Laser Beam Welding of IN625 Alloy with Equiaxed Grains: Influence of Process Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. IN625

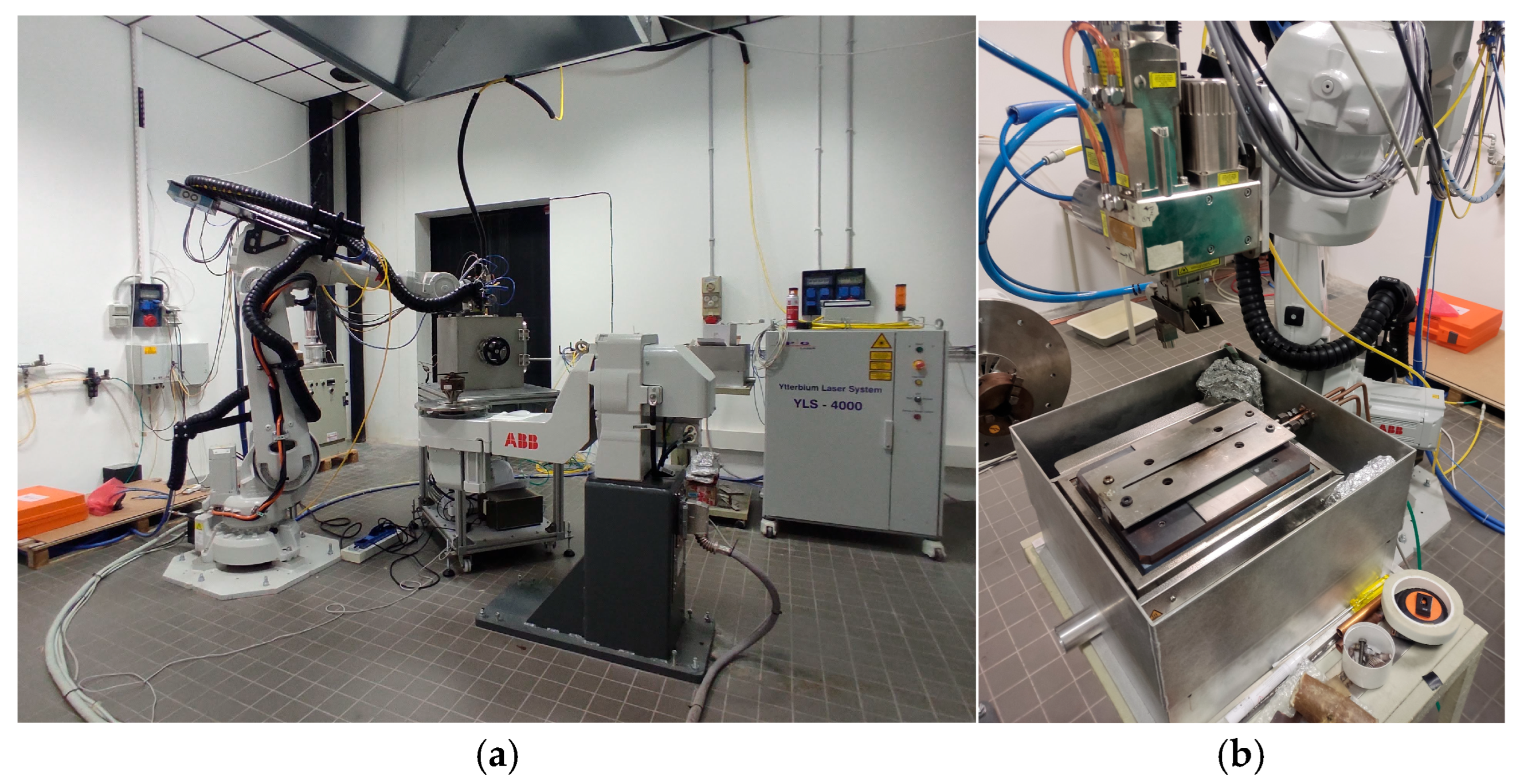

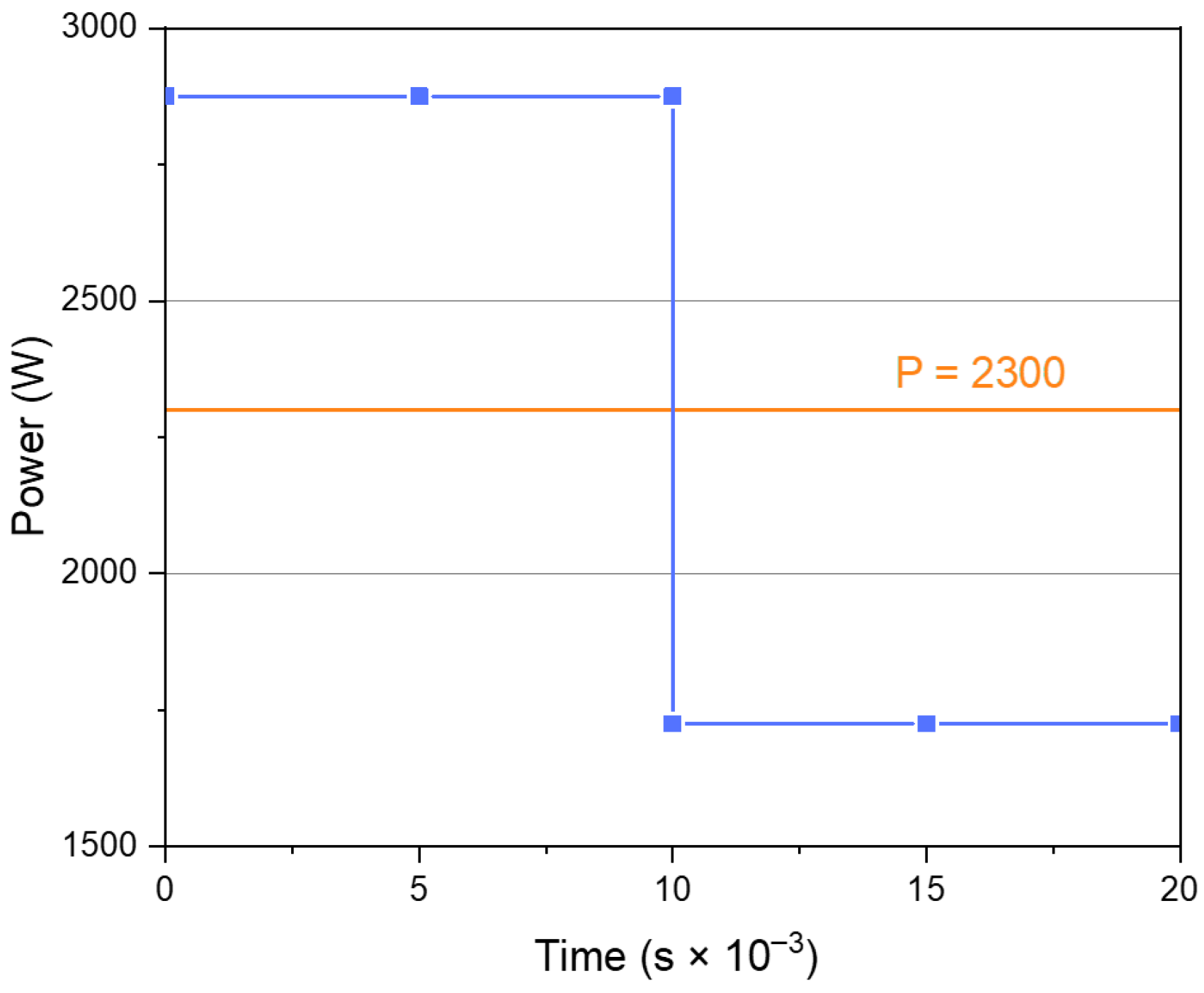

