Experimental Investigation on Electric Current-Aided Laser Stake Welding of Aluminum Alloy T-Joints

Abstract

:1. Introduction

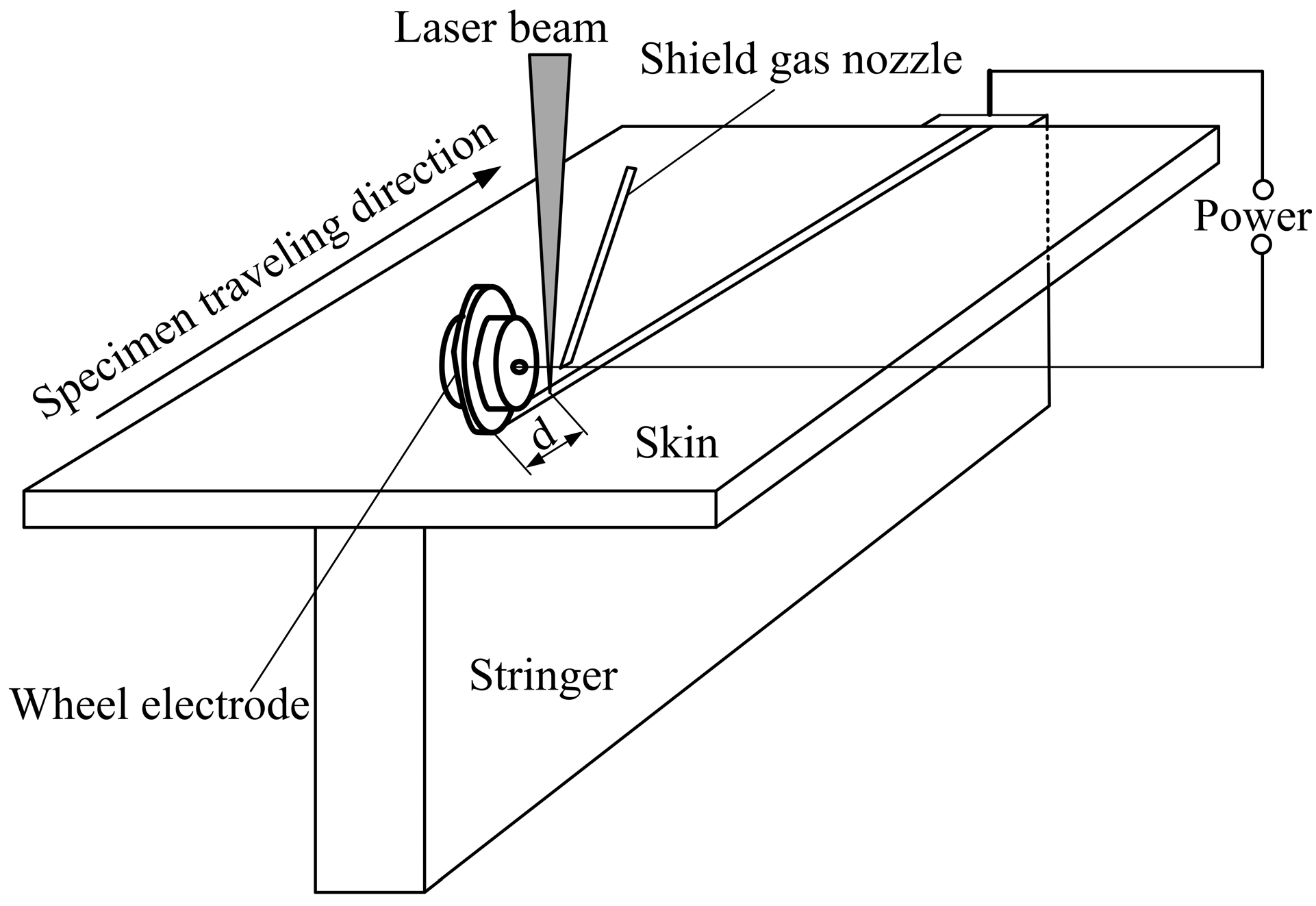

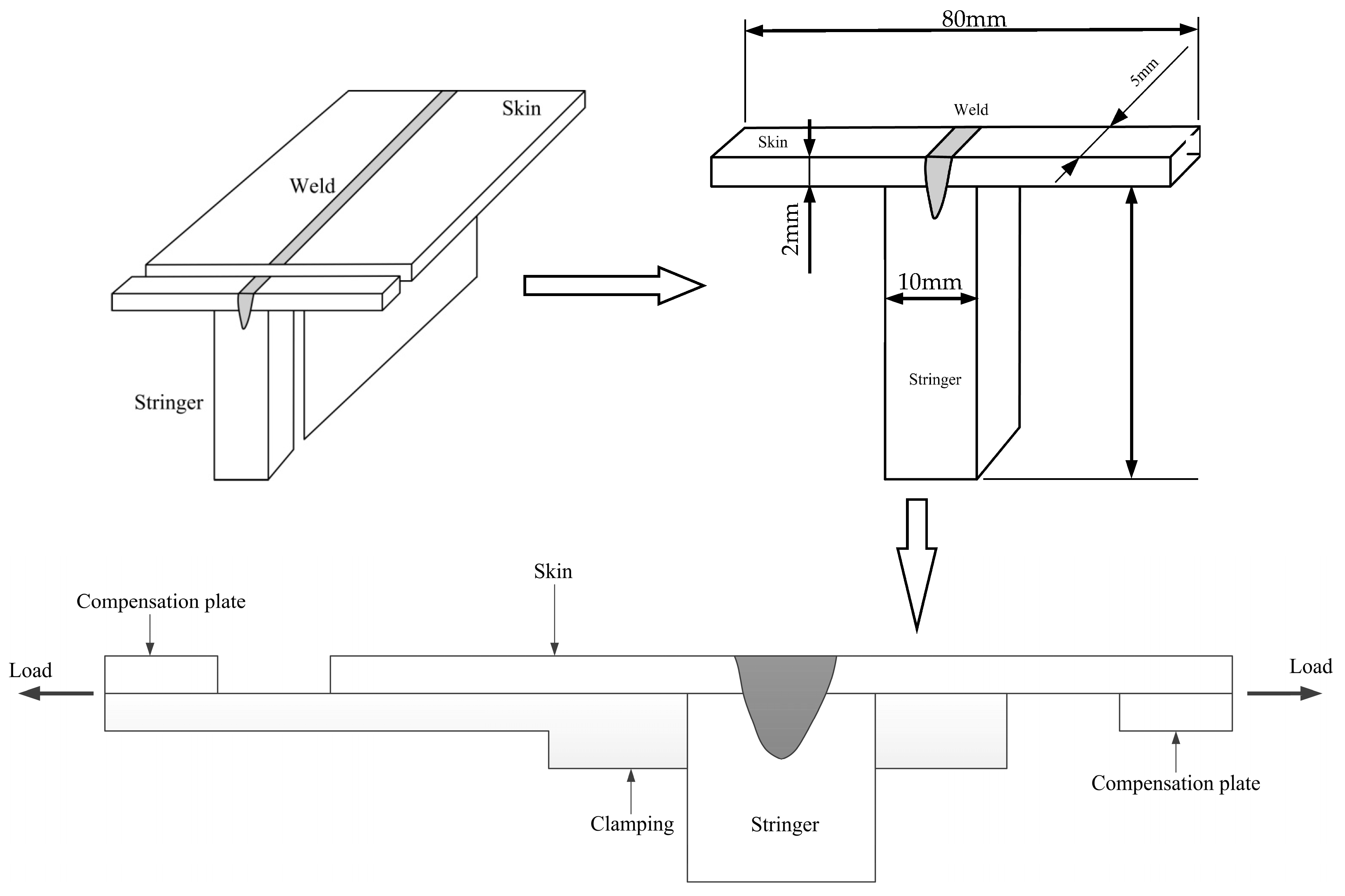

2. Materials and Methods

3. Experimental Results and Discussion

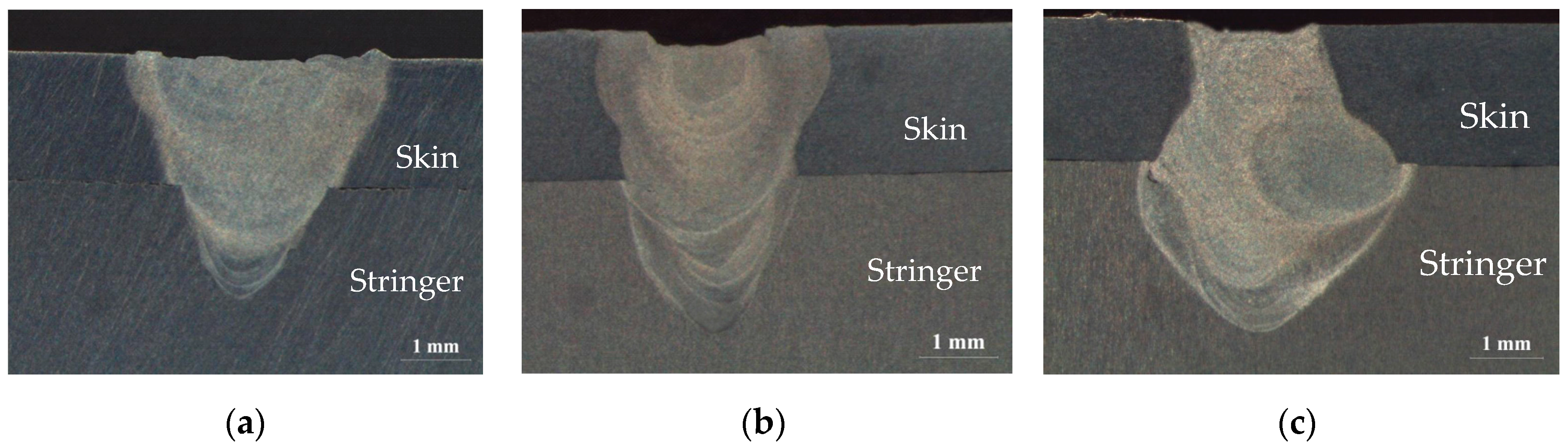

