Abstract

CSAM is a solid-state process for depositing metal or metal-based composite materials in which the fine particles of metal or composite material are accelerated to supersonic velocity, making successful bonding feasible due to the high-impact velocity and heavy plastic deformation, all without the melting of the feedstock material. This review examines the basic CSAM mechanism, including deposition dynamics, bonding mechanism, dynamic recrystallization, residual stress evolution, and post-spray heat treatments which affect microstructural and mechanical properties. Although controlled by a few key factors like particle velocity, strain rate, and temperature rise, the bonding efficiency itself refines the grains through dynamic recrystallization, hence improving coating strength and performance. The predominating compressive residual stresses that enhance fatigue resistance and mitigation strategies to improve coating durability by post-spray annealing and laser peening are discussed. This review, by providing an overview of material behavior, optimization techniques, and advanced modeling approaches, underlines the CSAM potential for high-performance applications in aerospace, biomedical industries, and machinery. It further underlines its importance for the advancement of manufacturing innovation and materials science.

1. Introduction

Cold spray additive manufacturing (CSAM) represents a step forward in metal additive manufacturing, wherein a solid-state deposition process is applied for the fabrication and repair of metallic components [1,2,3,4]. CSAM is different from traditional techniques of fusion-based processing because it does not involve melting and subsequent solidification. Instead, it accelerates the metal powders to supersonic velocities by means of a pressurized gas stream, enabling bonding through high-impact collisions without melting the feedstock material. This unique approach minimizes thermal degradation, making CSAM particularly suitable for temperature-sensitive materials and applications.

Material dynamics are a very important aspect in the CSAM, through which the possibilities and limits are determined. Relevant factors, in this case, refer to the bonding mechanisms of particles at interfaces, the evolution of residual stress during deposition, and accompanying microstructural changes in metals upon deposition. Furthermore, all these aspects have a strong impact on the performance and wear behavior of cold-sprayed coatings in their diverse applications, including but not limited to aerospace and biomedical industries, machinery, and more.

This review focuses on the complex physical and mechanical phenomena underlying CSAM: the bonding mechanisms driven by high-velocity impact, the influence of residual stress on coating integrity, and dynamic recrystallization on grain refinement and phase transformation. Considering these issues, this work seeks to provide an overview of the process parameters, material behavior, and optimization strategies that must be realized for CSAM to operate and fabricate high-performance metallic coatings with properties amenable to specific applications. By this exposition, CSAM is placed as one of the most advanced technologies that connect manufacturing innovation to material science. We refer to these excellent reviews to obtain comprehensive insights into the material dynamics of the cold spray (CS) process [5,6,7].

The rest of this review paper is organized as follows. Section 2 discusses the mechanisms and modeling of high-velocity impact and solid-state bonding in CSAM. Section 3 explains the bonding mechanism(s) in cold spray technology. Section 5 describes phase transformation and amorphization during cold spray. Section 5 explains residual stress in CSAM. Section 6 describes in situ grain refinement by dynamic recrystallization. Section 7 explores the contributions of metastable microstructures to post-spray heat treatment. Section 8 highlights the summary and outlook.

This review systematically explores the material dynamics in CSAM, focusing on the fundamental mechanisms governing bonding, residual stress evolution, phase transformations, and microstructural changes. The paper is structured to provide a comprehensive understanding of these aspects and their implications for high-performance applications.

The review begins with an in-depth analysis of bonding mechanisms in CSAM (Section 2), emphasizing adiabatic shear instabilities, mechanical interlocking, and metallurgical diffusion that facilitate particle adhesion. The section discusses the influence of particle velocity, substrate properties, and critical velocity thresholds on bond strength and presents experimental and computational studies demonstrating the localized strain distribution, temperature rise, and jet formation at impact sites.

Next, phase transformation and amorphization in cold spray (Section 3) are examined, highlighting how high strain rates induce phase transformations, such as martensitic transitions and nanocrystalline structures in certain alloys. This section also addresses the amorphization effects observed in materials like Zn, Ni, and Co-based alloys, where rapid cooling following impact disrupts lattice structures. High-resolution TEM and computational modeling approaches are reviewed to illustrate the microstructural evolution of cold-sprayed coatings.

The discussion then shifts to residual stress in CSAM (Section 4), a critical factor influencing the durability and performance of deposited coatings. This section examines the formation of compressive and tensile stresses due to particle impact, substrate interactions, and process conditions. It also reviews experimental techniques such as neutron diffraction and X-ray diffraction (XRD) for measuring residual stress distributions and explores mitigation strategies, including heat treatments, optimized deposition strategies, and laser shock peening.

In Section 5, the role of in situ grain refinement through dynamic recrystallization is analyzed. The review details how severe plastic deformation and high strain rates drive grain refinement, influencing the final microstructure and mechanical properties of cold-sprayed deposits. A comparison of grain evolution in FCC, BCC, and HCP metals is presented, along with the impact of particle size and deposition temperature on microstructural stability. The discussion extends to how dynamic recrystallization enhances hardness, ductility, and fatigue resistance, making CSAM an effective technique for producing dense, high-strength coatings.

Section 6 focuses on the stabilization of metastable microstructures through post-spray heat treatments, which play a crucial role in refining mechanical properties and eliminating defects. This section evaluates how post-deposition annealing, thermal diffusion, and microstructural coarsening influence coating performance. Studies on heat treatment’s effects on bonding strength, porosity reduction, and fatigue resistance are reviewed, providing insights into optimizing CSAM deposits for structural applications.

Finally, the summary and outlook (Section 7) consolidate key findings on bonding mechanisms, stress evolution, phase transformations, and microstructural refinement. It also identifies current limitations and future research directions, including real-time monitoring, AI-driven process optimization, and multi-material deposition strategies. The section highlights the growing potential of CSAM for aerospace, biomedical, and industrial applications, emphasizing its role in advancing next-generation additive manufacturing technologies.

2. High-Velocity Impact and Solid-State Bonding in CSAM: Mechanisms and Modeling

The deposition mechanism in CSAM is based on high-velocity particle impact and solid-state bonding to build a part layer by layer. The process begins with a high-pressure gas, such as helium, nitrogen, or air, which is heated and accelerated through a converging–diverging nozzle to supersonic speeds, typically between 300 and 1200 m/s [8]. In general, the gas stream conveys fine metal or composite powder particles, usually in the size range of 1–50 µm, at very high velocity toward the substrate. The particles undergo severe plastic deformation on impact so that their kinetic energy is converted into localized heat and pressure. This process is termed adiabatic shear instability that softens the material without melting, promoting solid-state bonding at the atomic level through both mechanical interlocking and metallurgical mechanisms.

Reducing the particle size leads to an increase in the critical adhesion velocity (Vcr) [9], which is attributed to the higher surface area-to-volume ratio in smaller particles. This results in reduced kinetic energy [10], faster heat dissipation from the bonding interface [8], and a greater presence of absorbents and oxides that obstruct bonding [11]. Additionally, a higher oxygen content in the powder further hinders bonding and reduces the ductility of the deposit.

The CSAM involves a substrate with high-velocity particles bonded by plastic deformation mechanisms or by solid-state bonding. Due to this, factors include particle velocity, impact energy, strain rate, and temperature rise that are mathematically described in the process.

where m is the mass of the particle and v is the velocity of the particle.

For effective deposition, particle velocity v must be higher than the critical velocity , which is the minimum velocity at which plastic deformation and bonding can be sufficient. If , the particle will rebound instead of sticking. Critical velocity depends on material properties such as hardness, ductility, and density and can be approximated by the following:

where is the yield strength of the material and is the density of the material.

Upon impact, particles undergo severe plastic deformation, characterized by a high strain rate, as follows:

where v is the impact velocity, and d is the diameter of the particle.