2.2. Welding Equipment and Parameters

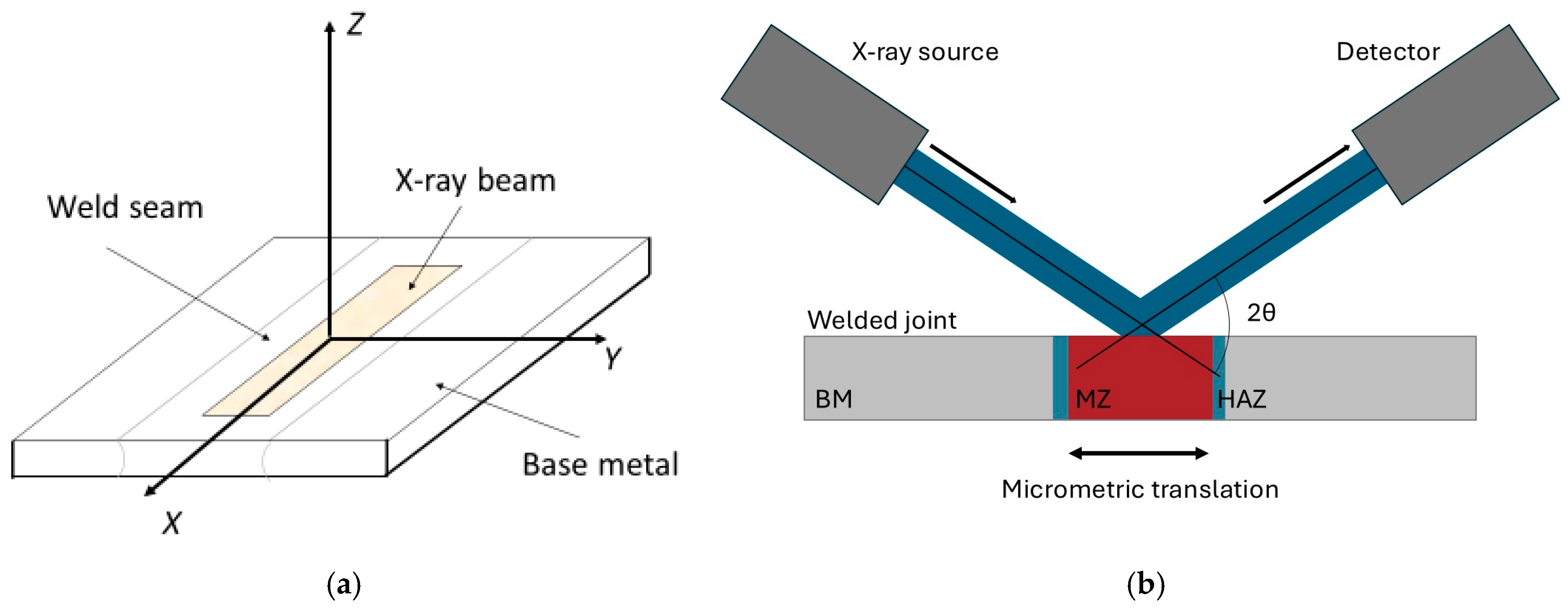

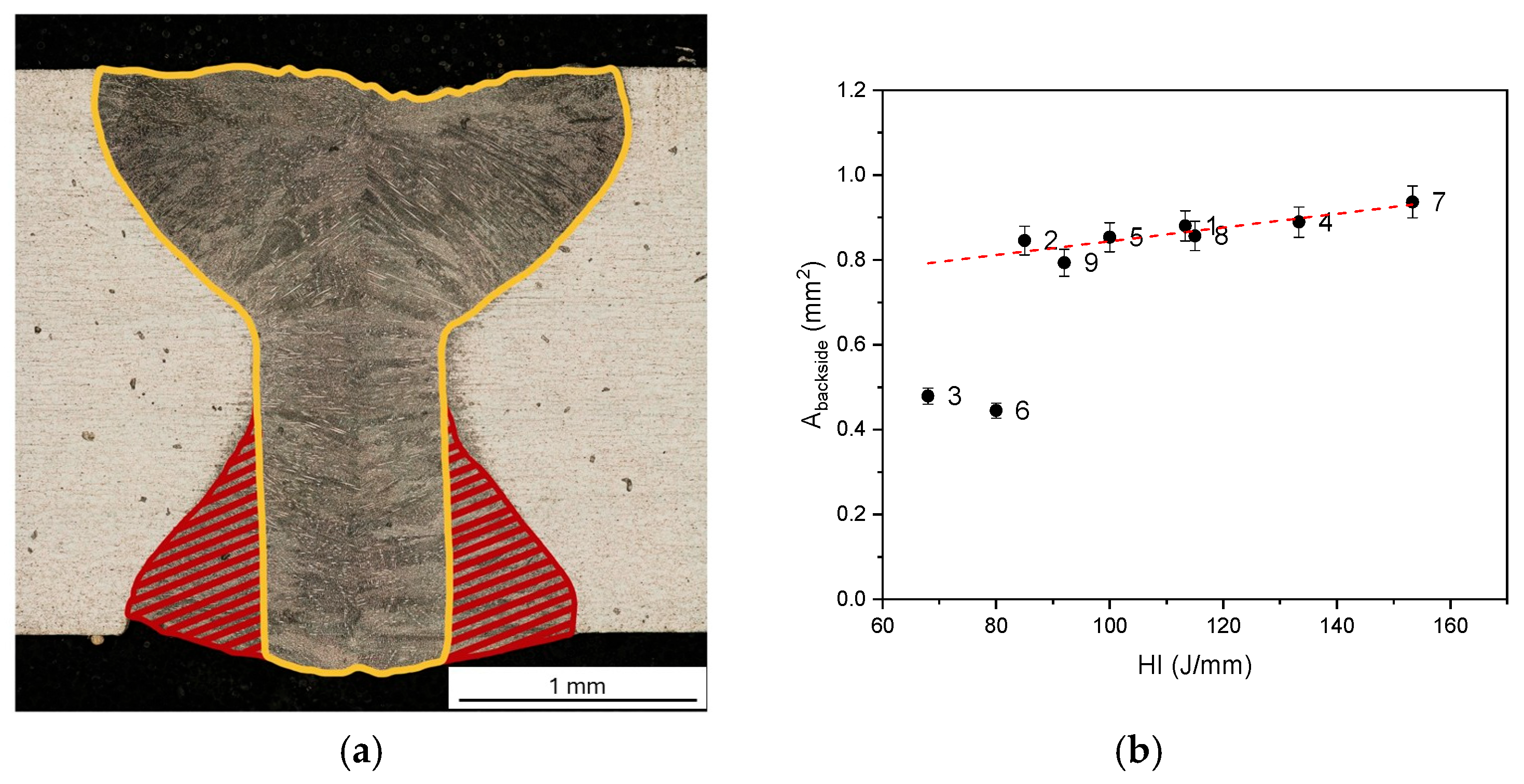