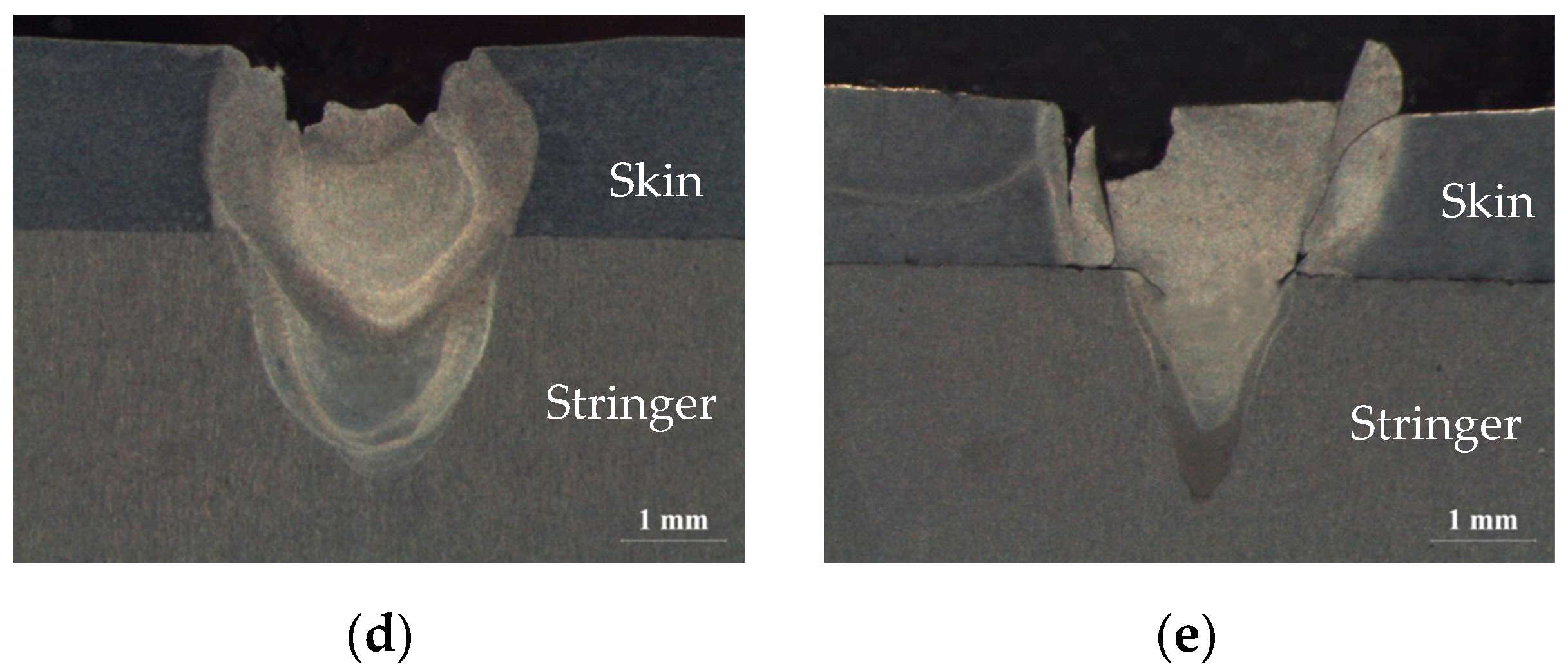

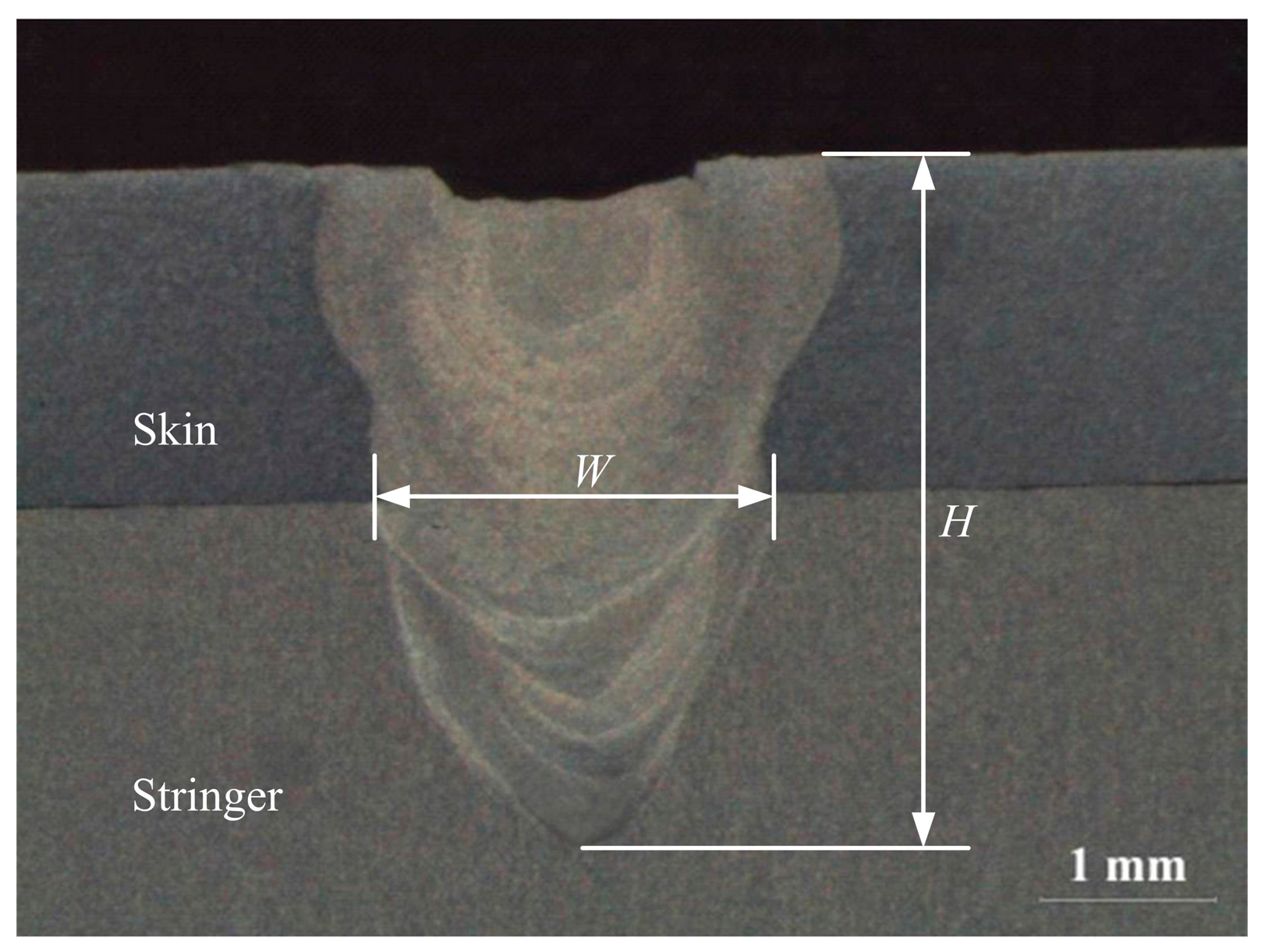

3.1. Weld Morphology of the T-Joint

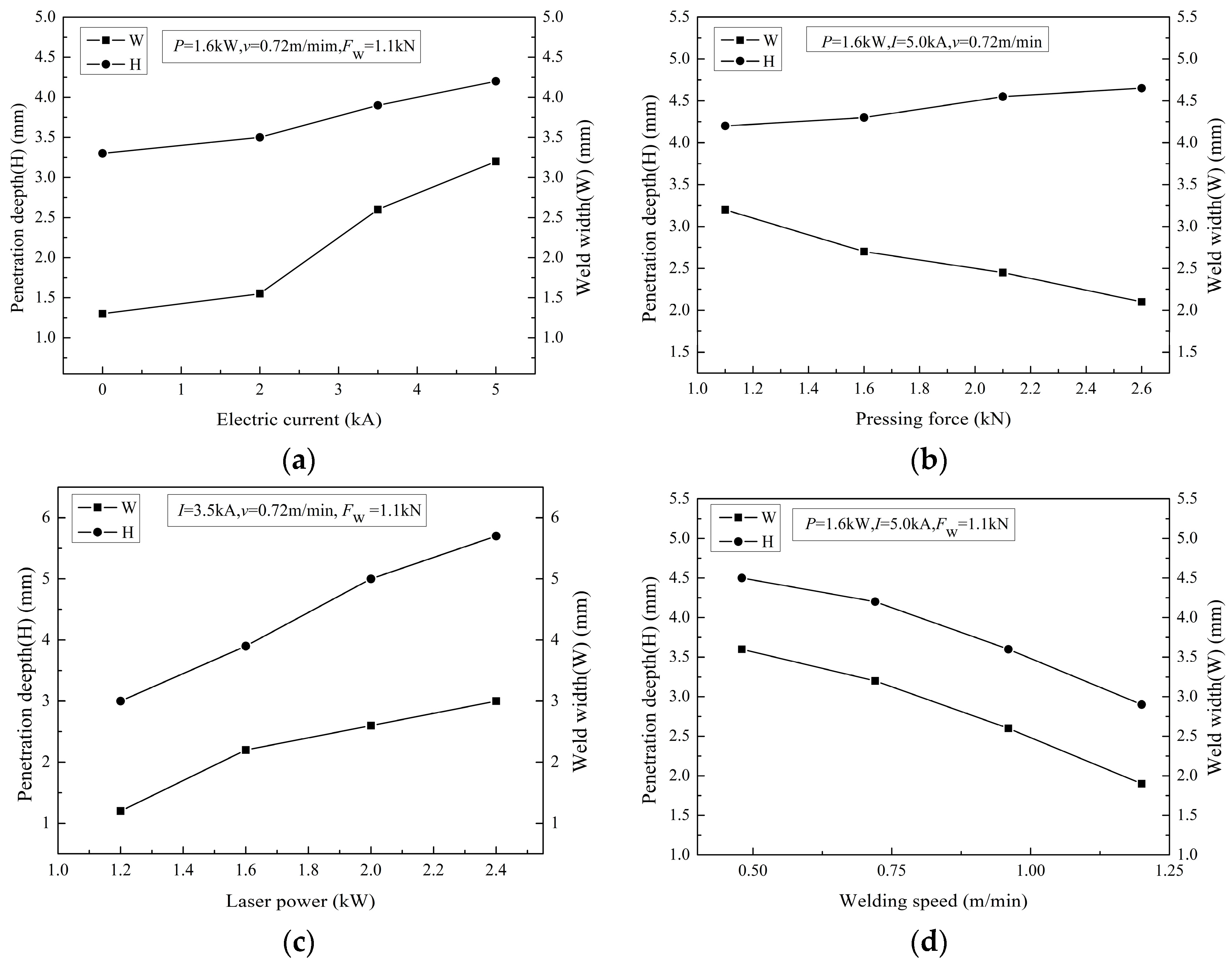

3.2. Effects of Process Parameters on the Weld Morphology

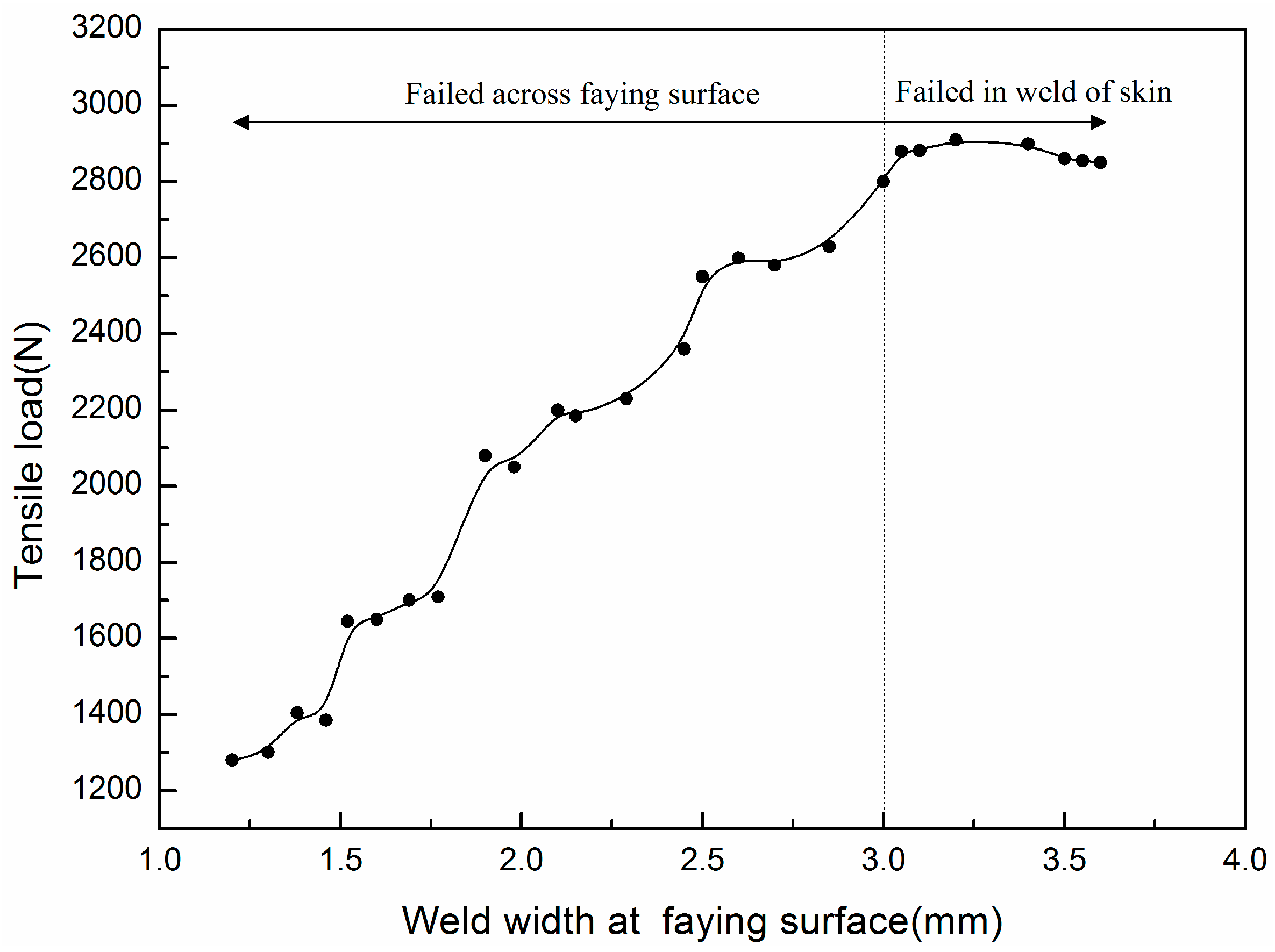

