Abstract

This study investigated the control of porosity during gas metal arc welding with pulsed arc (GMAW-P) of complex-phase 780 (CP780) galvanized steel. Due to the Zn coating on this type of steel, porosity forms during welding as a result of Zn vaporization. The objective was to optimize the welding parameters to minimize porosity with a design of experiments using an L9 orthogonal array to analyze the effects of peak current (Ip), pulse time (tp), and pulse frequency (f) in high-speed welding conditions. The results showed that porosity was significantly reduced with a peak current of 313 A, a frequency of 10 Hz, and a pulse time of 10 ms, achieving ~0% porosity in the validation welding trials. A microstructural analysis identified allotriomorphic ferrite, Widmanstätten ferrite, acicular ferrite, bainite, and martensite in the heat-affected zone (HAZ). A predictive model to anticipate the percentage of porosity with an R2 of 99.97% was developed, and an ANOVA determined the peak current as the most critical factor in porosity formation.

1. Introduction

The selection of materials is one of the most important steps in the fabrication of components, as it is a determining factor for the design and manufacturing criteria of the element. The automotive industry is an example of the importance of material selection, as parts are required to meet specific requirements, such as high mechanical strength, low weight, and high energy absorption, among others, ensuring that the component is suitable for vehicle-specific conditions while being manufacturable using existing techniques.

The automotive industry is currently experiencing a significant shift toward lightweight structures, primarily driven by the need for enhanced fuel efficiency, adherence to stringent safety standards, and the growing emphasis on environmental sustainability. The use of advanced materials, particularly galvanized complex-phase (CP) steels, has emerged as a promising solution to meet these demands. Galvanized CP steels possess several advantageous properties, including high strength, excellent formability, superior weldability, and remarkable corrosion resistance, making them ideal candidates for automotive applications [1]. Among the most used steels in the automotive industry are CP steels. These microalloyed steels are coated with a Zn surface layer through hot-dip galvanizing, thermal spraying, or electrodeposition processes [2]. The behavior of Zn coatings in environmental conditions involves the formation of a protective oxide film, which subsequently transforms into zinc hydroxide in the presence of humidity or electrolytes. Zinc hydroxide can react with atmospheric carbon dioxide to form zinc carbonate, a compound that is known for its corrosion-inhibiting properties [3]. During the joining process, particularly arc fusion welding, galvanized steels tend to present complications, as the coating promotes the formation of round or elongated cavities at the root, as well as porosities both volumetrically and on the weld face. This issue is attributed to the fact that Zn has an evaporation temperature of 906 °C, and since temperatures in the weld pool during GMAW processes often exceed 1500 °C, the Zn coating melts and evaporates within fractions of a second [4]. This scenario causes high-pressure Zn vapor to form at the interface of the Zn-coated sheets during welding. Welding speed significantly influences the porosity of galvanized steel, primarily due to the evaporation of Zn during the welding process. Higher welding speeds may lead to increased Zn vaporization, which contributes to the formation of pores in the weld bead. For instance, Das et al. [5] noted that at lower welding speeds, porosity was minimal, while at higher speeds, the instability of the arc and increased Zn evaporation resulted in defects. High welding speeds might lead to insufficient heat input, resulting in rapid cooling and inadequate melting of the base material, which in turn may cause porosity due to trapped gases. Conversely, lower welding speeds increase the heat input, enhancing the vaporization of the Zn coating, which can also lead to porosity formation as the escaping Zn vapor creates voids in the weld [6,7].

The implementation of single-pulsed and double-pulsed GMAW techniques has demonstrated significant improvements in the dynamic behavior of the weld pool. Single-pulsed GMAW enhances process stability by controlling heat input and refining droplet detachment, this interplay leads to improved weld bead formation and reduced spattering. In contrast, double-pulsed GMAW further optimizes metal transfer by introducing a secondary modulation, which refines thermal cycling, stabilizes the weld pool, and enhances fluidity. This refined thermal control not only contributes to better weld bead morphology but also reduces residual stresses and mitigates crack susceptibility. The combination of these techniques plays a key role in improving the mechanical integrity and overall performance of welded joints, particularly in applications requiring precise control over heat input and microstructural evolution [8,9,10].

In addition, the chemical composition of welding electrodes, specifically the levels of Ni, Mn and Si, significantly influences the formation of porosities in galvanized steels. Mn enhances the mechanical properties of welded joints by increasing strength and toughness, which is particularly beneficial in structural and automotive applications. Nevertheless, an excessive amount of Mn may lead to higher porosity levels due to its interaction with the Zn coating, altering the melting behavior and fluidity of the weld pool. Meanwhile, Si plays a dual role, as it improves fluidity and minimizes oxide formation, yet at elevated concentrations, it can intensify the reactivity of the steel during galvanization, increasing the likelihood of porosity. In this context, the addition of Ni has proven to counteract the reactivity of Si and P in steel, stabilizing the welding process and reducing the probability of porosity formation, making it crucial to optimize the balance of these elements to achieve high-quality welds with minimal defects, especially in applications where the integrity and durability of the welded joint are essential [6,11,12,13].

Porosities in welded joints are unacceptable defects as these voids represent a reduction in the effective area in the weld metal and function as stress concentrators making the welded joint highly susceptible to premature failure. Thus, the current study focuses on reducing porosity in welded joints of galvanized CP 780 steel using the GMAW process with pulsed transfer mode to guarantee the structural integrity of the welded joint. Rapid welding speeds were employed like those typically used in robotic welding applications, aiming to optimize fusion whilst minimizing the formation of defects. Bearing in mind that the electrode composition plays a determinant role in porosity formation, particularly in galvanized steels, the selection of the filler material is essential. Instead of using the ER70S-3 electrode, which contains high Si and low Ni contents, the SM70MT electrode is proposed, as its lower Si content and higher Ni concentration contribute to reducing the reactivity with the Zn coating, stabilizing the weld pool and preventing the formation of pores.

2. Experimentation and Design Approach

2.1. Chemical Composition of the Base Materials

For this study, CP780 steel sheets (2.5 mm thick, 200 mm long, and 155 mm wide) were prepared by grinding and degreasing to remove contaminants before welding. The welding process utilized an SM70MT (Hyundai Welding Co., Ltd., Seoul, Republic of Korea) filler wire of 1.2 mm in diameter. The chemical composition of the base material, electrode, and Zn coating were analyzed using spark optical emission spectroscopy and the results are presented in Table 1 and Table 2.

Table 1.

Chemical composition of CP780 steel and the SM-70MT electrode (wt.%).

Table 2.

Chemical composition of the coating of CP780 steel (wt.%).

2.2. Design of Experiments (DOEs) and L9 Orthogonal Array

The experimental design used in this study was based on the Taguchi L9 (33) orthogonal array, which enables the evaluation of three control factors, each at three different levels. This approach optimizes the number of experiments while maintaining statistical robustness, reducing variability, and improving process efficiency [14]. In this case, the selected control factors were peak current (Ip), pulse time (tp), and pulse frequency (f), as shown in Table 3. The specific combination of these factors and their corresponding levels, following the L9 design, are detailed in Table 4. This methodology ensures a systematic assessment of the influence of each parameter on the welding process, facilitating the identification of optimal conditions.

Table 3.

Welding parameters for each experimental level.

Table 4.

L9 experimental array.

2.3. Welding Process

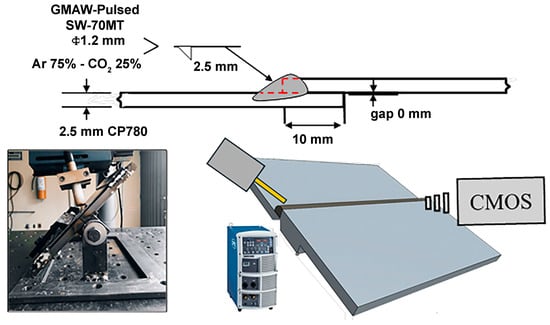

Considering that the lap joint geometry is particularly prone to porosity formation, this configuration was chosen with a 10 mm overlap of the base sheets. A constant welding length of 200 mm was maintained for all the welding trials. To minimize root opening and ensure consistent welding conditions and angles, a custom-designed fixture was fabricated, as shown in Figure 1. This fixture enables welding in various positions and inclinations, ensuring that the two sheets remain in full contact without any gap. This experimental setup guarantees a zero-root opening whilst minimizing data variability. Welding was carried out using the OTC Welbee P400 GMAW machine (OTC DAIHEN Inc., Osaka, Japan), which can be configured in DC, DC pulse, and DC wave pulse, following the parameters specified in the DC wave pulse mode. Furthermore, a welding carriage was employed to semi-automate the welding process, simulating the conditions of a robotic welding cell and ensuring precise and repeatable welds.

