Anode Protection Strategies for Next-Generation Lithium–Oxygen Batteries: Toward Dendrite-Free Lithium Metal at Practical Current Densities

Abstract

1. Introduction

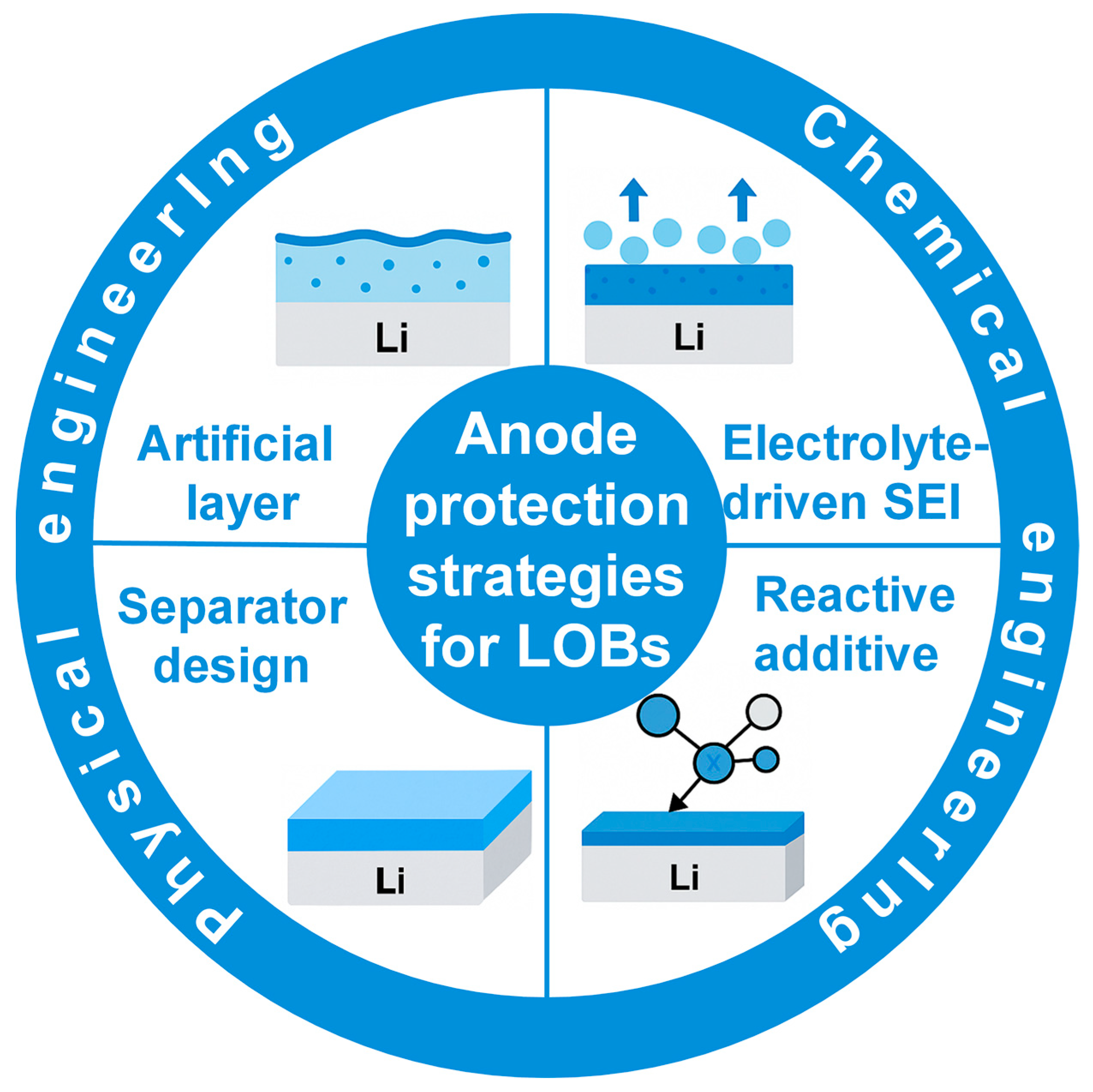

2. LMA Protection Strategies for High-Performance LOBs

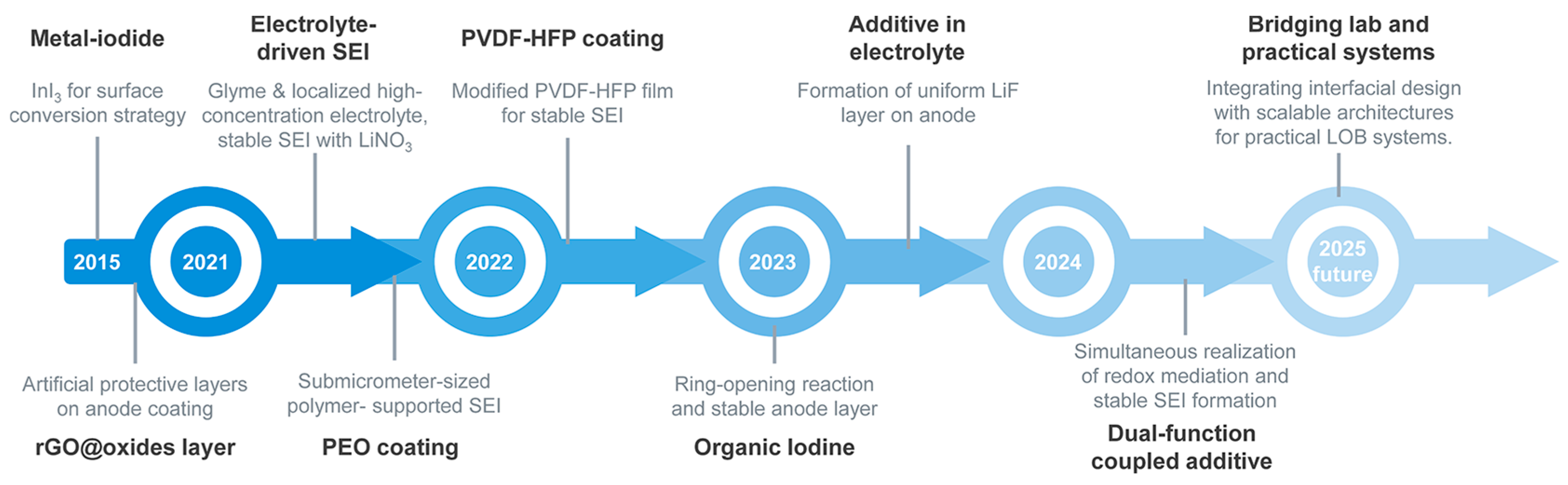

2.1. Artificial Protective Layers

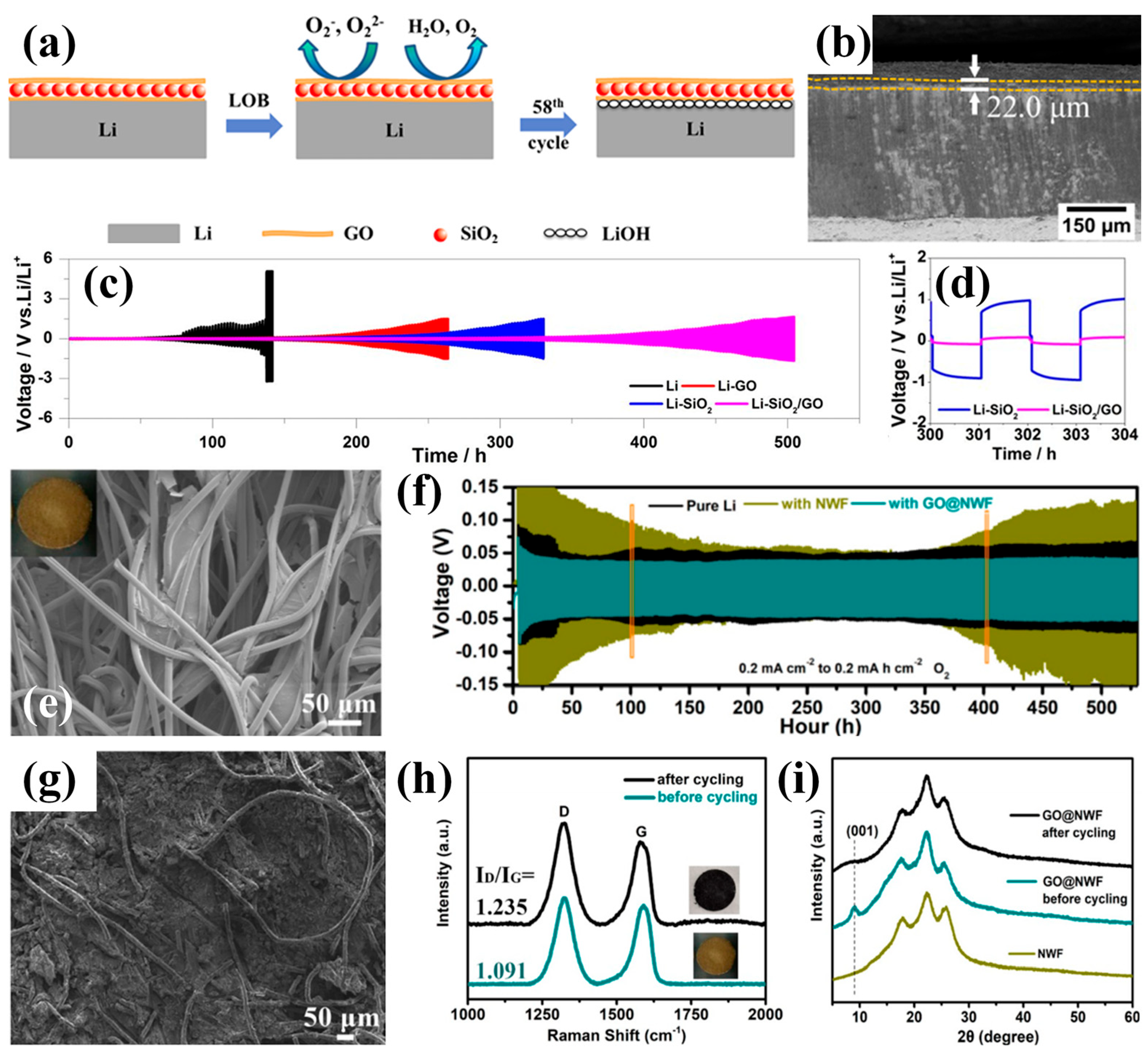

2.2. Separator Design and Modification

3. SEI/Interfacial Chemistry Engineering for LOBs

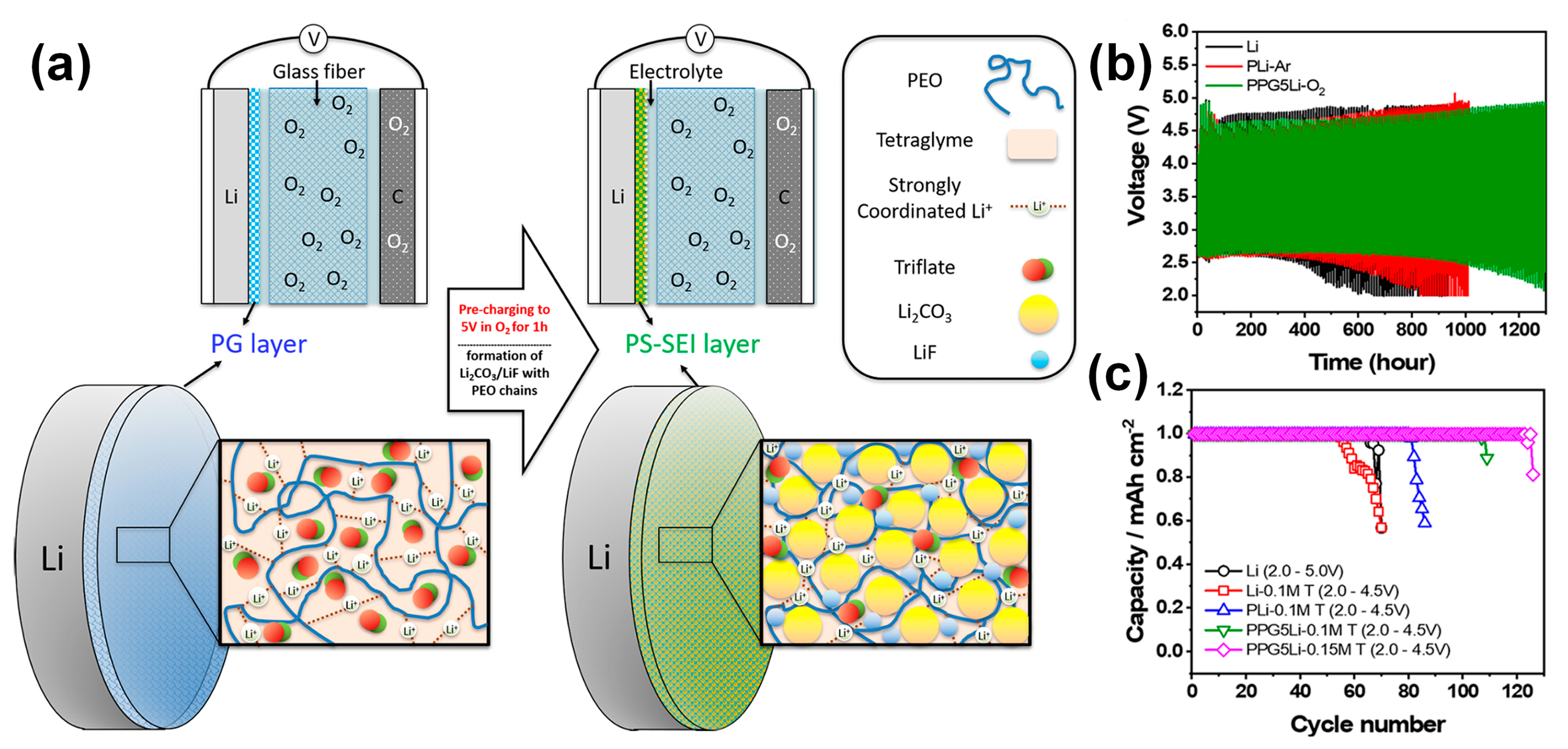

3.1. Electrolyte-Driven SEI Chemistry for Dendrite Suppression

3.2. Metal-Iodide-Induced Surface Conversion Strategy

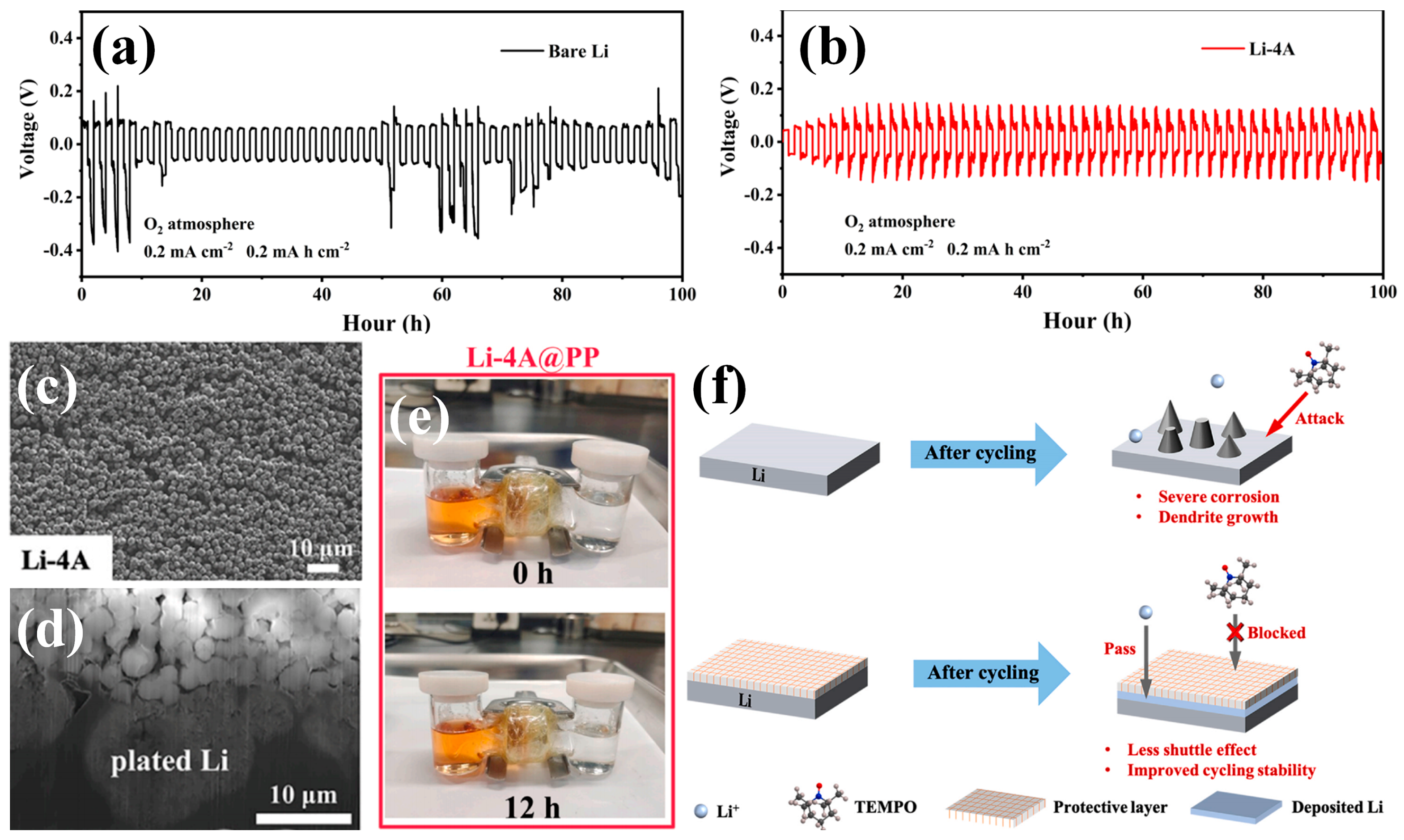

3.3. Reactive Additive Engineering for In Situ Interface Formation

4. Conclusions and Perspectives

4.1. Conclusions

4.2. Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bai, T.; Li, D.; Xiao, S.; Ji, F.; Zhang, S.; Wang, C.; Lu, J.; Gao, Q.; Ci, L. Recent progress on single-atom catalysts for lithium–air battery applications. Energy Environ. Sci. 2023, 16, 1431–1465. [Google Scholar] [CrossRef]

- Rao, Y.; Yang, J.; Chu, S.; Guo, S.; Zhou, H. Solid-state Li–air batteries: Fundamentals, challenges, and strategies. SmartMat 2023, 4, E1205. [Google Scholar] [CrossRef]

- Lee, J.; Park, Y.; Choi, J.W. Navigating interfacial challenges in lithium metal batteries: From fundamental understanding to practical realization. Nano Converg. 2025, 12, 25. [Google Scholar] [CrossRef]

- Lim, H.-S.; Kwak, W.-J.; Chae, S.; Wi, S.; Li, L.; Hu, J.; Tao, J.; Wang, C.; Xu, W.; Zhang, J.-G. Stable Solid Electrolyte Interphase Layer Formed by Electrochemical Pretreatment of Gel Polymer Coating on Li Metal Anode for Lithium–Oxygen Batteries. ACS Energy Lett. 2021, 6, 3321–3331. [Google Scholar] [CrossRef]

- Huang, J.; Li, C.; Jiang, D.; Gao, J.; Cheng, L.; Li, G.; Luo, H.; Xu, Z.L.; Shin, D.M.; Wang, Y.; et al. Solid-State Electrolytes for Lithium Metal Batteries: State-of-the-Art and Perspectives. Adv. Funct. Mater. 2024, 35, 2411171. [Google Scholar] [CrossRef]

