Fatigue Life Assessment of Railway Rails with Lubrication Holes: Experimental Validation and Finite Element Modelling

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

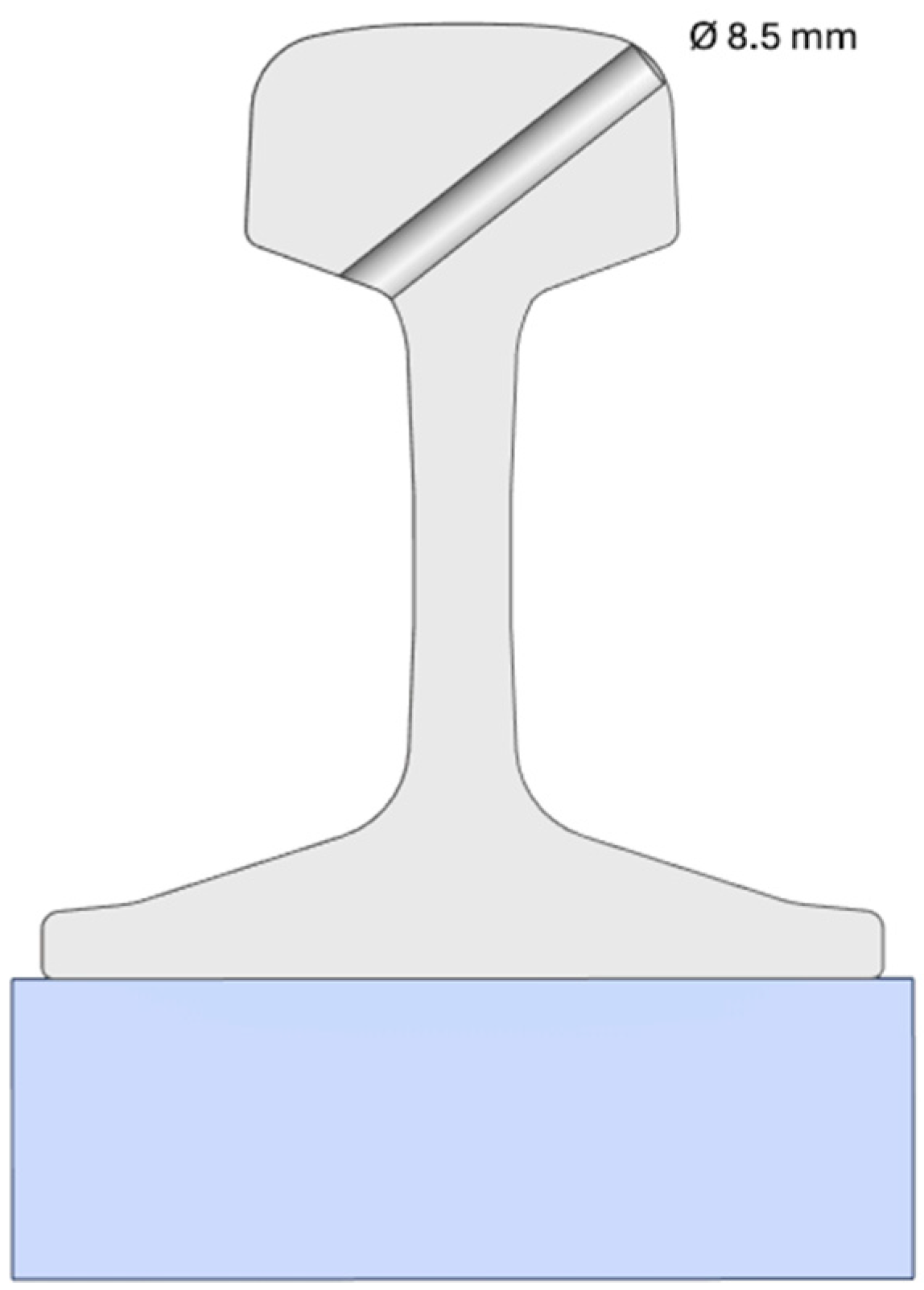

2.1.1. Tested Rails

2.1.2. Fatigue Tests

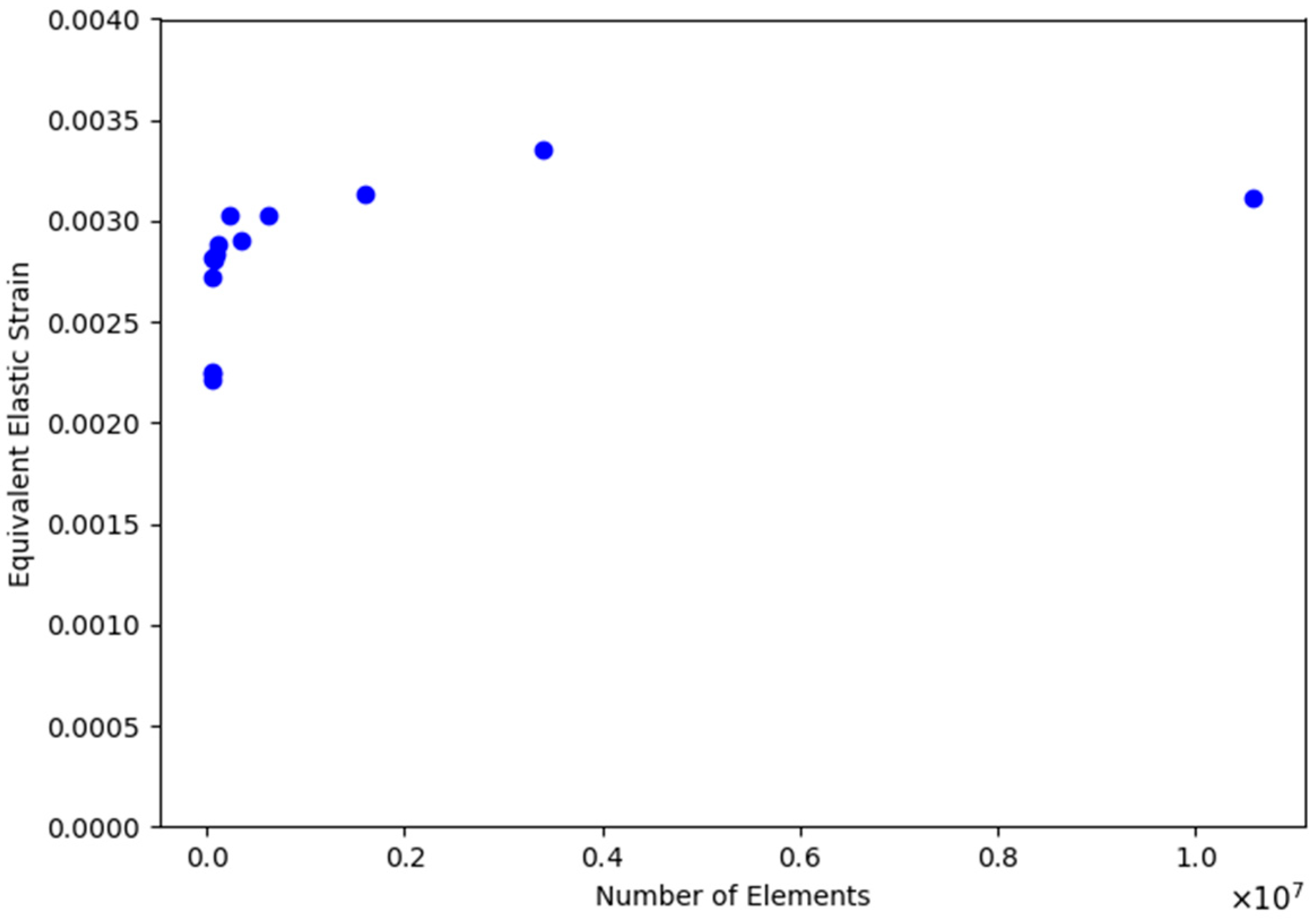

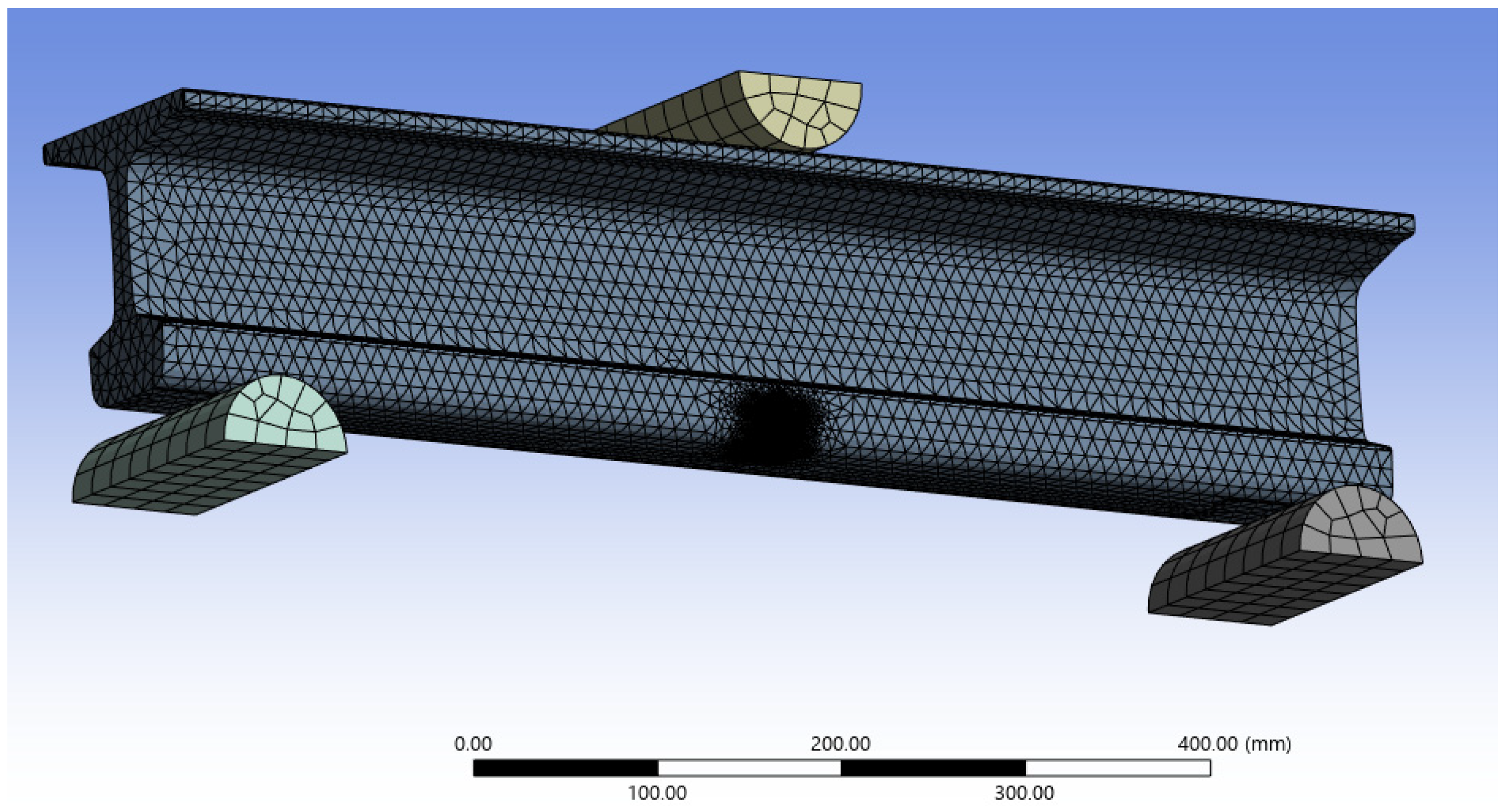