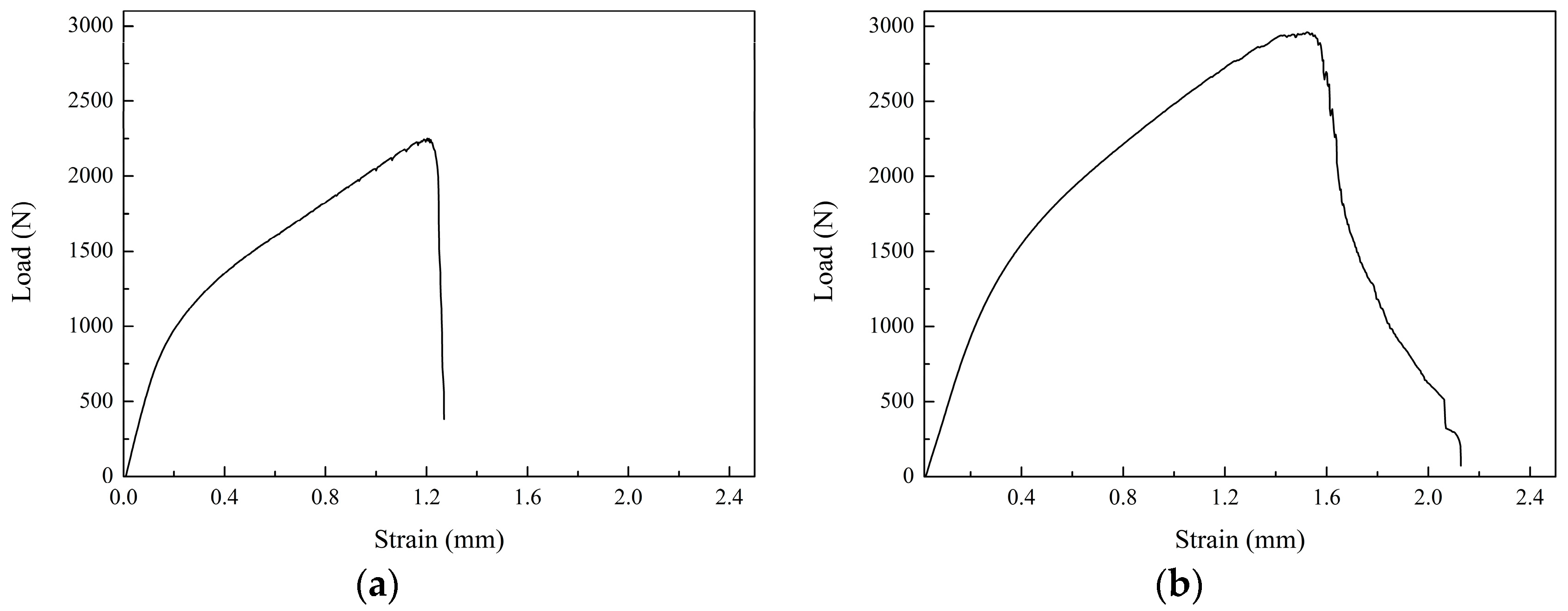

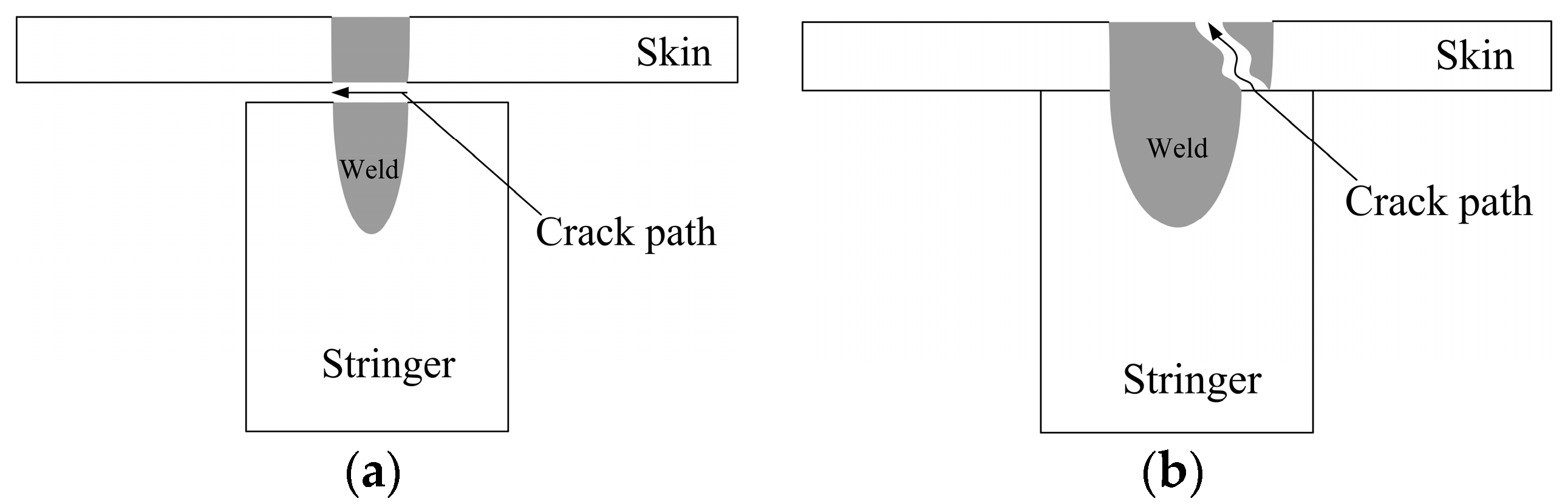

3.3. Tensile Shear Test

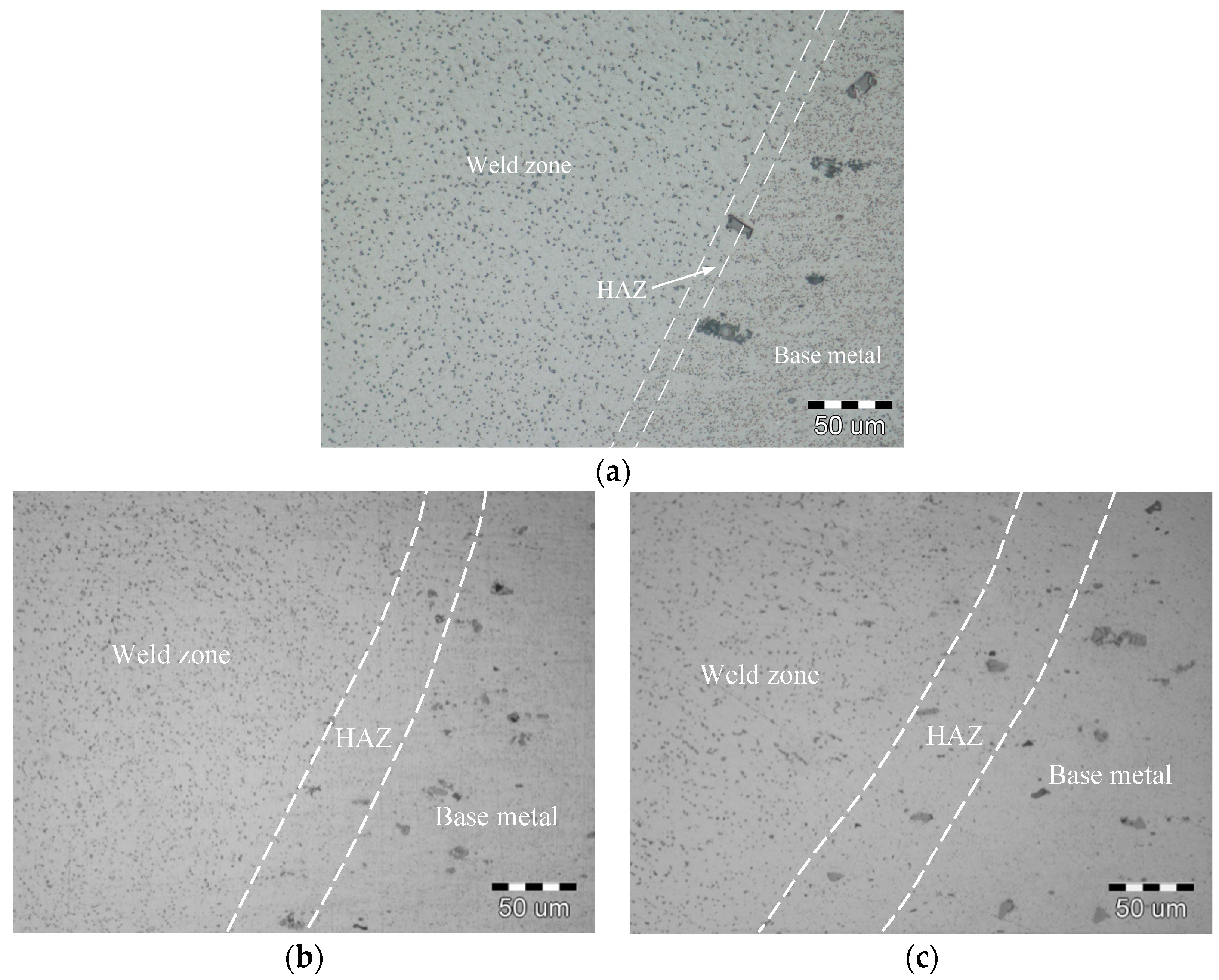

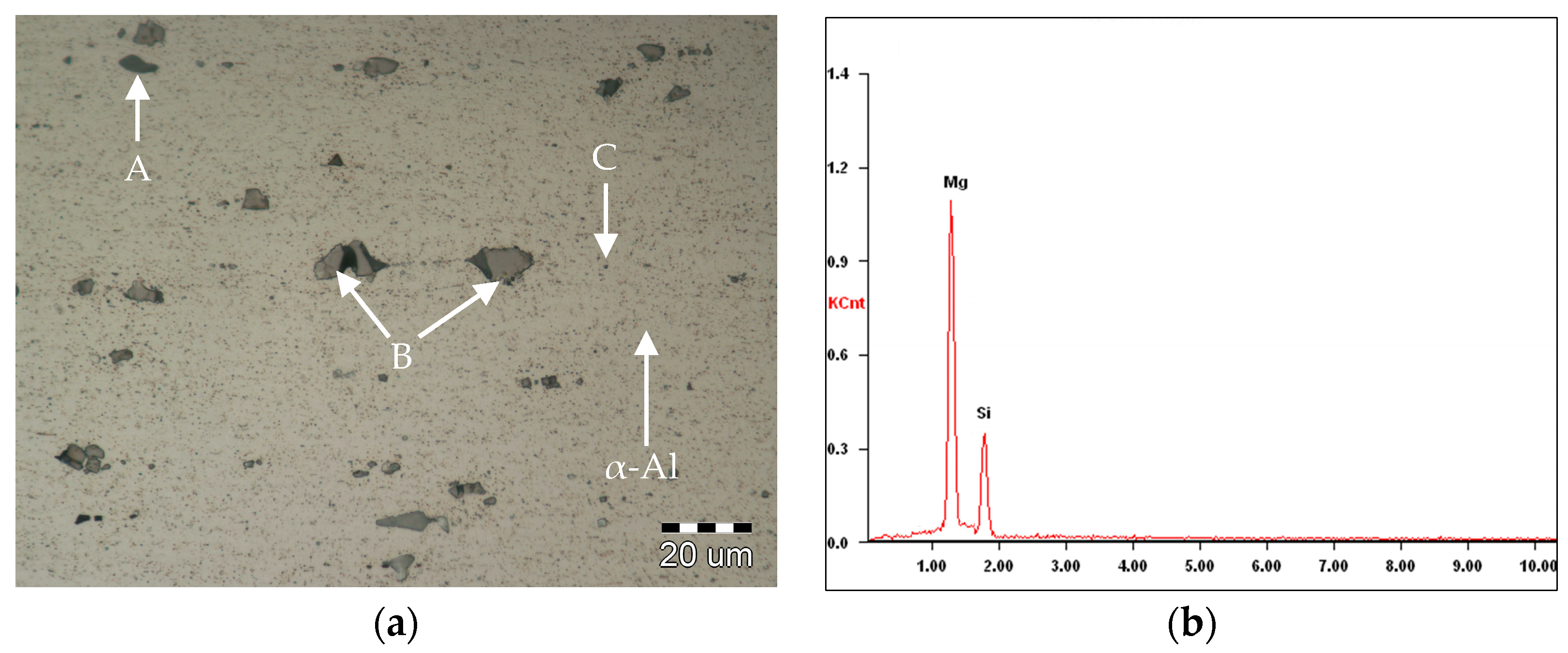

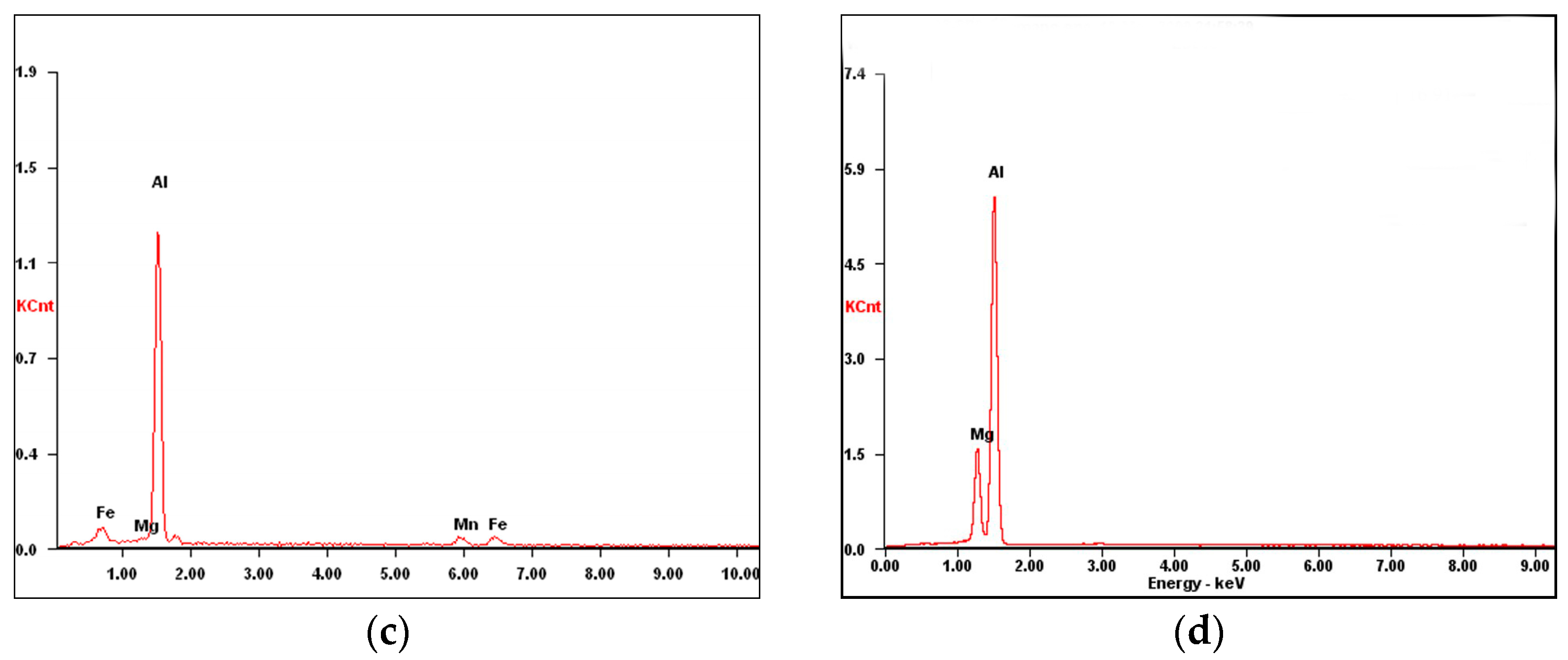

3.4. Microstructure

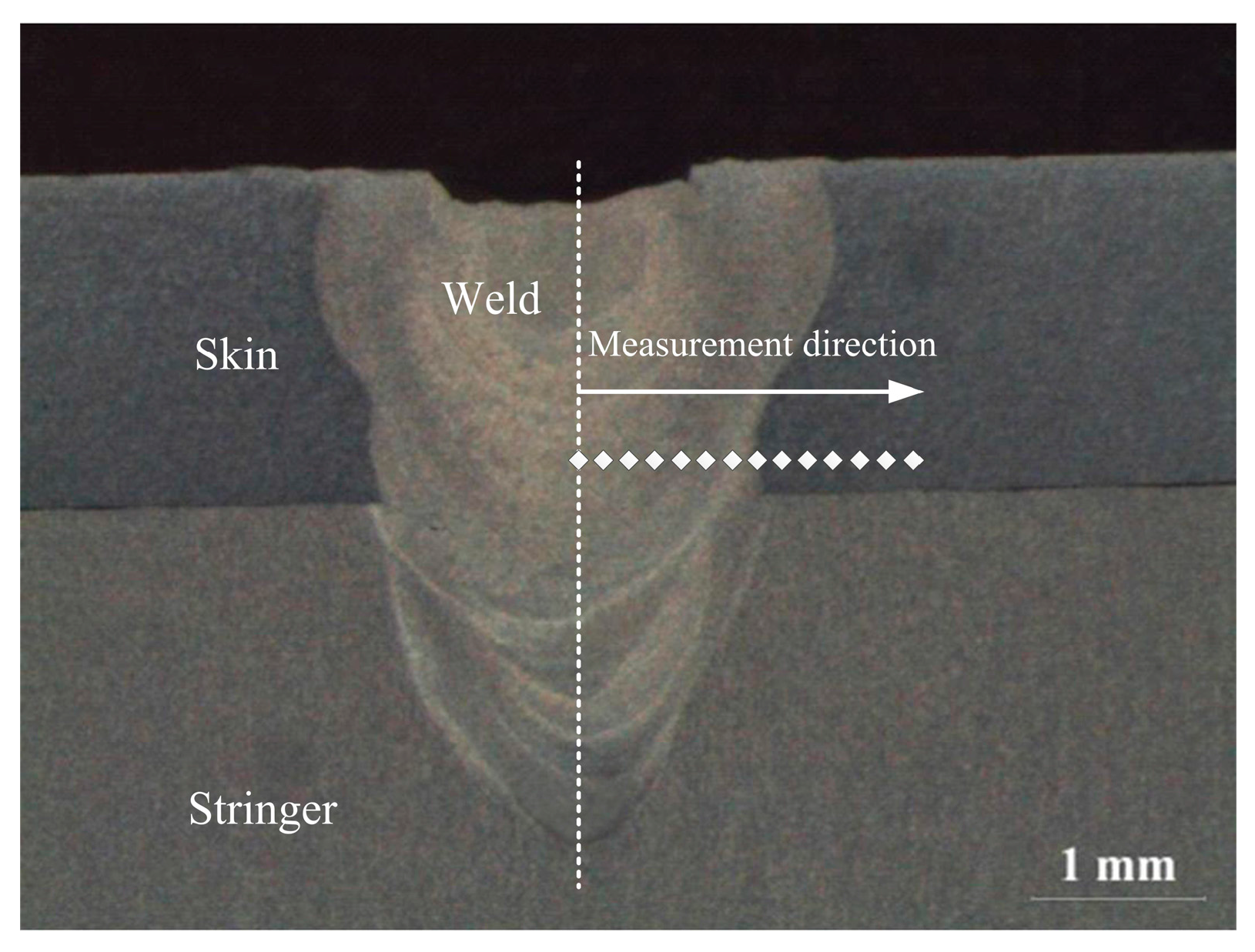

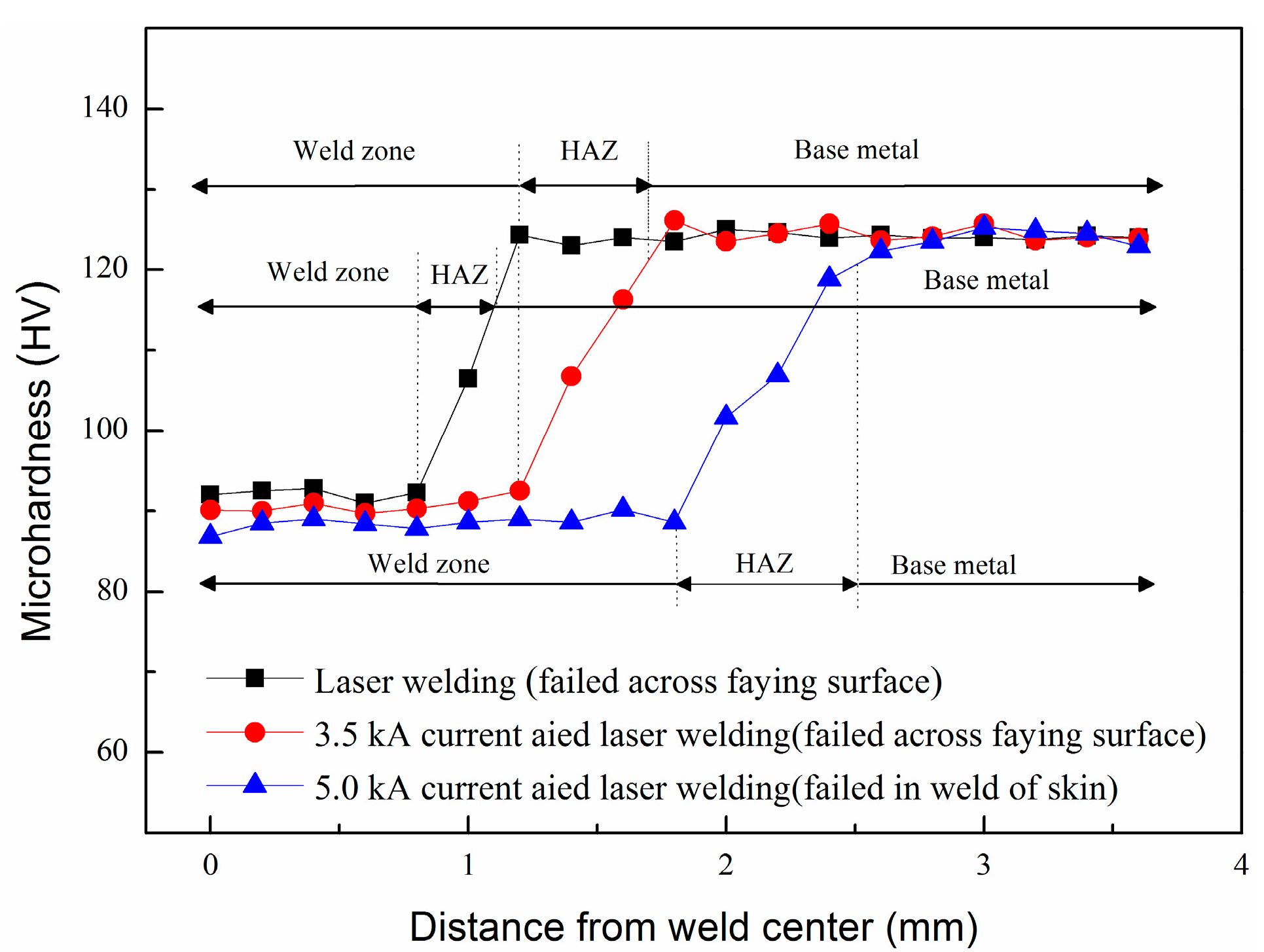

