1. Introduction

Advances in healthcare, nutrition, and living standards have resulted in an aging population in many regions worldwide. This, in turn, has led to a higher prevalence of degenerative arthritis and other joint-related disorders. According to the World Health Organization, the number of people affected by degenerative arthritis was predicted to rise globally between 2017 and 2024, with the elderly population accounting for a large proportion of those affected (approximately 50%) [

1]. Traditional treatments, such as medication, can provide temporary relief; however, they fail to address the underlying causes. Accordingly, artificial joint replacement is often regarded as a more effective long-term solution.

High-quality artificial joints must satisfy five fundamental criteria: good biocompatibility, high corrosion resistance, superior mechanical properties, enhanced wear resistance, and effective osseointegration. Various materials are used for biomedical implants, including titanium alloy (Ti6Al4V) [

2,

3], stainless steel (SSL) [

4], and cobalt chromium molybdenum (CoCrMo) alloys [

5,

6]. Among these materials, CoCrMo is one of the most commonly used owing to its excellent mechanical properties, corrosion resistance, and biocompatibility [

7,

8,

9]. However, CoCrMo alloy joints are subjected to complex and varying loads during in vivo service, which can lead to unbalanced wear of the metal surface and potential joint failure [

10]. Consequently, the surface properties of CoCrMo are of significant interest for ensuring the long-term success of the joint. Many surface modification treatments have been developed to enhance the wear resistance of alloys, such as doping [

11], plasma surface treatment [

12], chemical vapor deposition (CVD) [

13], physical vapor deposition (PVD) [

14], and laser processing [

15,

16]. However, many of these methods are constrained by factors such as implant geometry, size, and coating adhesion. For instance, plasma treatment suffers from limited controllability and poor repeatability, while PVD requires a high-vacuum environment and incurs a high processing cost. Laser processing offers several advantages over these techniques, including higher flexibility, localized treatment capability, faster processing speed, smaller heat-affected zone, and improved compatibility with automated systems. Numerous studies have demonstrated that laser surface modification can significantly enhance the surface properties and tribological performance of metallic alloys.

NgO and Chun [

17] employed a nanosecond laser with a wavelength of 355 nm in combination with heat treatment at 100 °C to modify the surface of stainless steel. The resulting surface exhibited both superhydrophobicity and excellent self-cleaning properties. Compared to nanosecond lasers, femtosecond lasers offer several advantages, including nanoscale precision, negligible heat-affected zones (HAZ), smooth post-processed surfaces, and broad material compatibility [

18]. Yang et al. [

19] showed that the application of femtosecond laser treatment to titanium substrates generated periodic nanostructures that significantly increased the contact angle and enhanced the corrosion resistance.

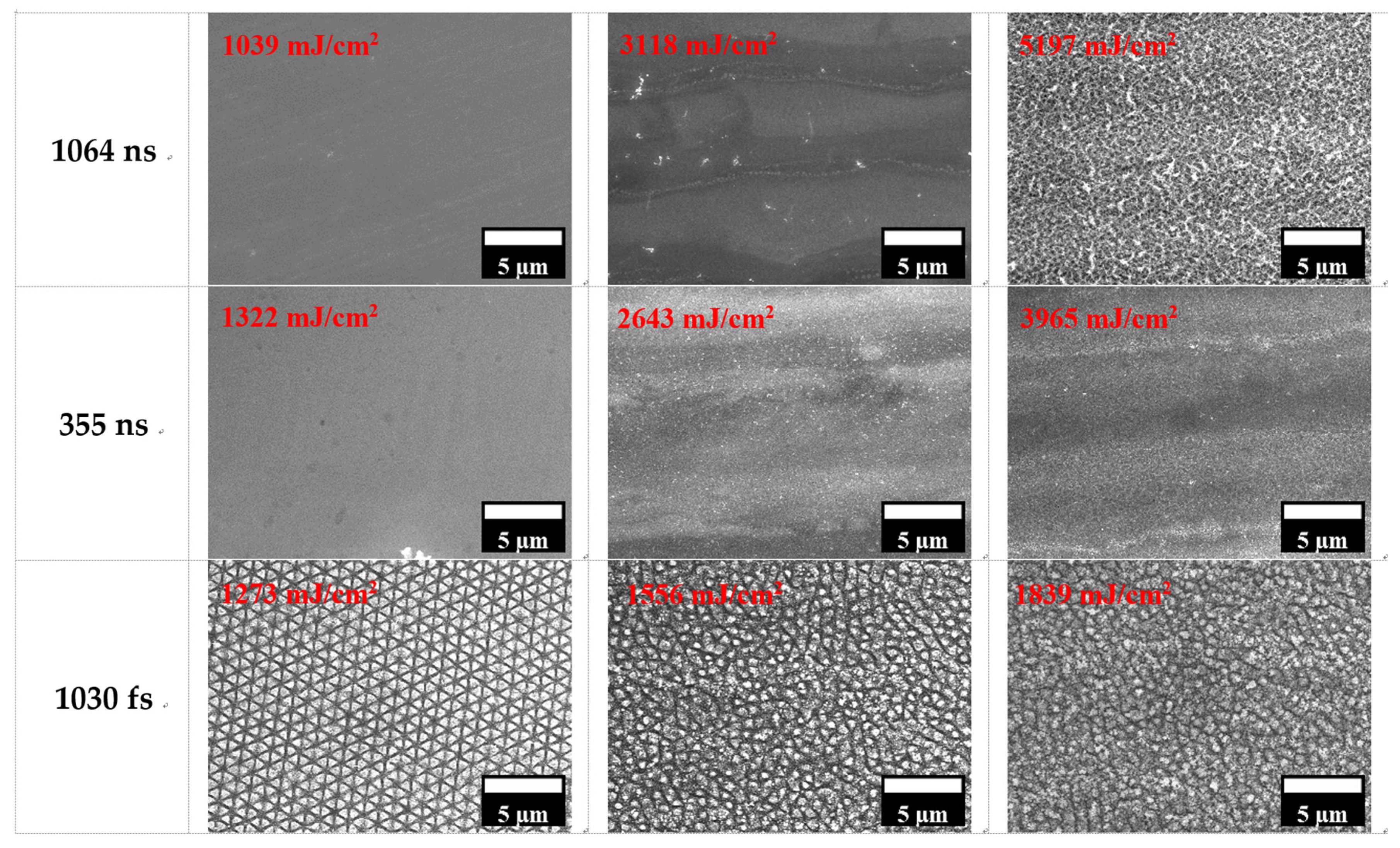

However, the literature contains scant information about the combined effects of laser pulse width (ns vs. fs) and post-annealing on the surface properties of CoCrMo alloys. The present study addresses this gap by evaluating the effects of different laser systems on the surface morphology, wettability, wear behavior, and electrocorrosion resistance of CoCrMo alloy plates. Three laser systems were used: two nanosecond lasers with wavelengths of 1064 and 355 nm, and one femtosecond laser with a wavelength of 1030 nm. All laser-treated samples were annealed at 160 °C to investigate the synergistic effects of laser processing and thermal treatment. The resulting surface morphologies and wettability were characterized and correlated with the observed improvements in the corrosion resistance and wear performance of the samples.

