The Combination of Direct Aging and Cryogenic Treatment Effectively Enhances the Mechanical Properties of 18Ni300 by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

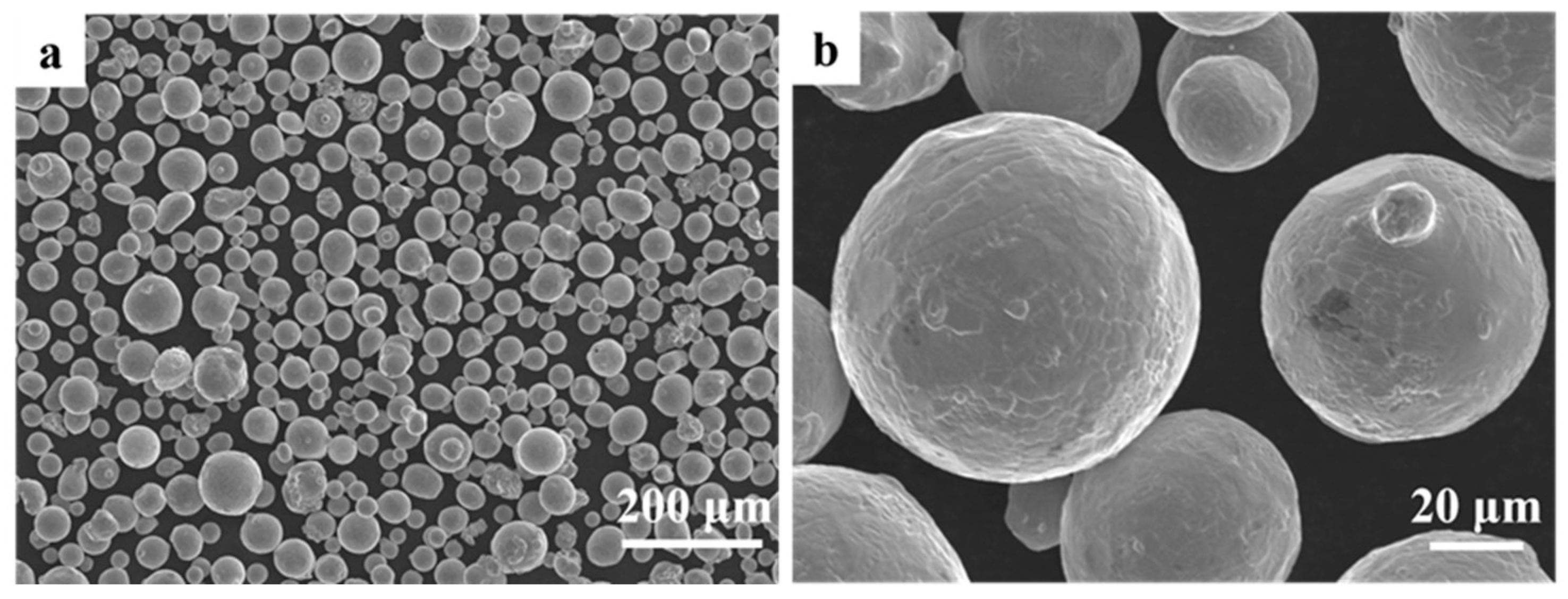

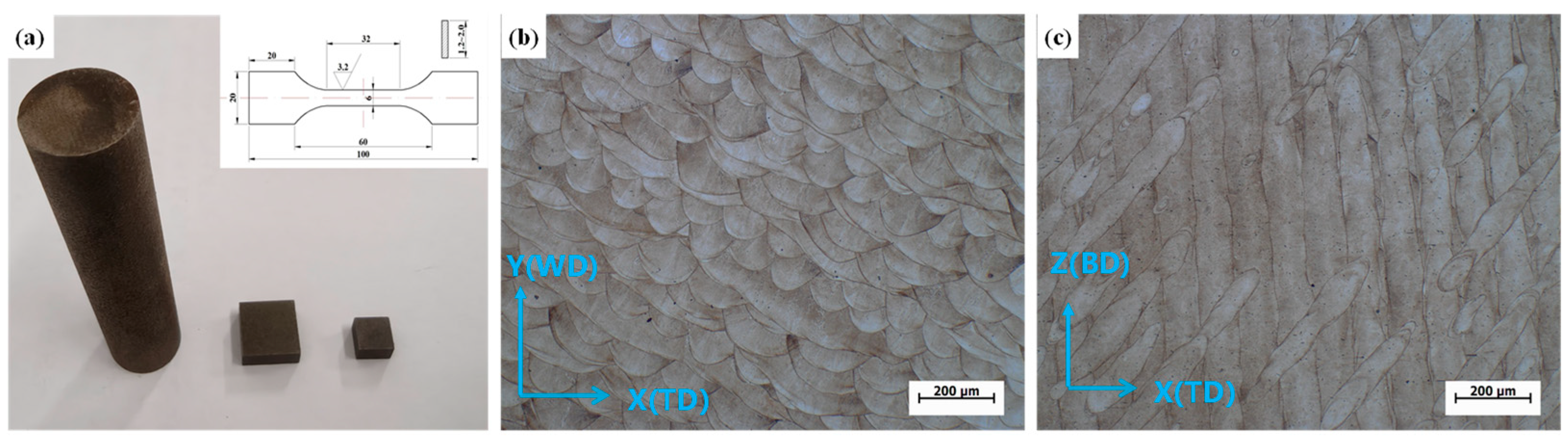

2.1. Preparation of 18Ni300 Samples

2.2. Sample Processing Procedure

2.3. Sample Characterization and Testing

3. Results and Discussions

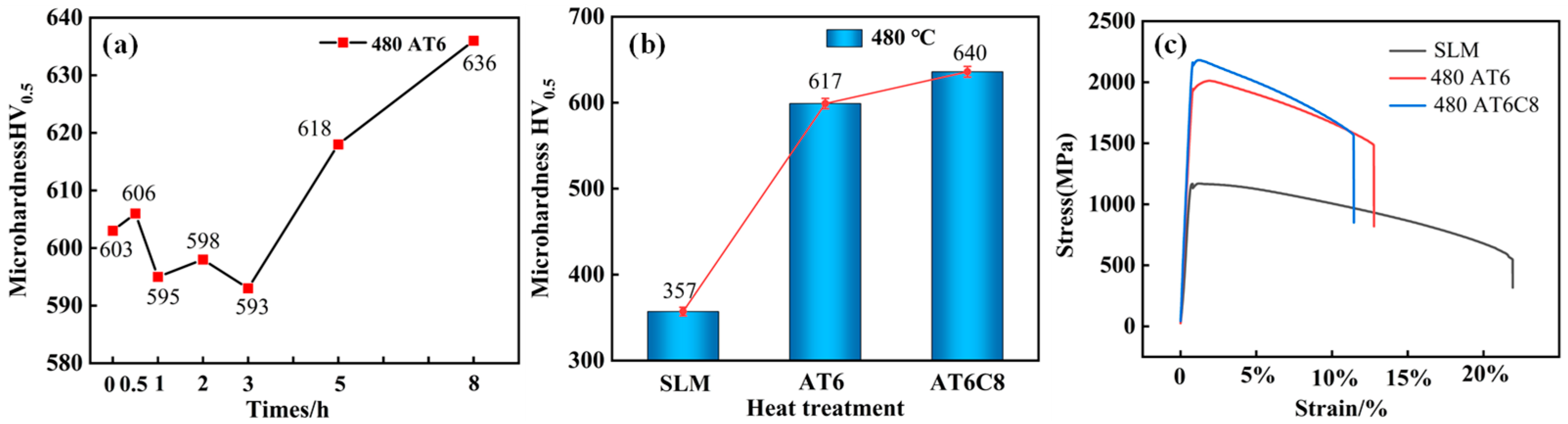

3.1. Mechanical Properties

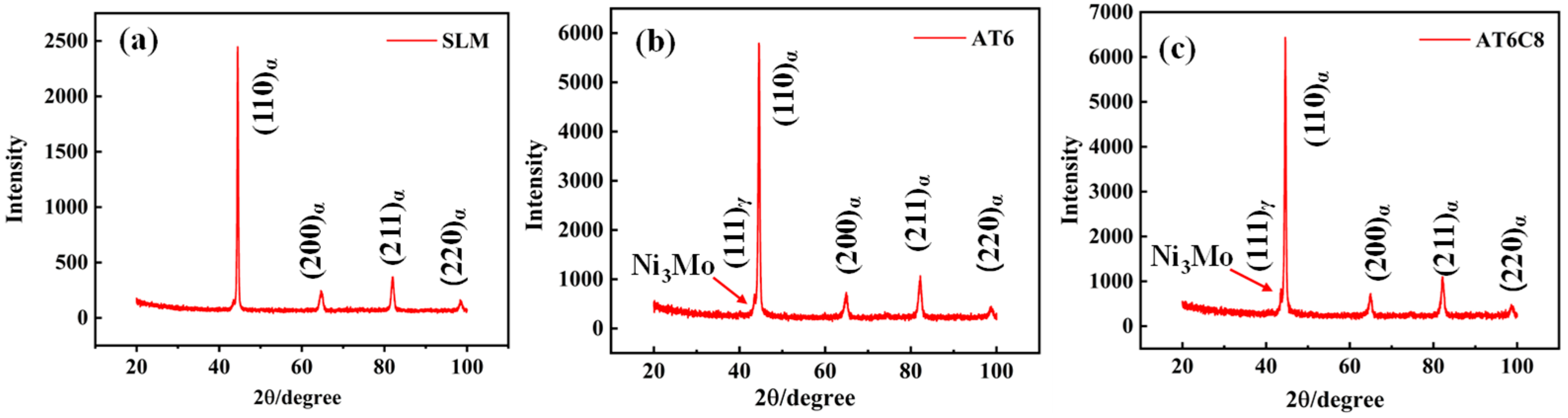

