Investigation of the Preparation and Interlayer Properties of Multi-Walled Carbon Nanotube-Reinforced Ultra-Thin TA1/CFRP Laminates

Abstract

1. Introduction

2. Materials Preparation

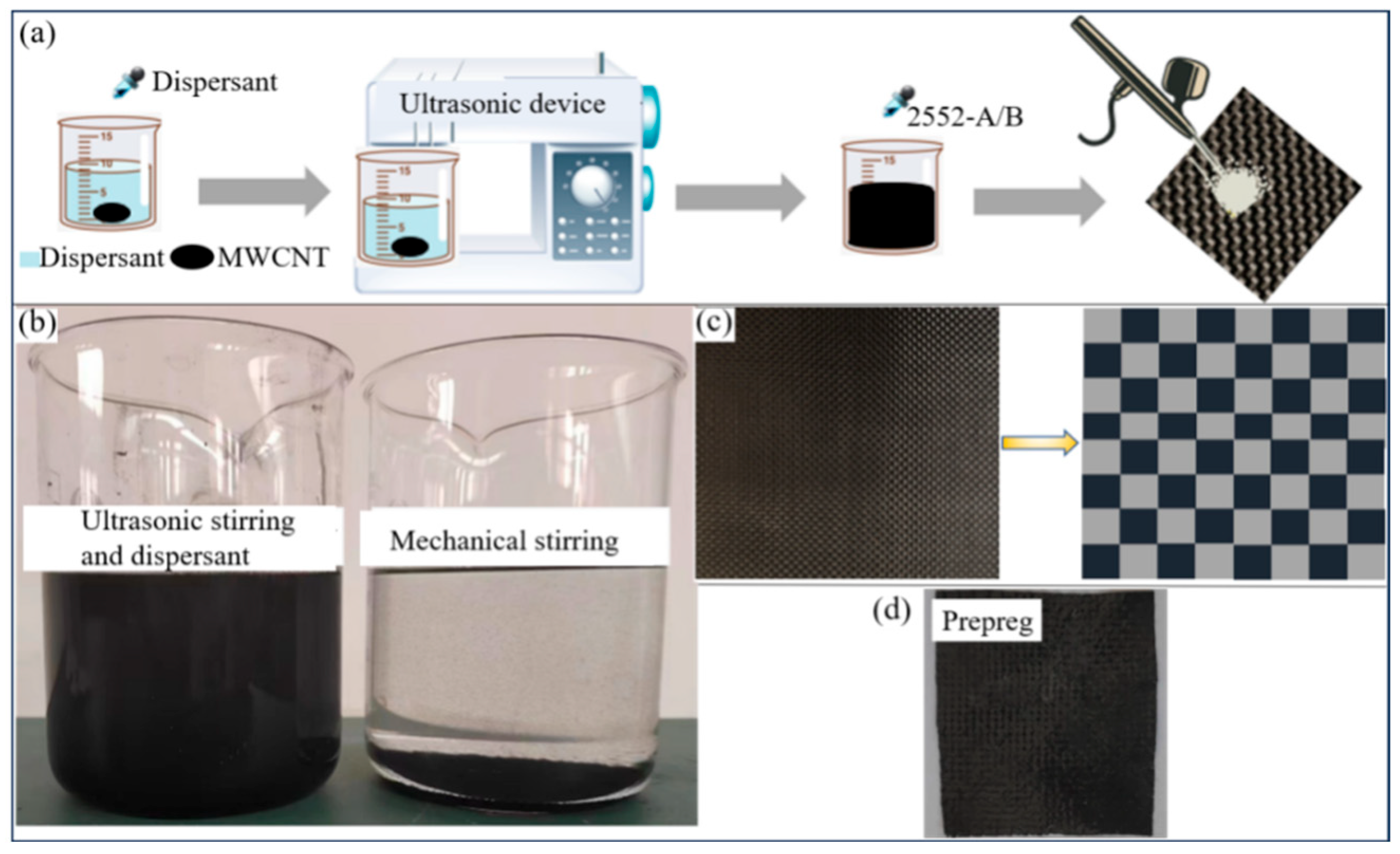

2.1. Preparation of Prepreg Containing MWCNT