2. Materials and Methods

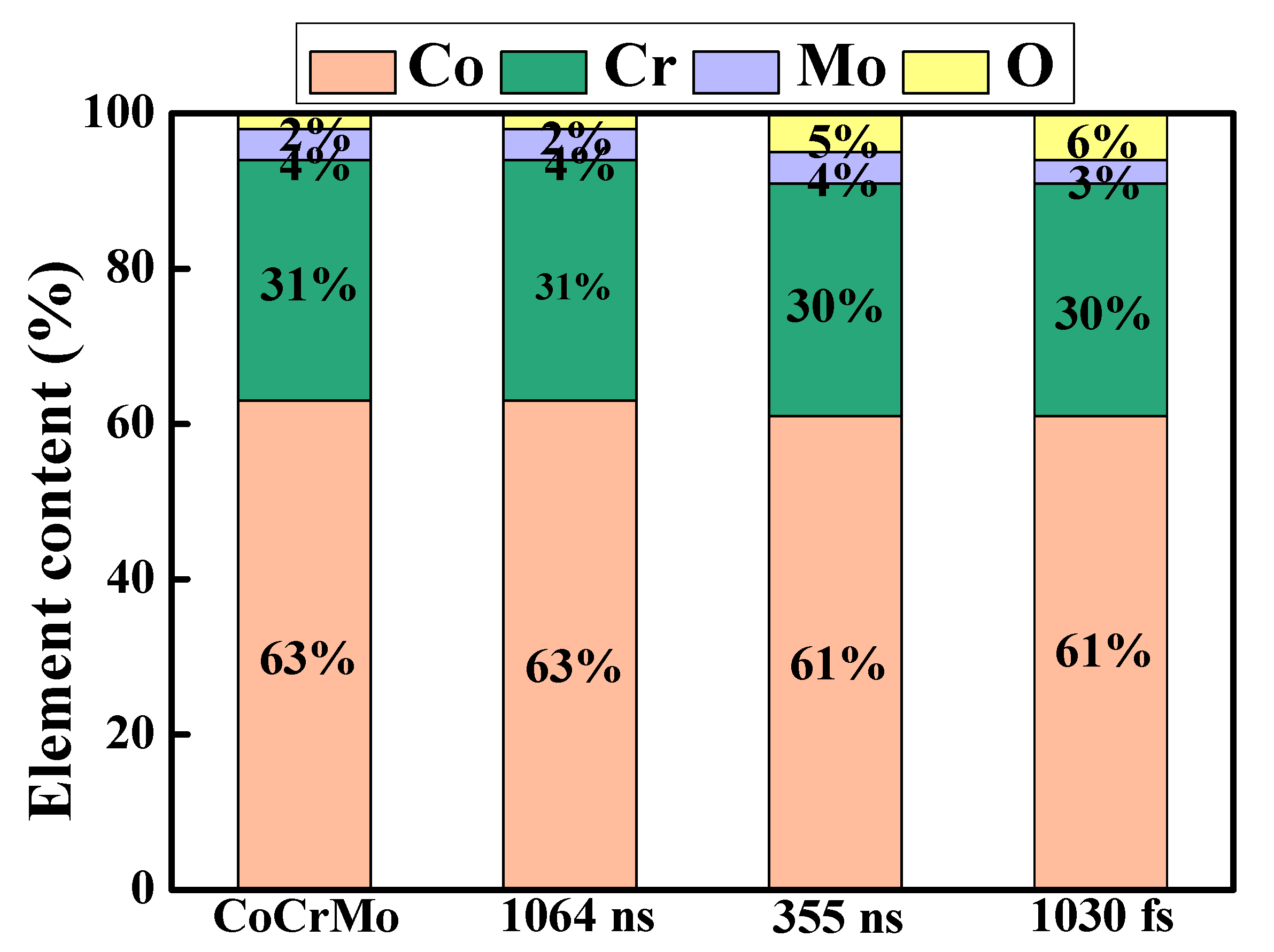

CoCrMo alloy with a composition of 63 wt.% Co, 31 wt.% Cr, 4 wt.% Mo, and minor amounts of O and other elements (totaling 2 wt.%) were obtained from Gloria Material Technology Corp. (Tainan city, Taiwan). The material was sectioned into plates with a thickness of approximately 2 mm, and the surfaces were then ground sequentially using silicon carbide papers ranging from #200 to #2000 grit size. After grinding, the sample surfaces were polished with alumina powder (particle size of approximately 1 µm) to obtain a mirror-like finish. The polished samples were processed using three laser systems with different wavelengths and pulse widths: (1) UV (Coherent AVIA 355-7000, Coherent corp., Santa Clara, CA, USA), (2) IR (G3 SM Series 12 W Pulsed Fiber Laser, SPI, Southampton, Hampshire, UK), and femtosecond (Laser P 400 U, GF, Biel, Switzerland). The laser processing parameters are presented in

Table 1. The laser wavelengths and pulse durations were selected to represent typical ranges for nanosecond and femtosecond laser systems used in metallic surface modification studies. Moreover, the energy density levels were chosen to encompass the threshold regimes for observable surface texturing and oxidation [

20]. For each laser treatment, the overlap percentage, pulse energy, and energy density were calculated as follows:

where D is the spot size (μm), W is the laser power (W), kHz is the pulse frequency (kHz), and speed is the scanning speed (mm/s).

The laser-treated samples were heated at 160 °C on a hot plate (JP-20D, Shin Kwang Machinery Industry Co., Ltd., Taipei City, Taiwan) for 2 h to stabilize the laser-induced structures and enhance surface properties. The surface morphologies of the samples were observed using a Field-Emission Scanning Electron Microscope (FE-SEM, JSM-7600F, JEOL Ltd., Tokyo, Japan) equipped with Energy-Dispersive X-ray Spectrometry (EDS, X-MAX50, Oxford Instruments, Oxford, UK). The crystal structures were examined by X-ray Diffraction (XRD, Bruker D8 Advance, Bruker Company, Billerica, MA, USA) using Cu-Kα radiation (λ = 0.154 nm) at operating voltages and currents of 40 kV and 40 mA. Grazing-incidence X-ray diffraction (GIXRD) measurements were carried out with a fixed incident angle of 0.7° to enhance surface sensitivity and minimize substrate contributions. The diffraction patterns were collected over a 2θ range of 20–80° with a step size of 0.04° and a counting time of 0.5 s per step. The surface hardness was measured using a Vickers hardness tester (Mitutoyo HM-113, Mitutoyo Corporation, Kawasaki, Japan) with an applied load of 10 kg. The surface roughness was determined using an Alpha-Step profiler (P6, KLA Corporation, Milpitas, CA, USA) at a speed of 20 μm/s, measurement distance of 200 μm, and applied load of 1 mg. Wettability was evaluated using deionized water droplets with a volume of 1 μL and a contact angle measuring system (OCA-15EC, DataPhysics Instruments GmbH, Filderstadt, Germany). The wear resistance of the samples was evaluated using a slow-speed cutting machine (Buehler, IsoMet, Lake Bluff, IL, USA) fitted with a stainless steel abrasive wheel with a diameter of 100 mm and a thickness of 5 mm. For all wear tests, the rotational speed of the wheel was set to 100 rpm, the normal contact load was 1075 g, and the wear time was 120 min. Water was used as the wet-abrasion medium for all samples. The electrochemical characteristics and corrosion behavior of the samples were evaluated in 0.9% NaCl solution using an electrochemical analyzer (CHI 6119E, CH Instruments, Bee Cave, TX, USA). Electrochemical tests were performed at 37 °C over a potential range of −1 to 1 V with a scanning rate of 1 mV/s.