Figure 1.

Schematic design of the welded joint, lap joint symbol, and fixture for holding the steel sheets at an inclination of 45°.

The joint design was developed in accordance with the standardized codes for thin sheet welding, specifically AWS D9.1 [15] and AWS D8.8 [16], as illustrated in Figure 1, which outlines the specifications for automotive industry welds. To ensure consistency across all welds, a set of constant parameters was established and applied to all the welding trials. Welding was performed with a drag angle of 70°, stick out of 12 mm, and displacement of the torch at 22.7 mm/s. Besides, the welding torch was tilted 15 ° with respect to the normal. The weld pool was shielded with a gas mixture of 25% CO2 + 75% Ar, flowing at 25 L/min. The joint inclination was 45°, 1F.

2.4. Radiographic Inspection

The objective of radiographic inspection is to identify and evaluate the presence and nature of macroscopic defects in the welded joints. This non-destructive testing method provides valuable insights into the internal integrity of the welded joints. For the radiographic imaging, an Ir-192 source was employed, offering a sensitivity of 5 (0.20 mm) and a focal point of 3.124 mm. The source-to-film distance was maintained at 2.38 mm to ensure optimal image clarity. The penetrometer used adhered to ASTM E1742-08 standards [17], ensuring consistency and accuracy in the measurements. The films were developed manually using an analog process (AGFA D4), allowing for precise control over the development of the images. Once the radiographs were obtained, a thorough analysis of porosity was conducted. The films were digitized and processed using the Sigma Scan image analysis software Version 5.0.0, which enabled the detailed assessment of porosity within the welds. Digital analysis provides an enhanced level of precision, facilitating the identification and quantification of any defect present in the welds.

2.5. Microstructural Characterization

For the microstructural analysis, the samples were initially polished using SiC abrasive paper of various grits, followed by polishing with a diamond paste to achieve a mirror-like finish. Afterward, the samples were etched with a 5% nitric acid (nital) solution to reveal the microstructure of the base metals and welded joints. To measure the Zn thickness of the coating, the samples were treated with distilled water and CO2 for 5 min with agitation. The samples were then characterized and analyzed using optical microscopy (OM) with an Axio Vert-A1 inverted microscope, Carl Zeiss, Oberkochen, Germany and scanning electron microscopy (SEM) with a Jeol-JSM7600f (JEOL, Tokyo, Japan) microscope.

2.6. Root Strength Test

To evaluate the root strength of the welded joints, chisel tests were performed in accordance with the AWS D8.7 standard [18]. In this procedure, a flat chisel was carefully and gradually inserted into the lap joint of the CP-780 steel plates, applying force until the weld at the interface between the two plates separated. Extra attention was given to ensure that the chisel tip did not come into direct contact with the section to be analyzed after the fracture, preventing any potential damage to the area of interest. Once the chisel test was completed, the fractured surface was carefully cut and prepared for further examination. The fractured area was then analyzed, in detail, using SEM. This advanced technique allowed for an in-depth assessment of the fracture behavior, revealing critical information about the integrity and performance of the weld, as well as any potential weaknesses or defects within the welded joints.

2.7. Image Capture of the Welding Process

To minimize the intense radiation generated by the electric arc and the weld pool within the visible light spectrum, the vision system incorporates an array of specialized optical filters. These include a long-pass optical filter (HB720) designed to block wavelengths below 720 nm, ZWB3 UG5 U-330, (Bohr Optics Co., Ltd., Changchun, China) filters, and additional long-pass filters configured to block wavelengths below 850 nm and 950 nm. Furthermore, a circular polarizing (CPL) filter and a variable-density lens filter (ND2-ND400) are utilized to enhance the image clarity by reducing glare and controlling light intensity.

The captured images were processed using a high-speed CMOS (Complementary Metal-Oxide Semiconductor) camera (Beijing Bopixel Technology Co., Ltd., Beijing, China), which is engineered to provide high-performance imaging under these challenging conditions. The camera operates with a resolution of 720 pixels at an ultra-high frame rate of 1000 frames per second (fps), making it ideal for capturing rapid changes in the welding environment. Additionally, it supports resolutions of 1080 pixels with frame rates of 240 fps and 120 fps, allowing for flexibility in adapting to different analytical requirements. These features ensure accurate, high-resolution data acquisition, enabling a detailed analysis of the welding process. On the other hand, the OTC P400 unit has a data acquisition function, taking samples at a rate of 1 s, 100 ms, and 10 ms. For this study, data acquisition was performed at a maximum sampling rate of 10 ms, obtaining pulsed waveforms at 1 s intervals.

3. Results

3.1. Base Material

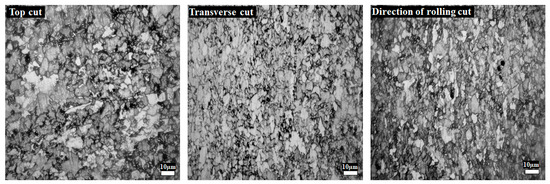

Figure 2 presents the microstructure of the as-received CP780 steel in different views, as observed in the optical microscope. These micrographs reveal an average grain size of approximately 7 μm in the longitudinal and transverse sections, while the top view exhibits a slightly larger grain size, reaching up to 10 μm. The presence of uniform and refined grains in all sections indicates that the material underwent dynamic recrystallization during the forming process. This process is essential in the production of CP steels, as it facilitates the formation of a well-balanced microstructure, primarily consisting of a bainitic matrix, along with secondary phases, such as martensite, ferrite, and retained austenite. Moreover, previous studies indicate that the typical microstructural composition of CP780 steel consists of approximately 53% bainitic matrix, 25% martensite, 20% ferrite, and 2% retained austenite [19].

Figure 2.

Micrographs of the as-received CP780 base metal showing the top, longitudinal, and transverse sections.

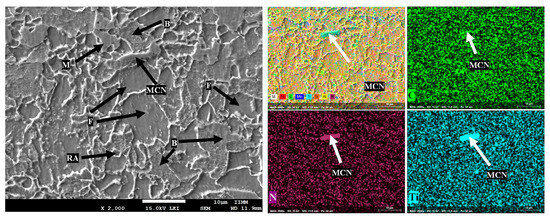

Figure 3 shows an SEM image of the as-received CP780 steel providing a more detailed observation of its microstructure. In the micrograph, the characteristic phases of the material are clearly identified, including bainite, martensite, ferrite, and retained austenite, as well as the presence of MCN-type carbonitrides, which are labeled in the image. Additionally, the elemental mapping performed in the SEM confirms the distribution and composition of these carbonitrides within the microstructure of the steel. The presence of alloying elements, such as Mn (1.14%), Si (0.265%), and carbide-forming stabilizers like Nb, Ti, and V plays a key role in providing the mechanical strength of this steel. These elements prevent the precipitation of Fe3C while promoting the formation of hard and wear-resistant phases [20].

Figure 3.

SEM micrograph and elemental X-ray dot mapping of the CP780 base metal, green carbon, purple nitrogen, light blue titanium.

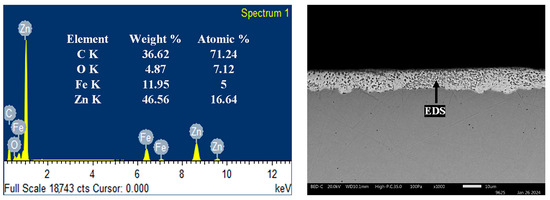

Figure 4 shows an SEM image of the Zn coating, and the spectra collected from the coating of an elemental analysis using energy dispersive X-ray spectroscopy (EDS). The EDS analysis confirms the presence of Zn in the galvanized coating of CP780 steel along with other alloying elements, such as Mg and Sn, in agreement with the composition given in Table 2. The thickness of the coating was found to vary between 8.16 to 15.01 μm and surface defects, such as cavities and cracks, were observed. On the outermost layer of galvanized steel, a protective ZnO layer forms, accompanied by other Zn-based compounds that assist in providing corrosion resistance. Among these, basic zinc carbonate (Zn5(OH)6(CO3)2), also known as zinc patina, is particularly significant [21]. This compound forms as a result of the reaction between Zn and atmospheric CO2, according to the following chemical reaction:

5Zn + 6H2O + 2CO2 → Zn5(OH)6(CO3)2

Figure 4.