The high strain rate generates localized heating due to adiabatic conditions. This heat facilitates bonding by softening the material. The deformation also increases the contact area between the particle and substrate, enhancing mechanical interlocking.

The rise in temperature during impact is caused by the conversion of kinetic energy into heat. It is given by the following:

where is the fraction of plastic work converted to heat, is the yield strength of the material, is the plastic strain, is the density of the material, and is the specific heat capacity. The process of adiabatic heating acts to promote bonding through the softening of the material at the particle–substrate interface without melting. This solid-state bonding preserves material integrity, which is of particular importance for CSAM applications.

The contact pressure P at the particle–substrate interface can be estimated using the Hertzian contact theory for elastic-plastic deformation:

where k is the proportionality constant depending on material properties, density of the particle, and is the particle velocity.

To predict deposition, material behavior is modeled using equations such as the Johnson-Cook plasticity model [12] for high strain rate conditions:

where A, B, C, n, and m are material constants, is strain, is the strain rate, T is temperature, is reference temperature, and is melting temperature.

Various material models can be used for this purpose, as discussed in [13], but finding an appropriate model is still a challenging task. The main reason for this situation is the lack of material data at very high strain rates during cold spray, up to , as mentioned in [14]. Even in the low-strain-rate regime, there is a general dearth of data on plastic constitutive properties of materials in this micro-sized particle form.

Numerical simulation is indispensable for the understanding of the underlying mechanisms of particle impact and deformation in CSAM. These are mainly performed by mesh-based numerical methods such as the finite element method because of their strength in solving complex mechanical interactions. The main goal is to predict the temporal development of deformation patterns and the associated field variables, such as stress, strain, and temperature, for different material and impact conditions. The jetting phenomenon has been explained by two main mechanisms: adiabatic shear instability (ASI) and hydrodynamic pressure-release (HPR) [15]. These mechanisms are mainly explained by the finite element method (FEM) simulations, a numerical technique that has its roots in continuum mechanics.

3. Bonding Mechanisms in CSAM

CSAM is unlike other methods of metal additive manufacturing, as the bonding occurs through solid-state impact rather than melting. When metal particles collide at high speeds with a substrate or previously deposited layers, they create strong metallurgical linkages through extreme plastic deformation. Generally, it is known that the powder particles can only attach themselves to the substrate when a critical velocity, Vcr, is reached. The particle velocity which is needed for the adhesion of particles to take place is called the critical velocity Vcr [12]. Particles just bounce off the surface of the substrate if their Vp is less than the Vcr [16]. Bonding that occurs at or over Vcr gives a cohesive overlay. For the most part, erosion of the substrate may occur when is more than Vcr. The plot of deposition efficiency, , as a function of , gives Vcr, where Mp is the total weight of particles impacting the substrate and Δms is the weight gain of the substrate. Vcr is in the range of 500 to 1000 m/s depending on parameters like gas temperature and pressure, powder characteristics, and substrate characteristics.

In cold spray deposition, two different bonding mechanisms should be distinguished, i.e., particle-to-substrate bonding and particle-to-particle bonding. Particle-to-substrate bonding is crucial for the formation of the first layer of particles and to determine the bonding strength between coating and substrate, and particle-to-particle bonding, which governs the build-up of the cold-sprayed deposit and is directly related to the cohesive strength and physical properties of the deposited material.

3.1. Fundamentals of Bond Formation

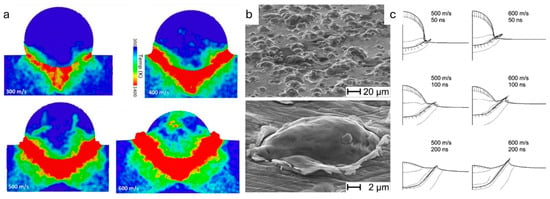

In cold spraying, the bonding mechanism of the particles onto a substrate is based on a solid-state cold-welding process. It happens due to extremely high strain-rate plastic deformation upon impacting, coupled with adiabatic shear instabilities at the particle–substrate interface [17]. These latter instabilities further develop and enhance localized deformation and heat rise, which is important in forming a good bond. Adiabatic shear instabilities at the particle/substrate interface cause exceptionally high-degree plastic deformation to localize around the contact boundary. In fact, the deformation is often so severe that it results in the formation of metal jets. Experimental and numerical studies are consistent in showing that plastic deformation within deposited particles is heterogeneous. It was shown that high deformation (strain > 10) is concentrated at inter-particle interfaces, whereas the particle caps (regions at the top or outermost parts of individual particles) undergo only slight deformation (strain < 0.5). This difference occurs over extremely short timescales, typically tens of nanoseconds. Figure 1a shows that increasing impact velocities (300–600 m/s) lead to higher localized temperatures at the particle–substrate interface, promoting bonding through plastic deformation. Figure 1b,c reveal the effects of particle impact, with SEM images showing material flow and jetting, while simulations demonstrate greater deformation and interfacial bonding at 600 m/s compared to 500 m/s [14].

The bonding can, in principle, take place without heating, fusion, or mechanical interlocking when atomically clean, flat surfaces of two components are brought into direct contact [18,19]. In practice, the metallic surfaces are never flat and are always covered by a thin oxide layer. These oxide layers must be either broken or removed for clean metallic surfaces to come into intimate contact and to enable solid-state bonding. This can be accomplished by compressing and stretching the interfacial region through plastic deformation. In the context of CS, bonding is believed to occur because of this type of interfacial deformation: severe plastic deformation breaks the oxide layer and allows for the atomic-level contact of metallic surfaces. Importantly, the oxide layer acts simply as a geometrical constraint rather than an “energy barrier” to metallurgical bonding, as it can be overcome through sufficient deformation at the interface. Another key discussion is the role of jetting, where material is ejected outward from the particle–substrate interface. The influence of the native surface oxide layer is also a subject of interest [11,20]. Additionally, researchers examine the effects of interfacial melting [21,22] and interface solid-state amorphization [23]. These mechanisms will be explored in detail in the following section.

The rapid deformation at the interface is accompanied by a corresponding rise in temperature. The rise in temperature is closely related to the effective strain experienced at the inter-particle interfaces. Simulations have been conducted that show the distributions of strain and temperature will not be uniform near the interface region when a spherical copper particle impacts on a flat copper substrate. For instance, for some conditions, the maximum interface temperature can be around 1150 K and may be much higher than the melting temperature if the initial particle temperature is high. These results reveal that the bonding process strongly depends on parameters like particle velocity and initial temperature. In this region of high strain rate deformation, extreme thermal events occur due to its limited spatial dimensions. Heating rates at the particle/substrate interface can reach ~1010 K/s, followed by rapid cooling rates of ~109 K/s during the deposition of a single particle. These extreme thermal dynamics are critical for the microstructural evolution of the coating formed during cold spraying. Higher gas temperatures during the process result in increased peak temperatures and longer durations of thermal exposure, further affecting bonding and the resultant coating microstructure.

Figure 1.

(a) Temperature profiles at six picoseconds during cold spray for different impact velocities, adapted from Ref. [24]. (b) Scanning electron micrographs of wipe test samples showing copper particles on a copper substrate, adapted from Ref. [14]. (c) Simulation of the impact of a copper particle on a copper substrate at initial velocities of 500 m/s and 600 m/s, adapted from Ref. [14].

The bonding process in cold spray is complex, and no single mechanism can fully explain it. Other factors likely contribute to effective bonding. Shear localization at impact interfaces, for example, can lead to microscale or nanoscale mixing or interlocking structures, as observed in cold-sprayed aluminum. These interfacial features, including roll-ups and bulges at the nanoscale, enhance mechanical interlocking at particle–particle boundaries. Similar phenomena have been observed in processes like explosive welding and cladding. Additionally, the intense localized deformation can break oxide layers on the particle surfaces, allowing for clean metallurgical contact between particles and substrates.