- Kwak, W.-J.; Rosy; Sharon, D.; Xia, C.; Kim, H.; Johnson, L.R.; Bruce, P.G.; Nazar, L.F.; Sun, Y.-K.; Frimer, A.A.; et al. Lithium–Oxygen Batteries and Related Systems: Potential, Status, and Future. Chem. Rev. 2020, 120, 6626–6683. [Google Scholar] [CrossRef]

- Wang, X.; Wan, K.; Xu, H.; Tian, G.; Liu, S.; Fan, F.; Liu, P.; Zeng, C.; Wang, C.; Wang, S.; et al. Recent progress in oxygen electrocatalysts for aprotic lithium-oxygen batteries. EnergyChem 2025, 7, 100150. [Google Scholar] [CrossRef]

- Chen, X.-R.; Chen, X.; Yan, C.; Zhang, X.-Q.; Zhang, Q.; Huang, J.-Q. Role of Lithiophilic Metal Sites in Lithium Metal Anodes. Energy Fuels 2021, 35, 12746–12752. [Google Scholar] [CrossRef]

- Qu, J.; Liu, J.; Leng, G.; Wang, Y.; Wang, S.; Shen, S.; Yin, H.; Hou, Z.; Duan, B. Overcoming the obstacles of lithium-metal anodes for high-energy batteries. Electrochem. Commun. 2023, 153, 107537. [Google Scholar] [CrossRef]

- Li, S.; Wu, F.; Chen, T.; Kang, K.; Guo, R.; Liu, C.; Niu, Y.; Gao, A.; Zhao, R.; Wang, X.; et al. Progress and Challenges for Energy-Dense and Cost-Effective Anode-Free Lithium Metal Batteries. Energy Mater. Adv. 2025, 6, 0168. [Google Scholar] [CrossRef]

- Chen, K.; Yang, D.-Y.; Huang, G.; Zhang, X.-B. Lithium–Air Batteries: Air-Electrochemistry and Anode Stabilization. Acc. Chem. Res. 2021, 54, 632–641. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Liu, J.; Liu, Z.; Xue, J.; Cui, X.; Liu, W.; Cheng, P.; Huang, T.; Yu, A. Recent Advances in Electrolytes for Nonaqueous Lithium-Oxygen Batteries. Chem. Rec. 2025, 25, e202400046. [Google Scholar] [CrossRef] [PubMed]

- Grande, L.; Paillard, E.; Hassoun, J.; Park, J.B.; Lee, Y.J.; Sun, Y.K.; Passerini, S.; Scrosati, B. The Lithium/Air Battery: Still an Emerging System or a Practical Reality? Adv. Mater. 2014, 27, 784–800. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.; Xing, S.; Zhang, Z.; Zhou, Z. Solving the Singlet Oxygen Puzzle in Metal-O2 Batteries: Current Progress and Future Directions. Electrochem. Energy Rev. 2024, 7, 6. [Google Scholar] [CrossRef]

