The Role of Local Orientations Gradients in the Formation of the Recrystallisation Texture in Cold-Rolled IF Steel

Abstract

1. Introduction

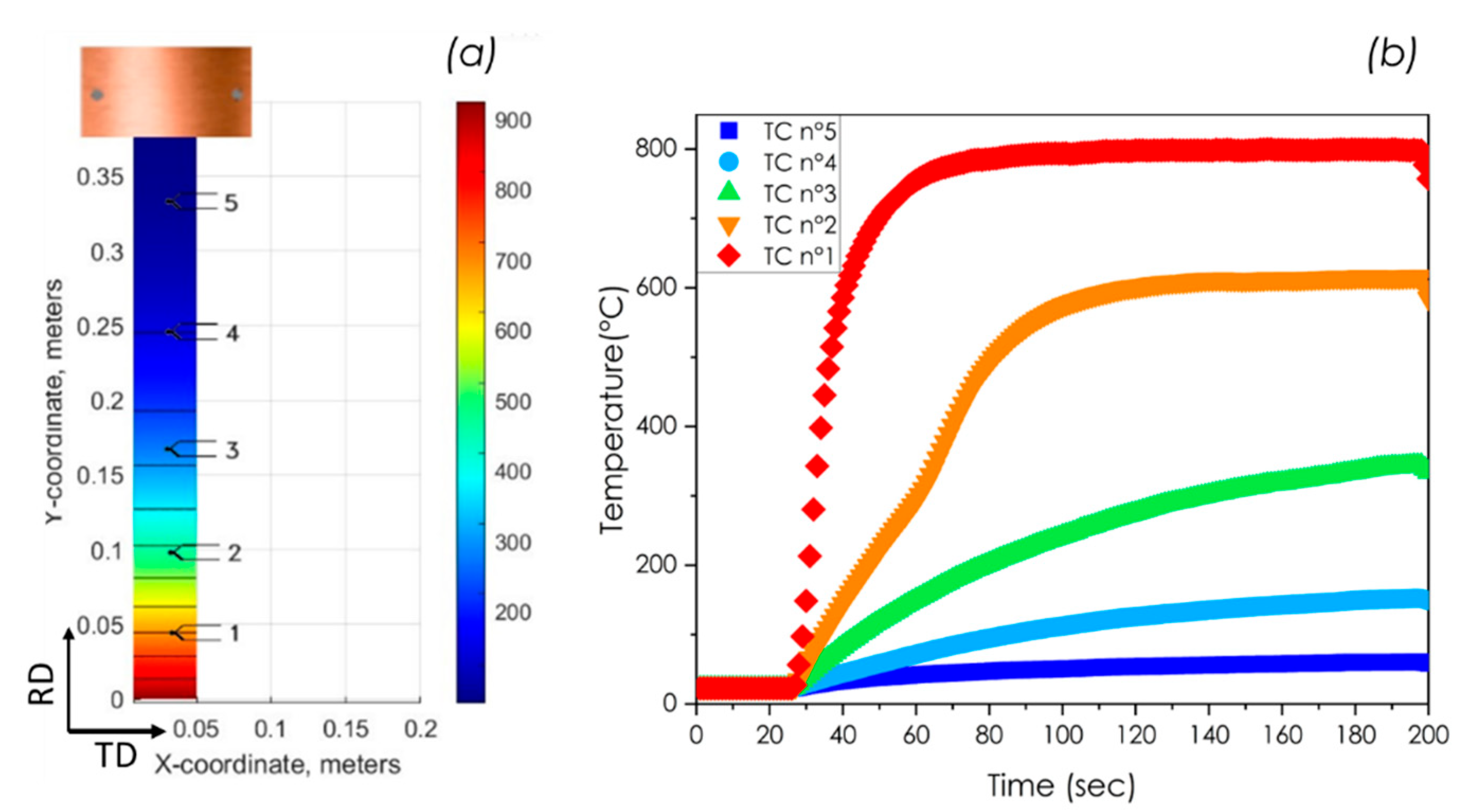

2. Materials and Methods

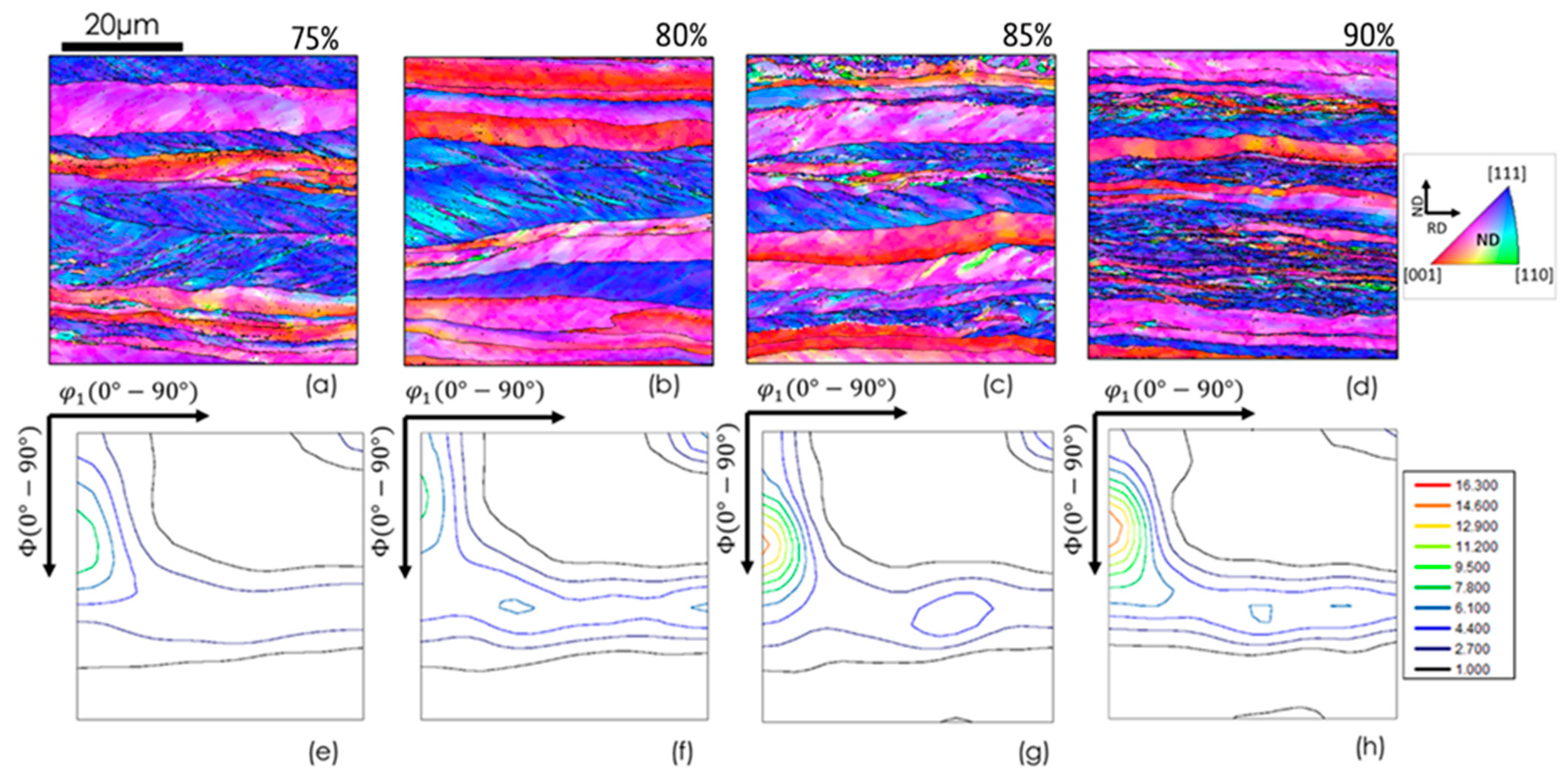

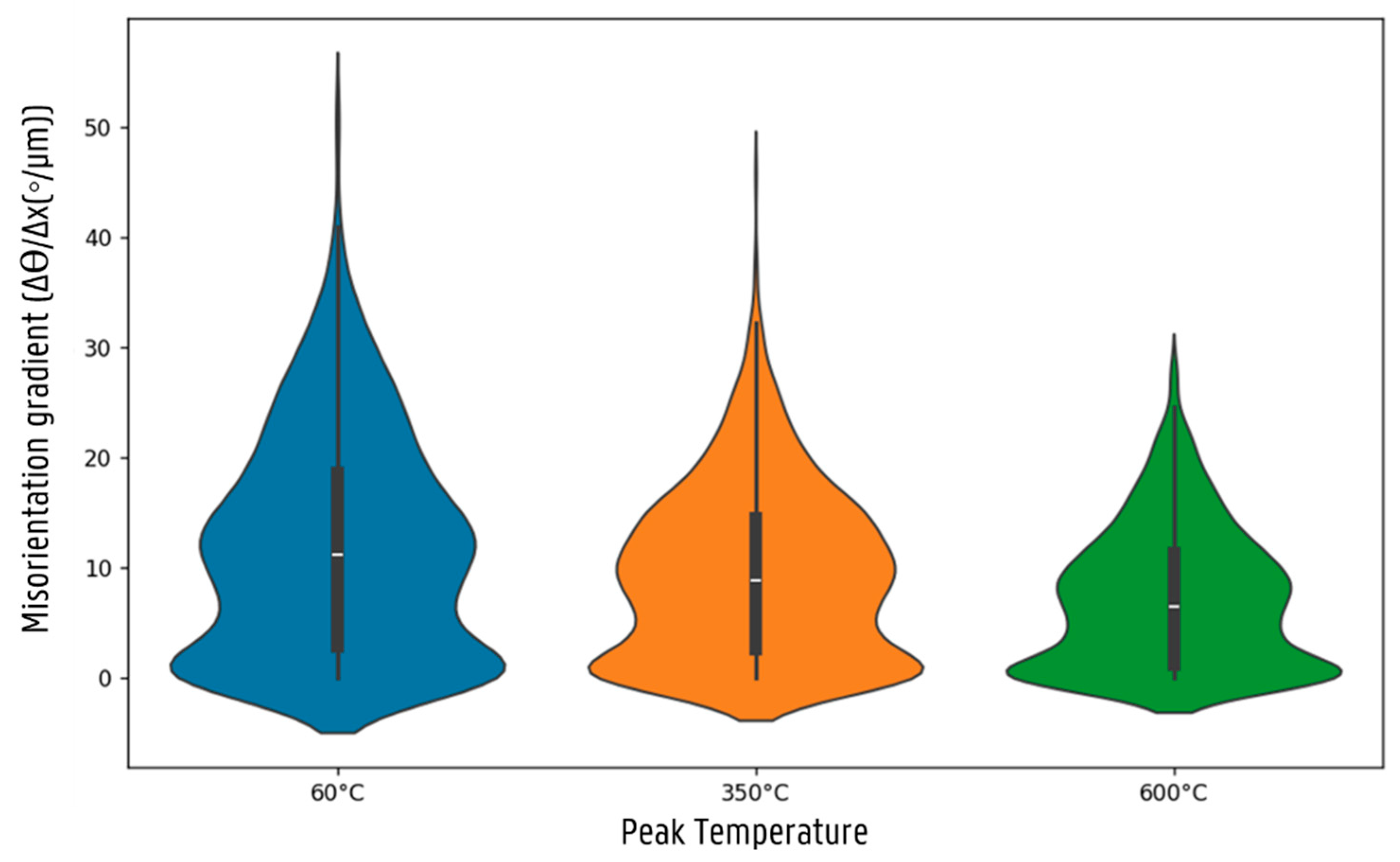

