Surface Integrity and Corrosion Resistance of Additively Manufactured AZ91 Mg Alloys Post-Processed by Laser Shock Peening

Abstract

1. Introduction

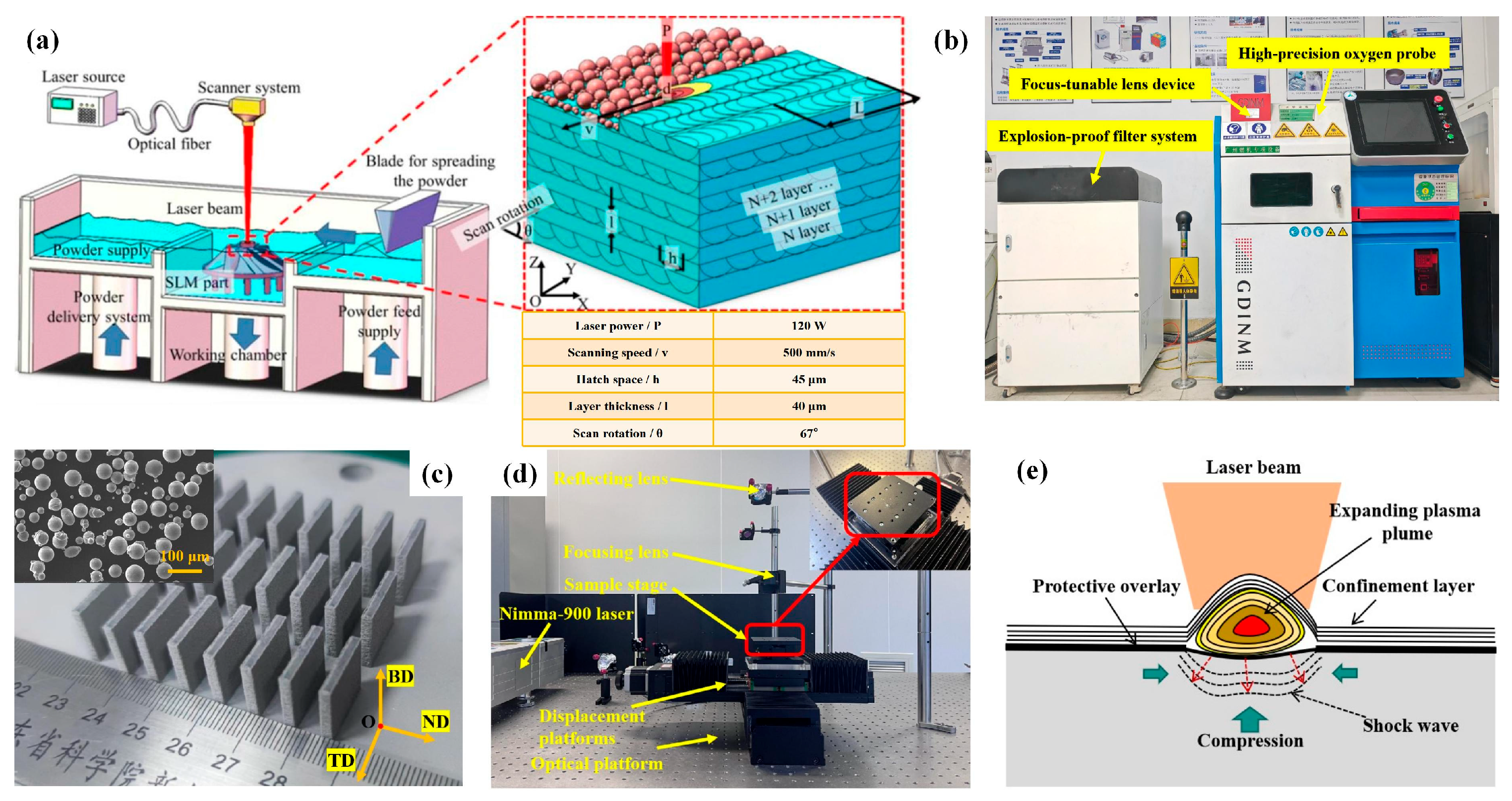

2. Materials and Methods

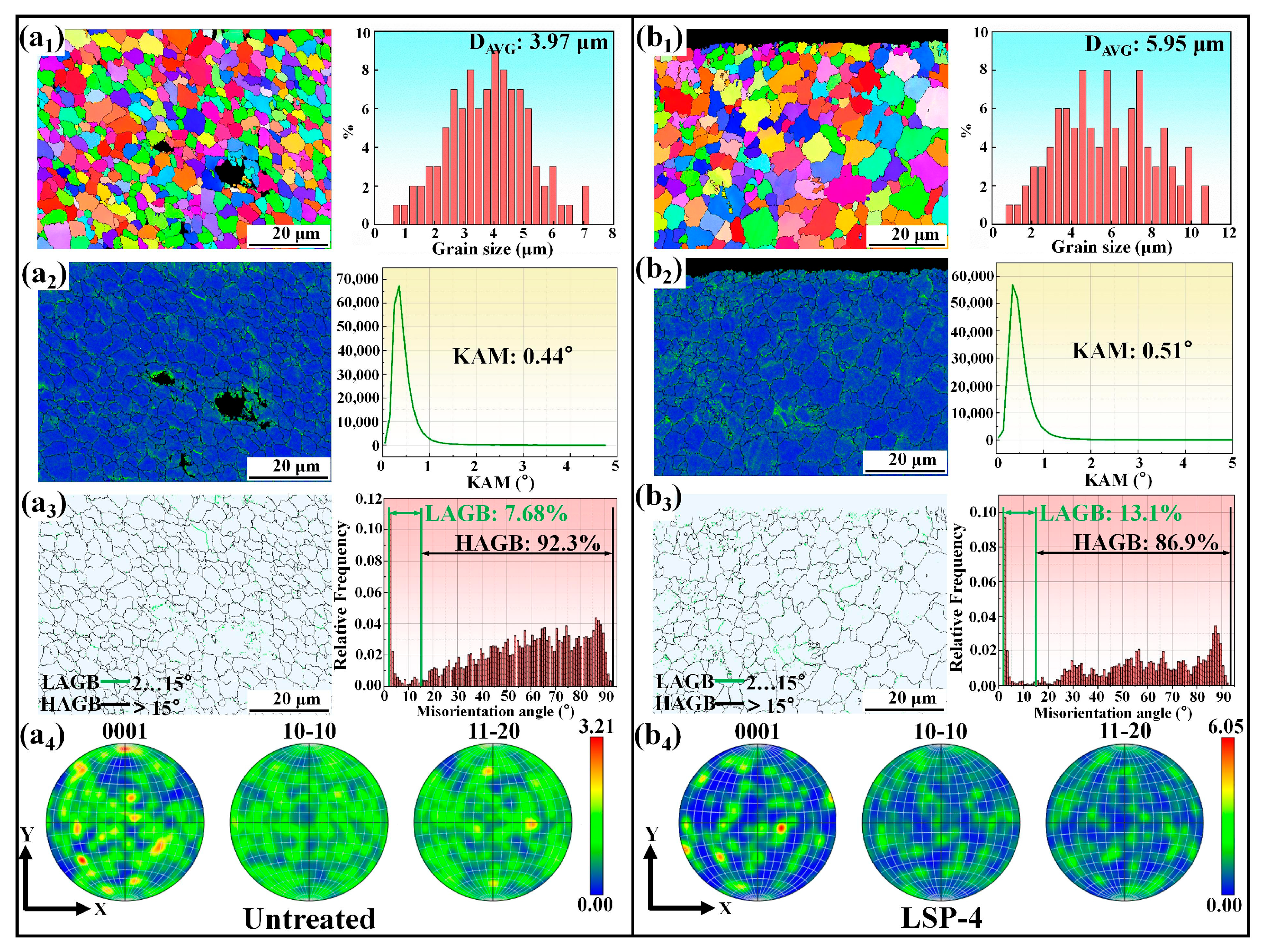

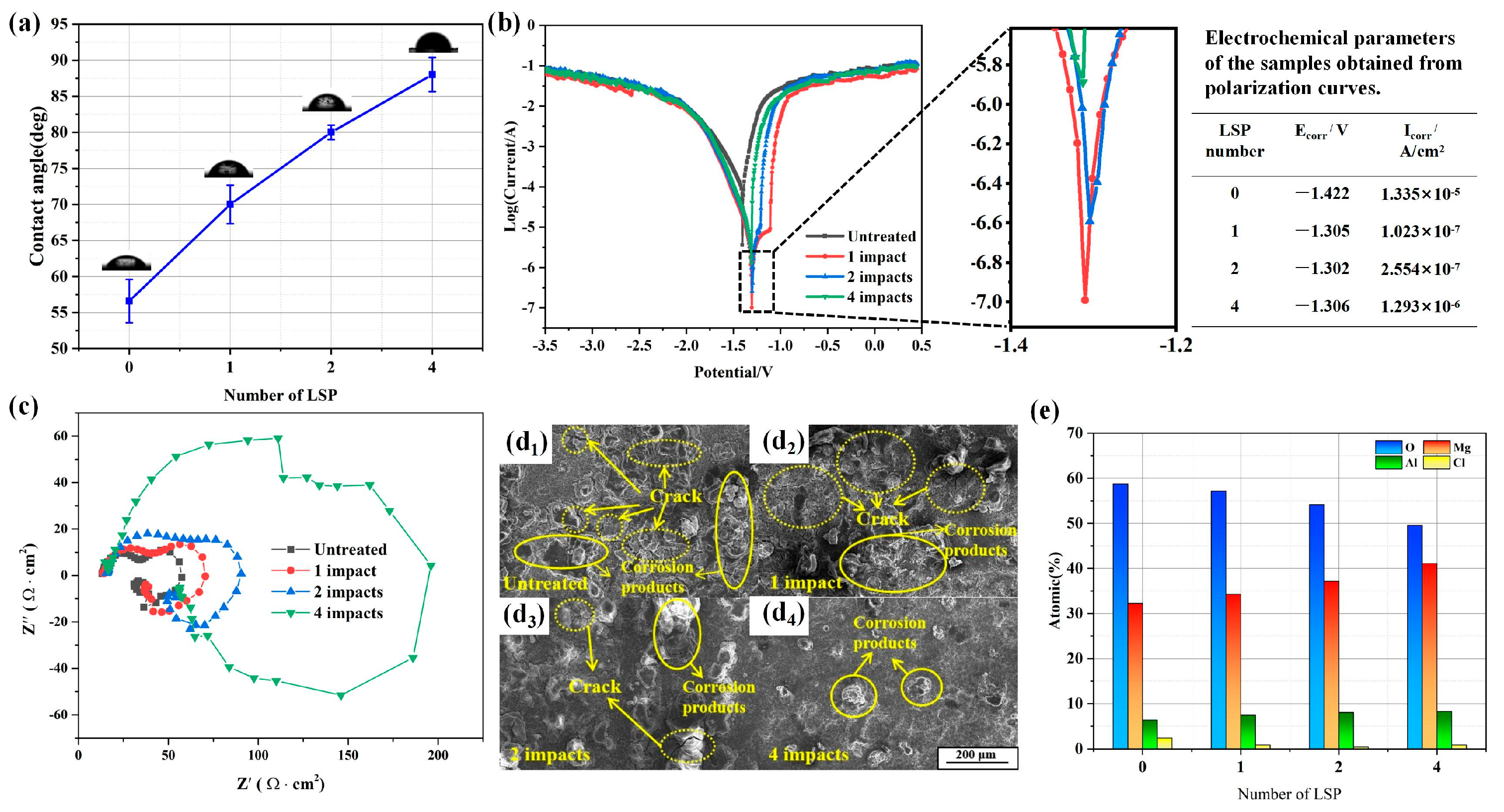

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| LSP | Laser shock peening |

| SLM | Selective laser melting |

| SEM | Scanning electron microscope |

| XRD | X-ray diffractometer |

| EDS | Energy dispersive spectrometer |

| EBSD | Electron back-scattered diffraction |

| HAGBs | High-angle grain boundaries |

| LAGBs | Low-angle grain boundaries |

| KAM | Kernel average misorientation |

References

- Chen, L.; Blawert, C.; Yang, J.; Hou, R.; Wang, X.; Zheludkevich, M.L.; Li, W. The stress corrosion cracking behaviour of biomedical Mg-1Zn alloy in synthetic or natural biological media. Corros. Sci. 2020, 175, 108876. [Google Scholar] [CrossRef]

- Gonzalez, J.; Hou, R.Q.; Nidadavolu, E.P.S.; Willumeit-Römer, R.; Feyerabend, F. Magnesium degradation under physiological conditions—Best practice. Bioact. Mater. 2018, 3, 174–185. [Google Scholar] [CrossRef]