- Naqvi, A.A.; Zahoor, A.; Shaikh, A.A.; Butt, F.A.; Raza, F.; Ahad, I.U. Aprotic lithium air batteries with oxygen-selective membranes. Mater. Renew. Sustain. Energy 2022, 11, 33–46. [Google Scholar] [CrossRef]

- Amici, J.; Banaudi, G.; Longo, M.; Gandolfo, M.; Zanon, M.; Francia, C.; Bodoardo, S.; Sangermano, M. Efficient Biorenewable Membranes in Lithium-Oxygen Batteries. Polymers 2023, 15, 3182. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, Z.; Yao, Z.; Cui, Z.; Wang, J.; Zhang, T. Halosilane triggers anodic silanization and cathodic redox for stable and efficient lithium–O2 batteries. J. Mater. Chem. A 2019, 7, 18237–18243. [Google Scholar] [CrossRef]

- Wen, Z.; Fang, W.; Wu, X.; Qin, Z.; Kang, H.; Chen, L.; Zhang, N.; Liu, X.; Chen, G. High-Concentration Additive and Triiodide/Iodide Redox Couple Stabilize Lithium Metal Anode and Rejuvenate the Inactive Lithium in Carbonate-Based Electrolyte. Adv. Funct. Mater. 2022, 32, 2204768. [Google Scholar] [CrossRef]

- Tan, Y.; Sun, Z.; Liu, Y.; Yan, H.; Wang, C.; Fan, J.; Zheng, M.; Dong, Q. Constructing an Ion-Wall to Achieve Excellent Lithium Anodes in Li–O2 Batteries with High DN Electrolytes. Adv. Energy Mater. 2024, 14, 2304153. [Google Scholar] [CrossRef]

- Zhang, Y.; Gou, Z.; Zheng, K.; Dou, Y.; Zhou, Z. Enhancing the Stability of Metallic Li Anodes for Aprotic Li-O2 Batteries with Dual-Anion Electrolytes. J. Phys. Chem. Lett. 2024, 15, 6598–6604. [Google Scholar] [CrossRef]

- Zhao, Z.; Pang, L.; Wu, Y.; Chen, Y.; Peng, Z. In Situ Spectroscopic Probing of Oxygen Crossover Effects on Solid Electrolyte Interphase in Aprotic Lithium-Oxygen Batteries. Adv. Energy Mater. 2023, 13, 2301127. [Google Scholar] [CrossRef]

- Kim, B.G.; Kim, J.S.; Min, J.; Lee, Y.H.; Choi, J.H.; Jang, M.C.; Freunberger, S.A.; Choi, J.W. A Moisture- and Oxygen-Impermeable Separator for Aprotic Li-O2 Batteries. Adv. Funct. Mater. 2016, 26, 1747–1756. [Google Scholar] [CrossRef]

- Guo, J.; Meng, X.; Wang, Q.; Zhang, Y.; Yan, S.; Luo, S. Advancements in Lithium–Oxygen Batteries: A Comprehensive Review of Cathode and Anode Materials. Batteries 2024, 10, 260. [Google Scholar] [CrossRef]