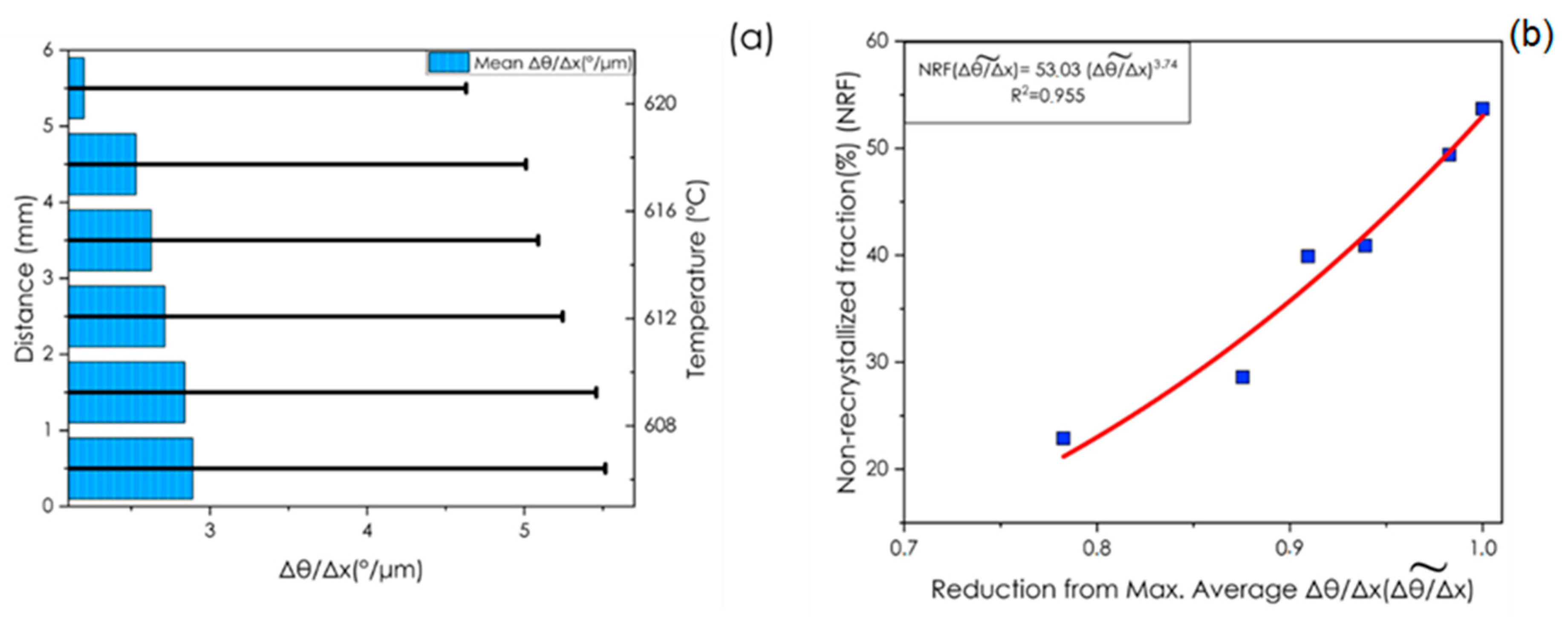

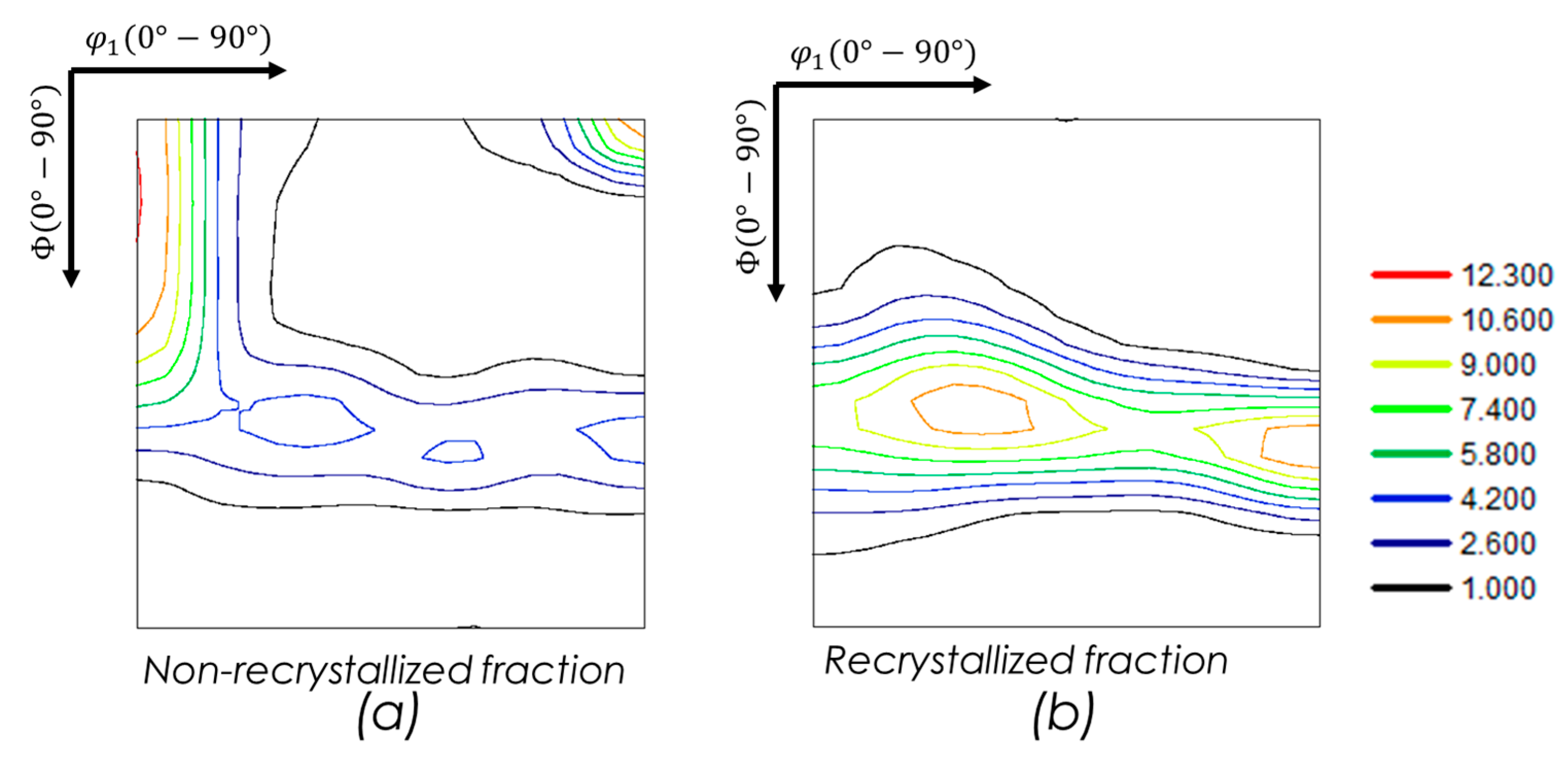

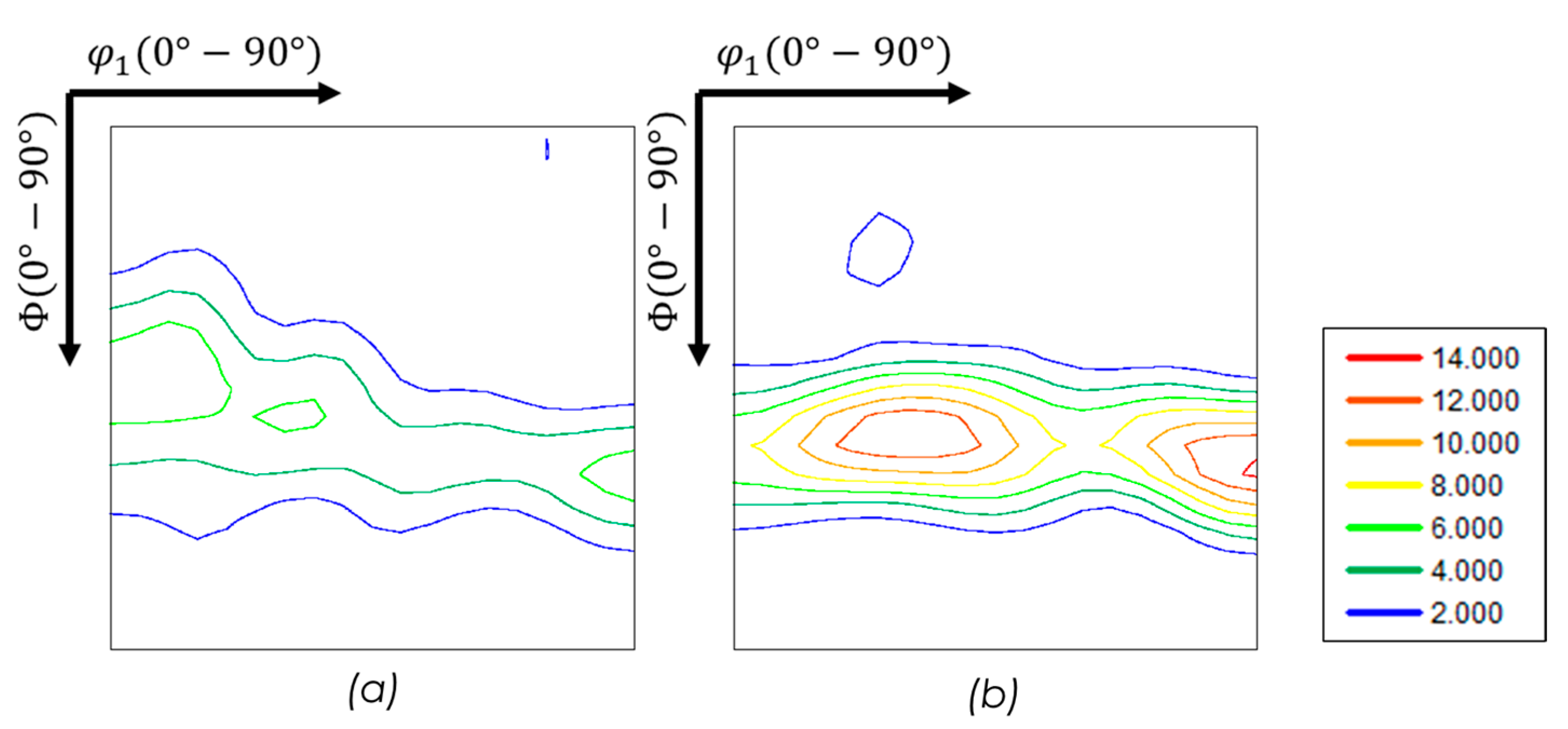

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, W.; Le Gall, R.; Saindrenan, G. A Study of the Recrystallization of an IF Steel by Kinetics Models. Mater. Sci. Eng. A 2002, 332, 41–46. [Google Scholar] [CrossRef]

- Saha, R.; Ray, R.K. Effect of Severe Cold Rolling and Annealing on the Development of Texture, Microstructure and Grain Boundary Character Distribution in an Interstitial Free (IF) Steel. ISIJ Int. 2008, 48, 976–983. [Google Scholar] [CrossRef]

