Abstract

In this study, solid particle erosion tests were conducted to evaluate the resistance of AISI 4340 (EN24) and 8620 alloy steels against silicon carbide (SiC). These steels were selected due to their high hardness, yield strength (σy), ultimate tensile strength (σuts) and elongation (%), which are significant parameters, influencing wear resistance. An erosion rig based on the ASTM G76-95 standard was used to perform the testing. Tests were carried out using different impact angles, 30°, 45°, 60° and 90°, with a particle velocity of 24 ± 2 m/s. The abrasive flow rate was 0.7 ± 0.5 g/min and the temperature was between 35 °C and 40 °C. Characterization techniques such as SEM were employed to identify the chemical composition of AISI 4340 and AISI 8620 steels and optical microscopy to determine the morphology of SiC abrasive particles. In addition, the SiC particle size was between 350 and 450 µm; it was determined by the particle size distribution technique. SEM micrographs were obtained to classify the wear mechanisms, characterized by micro-cutting, micro-ploughing, grooves, pitting actions and embedded particles on the surface at 30° and 90°. The results showed that AISI 8620 steel exhibited higher erosion resistance than AISI 4340 steel. Finally, AFM was used to evaluate the roughness variations before and after erosion tests, specifically in the central zone of the wear scars at 30° and 90° for both materials.

1. Introduction

Solid particle erosion is a wear process that occurs by the impingement of particles of different characteristics (hardnesses, sizes and shapes). As these particles strike a surface at different impact angles and particle velocities, they will progressively cause material removal from the surfaces, inflicting various wear mechanisms on mechanical elements and therefore material failure in a ductile or brittle manner. Due to this, several investigations have been carried out to evaluate the erosion resistance of different alloy steels with significant mechanical properties, such as AISI 4340 and AISI 8620, which have good performance due to having high hardness, yield strength, ultimate tensile strength, ductility (% elongation), work hardening ability and toughness. These alloy steels are employed to manufacture some mechanical elements exposed to erosive wear. Some examples are ploughshares, duck foot sweeps, sweep blades, rotavator blades for tillage tools, mining machinery gears and shafts, and parts for the plastics and rubber molding industry. With respect to the research works, Yang et al. [1] conducted interesting research work about the erosion wear of pipe steel for hydraulic fracturing. This was because this type of material is permanently subject to a high-pressure working environment and high-speed solid particles in the fluid. For this reason, AISI 4135 steel, with notorious mechanical properties, was used to conduct the erosion tests to analyze the effects of impact angle, particle velocities and applied stresses on surfaces. In this particular case, the specimens were subjected to tensile stresses at the same time as the abrasive particles impinged the surfaces of the steel alloy. This was intended to simulate the high-pressure conditions inside a pipe steel. AISI 4135 exhibited its maximum erosion rate at 30° and the erosion damage was reduced considerably as the impact angle was increased. The erosion rate and wear mechanisms were more pronounced as the applied stresses were amplified. The wear mechanisms inflicted on the steel surfaces showed that the sand particles mostly caused micro-cutting actions leading to the formation of furrows with lips in the front of the eroded area at a 30° impact angle. In contrast, typical craters due to plastic extrusion were observed at a higher impact angle, 90°. Then, Deng et al. [2] carried out research using a centrifugal accelerator type erosion tester on EN24 steel specimens. In this particular work, glass beads (spherical) and crushed glass beads (angular and irregular) were used to understand the effects of abrasive particle shapes on erosion rates. Although the test equipment was different from common sandblasting erosion rigs, the results indicated that the EN24 steel samples showed higher erosion rates as the angular crushed glass beads impacted the surfaces compared to the much smaller damage caused by the spherical particles. This trend was observed at all incidence angles used in the tests. The erosion rates were higher at low impact angles, between 12.5° and 32.5°, and were permanently reduced up to an impact angle of 62.5°. The wear mechanisms identified by SEM were severe cutting actions combined with ploughing actions as angular particles impacted the surfaces. In relation to the damage caused by spherical particles, they were primarily caused by ploughing actions, with material piled up on the sides and lips of material accumulating at the front of the impact craters. Foley & Levy [3] conducted a study about the solid particle erosion on heat-treated steels such as AISI 1020, AISI 304 SS and AISI 4340 steel to evaluate their performance against erosion caused by alumina particles. AISI 1020 steel was heat-treated to analyze how the microstructure modifications and therefore the mechanical properties could help to increase the erosion resistance. Furthermore, AISI 304 SS was tested in the as-received and annealed conditions and AISI 4340 steel was austenitized, quenched in oil and then tempered to reach high toughness values. With respect to the erosion results for AISI 304, this material exhibited a higher erosion resistance in its annealed condition. Then, AISI 1020 steel showed that the erosion resistance was increased as the sample hardness was reduced. AISI 4340 steel in the annealed condition showed slightly better erosion resistance than AISI 4340 in the as-quenched, tempered at 200 °C and tempered at 500 °C conditions. This steel showed higher elongation and reduction in area percentages in the annealed condition. All the tested heat-treated steels exhibited ductile behavior, reaching their maximum erosion rates at 30°, and the erosion damage decreased considerably at 90°. The most meaningful outcome in this paper was that ductility and malleability are significant mechanical properties that increase the erosion resistance of alloy steels. In addition, Chauhan et al. [4] performed research to determine the erosion resistance of 13Cr–4Ni martensitic stainless steel (as-cast) and 21Cr–4Ni–N nitronic steel (in as-cast and hot-rolled conditions), which are employed to manufacture hydro turbine underwater parts that are exposed to severe erosion damage. In this particular erosion work, the erosion rates for all materials were higher at 90° after 2 h, and this was related to the deep holes seen on the surfaces due to strain hardening and embrittlement of the materials. The erosion damage at 30° was mainly characterized by shallow ploughing actions on the surfaces which led to lower erosion rates. Higher erosion resistance was observed with 21Cr–4Ni–N nitronic steel in the hot-rolled condition since this material possessed the highest values of yield strength, ultimate tensile strength, ductility and hardness in comparison to the other two tested materials. Rodríguez et al. [5] carried out a study about the erosive wear caused by sand particles on AISI H13 and 4140 steels in the annealed and tempered martensitic conditions. According to the results obtained in this study, they showed that in most cases the erosion rates were higher between the impact angles of 30° and 40° in both alloy steels with low and medium hardness (165–513 HV). On the other hand, a transition from ductile to brittle behavior could be seen with the specimens of both steels with the highest hardness (~595 HV). In this case, the maximum erosion rates of these samples were reached at 60°. The erosion mechanisms identified on AISI H13 were grooves on the impinged surfaces at 10°. These grooves became more intense as the material hardness became lower (from 595 HV to 294 HV). With respect to the erosion damage at 30°, it was characterized by the plastic deformation of material with lower hardness (294 HV); the wear mechanisms were lips, metal chips nearly torn off the surface, embedded silica fragments and micro-cutting actions on the surfaces. In addition, craters and pits on the surfaces were observed at 90°. In this work, solid particle erosion tests were carried out to assess the erosion resistance of two alloy steels, that are tough and have significant mechanical properties that could contribute to reducing the erosion rate of mechanical elements, AISI 4340 and 8620, against silicon carbide (SiC) particles. In previous erosion works, material ductility played an important role in increasing the erosion resistance of different alloy steels. It was related to the greater capacity of ductile metals to deform plastically in a more permanent form before exceeding their yield strength. The SiC abrasive was used to subject these two materials to high erosive testing conditions and determine their erosion rates in accordance with ASTM G76.

