Control of Porosity and Spatter in Laser Welding of Thick AlMg5 Parts Using High-Speed Imaging and Optical Microscopy

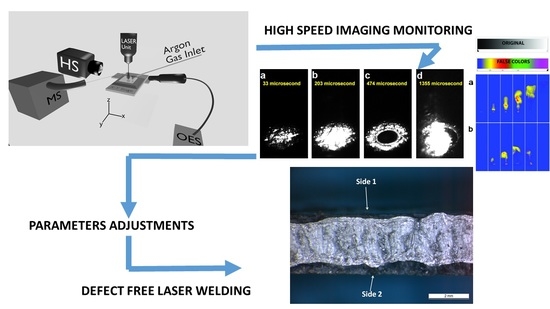

Abstract

:1. Introduction

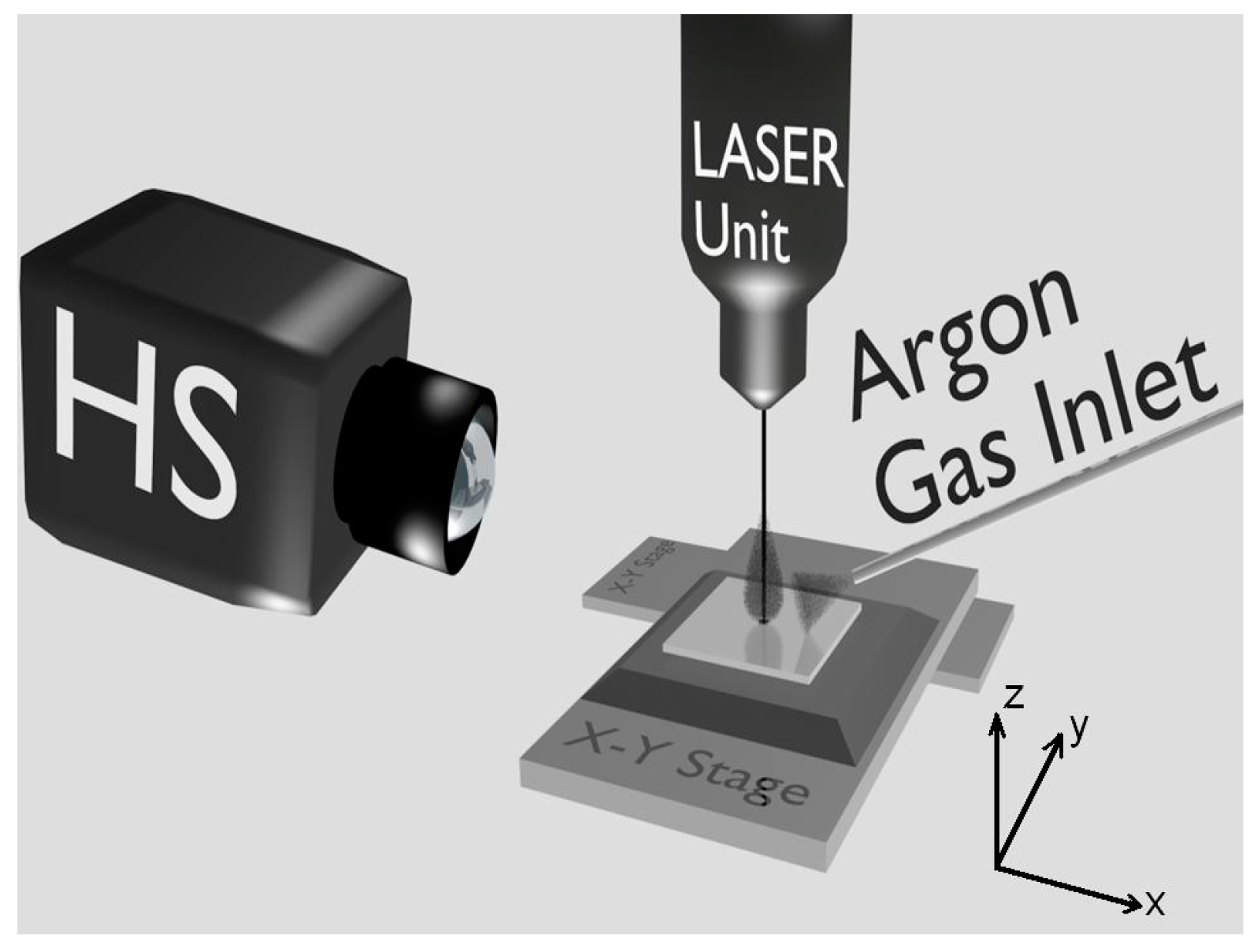

2. Materials and Methods

3. Results

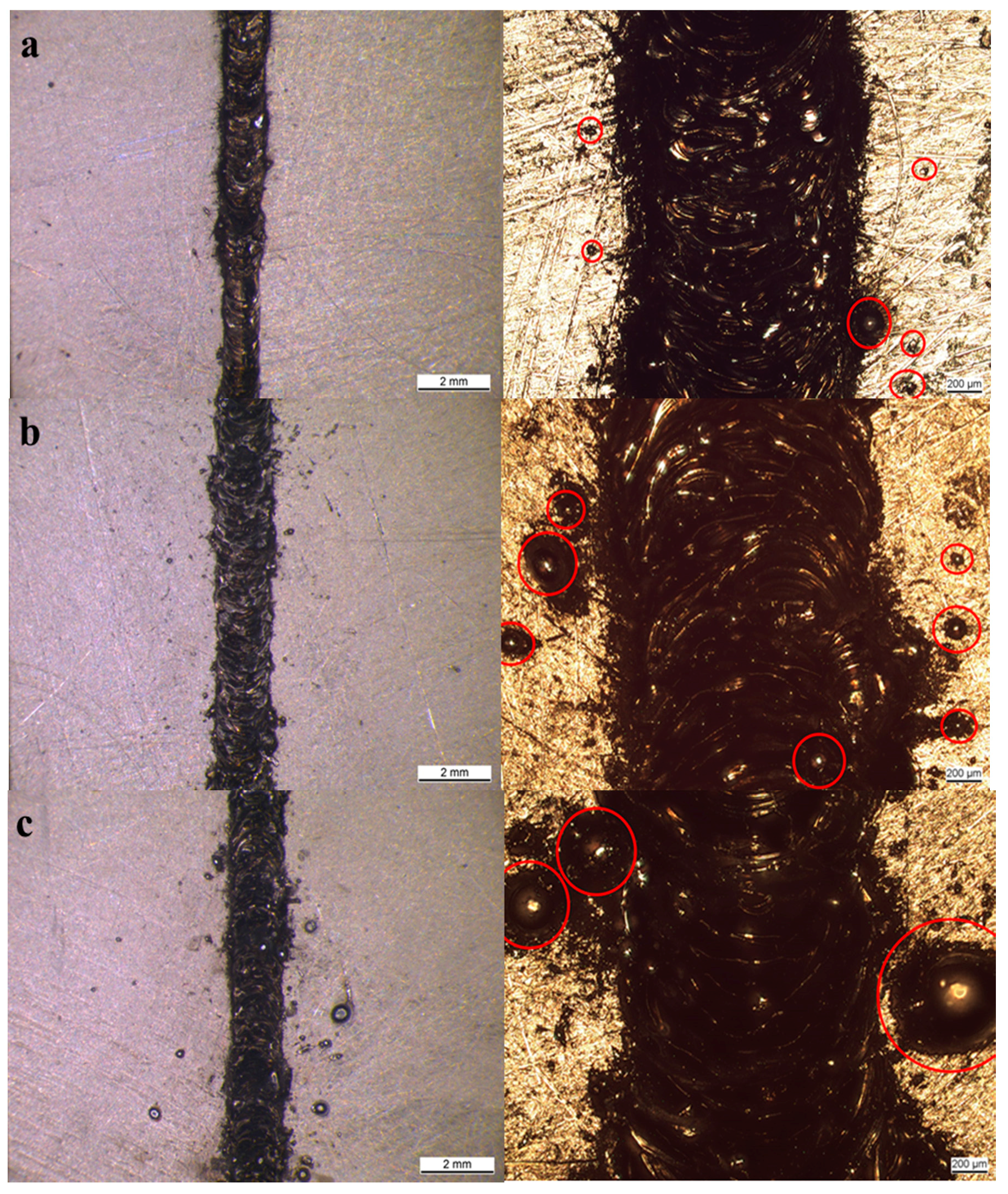

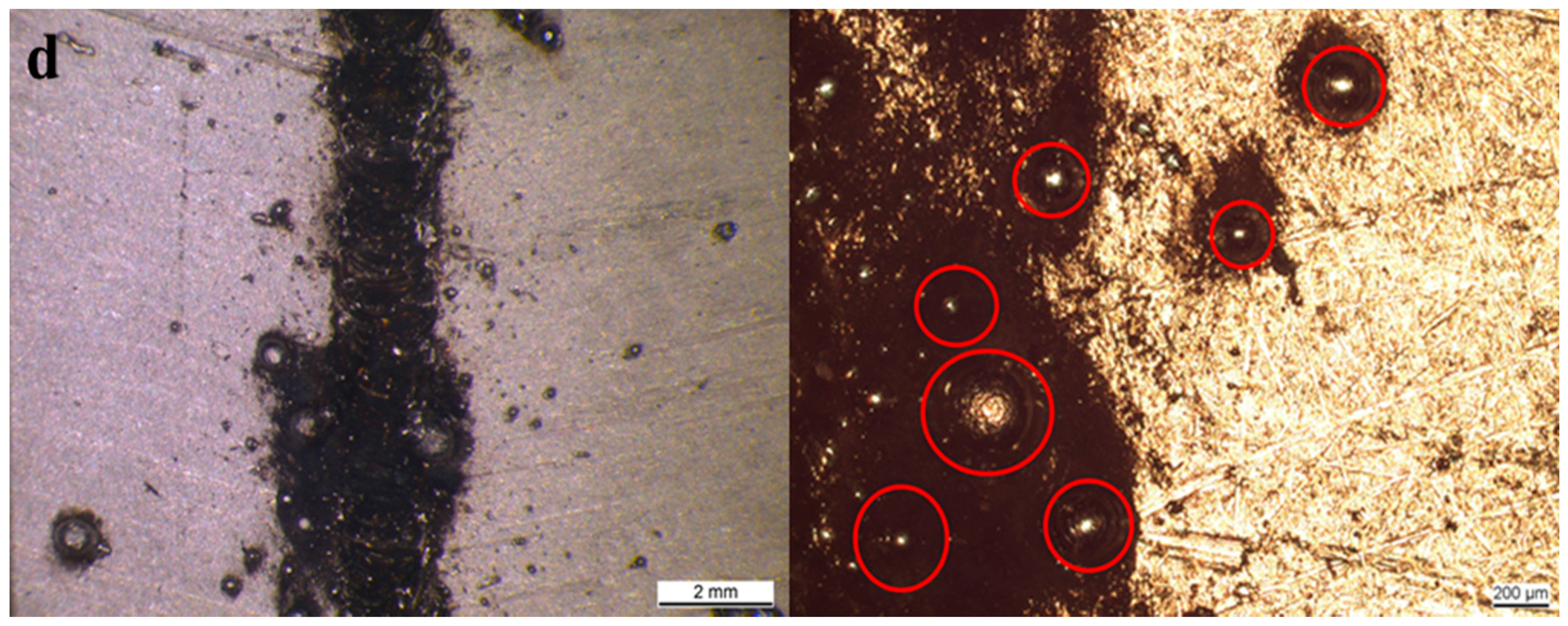