- Massardier, V.; Ngansop, A.; Fabrègue, D.; Merlin, J. Identification of the Parameters Controlling the Grain Refinement of Ultra-Rapidly Annealed Low Carbon Al-Killed Steels. Mater. Sci. Eng. A 2010, 527, 5654–5663. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. About Quantitative EBSD Analysis of Deformation and Recovery Substructures in Pure Tantalum. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2015, 89, 012038. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical Analysis of Dislocations and Dislocation Boundaries from EBSD Data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Lanjewar, H.; Naghdy, S.; Verleysen, P.; Kestens, L.A.I. Statistical Analysis of Dislocation Substructure in Commercially Pure Aluminum Subjected to Static and Dynamic High Pressure Torsion. Mater. Charact. 2020, 160, 110088. [Google Scholar] [CrossRef]

- Nye, J.F. Some Geometrical Relations in Dislocated Crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the Geometrically Necessary Dislocation Content by Conventional Electron Backscattering Diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- EDAX, OIM Analysis Help: Charts; EDAX Inc.: Mahwah, NJ, USA, 2013.

- Kuwahara, M.; Hachimura, K.; Eiho, S.; Kinoshita, M. Processing of RI-Angiocardiographic Images. In Digital Processing of Biomedical Images; Springer: Boston, MA, USA, 1976. [Google Scholar]

- Humphreys, F.J. Grain and Subgrain Characterisation by Electron Backscatter Diffraction. J. Mater. Sci. 2001, 36, 3833–3854. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Bate, P.S.; Hurley, P.J. Orientation Averaging of Electron Backscattered Diffraction Data. J. Microsc. 2001, 201, 50–58. [Google Scholar] [CrossRef] [PubMed]

- Brough, I.; Bate, P.S.; Humphreys, F.J. Optimising the Angular Resolution of EBSD. Mater. Sci. Technol. 2006, 22, 1279–1286. [Google Scholar] [CrossRef]

- Ayad, A.; Ramoul, M.; Rollett, A.D.; Wagner, F. Quantifying Primary Recrystallization from EBSD Maps of Partially Recrystallized States of an IF Steel. Mater. Charact. 2021, 171, 110773. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Cabrera, J.M.; Najafizadeh, A.; Calvillo, P.R. EBSD Study of a Hot Deformed Austenitic Stainless Steel. Mater. Sci. Eng. A 2012, 538, 236–245. [Google Scholar] [CrossRef]

- Alvi, M.H.; Cheong, S.W.; Suni, J.P.; Weiland, H.; Rollett, A.D. Cube Texture in Hot-Rolled Aluminum Alloy 1050 (AA1050)-Nucleation and Growth Behavior. Acta Mater. 2008, 56, 3098–3108. [Google Scholar] [CrossRef]

- Rollett, A.D.; Wagner, F.; Allain-Bonasso, N.; Field, D.P.; Lebensohne, R.A. Comparison of Gradients in Orientation and Stress between Experiment and Simulation. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2012; Volume 702–703. [Google Scholar]

- Traka, K.; Sedighiani, K.; Bos, C.; Galan Lopez, J.; Angenendt, K.; Raabe, D.; Sietsma, J. Topological Aspects Responsible for Recrystallization Evolution in an IF-Steel Sheet—Investigation with Cellular-Automaton Simulations. Comput. Mater. Sci. 2021, 198, 110643. [Google Scholar] [CrossRef]

- Traka, K.; Hernández, E.S.; Nguyen-Minh, T.; Sedighiani, K.; Sietsma, J.; Kestens, L.A.I. Prediction of Different Recrystallisation Textures under a Single Unified Physics-Based Model Description. Comput. Mater. Sci. 2025, 246, 113425. [Google Scholar] [CrossRef]

