Superstrength of Nanostructured Ti Grade 4 with Grain Boundary Segregations

Abstract

1. Introduction

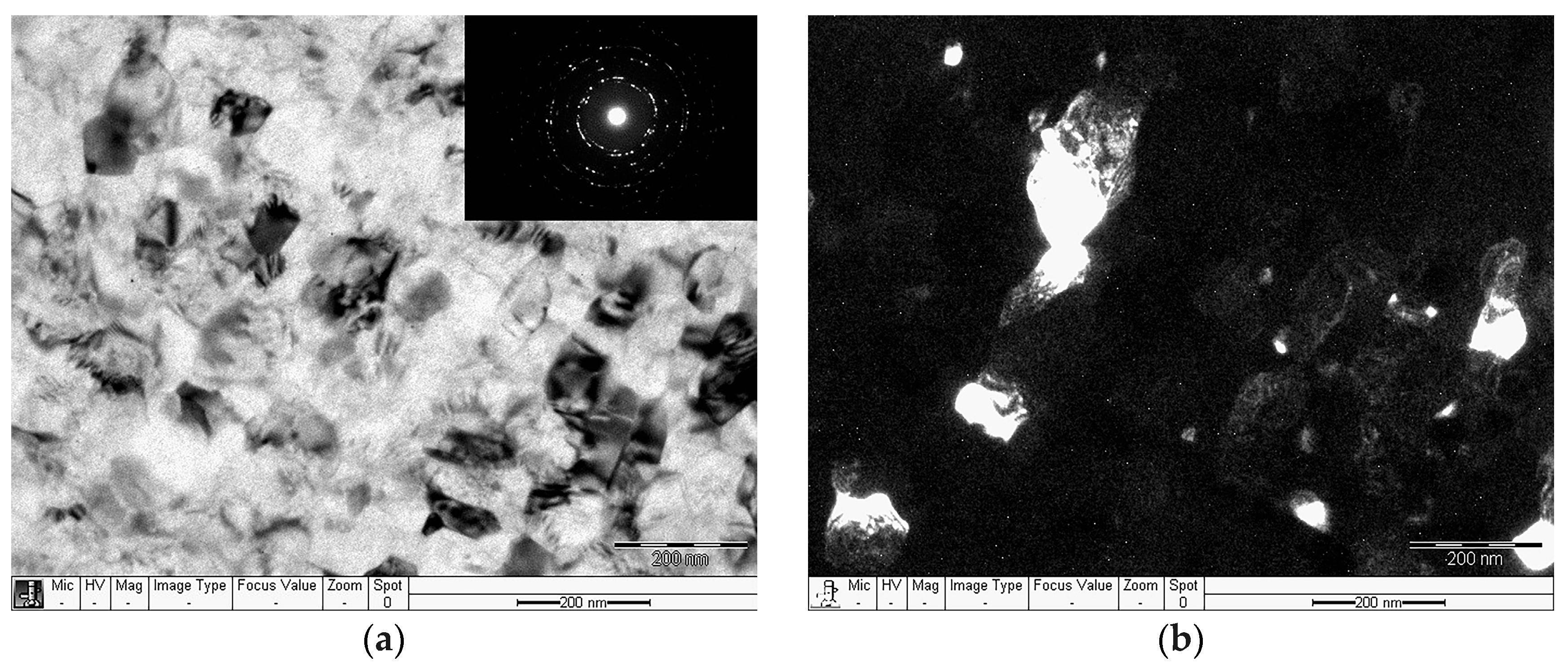

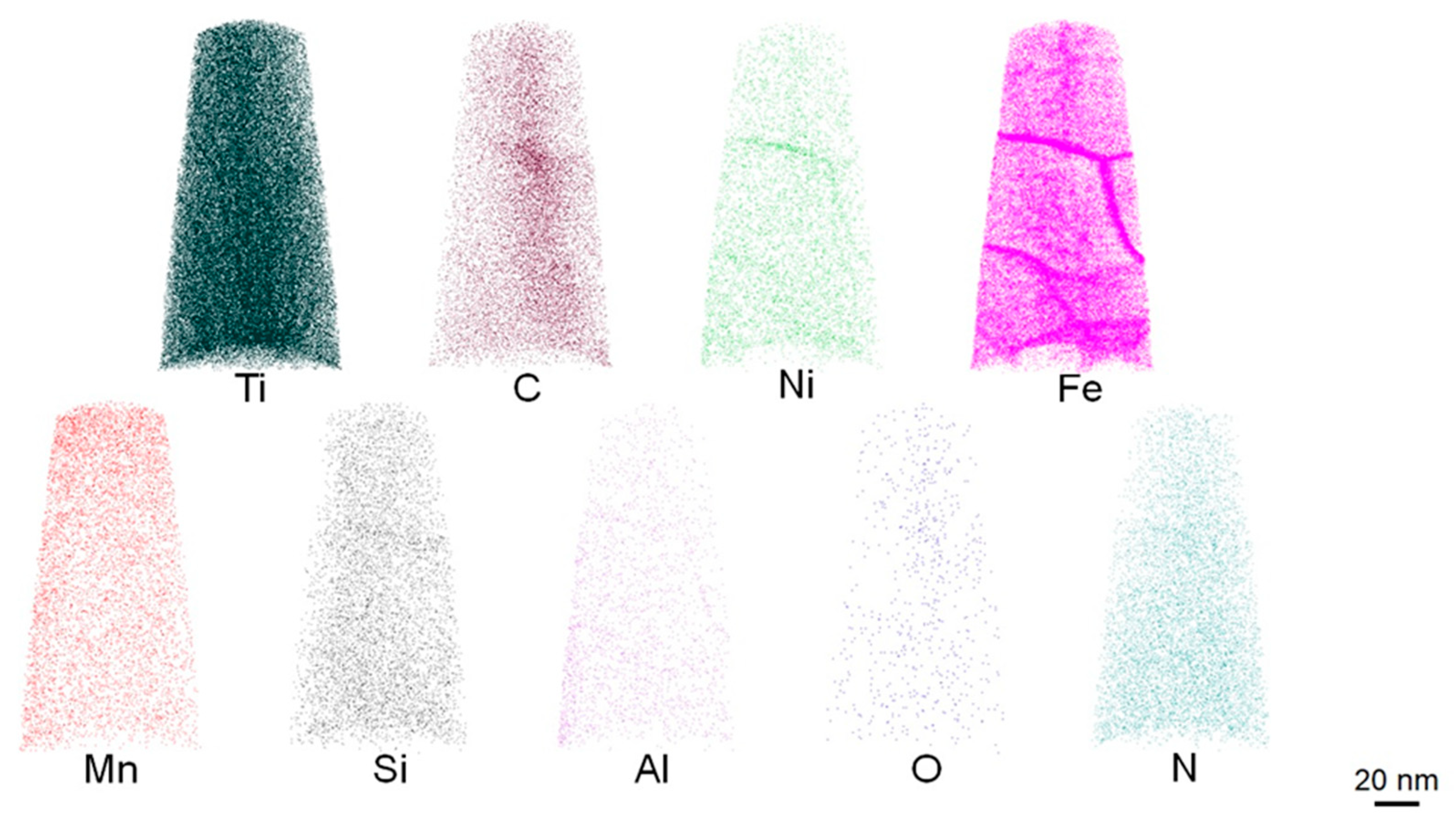