SEM micrograph of the Zn coating on the CP780 sheet and the EDS spectra of the punctual chemical analysis of the coating.

The formation of stable and dense patina significantly reduces the corrosion rate, thereby enhancing the longevity of the protective coating.

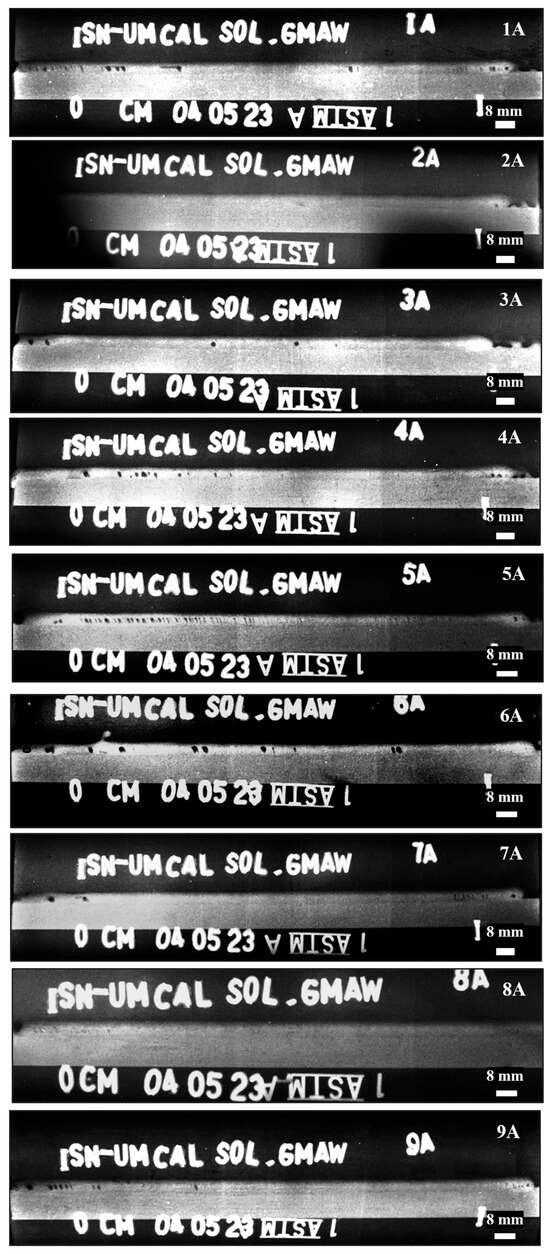

3.2. Porosity Assessment in the Welded Joint

The X-ray films of the welded specimens are shown in Figure 5. Weld 1 A exhibits clusters of porosity at the beginning and end of the weld bead, along with a small area of a lack of fusion, suggesting localized inconsistencies in heat input or shielding gas coverage. Although weld 2 A appears to be free of porosity, the central region reveals a slight lack of fusion and minor undercutting not exceeding 2 mm. This is likely owing to inadequate fusion between the base material and the filler metal. Weld 3 A displays individual spherical porosities of approximately 1 mm in diameter, primarily in the central and final sections of the weld bead. Besides, there is an unstable welding zone at the start, leading to the irregular deposition of the filler material and possible fluctuations in the stability of the arc. Weld 4 A contains clustered porosities with an irregular spherical morphology, along with an unstable deposition zone at the beginning of the weld, which could indicate issues with initial arc ignition or inconsistent shielding gas coverage. Weld 5 A presents a continuous distribution of irregular porosity along the entire weld bead length, possibly due to inadequate gas shielding, excessive travel speed, or contamination on the base material. Similarly, weld 6 A exhibits both individual spherical porosities and clusters throughout the deposit, suggesting potential gas entrapment during solidification. In contrast, weld 7 A has significantly fewer pores, which are only present in the arc instability zones at the beginning and end of the weld bead, demonstrating improved process control. In weld 8 A, the level of porosity was further reduced, with defects measuring less than 0.20 mm in diameter. These characteristics are undoubtedly signs of a more stable arc and optimized gas shielding conditions. Finally, weld 9 A shows only irregularly clustered porosities at the end of the weld deposit. These defects might be attributed to rapid solidification or shielding gas inconsistencies at the end. Table 5 summarizes the percentage of porosity measured for each welding condition. The values indicate that welds 2 A, 7 A, 8 A, and 9 A exhibit the lowest porosity percentages of 0%, 0.8%, 0.22%, and 0.57%, respectively, meeting the ISO 5817 standard [22]. Conversely, welds 1 A, 5 A, and 6 A display the highest porosity levels, of 3.57%, 4.38%, and 4.26%, respectively, suggesting a need for process optimization to reduce defect formation. These findings highlight the influence of welding parameters, such as peak current, pulse frequency, and shielding gas flow rate, on the formation of porosity, reinforcing the importance of precise process control in achieving high-quality welds.

Figure 5.

X-ray radiographic analysis of the weld beads obtained from the DOE L9 orthogonal array.

Table 5.

Percentages of porosity in each welded joint.

Additionally, the types of defects associated with each welding condition revealed distinctive characteristics related to the stability of the welding process and material interactions as detailed in Table 5. Specifically, welds 1 A, 4 A, 5 A, 7 A, and 9 A predominantly exhibited clustered porosity, generally attributed to unstable arc conditions or entrapped gas pockets during solidification. In contrast, welds 3 A and 6 A were mainly affected by spherical porosities, indicating localized gas entrapment in isolated regions of the weld pool. Meanwhile, weld 2 A was characterized by the lack of a fusion defect rather than porosity, which is directly associated with insufficient heat input or poor interaction between the molten filler metal and the base material. These observations provide valuable insights into tailoring the process parameters to control the formation of specific defect types and enhance the weld integrity.

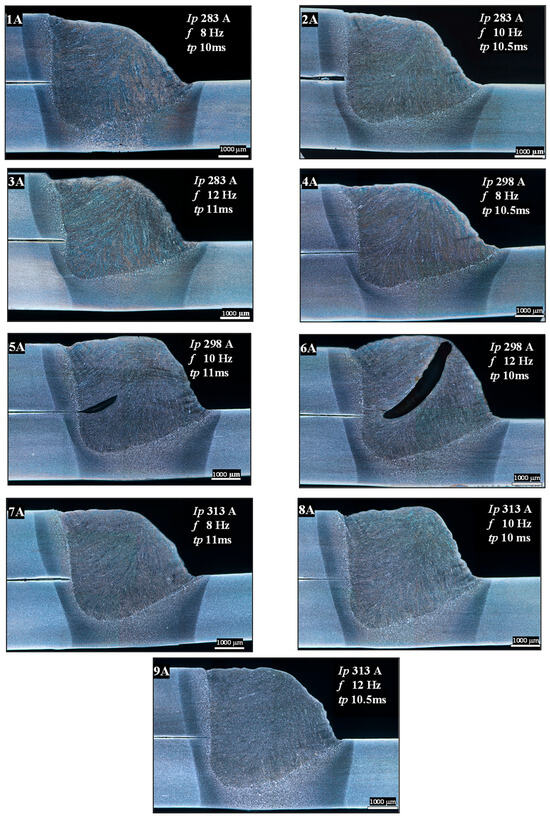

3.3. Macro- and Microstructural Analysis of the Welded Joints

The evaluation of the macrostructures of the welded joints, based on the orthogonal arrangement depicted in Figure 6, confirms that all the lap welds exhibit some degree of porosity or defects. In particular, the macrographs corresponding to welding conditions 5 A and 6 A reveal the presence of larger cavities and porosities, making these the joints with the highest defect levels, as registered in Table 5. This emphasizes the influence of the process parameters on weld integrity and highlights the need for optimized welding conditions to minimize defect formation. Weld beads 1 A, 2 A, 3 A, and 4 A exhibit a lower penetration into the bottom base plate, leading to smaller HAZs. In contrast, weld beads 7 A, 8 A, and 9 A, which were deposited with higher peak currents, penetrated deeper into the base plate. However, this increase in thermal energy not only enhanced penetration but also promoted a greater grain growth in the HAZ, giving rise to a higher presence of coarse martensite at the lower section of the weld bead, which might negatively impact the mechanical performance, particularly toughness and fatigue resistance. The macrographic analysis also revealed that porosities primarily form at the interface between the base sheets, initially appearing small but increasing in size as the overall porosity content rises, suggesting a direct correlation with the pressure difference induced by the heat input from the welding arc at the upper section of the weld bead. This observation further reinforces the importance of controlling process variables to minimize defect propagation and ensure structural integrity. Additionally, bainite is identified as the predominant microstructure in all the welding conditions, with its proportion varying according to the selected parameters. Intrinsically, a higher peak current promotes a slower cooling rate in the weld pool, leading to a more homogeneous microstructure and facilitating the release of trapped gases. However, when the optimum peak current is exceeded, excessive heat input exacerbates the volatilization of Zn from the coating, increasing the likelihood of porosity formation at the weld root, underscoring the necessity of balancing heat input to optimize weld quality while arresting the formation of defects.