4. Discussion

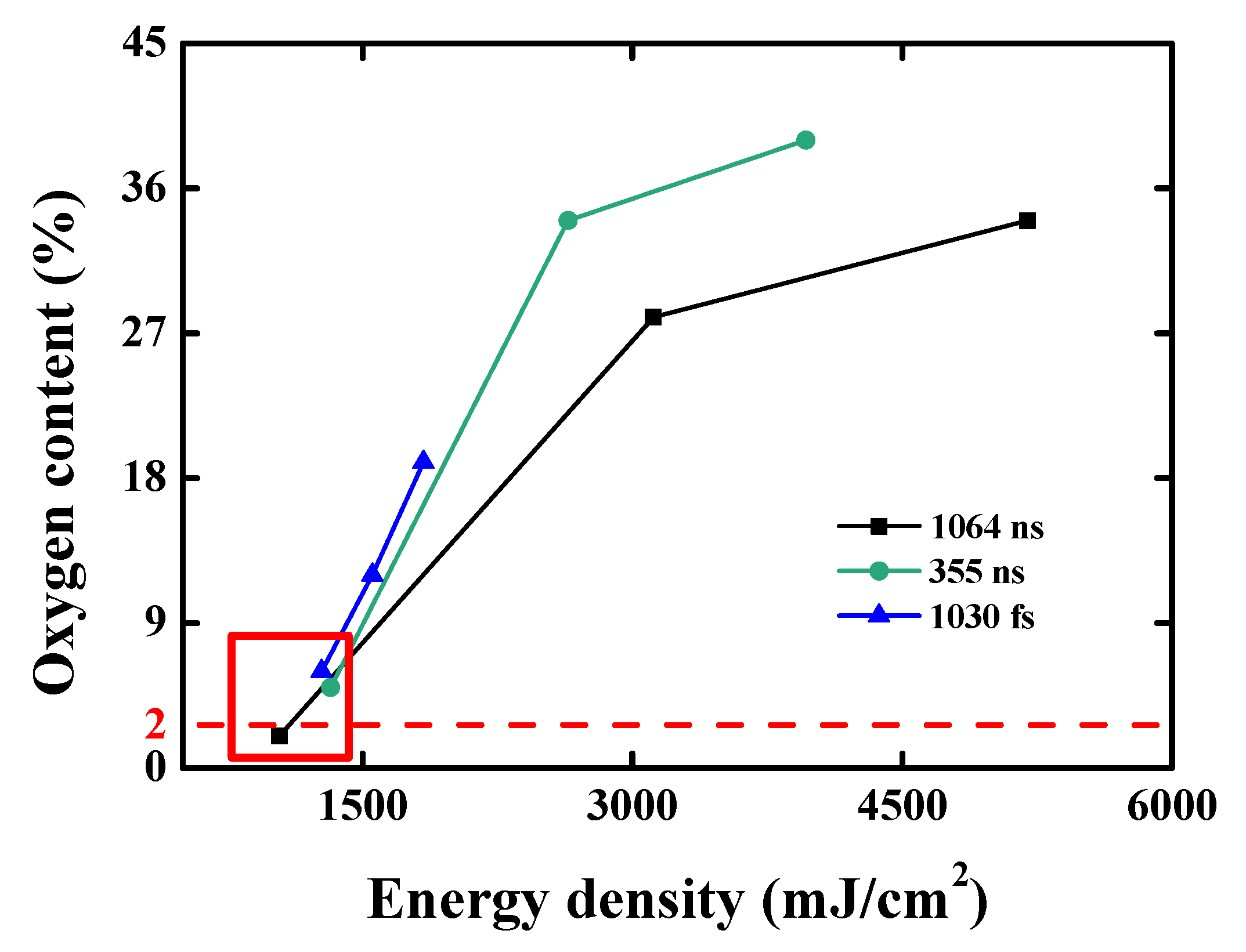

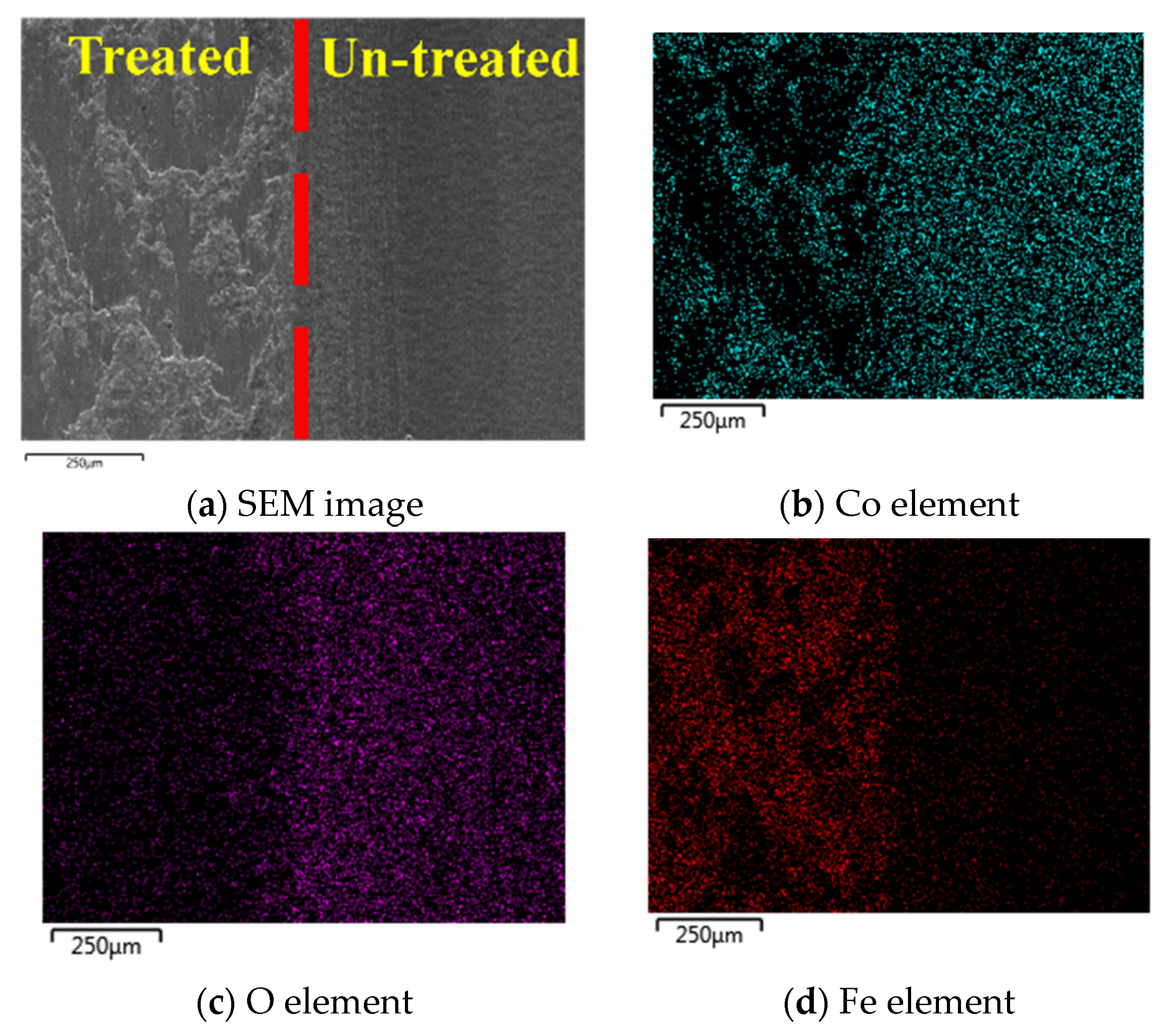

The femtosecond laser produced well-defined laser-induced periodic surface structures (LIPSS) on the treated surfaces. Although ultrashort-pulse lasers typically minimize thermal effects, oxidation can still occur in ambient air. Overall, the results suggest that while surface oxidation generally scales with increasing energy density, the relationship is not linear but depends on the type of laser and its processing parameters. In particular, femtosecond lasers induce greater oxidation at lower energies despite delivering a lower total energy input owing to their high peak power, localized energy deposition, and unique interaction mechanisms associated with ultrashort-pulse durations [

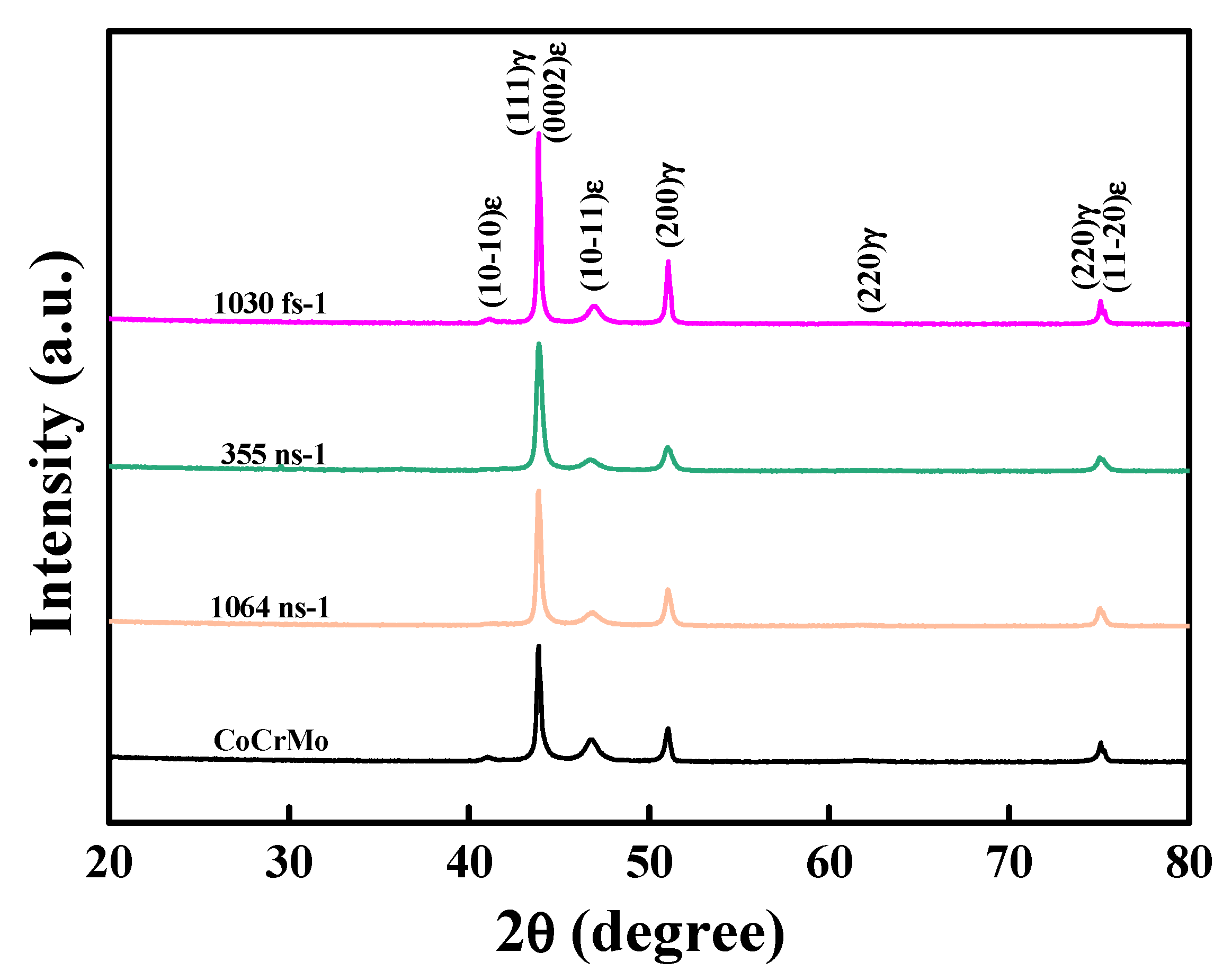

24]. XRD patterns of the original CoCrMo sample and the three laser-processed samples. The original sample exhibited a dual-phase structure consisting of hexagonal close-packed (HCP) and face-centered cubic (FCC) phases. Following laser treatment, no significant changes in the crystal phases were observed. This finding, together with the elemental analysis results in

Figure 3, indicates that the use of a femtosecond laser system can induce LIPSS structures without significantly altering either the surface phase composition or the elemental content. In other words, femtosecond laser structuring appears to be an effective surface modification technique for CoCrMo components that does not compromise their mechanical integrity. For the two nanosecond lasers, the roughness increased from around 30 nm to 480 nm as the energy density increased from 1273 to 1839 mJ/cm

2. For the femtosecond laser, an effective surface modification is achieved without compromising the mechanical dimensions. For biomedical implants, a higher surface roughness is beneficial for promoting early-stage osseointegration [

25]. However, excessively rough surfaces may lead to debris entrapment and increased bacterial adhesion in vivo. Therefore, effective control of the surface topography through appropriate tuning of the laser parameters is essential to balance these competing outcomes. For the nanosecond laser samples, the hardness increased to approximately 391 HV and 390 HV at laser energies of 3965 and 5197 mJ/cm

2 for the 355 and 1064 nm laser systems, respectively. Similarly, for the femtosecond laser sample, the hardness increased to a maximum value of 404 HV at an energy intensity of 1839 mJ/cm

2. The present findings are consistent with those of Dunn [

26], who reported that the use of a nanosecond laser to modify stainless steel surfaces induced the formation of an oxide layer at higher laser energy densities, which increased the surface hardness. A higher surface hardness reduces scratching, abrasion, and micro-motion-induced wear during joint articulation; therefore, it plays a key role in extending the functional lifespan of bio-implants in vivo [

27].