- Maiti, S.; Curnan, M.T.; Subhalaxmi, S.; Kim, K.W.; Narayan, R.; Hur, J.; Kim, J.K.; Maiti, K. Adapting Single-Atom Catalysts to Li-O2 Batteries: Enhancing Energy Storage. Small 2025, 21, e2505334. [Google Scholar] [CrossRef]

- Qiu, Q.; Long, J.; Yao, P.; Wang, J.; Li, X.; Pan, Z.-Z.; Zhao, Y.; Li, Y. Cathode electrocatalyst in aprotic lithium oxygen (Li-O2) battery: A literature survey. Catal. Today 2023, 420, 114138. [Google Scholar] [CrossRef]

- Suryatna, A.; Raya, I.; Thangavelu, L.; Alhachami, F.R.; Kadhim, M.M.; Altimari, U.S.; Mahmoud, Z.H.; Mustafa, Y.F.; Kianfar, E.; Liu, X. A Review of High-Energy Density Lithium-Air Battery Technology: Investigating the Effect of Oxides and Nanocatalysts. J. Chem. 2022, 2022, 2762647. [Google Scholar] [CrossRef]

- Wang, N.; Han, Z.; Cao, X.; Fu, J.; Chen, Y.; Xiong, D. Designing Long-Term Cycle Life for a Lithium–Air Battery with a Modified Gas Diffusion Layer in Terms of the Moisture Intrusion and Electrolyte Volatilization. J. Phys. Chem. C 2021, 125, 24787–24795. [Google Scholar] [CrossRef]

- Li, T.; Liu, D.; Gao, L.; Yu, D.; Liu, X.; Li, L.; Kang, W. Novel Guidelines of Redox Mediators for Practical Lithium–Oxygen Batteries: Characterization Mechanisms, Design Principle, and Engineering Strategies. Adv. Energy Mater. 2024, 15, 2403406. [Google Scholar] [CrossRef]

- Lu, T.; Qian, Y.; Liu, K.; Wu, C.; Li, X.; Xiao, J.; Zeng, X.; Zhang, Y.; Chou, S.L. Recent Progress of Electrolyte Materials for Solid-State Lithium–Oxygen (Air) Batteries. Adv. Energy Mater. 2024, 14, 2400766. [Google Scholar] [CrossRef]

- Xia, C.; Kwok, C.Y.; Nazar, L.F. A high-energy-density lithium-oxygen battery based on a reversible four-electron conversion to lithium oxide. Science 2018, 361, 777–781. [Google Scholar] [CrossRef]

- Luo, Z.; Zhu, G.; Yin, L.; Li, F.; Xu, B.B.; Dala, L.; Liu, X.; Luo, K. A Facile Surface Preservation Strategy for the Lithium Anode for High-Performance Li-O2 Batteries. ACS Appl. Mater. Interfaces 2020, 12, 27316–27326. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Pan, K.; Wang, W.; Xing, S.; Dou, Y.; Zhang, Z.; Zhou, Z. Constructing Rechargeable Solid-State Lithium-Oxygen Batteries. Batter. Supercaps 2023, 6, e202300230. [Google Scholar] [CrossRef]

- Li, J.; Hou, L.; Yu, M.; Li, Q.; Zhang, T.; Sun, H. Review and Recent Advances of Oxygen Transfer in Li-air Batteries. ChemElectroChem 2021, 8, 3588–3603. [Google Scholar] [CrossRef]

- Liang, Z.; Wang, W.; Lu, Y.-C. The path toward practical Li-air batteries. Joule 2022, 6, 2458–2473. [Google Scholar] [CrossRef]

- Kondori, A.; Esmaeilirad, M.; Harzandi, A.M.; Amine, R.; Saray, M.T.; Yu, L.; Liu, T.; Wen, J.; Shan, N.; Wang, H.-H.; et al. A room temperature rechargeable Li2O-based lithium-air battery enabled by a solid electrolyte. Science 2023, 379, 499–505. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, B.; Shen, Y.; Wu, J.; Zhao, Z.; Zhong, C.; Hu, W. Confronting the Challenges in Lithium Anodes for Lithium Metal Batteries. Adv. Sci. 2021, 8, 2101111. [Google Scholar] [CrossRef]

- Park, C.W.; Lee, J.H.; Seo, J.K.; Jo, W.Y.; Whang, D.; Hwang, S.M.; Kim, Y.J. Graphene collage on Ni-rich layered oxide cathodes for advanced lithium-ion batteries. Nat. Commun. 2021, 12, 2145. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Wang, W.; Liu, Z.; Shen, C. Electrochemical Atomic Force Microscopy Study on the Dynamic Evolution of Lithium Deposition. Materials 2023, 16, 2278. [Google Scholar] [CrossRef]

- Song, L.-N.; Zheng, L.-J.; Wang, X.-X.; Kong, D.-C.; Wang, Y.-F.; Wang, Y.; Wu, J.-Y.; Sun, Y.; Xu, J.-J. Aprotic Lithium–Oxygen Batteries Based on Nonsolid Discharge Products. J. Am. Chem. Soc. 2024, 146, 1305–1317. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; Wang, C.; Peng, X.; Fang, W.; Hou, Y.; Wang, J.; Ye, J.; Wu, Y. Li2O2 Formation Electrochemistry and Its Influence on Oxygen Reduction/Evolution Reaction Kinetics in Aprotic Li-O2 Batteries. Small Methods 2022, 6, e2101280. [Google Scholar] [CrossRef]

- Wood, K.N.; Teeter, G. XPS on Li-Battery-Related Compounds: Analysis of Inorganic SEI Phases and a Methodology for Charge Correction. ACS Appl. Energy Mater. 2018, 1, 4493–4504. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Q.; Wang, X.G.; Wang, C.; Chen, Y.N.; Xie, Z.; Zhou, Z. An Extremely Simple Method for Protecting Lithium Anodes in Li-O2 Batteries. Angew. Chem. Int. Ed. 2018, 57, 12814–12818. [Google Scholar] [CrossRef]

- Lee, D.J.; Lee, H.; Song, J.; Ryou, M.-H.; Lee, Y.M.; Kim, H.-T.; Park, J.-K. Composite protective layer for Li metal anode in high-performance lithium–oxygen batteries. Electrochem. Commun. 2014, 40, 45–48. [Google Scholar] [CrossRef]

- Kim, J.H.; Woo, H.S.; Kim, W.K.; Ryu, K.H.; Kim, D.W. Improved Cycling Performance of Lithium-Oxygen Cells by Use of a Lithium Electrode Protected with Conductive Polymer and Aluminum Fluoride. ACS Appl. Mater. Interfaces 2016, 8, 32300–32306. [Google Scholar] [CrossRef]

- Zhang, T.; Liao, K.; He, P.; Zhou, H. A self-defense redox mediator for efficient lithium–O2 batteries. Energy Environ. Sci. 2016, 9, 1024–1030. [Google Scholar] [CrossRef]

- Xin, X.; Ito, K.; Dutta, A.; Kubo, Y. Dendrite-Free Epitaxial Growth of Lithium Metal during Charging in Li-O2 Batteries. Angew. Chem. Int. Ed. 2018, 57, 13206–13210. [Google Scholar] [CrossRef] [PubMed]

- Hsia, T.N.; Lu, H.C.; Hsueh, Y.C.; Rajesh Kumar, S.; Yen, C.S.; Yang, C.C.; Lue, S.J. Superdry poly(vinylidene fluoride-co-hexafluoropropylene) coating on a lithium anode as a protective layer and separator for a high-performance lithium-oxygen battery. J. Colloid Interface Sci. 2022, 626, 524–534. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yao, Y.; Cheng, J.; Chen, L.; Dai, L.; Zhang, L.; Si, P.; Ci, L. Flexible rGO @ Nonwoven Fabrics’ Membranes Guide Stable Lithium Metal Anodes for Lithium–Oxygen Batteries. ACS Appl. Energy Mater. 2020, 3, 7944–7951. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, Y.; Zhai, Y.; Zhai, J.; Ren, W.; Wang, F.; Dong, S. Controlled synthesis of large-area and patterned electrochemically reduced graphene oxide films. Chem. Eur. J. 2009, 15, 6116–6120. [Google Scholar] [CrossRef]

- Bergner, B.J.; Schurmann, A.; Peppler, K.; Garsuch, A.; Janek, J. TEMPO: A mobile catalyst for rechargeable Li-O2 batteries. J. Am. Chem. Soc. 2014, 136, 15054–15064. [Google Scholar] [CrossRef]

- Kwak, W.-J.; Hirshberg, D.; Sharon, D.; Afri, M.; Frimer, A.A.; Jung, H.-G.; Aurbach, D.; Sun, Y.-K. Li–O2 cells with LiBr as an electrolyte and a redox mediator. Energy Environ. Sci. 2016, 9, 2334–2345. [Google Scholar] [CrossRef]