In CSAM, the consolidation of powder particles is achieved with minimal porosity. As each layer of powder is deposited, incoming particles undergo deformation, rotation, realignment, and bonding. With increasing layer thickness, continuous particle impact results in plastic deformation, tamping, and densification, like shot peening. Materials with high plasticity, such as face-centered cubic (FCC) metals (e.g., Al, Ni, and, Cu), are particularly suited for cold spray, yielding high-density parts with low porosity. In contrast, body-centered cubic (BCC) metals (e.g., W, Ta, Mo, Nb, α-Fe, and β-Ti) tend to exhibit lower plasticity, resulting in coatings with greater porosity. Hexagonal close-packed (HCP) metals (e.g., α-Ti, Zn, Zr, Co, and Mg), which have fewer slip systems, typically produce higher-porosity cold-sprayed parts compared to FCC metals under similar conditions. For instance, cold-sprayed titanium often exhibits greater porosity than cold-sprayed copper when using identical processing parameters. Ultimately, the porosity of cold-sprayed materials is influenced by both the properties of the particles (such as size and shape) and the process conditions (including gas temperature and pressure).

3.2. Adhesive and Cohesive Bonding in CSAM

Bonding mechanisms in CSAM can be classified as adhesive and cohesive. Adhesive bonding occurs at the particle–substrate interface, where the initial layer of particles adheres to the substrate through mechanical interlocking and plastic deformation. Cohesive bonding, on the other hand, occurs between successive layers of particles within the deposited material, strengthening the bulk of the deposit. Both bonding types contribute to the integrity and mechanical performance of the final CSAM part, with cohesive bonding being crucial for maintaining structural cohesion in thick deposits. ASTM C633-13(2021) is generally used for the Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings [25]. X. Wang et al. investigated the characterization and modeling of the bonding process in cold spray additive manufacturing [26]. Through the experimental investigation, the research concluded that bonding strength at the cold spray deposit–substrate interface increases as the spray angle decreases from 90° to 45°, where maximum bonding strength is achieved. However, as the spray angle decreases, deposition efficiency and strength of the bulk deposit material also decrease. S. Boese carried out the laser-assisted cold spray of aluminum alloy 6061 [27]. The adhesion test results demonstrate that bond strength increases with laser power, rising from 18.4 MPa at 1 kW to 76.8 MPa at 6 kW. Samples sprayed at higher powers (5 kW and 6 kW) experienced glue failure, indicating adhesion strengths above 77 MPa, as the coating itself did not fail. Lower power samples failed cohesively within the coating. The manufacturer-reported minimum adhesion strength of 68.9 MPa was exceeded in these tests. The increased bond strength is attributed to enhanced bonding at the interface and between splats, driven by the heat introduced by the laser. R. Huang developed a novel adhesion strength test to understand the adhesion mechanism in cold spray coatings [28]. The results showed that increasing particle velocity can enhance adhesion strength. The tensile strength of an A5052 substrate impacted by copper particles in nitrogen gas increased gradually with particle velocity, reaching a critical range of 600 to 900 m/s, where it experienced a rapid rise. Beyond this range, tensile strength plateaus near 250 MPa, indicating a maximum bonding capacity is reached despite further velocity increases. In another study by M.R. Rokni et al. on a 6061 Al substrate, the tensile adhesion strength and shear adhesion strength were found to be 78.2 MPa and 72.5 MPa, respectively [29]. Some of the previous work on the bonding mechanism has been summarized in Table 1.

Table 1.

Summarized previous work on the bonding mechanism.

4. Phase Transformation and Amorphization During Cold Spray

Phase transformation and amorphization are commonly observed phenomena in the cold spray process [30]. High strain rate deformation during cold spraying often induces phase transformations, such as the martensite phase transformation of austenite in steels and other material systems. For instance, P. Richer [30] studied microstructural changes in CoNiCrAlY during cold gas dynamic spraying, where intense plastic deformation from particle impact caused substantial grain refinement of the γ-phase matrix. This resulted in nanocrystalline structures with enhanced mechanical properties, along with a more uniform and stable microstructure due to the dissolution of β-phase precipitates into the γ-matrix caused by lattice instability and elevated energy states.

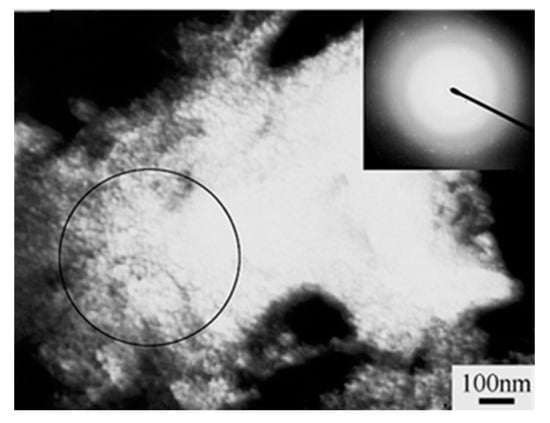

In cold-sprayed WC–Co coatings, cobalt undergoes a phase transformation from a close-packed hexagonal (HCP) to a face-centered cubic (FCC) lattice structure due to extreme plastic deformation and high strain rates during particle impact [9]. Similarly, amorphous microstructures have been identified in cold-sprayed zinc coatings through TEM analysis, as evidenced by halation features in selected areas in electron diffraction patterns instead of clear lattice fringes (Figure 2) [31]. Numerical simulations confirmed that these amorphous structures result from the melting of Zn particles under severe plastic deformation, followed by rapid cooling [31,32].

Figure 2.

TEM microstructure of the selected area in the coating indicating the presence of amorphous phase, adapted from Ref. [31].

Amorphization has also been observed at the particle–substrate interface during cold spray deposition. Q. Wang et al. [33] reported the inclusion of amorphous zones around the periphery of the particle–substrate interface. High-resolution TEM (HRTEM) investigations revealed the formation of a small amorphous zone (~3 nm radius) surrounded by random Al and Mg lattices. This was attributed to the disruption of the lattice structure caused by severe plastic deformation at high strain rates, which accommodated rapid material intermixing at the interface.

A summary of previous research on phase transformation and amorphization is presented in Table 2.

Table 2.

Summarized previous work on phase transformation and amorphization.

5. Residual Stress in CSAM

Residual stresses are a key feature of cold spray additive manufacturing (CSAM), arising primarily from the high-velocity impact and plastic deformation of particles during deposition. These stresses, predominantly compressive near the surface, significantly influence the mechanical properties and durability of CSAM components. For example, in commercially pure titanium, residual stresses are largely driven by thermal mismatch between the titanium and aluminum substrates due to differences in their coefficients of thermal expansion (CTE), particularly at elevated spraying temperatures [34]. This mismatch stress, often surpassing deposition stress, can be mitigated by matching CTEs or removing the baseplate post-deposition. While CSAM typically induces mild compressive deposition stress (e.g., −20 MPa in this study) that enhances crack resistance, excessively high spraying temperatures may introduce tensile stresses, increasing the risk of surface cracking. Stress distribution also depends on sample geometry, with planar coatings showing equal-biaxial stress and thick-wall deposits exhibiting uniaxial stress. When spraying parameters are carefully controlled, CSAM offers advantages over traditional methods like Selective Laser Melting (SLM) by generating lower residual stress levels.

In the CSAM of copper, residual stresses are generally compressive and beneficial, with measured values around −40 to −50 MPa [35]. These stresses, primarily resulting from peening effects rather than thermal mismatches, help prevent surface cracking and distortion, contributing to improved dimensional stability compared to SLM, which often induces tensile stresses. Spraying parameters, such as particle velocity and gas temperature, allow for control over residual stress levels, making CSAM a favorable method for producing durable, crack-resistant copper components with minimal distortion.