3.2. XRD Analyses

3.3. OM Analysis

3.4. Fracture Morphologies

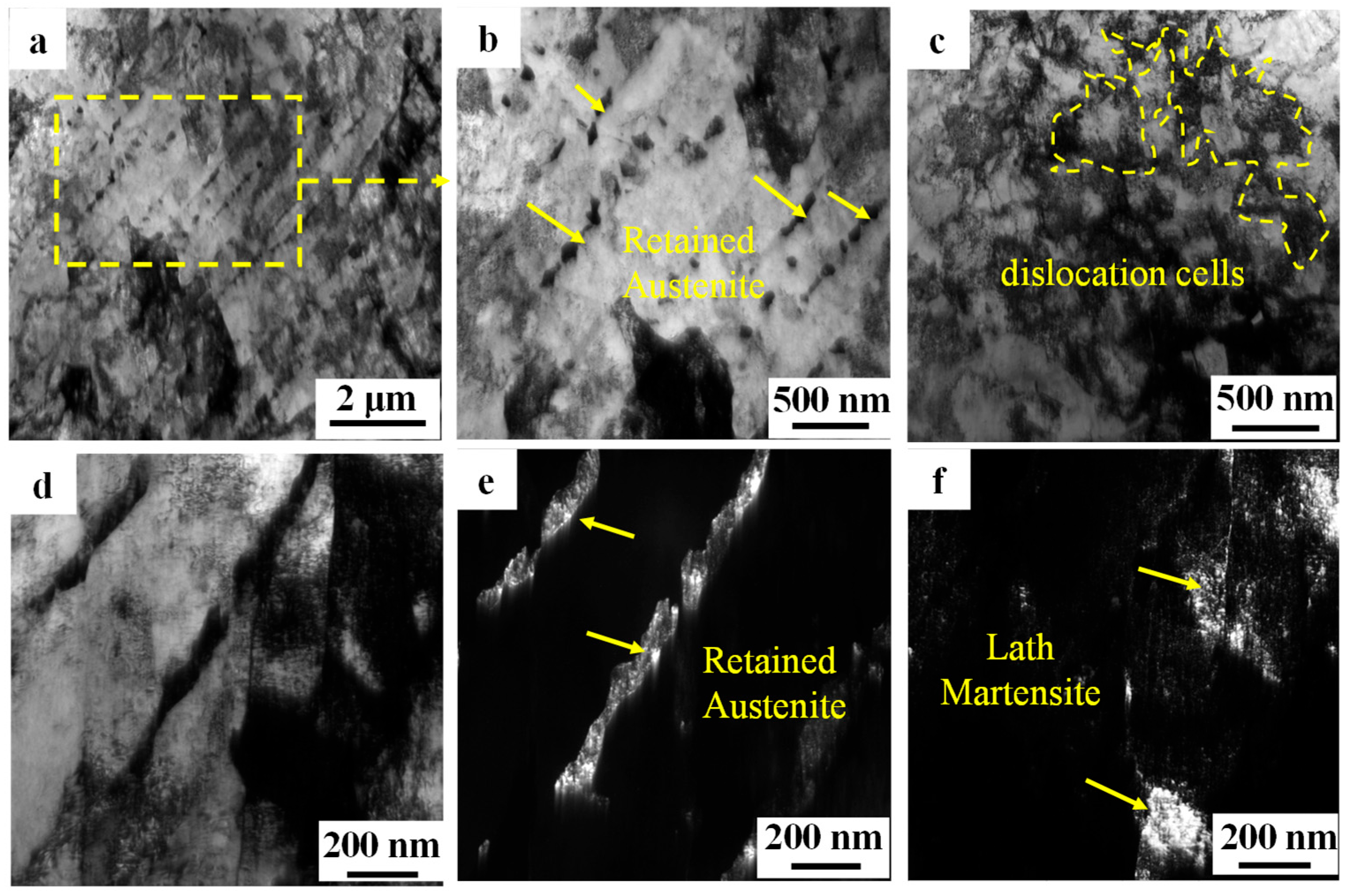

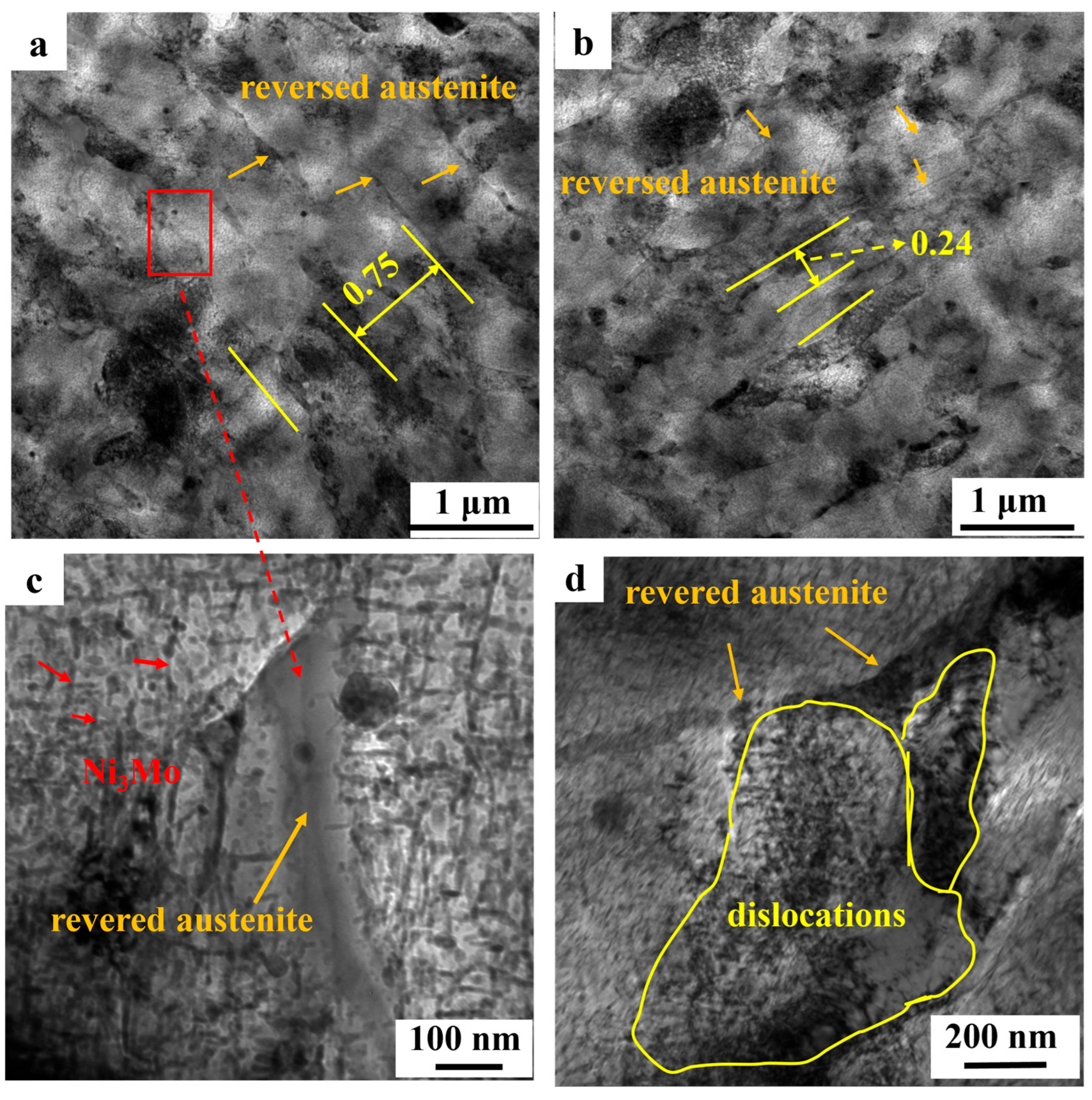

3.5. TEM Observations

4. Conclusions

- (1)

- Direct aging (480 °C/6 h) combined with cryogenic treatment (−196 °C/8 h, AT6C8) significantly improves the mechanical properties of SLM-fabricated 18Ni300 MS. Compared to the as-built sample, AT6C8 shows 104% higher microhardness (311→635 HV0.5) and 84% higher tensile strength (1182→2180 MPa), outperforming single direct aging (AT6). This confirms that cryogenic treatment synergizes with aging to enhance strength and hardness via microstructural modification.

- (2)

- The strength enhancement in directly aged AT6 (480 °C/6 h) mainly results from nanoscale intermetallic precipitation. TEM shows 20–50 nm-long, 5–10 nm-wide nanoprecipitates uniformly dispersing in the martensite matrix during aging, acting as effective dislocation barriers via the Orowan mechanism.

- (3)

- Cryogenic treatment induces significant austenite (γ-α) transformation, with hard–brittle martensite enhancing the hardness and strength. TEM observations reveal that the lath martensite grains are refined, with an increased density of grain boundaries. This hinders dislocation slip and effectively balances the enhancement in strength with the relaxation of residual stresses.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ostrovski, I.F.; Rabelo, A.; Bodziak, S.; Milan, J.C.G.; Lafratta, F.H.; Parucker, V.L.S.; Duarte, D.A. Effect of the plasma nitriding on the mechanical properties of the 18Ni300 steel obtained by selective laser melting. Surf. Coat. Technol. 2023, 466, 129688. [Google Scholar] [CrossRef]

- Li, S.; Chen, B.; Tan, C.; Song, X. Effects of oxygen content on microstructure and mechanical properties of 18Ni300 maraging steel manufactured by laser directed energy deposition. Opt. Laser Technol. 2022, 153, 108281. [Google Scholar] [CrossRef]