- Ahmadiparidari, A.; Fuladi, S.; Majidi, L.; Plunkett, S.; Sarnello, E.; Gholivand, H.; Hemmat, Z.; Rastegar, S.; Misal, S.N.; Jimenez, N.; et al. Enhancing the performance of lithium oxygen batteries through combining redox mediating salts with a lithium protecting salt. J. Power Sources 2021, 491, 229506. [Google Scholar] [CrossRef]

- Sun, D.; Shen, Y.; Zhang, W.; Yu, L.; Yi, Z.; Yin, W.; Wang, D.; Huang, Y.; Wang, J.; Wang, D.; et al. A solution-phase bifunctional catalyst for lithium-oxygen batteries. J. Am. Chem. Soc. 2014, 136, 8941–8946. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yu, W.; Wen, K.; Wang, H.; Wang, X.; Nan, C.-W.; Li, L. Strategies to suppress the shuttle effect of redox mediators in lithium-oxygen batteries. J. Energy Chem. 2021, 60, 135–149. [Google Scholar] [CrossRef]

- Lim, H.-D.; Lee, B.; Zheng, Y.; Hong, J.; Kim, J.; Gwon, H.; Ko, Y.; Lee, M.; Cho, K.; Kang, K. Rational design of redox mediators for advanced Li–O2 batteries. Nat. Energy 2016, 1, 16066. [Google Scholar] [CrossRef]

- Kim, M.; Kim, T.-S.; Choi, C. Applications of Metal–Organic Frameworks and Their Derivatives in Lithium–Sulfur Battery Separators: Advances and Prospectives Focusing on Cathode-Side Polysulfide Regulation. Inorganics 2025, 13, 294. [Google Scholar] [CrossRef]

- Seo, S.-D.; Choi, C.; Kim, D.-W. Fabrication of sulfur-impregnated porous carbon nanostructured electrodes via dual-mode activation for lithium–sulfur batteries. Mater. Lett. 2016, 172, 116–119. [Google Scholar] [CrossRef]

- Seo, S.-D.; Choi, C.; Kim, B.-K.; Kim, D.-W. Fabrication of highly porous carbon as sulfur hosts using waste green tea bag powder for lithium–sulfur batteries. Ceram. Int. 2017, 43, 2836–2841. [Google Scholar] [CrossRef]

- Kwak, W.J.; Park, S.J.; Jung, H.G.; Sun, Y.K. Optimized Concentration of Redox Mediator and Surface Protection of Li Metal for Maintenance of High Energy Efficiency in Li–O2 Batteries. Adv. Energy Mater. 2017, 8, 1702258. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Cai, Y.; Cheng, F.; Niu, Z.; Chen, J. Super P Carbon Modified Lithium Anode for High-Performance Li−O2 Batteries. ChemElectroChem 2018, 5, 1702–1707. [Google Scholar] [CrossRef]

- Cao, D.; Zhang, S.; Yu, F.; Wu, Y.; Chen, Y. Carbon-Free Cathode Materials for Li−O2 Batteries. Batter. Supercaps 2019, 2, 428–439. [Google Scholar] [CrossRef]

- Li, J.; Ding, S.; Zhang, S.; Yan, W.; Ma, Z.-F.; Yuan, X.; Mai, L.; Zhang, J. Catalytic redox mediators for non-aqueous Li-O2 battery. Energy Storage Mater. 2021, 43, 97–119. [Google Scholar] [CrossRef]

- Lee, D.J.; Lee, H.; Kim, Y.J.; Park, J.K.; Kim, H.T. Sustainable Redox Mediation for Lithium-Oxygen Batteries by a Composite Protective Layer on the Lithium-Metal Anode. Adv. Mater. 2016, 28, 857–863. [Google Scholar] [CrossRef]

- Wu, H.; Shen, Z.; Yu, W.; Wu, X.; Guan, S.; Wu, Y.-H.; Wen, K.; Yuan, H.; Liang, Y.; Nishihara, H.; et al. A lithiated zeolite-based protective layer to boost the cycle performance of lithium−oxygen batteries via redox mediator sieving. Next Energy 2024, 4, 100135. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Piszcz, M.; Coya, E.; Rojo, T.; Rodriguez-Martinez, L.M.; Armand, M.; Zhou, Z. Single lithium-ion conducting solid polymer electrolytes: Advances and perspectives. Chem. Soc. Rev. 2017, 46, 797–815. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, J.B.; Lim, H.S.; Sun, Y.K. An Advanced Separator for Li–O2 Batteries: Maximizing the Effect of Redox Mediators. Adv. Energy Mater. 2017, 7, 1602417. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Zhang, S.; Kang, Z.; Xie, H.; Liu, J. Poly (3,4-ethylenedioxythiophene):poly (styrenesulfonate)- decorated separator in Li-O2 batteries: Suppressing the shuttle effect of dual redox mediators by coulombic interactions. J. Power Sources 2020, 466, 228336. [Google Scholar] [CrossRef]

- Chen, Z.-F.; Lin, X.; Xia, H.; Hong, Y.; Liu, X.; Cai, S.; Duan, J.-N.; Yang, J.; Zhou, Z.; Chang, J.-K.; et al. A functionalized membrane for lithium–oxygen batteries to suppress the shuttle effect of redox mediators. J. Mater. Chem. A 2019, 7, 14260–14270. [Google Scholar] [CrossRef]

- Qiao, Y.; He, Y.; Wu, S.; Jiang, K.; Li, X.; Guo, S.; He, P.; Zhou, H. MOF-Based Separator in an Li–O2 Battery: An Effective Strategy to Restrain the Shuttling of Dual Redox Mediators. ACS Energy Lett. 2018, 3, 463–468. [Google Scholar] [CrossRef]

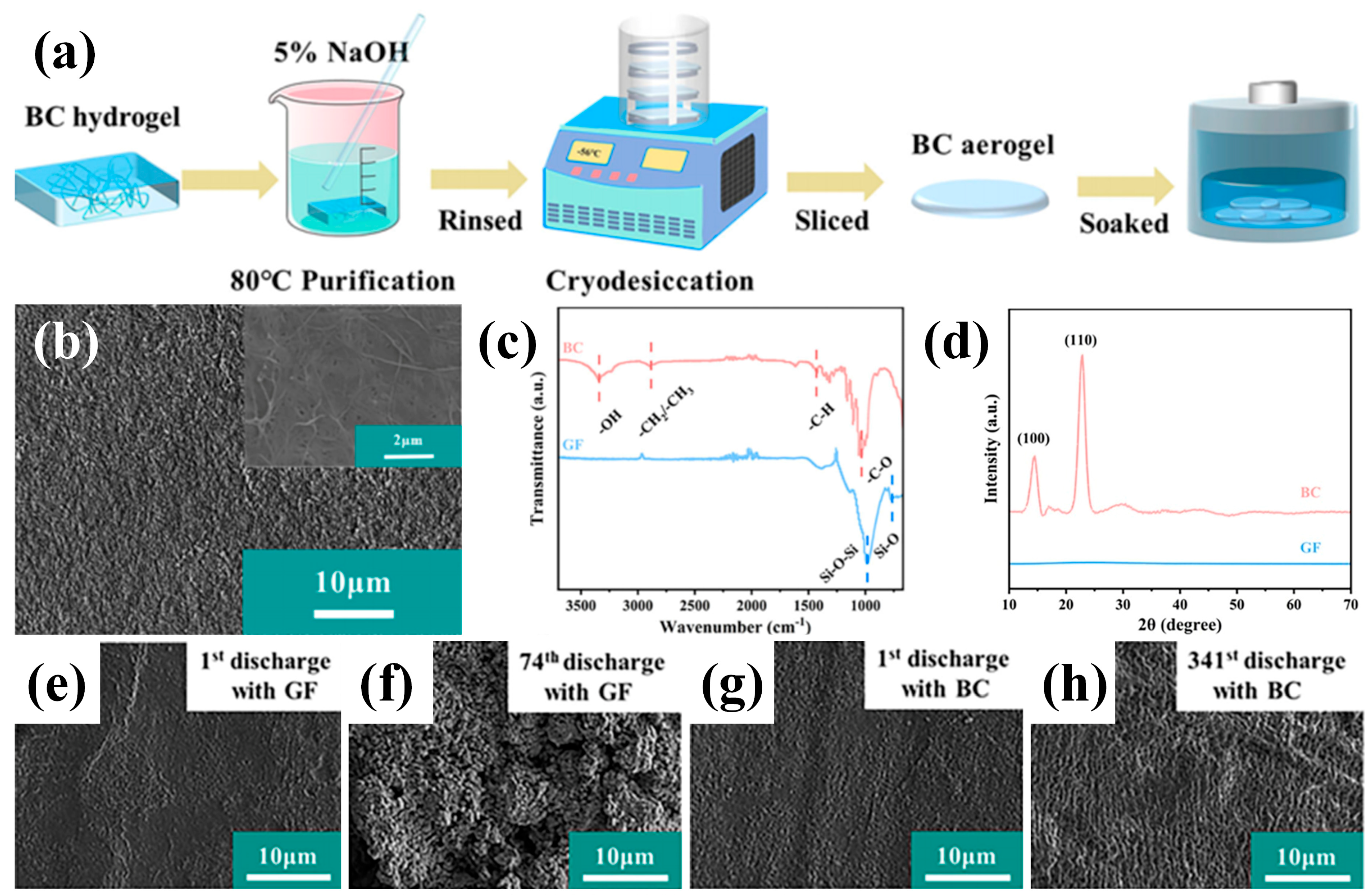

- Wu, A.; Wang, M.; Pang, Y.; Li, X.; Zhuge, X.; Luo, Z.; Ren, G.; Luo, K.; Ren, Y.; Liu, D.; et al. Single-Ion Conductive Bacterial Cellulose Membrane Towards High Performance Lithium-Oxygen Batteries. Battery Energy 2025, 4, e70027. [Google Scholar] [CrossRef]