Further studies have explored the behavior of residual stress in different materials under CSAM. V. Luzin [36] investigated the residual stress and thermo-mechanical properties of cold spray coatings of Cu and Al. Using neutron diffraction, Luzin showed that stress accumulation in these coatings is primarily driven by kinetic effects rather than thermal ones. Cu coatings exhibited higher residual stress due to greater plastic deformation during particle impact, resulting in superior compaction and mechanical properties closer to bulk material characteristics compared to Al coatings. These findings provide a robust framework for understanding residual stress behavior across various materials and spraying conditions.

M. Saleh [37] employed numerical simulations to analyze the deposition of Al-6061-T6 particles, focusing on both single and multi-particle impacts. The study highlighted that residual stress profiles result from a balance between dynamic strengthening, thermal softening, and kinetic shot peening effects, with kinetic effects dominating. Importantly, localized adiabatic heating at particle peripheries caused severe plastic deformation and melting, enhancing adhesion and the overall deposition mechanism.

Similarly, N.B. Maledi et al. [38] studied the influence of cold spray parameters on the microstructure and residual stresses of Zn coatings on mild steel. Their findings showed that high temperatures and pressures provide the necessary kinetic energy for mechanical bonding, which is evident in particle plastic deformation and flattening. Optimal parameters were identified as 525 °C, 8 bars, and a 15 mm stand-off distance, which yielded high hardness and low residual stresses. Increasing temperature and pressure reduced residual stress, while shorter stand-off distances further minimized them. However, excessive temperatures softened the material after an initial hardness increase, and higher pressures had minimal impact on micro-hardness. Residual stress for the mild steel substrate was measured at 0.5 ± 1.6 MPa under these optimal conditions.

These studies collectively demonstrate that controlling residual stress in CSAM through careful selection of spraying parameters and understanding material-specific behaviors is essential for producing high-performance components. The dominance of kinetic effects, as validated through experimental and numerical approaches, underscores the unique advantages of CSAM in minimizing residual stresses compared to traditional additive manufacturing methods.

5.1. Development of Residual Stresses

The plastic deformation during particle impact generates residual stress within the coating, which can enhance certain mechanical properties. Compressive stress, which is commonly found in CSAM, improve fatigue resistance and limit crack propagation, increasing the overall durability of the coating. However, tensile stress may develop in certain regions, which can reduce the coating’s long-term stability if not properly managed. Several key theories have been proposed regarding the deformation sequences and bonding mechanisms involved in the Cold Spray technique [14,21,37,39]. The primary theories focus on the interface temperature and the significant adiabatic instabilities that arise during the plastic deformation of both particles and the substrate. Other theories suggest that successful bonding is only achievable if a critical velocity is attained, which determines both the contact area and contact time.

Tsui and Clyne progressive deposition models are one of the most popular models used in the cold spray process which provides quantitative framework for understanding residual stress development during the deposition of coatings, particularly in processes like cold spraying [40]. This model considers that residual stresses accumulate incrementally as successive layers are deposited, with a strong emphasis on the interaction between the substrate, the deposited layers, and the process conditions. It distinguishes between thermal effects, such as cooling-induced thermal contraction, and kinetic effects, primarily caused by the high-velocity impact of particles. In cold spray processes, kinetic effects dominate due to the significant plastic deformation (peening) of the particles upon impact.

The model mathematically describes the residual stress accumulation as follows:

where residual stress stress from kinetic effects (particle impact), is stress from thermal effects (thermal contraction or expansion), E is Young’s modulus of the material, is Poisson’s ratio, H is hardness of the material, Y is yield strength of the material. A summary of the previous work on residual stress has been presented in Table 3.

Table 3.

Summarized previous work on residual stress.

5.2. Residual Stress Mitigation Techniques

Managing residual stress is crucial for ensuring the structural integrity and performance of components produced through cold spray additive manufacturing (CSAM). Excessive residual stresses can lead to issues such as distortion, delamination, or cracking, particularly in components exposed to cyclic loading. To address these challenges, several mitigation techniques have been developed, including post-spray annealing, laser peening, and optimized deposition strategies.

Post-spray annealing involves heating the coated component to a temperature below the melting point of the substrate and coating material. This process allows the redistribution of stress by promoting atomic diffusion and relieving localized stress concentrations. Annealing is particularly effective in reducing tensile residual stress, which is undesirable in most applications. Studies have shown that annealing can also improve microstructural cohesion between the substrate and the coating, further enhancing the mechanical properties and fatigue resistance of CSAM parts.

C.J. Huang studied post-spray modification of cold-sprayed Ni–Ti coatings by high-temperature vacuum annealing and friction stir processing [41]. This study explored two post-treatments, heat treatment in a vacuum atmosphere (HTVA) and friction stir processing (FSP), for synthesizing intermetallic compounds in cold-sprayed Ni–Ti coatings. While HTVA can create uniform intermetallic phases under controlled conditions, FSP demonstrated superior capability by significantly improving the microstructure, mechanical properties, and wear resistance of the coating. FSP enhanced the coating’s microhardness (1003.5 ± 65.9 HV0.1, approximately 4.5 times higher than the as-sprayed coating) and wear resistance (improved by ~2 times). The findings highlight FSP as a highly effective method for modifying metal-metal composite coatings and synthesizing dense intermetallic compounds, outperforming HTVA in this application.

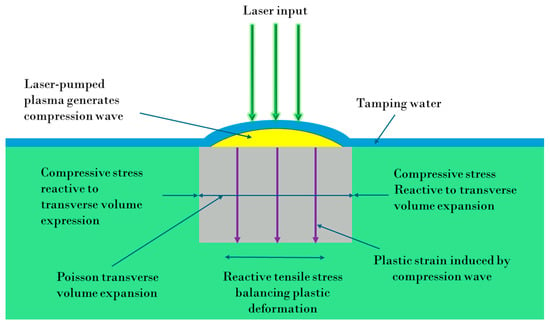

5.2.1. Laser Peening

Laser peening is another effective technique for residual stress mitigation in CSAM. This method involves directing high-energy laser pulses onto the surface of the component, inducing compressive stresses that counteract existing tensile residual stresses. Figure 3 illustrates the process of laser pinning. The process improves the surface hardness and fatigue life of the component, making it particularly beneficial for parts subjected to cyclic loading. Unlike traditional mechanical peening, laser peening offers more precise control over the depth and distribution of compressive stresses. It has been extensively utilized more recently in aircraft structures and nuclear-spent fuel storage canisters, as well as to extend the wear life of jet engine fans and compressor blades [42]. N. Maharajan reported the use of laser shock peening for post-processing of the cold-sprayed Ti6Al4V coating. The study concluded that in comparison to the as-sprayed condition, LSP on heat-treated Ti6Al4V coating increases bond strength by more than 2.2 times [43].

Figure 3.

Laser peening plastically compresses material normally to a surface, generating a transverse compressive stress field, adapted from Ref. [44].

5.2.2. Optimized Deposition Parameters

Controlling deposition parameters during the cold spray process itself is another strategy to mitigate residual stress. Parameters such as particle velocity, gas temperature, and stand-off distance can significantly influence the residual stress profile in the coating. Careful parameter optimization reduces the need for extensive post-spray treatments and ensures that the residual stress profile is inherently favorable. For instance, G. Benenati developed a deposition strategy for reduction in residual stress by using cold spray for an additive manufacturing process [45]. This technique involves depositing layers one after the other perpendicularly, that is, with a 90° relative orientation between successive layers. It can achieve maximum equivalent stress up to 32% lower than a 0° relative orientation angle for depositions of copper and aluminum.