2. Materials and Methods

The most important mechanical properties of both alloy steels, AISI 4340 and AISI 8620, are listed in Table 1. These properties correspond to the following heat treatment conditions. With respect to the AISI 4340 steel [6], it was heated up to roughly 850 °C for 30 min (austenitized), quenched by oil to obtain the martensite structure and then tempered at 400–500 °C for 2 h, whereas the AISI 8620 martensitic steel was heated at 850 °C austenitizing temperature, quenched in oil and then tempered at between 200 and 300 °C [7]. Both materials were supplied in the form of standard steel strips (25 mm wide and 3 mm thick) and then cut carefully with a hacksaw crosswise to achieve 50 mm length to acquire the sample dimensions 50 mm × 25 mm and 3 mm in thickness to be fixed in the sample holder of the erosion rig. The chemical composition of both alloy steels was obtained by Energy-Dispersive X-ray analysis (EDS), and this is presented in Table 2. Additionally, Vickers hardness tests were carried out using a durometer (Microhardness Tester LECO LM 700, LECO Corporation, Mexico City, Mexico.). The applied load to the Vicker’s indentor (square-based diamond pyramid) was 100 gf, whereas the dwell time was 15 s. An average hardness value was obtained after five measurements for each tested material. The hardnesses of both steels are included in Table 1. With respect to the selected erodent, angular SiC particles were employed to accelerate the erosion damage on the material surfaces. The morphology of the SiC particles was angular and their chemical composition was 63.39 wt.% C and 36.61 wt.% Si. The hardness of SiC particles is between 2100 and 2300 HV according to the supplier. For this reason, silicon carbide was used to evaluate the performance and toughness of these materials under severe wear conditions. The particle size of silicon carbide was between 350 and 450 µm. It was obtained by using an Analysette 28 Image Analyzer (Fritsch, Mexico City, Mexico). The average particle size was 342 µm ± 127 for the first measurement (19,285 SiC particles). On the other hand, a second measurement (14,507 particles) was carried out, and the average particle size was 353 µm ± 136. The two measurements were very close. In addition, an Atomic Force Microscope (AFM), Veeco brand, Model diMultimode (Veeco, Mexico City, Mexico) was used to conduct a roughness analysis of the materials before and after erosion impacts to show the surface variations. This microscope can make records in areas of 5 × 5 µm2 and 10 × 10 µm2. It used a Bruker brand tip, supported by a cantilever beam. The tip material was silicon nitride.