2.3. Characterization of the Seams

3. Results

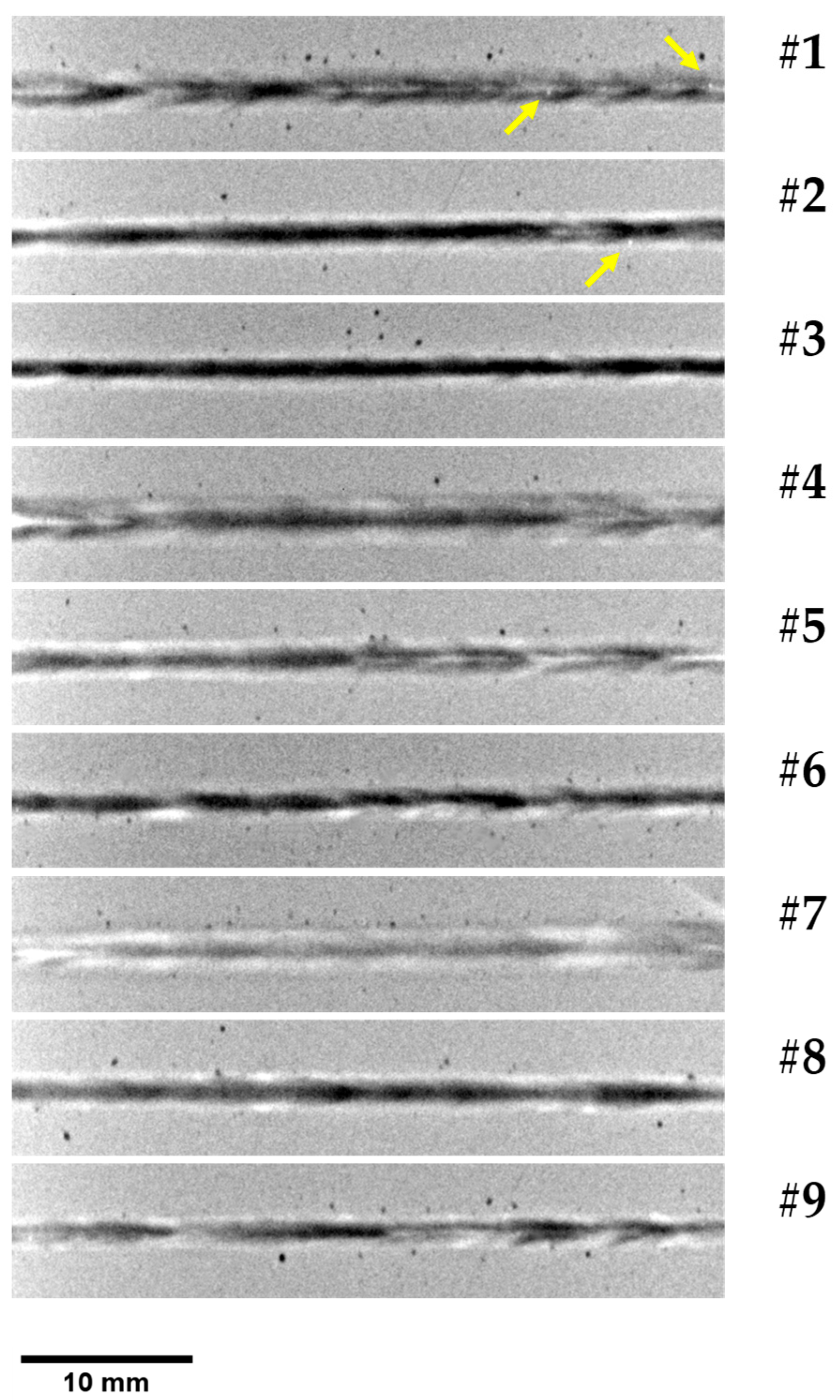