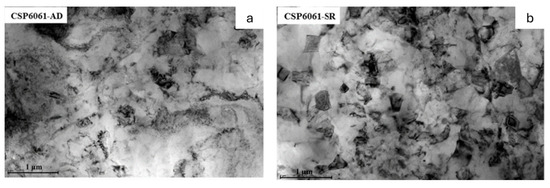

5.2.3. Heat Treatment

Heat treatment significantly helps in the reduction of residual stress. For instance, heat treatment at 800 °C reduced residual stress in cold-sprayed Inconel 625 and Inconel 718 coatings (with aluminum as the substrate) by minimizing porosities and enabling stress relaxation through the cancelation of opposing stresses [46]. An aluminum substrate was used in both cases. This process improved the mechanical performance of the coatings, as evidenced by the absence of cracks in heat-treated samples during micro indentation testing. In a study conducted by J.W. Murray et al., heat treatment significantly impacts cold-sprayed C355 Al by reducing porosity and residual stress [47]. It decreased porosity levels with increasing temperature, achieving up to 90% reduction at 225 °C, which improves particle–particle bonding through diffusion. Additionally, heat treatment reduces the compressive residual stress magnitude by half across the coating thickness, alleviating excessive stress that could cause adhesive or cohesive failures while retaining enough compressive stress to potentially improve fatigue life. These changes contribute to improved mechanical integrity and durability of the coatings. M.R. Rokni et al. studied the microstructure and mechanical properties of cold-sprayed 6061 Al in as sprayed and heat-treated conditions. Figure 4a shows the as-deposited (AD) microstructure of cold-sprayed 6061 aluminum, characterized by moderate dislocation density and multiple low-angle grain boundaries due to severe plastic deformation. In contrast, Figure 4b illustrates the stress-relieved (SR) condition, where well-defined ultrafine grains form with reduced dislocation density, indicating partial recovery through thermal annealing. Summary of previous work on residual stress mitigation techniques have been presented in Table 4.

Figure 4.

TEM micrographs of CSP 6061: (a) as-deposited condition and (b) stress relieved (SR) condition, adapted from Ref. [29].

Table 4.

Summarized previous work on residual stress mitigation technique.

6. Dynamic Recrystallization and In Situ Grain Refinement

The high strain rates inherent to CSAM result in substantial dislocation multiplication within the deposited material, a process that significantly contributes to work hardening and enhances the mechanical properties. Cold-spray coatings exhibit heterogeneous microstructures resulting from in situ grain refinement at inter-particle and particle–substrate interfaces, driven by dynamic recrystallization [48]. TEM analysis of Inconel 625 superalloy coatings (with 4130 steel as the substrate) has confirmed the heterogeneous nature of spat boundaries [49]. In a study by J. Wei, cold-sprayed Cu-10wt.%Ni (CuNi), Cu-10 wt.%Sn (CuSn), and Cu-7wt.%Ni-2wt.%Si-0.9wt.%Cr (HS Cu) coatings have been found to exhibit heterogeneous microstructures. It consists of fine grains at heavily deformed particle–particle interfaces [50]. These interfacial regions exhibit higher hardness in contrast to the particle interiors, which receive much less plastic deformation and work hardening. Further supporting this heterogeneity, severe deformation, and high defect densities prohibited indexing in CuSn and HS Cu during EBSD characterization. The mechanical properties and hard distribution are considerably affected by this micro-structural diversity within the coatings.

Material-specific studies on coatings with Ta [51], Al [33,52,53,54,55], Ti [56,57,58,59], Ni [60,61], and Cu [51,62,63,64,65] all show that under optimum conditions, small particle sizes and increased temperature give nanocrystalline coatings with significantly better mechanical properties. Mechanistically, this occurs either via the process of discontinuous dynamic recrystallization, as observed for grain boundary migration, or continuous dynamic recrystallization, which occurs with sub-grain rotation. These mechanisms give rise to ultra-fine equiaxed grains with high-angle boundaries and directional ribbon-like sub-grains near the interfaces, together with heavily deformed grains with dense dislocation walls. The refinement of grains depends much on deposition conditions, including particle velocity, temperature, and plastic deformation. Higher particle velocities and increased gas temperatures promote finer grain sizes, even down to several tens of nanometers, as reported in nanosized coatings with microstructures such as titanium and copper. This is responsible for heterogeneous mechanical property, including much higher hardness at particle interfaces than their interiors found by nanoindentation tests. Q. Wang et al. developed a new material model to predict the extreme deformation and grain refinement during cold spraying [66]. It was found that material deformation is dominated by ultra-high strain rate hardening, whereas jetting is controlled by thermal softening, and grain refinement primarily occurs at the microparticle–substrate interface because of dynamic recrystallization.

Dynamic recrystallization is both temperature- and deformation-dependent. If the spray particles are not preheated, severe plastic deformation, as well as noticeable temperature increment, only locates along the inter-particle boundaries. With the increasing initial particle temperature, the so-called thermal softening effect is gradually enhanced [57,58,67]. The proportion of high temperature (N0.4–0.5 Tm) and severe plastic deformed region in a particle increases. Therefore, with higher particle velocity and gas temperature, enhanced grain refinement can be achieved [57,58]. Summary of previous work on dynamic recrystallization has been presented in Table 5.

Table 5.

Summarized previous work on dynamic recrystallization.

7. Stabilizing Metastable Microstructures Through Post-Spray Heat Treatment

The most widely used method for microstructural stabilization and mechanical property improvement in CSAM coatings is post-spray annealing. Heat treatments allow the metastable phases to transform into stable configurations, thus optimizing the mechanical performance of the coatings. Other properties improved by post-spray annealing include toughness, porosity reduction, and fatigue resistance. Annealed CSAM coatings reportedly show better resistance to crack appearance and are thus suitable for applications involving high stress.

P. Vo et al. discussed the mechanical and microstructural characterization of cold-sprayed Ti-6Al-4V after heat treatment [68]. Their results showed that heat treatment enhanced the inter-particle bonding and tensile strength, especially for helium-sprayed coatings annealed at 600 °C, which reached a tensile strength close to 85% of the bulk material.

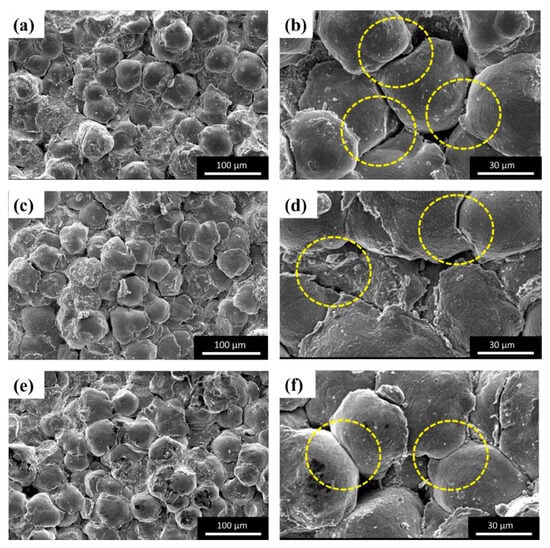

W. Sun et al. investigated the improvement in microstructure and mechanical properties of cold-sprayed Inconel 718 coatings after heat treatment with eddy currents [69]. The improvement was associated with reduced dislocation density and an increase in mass transport between splats. As can be clearly observed from the SEM micrographs shown in Figure 5, the particles are better bonded after heat treatment.

Figure 5.

SEM micrographs illustrate the surface morphologies of cold-sprayed IN718 coatings: (a,b) as-sprayed, (c,d) furnace heat-treated, and (e,f) induction heat-treated. The circled regions in (b,d,f) highlight the separated and bonded particles within the coatings, adapted from Ref. [69].