- Ren, J.; Wang, D.; Wu, X.; Yang, Y. Laser-based additive manufacturing of bulk metallic glasses: A review on principle, microstructure and performance. Mater. Des. 2025, 252, 113750. [Google Scholar] [CrossRef]

- Yao, Y.; Fan, L.; Ding, R.; Franke, C.; Yang, Z.; Liu, W.; Li, T.; Chen, H. On the role of cellular microstructure in austenite reversion in selective laser melted maraging steel. J. Mater. Sci. Technol. 2024, 184, 180–194. [Google Scholar] [CrossRef]

- Mao, Z.; Lu, X.; Yang, H.; Niu, X.; Zhang, L.; Xie, X. Processing optimization; microstructure, mechanical properties and nanoprecipitation behavior of 18Ni300 maraging steel in selective laser melting. Mater. Sci. Eng. A 2022, 830, 142334. [Google Scholar] [CrossRef]

- Song, J.; Tang, Q.; Feng, Q.; Han, Q.; Ma, S.; Chen, H.; Guo, F.; Setchi, R. Effect of remelting processes on the microstructure and mechanical behaviours of 18Ni-300 maraging steel manufactured by selective laser melting. Mater. Charact. 2022, 184, 111648. [Google Scholar] [CrossRef]

- Oliveira, G.H.M.; Sciuti, V.F.; Canto, R.B.; Arneitz, S.; Minkowitz, L.; Amancio-Filho, S.T.; Canto, L.B. Additive manufacturing of surface structured metal parts for high strength lightweight injection overmolded polymer-metal hybrid joints. Int. J. Adhes. Adhes. 2025, 141, 104045. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, P.; Zeng, Y.; Yao, H.; Chen, J. Additive manufacturing of Inconel 718/CuCrZr multi-metallic materials fabricated by laser powder bed fusion. Addit. Manuf. 2024, 92, 104377. [Google Scholar] [CrossRef]

- Zhao, M.; Shen, S.; Wang, H.; Niu, L.; Shi, J.; Chen, Z.; Wang, X.; Lu, B. Effect of heat treatment on microstructure and hydrogen embrittlement of additively manufactured and cast 18Ni300 maraging steel. J. Mater. Res. Technol. 2024, 33, 9566–9579. [Google Scholar] [CrossRef]

- Ma, Y.; Gao, Y.; Zhang, H.; Men, Z.; Yang, L. A comprehensive study on the microstructure evolution and mechanical property characterization of selective laser melted 18Ni300 stainless steel during heat treatment processes. J. Mater. Res. Technol. 2024, 33, 51–60. [Google Scholar] [CrossRef]

- Ding, R.; Liu, G.-L.; Liu, S.-C.; Ranjbar, M.; Potter, A.; Liu, H.-X. Effect of the combined use of cryogenic + aging treatment on mechanical and damping property of Mn-Cu alloy based on response surface model. Mater. Today Commun. 2025, 46, 112655. [Google Scholar] [CrossRef]

- Liu, J.; Shi, L.; Su, R.; Liu, T.; Li, G. Effect of deep cryogenic treatment on microstructure and properties of Al-Cu-Mg-Ag alloy with RRA. J. Alloys Compd. 2025, 1020, 179574. [Google Scholar] [CrossRef]

- Feng, Z.; Jiang, P.; Zou, H.; Liu, Y.; Wu, W.; Wang, Z.; Pan, H.; Wang, Q.; Li, X.; Zhang, Y. Effects of cryogenic treatment on microstructures, mechanical properties, and wear resistance of selective laser melted Ti-6Al-4V. Mater. Today Commun. 2025, 42, 111379. [Google Scholar] [CrossRef]

- ASTM E11-24; Standard Specification for Woven Wire Test Sieves. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024.