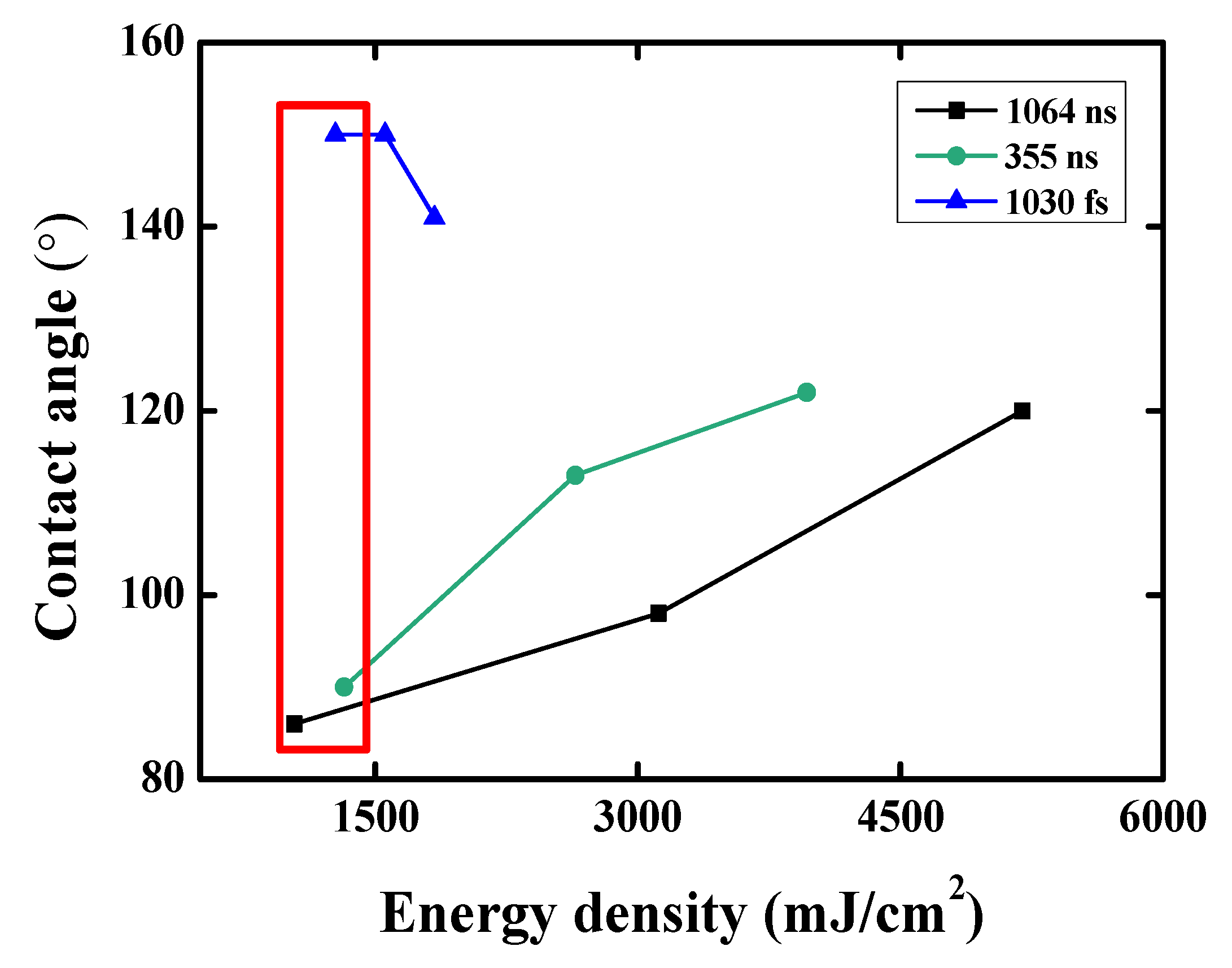

In our previous study [

20], a similar trend was observed. The transition to a steady-state hydrophobic condition occurred more slowly than that for the samples processed at a lower laser power, but the final wettability of the surface increased. The initial hydrophilicity of the samples after laser treatment can be attributed to the formation of reactive oxides on their surfaces. In contrast, the contact angle of the femtosecond-treated sample decreased sharply as the energy density increased. Exir [

28] reported that femtosecond laser processing, followed by aging, tends to increase the contact angles of alloys over time due to the gradual adsorption of organic matter on the surface and the entrapment of air in the periodic surface structures. Thus, in the present study, the reduction in the contact angle of the sample processed using the femtosecond laser system was most probably due to the loss of the LIPSS structures at higher energy densities, which led to the release of trapped air and a corresponding reduction in the surface hydrophobicity. The results in

Figure 7 suggest that the surface wettability of CoCrMo implants can be tuned to suit specific clinical priorities, such as promoting cell attachment or minimizing bacterial adhesion, through appropriate control of the laser processing conditions. Li [