2.2. Surface Treatment of Titanium Alloy Foils

2.3. Curing of TA1/CFRP Laminates

3. Experimental

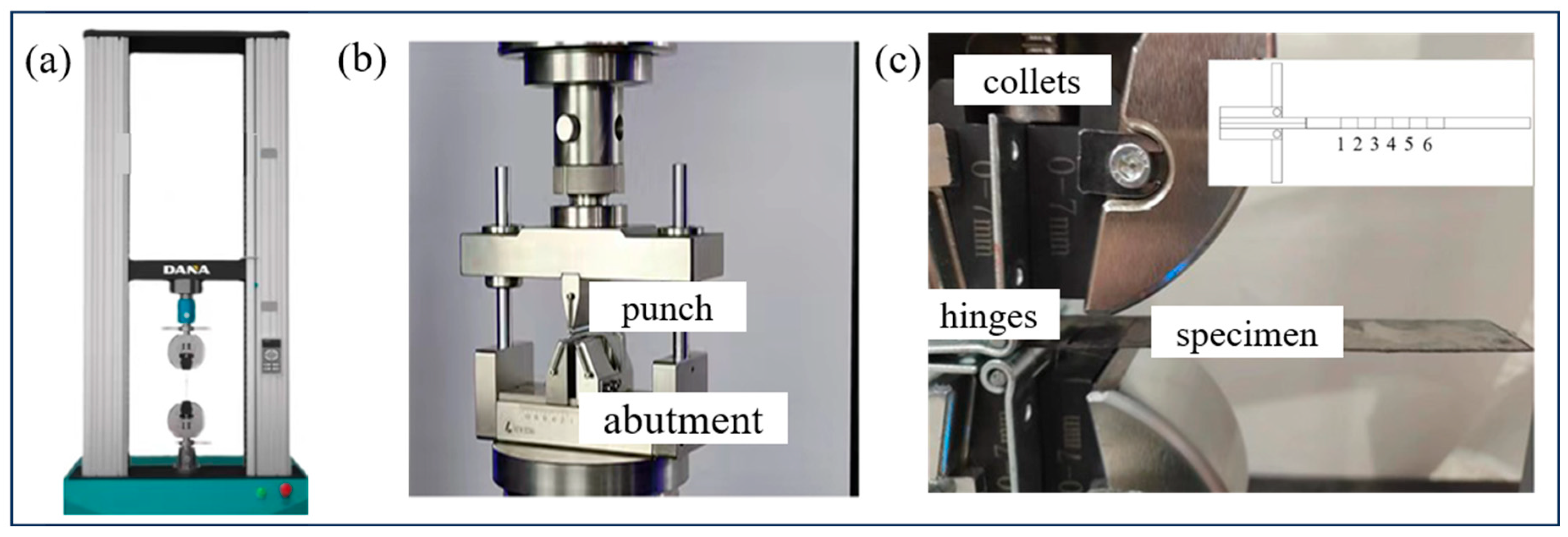

3.1. Experimental Equipment

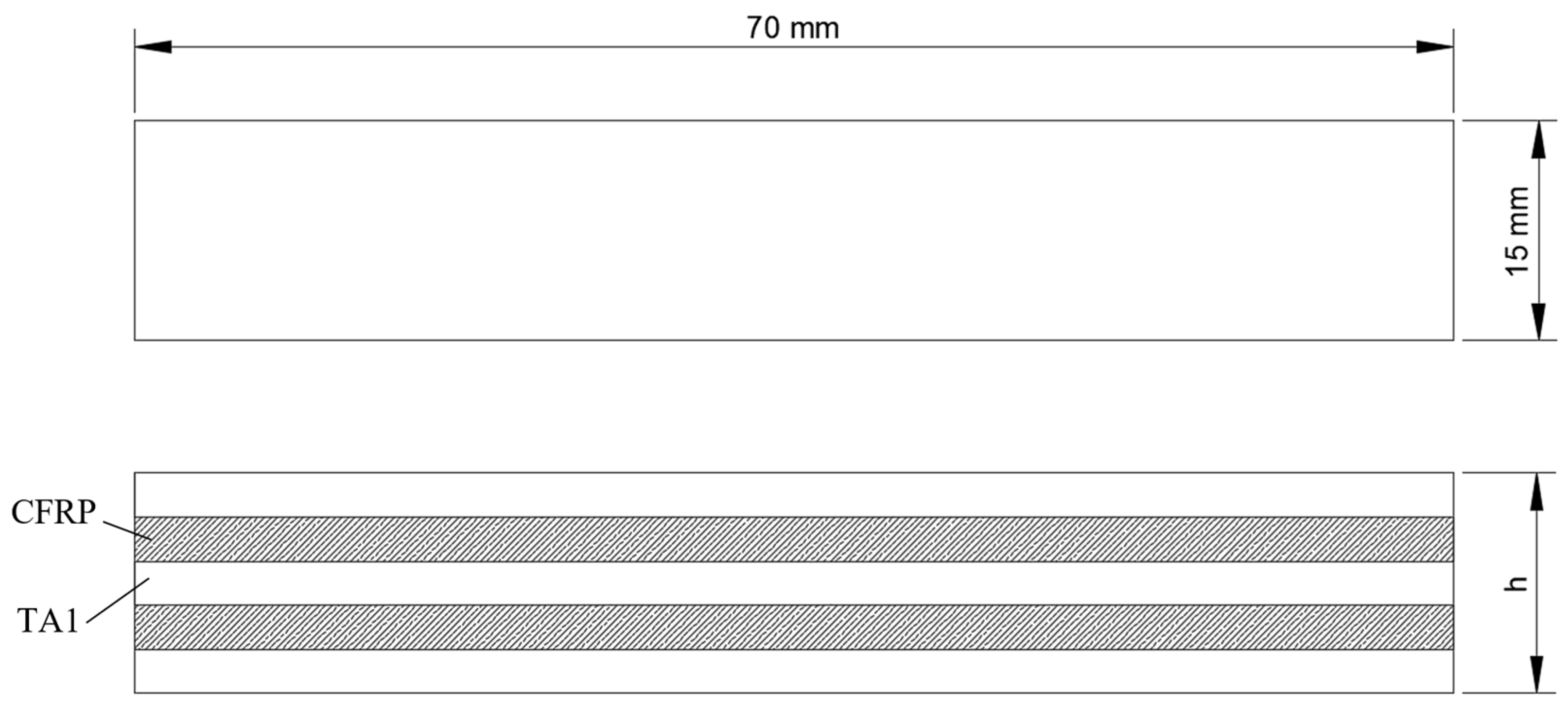

3.2. Interlayer Shear Strength Test

3.3. Interlayer Fracture Toughness Test