2. Materials and Methods

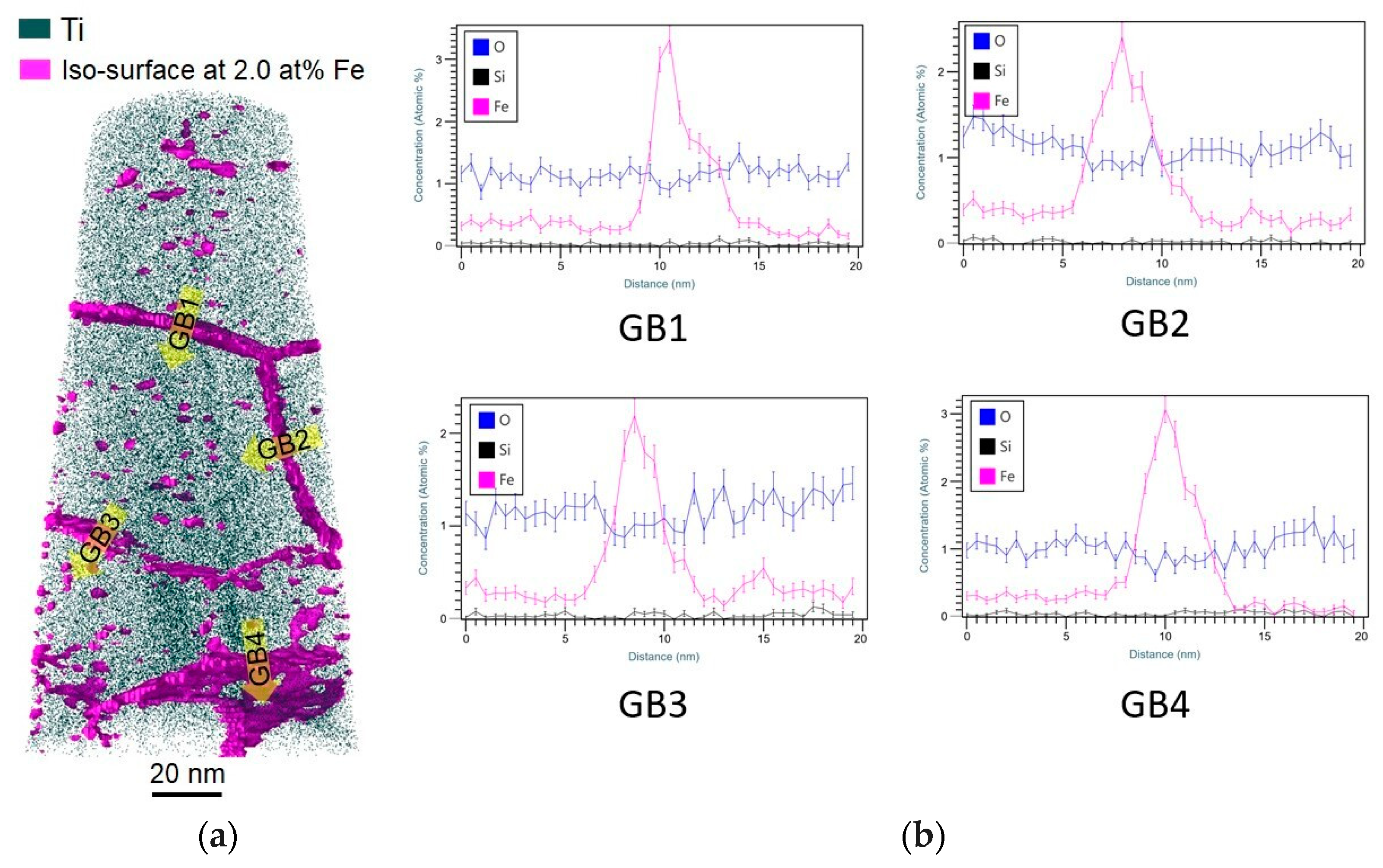

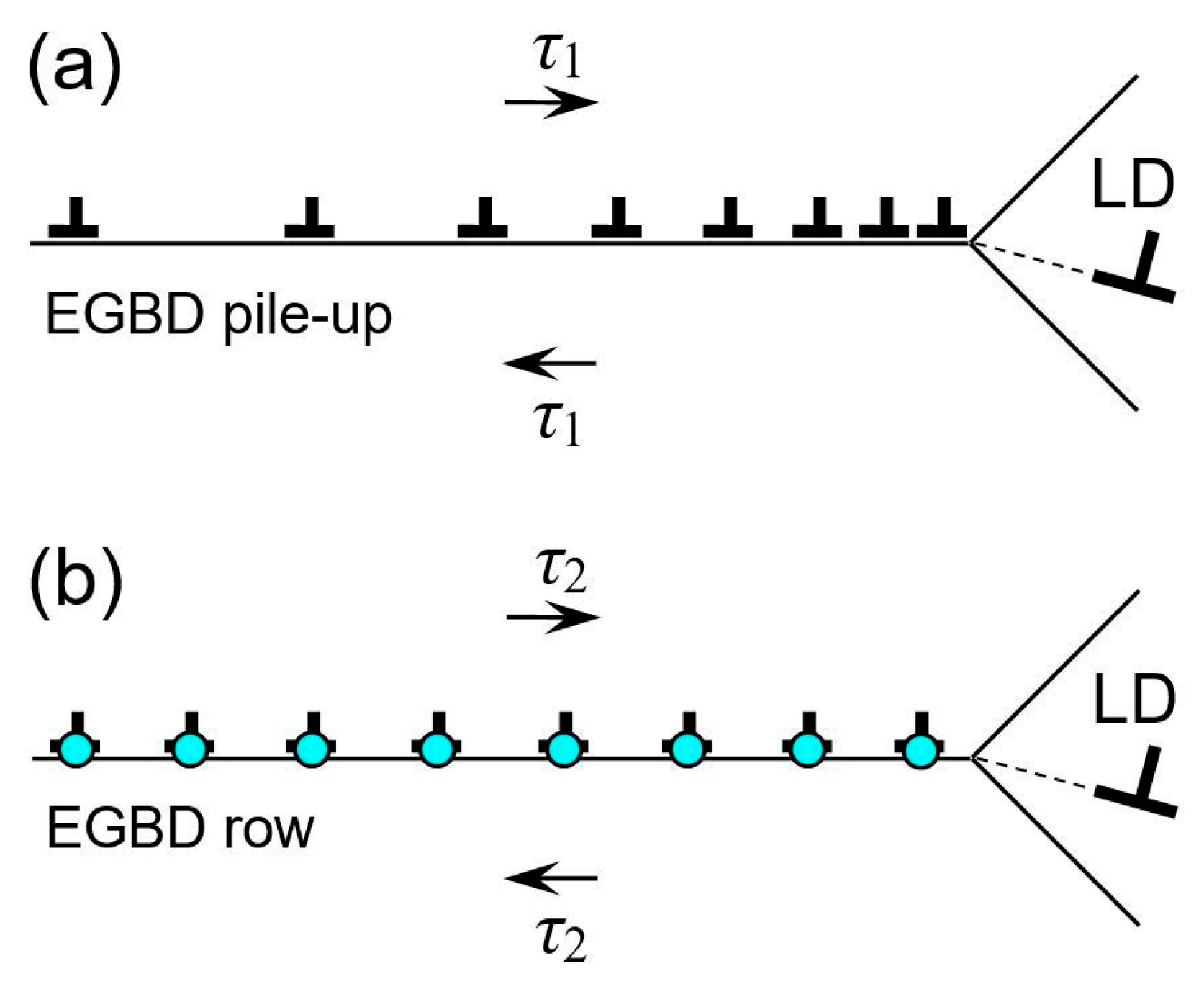

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hanawa, T. Overview of Metals and Applications. In Metals for Biomedical Devices; Elsevier: Amsterdam, The Netherlands, 2010; pp. 3–24. ISBN 978-1-84569-434-0. [Google Scholar]

- Froes, F.; Qian, M. Titanium in Medical and Dental Applications; Woodhead publishing series in biomaterials; Elsevier Woodhead Publishing: Amsterdam, The Netherlands, 2018; ISBN 978-0-12-812456-7. [Google Scholar]