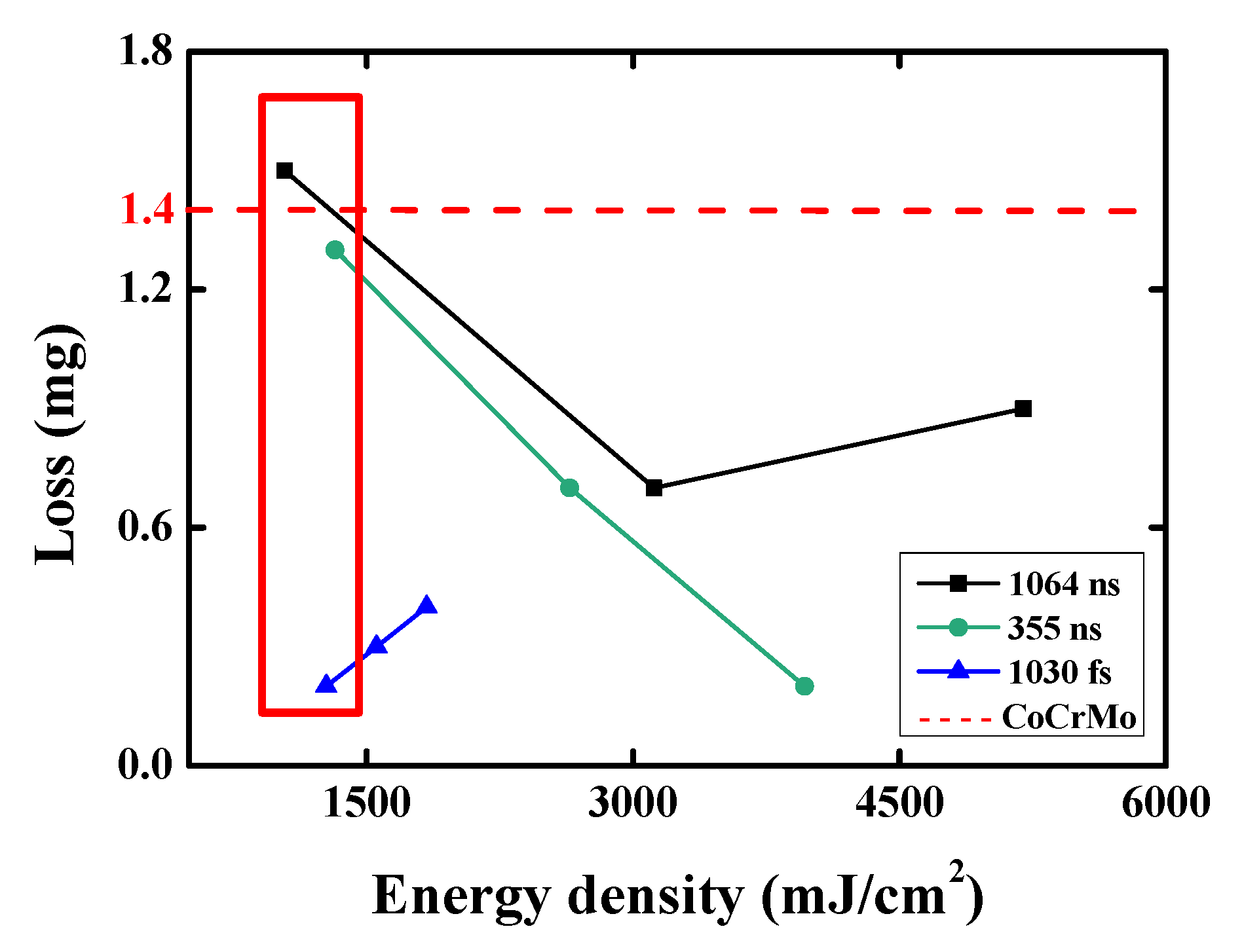

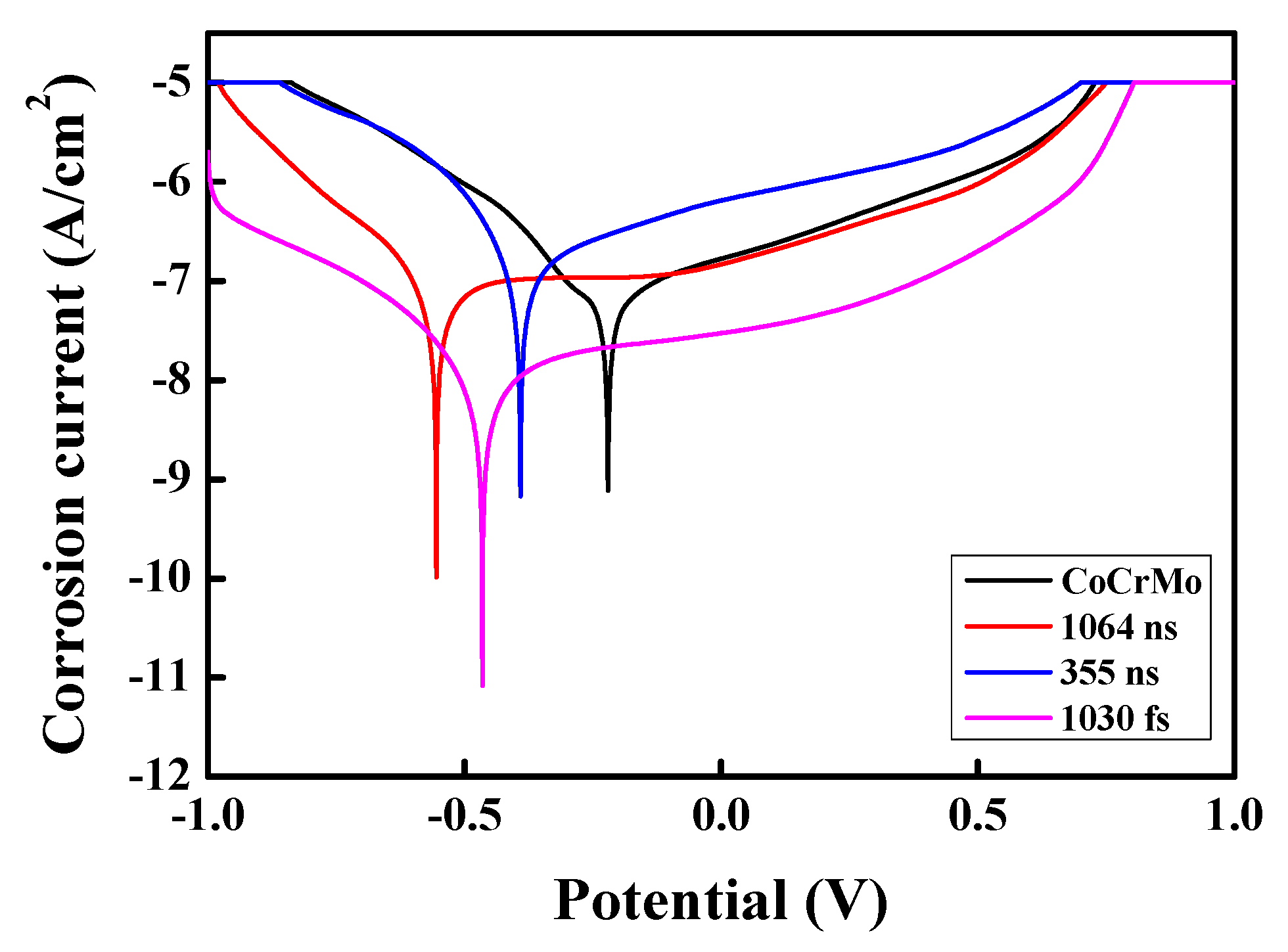

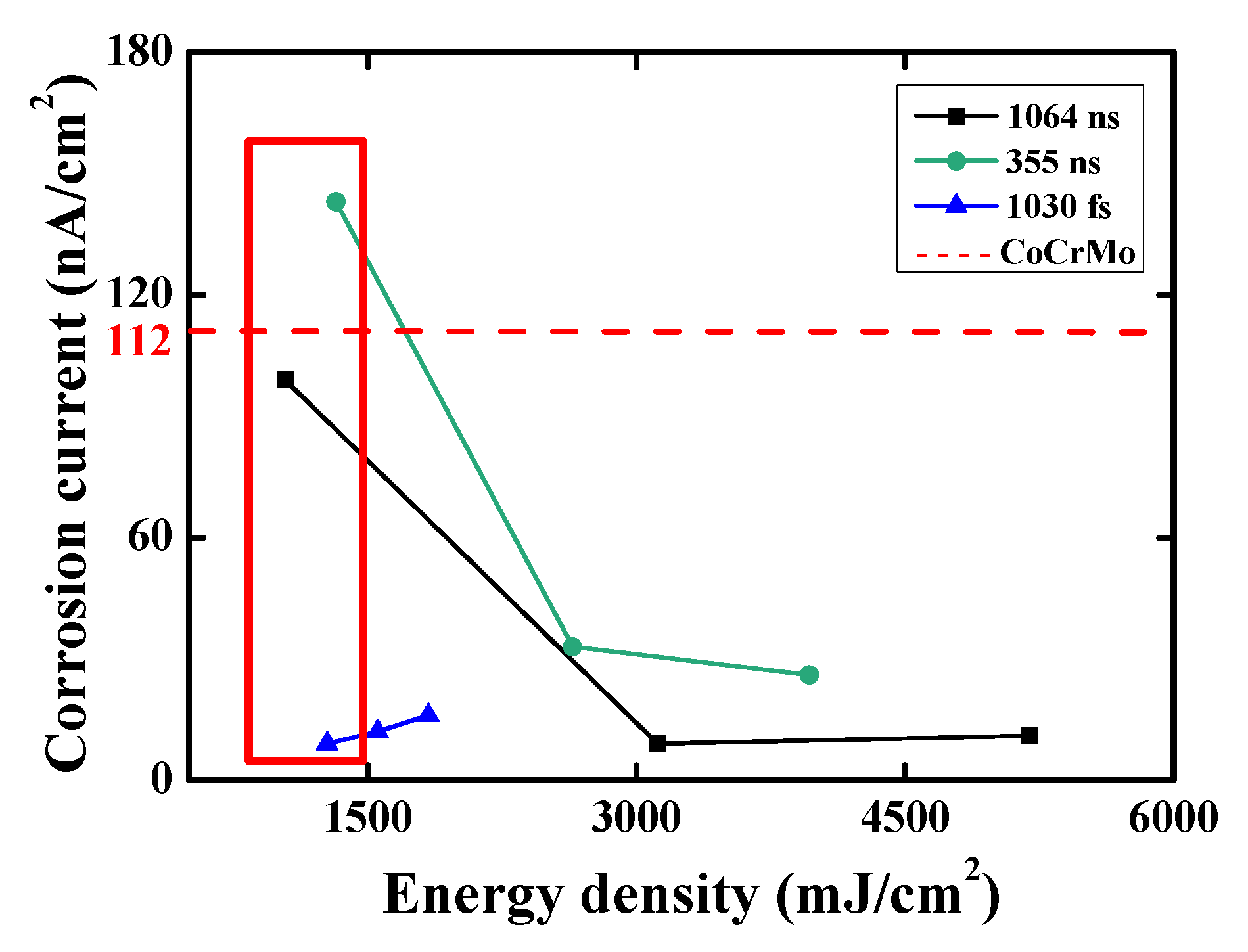

29] found that laser treatment followed by annealing enhanced the corrosion resistance of H59 brass alloy by forming air pockets within the laser-induced structures. These air gaps acted as protective barriers, reducing contact between the corrosive medium and the alloy surface. Therefore, better corrosion resistance can be achieved owing to the superhydrophobic surface. Overall, the findings in

Figure 11 show that femtosecond laser treatment provides excellent corrosion resistance, even without the formation of an oxide layer. This suggests that physical factors, such as surface geometry and wetting behavior, can be as influential as chemical passivation in determining the electrocorrosion properties of the CoCrMo alloy. In contrast, nanosecond laser treatment requires higher energy densities to achieve similar results, with the performance improvement being mainly the result of surface oxide formation. As shown in

Figure 11, irrespective of the laser system employed, a higher contact angle led to a lower corrosion current density, indicating improved corrosion resistance. This finding is reasonable since a higher contact angle reduces the wetted surface area exposed to the electrolyte, thereby limiting electrochemical activity and ion exchange. Moreover, the results in

Figure 8,

Figure 9,

Figure 10 and

Figure 11 demonstrate that, through appropriate control of the laser parameters and thermal annealing process (temperature and duration), the surface properties of CoCrMo implants can be precisely tuned to enhance wear resistance, corrosion protection, and wettability, thereby improving their performance in vivo.

Finally, the corrosion resistance properties of the CoCrMo samples subjected to combined laser processing and heat treatment were compared with those reported in the literature using two methods: (1) a direct comparison of the corrosion current and (2) a protection efficiency metric, defined as

where I

0 is the corrosion current before treatment and I is the corrosion current after treatment.

A comparison of the corrosion performance of the current CoCrMo samples with the results presented in

Table 2 [

30,

31,

32,

33,

34,

35,

36,

37,

38] shows that some of the doped alloys in the literature, such as CoCrMoCu, exhibited a low corrosion current of 29.1 nA/cm

2. In the present study, the samples treated using the 1064-ns and 1030-fs laser systems and then annealed at 160 °C showed similar values (36 nA/cm

2). Since the initial current values varied across the different studies, the protection efficiency was considered to provide a more consistent basis for comparison. The protection efficiency was approximately 92% for the 1064-ns sample, 77% for the 355-ns sample, and 92% for the 1030-fs sample. These values are all close to those of the DLC coatings reported in the literature (up to 97.3%). In other words, laser processing combined with heat treatment provides an effective approach for enhancing the corrosion resistance of CoCrMo implants, with optimized nanosecond laser systems achieving performance similar to that of femtosecond systems.

