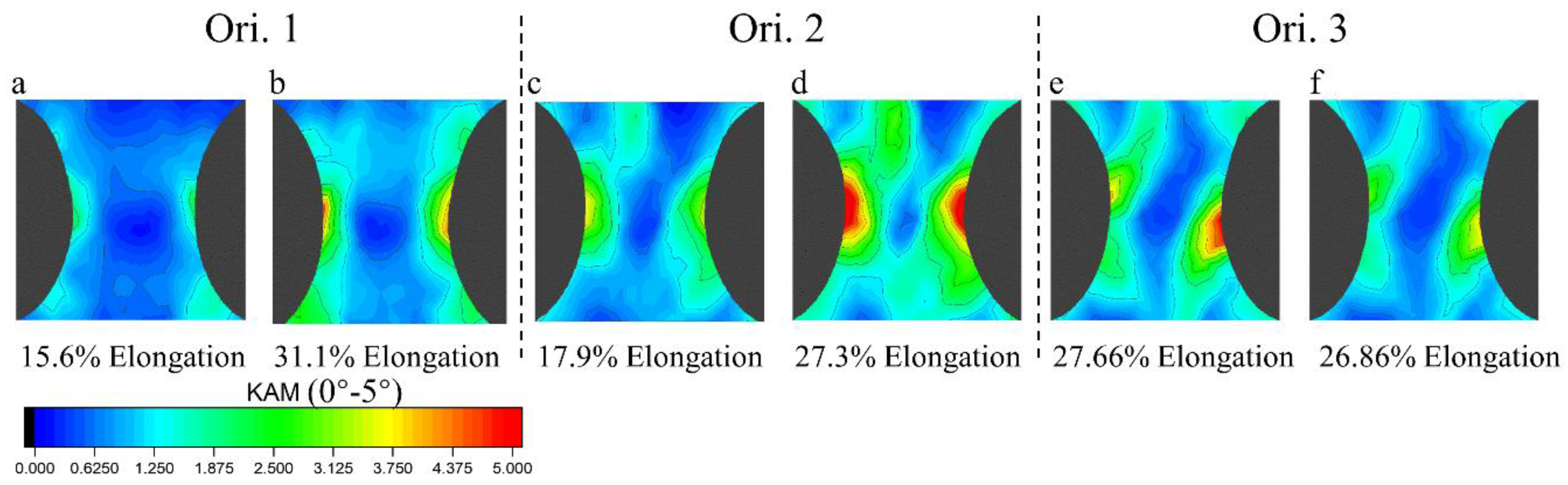

3.1. Deformation Characteristics

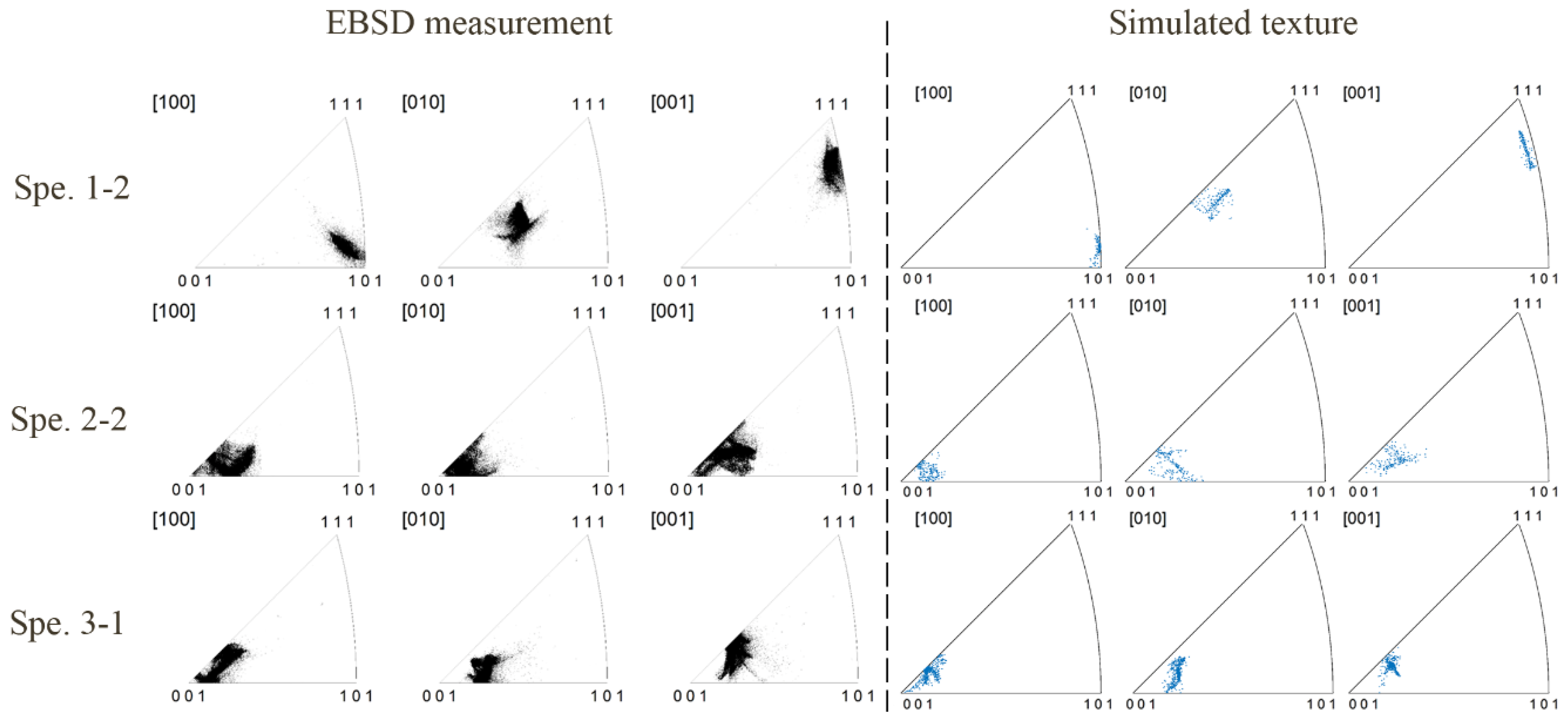

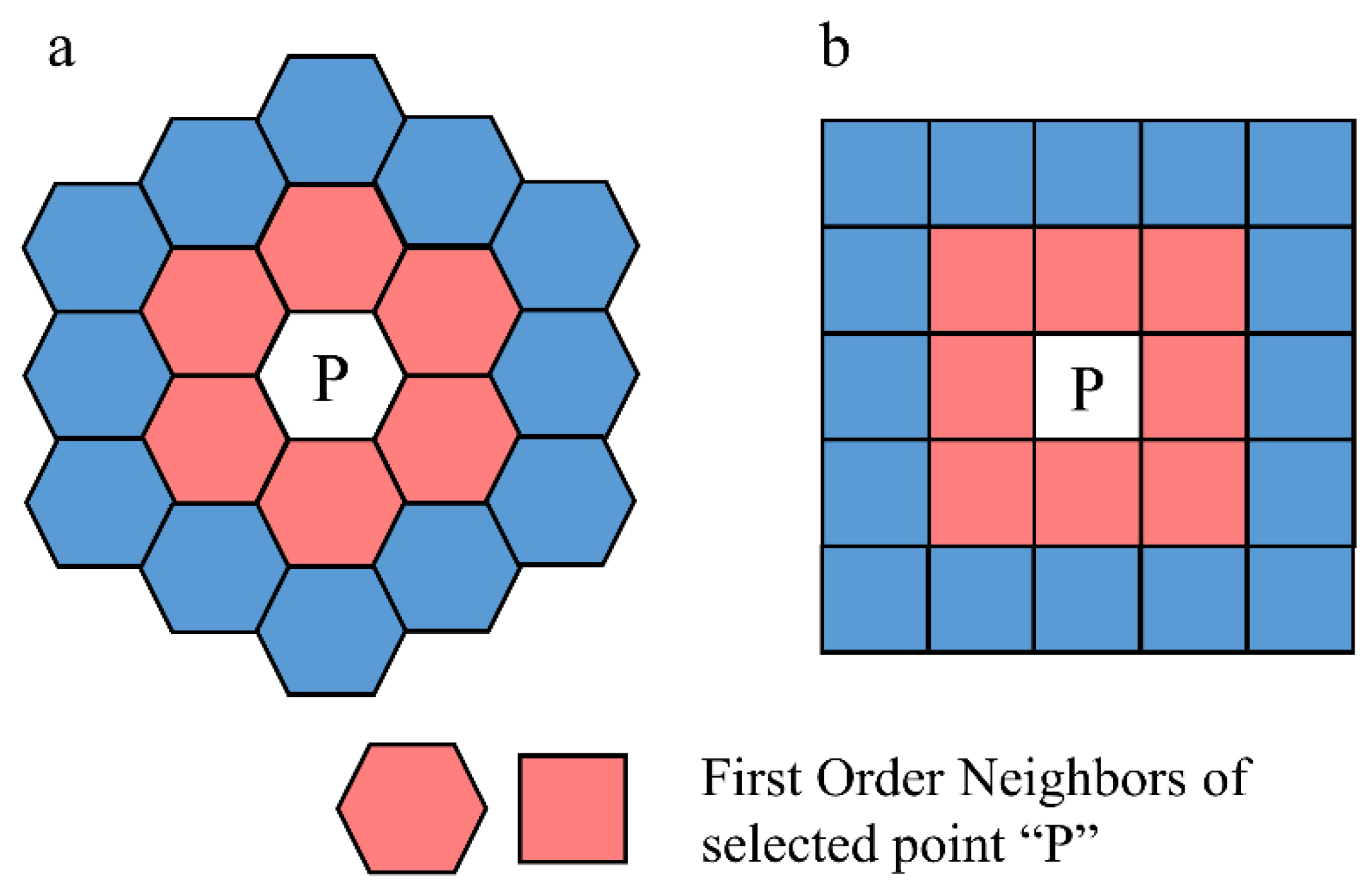

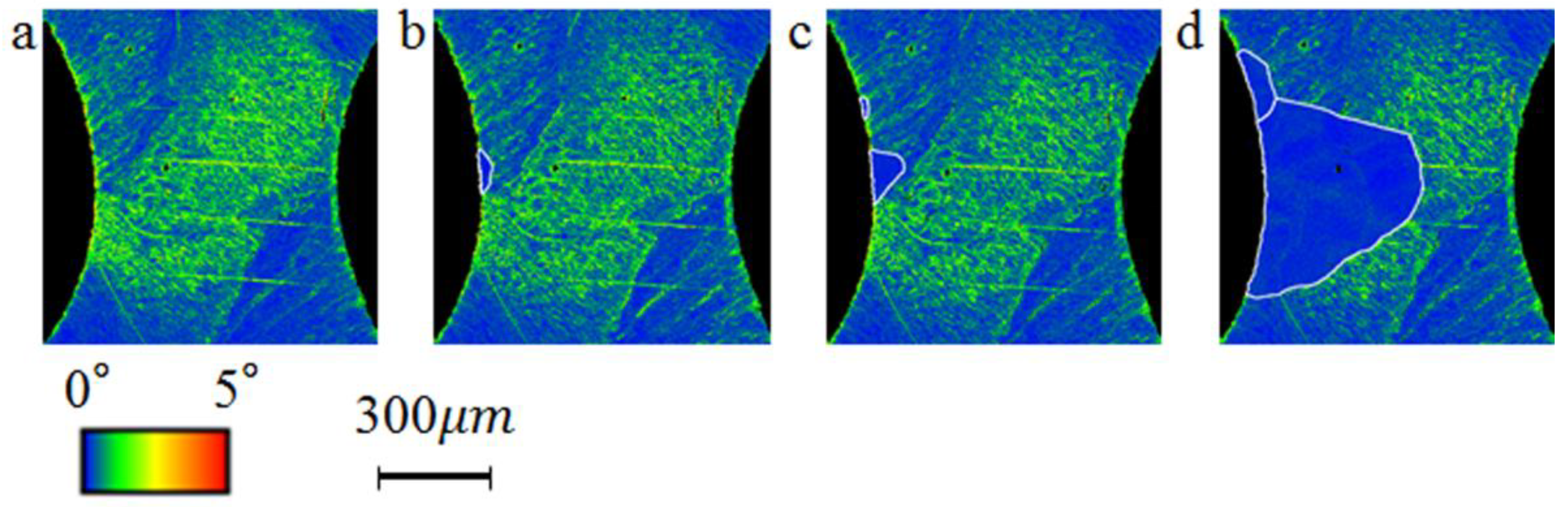

3.2. Deformation Heterogeneity

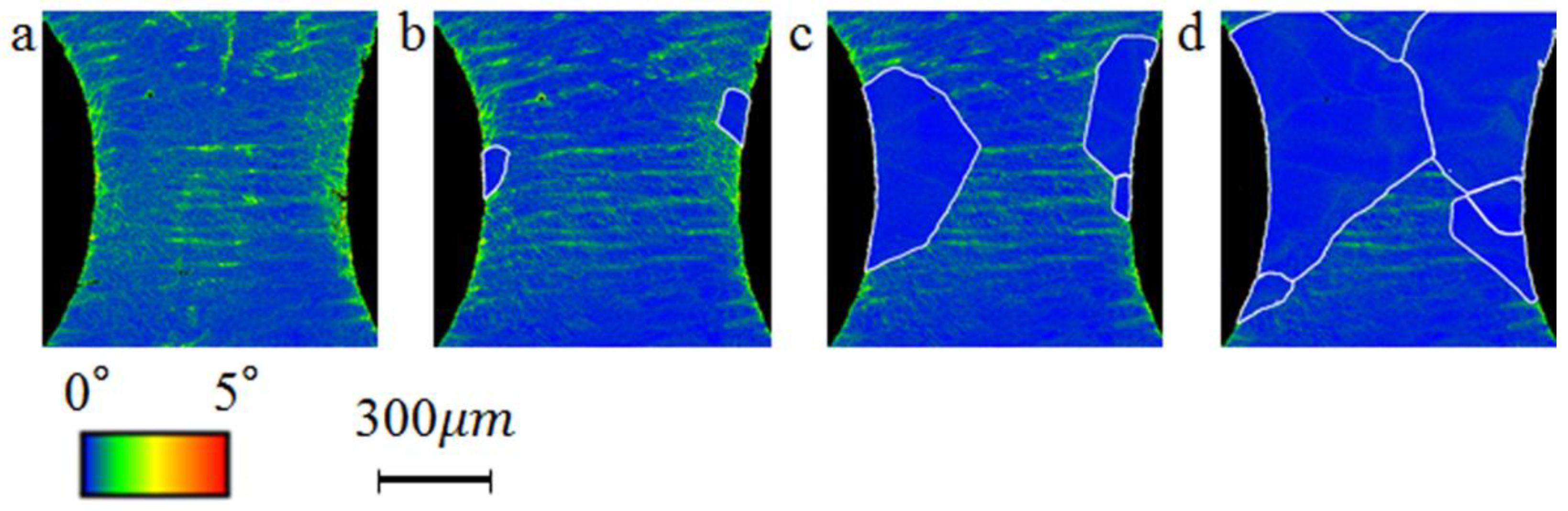

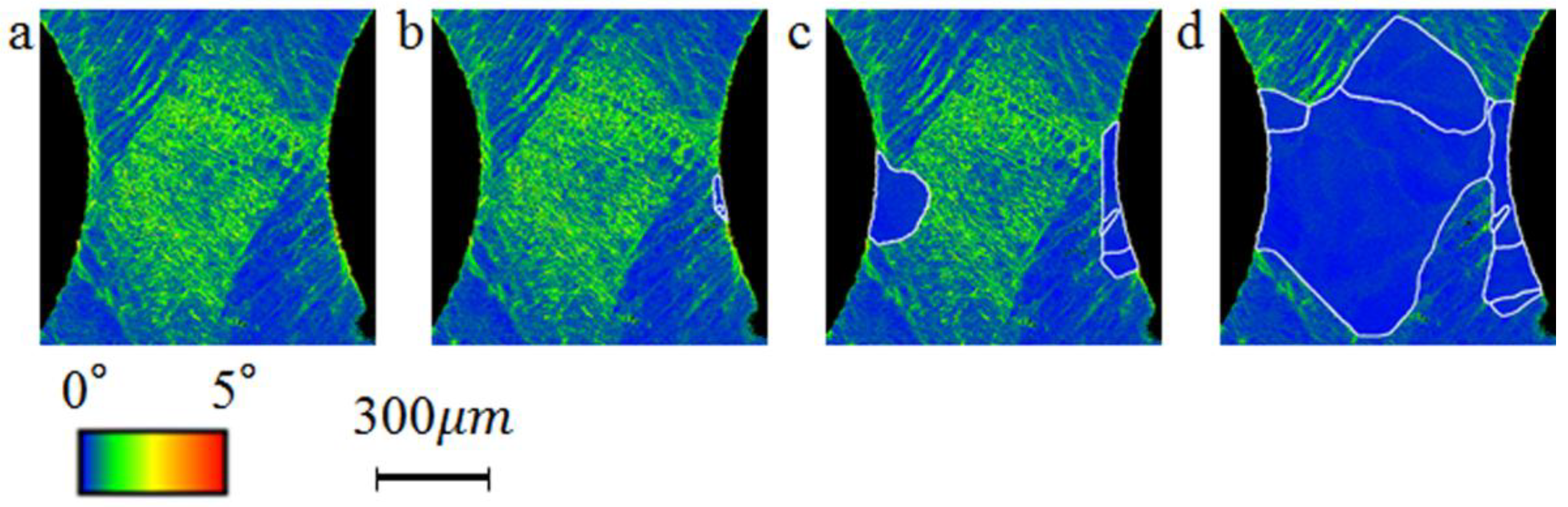

3.3. Nucleation Sites—Observation and Prediction

4. Conclusions

- Real-world scale CP-FEM calculations on single crystal iron tensile test were compared with experimental observations in four aspects: macroscopic deformation of specimen, load-stroke curve, deformed texture and kernel average misorientation maps. The capability of widely used phenomenological model in reproducing experimentally observed deformation characteristics was evaluated.

- Comparison was made between deformation heterogeneities expressed by KAM derived from EBSD observations and numerical simulations. Around the edges, high deformation heterogeneities were both found in experiments and simulations, while in the central of specimen neck, KAM maps contained more local deformation information than numerically calculated results. Failure in capturing microscale deformation heterogeneity in simulations may be attributed to relatively low grid resolution and incapability of employed constitutive equations in accounting for evolving of discrete dislocation structures inside the material.

- Areas with large distortion concentration in simulation has a qualitative coincidence with approximate nucleation sites in the first stage of recrystallization. This observation justifies the direct application of microstructure simulation methods such as cellular automaton model on energy/distortion distribution derived from CP-FEM for nucleation prediction.

- Experimentally-derived KAM maps have shown similar level of heterogeneity in a large portion of specimen edges. Experimentally observed KAM map is sensitive to local miniature features like zig-zags along edge curvature, surface unevenness, and impurity in specimen.

Author Contributions

Funding

Conflicts of Interest

References

- Torquato, S. Random Heterogeneous Materials: Microstructure and Macroscopic Properties; Springer Science & Business Media: Berlin, Germany, 2013; Volume 16, ISBN 1475763557. [Google Scholar]

- Zum Gahr, K.-H. Microstructure and Wear of Materials; Elsevier: Amsterdam, The Netherlands, 1987; Volume 10, ISBN 0080875742. [Google Scholar]

- Pérez-Prado, M.T.; Del Valle, J.A.; Contreras, J.M.; Ruano, O.A. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy. Scr. Mater. 2004, 50, 661–665. [Google Scholar] [CrossRef]