Table 1.

Mechanical properties of steel alloys. Reprinted from Refs. [6,7].

Table 2.

Chemical compositions of steel alloys.

Test Procedure

The erosion tests were performed using an erosion rig, based on the ASTM G76-95 standard and other erosion works [8,9,10]. The total mass loss was defined for both materials after 10 min; however, each sample was removed to determine the partial mass loss every 2 min. The impact angles were 30°, 45°, 60° and 90°. Two tests for each incident angle were carried out for both alloy steels. An angle adjustment device was mounted on one side of the rotating bar (metric rotary); therefore, the orient angle of the specimen could fit between 0° and 90° with respect to the abrasive impact direction. In addition, a 60 psi air pressure and a particle velocity of 24 + 2 m/s were used to run the tests. In relation to the particle velocity, this was measured with an opto-electronic flight-timer similar to that described by Shipway & Hutchings [11]. The velocity measurement method mainly involves two infra-red emitters and detectors held by a rectangular plastic block. A few abrasive particles pass through a glass tube attached at the end of the nozzle and are recognized by both light beams producing the signals that are processed through an amplification system connected to an oscilloscope. It is possible to determine the real time travelled by a few abrasive particles using the two signals, 1 and 2. The standard distance between signals was 10 ± 1 mm. Flight time data were continuously collected and stored. An average particle velocity was reached after 20 measurements. The infra-red emitters were set on each side to ensure that most of the abrasive particles were monitored when passing through the glass tube [12]. In addition, a low abrasive flow rate of 0.7 ± 0.5 g/min was used to reduce the interaction effects between the incident and the rebounding particles. The abrasive flow rate was measured and controlled by collecting the abrasive for 1 min inside a closed container within the erosion chamber. Ten measurements were taken, and the average value of the abrasive collected during that time, along with the standard deviation, was considered the abrasive flow rate for the tests. In all tests, the specimens were located 10 mm from the end of the stainless-steel nozzle. The nozzle dimensions were 4.7 mm internal diameter, 6.3 mm external diameter and 260 mm length. The temperature was between 35° C and 40° C. The specimens were weighed using an analytical balance (with an accuracy of ± 0.0001 g) before the start of each test and removed every 2 min, cleaned by using acetone and weighed again to measure the mass loss amount. SEM model FE JEOL JSM-7600F (JEOL, Mexico City, Mexico) was used to obtain the micrographs to identify the wear mechanisms at different incident angles.

3. Results

3.1. Wear Scars

The wear scars produced on the steel surfaces are present in Figure 1. Here, it is possible to observe that the wear scars at 30° and 45° seemed deeper than these observed at 60° and 90°. This particular fact related well to the maximum erosion results, which were reached as the steel surfaces were impacted at these two oblique angles. The wear scars on 4340 steel were to some extent more pronounced than those observed on 8620 steel. In fact, the erosion rates of AISI 4340 steel were slightly higher than those obtained with AISI 8620. With respect to the morphology of the wear scars on both steels, a roughly elliptical shape was clearly depicted at 30° and 45° because the abrasive particles first impinged the steel surfaces and then these same particles slid over the surfaces causing greater wear damage. This has been reported in other erosion studies [13,14,15]. On the other hand, the wear scars at 60° and 90° showed a larger worn area (red circles); however, the damage was not as deep or pronounced as the wear scars at 30° and 45°. It is possible that the silicon carbide particles are fragmented during contact with the surfaces, causing some particles to reimpact the surfaces but outside the central contact zone. Another phenomenon that occurs at higher impact angles is the interference between rebounding and incoming particles, which can cause a number of incoming particles to not impinge on the surfaces. This shielding effect was mentioned by different authors [16,17].

Figure 1.

Wear scars on both alloy steels caused by the angular SiC particles.