- Chen, W.; Luo, Z.; Zhuge, X.; Ding, Z.; Ren, Y.; Loya, A.; Li, Y.; Luo, K. Protecting lithium anode with ionic liquid modified poly(vinylidene fluoride) single ion conducting separators for iodide-assisted lithium oxygen batteries. J. Energy Storage 2022, 50, 104580. [Google Scholar] [CrossRef]

- Luntz, A.C.; McCloskey, B.D. Nonaqueous Li-air batteries: A status report. Chem. Rev. 2014, 114, 11721–11750. [Google Scholar] [CrossRef]

- Lin, Y.; Wen, Z.; Yang, C.; Zhang, P.; Zhao, J. Strengthening dendrite suppression in lithium metal anode by in-situ construction of Li–Zn alloy layer. Electrochem. Commun. 2019, 108, 106565. [Google Scholar] [CrossRef]

- Kwak, W.-J.; Chae, S.; Feng, R.; Gao, P.; Read, J.; Engelhard, M.H.; Zhong, L.; Xu, W.; Zhang, J.-G. Optimized Electrolyte with High Electrochemical Stability and Oxygen Solubility for Lithium–Oxygen and Lithium–Air Batteries. ACS Energy Lett. 2020, 5, 2182–2190. [Google Scholar] [CrossRef]

- Lin, X.-D.; Gu, Y.; Shen, X.-R.; Wang, W.-W.; Hong, Y.-H.; Wu, Q.-H.; Zhou, Z.-Y.; Wu, D.-Y.; Chang, J.-K.; Zheng, M.-S.; et al. An oxygen-blocking oriented multifunctional solid–electrolyte interphase as a protective layer for a lithium metal anode in lithium–oxygen batteries. Energy Environ. Sci. 2021, 14, 1439–1448. [Google Scholar] [CrossRef]

- Huang, Y.; Geng, J.; Jiang, Z.; Ren, M.; Wen, B.; Chen, J.; Li, F. Solvation Structure with Enhanced Anionic Coordination for Stable Anodes in Lithium-Oxygen Batteries. Angew. Chem. Int. Ed. 2023, 62, e202306236. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, M.; Xu, Y.; Li, C.; Rong, Y.; Liao, Y.; Gao, M.; Zhang, X.; Chen, W.; Lu, J. In situ high-quality LiF/Li3N inorganic and phenyl-based organic solid electrolyte interphases for advanced lithium–oxygen batteries. Carbon Energy 2024, 6, e576. [Google Scholar] [CrossRef]

- Marangon, V.; Hernandez-Rentero, C.; Levchenko, S.; Bianchini, G.; Spagnolo, D.; Caballero, A.; Morales, J.; Hassoun, J. Lithium–Oxygen Battery Exploiting Highly Concentrated Glyme-Based Electrolytes. ACS Appl. Energy Mater. 2020, 3, 12263–12275. [Google Scholar] [CrossRef]

- Li, C.L.; Huang, G.; Yu, Y.; Xiong, Q.; Yan, J.M.; Zhang, X.B. A Low-Volatile and Durable Deep Eutectic Electrolyte for High-Performance Lithium-Oxygen Battery. J. Am. Chem. Soc. 2022, 144, 5827–5833. [Google Scholar] [CrossRef]

- Deng, J.; Wang, Y.; Qu, S.; Liu, Y.; Zou, W.; Zhou, F.; Zhou, A.; Li, J. Fast Li+ Transport of Li−Zn Alloy Protective Layer Enabling Excellent Electrochemical Performance of Li Metal Anode. Batter. Supercaps 2020, 4, 140–145. [Google Scholar] [CrossRef]

- Huang, K.; Lu, Z.; Dai, S.; Fei, H. Recent Progress of Halide Redox Mediators in Lithium–Oxygen Batteries: Functions, Challenges, and Perspectives. Chem. Bio Eng. 2024, 1, 737–756. [Google Scholar] [CrossRef]

- Li, W.; Sheng, C.; Wang, L.; Sun, X.; Mu, X.; He, P.; Zhou, H. Bifunctional electrolyte additive MgI2 for improving cycle life in high-efficiency redox-mediated Li-O2 batteries. Chem. Commun. 2023, 59, 10141–10144. [Google Scholar] [CrossRef]

- Qian, H.; Li, X.; Chen, Q.; Liu, W.; Zhao, Z.; Ma, Z.; Cao, Y.; Wang, J.; Li, W.; Xu, K.; et al. LiZn/Li2O Induced Chemical Confinement Enabling Dendrite-Free Li-Metal Anode. Adv. Funct. Mater. 2023, 34, 2310143. [Google Scholar] [CrossRef]

- Xia, L.; Yan, X.; Zhang, Y.; Wu, H.; Zhang, S.; Chang, X.; Sa, B.; Lin, L.; Luo, Q.; Wang, L.; et al. Lithium zinc/lithium iodide composite modified layer toward highly stable lithium metal anodes. Electrochim. Acta 2024, 475, 143626. [Google Scholar] [CrossRef]

- Tułodziecki, M.; Leverick, G.M.; Amanchukwu, C.V.; Katayama, Y.; Kwabi, D.G.; Bardé, F.; Hammond, P.T.; Shao-Horn, Y. The role of iodide in the formation of lithium hydroxide in lithium–oxygen batteries. Energy Environ. Sci. 2017, 10, 1828–1842. [Google Scholar] [CrossRef]

- Zhang, C.; Jaradat, A.; Singh, S.K.; Rojas, T.; Ahmadiparidari, A.; Rastegar, S.; Wang, S.; Majidi, L.; Redfern, P.; Subramanian, A.; et al. Novel Co-Catalytic Activities of Solid and Liquid Phase Catalysts in High-Rate Li-Air Batteries. Adv. Energy Mater. 2022, 12, 2201616. [Google Scholar] [CrossRef]

- Lee, G.-H.; Sung, M.-C.; Kim, D.-W. Synergistic coupling of a self-defense redox mediator and anti-superoxide disproportionator in lithium-oxygen batteries for high stability. Chem. Eng. J. 2023, 453, 139878. [Google Scholar] [CrossRef]