- Estrin, Y.; Lapovok, R.; Medvedev, A.E.; Kasper, C.; Ivanova, E.; Lowe, T.C. Mechanical Performance and Cell Response of Pure Titanium with Ultrafine-Grained Structure Produced by Severe Plastic Deformation. In Titanium in Medical and Dental Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 419–454. ISBN 978-0-12-812456-7. [Google Scholar]

- Garbacz, H.; Semenova, I.P.; Zherebtsov, S.; Motyka, M. Nanocrystalline Titanium; Micro & nano technologies series; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-814599-9. [Google Scholar]

- Usmanov, E.I.; Rezyapova, L.R.; Valiev, R.Z. High-Strength State and Strengthening Mechanisms of Ultrafine-Grained Titanium. Phys. Mesomech. 2023, 26, 483–494. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical Properties of Nanocrystalline Materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Koch, C. Optimization of Strength and Ductility in Nanocrystalline and Ultrafine Grained Metals. Scr. Mater. 2003, 49, 657–662. [Google Scholar] [CrossRef]

- Balasubramanian, N.; Langdon, T.G. The Strength–Grain Size Relationship in Ultrafine-Grained Metals. Met. Mater. Trans. A 2016, 47, 5827–5838. [Google Scholar] [CrossRef]

- Luo, P.; Hu, Q.; Wu, X. Quantitatively Analyzing Strength Contribution vs Grain Boundary Scale Relation in Pure Titanium Subjected to Severe Plastic Deformation. Met. Mater. Trans. A 2016, 47, 1922–1928. [Google Scholar] [CrossRef]

- Babicheva, R.I.; Dmitriev, S.V.; Bai, L.; Zhang, Y.; Kok, S.W.; Kang, G.; Zhou, K. Effect of Grain Boundary Segregation on the Deformation Mechanisms and Mechanical Properties of Nanocrystalline Binary Aluminum Alloys. Comput. Mater. Sci. 2016, 117, 445–454. [Google Scholar] [CrossRef]

- He, T.; Qi, Y.; Ji, Y.; Feng, M. Grain Boundary Segregation-Induced Strengthening-Weakening Transition and Its Ideal Maximum Strength in Nanopolycrystalline FeNiCrCoCu High-Entropy Alloys. Int. J. Mech. Sci. 2023, 238, 107828. [Google Scholar] [CrossRef]

- Bobylev, S.V.; Sheinerman, A.G. Strengthening Induced by Grain Boundary Solute Segregations in Ultrafine-Grained and Nanocrystalline Alloys: A Brief Review. Rev. Adv. Mater. Tech. 2020, 2, 32–38. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2013; ISBN 978-1-118-09540-9. [Google Scholar]

- Wetscher, F.; Tian, B.H.; Stock, R.; Pippan, R. High Pressure Torsion of Rail Steels. MSF 2006, 503–504, 455–460. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. (Eds.) Special Issue on Superfunctional Nanomaterials by Severe Plastic Deformation. Mater. Trans. 2023, 64, 1271. [Google Scholar] [CrossRef]

- Bachmaier, A.; Hohenwarter, A.; Pippan, R. New Procedure to Generate Stable Nanocrystallites by Severe Plastic Deformation. Scr. Mater. 2009, 61, 1016–1019. [Google Scholar] [CrossRef]

- Kormout, K.S.; Pippan, R.; Bachmaier, A. Deformation-Induced Supersaturation in Immiscible Material Systems during High-Pressure Torsion. Adv. Eng. Mater. 2017, 19, 1600675. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. High-Pressure Torsion Deformation Induced Phase Transformations and Formations: New Material Combinations and Advanced Properties. Mater. Trans. 2019, 60, 1256–1269. [Google Scholar] [CrossRef]