3.2. Erosion on Surfaces of AISI 4340 and AISI 8620

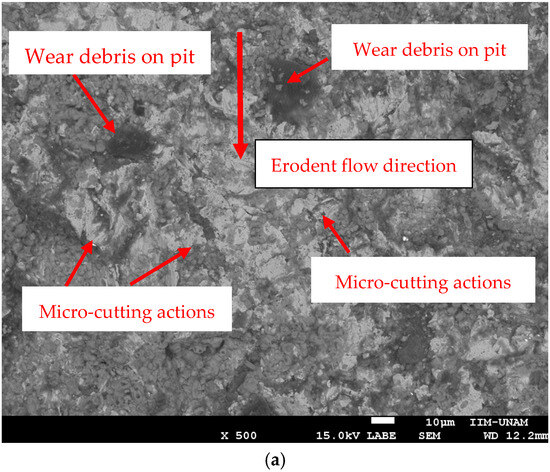

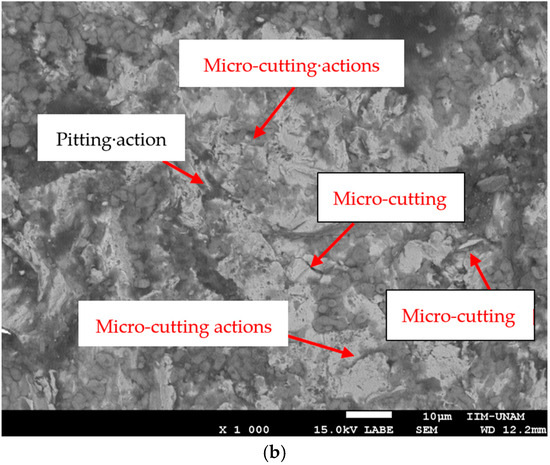

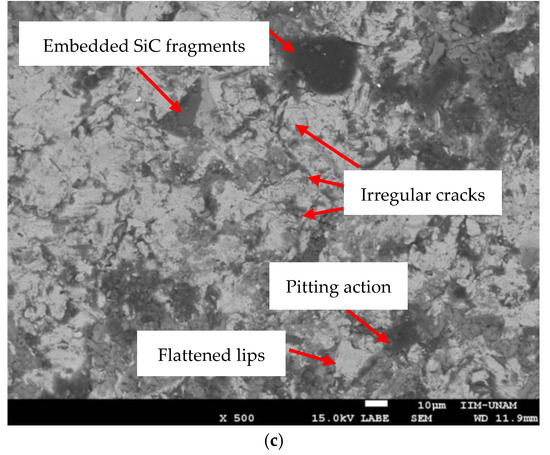

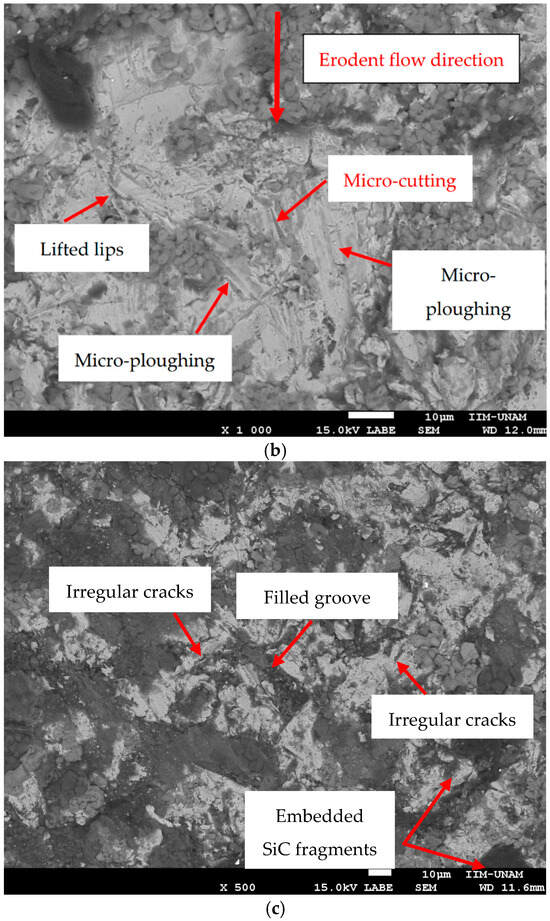

Figure 2 displays the SEM micrographs of the erosion damage caused by SiC on AISI 4340 steel. In Figure 2a,b, it is possible to observe different wear mechanisms such as pits filled with wear debris, probably caused by the first and direct impacts of the abrasive particle stream, which led to removal of material that was flattened on the material surfaces at 30° and 45°. In addition, the micro-cutting actions were occasioned by the subsequent contacts of the particles due to sliding along the surfaces. These wear mechanisms are well related to those observed in other erosion works [1,18,19,20,21,22]. In relation to the erosion damage at 90° (Figure 2c), different erosion mechanisms were present; embedded SiC fragments were observed in the worn region, which is a common mechanism at high impact angles due to the vertical component of the particle stream; irregular cracks were caused by vertical and random impacts on the steel surface [14]. Pitting action was also seen on the surfaces.

Figure 2.

Erosion damage on AISI 4340 surfaces: (a) 30°, (b) 45°, (c) 90°.