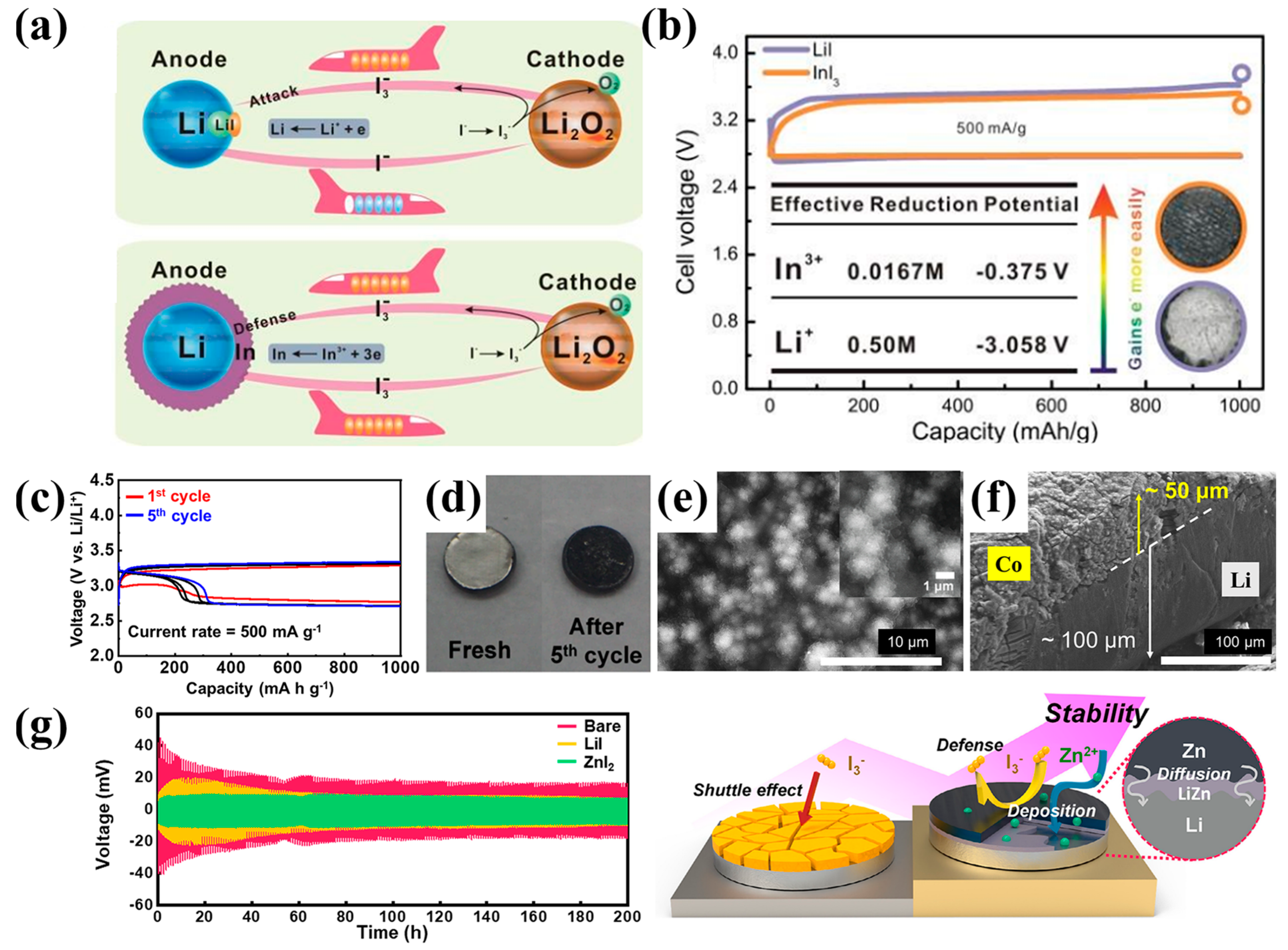

- Hwang, B.; Sung, M.C.; Jung, S.; Kim, M.S.; Kim, D.W. Boosting Li–O2 Battery Performance and Stability With ZnI2: Synergistic Effects on Anode Protection and Cathode Activation. SusMat 2025, 5, e70020. [Google Scholar] [CrossRef]

- Zhang, Z.; Dou, Y.; Zhao, Z.; Zhou, Z.; Peng, Z. Unlocking the Energy Capabilities of Aprotic Lithium-Oxygen Batteries by Anion-Specific Adsorption Induced Interfacial Remodeling. Adv. Funct. Mater. 2025, e15490. [Google Scholar] [CrossRef]

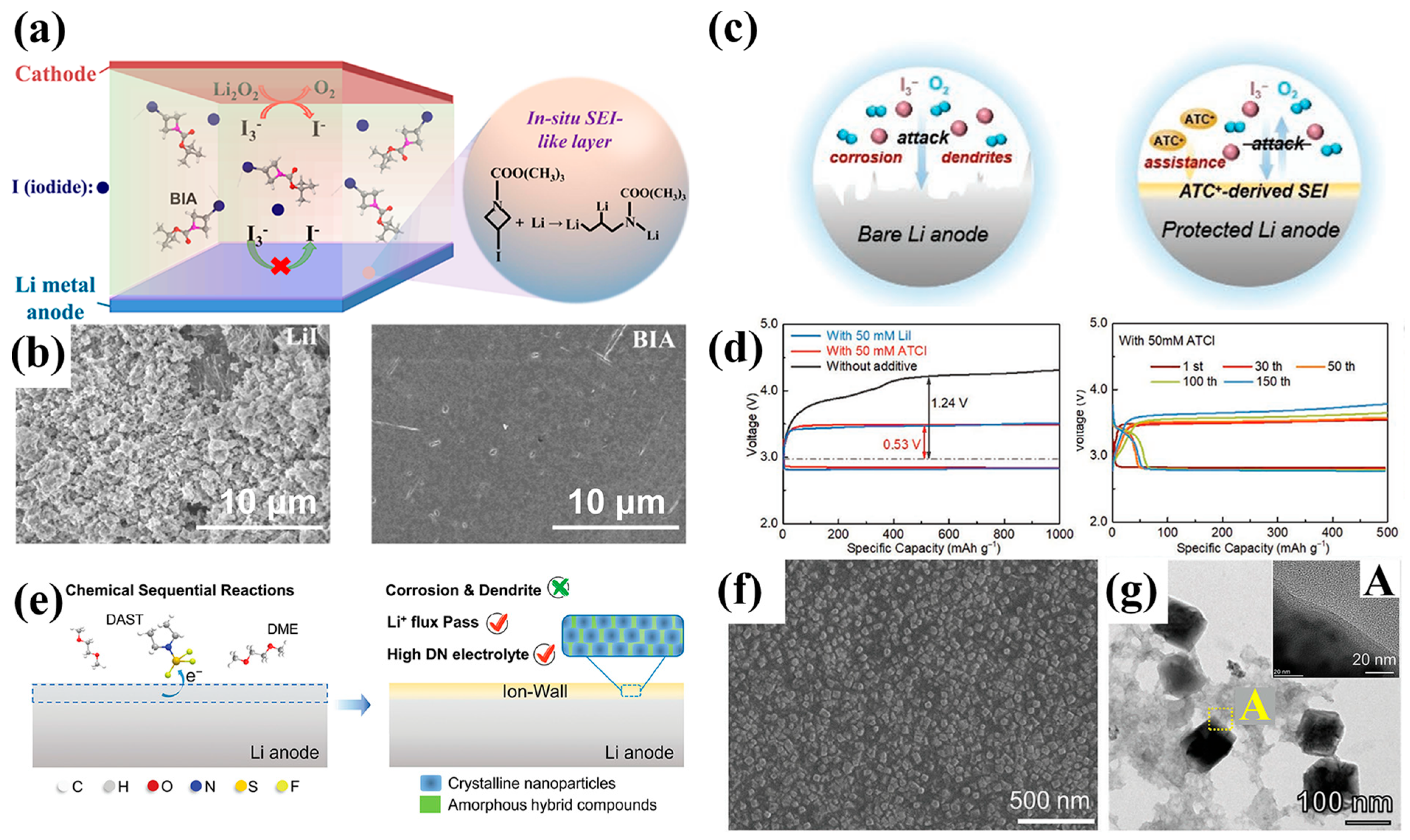

- Li, Y.N.; Jiang, F.L.; Sun, Z.; Yamamoto, O.; Imanishi, N.; Zhang, T. Bifunctional 1-Boc-3-Iodoazetidine Enhancing Lithium Anode Stability and Rechargeability of Lithium-Oxygen Batteries. ACS Appl. Mater. Interfaces 2021, 13, 16437–16444. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, Y.; Zhan, Y.; Li, K.; Dou, W.; Wang, C.; Lin, X.; Yuan, R.; Yan, J.; Zheng, M.; et al. An Organic Redox Mediator with a Defense-Donor for Lithium Anode in Lithium-Oxygen Batteries. Small Methods 2023, 7, e2201289. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Zheng, M.T.; Gao, M.L.; Liao, Y.L.; Zhang, X.P.; Fan, C.; Chen, W.R.; Lu, J. Simultaneously Generating Redox Mediator and Hybrid SEI for Lithium–oxygen Batteries by Lewis Acid Catalyzed Ring-opening Reaction of Organic Iodine. Adv. Funct. Mater. 2023, 34, 2312723. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, X.; Huang, Z.; Zhuang, X.; Gao, M. A Redox Mediator Containing Reversible Dynamic Boron-Oxygen Bonds to Construct an Adaptive SEI Layer for Advanced Li-O2 Batteries. ACS Appl. Mater. Interfaces 2025, 17, 19629–19637. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, W.; Li, Z.; Sun, H.; Zhang, T.; Li, J.; Xue, Z.; Zhang, T.; Yu, M.; Zhou, P. In-situ formed Li anode artificial solid electrolyte interface layer based on PEO and SnF2 for long-life lithium-oxygen batteries. J. Alloys Compd. 2025, 1017, 179109. [Google Scholar] [CrossRef]