- Lowe, T.C.; Reiss, R.A.; Illescas, P.E.; Davis, C.F.; Connick, M.C.; Sena, J.A. Effect of Surface Grain Boundary Density on Preosteoblast Proliferation on Titanium. Mater. Res. Lett. 2020, 8, 239–246. [Google Scholar] [CrossRef]

- Wang, H.; Shuro, I.; Umemoto, M.; Ho-Hung, K.; Todaka, Y. Annealing Behavior of Nano-Crystalline Austenitic SUS316L Produced by HPT. Mater. Sci. Eng. A 2012, 556, 906–910. [Google Scholar] [CrossRef]

- Aksyonov, D.A.; Hickel, T.; Neugebauer, J.; Lipnitskii, A.G. The Impact of Carbon and Oxygen in Alpha-Titanium: Ab Initio Study of Solution Enthalpies and Grain Boundary Segregation. J. Phys.: Condens. Matter 2016, 28, 385001. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Sha, G.; Jin, S.; Hou, Z.; Bayat, M.; Yang, N.; Tan, Q.; Yin, Y.; Liu, S.; et al. Designing against Phase and Property Heterogeneities in Additively Manufactured Titanium Alloys. Nat. Commun. 2022, 13, 4660. [Google Scholar] [CrossRef]

- Sauvage, X.; Wilde, G.; Divinski, S.V.; Horita, Z.; Valiev, R.Z. Grain Boundaries in Ultrafine Grained Materials Processed by Severe Plastic Deformation and Related Phenomena. Mater. Sci. Eng. A 2012, 540, 1–12. [Google Scholar] [CrossRef]

- Labusch, R. A Statistical Theory of Solid Solution Hardening. Phys. Status Solidi (B) 1970, 41, 659–669. [Google Scholar] [CrossRef]

- Firstov, S.O.; Rogul, T. G Features of Solid-Solution Hardening and Temperature Dependence of the Critical Shear Stress in Binary and Multicomponent Alloys. Prog. Phys. Met. 2024, 25, 545–569. [Google Scholar] [CrossRef]

- Toda-Caraballo, I.; Rivera-Díaz-del-Castillo, P.E.J. Modelling Solid Solution Hardening in High Entropy Alloys. Acta Mater. 2015, 85, 14–23. [Google Scholar] [CrossRef]

- Wagih, M.; Schuh, C.A. Spectrum of Grain Boundary Segregation Energies in a Polycrystal. Acta Mater. 2019, 181, 228–237. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Danoix, F.; Gouné, M.; Bagot, P.A.J.; Peng, Z.; Moody, M.P.; Gault, B. Reflections on the Analysis of Interfaces and Grain Boundaries by Atom Probe Tomography. Microsc. Microanal. 2020, 26, 247–257. [Google Scholar] [CrossRef] [PubMed]

- Masuda, T.; Sauvage, X.; Hirosawa, S.; Horita, Z. Achieving Highly Strengthened Al–Cu–Mg Alloy by Grain Refine-ment and Grain Boundary Segregation. Mater. Sci. Eng. A 2020, 793, 139668. [Google Scholar] [CrossRef]

- Devulapalli, V.; Hans, M.; Sukumar, P.T.; Schneider, J.M.; Dehm, G.; Liebscher, C.H. Microstructure, Grain Boundary Evolution and Anisotropic Fe Segregation in (0001) Textured Ti Thin Films. Acta Mater. 2022, 238, 118180. [Google Scholar] [CrossRef]

- Felfer, P.; Scherrer, B.; Demeulemeester, J.; Vandervorst, W.; Cairney, J.M. Mapping Interfacial Excess in Atom Probe Data. Ultramicroscopy 2015, 159, 438–444. [Google Scholar] [CrossRef]

- Devulapalli, V.; Chen, E.; Brink, T.; Frolov, T.; Liebscher, C.H. Topological Grain Boundary Segregation Transitions. Science 2024, 386, 420–424. [Google Scholar] [CrossRef]