Author Contributions

H.-K.L.: conceptualization, writing—original draft, writing—review & editing, and funding acquisition. P.-W.C.: methodology, investigation, data curation, and writing—original draft. Y.-M.D.: investigation, formal analysis. Y.-T.L.: formal analysis and writing—review & editing. Y.-J.C.: investigation, formal analysis. W.-H.L.: conceptualization, writing—review & editing. All authors have discussed the results and commented on the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Council, ROC, under Project No. NSTC 114-2221-E-020-016.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, Z. Advancements of biomaterial in hip replacement technology incorporating ceramic materials. J. Orthop. 2025, 62, 27–35. [Google Scholar] [CrossRef]

- Long, M.; Rack, H. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Hermawan, H.; Ramdan, D.; Djuansjah, J.R. Metals for biomedical applications. Biomed. Eng.-Theory Appl. 2011, 1, 411–430. [Google Scholar]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Buford, A.; Goswami, T. Review of wear mechanisms in hip implants: Paper I—General. Mater. Des. 2004, 25, 385–393. [Google Scholar] [CrossRef]

- Saldívar-García, A.; López, H. Microstructural effects on the wear resistance of wrought and as-cast Co-Cr-Mo-C implant alloys. J. Biomed. Mater. Res. Part A 2005, 74, 269–274. [Google Scholar] [CrossRef]

- Liao, Y.; Pourzal, R.; Stemmer, P.; Wimmer, M.; Jacobs, J.; Fischer, A.; Marks, L. New insights into hard phases of CoCrMo metal-on-metal hip replacements. J. Mech. Behav. Biomed. Mater. 2012, 12, 39–49. [Google Scholar] [CrossRef]

- Lashgari, H.; Zangeneh, S.; Hasanabadi, F.; Saghafi, M. Microstructural evolution during isothermal aging and strain-induced transformation followed by isothermal aging in Co-Cr-Mo-C alloy: A comparative study. Mater. Sci. Eng. A 2010, 527, 4082–4091. [Google Scholar] [CrossRef]

- Toh, S.M.S.; Ashkanfar, A.; English, R.; Rothwell, G. Computational method for bearing surface wear prediction in total hip replacements. J. Mech. Behav. Biomed. Mater. 2021, 119, 104507. [Google Scholar] [CrossRef] [PubMed]

- Qiang, L.; Zhang, B.; Zhou, Y.; Zhang, J. Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci. 2013, 20, 17–22. [Google Scholar] [CrossRef]

- Kusmanov, S.; Silkin, S.; Smirnov, A.; Belkin, P. Possibilities of increasing wear resistance of steel surface by plasma electrolytic treatment. Wear 2017, 386, 239–246. [Google Scholar] [CrossRef]

- Wagner, J.; Mitterer, C.; Penoy, M.; Michotte, C.; Wallgram, W.; Kathrein, M. The effect of deposition temperature on microstructure and properties of thermal CVD TiN coatings. Int. J. Refract. Met. Hard Mater. 2008, 26, 120–126. [Google Scholar] [CrossRef]