- Urabe, T.; Jonas, J.J. Modeling Texture Change during the Recrystallization of an IF Steel. ISIJ Int. 1994, 34, 435–442. [Google Scholar] [CrossRef]

- De Siqueira, R.P.; Sandim, H.R.Z.; Raabe, D. Particle Stimulated Nucleation in Coarse-Grained Ferritic Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2013, 44, 469–478. [Google Scholar] [CrossRef]

- Beck, P.A.; Hu, H. Recrystallization, Grain Growth and Textures; American Society for Metals: Metals Park, OH, USA, 1966; pp. 393–433. [Google Scholar]

- Doherty, R.D.; Hughes, D.A.; Humphreys, F.J.; Jonas, J.J.; Juul Jensen, D.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current Issues in Recrystallization: A Review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

- Sepúlveda Hernández, E.; Nguyen-Minh, T.; Traka, K.; Castro Cerda, F.; Kestens, L.A.I. Orientation Dependence of Dynamic Compared to Static Recovery in Interstitial Free Steel. Scr. Mater. 2024, 249, 116151. [Google Scholar] [CrossRef]

- Gilbert, M.R.; Queyreau, S.; Marian, J. Stress and Temperature Dependence of Screw Dislocation Mobility in α-Fe by Molecular Dynamics. Phys. Rev. B Condens. Matter. Mater. Phys. 2011, 84, 174103. [Google Scholar] [CrossRef]

- Rios, P.R.; Siciliano, F.; Sandim, H.R.Z.; Plaut, R.L.; Padilha, A.F. Nucleation and Growth during Recrystallization. Mater. Res. 2005, 8, 225–238. [Google Scholar] [CrossRef]

- Furu, T.; Ørsund, R.; Nes, E. Subgrain Growth in Heavily Deformed Aluminium-Experimental Investigation and Modelling Treatment. Acta Metall. Mater. 1995, 43, 2209–2232. [Google Scholar] [CrossRef]

- Castro Cerda, F.M.; Kestens, L.A.I.; Monsalve, A.; Petrov, R.H. The Effect of Ultrafast Heating in Cold-Rolled Low Carbon Steel: Recrystallization and Texture Evolution. Metals 2016, 6, 288. [Google Scholar] [CrossRef]

- Castro Cerda, F.M.; Kestens, L.A.I.; Petrov, R.H. “Flash” Annealing in a Cold-Rolled Low Carbon Steel Alloyed with Cr, Mn, Mo, and Nb: Part II—Anisothermal Recrystallization and Transformation Textures. Steel Res. Int. 2019, 90, 1800277. [Google Scholar] [CrossRef]

| C | Mn | Al | N | Ti |

|---|---|---|---|---|

| 0.002 | 0.095 | 0.05 | 0.002 | 0.045 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, E.A.S.; Castro Cerda, F.M.; Kestens, L.A.I. The Role of Local Orientations Gradients in the Formation of the Recrystallisation Texture in Cold-Rolled IF Steel. Metals 2025, 15, 939. https://doi.org/10.3390/met15090939

Hernández EAS, Castro Cerda FM, Kestens LAI. The Role of Local Orientations Gradients in the Formation of the Recrystallisation Texture in Cold-Rolled IF Steel. Metals. 2025; 15(9):939. https://doi.org/10.3390/met15090939

Chicago/Turabian StyleHernández, Estefania A. Sepulveda, Felipe M. Castro Cerda, and Leo A. I. Kestens. 2025. "The Role of Local Orientations Gradients in the Formation of the Recrystallisation Texture in Cold-Rolled IF Steel" Metals 15, no. 9: 939. https://doi.org/10.3390/met15090939

APA StyleHernández, E. A. S., Castro Cerda, F. M., & Kestens, L. A. I. (2025). The Role of Local Orientations Gradients in the Formation of the Recrystallisation Texture in Cold-Rolled IF Steel. Metals, 15(9), 939. https://doi.org/10.3390/met15090939