- Aksyonov, D.A.; Lipnitskii, A.G. Solubility and Grain Boundary Segregation of Iron in Hcp Titanium: A Computational Study. Comput. Mater. Sci. 2017, 137, 266–272. [Google Scholar] [CrossRef]

- Jia, H.; Bjørge, R.; Cao, L.; Song, H.; Marthinsen, K.; Li, Y. Quantifying the Grain Boundary Segregation Strengthening Induced by Post-ECAP Aging in an Al-5Cu Alloy. Acta Mater. 2018, 155, 199–213. [Google Scholar] [CrossRef]

- Nes, E.; Holmedal, B.; Evangelista, E.; Marthinsen, K. Modelling Grain Boundary Strengthening in Ultra-Fine Grained Aluminum Alloys. Mater. Sci. Eng. A 2005, 410–411, 178–182. [Google Scholar] [CrossRef]

- Vo, N.Q.; Schäfer, J.; Averback, R.S.; Albe, K.; Ashkenazy, Y.; Bellon, P. Reaching Theoretical Strengths in Nanocrystalline Cu by Grain Boundary Doping. Scr. Mater. 2011, 65, 660–663. [Google Scholar] [CrossRef]

- Zhao, D.; Løvvik, O.M.; Marthinsen, K.; Li, Y. Segregation of Mg, Cu and Their Effects on the Strength of Al Σ5 (210)[001] Symmetrical Tilt Grain Boundary. Acta Mater. 2018, 145, 235–246. [Google Scholar] [CrossRef]

- Skiba, N.V.; Gutkin, M.Y.; Orlova, T.S. Influence of grain boundary segregations of Mg atoms on the mechanical properties of ultrafine-grained Al-Mg-Zr alloy. Phys. Mesomech. 2025, 28, 157775. [Google Scholar]

- Skiba, N.V.; Orlova, T.S.; Gutkin, M.Y. Mechanism of Implementation of High Ductility in Ultrafine-Grained Aluminum after Annealing and Subsequent Deformation. Phys. Solid State 2020, 62, 2094–2100. [Google Scholar] [CrossRef]

| Grain Boundary | Width of Fe Grain Boundary Segregations, nm | Fe Concentration at GB, at.% | GB Solute Excesses of Fe, Atom/nm2 |

|---|---|---|---|

| GB1 | 5.5 ± 0.25 | 3.30 ± 0.20 | 4.50 |

| GB2 | 6.5 ± 0.25 | 2.39 ± 0.18 | 4.20 |

| GB3 | 6.0 ± 0.25 | 2.19 ± 0.19 | 2.48 |

| GB4 | 6.5 ± 0.25 | 3.01 ± 0.12 | 5.46 |

| Average | 6.13 ± 0.45 | 2.72 ± 0.47 | 4.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usmanov, E.I.; Gutkin, M.Y.; Wu, Y.; Sha, G.; Valiev, R.Z. Superstrength of Nanostructured Ti Grade 4 with Grain Boundary Segregations. Metals 2025, 15, 618. https://doi.org/10.3390/met15060618

Usmanov EI, Gutkin MY, Wu Y, Sha G, Valiev RZ. Superstrength of Nanostructured Ti Grade 4 with Grain Boundary Segregations. Metals. 2025; 15(6):618. https://doi.org/10.3390/met15060618

Chicago/Turabian StyleUsmanov, Emil I., Michail Yu. Gutkin, Yinxing Wu, Gang Sha, and Ruslan Z. Valiev. 2025. "Superstrength of Nanostructured Ti Grade 4 with Grain Boundary Segregations" Metals 15, no. 6: 618. https://doi.org/10.3390/met15060618

APA StyleUsmanov, E. I., Gutkin, M. Y., Wu, Y., Sha, G., & Valiev, R. Z. (2025). Superstrength of Nanostructured Ti Grade 4 with Grain Boundary Segregations. Metals, 15(6), 618. https://doi.org/10.3390/met15060618