- Chang, C.; Liao, H.; Yi, L.; Dai, Y.; Cox, S.C.; Yan, M.; Liu, M.; Yan, X. Achieving ultra-high strength and ductility in Mg–9Al–1Zn–0.5Mn alloy via selective laser melting. Adv. Powder Mater. 2023, 2, 100097. [Google Scholar] [CrossRef]

- Cho, D.H.; Dean, D.; Luo, A.A. Mechanical and corrosion properties of full liquid phase sintered WE43 magnesium alloy specimens fabricated via binder jetting additive manufacturing. J. Magnes. Alloys 2024, 12, 2711–2724. [Google Scholar] [CrossRef]

- Fu, Q.; Liang, W.; Huang, J.; Jin, W.; Guo, B.; Li, P.; Xu, S.; Chu, P.K.; Yu, Z. Research perspective and prospective of additive manufacturing of biodegradable magnesium-based materials. J. Magnes. Alloys 2023, 11, 1485–1504. [Google Scholar] [CrossRef]

- Li, X.; Fang, X.; Wang, S.; Wang, S.; Zha, M.; Huang, K. Selective laser melted AZ91D magnesium alloy with superior balance of strength and ductility. J. Magnes. Alloys 2023, 11, 4644–4658. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; Tomus, D.; Davies, C.H.J. Surface roughness of Selective Laser Melted Ti-6Al-4V alloy components. Addit. Manuf. 2018, 21, 91–103. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, W.; Zhang, H.; Han, P.; Li, S.; Zhao, J.; Cui, Z.; Zhu, Y.; Zhang, H. Synergistic enhancement of strength and plasticity for laser direct energy deposited Ti60 joint by locally applied laser shock peening. Mater. Sci. Eng. A 2025, 932, 148255. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, S.; Zhou, C.; Zhang, B.; Zhang, Y. Effects of laser shock peening on the ultra-high cycle fatigue performance of additively manufactured Ti6Al4V alloy. Opt. Laser Technol. 2021, 144, 107391. [Google Scholar] [CrossRef]

- Bai, C.; Lan, L.; Jiang, L.; He, B.; Li, Y.; Zhang, Y. Improvement of low-cycle fatigue properties in electron beam powder bed fusion processed Ti-6Al-4V alloy by laser shock peening. Eng. Fract. Mech. 2025, 319, 110992. [Google Scholar] [CrossRef]

- Dou, S.; Ji, P.; Zhang, J.; Zheng, L.; Zhao, F.; Lian, Y.; Xu, W.; Chen, X.; Wu, L.; Luo, J.; et al. Effect of laser shock peening on near-surface residual stress and microstructure of laser additive manufacturing AlSi10Mg alloy. Opt. Laser Technol. 2025, 189, 113114. [Google Scholar] [CrossRef]

- Sandmann, P.; Keller, S.; Kashaev, N.; Ghouse, S.; Hooper, P.A.; Klusemann, B.; Davies, C.M. Influence of laser shock peening on the residual stresses in additively manufactured 316L by Laser Powder Bed Fusion: A combined experimental–numerical study. Addit. Manuf. 2022, 60, 103204. [Google Scholar] [CrossRef]

- Tong, Z.; Liu, H.; Jiao, J.; Zhou, W.; Yang, Y.; Ren, X. Microstructure, microhardness and residual stress of laser additive manufactured CoCrFeMnNi high-entropy alloy subjected to laser shock peening. J. Mater. Process. Technol. 2020, 285, 116806. [Google Scholar] [CrossRef]

- Li, X.; Fang, X.; Zhang, M.; Zhang, H.; Duan, Y.; Huang, K. Gradient microstructure and prominent performance of wire-arc directed energy deposited magnesium alloy via laser shock peening. Int. J. Mach. Tools Manuf. 2023, 188, 104029. [Google Scholar] [CrossRef]

- Jia, M.; Wang, Y.; Yue, J.; Cao, C.; Li, K.; Yu, Y.; Li, Y.; Lu, Z. Recent progress in laser shock peening: Mechanism, laser systems and development prospects. Surf. Interfaces 2024, 44, 103757. [Google Scholar] [CrossRef]