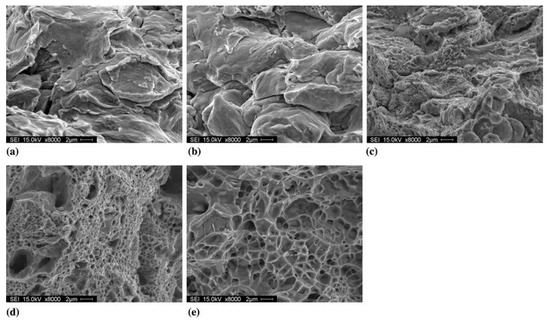

In another study, B.A. Mangour investigated the effects of heat treatment on the microstructure and mechanical properties of cold-sprayed stainless steel 316 L coatings produced using N2 and He as propellant gasses Figure 6 [70]. For N2-sprayed coatings, tensile strength and elongation at fracture were initially low 113 ± 5 MPa and 1.3 ± 0.1%, respectively, in the as-sprayed condition. Nevertheless, a remarkable improvement was noted after annealing at 1000 °C (571 ± 50 MPa; 14.2 ± 1.1%). Strength decreased at 1100 °C (433 ± 39 MPa) due to grain coarsening. In contrast, He-sprayed coatings showed twice the tensile strength of N2-sprayed coatings in the as-sprayed condition but lower strength and ductility after annealing, probably due to inter-connected defects. The tensile strength and ductility were significantly higher for the bulk samples, at 1048 ± 6 MPa and 91 ± 11%, respectively, thus underlining the gap between the properties of bulk material and cold-sprayed coatings.

Figure 6.

SEM micrographs of the fracture surfaces of coatings produced using N2 as the process gas: (a) in the as-sprayed condition; (b) after heat treatment at 400 °C; (c) at 800 °C; (d) at 1000 °C; and (e) at 1100 °C, adapted from Ref. [70].

8. Summary and Outlook

This review provides an in-depth analysis of the material dynamics governing CSAM, focusing on bonding mechanisms, residual stress development, phase transformations, and microstructural evolution. It is found that high-velocity particle impacts enable solid-state bonding, driven by adiabatic shear instabilities and severe plastic deformation. Particle-to-substrate and particle-to-particle interaction active bonding mechanisms play a determining role in coating integrity and mechanical properties.

The review further emphasizes the creation of metastable microstructures, including grain refinement and phase transformation due to extreme strain rates. Residual stress evolution, basically compressive, improves fatigue resistance; poor selection of parameters can generate unwanted tensile stresses, for which mitigation techniques have been developed, like post-spray heat treatment and laser peening. Numerical modeling techniques, such as finite element analysis and molecular dynamics simulations, have been very effective in predicting particle impact behavior, strain localization, and temperature evolution.

It proceeds to a more detailed approach in the selection of materials in saying, “ductile metals (FCC structures) can achieve a superior bonding with minimal porosity whereas BCC and HCP metals have been challenged due to few slip systems. Substrate properties such as roughness and mismatch of the coefficient of thermal expansion are found very critical towards determining coating adhesion and mechanical performance”. In addition, nozzle design and some process parameters like particle velocity, gas temperature, and standoff distance showed a great influence on deposition efficiency and coating quality.

While CSAM has demonstrated significant advantages in aerospace, biomedical, and industrial applications, challenges remain in fully optimizing the process for diverse materials and geometries. The following areas require further research and development:

- Material Behavior at Extreme Strain Rates: Process modeling is bound to suffer from inaccuracies due to the absence of a valid material database on deformation at high strain rates of up to 109 s⁻1. Further studies should be performed to measure and characterize material responses under CSAM conditions.

- Residual Stress Management: While compressive stress is generally beneficial, tensile stress formation due to thermal mismatch can lead to coating delamination. Advanced stress-relief strategies, such as in situ laser peening or cryogenic cooling, should be investigated to mitigate these effects.

- Nozzle and Powder Morphology Optimization: Increased nozzle expansion ratios and optimized powder size distributions further enhance particle velocity, uniformity, and bonding efficiency. Future work may consider adaptive nozzle geometries as well as hybrid gas mixing for optimization of acceleration.

- Multi-Material and Functionally Graded Structures: The capabilities of CSAM in the fabrication of gradient materials and multi-layered coatings remain largely unexplored. The research should be directed toward process adaptation for dissimilar material deposition, especially for aerospace and biomedical implants.

- Integration of Post-Processing Techniques: While some successes regarding the mechanical properties of coatings have been obtained through post-spray annealing and sintering, hybrid approaches-mechanical cold spray combined with HIP or FSP-may give further enhancements in material integrity.

- Advanced In Situ Monitoring and AI Optimization: Real-time thermo-mechanical monitoring may be the path to enhancing deposition consistency. Future research needs to combine high-speed imaging, infrared thermography, and machine learning models to dynamically fine-tune process parameters.

Author Contributions

Conceptualization, A.K., S.L. and W.Z.; methodology, A.K.; software, A.K.; validation, A.K. and W.Z.; formal analysis, A.K.; investigation, A.K., S.L., R.S. and W.Z.; writing—original draft preparation, A.K.; writing—review and editing, A.K., S.L., R.S. and W.Z.; visualization, A.K.; supervision, W.Z.; project administration, W.Z.; funding acquisition, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The work was partially supported by the United States Department of Agriculture grants #2021-67022-34889, 2022-67022-37867, and 2023-51300-40853, National Science Foundation grants #1950036, #2141674, and #2220683, US. Environmental Protection Agency 02D48123, US. Department of Education P116S23007, and the George Foundation Grant to University of Houston at Sugar Land. The APC was funded by the Metals journal.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

We would like to thank all the members of UH Computational Optimization and Smart System lab for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kafle, A.; Silwal, R.; Koirala, B.; Zhu, W. Advancements in Cold Spray Additive Manufacturing: Process, Materials, Optimization, Applications, and Challenges. Materials 2024, 17, 5431. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold Spray Additive Manufacturing and Repair: Fundamentals and Applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Yin, S.; Yang, X.; Xu, Y.; Lupoi, R. Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Vaz, R.F.; Garfias, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. A Review of Advances in Cold Spray Additive Manufacturing. Coatings 2023, 13, 267. [Google Scholar] [CrossRef]

- Luo, X.T.; Li, C.X.; Shang, F.L.; Yang, G.J.; Wang, Y.Y.; Li, C.J. High Velocity Impact Induced Microstructure Evolution during Deposition of Cold Spray Coatings: A Review. Surf. Coat. Technol. 2014, 254, 11–20. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold Spraying—A Materials Perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Adaan-Nyiak, M.A.; Tiamiyu, A.A. Recent Advances on Bonding Mechanism in Cold Spray Process: A Review of Single-Particle Impact Methods. J. Mater. Res. 2023, 38, 69–95. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Singh, N.K.; Uddin, K.Z.; Muthulingam, J.; Jha, R.; Koohbor, B. Analyzing the Effects of Particle Diameter in Cold Spraying of Thermoplastic Polymers. J. Therm. Spray Technol. 2021, 30, 1226–1238. [Google Scholar] [CrossRef]

- Dowding, I.; Hassani, M.; Sun, Y.; Veysset, D.; Nelson, K.A.; Schuh, C.A. Particle Size Effects in Metallic Microparticle Impact-Bonding. Acta Mater. 2020, 194, 40–48. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a Generalized Parameter Window for Cold Spray Deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Assadi, H.; Kreye, H. Microstructural and Macroscopic Properties of Cold Sprayed Copper Coatings. J. Appl. Phys. 2003, 93, 10064–10070. [Google Scholar] [CrossRef]