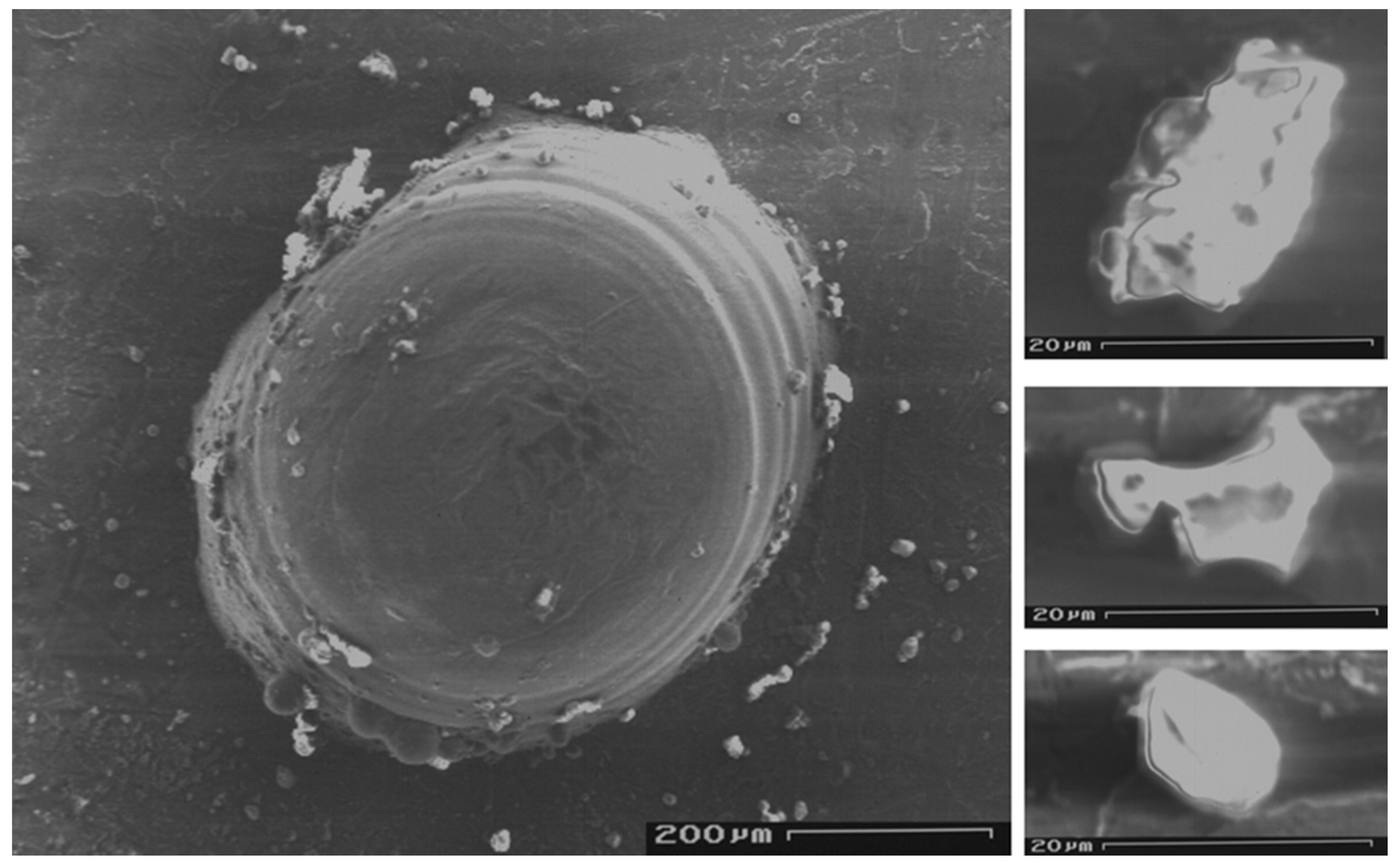

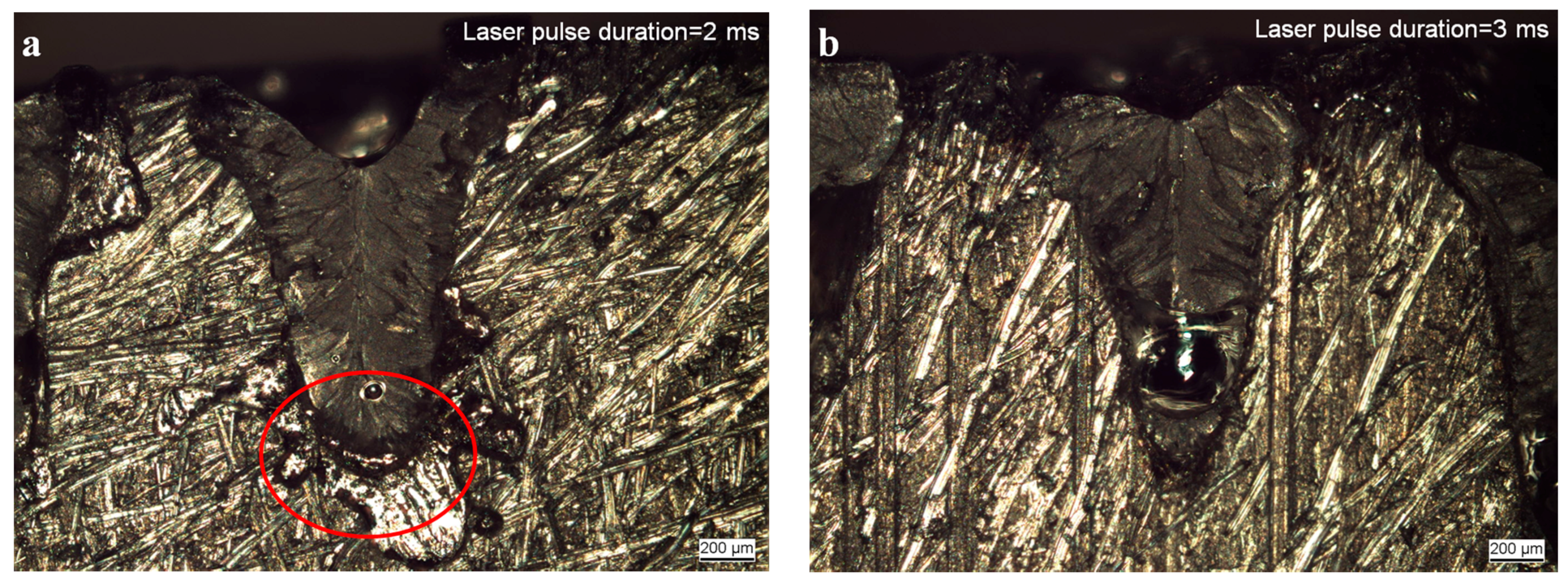

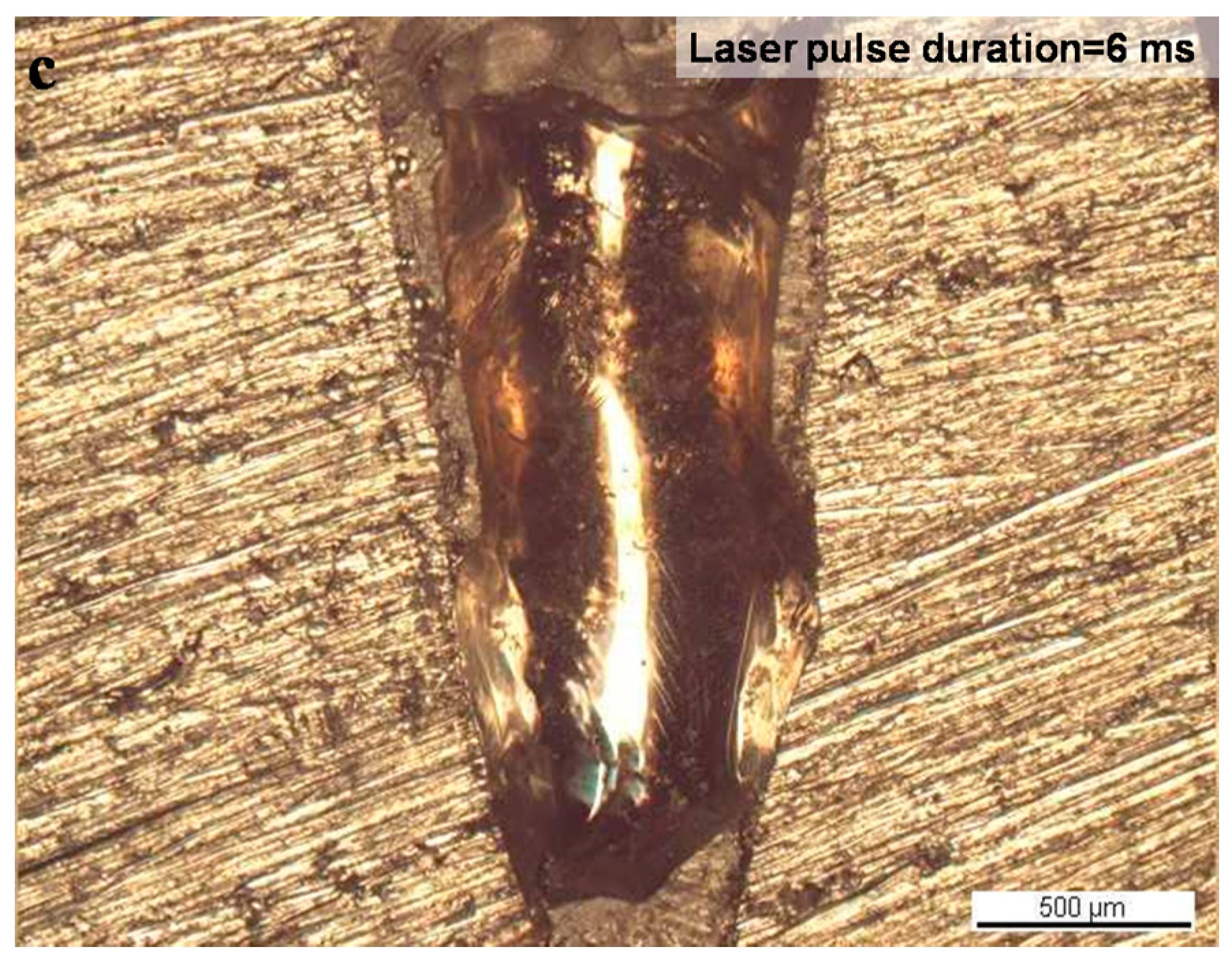

3.1. Parameters Adjustment