- Du, H.; Cai, J.-H.; Wang, Y.-S.; Yao, J.-Q.; Chen, Q.; Cui, Y.; Liu, X.-W. Effect of partial recrystallization on microstructure and tensile properties of NiFeCoCrMn high-entropy alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 947–956. [Google Scholar] [CrossRef]

- Lu, B.; Xiao, P.; Sun, M.; Nie, J. Reducing volume shrinkage by low-temperature photopolymerization. J. Appl. Polym. Sci. 2007, 104, 1126–1130. [Google Scholar] [CrossRef]

- Jeong, W.; Suh, J.; Kang, S.H.; Kang, Y.; Lee, M.; Lee, T.; Lee, K.T.; Ryu, H.J. Ultra-high temperature ceramic (HfC) reinforcement of laser powder-directed energy deposited inconel 718: Microstructural evolution and tensile properties at room and high temperatures. Compos. Part B Eng. 2025, 297, 112281. [Google Scholar] [CrossRef]

- Qi, H.; Lv, Q.; Li, G.; Qu, Y.; Su, R.; Qiu, K.; Zhang, W.; Yu, B. Effect of cryogenic treatment on B2 nanophase, dislocation and mechanical properties of Al1.4CrFe2Ni2 (BCC) high entropy alloy. Mater. Sci. Eng. A 2023, 878, 145183. [Google Scholar] [CrossRef]

- Gao, Q.; Jiang, X.; Sun, H.; Fang, Y.; Mo, D.; Li, X.; Shu, R. Effect mechanism of cryogenic treatment on ferroalloy and nonferrous alloy and their weldments: A review. Mater. Today Commun. 2022, 33, 104830. [Google Scholar] [CrossRef]

- Xu, L.Y.; Zhu, J.; Jing, H.Y.; Zhao, L.; Lv, X.Q.; Han, Y.D. Effects of deep cryogenic treatment on the residual stress and mechanical properties of electron-beam-welded Ti–6Al–4V joints. Mater. Sci. Eng. A 2016, 673, 503–510. [Google Scholar] [CrossRef]

- Chen, T.; Chang, R.; Cheng, Z.; Qian, B.; Qiu, J.; Liang, Z.; Ning, X.; Sun, S.; Liu, B. Selective laser melting fabricated carbon nanotube reinforced 18Ni300 maraging steel directly used for mold repairing. Vacuum 2024, 228, 113448. [Google Scholar] [CrossRef]

- Vermeij, T.; Mornout, C.J.A.; Rezazadeh, V.; Hoefnagels, J.P.M. Martensite plasticity and damage competition in dual-phase steel: A micromechanical experimental–numerical study. Acta Mater. 2023, 254, 119020. [Google Scholar] [CrossRef]

- Zhang, W.; Chabok, A.; Wang, H.; Shen, J.; Oliveira, J.P.; Feng, S.; Schell, N.; Kooi, B.J.; Pei, Y. Ultra-strong and ductile precipitation-strengthened high entropy alloy with 0.5 % Nb addition produced by laser additive manufacturing. J. Mater. Sci. Technol. 2024, 187, 195–211. [Google Scholar] [CrossRef]

- Dong, Y.; Gu, H.; Hou, C.; Zhang, Q.; Miao, D.; Duan, S. Microstructural evolution and mechanical enhancement of Co-free AlCrFeNi3 eutectic medium entropy alloy via heat treatment after selective laser melting. Mater. Sci. Eng. A 2025, 933, 148307. [Google Scholar] [CrossRef]

- Okada, K.; Shibata, A.; Tsuji, N. Characteristics and formation mechanism of serrated markings on the hydrogen-related quasi-cleavage fracture in as quenched low-carbon martensitic steel. Scr. Mater. 2023, 234, 115568. [Google Scholar] [CrossRef]

- Hagihara, K.; Tanaka, T.; Fujimoto, H.; Nakano, T.; Umakoshi, Y. Microstructure and plastic deformation behavior of Ni3(Ti,X) (X = Nb,Al) single crystals with long-period geometrically closely packed crystal structures. Intermetallics 2006, 14, 1332–1338. [Google Scholar] [CrossRef]