- Rahmati, S.; Ghaei, A. The Use of Particle/Substrate Material Models in Simulation of Cold-Gas Dynamic-Spray Process. J. Therm. Spray Technol. 2014, 23, 530–540. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding Mechanism in Cold Gas Spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Rahmati, S.; Mostaghimi, J.; Coyle, T.; Dolatabadi, A. Jetting Phenomenon in Cold Spray: A Critical Review on Finite Element Simulations. J. Therm. Spray Technol. 2024, 33, 1233–1250. [Google Scholar] [CrossRef]

- Tiamiyu, A.A.; Sun, Y.; Nelson, K.A.; Schuh, C.A. Site-Specific Study of Jetting, Bonding, and Local Deformation during High-Velocity Metallic Microparticle Impact. Acta Mater. 2021, 202, 159–169. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Formation of Persistent Dislocation Loops by Ultra-High Strain-Rate Deformation during Cold Spraying. Acta Mater. 2005, 53, 2991–3000. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic Shear Instability Is Not Necessary for Adhesion in Cold Spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Response to Comment on “Adiabatic Shear Instability Is Not Necessary for Adhesion in Cold Spray. ” Scr. Mater. 2019, 162, 515–519. [Google Scholar] [CrossRef]

- Nikbakht, R.; Seyedein, S.H.; Kheirandish, S.; Assadi, H.; Jodoin, B. Asymmetrical Bonding in Cold Spraying of Dissimilar Materials. Appl. Surf. Sci. 2018, 444, 621–632. [Google Scholar] [CrossRef]

- Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Lee, C. General Aspects of Interface Bonding in Kinetic Sprayed Coatings. Acta Mater. 2008, 56, 4858–4868. [Google Scholar] [CrossRef]

- Liu, T.; Leazer, J.D.; Brewer, L.N. Particle Deformation and Microstructure Evolution during Cold Spray of Individual Al–Cu Alloy Powder Particles. Acta Mater. 2019, 168, 13–23. [Google Scholar] [CrossRef]

- Ko, K.H.; Choi, J.O.; Lee, H.; Seo, Y.K.; Jung, S.P.; Yu, S.S. Cold Spray Induced Amorphization at the Interface between Fe Coatings and Al Substrate. Mater. Lett. 2015, 149, 40–42. [Google Scholar] [CrossRef]

- Reddy, C.D.; Zhang, Z.Q.; Msolli, S.; Guo, J.; Sridhar, N. Impact Velocity-Dependent Bonding Mechanisms in Metal Cold Spray. Surf. Coat. Technol. 2022, 433, 128085. [Google Scholar] [CrossRef]

- ASTM C633-13; Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Wang, X.; Feng, F.; Klecka, M.A.; Mordasky, M.D.; Garofano, J.K.; El-Wardany, T.; Nardi, A.; Champagne, V.K. Characterization and Modeling of the Bonding Process in Cold Spray Additive Manufacturing. Addit. Manuf. 2015, 8, 149–162. [Google Scholar] [CrossRef]

- Boese, S.; Sevinsky, A.; Nourian-Avval, A.; Özdemir, O.; Müftü, S. Laser Assisted Cold Spray of Aluminum Alloy 6061: Experimental Results. Addit. Manuf. 2024, 95, 104548. [Google Scholar] [CrossRef]

- Huang, R.; Fukanuma, H. Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits. J. Therm. Spray Technol. 2012, 21, 541–549. [Google Scholar] [CrossRef]

- Rokni, M.R.; Widener, C.A.; Ozdemir, O.C.; Crawford, G.A. Microstructure and Mechanical Properties of Cold Sprayed 6061 Al in As-Sprayed and Heat Treated Condition. Surf. Coat. Technol. 2017, 309, 641–650. [Google Scholar] [CrossRef]

- Richer, P.; Zúñiga, A.; Yandouzi, M.; Jodoin, B. CoNiCrAlY Microstructural Changes Induced during Cold Gas Dynamic Spraying. Surf. Coat. Technol. 2008, 203, 364–371. [Google Scholar] [CrossRef]

- Li, C.J.; Li, W.Y.; Wang, Y.Y. Formation of Metastable Phases in Cold-Sprayed Soft Metallic Deposit. Surf. Coat. Technol. 2005, 198, 469–473. [Google Scholar] [CrossRef]

- Li, W.Y.; Li, C.J.; Yang, G.J. Effect of Impact-Induced Melting on Interface Microstructure and Bonding of Cold-Sprayed Zinc Coating. Appl. Surf. Sci. 2010, 257, 1516–1523. [Google Scholar] [CrossRef]

- Wang, Q.; Qiu, D.; Xiong, Y.; Birbilis, N.; Zhang, M.X. High Resolution Microstructure Characterization of the Interface between Cold Sprayed Al Coating and Mg Alloy Substrate. Appl. Surf. Sci. 2014, 289, 366–369. [Google Scholar] [CrossRef]

- Luzin, V.; Kirstein, O.; Zahiri, S.H.; Fraser, D. Residual Stress Buildup in Ti Components Produced by Cold Spray Additive Manufacturing (CSAM). J. Therm. Spray Technol. 2020, 29, 1498–1507. [Google Scholar] [CrossRef]

- Sinclair-Adamson, R.; Luzin, V.; Duguid, A.; Kannoorpatti, K.; Murray, R. Residual Stress Distributions in Cold-Sprayed Copper 3D-Printed Parts. J. Therm. Spray Technol. 2020, 29, 1525–1537. [Google Scholar] [CrossRef]

- Luzin, V.; Spencer, K.; Zhang, M.X. Residual Stress and Thermo-Mechanical Properties of Cold Spray Metal Coatings. Acta Mater. 2011, 59, 1259–1270. [Google Scholar] [CrossRef]

- Saleh, M.; Luzin, V.; Spencer, K. Analysis of the Residual Stress and Bonding Mechanism in the Cold Spray Technique Using Experimental and Numerical Methods. Surf. Coat. Technol. 2014, 252, 15–28. [Google Scholar] [CrossRef]

- Maledi, N.B.; Oladijo, O.P.; Botef, I.; Ntsoane, T.P.; Madiseng, A.; Moloisane, L. Influence of Cold Spray Parameters on the Microstructures and Residual Stress of Zn Coatings Sprayed on Mild Steel. Surf. Coat. Technol. 2017, 318, 106–113. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, C.; Li, C.J.; Liao, H. Modeling Aspects of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis. J. Therm. Spray Technol. 2009, 18, 921–933. [Google Scholar] [CrossRef]

- Tsui, Y.C.; Clyne, T.W. An Analytical Model for Predicting Residual Stresses in Progressively Deposited Coatings Part 1: Planar Geometry. Thin Solid. Films 1997, 306, 23–33. [Google Scholar] [CrossRef]

- Huang, C.J.; Yan, X.C.; Li, W.Y.; Wang, W.B.; Verdy, C.; Planche, M.P.; Liao, H.L.; Montavon, G. Post-Spray Modification of Cold-Sprayed Ni-Ti Coatings by High-Temperature Vacuum Annealing and Friction Stir Processing. Appl. Surf. Sci. 2018, 451, 56–66. [Google Scholar] [CrossRef]

- Boeing Awards MIC Laser Peening Contract to Form 747-8 Wing Sections|Curtiss-Wright Surface Technologies. Available online: https://cwst.com/news/boeing-awards-mic-laser-peening-contract-to-form-747-8-wing-sections (accessed on 3 December 2024).