Using Optical Microscopy Data

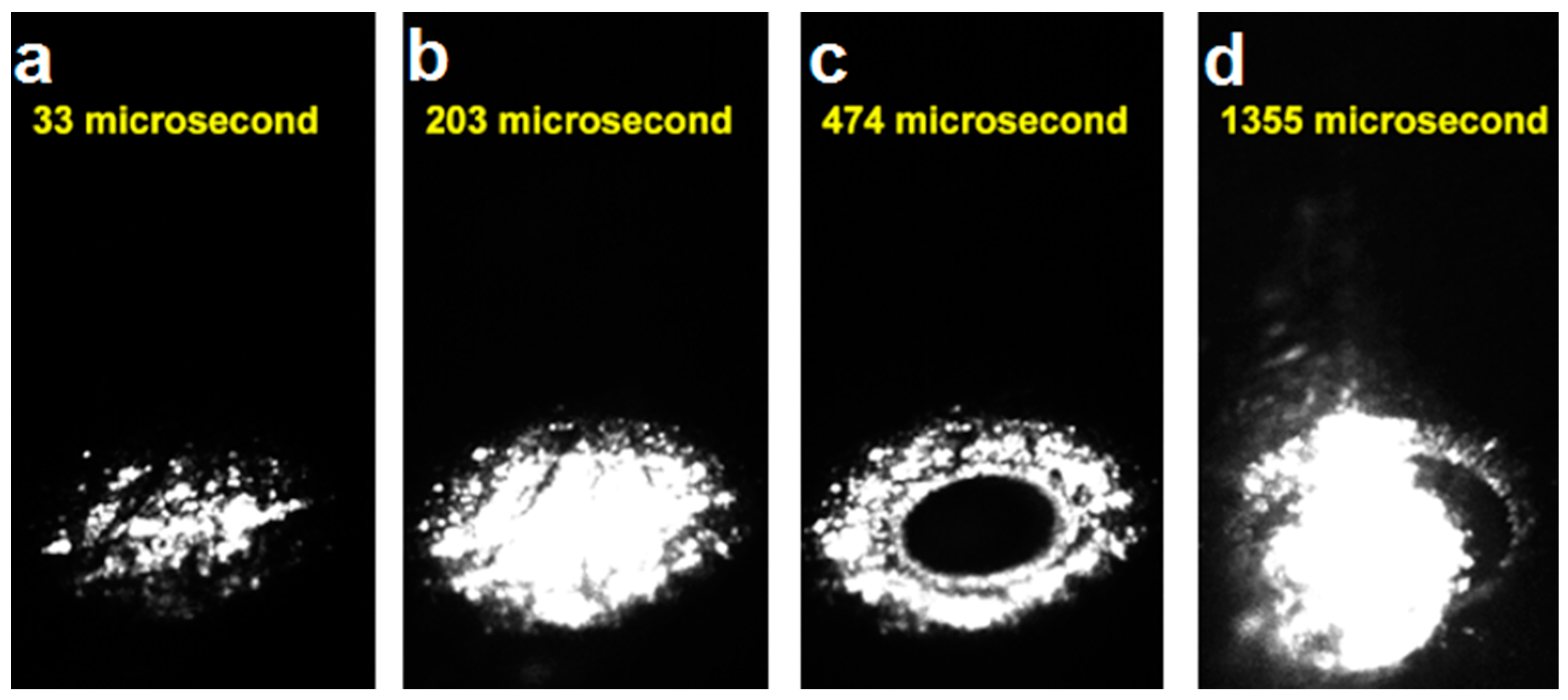

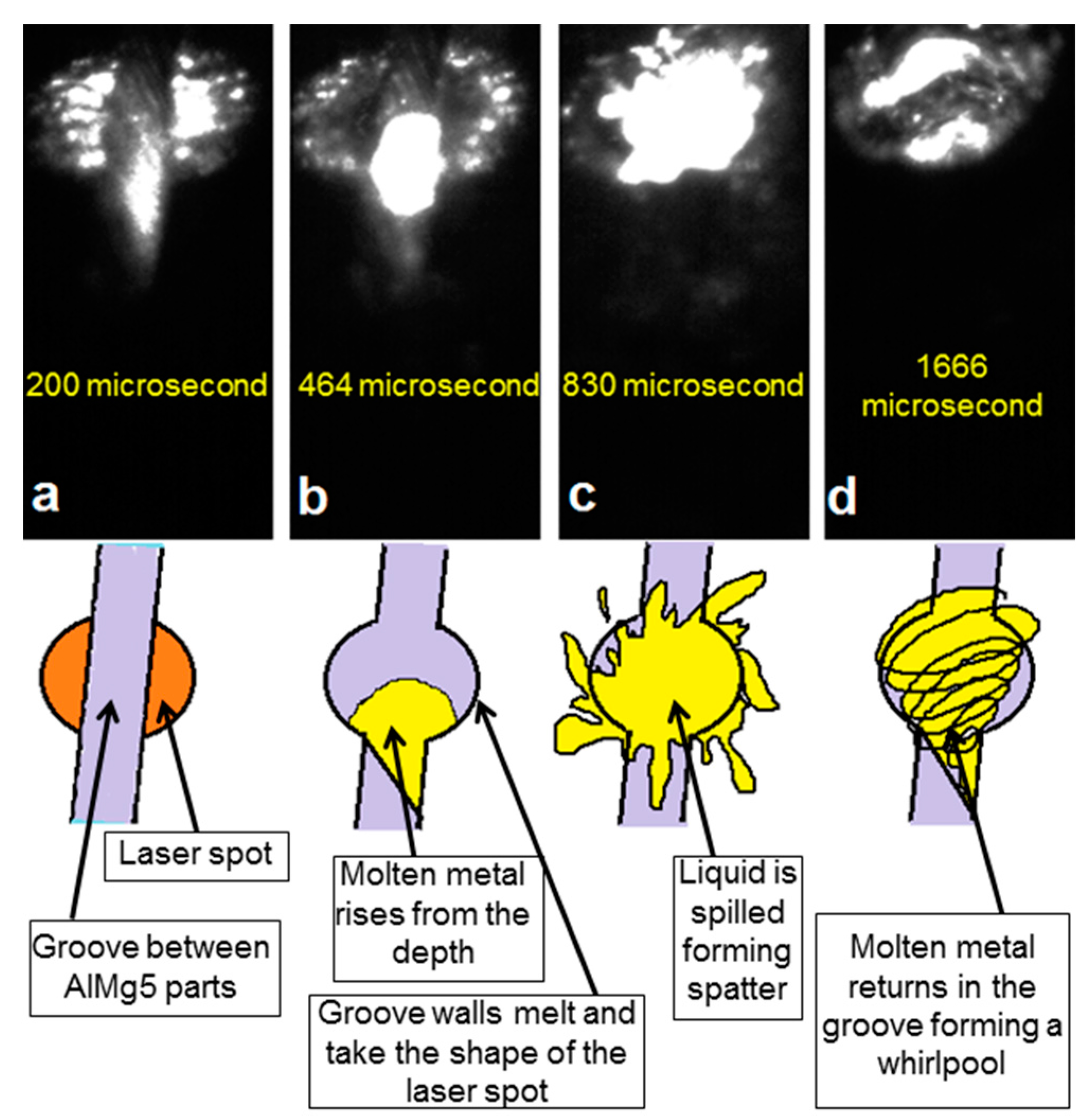

3.2. Parameters Adjustment Using High-Speed Imaging Data