- Li, B.L.; Godfrey, A.; Meng, Q.C.; Liu, Q.; Hansen, N. Microstructural evolution of IF-steel during cold rolling. Acta Mater. 2004, 52, 1069–1081. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 008098388X. [Google Scholar]

- Lu, C.; Gao, Y.; Deng, G.Y.; Michal, G.; Huynh, N.N.; Liu, X.H.; Tieu, A.K. Atomic-scale anisotropy of nanoscratch behavior of single crystal iron. Wear 2009, 267, 1961–1966. [Google Scholar] [CrossRef]

- Tang, M.; Marian, J. Temperature and high strain rate dependence of tensile deformation behavior in single-crystal iron from dislocation dynamics simulations. Acta Mater. 2014, 70, 123–129. [Google Scholar] [CrossRef]

- Domain, C.; Monnet, G. Simulation of Screw Dislocation Motion in Iron by Molecular Dynamics Simulations. Phys. Rev. Lett. 2005, 95, 215506. [Google Scholar] [CrossRef] [PubMed]

- Gordon, P.A.; Neeraj, T.; Li, Y.; Li, J. Screw dislocation mobility in BCC metals: The role of the compact core on double-kink nucleation. Model. Simul. Mater. Sci. Eng. 2010, 18, 13. [Google Scholar] [CrossRef]

- Lens, A.; Maurice, C.; Driver, J.H. Grain boundary mobilities during recrystallization of Al-Mn alloys as measured by in situ annealing experiments. Mater. Sci. Eng. A 2005, 403, 144–153. [Google Scholar] [CrossRef]

- Zhu, K.Y.; Chaubet, D.; Bacroix, B.; Brisset, F. A study of recovery and primary recrystallization mechanisms in a Zr-2Hf alloy. Acta Mater. 2005, 53, 5131–5140. [Google Scholar] [CrossRef]

- Helbert, A.L.; Wang, W.; Brisset, F.; Baudin, T.; Penelle, R. In situ EBSD investigation of recrystallization in a partially annealed and cold-rolled aluminum alloy of commercial purity. Adv. Eng. Mater. 2012, 14, 39–44. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Kerisit, C.; Logé, R.E.; Jacomet, S.; Llorca, V.; Bozzolo, N. EBSD coupled to SEM in situ annealing for assessing recrystallization and grain growth mechanisms in pure tantalum. J. Microsc. 2013, 250, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Zaafarani, N.; Raabe, D.; Singh, R.N.; Roters, F.; Zaefferer, S. Three-dimensional investigation of the texture and microstructure below a nanoindent in a Cu single crystal using 3D EBSD and crystal plasticity finite element simulations. Acta Mater. 2006, 54, 1863–1876. [Google Scholar] [CrossRef]

- Zambaldi, C.; Roters, F.; Raabe, D.; Glatzel, U. Modeling and experiments on the indentation deformation and recrystallization of a single-crystal nickel-base superalloy. Mater. Sci. Eng. A 2007, 454–455, 433–440. [Google Scholar] [CrossRef]

- Forest, S. Modeling slip, kink and shear banding in classical and generalized single crystal plasticity. Acta Mater. 1998, 46, 3265–3281. [Google Scholar] [CrossRef]

- Meric, L.; Cailletaud, G. Single Crystal Modeling for Structural Calculations: Part 2—Finite Element Implementation. J. Eng. Mater. Technol. 1991, 113, 171–182. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Godfrey, A.; Liu, Q.; Liu, W.; Jensen, D.J. Analysis of the growth of individual grains during recrystallization in pure nickel. Acta Mater. 2009, 57, 2631–2639. [Google Scholar] [CrossRef]

- Ateba Betanda, Y.; Helbert, A.L.; Brisset, F.; Mathon, M.H.; Waeckerlé, T.; Baudin, T. Measurement of stored energy in Fe-48%Ni alloys strongly cold-rolled using three approaches: Neutron diffraction, Dillamore and KAM approaches. Mater. Sci. Eng. A 2014, 614, 193–198. [Google Scholar] [CrossRef]