- Maharjan, N.; Ramesh, T.; Pham, D.Q.; Zhai, W.; Ang, A.; Zhou, W. Post-Processing of Cold Sprayed Ti6Al4V Coating by Laser Shock Peening. J. Mater. Process Technol. 2024, 330, 118461. [Google Scholar] [CrossRef]

- Hackel, L.; Rankin, J.R.; Rubenchik, A.; King, W.E.; Matthews, M. Laser Peening: A Tool for Additive Manufacturing Post-Processing. Addit. Manuf. 2018, 24, 67–75. [Google Scholar] [CrossRef]

- Benenati, G.; Lupoi, R. Development of a Deposition Strategy in Cold Spray for Additive Manufacturing to Minimize Residual Stresses. Procedia CIRP 2016, 55, 101–108. [Google Scholar] [CrossRef]

- Shrestha, D.; Azarmi, F.; Tangpong, X.W. Effect of Heat Treatment on Residual Stress of Cold Sprayed Nickel-Based Superalloys. J. Therm. Spray Technol. 2022, 31, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Murray, J.W.; Zuccoli, M.V.; Hussain, T. Heat Treatment of Cold-Sprayed C355 Al for Repair: Microstructure and Mechanical Properties. J. Therm. Spray Technol. 2018, 27, 159–168. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Haché, M.J.R.; Chu, X.; Irissou, E.; Zou, Y. Prediction of Heterogeneous Microstructural Evolution in Cold Sprayed Copper Coatings Using Local Zener-Hollomon Parameter and Strain. Acta Mater. 2020, 193, 191–201. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Raghupathy, Y.; Srinivasan, D.; Suwas, S.; Srivastava, C. Microstructural Evolution of Cold-Sprayed Inconel 625 Superalloy Coatings on Low Alloy Steel Substrate. Acta Mater. 2017, 129, 11–25. [Google Scholar] [CrossRef]

- Wei, J.; Aghasibeig, M.; Lyu, T.; Liu, Z.; Chen, H.; Irissou, E.; Zou, Y. Cold Spray Deposition and Microstructure Characterization of CuNi, CuSn, and CuNiSiCr Coatings. Surf. Coat. Technol. 2024, 480, 130621. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Honkanen, M.; Vuoristo, P. Cold-Sprayed Copper and Tantalum Coatings—Detailed FESEM and TEM Analysis. Surf. Coat. Technol. 2010, 204, 2353–2361. [Google Scholar] [CrossRef]

- Lahiri, D.; Gill, P.K.; Scudino, S.; Zhang, C.; Singh, V.; Karthikeyan, J.; Munroe, N.; Seal, S.; Agarwal, A. Cold Sprayed Aluminum Based Glassy Coating: Synthesis, Wear and Corrosion Properties. Surf. Coat. Technol. 2013, 232, 33–40. [Google Scholar] [CrossRef]

- Balani, K.; Agarwal, A.; Seal, S.; Karthikeyan, J. Transmission Electron Microscopy of Cold Sprayed 1100 Aluminum Coating. Scr. Mater. 2005, 53, 845–850. [Google Scholar] [CrossRef]

- Wang, Q.; Birbilis, N.; Zhang, M.X. Interfacial Structure between Particles in an Aluminum Deposit Produced by Cold Spray. Mater. Lett. 2011, 65, 1576–1578. [Google Scholar] [CrossRef]

- Tao, Y.; Xiong, T.; Sun, C.; Kong, L.; Cui, X.; Li, T.; Song, G.L. Microstructure and Corrosion Performance of a Cold Sprayed Aluminium Coating on AZ91D Magnesium Alloy. Corros. Sci. 2010, 52, 3191–3197. [Google Scholar] [CrossRef]

- Bae, G.; Kang, K.; Kim, J.J.; Lee, C. Nanostructure Formation and Its Effects on the Mechanical Properties of Kinetic Sprayed Titanium Coating. Mater. Sci. Eng. A 2010, 527, 6313–6319. [Google Scholar] [CrossRef]

- Kim, K.H.; Watanabe, M.; Kuroda, S. Thermal Softening Effect on the Deposition Efficiency and Microstructure of Warm Sprayed Metallic Powder. Scr. Mater. 2009, 60, 710–713. [Google Scholar] [CrossRef]

- Kim, K.H.; Watanabe, M.; Kawakita, J.; Kuroda, S. Grain Refinement in a Single Titanium Powder Particle Impacted at High Velocity. Scr. Mater. 2008, 59, 768–771. [Google Scholar] [CrossRef]

- Kang, K.; Won, J.; Bae, G.; Ha, S.; Lee, C. Interfacial Bonding and Microstructural Evolution of Al in Kinetic Spraying. J. Mater. Sci. 2012, 47, 4649–4659. [Google Scholar] [CrossRef]

- Zou, Y.; Qin, W.; Irissou, E.; Legoux, J.G.; Yue, S.; Szpunar, J.A. Dynamic Recrystallization in the Particle/Particle Interfacial Region of Cold-Sprayed Nickel Coating: Electron Backscatter Diffraction Characterization. Scr. Mater. 2009, 61, 899–902. [Google Scholar] [CrossRef]

- Moy, C.K.S.; Cairney, J.; Ranzi, G.; Jahedi, M.; Ringer, S.P. Investigating the Microstructure and Composition of Cold Gas-Dynamic Spray (CGDS) Ti Powder Deposited on Al 6063 Substrate. Surf. Coat. Technol. 2010, 204, 3739–3749. [Google Scholar] [CrossRef]

- Seo, D.; Ogawa, K.; Sakaguchi, K.; Miyamoto, N.; Tsuzuki, Y. Influence of Crystallite Size and Lattice Spacing on Thermal Conduction of Polycrystalline Copper Deposited by Solid Particle Impingement: Contribution of Electron and Phonon Conduction. Surf. Coat. Technol. 2012, 207, 233–239. [Google Scholar] [CrossRef]

- King, P.C.; Zahiri, S.H.; Jahedi, M. Microstructural Refinement within a Cold-Sprayed Copper Particle. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 2115–2123. [Google Scholar] [CrossRef]

- Eason, P.D.; Fewkes, J.A.; Kennett, S.C.; Eden, T.J.; Tello, K.; Kaufman, M.J.; Tiryakioĝlu, M. On the Characterization of Bulk Copper Produced by Cold Gas Dynamic Spray Processing in as Fabricated and Annealed Conditions. Mater. Sci. Eng. A 2011, 528, 8174–8178. [Google Scholar] [CrossRef]

- Xiong, Y.; Xiong, X.; Yoon, S.; Bae, G.; Lee, C. Dependence of Bonding Mechanisms of Cold Sprayed Coatings on Strain-Rate-Induced Non-Equilibrium Phase Transformation. J. Therm. Spray Technol. 2011, 20, 860–865. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, N.; Takahashi, M.; Luo, X.; Li, C. Development of a Material Model for Predicting Extreme Deformation and Grain Refinement during Cold Spraying. Acta Mater. 2020, 199, 326–339. [Google Scholar] [CrossRef]

- Yin, S.; Wang, X.F.; Li, W.Y.; Jie, H.E. Effect of Substrate Hardness on the Deformation Behavior of Subsequently Incident Particles in Cold Spraying. Appl. Surf. Sci. 2011, 257, 7560–7565. [Google Scholar] [CrossRef]

- Vo, P.; Irissou, E.; Legoux, J.G.; Yue, S. Mechanical and Microstructural Characterization of Cold-Sprayed Ti-6Al-4V after Heat Treatment. J. Therm. Spray Technol. 2013, 22, 954–964. [Google Scholar] [CrossRef]

- Sun, W.; Bhowmik, A.; Tan, A.W.Y.; Li, R.; Xue, F.; Marinescu, I.; Liu, E. Improving Microstructural and Mechanical Characteristics of Cold-Sprayed Inconel 718 Deposits via Local Induction Heat Treatment. J. Alloys Compd. 2019, 797, 1268–1279. [Google Scholar] [CrossRef]

- Al-Mangour, B.; Vo, P.; Mongrain, R.; Irissou, E.; Yue, S. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Stainless Steel 316L Coatings Produced by Cold Spray for Biomedical Applications. J. Therm. Spray Technol. 2014, 23, 641–652. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).