- Balaish, M.; Jung, J.W.; Kim, I.D.; Ein-Eli, Y. A Critical Review on Functionalization of Air-Cathodes for Nonaqueous Li–O2 Batteries. Adv. Funct. Mater. 2019, 30, 1808303. [Google Scholar] [CrossRef]

- Bruce, P.G.; Freunberger, S.A.; Hardwick, L.J.; Tarascon, J.M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 2011, 11, 19–29. [Google Scholar] [CrossRef]

- Sung, M.C.; Lee, G.H.; Kim, D.W. Efficient Li2O2 oxidation kinetics of perovskite-type lanthanum chromium-based oxide by promoter interface formation for lithium-oxygen batteries. Energy Storage Mater. 2023, 60, 102829. [Google Scholar] [CrossRef]

- Ottakam Thotiyl, M.M.; Freunberger, S.A.; Peng, Z.; Chen, Y.; Liu, Z.; Bruce, P.G. A stable cathode for the aprotic Li-O2 battery. Nat. Mater. 2013, 12, 1050–1056. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhou, C.; Fang, W.; Hou, Y.; Wu, Y. Rational design of Ru/TiO2/CNTs as cathode: Promotion of cycling performance for aprotic lithium-oxygen battery. Energy Mater. 2023, 3, 300011. [Google Scholar] [CrossRef]

- Gao, J.; Zhu, Y.; Wang, L.; Wang, C.; Yin, L.; Wang, R.; Zhang, Z. Catalytic Performance of Amorphous and Crystalline RuO2 Loading on TiO2 Nanosheets in Lithium–Oxygen Batteries. ACS Appl. Nano Mater. 2023, 7, 27837–27845. [Google Scholar] [CrossRef]

- Wei, C.; Tan, L.; Zhang, Y.; Wang, Z.; Xi, B.; Xiong, S.; Feng, J. Interfacial engineering on metal anodes in rechargeable batteries. EnergyChem 2022, 4, 100089. [Google Scholar] [CrossRef]

- Jia, S.-X.; Liang, S.; Xiang, T.-Q.; Zhang, J.-R.; Yan, D.-D.; Zhou, J.-J.; Li, L. Liquid electrolyte confined in polymer crystals: A novel strategy for quasi-solid-state lithium-oxygen batteries. J. Energy Storage 2025, 106, 114806. [Google Scholar] [CrossRef]

| Category | Protection Strategy /Material | Coating /Fabrication Method | Protection Mechanism | Cycle (Current Density) | Reference |

|---|---|---|---|---|---|

| Artificial film | Biorenewable cellulose- derived membrane | UV-curing of methacrylated chitosan | Radical scavenging Li+ conduction improvement | 40 cycles (0.1 mA/cm2) | [16] |

| SiO2/GO hybrid layer | Drop-casting | Barrier effect, uniform Li+ flux guidance | 348 cycles (1000 mA/g) | [31] | |

| rGO@nonwoven fabric membrane | Dipping and in situ reduction | rGO network Li+ flux uniformity | 500 cycles (500 mA/g) | [48] | |

| Lithiated zeolite-based protective layer | Slurry casting on Li foil | Molecular sieving Li+ conduction | 267 cycles (250 mA/g) | [65] | |

| Single-ion bacterial cellulose membrane | In situ polymerization on BC membrane | Single Li+ conduction Anion blocking | 341 cycles (1000 mA/g) | [71] | |

| Polymer film | Electrochemically pretreated PEO gel coating | Spin coating & Precharging | Polymer-supported Inorganic-rich SEI | 130 cycles (0.2 mA/cm2) | [4] |

| PVDF–HFP dense film | Doctor-blade casting | Dense PVDF-HFP layer O2/H2O blocking | 170 cycles (0.05 mA/cm2) | [47] | |

| Ionic liquid-modified sulfonated PVDF (MSP) | Solution casting and sulfonation | Li+-selective transport O2/H2O blocking | 200 cycles (1000 mA/g) | [72] |

| Category | Protection Strategy /Material | Coating /Fabrication Method | Protection Mechanism | Cycle (Current Density) | Reference |

|---|---|---|---|---|---|

| Electrolyte-driven SEI | LiNO3 + LiFPFSI basalt electrolyte (TEGDME) | In situ SEI formation | LiF/Li3N/Li2S SEI O2-resistant layer | 100 cycles (500 mA/g) | [20] |

| Oxygen-regulated SEI (DMSO-based) | In situ SEI under O2 | O2 suppresses C–S cleavage dense SEI | 34 cycles (0.1 mA/cm2) | [21] | |

| LiNO3 + LiI dual-salt/ TEGDME–IL | In situ SEI formation | LiNxOy SEI Li protection | 500 cycles (100 mA/g) | [53] | |

| LHCE (LiTf–G4 + OTE) | In situ SEI formation | Li2CO3 SEI dendrite suppression | 50 cycles (0.2 mA/cm2) | [75] | |

| LiNO3-derived N-SEI | Electrochemical polishing | O2-blocking layer NO2 entrapment | 350 cycles (400 mA/g) | [76] | |

| LiTFSI–LiTFA bisalt electrolyte (G4) | In situ SEI formation | Anion-dominant solvation LiF/Li2O SEI | 140 cycles (250 mA/g) | [77] | |

| HCE (LiTFSI + LiNO3/ TEGDME) | In situ SEI formation | LiF/Li2CO3/Li3N SEI dendrite suppression | 50 cycles (100 mA/g) | [79] | |

| DEE (NMA + LiTFSI, 4:1) | In situ SEI formation | LiF/LixN SEI O2 stability | 280 cycles (500 mA/g) | [80] | |

| Metal- iodide | InI3 | Electrolyte additive | In3+ reduction to In layer Li surface stabilization | >50 cycles (500 mA/g) | [45] |

| CoI2 | Electrolyte additive | Co2+ reduction to Co layer resistance to I3−/O2− attack | 300 cycles (1000 mA/g) | [88] | |

| ZnI2 | Electrolyte additive | In situ LiZn/Zn layer formation uniform Li deposition | 953 cycles (500 mA/g) | [89] | |

| Reactive additive | DAST additive (LiTFSI/TEGDME) | Pre-chemical sequential reaction | LiF/Li3N/Li2S hybrid SEI electron blocking | 400 cycles (500 mA/g) | [19] |

| NBSF reactive additive (LiTFSI/TEGDME) | In situ reaction with LiOH | LiF/Li3N/phenyl SEI ROS and dendrite suppression | 286 cycles (1000 mA/g) | [78] | |

| BIA additive (LiTFSI/TEGDME) | In situ Li–BIA reaction | LiI/Li-organic SEI RM blocking | 260 cycles (100 mA/g) | [91] | |

| ATCI additive (LiTFSI/TEGDME) | In situ reaction catalyzed by ATCI | Li3N/Li2S SEI O2/I3− blocking | 190 cycles (500 mA/g) | [92] | |

| IOD + AlCl3 additive (LiTFSI/TEGDME) | In situ reaction catalyzed by AlCl3 | Hybrid SEI (Al2O3/LiCl/oligomer) | 150 cycles (1000 mA/g) | [93] | |

| BPLA additive (LiTFSI/TEGDME) | In situ self-assembly via B–O coordination | Dynamic B–O SEI self-healing | 180 cycles (1000 mA/g) | [94] | |

| SnF2 additive (PEO–LiTFSI/TEGDME) | In situ interfacial reaction | LiF/LiSn SEI Li+ transport facilitation | 116 cycles (0.25 mA/cm2) | [95] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sung, M.-C.; Kim, M.; Yu, J.; Choi, C. Anode Protection Strategies for Next-Generation Lithium–Oxygen Batteries: Toward Dendrite-Free Lithium Metal at Practical Current Densities. Metals 2025, 15, 1373. https://doi.org/10.3390/met15121373

Sung M-C, Kim M, Yu J, Choi C. Anode Protection Strategies for Next-Generation Lithium–Oxygen Batteries: Toward Dendrite-Free Lithium Metal at Practical Current Densities. Metals. 2025; 15(12):1373. https://doi.org/10.3390/met15121373

Chicago/Turabian StyleSung, Myeong-Chang, Minhe Kim, Jiyoon Yu, and Changhoon Choi. 2025. "Anode Protection Strategies for Next-Generation Lithium–Oxygen Batteries: Toward Dendrite-Free Lithium Metal at Practical Current Densities" Metals 15, no. 12: 1373. https://doi.org/10.3390/met15121373

APA StyleSung, M.-C., Kim, M., Yu, J., & Choi, C. (2025). Anode Protection Strategies for Next-Generation Lithium–Oxygen Batteries: Toward Dendrite-Free Lithium Metal at Practical Current Densities. Metals, 15(12), 1373. https://doi.org/10.3390/met15121373