- Liu, Q.; Juul Jensen, D.; Hansen, N. Effect of grain orientation on deformation structure in cold-rolled polycrystalline aluminium. Acta Mater. 1998, 46, 5819–5838. [Google Scholar] [CrossRef]

- Malta, P.O.; Alves, D.S.; Ferreira, A.O.V.; Moutinho, I.D.; Dias, C.A.P.; Santos, D.B. Static Recrystallization Kinetics and Crystallographic Texture of Nb-Stabilized Ferritic Stainless Steel Based on Orientation Imaging Microscopy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 1288–1309. [Google Scholar] [CrossRef]

- Radhakrishnan, B.; Sarma, G. Simulating the deformation and recrystallization of aluminum bicrystals. JOM 2004, 56, 55–62. [Google Scholar] [CrossRef]

- Zaefferer, S.; Kuo, J.C.; Zhao, Z.; Winning, M.; Raabe, D. On the influence of the grain boundary misorientation on the plastic deformation of aluminum bicrystals. Acta Mater. 2003, 51, 4719–4735. [Google Scholar] [CrossRef]

- Korte-Kerzel, S. Microcompression of brittle and anisotropic crystals: Recent advances and current challenges in studying plasticity in hard materials. MRS Commun. 2017, 7, 109–120. [Google Scholar] [CrossRef]

- Chen, R.; Sandlöbes, S.; Zehnder, C.; Zeng, X.; Korte-Kerzel, S.; Raabe, D. Deformation mechanisms, activated slip systems and critical resolved shear stresses in an Mg-LPSO alloy studied by micro-pillar compression. Mater. Des. 2018, 154, 203–216. [Google Scholar] [CrossRef]

- Bunge, H.J.; Esling, C. Deutsche Gesellschaft für Metallkunde; Quantitative texture analysis; DGM Informationsgesellschaft: Berlin, German, 1986; pp. 52–126. [Google Scholar]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Rost, M.J.; Quist, D.A.; Frenken, J.W.M. Grains, Growth, and Grooving. Phys. Rev. Lett. 2003, 91, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Jensen, D.J.; Schmidt, S. Time Evolution in 3D Metal Microstructures—Recrystallization. Mater. Trans. 2009, 50, 1655–1659. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Asaro, R.J. Crystal plasticity. Trans. ASME J. Appl. Mech. 1983, 50, 921–934. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Groh, S.; Marin, E.B.; Horstemeyer, M.F.; Zbib, H.M. Multiscale modeling of the plasticity in an aluminum single crystal. Int. J. Plast. 2009, 25, 1456–1473. [Google Scholar] [CrossRef]

- Ali, D.; Mushtaq, N.; Butt, M.Z. Investigation of active slip-systems in some body-centered cubic metals. J. Mater. Sci. 2011, 46, 3812–3821. [Google Scholar] [CrossRef]

- Li, S.; Gazder, A.A.; Beyerlein, I.J.; Davies, C.H.J.; Pereloma, E.V. Microstructure and texture evolution during equal channel angular extrusion of interstitial-free steel: Effects of die angle and processing route. Acta Mater. 2007, 55, 1017–1032. [Google Scholar] [CrossRef]

- Ledbetter, H.M.; Reed, R.P. Elastic Properties of Metals and Alloys, I. Iron, Nickel, and Iron-Nickel Alloys. J. Phys. Chem. Ref. Data 1973, 2, 531–618. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Humphreys, F.J. Nucleation in Recrystallization. Mater. Sci. Forum 2004, 467–470, 107–116. [Google Scholar] [CrossRef]

- Zouari, M.; Bozzolo, N.; Loge, R.E. Mean field modelling of dynamic and post-dynamic recrystallization during hot deformation of Inconel 718 in the absence of δ phase particles. Mater. Sci. Eng. A 2016, 655, 408–424. [Google Scholar] [CrossRef]

- Signorelli, J.; Fourty, A.; Roatta, A.; Schwindt, C.; Schlosser, F.; Bolmaro, R. Study of Plastic Heterogeneity in a Low Carbon Steel Sheet by EBSD. Procedia Mater. Sci. 2015, 8, 986–993. [Google Scholar] [CrossRef]