3.5. Microhardness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Romanoff, J.; Varsta, P.; Remes, H. Laser-welded web-core sandwich plates under patch-loading. Mar. Struct. 2007, 20, 25–48. [Google Scholar] [CrossRef]

- Jelovica, J.; Romanoff, J.; Klein, R. Eigenfrequency analyses of laser-welded web-core sandwich panels. Thin-Walled Struct. 2016, 101, 120–128. [Google Scholar] [CrossRef]

- Jelovica, J.; Romanoff, J.; Ehlers, S.; Varsta, P. Influence of weld stiffness on the buckling strength of laser-welded web-core sandwich plates. J. Constr. Steel Res. 2012, 77, 12–18. [Google Scholar] [CrossRef]

- Janasekaran, S.; Tan, A.W.; Yusof, F.; Abdul Shukor, M.H. Influence of the overlapping factor and welding speed on T-Joint welding of Ti6Al4V and Inconel600 using low-power fiber laser. Metals 2016, 6, 134. [Google Scholar] [CrossRef]

- Knox, E.M.; Cowling, M.J.; Winkle, I.E. Adhesively bonded steel corrugated core sandwich construction for marine applications. Mar. Struct. 1998, 11, 185–204. [Google Scholar] [CrossRef]

- Silva, L.F.M.; Adams, R.D. The strength of adhesively bonded T-joints. Int. J. Adhes. Adhes. 2002, 22, 311–315. [Google Scholar] [CrossRef]