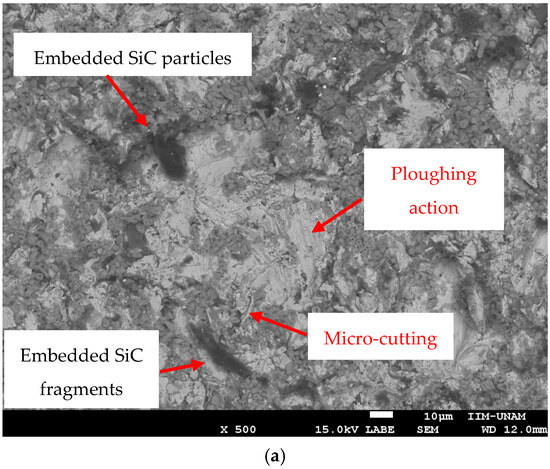

With respect to the erosion damage on AISI 8620 steel, the wear mechanisms were quite similar to those observed on AISI 4340 surfaces and in other erosion studies [18,19]. Figure 3a,b show embedded SiC fragments in different locations, abrasive particle residues and micro-cutting and ploughing actions in randomly located positions at 30° and 45° incidence angles. In contrast, irregular cracks, filled grooves and embedded SiC chunks are visible at normal incidence, 90° (Figure 3c). In this particular case, this material presented a higher erosion resistance compared to AISI 4340 steel.

Figure 3.

Erosion damage on AISI 8620 surfaces: (a) 30°, (b) 45°, (c) 90°.

3.3. Mass Loss and Total Erosion Results

The mass loss results (Table 3) of the test materials were obtained using the following formula:

Mass loss = Initial weight − Weight lost every 2 min,

Table 3.

Mass loss (g) and total erosion rate (g/g) results.

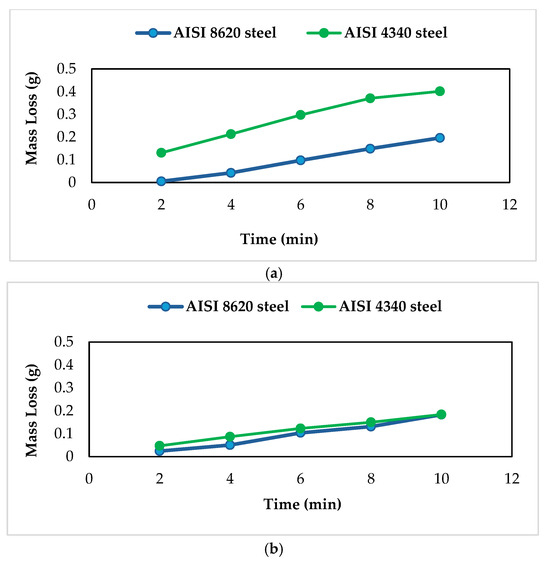

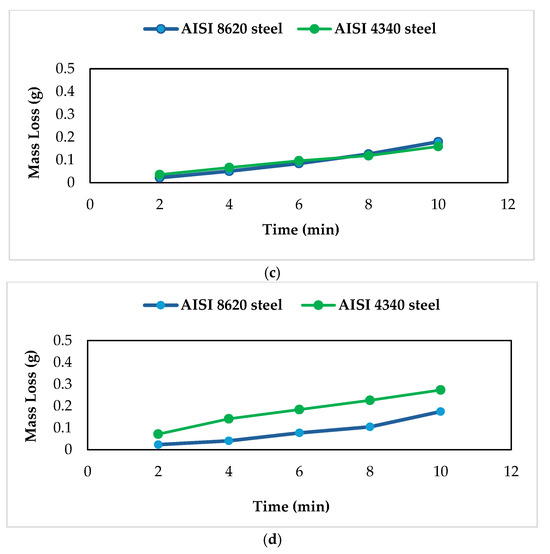

To accomplish this, it was necessary to obtain the initial weight of each sample before erosion testing. Subsequently, the test samples were removed every 2 min to measure the partial mass loss. A digital balance with a capacity to weigh 120 g (model WH Series—Electronic Analytical Balance) was used to perform the weighing measurements. Figure 4a–d show the mass loss vs. time graphs of the testing materials at all incident angles. In this particular case, the erosion damage was proportional to the elapsed time. A higher mass loss was clearly observed from 2 min to 10 min. This meant that the deformation of the alloy steels progressively increased as the number of particle impacts became higher. This trend was observed in other erosion studies [1,2,3,4,5]. The AISI 8620 steel exhibited higher resistance at 30°, 45° and 90° than AISI 4340 steel. Here, the higher ductility (% elongation) of this material was significant in providing a greater capacity to deform plastically without excessive material removal. This trend changed at 60°, where AISI 4340 steel in the last 4 min of the graph (Figure 4c) showed a higher erosion resistance. It was thought that its slightly higher hardness could allow it to withstand the impacts and sliding actions of abrasive particles on its surfaces without the material being penetrated as extensively, resulting in lower erosion damage.

Figure 4.

Graphs of mass loss (g) versus time (min): (a) 30°, (b) 45°, (c) 60°, (d) 90°.