4. Results and Discussion

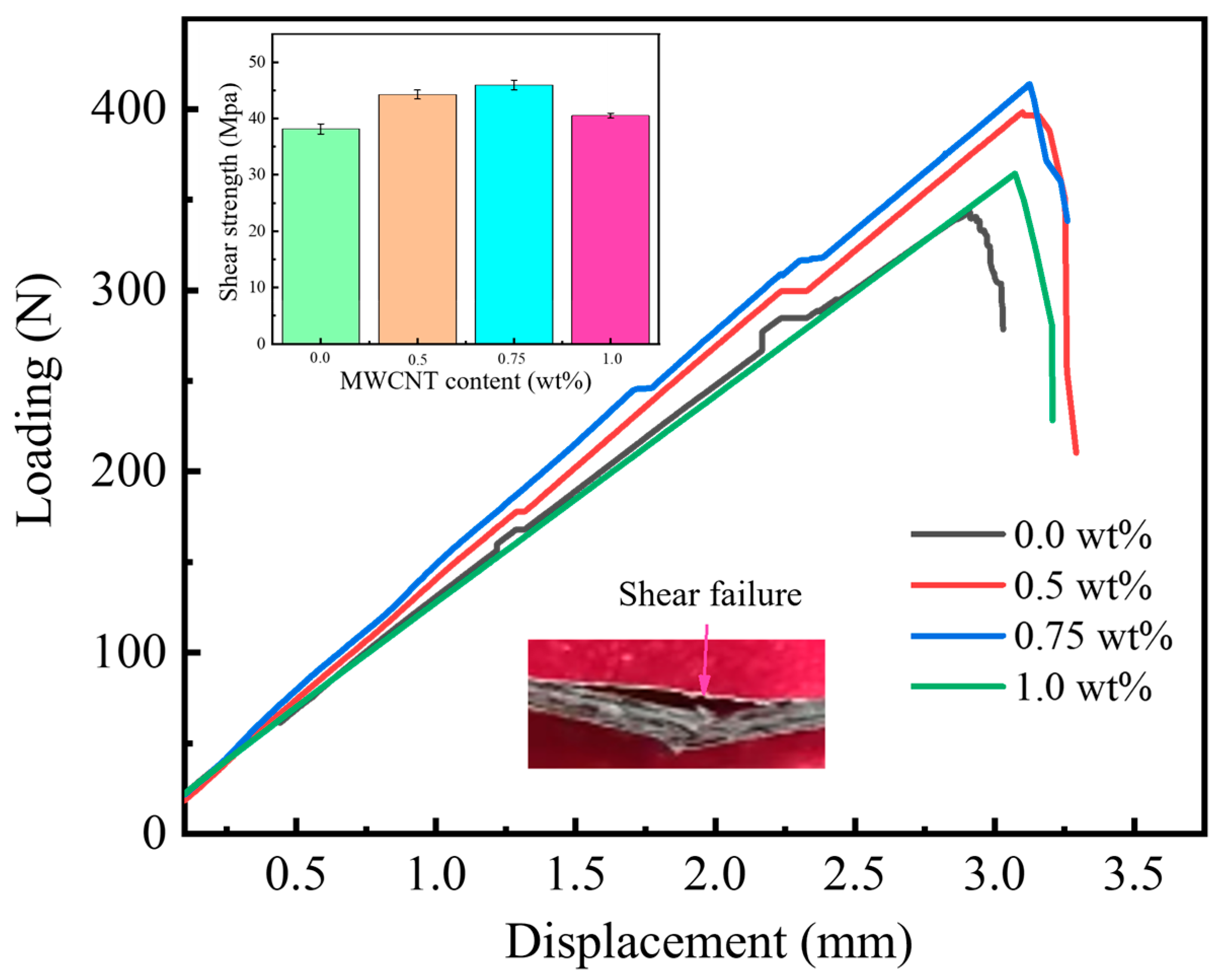

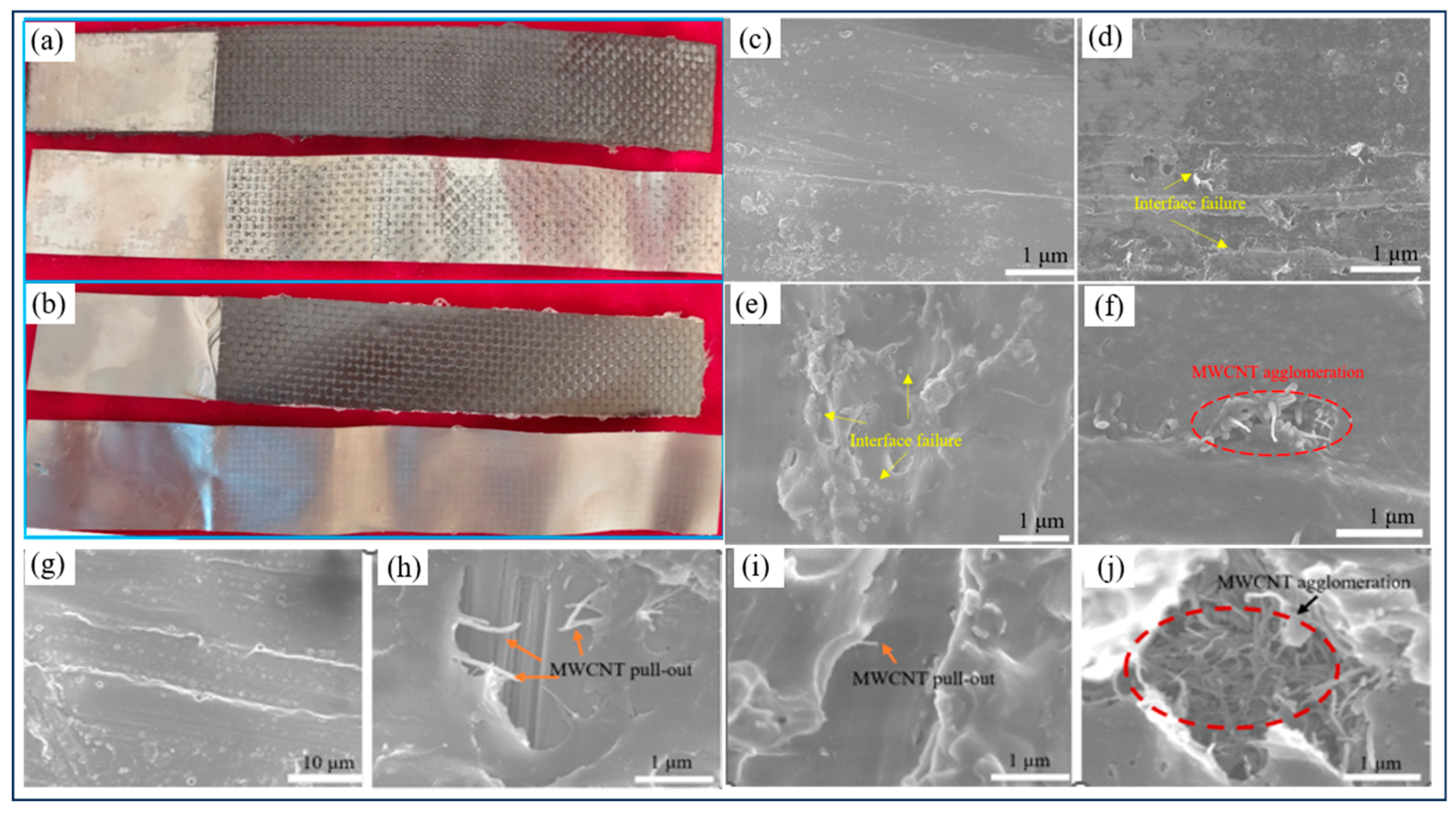

4.1. Effect of MWCNT Content on Shear Strength

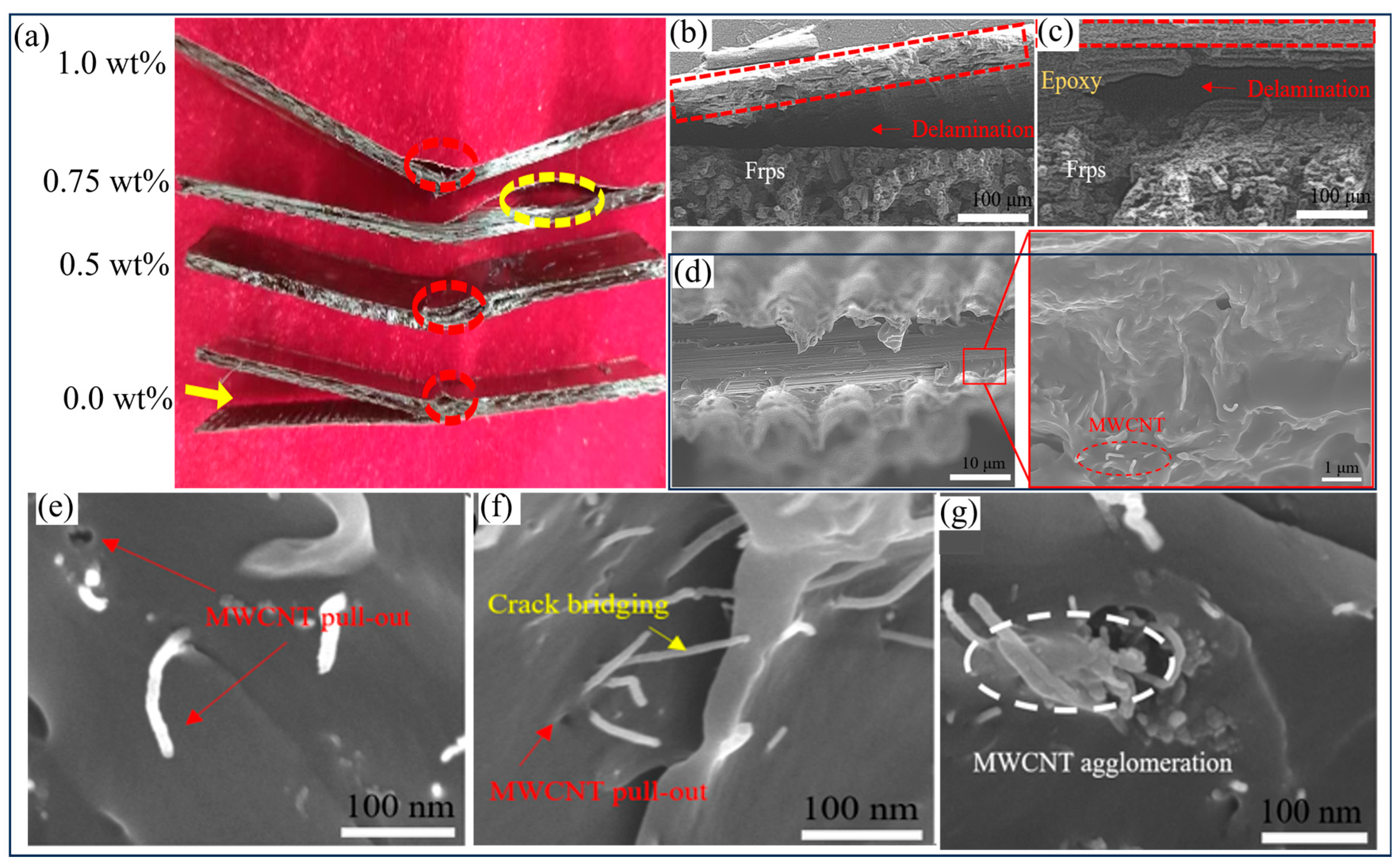

4.2. Effect of MWCNT Content on Fracture Toughness

5. Conclusions

- (1)

- Ultrasonic dispersion and dispersant sharing methods were employed to achieve a well-dispersed Tai/CFRP laminates with MWCNT in the resin matrix. Through carefully controlling the temperature profile and vacuum pressure during the curing process, laminates with minimized glue overflow were successfully prepared. These controlled parameters ensure uniform distribution of MWCNT within the resin matrix and reduce the overflow during curing, ultimately contributing to the overall quality and performance of the laminates.