Figure 6.

Macrographs of the cross-section of the welded joints obtained in the DOE L9 orthogonal array.

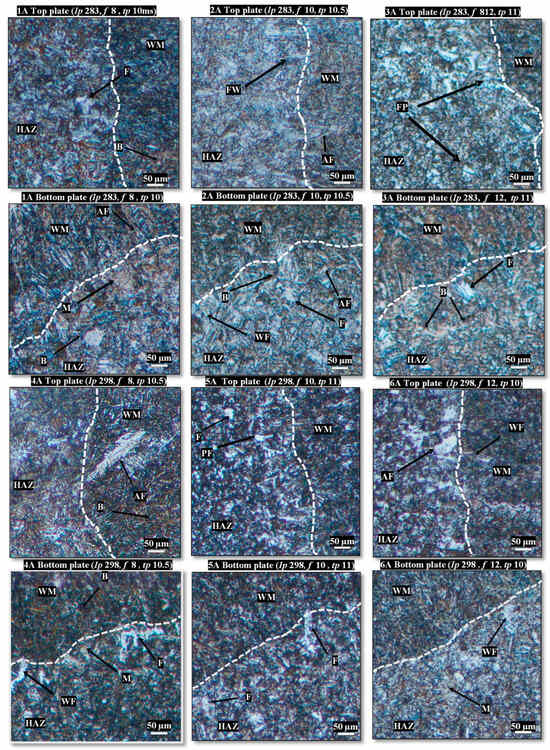

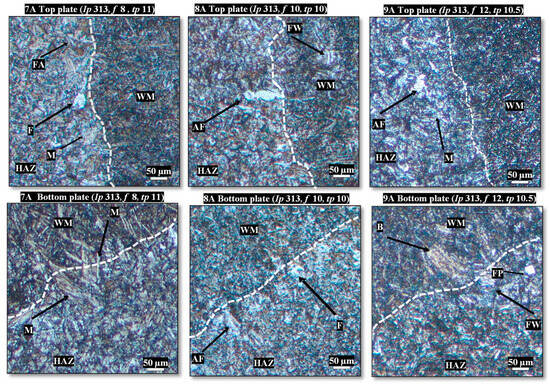

The microstructural analysis of the welded joints is shown in Figure 7. The optical micrographs reveal the influence of the GMAW-P parameters on the phases formed at the HAZ and weld metal (WM) of the CP780 steel lap welded joints. The evaluation of the microstructures and their relationship with mechanical properties provides a deep understanding of how the welding parameters impact the quality and performance of the welded joints. The HAZ and WM exhibit the presence of various phases, resulting from the interaction between thermal input and cooling rate, as dictated by the welding parameters. Specifically, phases such as allotriomorphic ferrite (AL), Widmanstätten ferrite (WF), dispersed acicular ferrite (AF), bainite, and occasional martensite are present. The allotriomorphic ferrite (samples 4 A, 6 A, 8 A, and 9 A) forms in areas near the WM under high-temperature conditions through diffusion, exhibiting an equiaxed structure that primarily enhances ductility and toughness, improving energy absorption and crack propagation resistance. On the other hand, Widmanstätten ferrite (all samples: 1 A–9 A) formed at lower temperatures without diffusion, and exhibits a distinctive lamellar structure that reinforces the metal matrix [23]. This phase increases the tensile strength and hardness, enhancing the capacity of the welded joint to resist static mechanical stresses [24]. In the HAZ, bainite (samples 2 A and 5 A) forms during cooling at intermediate temperatures. This phase is characterized by an acicular or lamellar structure; it combines high strength and toughness, making it ideal for applications under cyclic loading and fatigue. The presence of bainite enhances the structural integrity of the joint, protecting the weld from crack propagation under repetitive stress [25]. Additionally, martensite, though less frequent, appears in areas at the WM/HAZ interface where extremely fast cooling rates take place [26]. This phase, with a hard and brittle structure, provides high strength but low toughness, which can be unfavorable in dynamic loading conditions [27]. In the WM, from the fusion line, the epitaxial growth of ferritic and bainitic grains is observed, indicating a strong interaction between the phases formed in both alloys. Specifically, columnar grains show a high concentration of acicular ferrite. This epitaxial growth and concentration of acicular ferrite are important factors in improving the resistance and toughness of the welded joint. The control of the welding parameters, particularly the cooling rate and thermal input, significantly influences the formation and distribution of the phases, which in turn dictates the mechanical properties of the welded joint. Rapid cooling, characteristic of the GMAW-P process, promotes the formation of fine and evenly distributed acicular ferrite and bainite, contributing to the improvement of the joint properties [28,29]. In contrast, slower cooling favors the formation of allotriomorphic and Widmanstätten ferrite, increasing the hardness and tensile strength but potentially compromising toughness. The interaction between the phases of allotriomorphic, Widmanstätten, and acicular ferrite, along with bainite, and martensite, defines the quality and performance of the welded joints. The distribution and proportion of these phases, controlled through the precise management of the welding parameters, are key to ensuring the structural strength, toughness, and durability of the welded joints, which are essential for applications requiring high reliability and resistance to fatigue, impact, and fracture.

Figure 7.

Microstructures of the welded joints according to the L9 orthogonal array at the different WM/HAZ interfaces.

3.4. Chisel Test

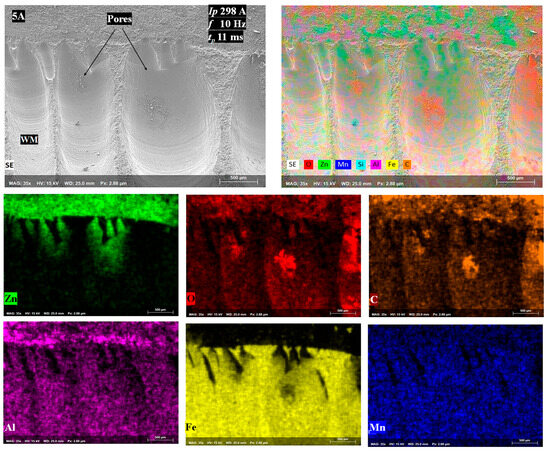

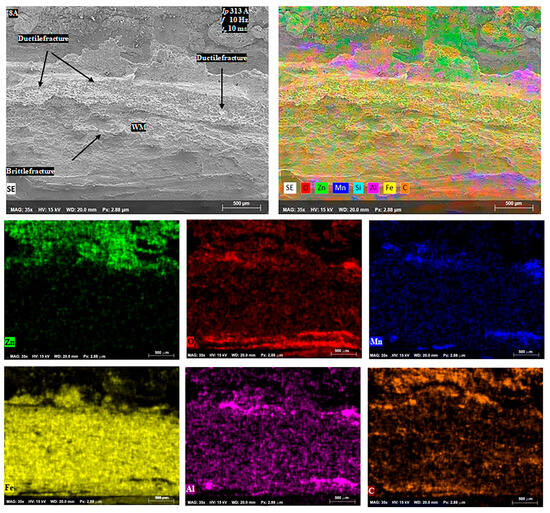

The qualitative results of the chisel test are shown in Figure 8 and Figure 9 in terms of the fracture characteristics. The SEM fractographies revealed cracks propagating through porosities from the root of each welded joint, as seen in Figure 8. These porosities form due to the vaporization of the Zn coating during arc welding, a process that creates gas pockets in the weld pool, leading to the formation of voids. The images of Figure 9 correspond to trial 2, which presents porosities with a high Zn content as confirmed using an EDS mapping analysis. This analysis shows the presence of Zn in both the porosities and the fume deposits at the weld root. In addition to the observed porosities, Figure 9 also shows distinctive dimples that are characteristic of a ductile fracture in the middle section of the weld. These dimples indicate localized plastic deformation, which typically occurs when the material undergoes tensile stress and deforms before fracture. However, in the upper section of the weld, near the weld face, a brittle cleavage fracture is observed. This type of fracture is more abrupt and typically occurs under conditions of high stress, often influenced by the formation of detrimental phases at the weld root. The presence of both ductile and brittle fracture modes suggests that the mechanical properties of the weld vary significantly along its cross-section, likely due to differences in the cooling rates and the resulting microstructures [28,29,30].