- Liao, L.; Gao, R.; Yang, Z.; Wu, S.; Wan, Q. A study on the wear and corrosion resistance of high-entropy alloy treated with laser shock peening and PVD coating. Surf. Coat. Technol. 2022, 437, 128281. [Google Scholar] [CrossRef]

- Pan, X.; Zhou, L.; Hu, D.; He, W.; Liu, P.; Yu, Z.; Liang, X. Superior wear resistance in cast aluminum alloy via femtosecond laser induced periodic surface structures and surface hardening layer. Appl. Surf. Sci. 2023, 636, 157866. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, L.; Cai, Z.; Luo, S.; Pan, X.; Zhou, J.; He, W. Research on the mechanism of DD6 single crystal superalloy wear resistance improvement by femtosecond laser modification. Appl. Surf. Sci. 2022, 577, 151691. [Google Scholar] [CrossRef]

- Ngo, C.-V.; Chun, D.-M. Fast wettability transition from hydrophilic to superhydrophobic laser-textured stainless steel surfaces under low-temperature annealing. Appl. Surf. Sci. 2017, 409, 232–240. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Yang, L.; Ding, X.; Zhou, Y. Femtosecond laser induced periodic nanostructures towards enhanced anti-corrosive property of titanium. Surf. Coat. Technol. 2023, 463, 129533. [Google Scholar] [CrossRef]

- Lin, H.-K.; Yang, S.-J.; Chang, P.-W.; Lu, W.-H.; Chang, Y.-J. Effects of laser patterning and heat treatment on hydrophobicity, wear, and corrosion resistance of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2025, 137, 5511–5520. [Google Scholar] [CrossRef]

- Vaghasiya, H.; Miclea, P.-T. Investigating Laser-Induced Periodic Surface Structures (LIPSS) Formation in Silicon and Their Impact on Surface-Enhanced Raman Spectroscopy (SERS). Optics 2023, 4, 538–550. [Google Scholar] [CrossRef]

- Fava, A.; Kaciulis, S.; Mezzi, A.; Montanari, R.; Palombi, A.; Varone, A. XPS Study of Co28Cr6Mo Biocompatible Alloy. Surf. Interface Anal. 2025. [Google Scholar] [CrossRef]

- Cui, M.; Huang, C.; Jiang, Q.; Xiao, R.; Huang, T. Understanding the effect of oxide accumulation on femtosecond laser machining of nickel-based superalloy alloy. Appl. Surf. Sci. 2025, 705, 163543. [Google Scholar] [CrossRef]

- Earl, C.; Castrejón-Pita, J.; Hilton, P.; O’Neill, W. The dynamics of laser surface modification. J. Manuf. Process. 2016, 21, 214–223. [Google Scholar] [CrossRef]

- Hong, T.F. Laser Surface Modification for Rapid Oxide Layer Formation on Ti-6Al-4V. J. Laser Micro/Nanoeng. 2014, 9, 64–67. [Google Scholar] [CrossRef]

- Dunn, A.; Carstensen, J.V.; Wlodarczyk, K.L.; Hansen, E.B.; Gabzdyl, J.; Harrison, P.M.; Shephard, J.D.; Hand, D.P. Nanosecond laser texturing for high friction applications. Opt. Lasers Eng. 2014, 62, 9–16. [Google Scholar] [CrossRef]

- Moghadasi, K.; Isa, M.S.M.; Ariffin, M.A.; Mohd jamil, M.Z.; Raja, S.; Wu, B.; Yamani, M.; Muhamad, M.R.B.; Yusof, F.; Jamaludin, M.F.; et al. A review on biomedical implant materials and the effect of friction stir based techniques on their mechanical and tribological properties. J. Mater. Res. Technol. 2022, 17, 1054–1121. [Google Scholar] [CrossRef]

- Exir, H.; Weck, A. Mechanism of superhydrophilic to superhydrophobic transition of femtosecond laser-induced periodic surface structures on titanium. Surf. Coat. Technol. 2019, 378, 124931. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Y.; Jiang, Z.; Li, Y.; Wen, C.; Zhang, D.; Lian, J.; Zhang, Z. Improvement of corrosion resistance of H59 brass through fabricating superhydrophobic surface using laser ablation and heating treatment. Corros. Sci. 2021, 180, 109186. [Google Scholar] [CrossRef]

- Jakovljević, S.; Alar, V.; Ivanković, A. Electrochemical behaviour of PACVD TiN-coated CoCrMo medical alloy. Metals 2017, 7, 231. [Google Scholar] [CrossRef]

- Zhang, T.; Deng, Q.; Liu, B.; Wu, B.; Jing, F.; Leng, Y.; Huang, N. Wear and corrosion properties of diamond like carbon (DLC) coating on stainless steel, CoCrMo and Ti6Al4V substrates. Surf. Coat. Technol. 2015, 273, 12–19. [Google Scholar] [CrossRef]

- Xie, D.; Wang, H.; Ganesan, R.; Leng, Y.; Sun, H.; Huang, N. Fatigue durability and corrosion resistance of TiO2 films on CoCrMo alloy under cyclic deformation. Surf. Coat. Technol. 2015, 275, 252–259. [Google Scholar] [CrossRef]

- Gan, Y.; Zhou, M.; Ji, C.; Huang, G.; Chen, Y.; Li, L.; Huang, T.; Lu, Y.; Lin, J. Tailoring the tribology property and corrosion resistance of selective laser melted CoCrMo alloys by varying copper content. Mater. Des. 2023, 228, 111869. [Google Scholar] [CrossRef]

- Chen, S.; Wu, B.; Xie, D.; Jiang, F.; Liu, J.; Sun, H.; Zhu, S.; Bai, B.; Leng, Y.; Huang, N. The adhesion and corrosion resistance of Ti–O films on CoCrMo alloy fabricated by high power pulsed magnetron sputtering (HPPMS). Surf. Coat. Technol. 2014, 252, 8–14. [Google Scholar] [CrossRef]

- Corona-Gomez, J.; Sandhi, K.; Yang, Q. Wear and corrosion behaviour of nanocrystalline TaN, ZrN, and TaZrN coatings deposited on biomedical grade CoCrMo alloy. J. Mech. Behav. Biomed. Mater. 2022, 130, 105228. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Liu, B.; Wu, B.; Liu, J.; Sun, H.; Leng, Y.; Huang, N. The stability of DLC film on nitrided CoCrMo alloy in phosphate buffer solution. Appl. Surf. Sci. 2014, 308, 100–105. [Google Scholar] [CrossRef]

- Wang, R.; Wang, R.; Chen, D.; Qin, G.; Zhang, E. Novel CoCrWNi alloys with Cu addition: Microstructure, mechanical properties, corrosion properties and biocompatibility. J. Alloys Compd. 2020, 824, 153924. [Google Scholar] [CrossRef]

- Hu, Y.; Dong, C.; Kong, D.; Ding, J.; He, X.; Ni, X.; Zhang, L.; Li, X. Effects of post-production heat treatment on the mechanical and corrosion behaviour of CoCrMoW alloy manufactured through selective laser melting. Mater. Today Commun. 2021, 29, 102994. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).