2.2. Finite Element Modeling

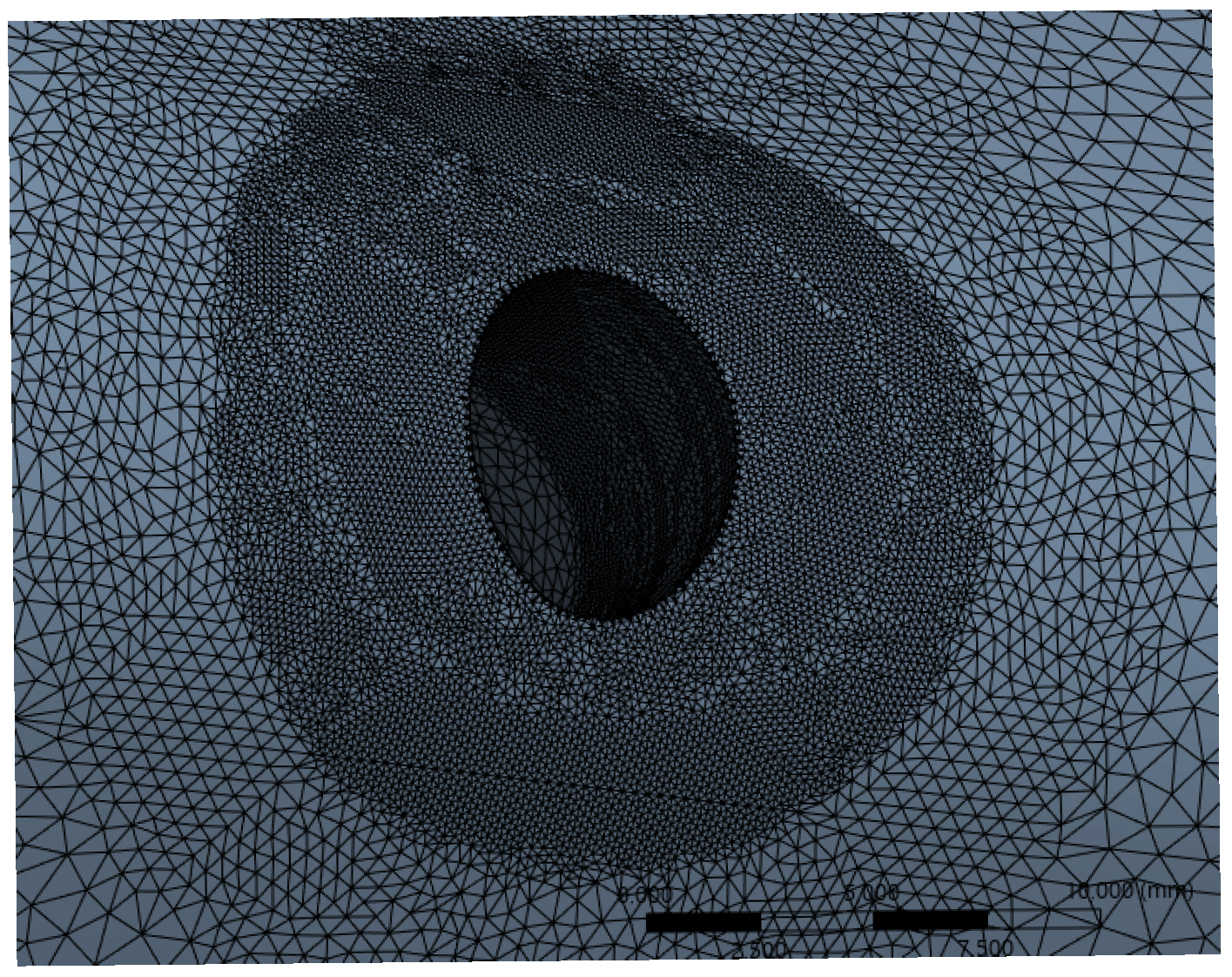

2.2.1. Model 1—Reduced Geometry

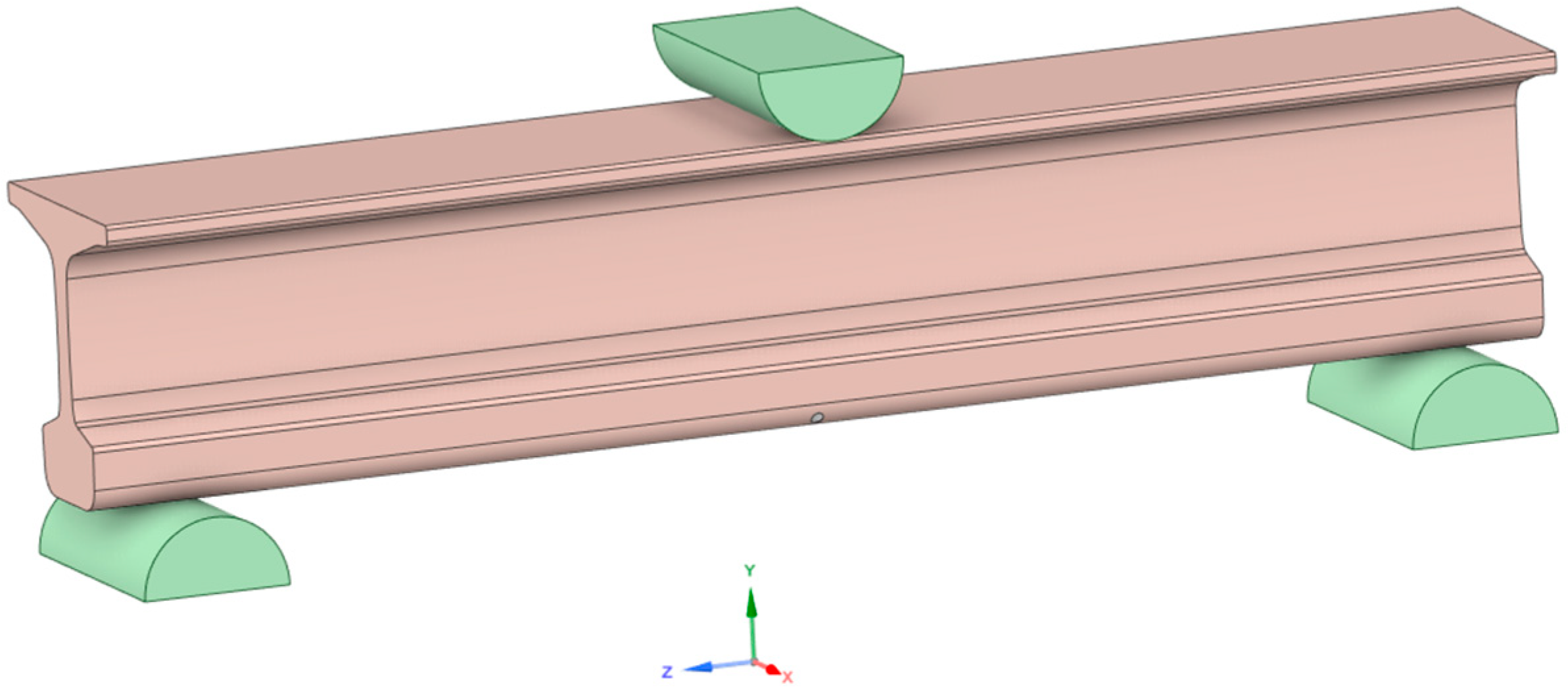

2.2.2. Model 2—Full Track Section

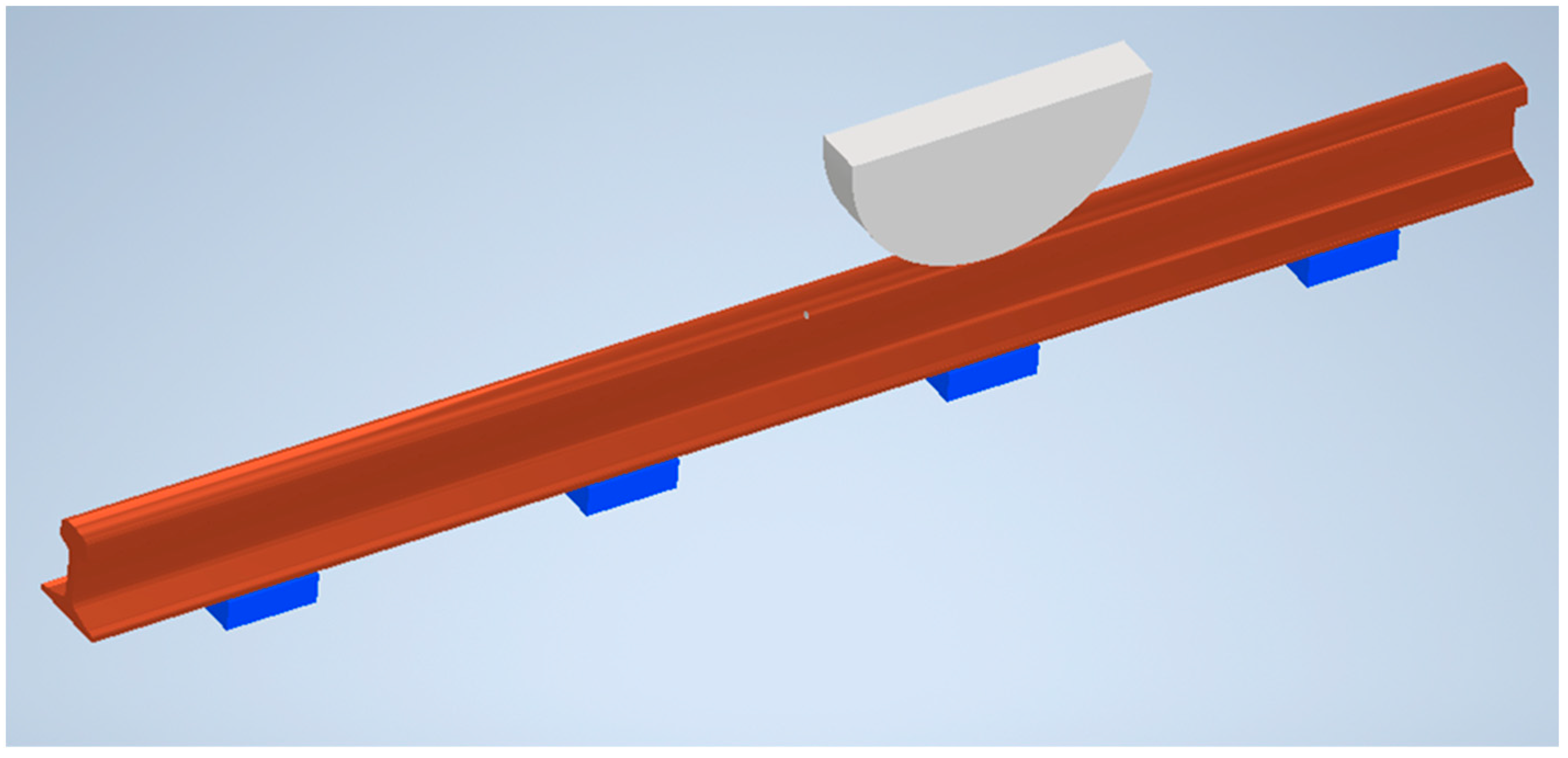

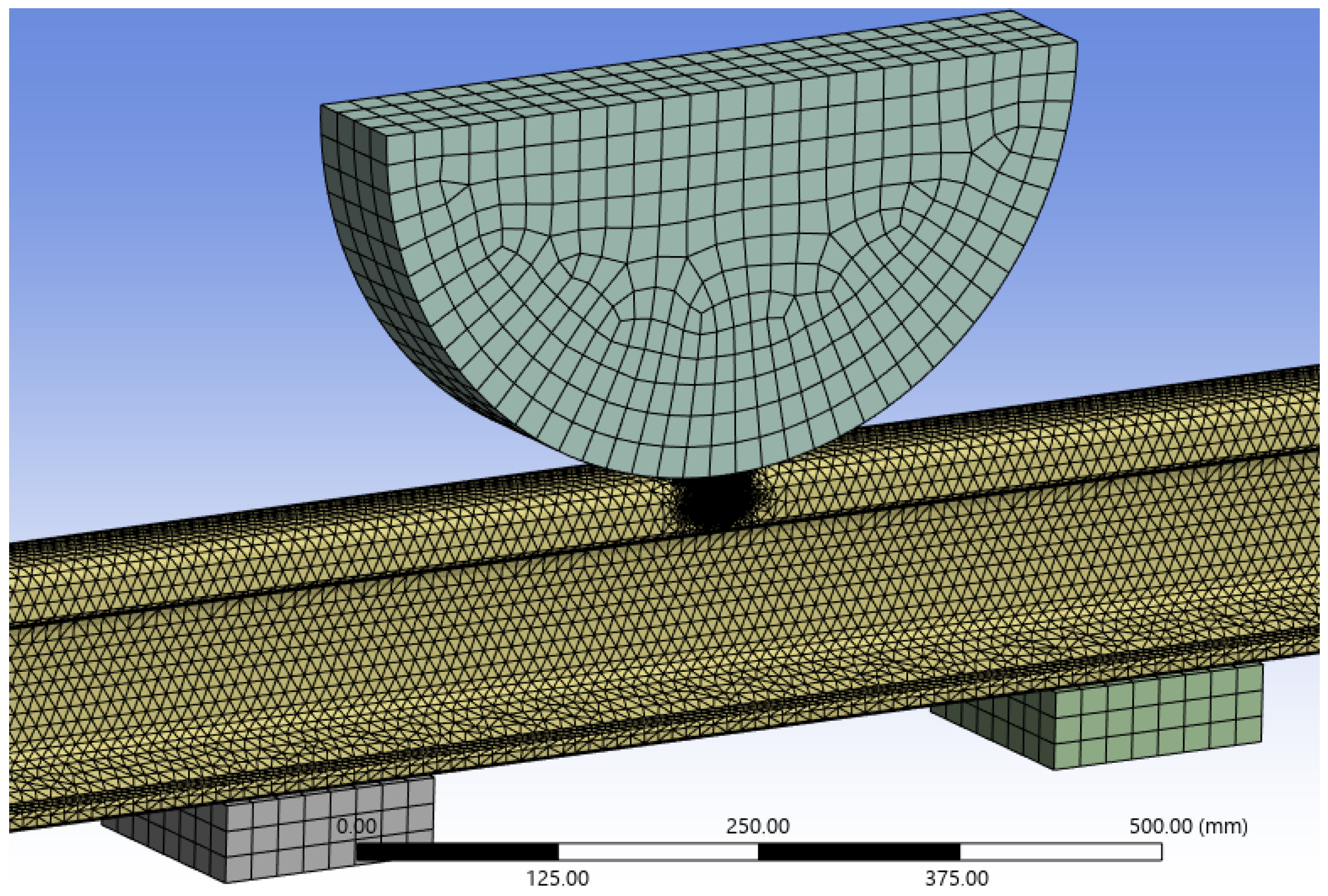

3. Results

3.1. Experimental Results

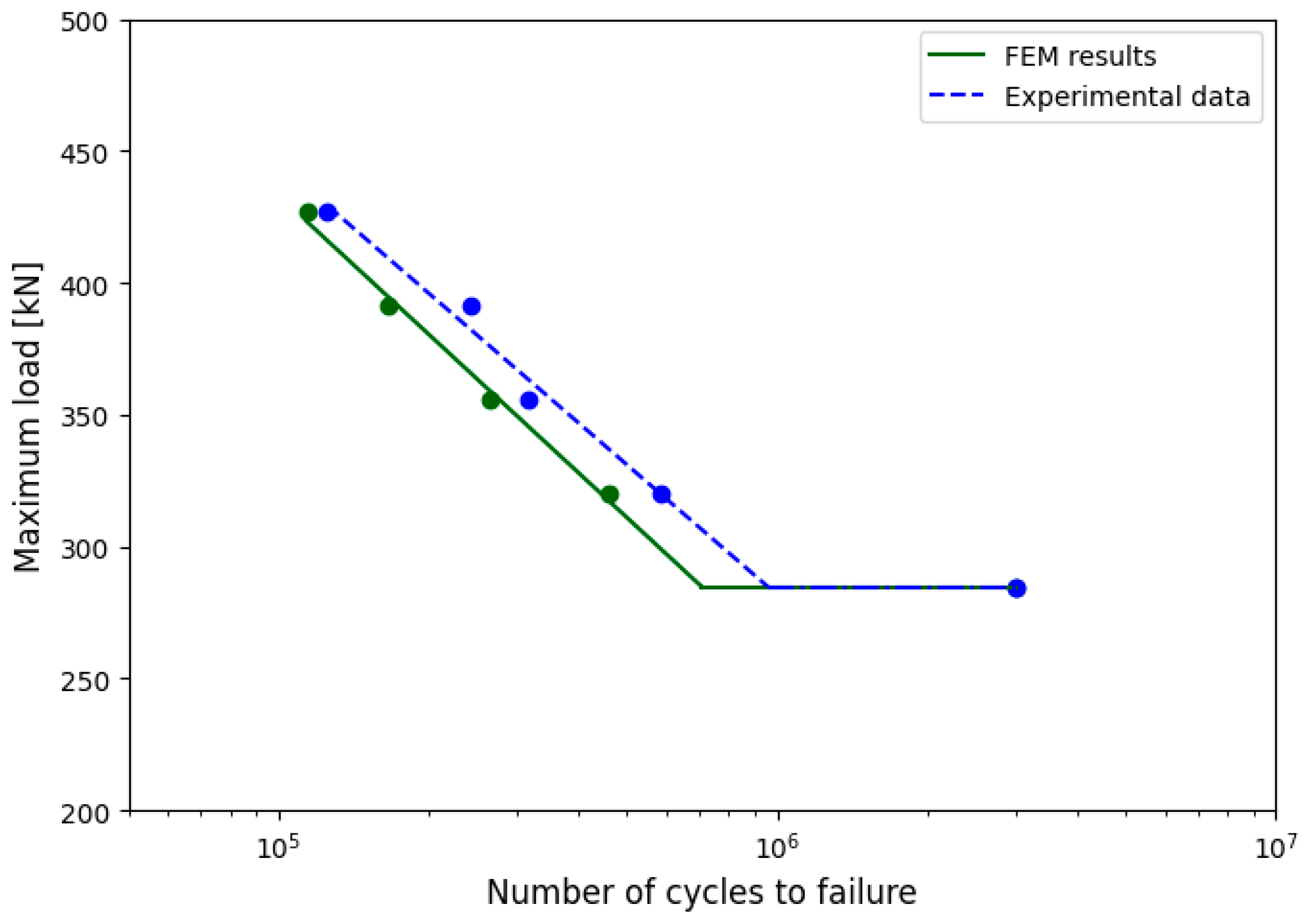