The total erosion rates (g/g) (Table 3) are obtained by dividing the following:

Total erosion rate (g/g) = Total mass loss/Total mass of particles impacted the surface during 10 min test,

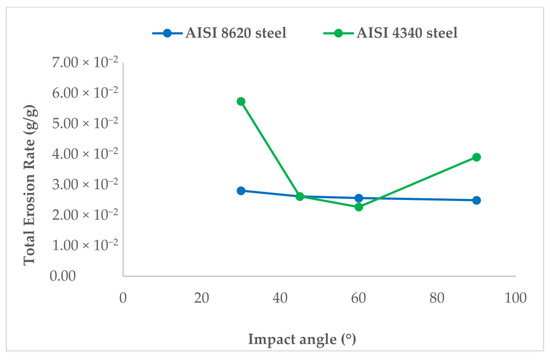

The total mass of particles impinging on the material surfaces was obtained by multiplying the abrasive flow rate, 0.7 g/min by 10 min. Thus, the total mass was 7 g per 10 min, which was the total duration of each test. Figure 5 shows the graph of total erosion rate (g/g) versus impact angle (°). Here, it is possible to remark that AISI 8620 steel exhibited the highest erosion resistance at 30°, 45° and 90° under these testing conditions. Both steels showed higher erosion rates at lower impact angles (α ≤ 45°), and these were reduced as the impact angle increased to 60° and 90°. Based on this fact, it was possible to conclude that these materials exhibited ductile-type behavior based on the results presented in other erosion works [20,21,22].

Figure 5.

Total erosion rate (g/g) versus impact angle (°).

3.4. Roughness Results

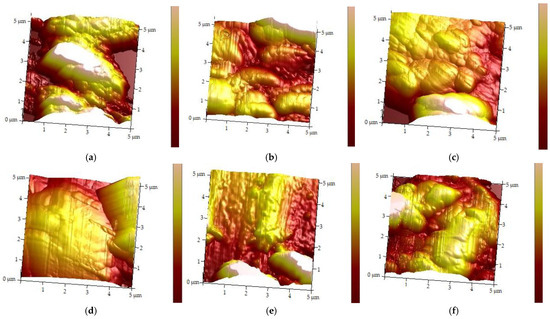

The roughness examination results before and after the erosion tests are presented in Figure 6a–f. The average roughness (Ra) results along with the standard deviation values were obtained after five measurements performed in different locations on unworn surfaces (as-received condition) and the central part of worn surfaces after impingement at 30° and 90° (Table 4). In this way, it was possible to observe the influence of the impact of the SiC particles on the surfaces. When the test materials were attacked at an incidence angle of 90°, the surface roughness of each material increased. It was thought that the vertical and direct action of the abrasive particles originated more pits on the surfaces, and thus more imperfections and irregularities led to an increase in the roughness.

Figure 6.

Roughness results: AISI 4340 steel: (a) as-received condition (110 nm), (b) 195 nm at 30°, (c) 295 nm at 90°; AISI 8620: (d) as-received condition (105 nm), (e) 185 nm at 30°, (f) 210 nm at 90°.

Table 4.

Average roughness results (nm).

4. Discussion

Solid particle erosion tests were carried out on two alloy steels, AISI 4340 (EN24) and AISI 8620, using a very hard and irregular abrasive such as SiC with a much higher hardness than the tested steels. Wear scars on every alloy steel were presented at each impact angle and it was clearly observed how the scars were much more intense and pronounced at impact angles of 30° and 45°, and although the area of the scars was more dispersed at 60° and 90°, the depth and intensity were much lower at these impact angles (Figure 1). This greater damage generated at low impact angles, 30° and 45°, may be due to a combination of several wear mechanisms such as pitting, micro-cutting actions and micro-ploughing which lead to greater material removal, achieving the formation of craters on the surfaces of both alloy steels. Regarding the damage generated at 60° and 90° for AISI 8620 steel, although the contact area of the abrasive particles on the surfaces appears to be greater, the intensity of the damage was clearly reduced, and there appears to be only slight surface damage on the alloy steel, which was consistent with the erosion rates obtained in this study. In relation to the increase in wear rate at 90° for AISI 4340 steel, it was related to a larger contact area of the abrasive particles on the surfaces, as observed in Figure 1. At this impact angle, the particles may first impact the surface, rebound and come into contact with an area of the stainless-steel nozzle, and then reimpact or slide again on the surfaces, causing greater erosion damage. Of course, there may also be a hardening phenomenon due to the direct impact of the particles on the samples, although the hardening sometimes contributes to a reduction in the erosion wear rate, especially in materials with lower hardness. At these impact angles, wear mechanisms were silicon carbide fragments inserted and scattered across the surface. Additionally, cracks in different positions due to the direct impact of the particles were also observed, and in some areas, completely crushed material was confirmed. In less detail, however, some pits can be seen on the surface, as well as micro-ploughing and micro-cutting actions due to particles impacting and re-impacting the surfaces in an irregular direction. These mechanisms were clearly identified using the SEM micrographs in Figure 2 and Figure 3. These mechanisms correlate well with those observed in previous erosion studies [13,18]. In relation to the results of the erosion rates, it was observed that AISI 4340 steel (EN 24) showed the highest wear rates at impact angles of 30°, 45° and 90°. On the other hand, AISI 8620 steel showed higher erosion rates at 60°. Possibly, 8620 steel at this impact angle could have suffered a combination of wear mechanisms that increased the damage on its surfaces. Due to what was observed for both alloy steels and their nature in terms of mechanical properties, it was possible to conclude that both had ductile behavior, and were highly resistant and had excellent resilience, reaching their maximum erosion rates at 30°, as observed in Figure 5. With respect to the roughness results obtained by AFM, the interesting thing was to show how the unworn surfaces of the alloy steels presented much lower roughness values than those data obtained after the erosion tests at 30° and 90°. This was based on the comparison of the roughness results (Ra) of both steels, before and after the impact of the particles at 30° and 90°. The higher surface roughness was obtained at 90°, due to a combination of facts, namely the direct impact of abrasive particles on the surfaces and also the secondary reimpact due to collisions between rebounding and incoming particles and sliding actions of particles that had already first made contact with the surfaces.