- (2)

- The shear strength of specimens with added MWCNT exhibited an increase at concentrations of 0.5 wt%, 0.75 wt%, and 1.0 wt% compared to pure epoxy laminates. However, this increase followed a trend of initially rising and then decreasing. A significant observation was the alteration of the failure mode from bonding failure to cohesion failure with the addition of MWCNT. This change in failure mode suggests that MWCNT incorporation influenced the interfacial bonding within the laminates, leading to enhanced cohesion between the layers.

- (3)

- The type I fracture toughness of the laminates was assessed using the double-arm suspension beam method across various MWCNT contents. The incorporation of MWCNT led to a notable enhancement in the type I fracture toughness of the laminates compared to pure epoxy resin laminates. Upon analysis of the interlayer morphology and mechanism of MWCNT enhancement, it was observed that MWCNT played a crucial role through mechanisms such as pull-out and fractures, effectively impeding the pre-constrained expansion of cracks within the matrix. This mechanism ultimately contributed to the improvement in interlayer fracture toughness of the laminates.

- (4)

- This study successfully revealed the reinforcing effect of MWCNTs on the mechanical properties of composites. However, there are certain limitations. On the one hand, the key range for optimal performance may not have been fully captured due to the selected MWCNT content range. On the other hand, the study only focused on the mechanical behavior at room temperature, lacking adequate evaluation of material performance in complex service environments like high temperatures. Future research should systematically expand the range of MWCNT content and include performance tests under different temperature conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Matthews, F.L. Glare: History of the development of a new aircraft material. Aeronaut. J. 2002, 106, 1–20. [Google Scholar]

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts–sciencedirect. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar]

- Matthews, F.L.; Rawlings, R.D. Composite materials: Engineering and science. Mater. Des. 1995, 16, 119–120. [Google Scholar]

- Jin, K.; Wang, H.; Tao, J.; Du, D. Mechanical analysis and progressive failure prediction for fibre metal laminates using a 3D constitutive model. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105490. [Google Scholar] [CrossRef]

- Mamalis, D.; Obande, W.; Koutsos, V.; Blackford, J.R.; Br’adaigh, C.M. Novel thermoplastic fibre-metal laminates manufactured by vacuum resin infusion: The effect of surface treatments on interfacial bonding. Mater. Des. 2019, 162, 331–344. [Google Scholar] [CrossRef]

- Hu, Y.; Zheng, X.; Wang, D.; Zhang, Z.; Xie, Y.; Yao, Z. Application of laser peen forming to bend fibre metal laminates by high dynamic loading. J. Mater. Process. Technol. 2015, 226, 32–39. [Google Scholar] [CrossRef]

- He, P.; Huang, M.; Fisher, S.; Yue, C.Y.; Yang, J. Effects of primer and annealing treatments on the shear strength between anodized Ti6Al4V and epoxy. Int. J. Adhes. Adhes. 2015, 57, 49–56. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Imran, R.; Arif, Z.U.; Akram, N.; Arshad, H.; Al Rashid, A.; Márquez, F.P.G. Developments in chemical treatments, manufacturing techniques and potential applications of natural-fibers-based biodegradable composites. Coatings 2021, 11, 293. [Google Scholar] [CrossRef]

- Ye, J.; Wang, H.; Dong, J.; Liu, C.; Gao, Y.; Gong, B.; Su, B.; Peng, H.-X. Metal surface nanopatterning for enhanced interfacial adhesion in fiber metal laminates. Compos. Sci. Technol. 2021, 205, 108651. [Google Scholar] [CrossRef]

- Rubio-González, C.; Chávez, F.; José-Trujillo, E.; Rodríguez-González, J.A.; Ruiz, A. Impact behavior of carbon fiber/epoxy composites and fiber metal laminates with open holes. Fibers Polym. 2021, 22, 772–785. [Google Scholar] [CrossRef]

- Harfoush, A.; Haapala, K.R.; Tabei, A. Application of artificial intelligence in incremental sheet metal forming: A review. Procedia Manuf. 2021, 53, 606–617. [Google Scholar] [CrossRef]

- Hu, C.; Sang, L.; Jiang, K.; Xing, J.; Hou, W. Experimental and numerical characterization of flexural properties and failure behavior of CFRP/Al laminates. Compos. Struct. 2022, 281, 115036. [Google Scholar] [CrossRef]

- Jamali, N.; Khosravi, H.; Rezvani, A.; Tohidlou, E. Mechanical properties of multiscale graphene oxide/basalt fiber/epoxy composites. Fibers Polym. 2019, 20, 138–146. [Google Scholar] [CrossRef]