Figure 8.

SEM fractography and elemental mapping showing crack propagation through porosities and the weld root in weld 5 A, green zinc, red oxigen, orange carbon, purple aluminium, yellow iron, blue manganese.

Figure 9.

SEM fractography and elemental mapping showing crack propagation in weld 8 A green zinc, red oxigen, blue manganese, yellow iron, purple aluminium, orange carbon.

The morphology of the pores indicates that they nucleated at the root, traversing the weld throat, and displacing toward the weld face as observed in Figure 8. The displacement of the Zn gas entrapped within the weld pool highlights the dynamic behavior of the liquid metal during solidification. Additionally, both fracture surfaces show significant Al and Zn segregation at the weld root. This segregation leads to the formation of complex intermetallic phases, which negatively impact the mechanical properties of the welded joint, making it more susceptible to cracking and failure. The experimental results indicate that a higher peak current improves porosity reduction by promoting a slower cooling rate in the weld pool. This slower cooling rate assists in creating a more fluid pool, delaying solidification, and allowing trapped gases to escape more effectively. Conversely, a lower peak current results in a faster solidification process, preventing gas release and contributing to abrupt cooling conditions that favor the formation of detrimental phases within the WM and HAZ. These detrimental phases are often associated with reduced toughness and increased brittleness. Based on these findings, an optimized experimental approach that carefully controls the welding parameters, such as peak current, dwell peak time, and pulse frequency, may significantly reduce porosity formation and improve the overall integrity of welded joints. The presence of Zn within the porosities clearly highlights the critical role of Zn vaporization during arc welding in the formation of defects. Moreover, the observed correlation between the Zn content and the pore size indicates that regulating an adequate heat input and cooling rate can effectively control Zn volatilization, ultimately minimizing the levels of porosity and enhancing the mechanical properties of the welded joint [9]. These insights highlight the importance of refining welding parameters to produce high-quality, defect-free welds.

Saarimaa et al. [31] investigated the formation of crystalline structures in the zinc patina, promoting the precipitation of zinc carbonate at pressures of 65 and 80 bar. Although in the GMAW-P process such high pressures are not reached, the pressures within the molten pool are sufficient to generate porosities due to the trapped gases caused by the volatilization of Zn, which occurs at approximately 907 °C. This accumulation of Zn vapor largely contributes to the formation of pores.

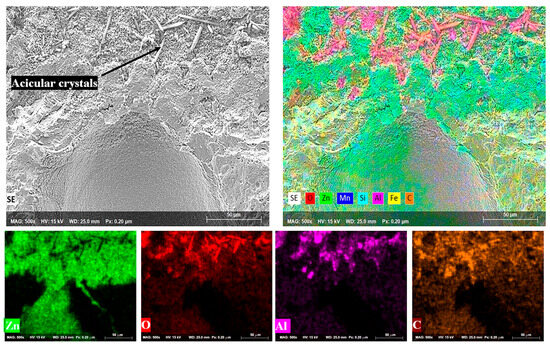

Figure 10 shows an SEM image with elemental mapping revealing the presence of acicular crystals rich in C, Al, and O, whereas Figure 11 shows, in detail, the morphologies of these complex phases. These crystals are forming primarily at the weld root, where the Zn content has decreased due to evaporation during the welding process. The interaction of these elements in the HAZ leads to the formation of these acicular structures. Deeper insight into the formation and possible effect of these structures in the performance of the welded joints goes beyond the scope of the present study. It is important to emphasize that these complex structures were not seen in welds with reduced levels of porosity.

Figure 10.

SEM image at the root weld and elemental EDS mapping revealing the presence of acicular crystals, green zinc, red oxygen, purple aluminium, orange carbon.

Figure 11.

Formation of patina and oxide crystals at the root of the pores.

In the GMAW-P process, the welding current oscillates between two values, namely, the peak current and base current, which allows manipulation and control of the energy of the electric arc, reducing distortion and enabling more controlled and precise penetration [32]. The arc power, weld penetration, and HAZ size for each welding trial are given in Table 6. The arc power was calculated by multiplying the arc voltage by the current and it directly influences the amount of heat generated in the fusion zone. The arc power values ranged from 6615 to 6912 W, with higher power values, such as in trial A9 (6912 W) with a weld penetration of 1.7 mm, indicating more heat transfer to the base material and, consequently, greater penetration. Conversely, in trials with a lower arc power, such as trial A4 (6615 W), the penetration decreases to 1.3 mm, suggesting that a lower arc power might not generate sufficient heat for adequate penetration.

Table 6.

Arc power, weld penetration, and HAZ size for the welding trials.

Thus, it is evident that the GMAW-P process allows for precise control over the thermal energy in the weld zone, which is reflected in the variation of penetration depending on the arc power. To emphasize, higher arc power values promote greater penetration due to increased heat generation. Nevertheless, it is essential to maintain a balance, as excessive power may lead to higher risks of porosity along with significant alterations in the microstructure of the weld zone [32,33].

Regarding the extent of the HAZ, the values ranged from 9.48 to 10.74 mm2. The results indicate that although a higher arc power promotes greater penetration, it does not necessarily correlate directly with a larger HAZ area. For instance, trial A4 with the lowest arc power (6615 W) exhibited a relatively large HAZ area of 10.17 mm2, while trial A2 with an intermediate arc power (6765 W) presented the smallest HAZ area of 9.48 mm2. This behavior suggests that the HAZ size is dictated not only by the arc power but also by other variables such as the welding speed, arc stability, and thermal diffusivity of the material. In this sense, a higher arc power does not always guarantee an increase in the extent of the HAZ, reinforcing the importance of optimizing the welding parameters to control both penetration and the extent of the thermally affected zone, which significantly impact the mechanical properties of the welded joint.

3.5. Analysis of Variance (ANOVA)

This analysis focuses on the data shown in Table 7, evaluating the influence of various parameters of the welding process on porosity formation in the welded joints. Through the ANOVA, the effects of key factors such as penetration, peak current, frequency, and peak time on porosity were investigated. A significance level of α = 0.05 was chosen, as this value is widely accepted in engineering and applied sciences. It offers a balanced compromise between a Type I error (false positive) and a Type II error (false negative), ensuring a low probability of incorrectly rejecting a true null hypothesis while maintaining sufficient sensitivity to detect meaningful effects in the process parameters. The hypotheses tested in the study are as follows:

Table 7.

ANOVA analysis.

- ○

- Null Hypothesis (H0): There is no significant difference in porosity across the different levels of peak current (Ip).Alternative Hypothesis (H1): There is a significant difference in porosity across the different levels of peak current (Ip).Case: This hypothesis tests whether variations in the peak current (Ip) significantly affect the porosity levels in the welded joints. Peak current is a critical factor that influences the temperature and dynamics of the weld pool.

- ○

- Null Hypothesis (H0): There is no significant difference in porosity across the different levels of pulse time (tp).Alternative Hypothesis (H1): There is a significant difference in porosity across the different levels of pulse time (tp).Case: This hypothesis examines the influence of the pulse time (tp) on porosity formation. Pulse time affects the duration of each pulse and the cooling rate of the weld, which in turn impacts gas release and the formation of pores.

- ○

- Null Hypothesis (H0): There is no significant difference in porosity across the different levels of pulse frequency (f).Alternative Hypothesis (H1): There is a significant difference in porosity across the different levels of pulse frequency (f).Case: This hypothesis investigates how variations in the pulse frequency (f) influence the formation of porosity. Pulse frequency controls the number of pulses per unit of time, affecting the cooling and solidification rates of the weld pool.

- ○

- Null Hypothesis (H0): There is no significant interaction between the welding parameters (peak current, pulse time, and pulse frequency) on porosity formation.Alternative Hypothesis (H1): There is a significant interaction between the welding parameters (peak current, pulse time, and pulse frequency) on porosity formation.Case: This hypothesis tests whether the combined effects of the peak current, pulse time, and pulse frequency lead to a significant interaction that influences porosity formation. The interaction effects may result in non-linear effects that cannot be understood by examining each parameter individually.

By testing these hypotheses, the study aimed to understand the individual and combined effects of welding parameters on porosity formation, a critical factor in ensuring high-quality welded joints. The significance level of α = 0.05 was chosen to ensure a reliable balance between Type I and Type II errors, which is essential for producing reproducible and robust results in the optimization of the welding process. The use of an L9 orthogonal array design allowed for a systematic approach to analyze these factors efficiently.