5. Conclusions

The results presented in the Discussion section led to the following conclusions in relation to the erosion performance of AISI 4340 and AISI 8620 steels against SiC particles.

- During the tests, the behavior of each material was studied using different impact angles (30°, 45°, 60° and 90°). It was observed that AISI 8620 steel exhibited greater erosion resistance than AISI 4340 steel. This could be due to its higher ductility allowing it to withstand the constant impacts and sliding actions of the abrasive particles at all incident angles. This material had the ability to deform plastically before reaching its yield strength (Sy), so there was much less material removal, especially at angles such as 30°, 45° and 90°.

- Regarding the wear mechanisms, these were identified using SEM and characterized by intense micro-cutting and ploughing actions, pits, lifted lips and irregular indentations at 30° and 45°. In contrast, cracks on the surface, flattened lips, filled groves and embedded SiC fragments could be seen at normal incidence, 90°.

- Additionally, Atomic Force Microscopy (AFM) was employed to conduct a roughness analysis of each material before and after testing at 30° and 90°. The results showed that the roughness was modified and increased after the impingement of the silicon carbide particles on the surfaces. That is, the imperfections on the surfaces of both materials were increased by the impact and sliding actions of the SiC particles.

Author Contributions

All persons who meet authorship criteria are listed as authors, and all authors certify that they have participated sufficiently in this work to take public responsibility for the content, including participation in the concept, design, analysis, writing, or revision of the manuscript. Furthermore, each author certifies the present manuscript is original and has been developed in the Faculty of Mechanical and Electrical Engineering by all the authors included in the paper. This paper does not contain material that has been published previously. J.R.L.-C., E.A.G.-H., M.V.-T. and C.M.C.-R.: conceptualization, methodology, supervision. V.V.-M. and K.I.Z.-D.L.: data curation, visualization, validation. S.M.S.-Y.: writing—original draft preparation, writing—reviewing and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We recognize the experimental support of the Mechanical Laboratory of the Faculty of Mechanical and Electrical Engineering of the Universidad Veracruzana in Poza Rica and the Center for Nanosciences and Micro and Nanotechnology of the National Polytechnic Institute (CNMN-IPN) in completing the present work. We would also like to thank SECIHTI for its support in awarding a grant to Juan R. Laguna-Camacho for his postdoctoral fellowship.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SPE | Solid Particle Erosion |

| ASTM | American Society for Testing and Materials |

| AISI | American Iron and Steel Institute |

References

- Yang, S.Q.; Fan, J.C.; Liu, M.T.; Li, D.N.; Li, J.L.; Han, L.H.; Wang, J.J.; Yang, S.Y.; Dai, S.W.; Zhang, L.B. Research on the solid particle erosion wear of pipe steel for hydraulic fracturing based on experiments and numerical simulations. Pet. Sci. 2024, 21, 2779–2792. [Google Scholar] [CrossRef]

- Deng, T.; Bingley, M.S.; Bradley, M.S.A. The influence of particle rotation on the solid particle erosion rate of metals. Wear 2004, 256, 1037–1049. [Google Scholar] [CrossRef]

- Foley, T.; Levy, A. The erosion of heat-treated steels. Wear 1983, 91, 45–64. [Google Scholar] [CrossRef]

- Chauhan, A.K.; Goel, D.B.; Prakash, S. Solid particle erosion behaviour of 13Cr–4Ni and 21Cr–4Ni–N steels. J. Alloys Compd. 2009, 467, 459–464. [Google Scholar] [CrossRef]