- Agyapong, J.; Czekanski, A.; Yiadom, S.B. Microstructural evolution and high strain rate deformation response of SLM-printed CoCrFeMnNi after annealing and deep-cryogenic treatment. Mater. Charact. 2024, 218, 114506. [Google Scholar] [CrossRef]

- Qi, H.; Zhang, Z.; Huang, M.; Song, C.; Yang, X.; Tang, H. Enhancing the mechanical behaviors of 18Ni300 steel through microstructural evolution in Electron Beam Powder Bed Fusion. J. Mater. Res. Technol. 2025, 36, 4215–4228. [Google Scholar] [CrossRef]

- Niu, W.Y.; Zhang, X.L.; Liang, J.W.; Shen, Y.F.; Xue, W.Y.; Li, J.P. Role of nano-bainite laths and nanosized precipitates: Strengthening a low-alloy steel to 1870 MPa. J. Mater. Res. Technol. 2024, 33, 2331–2342. [Google Scholar] [CrossRef]

- Liu, G.; Guo, H.; Wang, S.; Liao, T.; Wu, H.; Huang, Y.; Zhao, H.; Zhang, Z.; Feng, Q.; Li, H.; et al. Revealing the reversed austenite transformation behavior and mechanical properties evolution during hot forming process of press-hardened steel sheets. J. Mater. Process. Technol. 2024, 332, 118536. [Google Scholar] [CrossRef]

- Li, Z.; Lu, C.; Tan, Z.; Wang, R.; Kong, C.; Yu, H. Strain hardening behavior of pure Ni at cryogenic temperatures: Experiments and modeling. Int. J. Mech. Sci. 2025, 295, 110293. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, Z.; Wang, Y. The effect of cryogenic treatment on the mechanical properties and cutting performance of coated cemented carbide tools with different Co contents. CIRP J. Manuf. Sci. Technol. 2025, 59, 18–33. [Google Scholar] [CrossRef]

| Element | Ni | Co | Mo | Ti | Al | Si | Mn | Cr | P | C | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt% | 17.69 | 8.59 | 4.59 | 0.70 | 0.12 | 0.086 | 0.014 | 0.018 | 0.014 | <0.005 | Bal |

| Sample Name | SLMed 18Ni300 | Direct Aging Treatment at 480 °C for 6 h | Direct Aging Treatment at 480 °C for 6 h |

|---|---|---|---|

| As-built | √ | ||

| AT6 | √ | √ | |

| AT6C8 | √ | √ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Chen, X.; Qu, B.; Tao, Y.; Zeng, W.; Chen, B. The Combination of Direct Aging and Cryogenic Treatment Effectively Enhances the Mechanical Properties of 18Ni300 by Selective Laser Melting. Metals 2025, 15, 766. https://doi.org/10.3390/met15070766

Zhang Y, Chen X, Qu B, Tao Y, Zeng W, Chen B. The Combination of Direct Aging and Cryogenic Treatment Effectively Enhances the Mechanical Properties of 18Ni300 by Selective Laser Melting. Metals. 2025; 15(7):766. https://doi.org/10.3390/met15070766

Chicago/Turabian StyleZhang, Yaling, Xia Chen, Bo Qu, Yao Tao, Wei Zeng, and Bin Chen. 2025. "The Combination of Direct Aging and Cryogenic Treatment Effectively Enhances the Mechanical Properties of 18Ni300 by Selective Laser Melting" Metals 15, no. 7: 766. https://doi.org/10.3390/met15070766

APA StyleZhang, Y., Chen, X., Qu, B., Tao, Y., Zeng, W., & Chen, B. (2025). The Combination of Direct Aging and Cryogenic Treatment Effectively Enhances the Mechanical Properties of 18Ni300 by Selective Laser Melting. Metals, 15(7), 766. https://doi.org/10.3390/met15070766