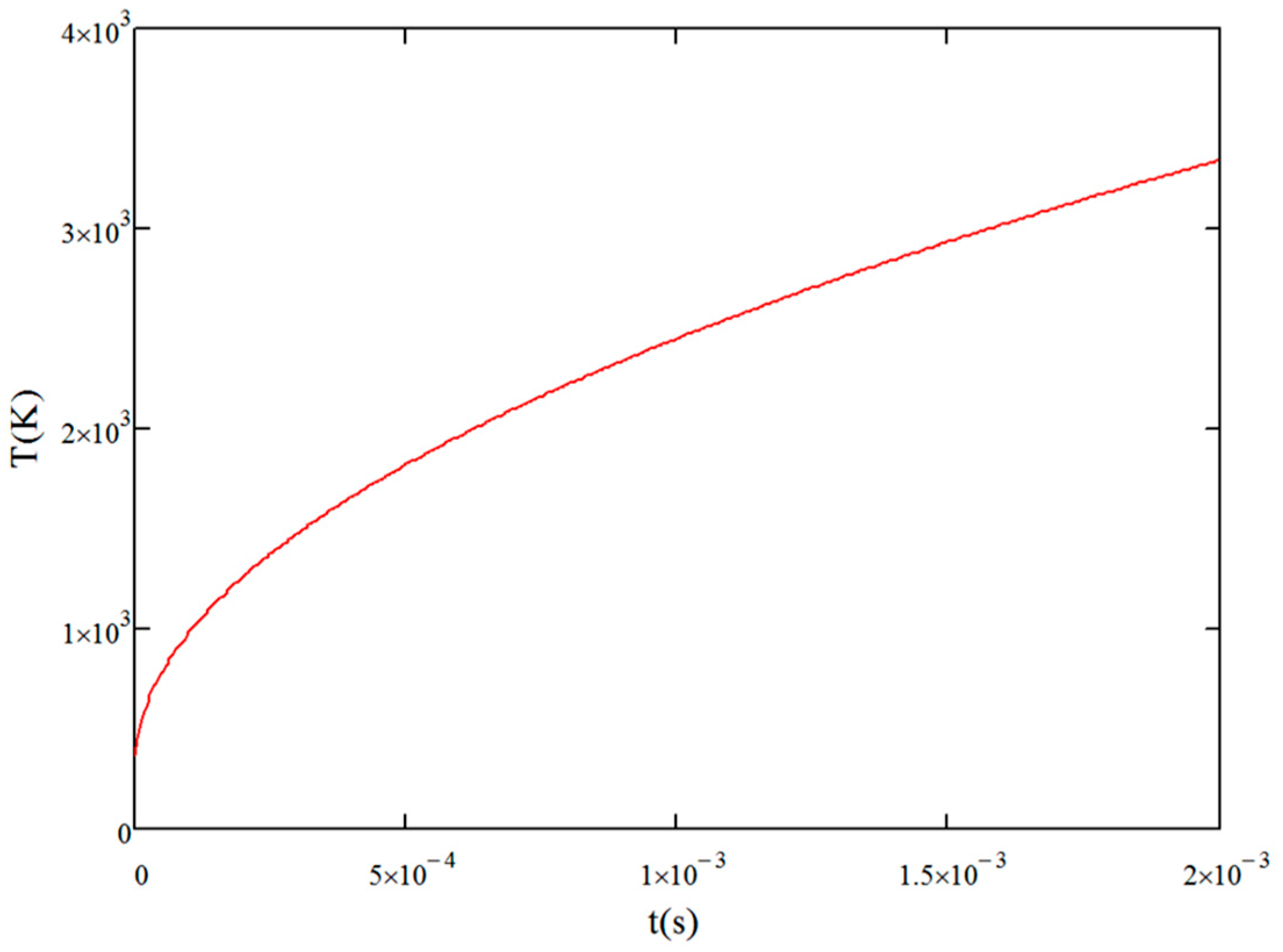

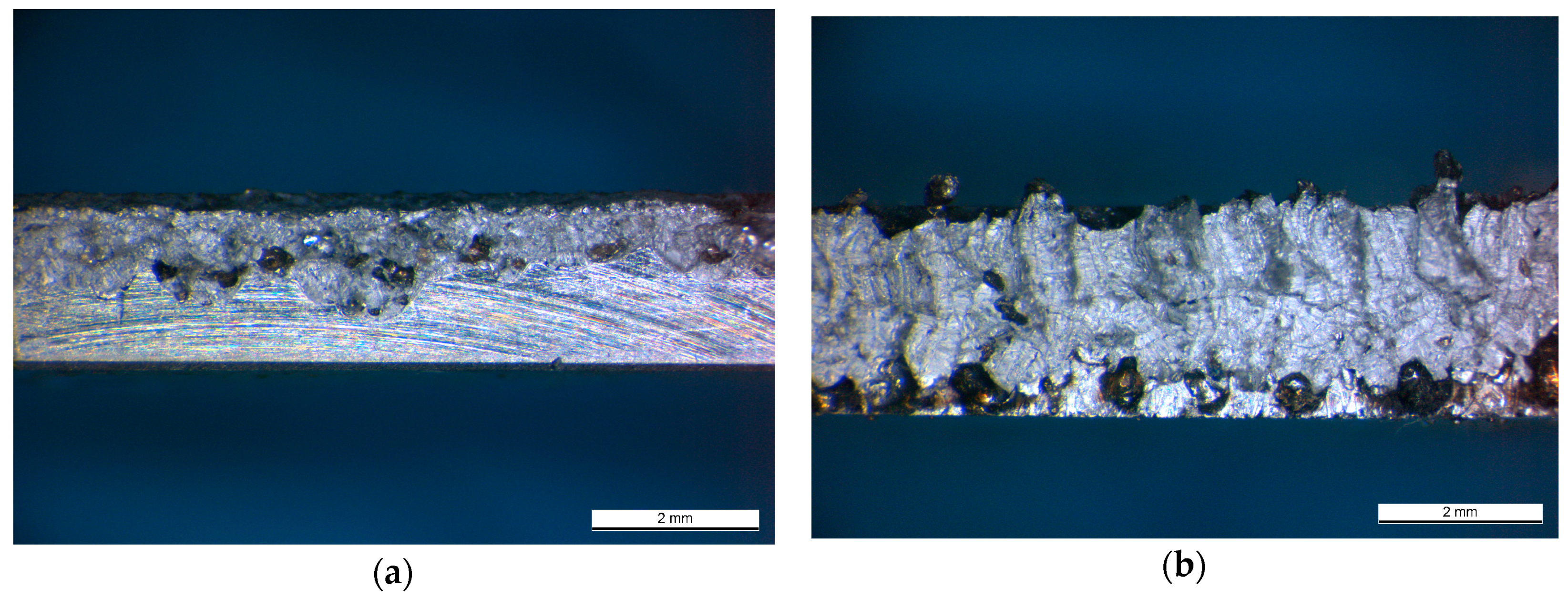

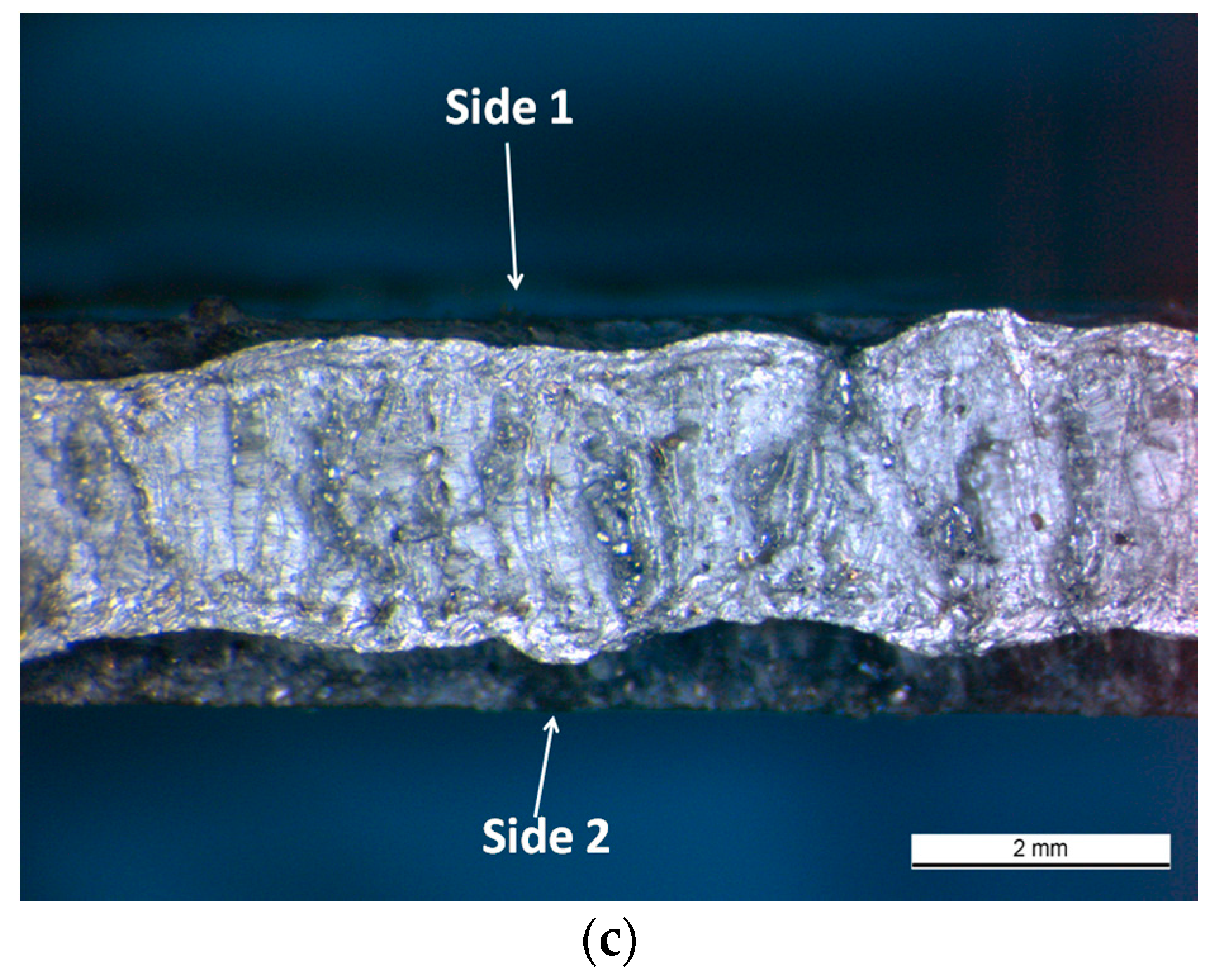

3.3. Obtaining Pore-Free Welds in AlMg5 Alloy Using an Infrared Millisecond Laser Source

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arcelor Mittal. Available online: http://automotive.arcelormittal.com/tailoredblanks (accessed on 31 August 2017).

- Wisco Tailored Blanks. Available online: http://www.tailored-blanks.com/en/about.php (accessed on 31 August 2017).