The results revealed that these parameters have a significant impact on porosity formation during welding, with the peak current being the factor with the greatest contribution to the observed variability. In the variance analysis, penetration shows a significant contribution with an F value of 494.08 and a p-value of 0.029, indicating that this factor has a direct impact on porosity, as higher penetration improves the bonding of the base metal and facilitates the release of trapped gases. The peak current showed a high F value of 1032.83 and a p-value of 0.022, indicating its significant relationship with porosity formation, likely due to heat generation effects and the solidification rate that determine the ability to evacuate gases. The frequency of the pulse and peak time also showed significant effects, contributing 11.68% and 12.02%, respectively. The dynamics of fluid motion within the weld pool are affected by the frequency of the pulse and thereby also affect pore formation, while the peak time controls cooling and solidification of the weld pool. Thus, the release of gases trapped in the weld pool also relies on the interplay of these two parameters.

3.6. Model Summary

A mathematical model was developed using multiple regression equations to predict the percentage of porosity in the welded joints. The model achieved a confidence level of 95.36% with an associated error of 4.64%, indicating an acceptable reproducibility rate. The independent variables considered in the model include peak current, frequency, and dwell peak pulse, which are critical parameters in GMAW-P. The statistics of the model are given in Table 8. The predictive accuracy of the model was quantified through the coefficient of determination (R2), a key statistical metric that evaluates the goodness of fit. As the R2 value approaches unity, the reliability and predictive capability of the model increase, confirming its robustness and validity for process optimization. The resulting regression model shows a high fit, with an R-squared of 99.97% and an adjusted R-squared of 99.74%, suggesting that the model explains almost all the observed variability in porosity formation.

Table 8.

Summary of the model.

The regression equation shows how the factors and their interactions affect porosity in welding:

%Porosity = (−16.472) + (11.846⋅Penetration) + (−0.1923⋅Ip⋅283) + (2.8974⋅Ip⋅298) + (−2.7051⋅Ip⋅313) + (1.1026⋅f⋅8) + (−0.9487⋅f⋅10) + (−0.1538⋅f⋅12) + (−0.9667⋅tp⋅10.0) + (−0.1974⋅tp⋅10.5) + (1.1641⋅tp⋅11.0)

This equation is a multiple linear regression model, where the dependent variable, %porosity, is modeled as a linear combination of several independent variables: penetration, peak current (at different levels), frequency (at different levels), and peak time (at different levels). According to this equation, it can be observed that penetration has a direct relationship with porosity, while certain peak current and peak time levels contribute to a decrease in porosity. However, an increase in frequency and certain peak current values tend to increase porosity in the weld. The adjusted mean values for each parameter and their respective standard errors are provided in Table 9. It is observed that penetration has a mean of 1.556 with a standard deviation of 0.159, indicating that the variability of this factor is moderate and has an important impact on porosity formation. The coefficients indicate the effect of each factor on porosity, with positive values suggesting an increase in porosity, and negative values indicating a decrease.

Table 9.

Adjusted means, coefficients, and statistical characteristics for the model predicting porosity.

Table 10 presents the results for the validation of the model. The variability of the model was checked to validate if it is acceptable, and whether the predicted response from the model matches the experimental results. To confirm the proposed mathematical model, the evaluation of the predictive equation was carried out using each of the factor values and their respective levels. This resulted in the estimation of the percentage of porosity obtained for the nine previously conducted experiments.

Table 10.

Comparison of the predicted porosity by the model with respect to experimental measurements of porosity.

- Best Predicted Results:

The best predicted result is the 0% porosity, which indicates that the welding process was optimized to avoid the formation of pores in the weld.

- At 313 A, 10 Hz, and 10.0 ms (penetration 1.8 mm), the model predicted 0.2308% porosity, which is very close to the optimal 0% porosity.

- Similarly, at 313 A, 12 Hz, and 10.5 ms (penetration 1.7 mm), the model predicted 0.6102% porosity, which is a small value, reflecting a good optimization for minimal porosity.

- Worst Predicted Results:

The worst predicted results occur when the porosity percentage is significantly higher, which means that the welding conditions did not fully minimize the porosity.

- At 298 A, 10 Hz, and 11.0 ms (penetration 1.5 mm), the model predicted 4.4100% porosity, indicating a suboptimal welding process that leads to higher porosity.

- At 298 A, 12 Hz, and 10.0 ms (penetration 1.6 mm), the model predicted 4.2586% porosity, which is also a higher value, suggesting that the process is not fully optimized for porosity reduction.

3.7. Optimization and Prediction of Porosity

The optimized condition obtained from the ANOVA analysis, as shown in Table 11, corresponds to the following factor levels: a peak current of 313 A, a pulse frequency of 10 Hz, and a pulse time of 10 ms. Under these conditions, the predicted porosity from the regression model is 0.230769. The standard error of fit (SE Fit) is 0.0851961, reflecting the precision of the estimate. The 95% confidence interval (CI) indicates that the true porosity value is expected to fall within the range from −0.851750 to 1.31329 with a 95% probability. Additionally, the 95% prediction interval (PI), which is wider than the confidence interval, suggests that future measurements or predictions of porosity will fall within the range from −1.34928 to 1.81082 with a 95% probability. These results provide a good estimation of porosity along with the associated uncertainty, both in terms of the model parameters and future predictions, based on the optimized ANOVA conditions.

Table 11.

Prediction of porosity according to the optimized GMAW-P parameters.

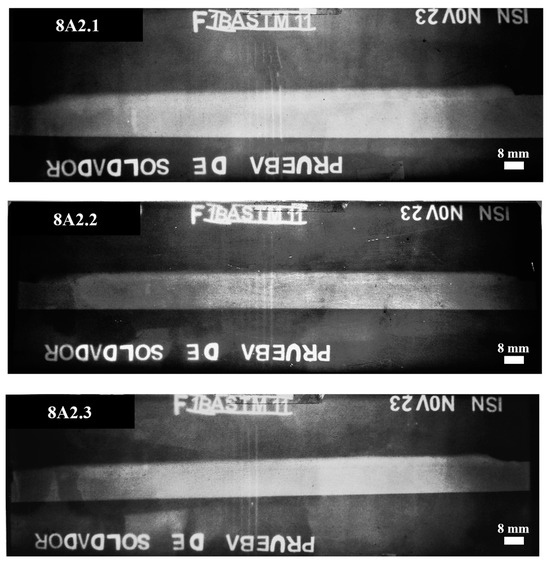

3.8. Validation of Results

To validate the repeatability of the experiment with the predicted values, three welds were produced using the parameters obtained from the analysis: peak current = 313 A, pulse time = 10 ms, and pulse frequency = 10 Hz. Subsequently, the average porosity was measured again for comparison. An X-ray radiographic inspection of the welds was conducted to ensure that the porosity levels were within the acceptable limits. The results of this analysis are displayed in Figure 12 for the three replicas. In the case of repetition #1, 0% porosity is observed in the length of the weld. In contrast with the previous observations of the welding trials of the L9 orthogonal experimental array, it is evident that there is no instability of the electric arc at the beginning and end of the weld deposit, which demonstrates that using a peak current of 313 A aids in immediately stabilizing the welding arc. For repetition #2, almost null porosity is observed; very few pores are seen with diameters of less than 0.2 mm. These pores are located mainly at the start and end of the weld bead. Nonetheless, these zones are prone to the generation of pores due to the instability of the welding arc. Finally, repetition #3 also showed 0% porosity, similar to repetition #1, confirming the reproducibility of the model and validating the predicted optimized values of the welding parameters for controlling the porosity during the GMA welding of galvanized CP780 sheets with a pulsed arc.

Figure 12.

X-rays radiographs of the welds performed with the optimal values according to the prediction.