- Afrouzian, A.; Movahhedi Aleni, H.; Liaghat, G.; Ahmadi, H. Effect of nano-particles on the tensile, flexural and perforation properties of the glass/epoxy composites. J. Reinf. Plast. Compos. 2017, 36, 900–916. [Google Scholar] [CrossRef]

- Feiz, A.; Khosravi, H. Multiscale composites based on a nanoclay-enhanced matrix and E-glass chopped strand mat. J. Reinf. Plast. Compos. 2019, 38, 591–600. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Khosravi, H.; Shahrabi-Farahani, A. Improving the flexural properties of E-glass fibers/epoxy isogrid stiffened composites through addition of 3-glycidoxypropyltrimethoxysilane functionalized nanoclay. Silicon 2020, 12, 2515–2523. [Google Scholar] [CrossRef]

- Ebrahimnezhad, K.H.; Eslami, F.R. Thermal and mechanical properties of hybrid carbon/oxidized polyacrylonitrile fibers-epoxy composites. Polym. Compos. 2017, 38, 1412–1417. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Dyke, C.A.; Tour, J.M. Covalent functionalization of single-walled carbon nanotubes for materials applications. J. Phys. Chem. A 2004, 108, 11151–11159. [Google Scholar] [CrossRef]

- Sánchez, M.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part B Eng. 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Cividanes, L.S.; Simonetti, E.A.N.; Moraes, M.B.; Fernandes, F.W.; Thim, G.P. Influence of carbon nanotubes on epoxy resin cure reaction using different techniques: A comprehensive review. Polym. Eng. Sci. 2014, 54, 2461–2469. [Google Scholar] [CrossRef]

- de Souza, C.F.; Leite, J.L.; Salmoria, G.V.; Pouzada, A.S. Influence of graphite and carbon nanotubes on the mechanical and electrical properties of cast epoxy composites. Mater. Sci. Forum 2013, 730, 909–914. [Google Scholar] [CrossRef]

- Konstantakopoulou, M.; Kotsikos, G. Effect of MWCNT filled epoxy adhesives on the quality of adhesively bonded joints. Plast. Rubber Compos. 2016, 45, 166–172. [Google Scholar] [CrossRef]

- Khurram, A.A.; Hussain, R.; Afzal, H.; Akram, A.; Subhanni, T. Carbon nanotubes for enhanced interface of fiber metal laminate. Int. J. Adhes. Adhes. 2018, 86, 29–34. [Google Scholar] [CrossRef]

- Khoramishad, H.; Alikhani, H.; Dariushi, S. An experimental study on the effect of adding multi-walled carbon nanotubes on high-velocity impact behavior of fiber metal laminates. Compos. Struct. 2018, 201, 561–569. [Google Scholar] [CrossRef]

- Aghamohammadi, H.; Eslami-Farsani, R.; Tcharkhtchi, A. The effect of multi-walled carbon nanotubes on the mechanical behavior of basalt fibers metal laminates: An experimental study. Int. J. Adhes. Adhes. 2020, 98, 102538. [Google Scholar] [CrossRef]

- Yu, S.Z.; Min, N.T.; Gary, C. Use of carbon nanotubes reinforced epoxy as adhesives to join aluminum plates. Mater. Des. 2010, 31, 126–129. [Google Scholar] [CrossRef]

- Goh, K.L. Discontinuous-Fibre Reinforced Composites: Fundamentals of Stress Transfer and Fracture Mechanics; Springer: London, UK, 2017. [Google Scholar]

| Raw Material | Model | Producer | City/Country |

|---|---|---|---|

| Epoxy resin | SWANCOR2552-A | Swancor Advanced Materials Co., Ltd. | Shanghai/China |

| Curing agent | SWANCOR2552-B | Swancor Advanced Materials Co., Ltd. | Shanghai/China |

| Acetone | Q-102 | Dawei Chemical Co., Ltd. | Dongguan/China |

| Dispersant | Carbon Search Nano Co., Ltd. | Nanjing/China | |

| Mwcns (20–30 nm) | Carbon Search Nano Co., Ltd. | Nanjing/China |

| Device | Model | Producer | City/Country |

|---|---|---|---|

| Electric spray gun | SG9620ST | Prijie Co., Ltd. | Jiangsu/China |

| Analytical balance | WT-B | Wante Weighing Instrument Franchise Store | Hangzhou/China |

| CNC ultrasonic generator | KH-2860J | Kaiyue Ultrasound Co., Ltd. | Shenzhen/China |