- Luo, K.; Sun, M.; Lu, J.; Zhang, Q.; Jiang, X.; Wang, C.; Lu, J. The effect of laser shock peening with and without coating on microstructure and electrochemical corrosion behavior of AZ31b magnesium alloy. Surf. Coat. Technol. 2025, 496, 131709. [Google Scholar] [CrossRef]

- Zhang, W.-n.; Wang, L.-z.; Feng, Z.-x.; Chen, Y.-m. Research progress on selective laser melting (SLM) of magnesium alloys: A review. Optik 2020, 207, 163842. [Google Scholar] [CrossRef]

- Pawlak, A.; Rosienkiewicz, M.; Chlebus, E. Design of experiments approach in AZ31 powder selective laser melting process optimization. Arch. Civ. Mech. Eng. 2017, 17, 9–18. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, X.; Yu, W.; Zheng, H.; Wang, Z. Effect of Laser Shock Peening on Surface Integrity of Additively Manufactured MgAlloy. Surf. Technol. 2025, 54, 173–183. [Google Scholar] [CrossRef]

- Tong, Z.; Liu, H.; Jiao, J.; Zhou, W.; Yang, Y.; Ren, X. Improving the strength and ductility of laser directed energy deposited CrMnFeCoNi high-entropy alloy by laser shock peening. Addit. Manuf. 2020, 35, 101417. [Google Scholar] [CrossRef]

- Xiao, J.; Guo, W.; Zhang, H.; Dai, W.; Zhu, Y.; Cong, B.; Qi, Z.; Zhu, H.; Ren, X.; Li, M. Microstructure and mechanical properties of wire and arc additive manufactured 2319 aluminum alloy treated by laser shock peening. Mater. Charact. 2024, 217, 114354. [Google Scholar] [CrossRef]

- Kalentics, N.; de Seijas, M.O.V.; Griffiths, S.; Leinenbach, C.; Logé, R.E. 3D laser shock peening—A new method for improving fatigue properties of selective laser melted parts. Addit. Manuf. 2020, 33, 101112. [Google Scholar] [CrossRef]

- Ye, Y.; Feng, Y.; Lian, Z.; Hua, Y. Mold-free fs laser shock micro forming and its plastic deformation mechanism. Opt. Lasers Eng. 2015, 67, 74–82. [Google Scholar] [CrossRef]

- Kong, M.; Zang, T.; Wang, Z.; Zhu, L.; Zheng, H.; Gao, S.; Ngwangwa, H.M. A study on the tribological behavior of AZ31 magnesium alloy sheets processed by temperature-assisted ultrasonic shot peening. J. Mater. Res. Technol. 2023, 27, 1223–1241. [Google Scholar] [CrossRef]

- Yang, B.; Tan, C.; Zhao, Y.; Wu, L.; Chen, B.; Song, X.; Zhao, H.; Feng, J. Influence of ultrasonic peening on microstructure and surface performance of laser-arc hybrid welded 5A06 aluminum alloy joint. J. Mater. Res. Technol. 2020, 9, 9576–9587. [Google Scholar] [CrossRef]

- Zang, T.; Wang, Z.; Chen, L.; Kong, M.; Gao, S.; Ngwangwa, H.M.; Zhu, L.; Yu, W.; Zheng, H. Influence of pulse energy on surface integrity of AZ31 magnesium alloy processed by femtosecond laser shock peening. J. Mater. Res. Technol. 2023, 25, 4425–4440. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Z.; Jia, X.; Yang, W.; Nassreddin, N.; Dong, Y.; Ye, C.; Fortunato, A.; Zhao, X. The effects of the confining medium and protective layer during femtosecond laser shock peening. Manuf. Lett. 2021, 27, 26–30. [Google Scholar] [CrossRef]

- He, Z.; Shen, Y.; Tao, J.; Chen, H.; Zeng, X.; Huang, X.; El-Aty, A.A. Laser shock peening regulating aluminum alloy surface residual stresses for enhancing the mechanical properties: Roles of shock number and energy. Surf. Coat. Technol. 2021, 421, 127481. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Cui, C.Y.; Sun, G.F.; Zhou, J.Z.; Zhang, L.; You, J.; Chen, K.M.; Zhong, J.W. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts. Acta Mater. 2010, 58, 3984–3994. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, X.; Hu, W.; Zhou, L.; Liu, S.; Zheng, D. Laser shock peening for improving fatigue property of additively manufacturedmetals. Aeronaut. Manuf. Technol. 2023, 66, 38–49. [Google Scholar] [CrossRef]