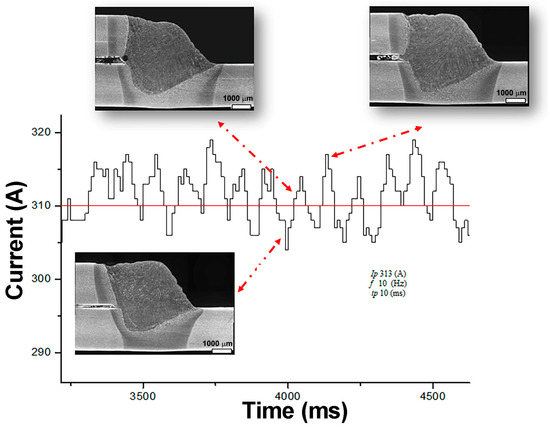

3.9. Effect of Pulsed Waveform

To analyze the shape of the pulsed waveform during metal transfer, the welding current was monitored and recorded every 10 ms. Figure 13 shows the variation in the welding current with time for the optimized welding parameters. In an interval of one second (2500 to 3500 ms), it can be observed that 10 peaks of maximum current (313 A) corresponding to the frequency of 10 Hz are used in the process. On the other hand, a 10 ms period can be observed in the frequency peaks, which agrees with the pulse time set in the equipment. The coarse shape of the waveform is due to the data acquisition speed, which is not fast enough to correctly define the waveform; however, it manages to adequately represent the welding conditions used in the optimization process. The macrographs inserted in the graph of Figure 13 correspond to the optimized welding replicas, providing a detailed representation of the weld bead characteristics at different positions in the weld with respect to the pulse wave. The correlation of the images with the waveform at different times reveals that different regions of the weld bead exhibit distinct attributes in terms of microstructural evolution: penetration depth, and the formation, growth, and subsequent evacuation of Zn vapors generated during the welding process. When the welding current reaches its minimum during the pulse cycle, reduced penetration is observed along with diminution of the thermal affection of the sheets. As the current increases after reaching this minimum, a direct correlation emerges between the rising temperature of the molten pool and the increasing pressure of the Zn gas. This effect promotes the growth of the vapor bubbles trapped within the molten metal until they are released. Consequently, maintaining high peak currents is essential in ensuring that the weld pool raises its temperature sufficiently and holds it, so that the nucleation, growth, and expulsion of the Zn bubbles takes place, preventing their entrapment during solidification and thereby reducing the porosity levels in the final weld. Izutani et al. [34] confirmed that using a pulsed current frequency with varying peak and base currents generates more energy, which is absorbed by the weld pool. The increment in the temperature of the liquid metal enhances the pressure of the Zn vapor bubbles trapped within the weld pool. This rise in the vapor pressure of Zn overcomes the atmospheric pressure, enabling the ascension and escape of the bubbles generated during the pre-welding heat ramp.

Figure 13.

Effect of pulsed waveform on weld penetration and Zn vapor evacuation.

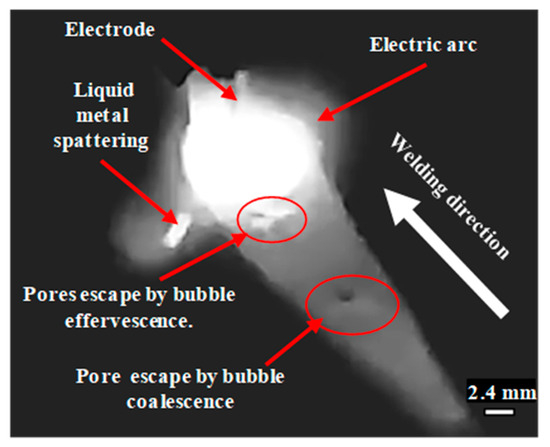

The analysis of the image shown in Figure 14 reveals the dynamics of Zn vapor bubble formation and release from the weld pool during welding. High-speed imaging at 240 fps was used to capture the key mechanisms involved. The image shows the electric arc generated by the electrode, along with metal spattering, indicating the expulsion of molten material due to the high energy of the arc. Additionally, porosities are observed, which result from the release of trapped gas bubbles in the liquid metal. Two bubble escape mechanisms may be distinguished:

Figure 14.

Image during welding showing the behavior of Zn vapor release from the weld pool.

- (i)

- Bubble effervescence, a phenomenon driven by the high temperature of the molten metal and at the periphery at the electric arc. Bubble effervescence is an extremely rapid formation and expulsion of the Zn vapor bubbles. This mechanism is further accelerated by the convective flows occurring in this region, induced by the movement and concomitant deposition of molten metal, facilitating the rapid release of high-pressure bubbles before coalescing and growing significantly. The bubble effervescence mechanism is pointed in the image of Figure 14.

- (ii)

- Bubble coalescence: the heat source moves forward, leaving behind liquid metal that is still at an elevated temperature, and small bubbles merge before escaping the weld pool. In this region, the molten metal begins to cool and increase in viscosity, making it more difficult for gas bubbles to escape. As a result, higher pressures are required to overcome the surface tension of the liquid metal and atmospheric pressure before escaping from the weld pool. A bubble escaping by this mechanism is also pointed in the image of Figure 14.

Finally, the current study proves that the electrode composition plays a significant role in the behavior of the gas within the weld pool. The SM70MT electrode, which contains a higher Ni content as compared with the ER70S-3 electrode used in previous studies, exhibits distinct behavior. According to the manufacturer, the SM70MT electrode has a lower viscosity and shifts oxide formation toward the edges of the molten metal, thereby promoting gas release from the weld pool. In contrast, the ER70S-3 electrode, as observed in a previous study [10], generates oxides that accumulate on the surface of the weld pool. These oxides act as slag, increasing the surface tension and hindering gas escape, ultimately leading to greater levels of porosity in the weld bead [35]. A pulsed waveform analysis, along with the macro- and microstructure of the welds, confirmed that maintaining high peak currents is essential to ensuring that the weld pool reaches sufficient temperatures for the full evacuation of Zn vapor, preventing entrapment and minimizing porosity in the welded joint. The release of trapped gases was successfully recorded using a high-speed camera with a CMOS sensor and a light filter array, capturing the moment when porosities were evacuated from the weld pool. From these visual data, it was possible to distinguish two mechanisms for Zn vapor escape: bubble effervescence and bubble coalescence.

4. Conclusions

The optimization of the welding parameters in the GMAW-P process significantly reduced porosity in the welded joints of CP780 galvanized steel. The use of the SM70MT electrode, with lower Si and higher Ni, improved the welding pool stability and minimized the interaction with the Zn coating, reducing porosity formation in comparison with high-silicon electrodes like ER70S-3.

Through the parameters’ analysis, it was observed that a high peak current (Ip = 313 A) facilitates the release of trapped gases, while the optimal combination of pulse frequency (f = 10 Hz) and pulse time (tp = 10 ms) influences the weld pool dynamics and vapor evacuation. The L9 orthogonal array design of the experiments allowed for the systematic identification of these optimal conditions. The study confirmed that porosity is directly related to Zn vaporization, where Zn gas exerts pressure on the weld pool. Additionally, proper WM penetration improves gas release and enhances joint integrity. A microstructural analysis revealed that bainite was the predominant phase in the HAZ, alongside allotriomorphic ferrite, Widmanstätten ferrite, acicular ferrite, and martensite, which were present in varying proportions depending on the welding parameters.

A fractographic analysis of the chisel test indicated that porosity serves as crack propagation sites, while Al and Zn segregation at the weld root promote the formation of intermetallics. Experimental validation confirmed the reproducibility of the optimized GMAW-P process, and the developed mathematical model, based on multiple regression, achieved a high accuracy (R2 = 99.97%) in predicting porosity formation in the weld beads.

Author Contributions

Conceptualization, C.A.G.O., F.F.C.-L., J.J.T.-T. and M.G.G.; Methodology, C.A.G.O., F.F.C.-L., A.M.F. and M.G.G.; Validation, J.A.V.M., F.F.C.-L., V.H.L.-M., J.J.T.-T. and M.G.G.; Formal analysis, C.A.G.O., J.A.V.M., F.F.C.-L., A.M.F. and M.G.G.; Investigation, C.A.G.O., J.A.V.M., V.H.L.-M. and A.M.F.; Resources, J.A.V.M., F.F.C.-L., V.H.L.-M. and J.J.T.-T.; Data curation, A.M.F. and M.G.G.; Writing—original draft, C.A.G.O., F.F.C.-L., J.J.T.-T. and M.G.G.; Writing—review and editing, J.A.V.M., F.F.C.-L. and V.H.L.-M.; Visualization, C.A.G.O. and A.M.F.; Supervision, J.A.V.M., F.F.C.-L. and V.H.L.-M.; Project administration, F.F.C.-L. and J.J.T.-T.; Funding acquisition, F.F.C.-L. and J.J.T.-T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy.