- Grant, L.D.R.; Adams, R.D.; Silva, L.F.M. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 535–542. [Google Scholar] [CrossRef]

- Frank, D. Fatigue strength assessment of laser stake-welded T-joints using local approaches. Int. J. Fatigue 2015, 73, 77–87. [Google Scholar] [CrossRef]

- Meng, W.; Li, Z.G.; Huang, J.; Wu, Y.X.; Cao, R. Effect of gap on plasma and molten pool dynamics during laser lap welding for T-joints. Int. J. Adv. Manuf. Technol. 2013, 69, 1105–1112. [Google Scholar] [CrossRef]

- Duley, W.W. Laser Welding, 1st ed.; John Wiley and Sons Ltd.: New York, NY, USA, 1998; pp. 1–9. [Google Scholar]

- Köse, C.; Karaca, E. Robotic Nd:YAG fiber Laser welding of Ti-6Al-4V alloy. Metals 2017, 7, 221. [Google Scholar] [CrossRef]

- Meng, W.; Li, Z.G.; Huang, J.; Wu, Y.X.; Chen, J.H.; Katayama, S. The influence of various factors on the geometric profile of laser lap welded T-joints. Int. J. Adv. Manuf. Technol. 2014, 74, 1625–1636. [Google Scholar] [CrossRef]

- Romanoff, J.; Remes, H.; Socha, G.; Jutila, M.; Varsta, P. The stiffness of laser stake welded T-joints in web-core sandwich structures. Thin-Walled Struct. 2007, 45, 453–462. [Google Scholar] [CrossRef]

- Li, K.; Lu, F.G.; Cui, H.C.; Li, X.B.; Tang, X.H.; Li, Z.G. Investigation on the effects of shielding gas on porosity in fiber laser welding of T-joint steels. Int. J. Adv. Manuf. Technol. 2015, 77, 1881–1888. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, M.L.; Wei, Q.; Gu, K.F. Technique of laser-TIG hybrid T-shape joint welding of titanium Alloy. Adv. Mater. Res. 2011, 291–294, 841–847. [Google Scholar] [CrossRef]

- Hou, Z.L.; Li, C.B.; Liu, L.M. Laser-TIG Hybrid Welding of Magnesium Alloy T-Joint with Cold Filler Wire. Mater. Trans. 2015, 56, 1242–1247. [Google Scholar] [CrossRef]

- Li, C.B.; Liu, L.M. Investigation on weldability of magnesium alloy thin sheet T-joints: Arc welding, laser welding, and laser-arc hybrid welding. Int. J. Adv. Manuf. Technol. 2013, 65, 27–34. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Influence of material characteristics on plastomechanics of the FSW process for T-joints. Mater. Des. 2009, 30, 2435–2445. [Google Scholar] [CrossRef]

- Cui, L.; Yang, X.Q.; Zhou, G.; Xu, X.D.; Shen, Z.K. Characteristics of defects and tensile behaviors on friction stir welded AA6061-T4 T-joints. Mater. Sci. Eng. A 2012, 543, 58–68. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, L.L.; Wang, Q.Z.; Yan, K.; Zou, J.S. Defects and tensile properties of 6013 aluminum alloy T-joints by friction stir welding. Mater. Des. 2014, 57, 146–155. [Google Scholar] [CrossRef]

- Urbikain, G.; Perez, J.M.; Lacalle, L.N.L.D.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016. [Google Scholar] [CrossRef]

- Hong, K.M.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Corrado, G.; Argenio, P.; Barbieri, G.; Acerra, F.; Innaro, V. Laser beam welding of a Ti–6Al–4V support flange for buy-to-fly reduction. Metals 2017, 7, 183. [Google Scholar] [CrossRef]

- Hou, X.P.; Yang, X.Q.; Cui, L.; Zhou, G. Influences of joint geometry on defects and mechanical properties of friction stir welded AA6061-T4 T-joints. Mater. Des. 2014, 53, 106–117. [Google Scholar] [CrossRef]

- Lee, H.S.; Yoon, J.H.; Yoo, J.T.; No, K. Friction stir welding process of aluminum-lithium alloy 2195. Procedia Eng. 2016, 149, 62–66. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; Lacalle, L.N.L.D.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1–11. [Google Scholar] [CrossRef]

- Ertek Emre, H.; Kaçar, R. Resistance Spot Weldability of Galvanize Coated and Uncoated TRIP Steels. Metals 2016, 6, 299. [Google Scholar] [CrossRef]

- Gao, S.; Wu, Z.S.; Jin, P.F.; Wang, J.J.; Shuai, P. Effect of deep cryogenic treatment on microstructure of 5A06 aluminum alloy MIG welded joint welding. Mater. Sci. Forum 2012, 724, 182–185. [Google Scholar] [CrossRef]

- Wang, L.X.; Cong, B.Q.; Qi, B.J.; Li, W.; Yang, M.X.; Yang, Z.; Li, Y.L. Effect of ultra-high frequency pulse square-wave current on 5A06 aluminum alloy HPVP-GTAW joints. Trans. China Weld. Inst. 2013, 34, 61–64. [Google Scholar]

- Chen, Y.B.; Miao, Y.G.; Li, L.Q.; Wu, L. Joint performance of laser-TIG double-side welded 5A06 aluminum alloy. Trans. Nonferrous Met. Soc. China 2009, 19, 26–31. [Google Scholar] [CrossRef]

| Material | Mg | Mn | Si | Cu | Zn | Fe | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 5A06 | 5.8–6.8 | 0.5–0.8 | 0.4 | 0.1 | 0.2 | 0.4 | 0.02 | Balance |

| Equipment | Model, Supplier |

|---|---|

| CO2 laser source | DC030; Rofin-Sinar, GmbH |

| Electric current supply device | PSG6130 and PSI6200; Bosch Rexroth Company |

| Tensile test machine | Instron5500R, Adivision of Illinois Tool Works Inc. |

| Optical microscope | Eclipse E200, Nikon Instruments, Ltd. |

| Microhardness test machine | HXD-1000TM; Zhuhai Precision Instrument Co., Ltd. |

| Scanning electron microscopy | S-4700; Hitachi, Ltd. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, L.; Chen, Y.; Yang, Z.; Zhu, X. Experimental Investigation on Electric Current-Aided Laser Stake Welding of Aluminum Alloy T-Joints. Metals 2017, 7, 467. https://doi.org/10.3390/met7110467

Zhang X, Li L, Chen Y, Yang Z, Zhu X. Experimental Investigation on Electric Current-Aided Laser Stake Welding of Aluminum Alloy T-Joints. Metals. 2017; 7(11):467. https://doi.org/10.3390/met7110467

Chicago/Turabian StyleZhang, Xinge, Liqun Li, Yanbin Chen, Zhaojun Yang, and Xiaocui Zhu. 2017. "Experimental Investigation on Electric Current-Aided Laser Stake Welding of Aluminum Alloy T-Joints" Metals 7, no. 11: 467. https://doi.org/10.3390/met7110467

APA StyleZhang, X., Li, L., Chen, Y., Yang, Z., & Zhu, X. (2017). Experimental Investigation on Electric Current-Aided Laser Stake Welding of Aluminum Alloy T-Joints. Metals, 7(11), 467. https://doi.org/10.3390/met7110467