- Rodríguez, E.; Flores, M.; Pérez, A.; Mercado-Solis, R.D.; González, R.; Rodríguez, J.; Valtierra, S. Erosive wear by silica sand on AISI H13 and 4140 steels. Wear 2009, 267, 2109–2115. [Google Scholar] [CrossRef]

- Lee, W.S.; Su, T.T. Mechanical properties and microstructural features of AISI 4340 high-strength alloy steel under quenched and tempered conditions. J. Mater. Process. Technol. 1999, 87, 198–206. [Google Scholar] [CrossRef]

- Erdogan, M.; Tekeli, S. The effect of martensite volume fraction and particle size on the tensile properties of a surface-carburized AISI 8620 steel with a dual-phase core microstructure. Mater. Charact. 2003, 49, 445–454. [Google Scholar] [CrossRef]

- ASTM G76-95; Standard Practice for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM: Philadelphia, PA, USA, 2018; (Last updated in 2018). Available online: https://store.astm.org/g0076-18.html (accessed on 3 July 2025).

- Kumar, M.; Kumar, S. Experimental analysis of Solid particle erosion on SS 410 stainless steel. J. Phys. Conf. Ser. 2024, 2818, 012014. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Shakoor, R.A.; Ahmed, E.; Mohamed, A.M.A. Erosive wear performance of API X42 pipeline steel. Eng. Fail. Anal. 2016, 60, 86–95. [Google Scholar] [CrossRef]

- Shipway, P.H.; Hutchings, I.M. Influence of nozzle roughness on conditions in a gas-blast erosion rig. Wear 1993, 60, 148–158. [Google Scholar] [CrossRef]

- Laguna-Camacho, J.R.; Vite-Torres, M.; Gallardo-Hernández, E.A.; Vera-Cárdenas, E.E. Solid Particle Erosion on Different Metallic Materials. Tribology in Engineering, 1st ed.; Pihtili, H., Ed.; Intech: Rijeka, Croatia, 2013; Volume 5, pp. 63–78. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Sliem, M.H.; Sk, M.H.; Shakoor, R.A.; Mohamed, A.M.A.; Abdullah, A.M.; Kahraman, R. Erosion behavior of API X120 Steel: Effect of Particle Speed and Impact Angle. Coatings 2018, 8, 343. [Google Scholar] [CrossRef]

- Harsha, A.P.; Bhaskar, D.K. Solid particle erosion behaviour of ferrous and non-ferrous materials and correlation of erosion data with erosion models. Mater. Des. 2008, 29, 1745–1754. [Google Scholar] [CrossRef]

- Zhang, J.; Lian, Z.; Zhou, Z.; Xiong, M.; Yang, X. Erosion Wear of KQ52 Alloy Steel Multi-function Four-Way Valve Emergent Discharge Behaviors. Trans. Indian Inst. Met. 2022, 75, 217–228. [Google Scholar] [CrossRef]

- Anand, K.; Hovis, S.K.; Conrad, H.; Scattergood, R.O. Flux effects on solid particle erosion. Wear 1987, 118, 243–257. [Google Scholar] [CrossRef]

- Brown, R.; Jun, E.J.; Edington, J.W. Erosion of α-Fe by spherical glass particles. Wear 1981, 70, 347–363. [Google Scholar] [CrossRef]

- Hong, B.; Li, Y.; Li, X.; Li, G.; Huang, A.; Ji, S.; Li, W.; Gong, J.; Guo, J. Experimental investigation of erosion rate for gas-solid two-phase flow in 304 stainless /L245 carbon steel. Pet. Sci. 2022, 19, 1347–1360. [Google Scholar] [CrossRef]

- Hutchings, I.M.; Winter, R.E. Particle erosion of ductile metals: A mechanism of material removal. Wear 1974, 27, 121–128. [Google Scholar] [CrossRef]

- Hutchings, I.M.; Shipway, P. Wear by hard particles. In Tribology: Friction and Wear of Engineering Materials, 1st ed.; Edward Arnold: London, UK, 1992. [Google Scholar]

- Laguna-Camacho, J.R.; Hernández-Romero, I.; Escalante-Martínez, J.E.; Márquez-Vera, C.A.; Galván-López, J.L.; Méndez-Méndez, J.V.; Arzate-Vázquez, I.; Andraca-Adame, J.A. Erosion Wear of AISI 420 Stainless Steel Caused by Walnut Shell Particles. Trans. Indian Inst. Met. 2015, 68, 633–647. [Google Scholar] [CrossRef]

- Laguna-Camacho, J.R.; Sánchez-Yáñez, S.M.; Calderón-Ramón, C.; Escalante-Martínez, J.E.; Juárez-Morales, G.; Cruz-Orduña, M.I.; Ramos-González, L.M.; Galicia-Badillo, A. Erosion of metals using angular silicon carbide particles. Tribol.-Mater. Surf. Interfaces 2019, 13, 215–222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).