- Cereceda, D.; Diehl, M.; Roters, F.; Raabe, D.; Perlado, J.M.; Marian, J. Unraveling the temperature dependence of the yield strength in single-crystal tungsten using atomistically-informed crystal plasticity calculations. Int. J. Plast. 2016, 78, 242–265. [Google Scholar] [CrossRef]

- Admal, N.C.; Po, G.; Marian, J. A unified framework for polycrystal plasticity with grain boundary evolution. Int. J. Plast. 2018, 106, 1–30. [Google Scholar] [CrossRef]

- Beck, P.A. The formation of recrystallization nuclei. J. Appl. Phys. 1949, 20, 633–634. [Google Scholar] [CrossRef]

- Cahn, R.W. A New Theory of Recrystallization Nuclei. Proc. Phys. Soc. Sect. A 1950, 63, 323–336. [Google Scholar] [CrossRef]

- Cottrell, A.H. Theory of dislocations. Prog. Met. Phys. 1953, 4, 205–264. [Google Scholar] [CrossRef]

- Beck, P.A.; Sperry, P.R. Strain induced grain boundary migration in high purity aluminum. J. Appl. Phys. 1950, 21, 150–152. [Google Scholar] [CrossRef]

- Dillamore, I.L.; Katoh, H. The Mechanisms of Recrystallization in Cubic Metals with Particular Reference to Their Orientation-Dependence. Met. Sci. 1974, 8, 73–83. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

| Orientation No. | Specimen No. | Neck Elongation (%) | Initial Crystal Orientation (In Bunge’s Convention) |

|---|---|---|---|

| Orientation 1 | 1-1 | 15.6 | 146.7, 133.1, 329.2 |

| 1-2 | 31.1 | ||

| Orientation 2 | 2-1 | 17.9 | 272.5, 95.7, 347.8 |

| 2-2 | 27.3 | ||

| Orientation 3 | 3-1 | 27.66 | 60.9, 11.5, 33.8 |

| 3-2 | 26.86 |

| Category | Parameter | Meaning | Value |

|---|---|---|---|

| Elastic | Elastic coefficient | ||

| <110> systems | Strain rate sensitivity factor | 0.05 | |

| Reference shear rate | 0.01 | ||

| Initial hardening rate | 150.5 (MPa) | ||

| Initial critical shear stress | 40.0 (MPa) | ||

| Saturation shear stress | 250.875 (MPa) | ||

| <112> systems | Strain rate sensitivity factor | 0.05 | |

| Reference shear rate | 0.01 | ||

| Initial hardening rate | 67.5 (MPa) | ||

| Initial critical shear stress | 58 (MPa) | ||

| Saturation shear stress | 250.0 (MPa) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Yoshino, M.; Terano, M.; Yamanaka, A. Prediction of Static Recrystallization Nucleation Sites in Tensile Deformed Single Crystal Pure Iron through a Combination of In-Situ EBSD and CP-FEM. Metals 2018, 8, 858. https://doi.org/10.3390/met8100858

Luo Z, Yoshino M, Terano M, Yamanaka A. Prediction of Static Recrystallization Nucleation Sites in Tensile Deformed Single Crystal Pure Iron through a Combination of In-Situ EBSD and CP-FEM. Metals. 2018; 8(10):858. https://doi.org/10.3390/met8100858

Chicago/Turabian StyleLuo, Zichao, Masahiko Yoshino, Motoki Terano, and Akinori Yamanaka. 2018. "Prediction of Static Recrystallization Nucleation Sites in Tensile Deformed Single Crystal Pure Iron through a Combination of In-Situ EBSD and CP-FEM" Metals 8, no. 10: 858. https://doi.org/10.3390/met8100858

APA StyleLuo, Z., Yoshino, M., Terano, M., & Yamanaka, A. (2018). Prediction of Static Recrystallization Nucleation Sites in Tensile Deformed Single Crystal Pure Iron through a Combination of In-Situ EBSD and CP-FEM. Metals, 8(10), 858. https://doi.org/10.3390/met8100858