3.2. Experimental vs. Numerical S–N Comparison (Model 1)

3.3. Parametric Study (Model 2)

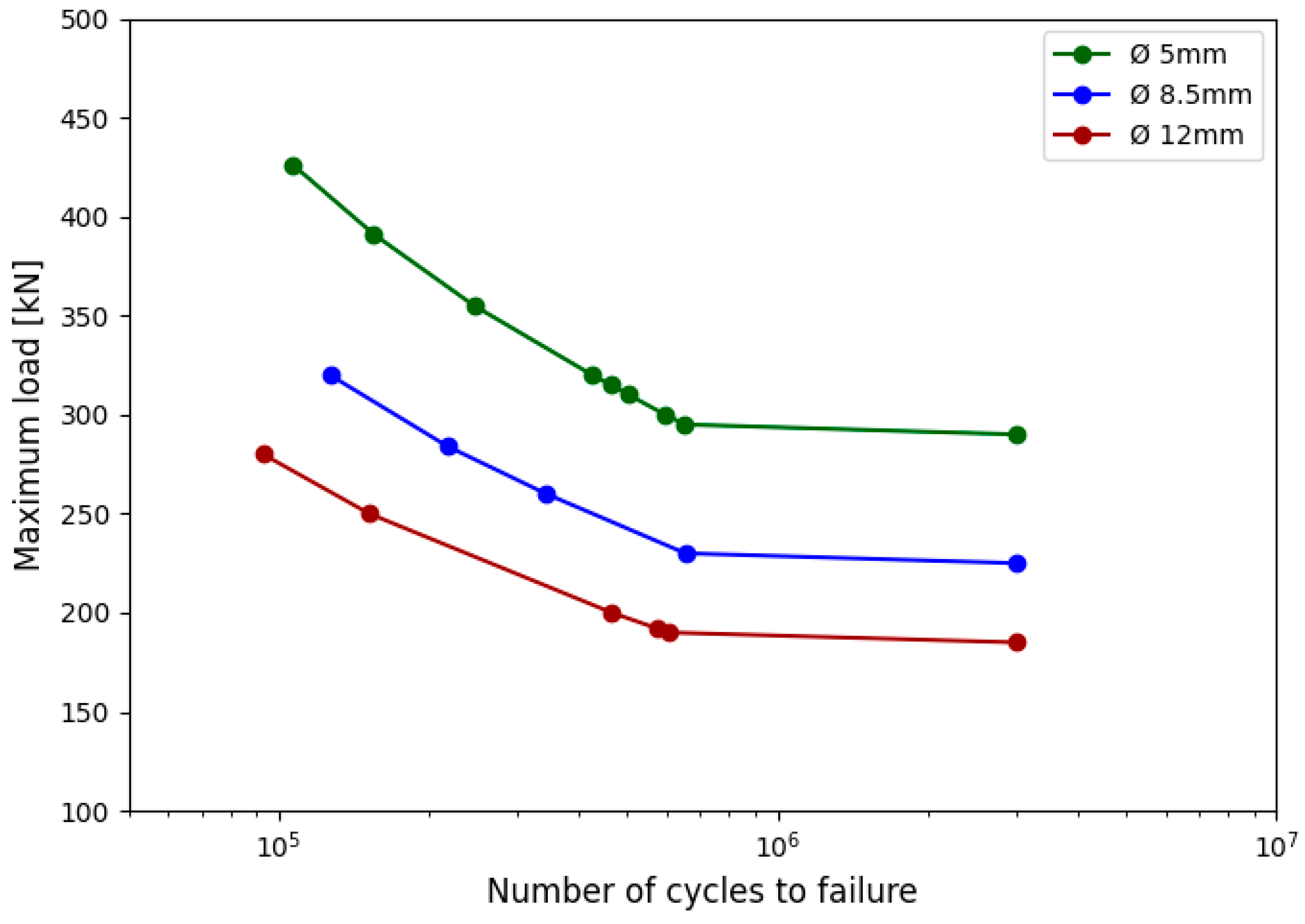

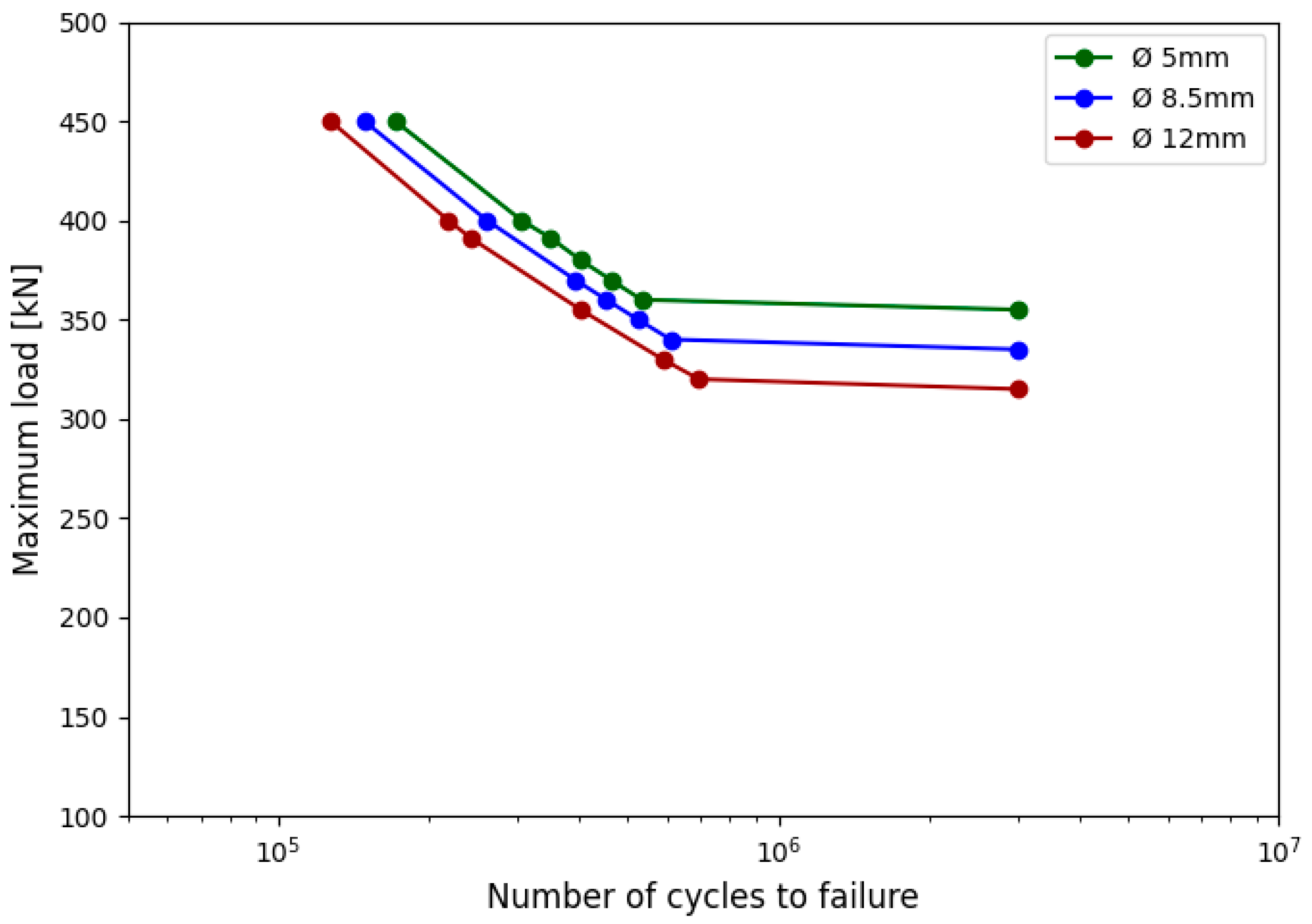

3.3.1. Influence of Hole Diameter

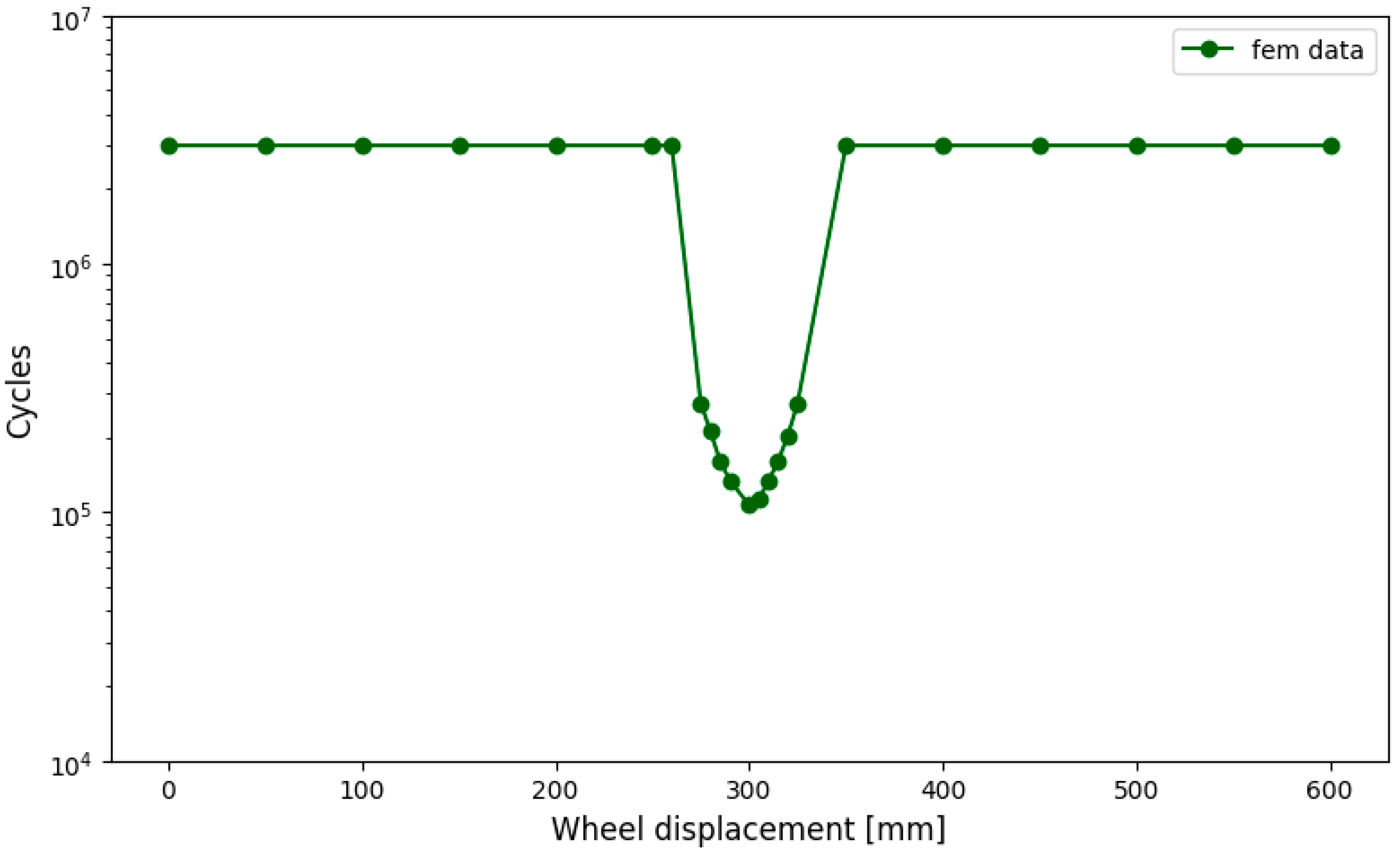

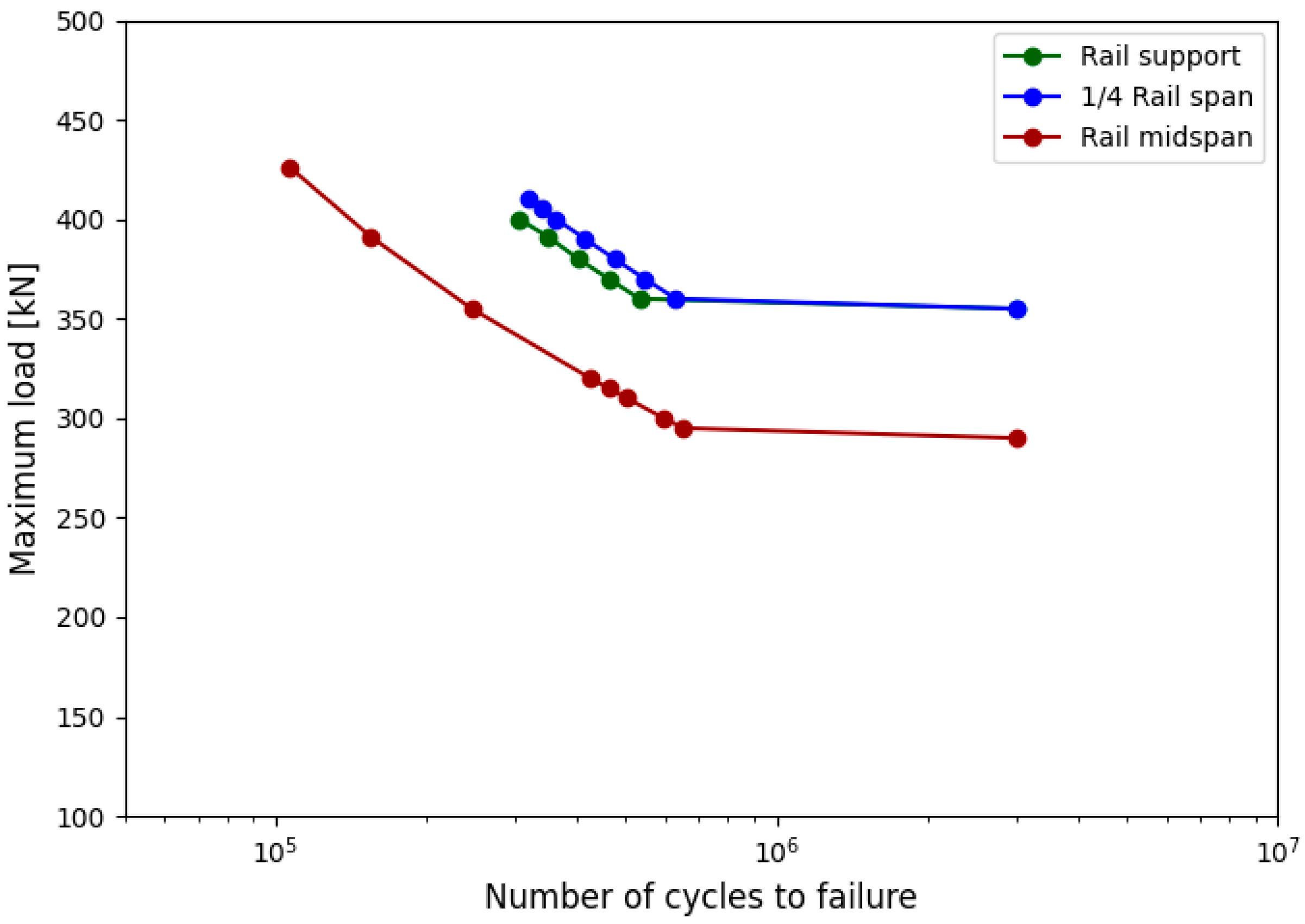

3.3.2. Influence of the Hole Position

4. Discussion

5. Conclusions