Acknowledgments

The authors express their gratitude to Metalsa for supplying the materials, as well as to the Coordinación de la Investigación Científica (CIC), the aid of Antonio Rodriguez and Giovanni Justo in the laboratory facilities of the Universidad Michoacana de San Nicolás de Hidalgo for their support. Additionally, C.A.G.-O. acknowledges CONAHCYT for granting a scholarship during his doctorate studies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schmitt, J.H.; Iung, T. New developments of advanced high-strength steels for automotive applications. Comptes Rendus Phys. 2018, 19, 641–656. [Google Scholar] [CrossRef]

- Šmak, M.; Kubíček, J.; Kala, J.; Podaný, K.; Vaněrek, J. The influence of hot-dip galvanizing on the mechanical properties of high-strength steels. Materials 2021, 14, 5219. [Google Scholar] [CrossRef] [PubMed]

- Thierry, D.; LeBozec, N.; Gac, A.L.; Persson, D. Long-term atmospheric corrosion rates of hot dip galvanised steel and zinc-aluminium-magnesium coated steel. Mater. Corros. 2019, 70, 2220–2227. [Google Scholar] [CrossRef]

- Bhattacharya, D. Liquid metal embrittlement during resistance spot welding of Zn-coated high-strength steels. Mater. Sci. Technol. 2018, 34, 1809–1829. [Google Scholar] [CrossRef]

- Das, A.; Shome, M.; Das, C.R.; Goecke, S.F.; De, A. Joining of galvannealed steel and aluminium alloy using controlled short circuiting gas metal arc welding process. Sci. Technol. Weld. Join. 2015, 20, 402–408. [Google Scholar] [CrossRef]

- Ahsan, M.R.U.; Kim, Y.R.; Kim, C.; Kim, J.W.; Ashiri, R.; Park, Y.D. Porosity formation mechanisms in cold metal transfer (cmt) gas metal arc welding (GMAW) of zinc coated steels. Sci. Technol. Weld. Join. 2016, 21, 209–215. [Google Scholar] [CrossRef]

- Sarpe, M.; Treutler, K.; Wesling, V.; Dewald, P.; Schmale, H.C. Influence of classified pore contents on the quasi-static and cyclic strength properties of the welded joint in gas-shielded metal arc welding of galvanized, high-strength steels. J. Adv. Join. Process. 2022, 5, 100094. [Google Scholar] [CrossRef]

- Yao, P.; Zhou, K.; Lin, H.; Xu, Z.; Yue, S. Exploration of weld bead forming rule during double-pulsed GMAW process based on grey relational analysis. Materials 2019, 12, 3662. [Google Scholar] [CrossRef]

- García-Gómez, M.; Curiel-López, F.F.; Taha-Tijerina, J.J.; López-Morelos, V.H.; Verduzco-Juárez, J.C.; García-Ochoa, C.A. Reduction in porosity in GMAW-P welds of CP780 galvanized steel with Er70S-3 electrode using the Taguchi methodology. Metals 2024, 14, 857. [Google Scholar] [CrossRef]

- Garcia-Guerrero, J.C.; Curiel-López, F.F.; López, V.H.; Taha-Tijerina, J.; Sánchez-Cruz, T.J.; Ramírez-López, M.d.C.; Cortés-Carrillo, E.; Quinones-Salinas, M.A. Impact of welding parameters in the porosity of a dissimilar welded lap joint of CP800-XPF1000 steel weldment by GMAW-P. Metals 2024, 14, 309. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B.; Węgrzyn, T.; Jurek, A. Formation of oxides and sulfides during the welding process of S700MC steel by using new electrodes wires. Materials 2024, 17, 2974. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, C.; Bustos, Ó.; Artigas, A.; Bruna, H. Silicon effect and microstructural evolution of hot dip galvanized coating of structural steels. Metals 2023, 13, 1892. [Google Scholar] [CrossRef]

- Bondareva, O.S.; Turovsky, A.M.; Turovsky, Y.M. Application of nickel tablets in hot-dip galvanizing for silicon and phosphorus steel reactivity control. Mater. Sci. Forum 2020, 992, 689–694. [Google Scholar] [CrossRef]

- Tesfaye, F.K. Parameter optimizations of GMAW process for dissimilar steel welding. Int. J. Adv. Manuf. Technol. 2023, 126, 4513–4520. [Google Scholar] [CrossRef]

- AWS D9.1; Sheet metal welding code; AWS: Miami, FL, USA, 2018.

- AWS D8.8; Specification for automotive weld quality; AWS: Miami, FL, USA, 2007.

- ASTM E1742; Standard practice for eadiographic examination. ASTM International: West Conshohocken, PA, USA, 2010.

- AWS D8.7; Recomended practice for automotive weld quality; AWS: Miami, FL, USA, 2005.

- Romero-Orozco, A.J.; Taha-Tijerina, J.J.; De Luna-Alanís, R.; López-Morelos, V.H.; Ramírez-López, M.d.C.; Salazar-Martínez, M.; Curiel-López, F.F. Evaluation of microstructural and mechanical behavior of ahss CP780 steel welded by GMAW-pulsed and GMAW-pulsed-brazing processes. Metals 2022, 12, 530. [Google Scholar] [CrossRef]

- Rivero, P.J.; Berlanga, C.; Palacio, J.F.; Moraleda, M.V.B. Effect of Ti on microstructure, mechanical properties and corrosion behavior of a nickel-aluminum bronze alloy. Mater. Res. 2021, 24, e20200335. [Google Scholar] [CrossRef]

- Kamburova, K.; Boshkova, N.; Boshkov, N.; Radeva, T. Hybrid zinc coating with CuO nanocontainers containing corrosion inhibitor for combined protection of mild steel from corrosion and biofouling. Coatings 2022, 12, 1254. [Google Scholar] [CrossRef]

- ISO 5817; Fusion welding joints in steel, nickel, titanium, and their alloy. ISO International: Geneva, Switzerland, 2023.

- Zhang, Y.; Zhang, Y.; Yang, J.; Li, T.; Chen, Y. Influence of Ti/N ratio on inclusions, microstructures, and toughness in heat-affected zone of shipbuilding steel plates with Mg deoxidation after high heat input welding. Steel Res. Int. 2023, 95, 2300283. [Google Scholar] [CrossRef]

- Fu, Z.; Yang, G.; Xu, Y.; Han, R.; Yin, Q.; Bao, S.; Zhao, G. Continuous cooling transformation behaviour of 30CrMo steel simulated by CSP process. Ironmak. Steelmak. 2021, 48, 1094–1101. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, H.; Gao, S.; Luo, Y. Processing fundamentals and performance investigation of selective laser melting of high-speed steel in reactive N2 atmosphere. Steel Res. Int. 2023, 94, 2200807. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, Y.; Liu, S.; Su, L.; Fletcher, L.; Li, H.; Wang, B.; Zhu, H. Inhomogeneous strain behaviors of the high strength pipeline girth weld under longitudinal loading. Materials 2024, 17, 2855. [Google Scholar] [CrossRef]

- Yang, M.; Lu, J.; Chen, J.; Li, Y.; Liu, Y.; Yang, H. Effect of welding speed on microstructure and corrosion resistance of Al–Li alloy weld joint. Mater. Corros. 2019, 71, 300–308. [Google Scholar] [CrossRef]

- Cooman, B.C.D.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Kah, P. Advancements in Intelligent Gas Metal Arc Welding Systems: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals i: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef]

- Saarimaa, V.; Kaleva, A.; Nikkanen, J.P.; Manni, J.; Lange, C.; Paunikallio, T.; Laihinen, T.; Heinonen, S.; Levänen, E.; Väisänen, P.; et al. Tailoring of versatile surface morphologies on hot dip galvanized steel in wet CO2: Aspects on formation, barrier properties, and utilization as a substrate for coatings. Acs Appl. Mater. Interfaces 2018, 10, 21730–21739. [Google Scholar] [CrossRef] [PubMed]

- Hertel, M.; Rose, S.; Füssel, U. Numerical simulation of arc and droplet transfer in pulsed GMAW of mild steel in Argon. Weld. World 2016, 60, 1055–1061. [Google Scholar] [CrossRef]

- Matsumoto, N.; Kawahito, Y.; Nishimoto, K.; Katayama, S. Effects of laser focusing properties on weldability in high-power fiber laser welding of thick high-strength steel plate. J. Laser Appl. 2016, 29, 012003. [Google Scholar] [CrossRef]

- Izutani, S.; Yamazaki, K.; Suzuki, R. New welding process,“J-solutionTM Zn”, suitable for galvanized steel in the automotive industry. Eng. Mater. Sci. 2013, 32, 16–23. [Google Scholar]

- Cardenas, C.; Hernandez, L.; Taha-Tijerina, J.J. Effects of GMAW conditions on the tensile properties of hot rolled Complex Phase 780 steel. In Proceedings of the Great Designs in Steel Seminar—GDSI (2015), Detroit, MI, USA, 13 May 2015. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).