- Leo, J.R.O.; Zabeen, S.; Fitzpatrick, M.E.; Zou, J.; Attallah, M.M. A study on the effects of laser shock peening on the microstructure and substructure of Ti–6Al–4V manufactured by Selective Laser Melting. J. Mater. Process. Technol. 2023, 316, 117959. [Google Scholar] [CrossRef]

- Wang, W.; Kattoura, M.; Bovid, S.; Zhang, Z.; Lahrman, D.; Cai, W. Effects of nanosecond laser shock peening on residual stress, corrosion and tribocorrosion behavior of WE43 magnesium alloys. Wear 2023, 524–525, 204866. [Google Scholar] [CrossRef]

- Warzanskyj, W.; Angulo, I.; Cordovilla, F.; Díaz, M.; Porro, J.A.; García-Beltrán, A.; Cabeza, S.; Ocaña, J.L. Analysis of the thermal stability of residual stresses induced in Ti-6Al-4 V by high density LSP treatments. J. Alloys Compd. 2023, 931, 167530. [Google Scholar] [CrossRef]

- Liu, P.; Sun, S.; Hu, J. Effect of laser shock peening on the microstructure and corrosion resistance in the surface of weld nugget zone and heat-affected zone of FSW joints of 7050 Al alloy. Opt. Laser Technol. 2019, 112, 1–7. [Google Scholar] [CrossRef]

- Yang, L.; Ding, X.; Zhou, Y. Femtosecond laser induced periodic nanostructures towards enhanced anti-corrosive property of titanium. Surf. Coat. Technol. 2023, 463, 129533. [Google Scholar] [CrossRef]

- Luo, Y.; Huang, J.; Yu, X.; Xie, Y.; Zhang, J.; Yu, S.; Fan, D.; Liu, J. Surface microstructure and corrosion characterization of AZ31 magnesium alloys fabricated by laser surface-modification. J. Alloys Compd. 2024, 994, 174708. [Google Scholar] [CrossRef]

- Zhou, W.; Xue, J.; Zhang, Z. Improving Electrochemical Corrosion Property of Magnesium Alloy Prepared by the Combination of Ultrasonic Shot Peening and Laser Etching. J. Mater. Eng. Perform. 2025, 34, 23311–23320. [Google Scholar] [CrossRef]

- Hong, B.; Bao, D.; Yuan, C.; Jiang, L.; Li, Q.; Zhang, X.; Li, X.; Deng, Z. Microstructure, wear and corrosion behavior of AZ91D magnesium alloys fabricated by laser surface-modification. Surf. Coat. Technol. 2025, 498, 131863. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Wang, W.; Zhao, X.; Yu, W.; Zheng, H.; Yan, X.; Chang, C.; Ngwangwa, H.M.; Cui, X.; Wang, Z. Surface Integrity and Corrosion Resistance of Additively Manufactured AZ91 Mg Alloys Post-Processed by Laser Shock Peening. Metals 2025, 15, 1374. https://doi.org/10.3390/met15121374

Gao S, Wang W, Zhao X, Yu W, Zheng H, Yan X, Chang C, Ngwangwa HM, Cui X, Wang Z. Surface Integrity and Corrosion Resistance of Additively Manufactured AZ91 Mg Alloys Post-Processed by Laser Shock Peening. Metals. 2025; 15(12):1374. https://doi.org/10.3390/met15121374

Chicago/Turabian StyleGao, Shan, Wenquan Wang, Xintian Zhao, Wenhui Yu, Hongyu Zheng, Xingchen Yan, Cheng Chang, Harry M. Ngwangwa, Xiaoli Cui, and Zongshen Wang. 2025. "Surface Integrity and Corrosion Resistance of Additively Manufactured AZ91 Mg Alloys Post-Processed by Laser Shock Peening" Metals 15, no. 12: 1374. https://doi.org/10.3390/met15121374

APA StyleGao, S., Wang, W., Zhao, X., Yu, W., Zheng, H., Yan, X., Chang, C., Ngwangwa, H. M., Cui, X., & Wang, Z. (2025). Surface Integrity and Corrosion Resistance of Additively Manufactured AZ91 Mg Alloys Post-Processed by Laser Shock Peening. Metals, 15(12), 1374. https://doi.org/10.3390/met15121374