- -

- The finite element model developed to reproduce the inverted three-point bending test configuration showed excellent agreement with the experimental S–N curve, validating the numerical methodology for fatigue life prediction in drilled rails.

- -

- The diameter of the lubrication hole was identified as a key parameter influencing fatigue performance. Larger holes produced significantly lower fatigue life due to increased stress concentration at the hole edge.

- -

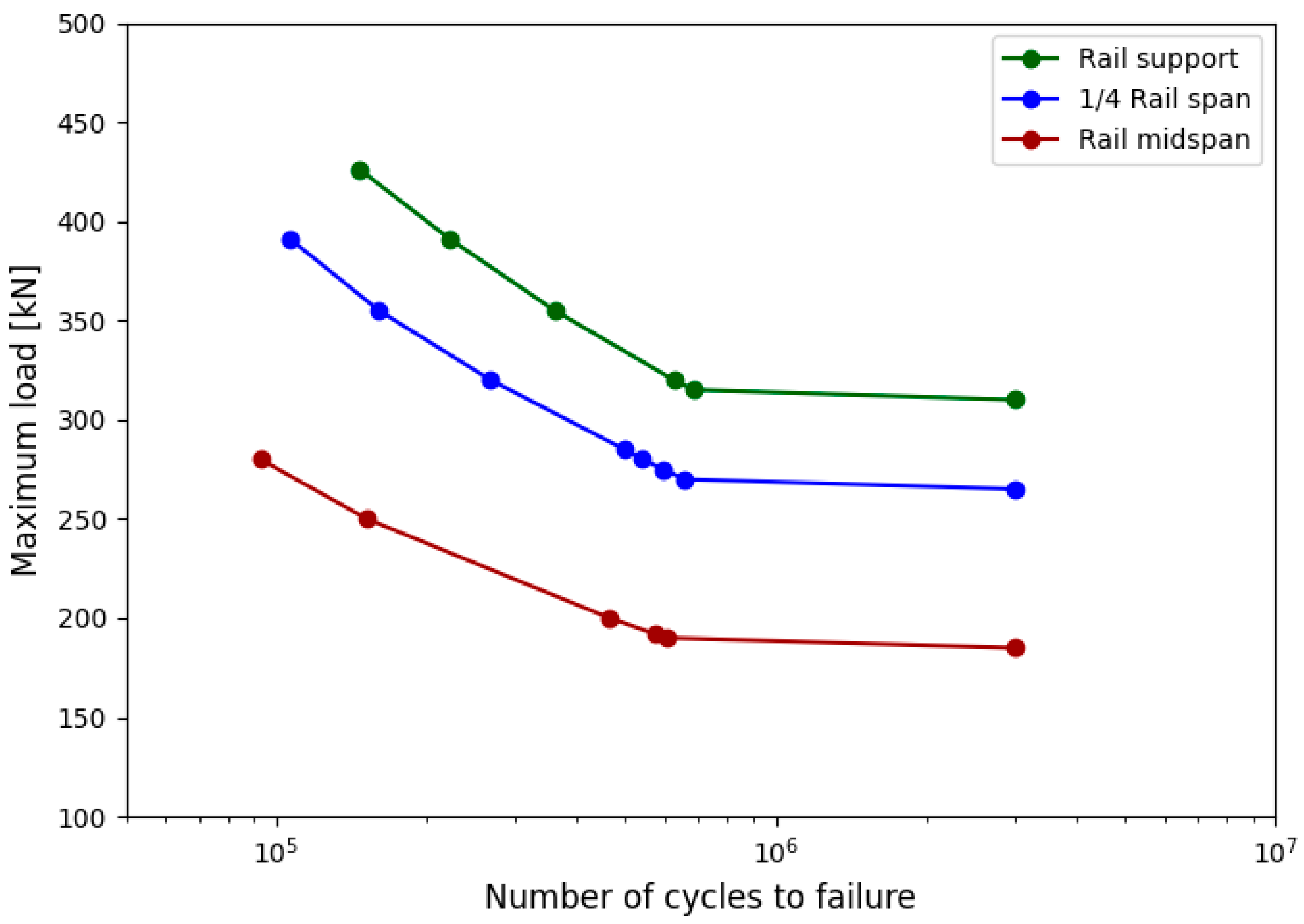

- The position of the hole relative to the track supports also had a notable effect. The midspan location proved to be the most critical, corresponding to the region of maximum bending moment, while holes placed near supports resulted in higher fatigue life.

- -

- The full-track finite element model, calibrated with experimental data, enabled the identification of the worst-case loading condition for each structural configuration by sweeping the wheel load along the rail. This approach proved effective for constructing conservative S–N curves representing each design scenario.

- -

- Under realistic service loads, the current design—with an 8.5 mm hole located at midspan—was shown to lie on the safe side, with fatigue lives well above critical thresholds. This provides confidence in the continued use of the existing configuration under current operating conditions.