| Magnetic stirrer | DF-110S | Shangke Instrument Co., Ltd. | Shanghai/China |

| Test Materials | Manufacturer | City/Country | Material Model |

|---|---|---|---|

| Vacuum bag | EasyComposites | Beijing/China | VB200 |

| Breathable felt | BR-180 | ||

| Release cloth | PP-230 | ||

| Mold release agent | Easy-Lease-150 | ||

| bake out furnace | OV301 | ||

| Vacuum pump | VP425 | ||

| Sealing tape | GT-200 |

| Punch Downward Speed/mm/min | MWCNT Content/wt% | Test Temperature/°C |

|---|---|---|

| 1 | 0 | 20 |

| 0.5 | ||

| 0.75 | ||

| 1 |

| Observation Point | Observation Point Displacement /mm | Observation Point Critical Load /N | Type I Fracture Toughness /J/m2 |

|---|---|---|---|

| 1 | 23.84 | 3.36 | 112.9263 |

| 2 | 31.45 | 3.21 | 115.5527 |

| 3 | 43.61 | 3.07 | 128.0561 |

| 4 | 55.68 | 2.88 | 130.3904 |

| 5 | 63.35 | 2.53 | 115.9736 |

| 6 | 73.59 | 2.29 | 108.5599 |

| Observation Point | Observation Point Displacement /mm | Observation Point Critical Load /N | Type I Fracture Toughness /J/m2 |

|---|---|---|---|

| 1 | 24.96 | 4.43 | 149.997 |

| 2 | 36.42 | 4.06 | 161.1317 |

| 3 | 46.03 | 3.54 | 153.7712 |

| 4 | 58.14 | 2.82 | 130.7976 |

| 5 | 68.73 | 2.69 | 129.0937 |

| 6 | 79.91 | 2.65 | 130.5022 |

| Observation Point | Observation Point Displacement /mm | Observation Point Critical Load /N | Type I Fracture Toughness /J/m2 |

|---|---|---|---|

| 1 | 25.22 | 4.5 | 157.1521 |

| 2 | 36.57 | 4.13 | 168.1582 |

| 3 | 45.43 | 3.22 | 140.8614 |

| 4 | 57.08 | 3.37 | 152.7067 |

| 5 | 66.91 | 2.61 | 123.2283 |

| 6 | 76.33 | 2.58 | 125.3542 |

| Observation Point | Observation Point Displacement /mm | Observation Point Critical Load /N | Type I Fracture Toughness /J/m2 |

|---|---|---|---|

| 1 | 24.8 | 3.58 | 129.7379 |

| 2 | 36.26 | 3.32 | 129.2821 |

| 3 | 48.15 | 2.95 | 136.23 |

| 4 | 59.03 | 2.57 | 123.9775 |

| 5 | 69.8 | 2.26 | 113.1757 |

| 6 | 81.29 | 2.01 | 102.3231 |

| MWCNT Content /wt% | Maximum Type I Fracture Toughness /J/m2 | Minimum Type I Fracture Toughness /J/m2 | Average Type I Fracture Toughness |

|---|---|---|---|

| 0.0 | 130.3904 | 108.5599 | 118.5765 |

| 0.5 | 161.1317 | 129.0937 | 142.5489 |

| 0.75 | 168.1582 | 123.2283 | 144.5768 |

| 1.0 | 136.23 | 102.3231 | 122.4544 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhang, Z.; Cao, J.; Wang, Y.; Sun, Z. Investigation of the Preparation and Interlayer Properties of Multi-Walled Carbon Nanotube-Reinforced Ultra-Thin TA1/CFRP Laminates. Metals 2025, 15, 765. https://doi.org/10.3390/met15070765

Zhang Q, Zhang Z, Cao J, Wang Y, Sun Z. Investigation of the Preparation and Interlayer Properties of Multi-Walled Carbon Nanotube-Reinforced Ultra-Thin TA1/CFRP Laminates. Metals. 2025; 15(7):765. https://doi.org/10.3390/met15070765

Chicago/Turabian StyleZhang, Quanda, Zhongxiao Zhang, Jiahua Cao, Yao Wang, and Zhiying Sun. 2025. "Investigation of the Preparation and Interlayer Properties of Multi-Walled Carbon Nanotube-Reinforced Ultra-Thin TA1/CFRP Laminates" Metals 15, no. 7: 765. https://doi.org/10.3390/met15070765

APA StyleZhang, Q., Zhang, Z., Cao, J., Wang, Y., & Sun, Z. (2025). Investigation of the Preparation and Interlayer Properties of Multi-Walled Carbon Nanotube-Reinforced Ultra-Thin TA1/CFRP Laminates. Metals, 15(7), 765. https://doi.org/10.3390/met15070765