- Lu, J.; Kujanpää, V. Review study on remote laser welding with fiber lasers. J. Laser Appl. 2013, 25, 052008. [Google Scholar] [CrossRef]

- Kose, C.; Karaca, E. Robotic Nd:YAG fiber laser welding of Ti-6Al-4V Alloy. Metals 2017, 7, 221. [Google Scholar] [CrossRef]

- Wu, Q.; Gong, J.K.; Chen, G.Y.; Xu, L. Research on laser welding of vehicle body. Opt. Laser Technol. 2008, 40, 420–426. [Google Scholar] [CrossRef]

- Lanza, M.; Lauro, A.; Scanavino, S. Fabrication and weldability in structures. AL Alumin. Alloys 2001, 13, 80–86. [Google Scholar]

- Gao, X.; Zhang, L.; Liu, J.; Zhang, J. A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 599, 14–21. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Casalino, G. Hybrid welding of AA5754 annealed alloy: Role of post weld heat treatment on microstructure and mechanical properties. Mater. Des. 2016, 90, 777–786. [Google Scholar] [CrossRef]

- Good Fellow. Available online: http://www.goodfellow.com/E/Aluminum.html;http://www.goodfellow.com/E/Stainless-teel-AISI-304.html (accessed on 31 August 2017).

- Jeffus, L.F. Welding: Principles and Applications, 6th ed.; Cengage Learning: New York, NY, USA, 2007. [Google Scholar]

- Harvey, J.P.; Chartrand, P. Modeling the hydrogen solubility in liquid aluminum alloys. Metall. Mater. Trans. B 2010, 41, 908–924. [Google Scholar] [CrossRef]

- Ola, O.; Doern, F. Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int. J. Adv. Manuf. Technol. 2015, 80, 3–10. [Google Scholar] [CrossRef]

- Scintilla, L.D. Continuous-wave fiber laser cutting of aluminum thin sheets: Effect of process parameters and optimization. Opt. Eng. 2014, 53, 66–113. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al-Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Karlsson, J.; Kaplan, A.F.H. Analysis of a fibre laser welding case study, utilising a matrix flow chart. Appl. Surf. Sci. 2011, 257, 4113–4122. [Google Scholar] [CrossRef]

- Popescu, A.C.; Delval, C.; Shadman, S.; Leparoux, M. Investigation and in situ removal of spatter generated during laser ablation of aluminium composites. Appl. Surf. Sci. 2016, 378, 102–113. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Powell, J. Spatter in laser welding. J. Laser Appl. 2011, 23, 032005. [Google Scholar] [CrossRef]

- You, D.; Gao, X.; Katayama, S. Monitoring of high-power laser welding using high-speed photographing and image processing. Mech. Syst. Signal Process. 2013, 20, 39–52. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, G.; Wei, H.; Zhang, J. A novel “sandwich” method for observation of the keyhole in deep penetration laser welding. Opt. Lasers Eng. 2008, 46, 133–139. [Google Scholar] [CrossRef]

- You, D.; Gao, X.; Katayama, S. Visual-based spatter detection during high-power disk laser welding. Opt. Laser Eng. 2014, 54, 1–7. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Katayama, S.; Zhang, Y. Relationship between spatter formation and dynamic molten pool during high-power deep-penetration laser welding. Appl. Surf. Sci. 2014, 303, 481–488. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb-YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Xue, X.; Amorim, B.P.J.; Liao, J. Effects of pulsed Nd:YAG laser welding parameters on penetration and microstructure characterization of a DP1000 steel butt joint. Metals 2017, 7, 292. [Google Scholar] [CrossRef]

- Sands, D. Pulsed laser heating and melting. In Heat Transfer—Engineering Applications; Vikhrenko, S.V., Ed.; InTech: Rijeka, Croatia, 2011; pp. 47–70. [Google Scholar]

- Gill, D.H.; Newnam, B.E. Picosecond-pulse damage studies of diffraction gratings. In Damage in Laser Materials; Bennet, H.E., Guenther, A.H., Milam, D., Newnam, B.E., Eds.; National Bureau of Standards Special Publication: Gaithersburg, MD, USA, 1986; Volume 727, pp. 154–161. [Google Scholar]

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 97th ed.; CRC Press: New York, NY, USA, 2017. [Google Scholar]

- Svenungsson, J.; Choqueta, I.; Kaplan, A.F.H. Laser welding process—A review of keyhole welding modeling. Phys. Procedia 2015, 78, 182–191. [Google Scholar] [CrossRef]

- Jin, X.; Cheng, Y.; Zeng, L.; Zou, Y.; Zhang, H. Multiple reflections and Fresnel absorption of Gaussian laser beam in an actual 3D keyhole during deep-penetration laser welding. Int. J. Opt. 2012, 361818, 1–8. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popescu, A.C.; Delval, C.; Leparoux, M. Control of Porosity and Spatter in Laser Welding of Thick AlMg5 Parts Using High-Speed Imaging and Optical Microscopy. Metals 2017, 7, 452. https://doi.org/10.3390/met7110452

Popescu AC, Delval C, Leparoux M. Control of Porosity and Spatter in Laser Welding of Thick AlMg5 Parts Using High-Speed Imaging and Optical Microscopy. Metals. 2017; 7(11):452. https://doi.org/10.3390/met7110452

Chicago/Turabian StylePopescu, Andrei C., Christophe Delval, and Marc Leparoux. 2017. "Control of Porosity and Spatter in Laser Welding of Thick AlMg5 Parts Using High-Speed Imaging and Optical Microscopy" Metals 7, no. 11: 452. https://doi.org/10.3390/met7110452

APA StylePopescu, A. C., Delval, C., & Leparoux, M. (2017). Control of Porosity and Spatter in Laser Welding of Thick AlMg5 Parts Using High-Speed Imaging and Optical Microscopy. Metals, 7(11), 452. https://doi.org/10.3390/met7110452