- -

- The numerical methodology developed in this study can serve as a reliable predictive tool for assessing the impact of geometric modifications in drilled rails and can be extended to evaluate other discontinuities or loading conditions in future work.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Wen, B.; Ren, D.; Ding, Y.; Wen, Z.; Dong, D.; Tao, G. Analysis of the causes of severe side wear of the high rail on metro curves by numerical simulation and field investigation. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit. 2024, 238, 381–393. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Wu, B.; Shi, L.; Zhang, S.; Ding, H.; Wang, W.; Liu, Q. Influence of Lubricating Materials on Wheel-Rail Wear and Rolling Contact Fatigue. Mocaxue Xuebao/Tribol. 2022, 42, 935–944. [Google Scholar] [CrossRef]

- Milanese, M.; Iacobazzi, F.; Stark, M.; de Risi, A. Development of common rail lube oil injector for large two-stroke marine diesel engines. Int. J. Engine Res. 2022, 23, 1131–1143. [Google Scholar] [CrossRef]

- Shu, K.; Zani, N.; Ghidini, L.; Petrogalli, C.; Yu, L.L.; Mazzù, A.; Ding, H.H.; Wang, W.J. Wear and damage behaviors of wheel-rail with different material matchings under various sand deposition densities of rail top in desert environments. Wear 2025, 560–561, 205622. [Google Scholar] [CrossRef]

- Fang, X.-Y.; Zhang, H.-N.; Ma, D.-W.; Wu, Z.-J.; Huang, W. Influence of welding residual stress on subsurface fatigue crack propagation of rail. Eng. Fract. Mech. 2022, 271, 108642. [Google Scholar] [CrossRef]

- Ringsberg, J.W.; Josefson, B.L. Assessment of uncertainties in life prediction of fatigue crack propagation in welded rails. In Proceedings of the 12th International Conference on Fracture 2009, ICF-12, Ottawa, ON, Canada, 12–17 July 2009; pp. 5837–5846. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84869811698&partnerID=40&md5=8b1b6660215bb5c9d8e2dc9f26d40741 (accessed on 6 July 2025).

- Ma, X.; Wang, Y.; Wang, X.; Yin, W.; Liu, L.; Xu, J. Investigation on fatigue crack propagation behaviour of U71Mn and U75V rails using peridynamics. Eng. Fract. Mech. 2023, 281, 109097. [Google Scholar] [CrossRef]

- Boyacioglu, P.; Bevan, A. Rail surface damage management through monitoring and modelling. Int. J. Rail Transp. 2025, 13, 231–247. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Amudjev, I.M.; Anchev, A.P.; Ganev, N. A new approach for pre-stressing of rail-end-bolt holes. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2017, 231, 2275–2283. [Google Scholar] [CrossRef]

- Nejad, R.M.; Shariati, M.; Farhangdoost, K. Prediction of fatigue crack propagation and fractography of rail steel. Theor. Appl. Fract. Mech. 2019, 101, 320–331. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, S.M.; Carboni, M.; Guagliano, M. Finite element approach toward an advanced understanding of deep rolling induced residual stresses, and an application to railway axles. Mater. Des. 2015, 83, 689–703. [Google Scholar] [CrossRef]

- Eden, H.C.; Garnham, J.E.; Davis, C.L. Influential microstructural changes on rolling contact fatigue crack initiation in pearlitic rail steels. Mater. Sci. Technol. 2005, 21, 623–629. [Google Scholar] [CrossRef]

- Pucillo, G.P.; Carrabs, A.; Cuomo, S.; Elliott, A.; Meo, M. Cold expansion of rail-end-bolt holes: Finite element predictions and experimental validation by DIC and strain gauges. Int. J. Fatigue 2021, 149, 106275. [Google Scholar] [CrossRef]

- Xu, X.; Xie, L.; Zhou, S.; An, J.; Huang, Y.; Li, D. Fatigue Crack Propagation Behavior and Life Prediction of Welded Joints of SMA490BW Steel for Bogies. Processes 2023, 11, 1984. [Google Scholar] [CrossRef]

- Ferreño, D.; Casado, J.A.; Carrascal, I.A.; Diego, S.; Ruiz, E.; Saiz, M.; Sainz-Aja, J.A.; Cimentada, A.I. Experimental and finite element fatigue assessment of the spring clip of the SKL-1 railway fastening system. Eng. Struct. 2019, 188, 553–563. [Google Scholar] [CrossRef]

- Duncheva, G.V.; Maximov, J.T. A new approach to enhancement of fatigue life of rail-end-bolt holes. Eng. Fail. Anal. 2013, 29, 167–179. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Numerical Modeling of Crack Growth under Mixed-Mode Loading. Appl. Sci. 2021, 11, 2975. [Google Scholar] [CrossRef]

| Number of Cycles to Failure [N] | Stress [MPa] |

| 80,000 | 500 |

| 160,000 | 390 |

| 280,000 | 330 |

| 600,000 | 270 |

| 700,000 | 260 |

| 3,000,000 (run-out) | 260 |

| Lab Test | Max. Stress [MPa] | Stress Amplitude [MPa] | Number of Cycles |

| CAR-3 | 258 | 232 | 125.450 |

| CAR-4 | 235 | 212 | 244.000 |

| CAR-5 | 214 | 193 | 316.412 |

| CAR-6 | 193 | 174 | 586.313 |

| CAR-7 | 171 | 154 | >3.000.000 |

| Rail Support | ¼ Rail Support | Rail Midspan | |

| Ø 12 mm | Low | Moderate | High |

| Ø 8.5 mm | Low | Low | Moderate |

| Ø 5 mm | Low | Low | Low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sainz-Aja, J.; San Roman, P.; Casado, J.A.; Carrascal, I.; Arroyo, B.; Ferreño, D.; Moreno, R.; Peribañez, D.; Vegas, H.; Diego, S. Fatigue Life Assessment of Railway Rails with Lubrication Holes: Experimental Validation and Finite Element Modelling. Metals 2025, 15, 992. https://doi.org/10.3390/met15090992

Sainz-Aja J, San Roman P, Casado JA, Carrascal I, Arroyo B, Ferreño D, Moreno R, Peribañez D, Vegas H, Diego S. Fatigue Life Assessment of Railway Rails with Lubrication Holes: Experimental Validation and Finite Element Modelling. Metals. 2025; 15(9):992. https://doi.org/10.3390/met15090992

Chicago/Turabian StyleSainz-Aja, Jose, Pablo San Roman, Jose A. Casado, Isidro Carrascal, Borja Arroyo, Diego Ferreño, Raul Moreno, David Peribañez, Hugo Vegas, and Soraya Diego. 2025. "Fatigue Life Assessment of Railway Rails with Lubrication Holes: Experimental Validation and Finite Element Modelling" Metals 15, no. 9: 992. https://doi.org/10.3390/met15090992

APA StyleSainz-Aja, J., San Roman, P., Casado, J. A., Carrascal, I., Arroyo, B., Ferreño, D., Moreno, R., Peribañez, D., Vegas, H., & Diego, S. (2025). Fatigue Life Assessment of Railway Rails with Lubrication Holes: Experimental Validation and Finite Element Modelling. Metals, 15(9), 992. https://doi.org/10.3390/met15090992