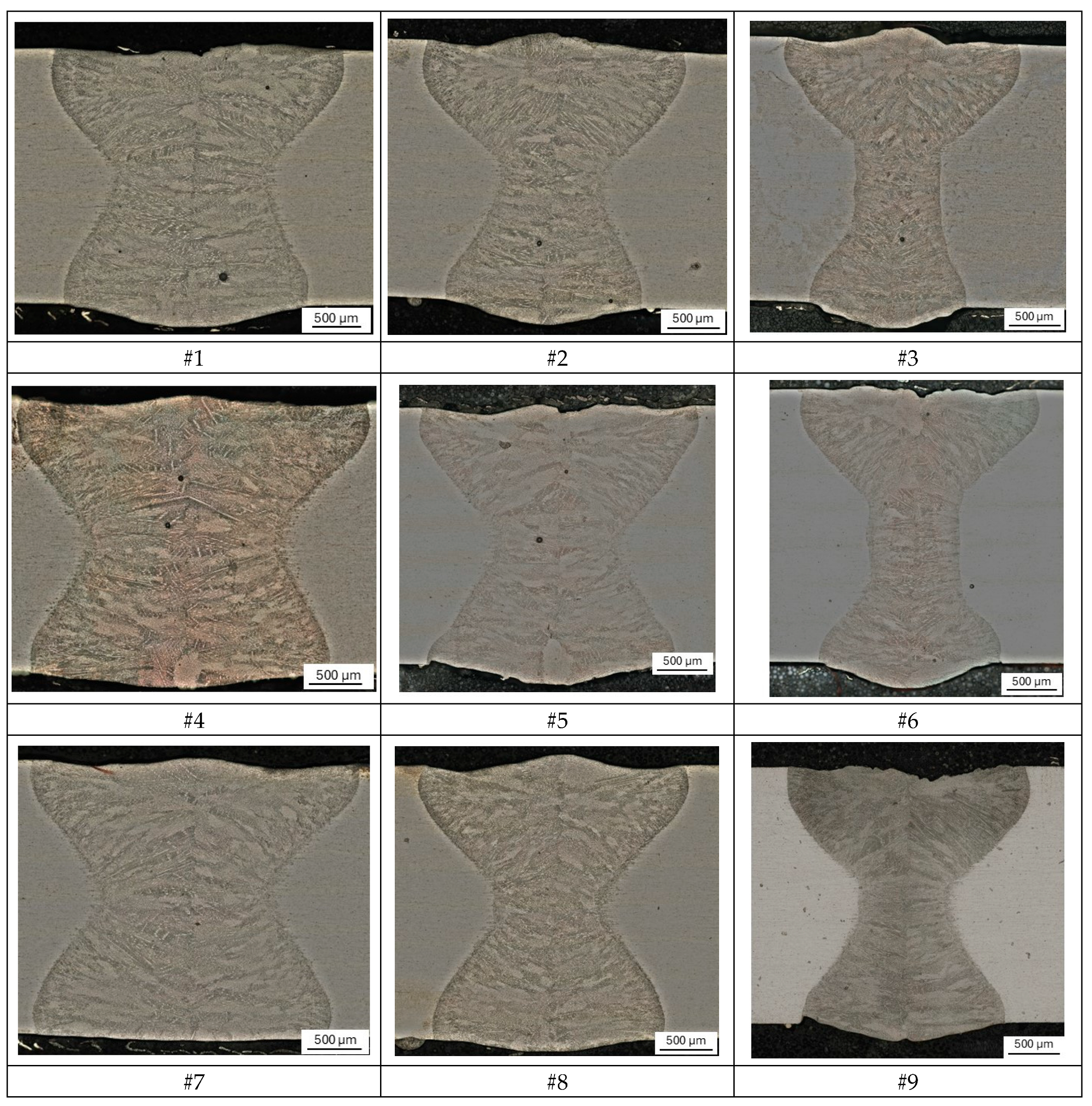

3.1. Quality of Welds

3.2. Microstructural and Mechanical Characterization of Welds

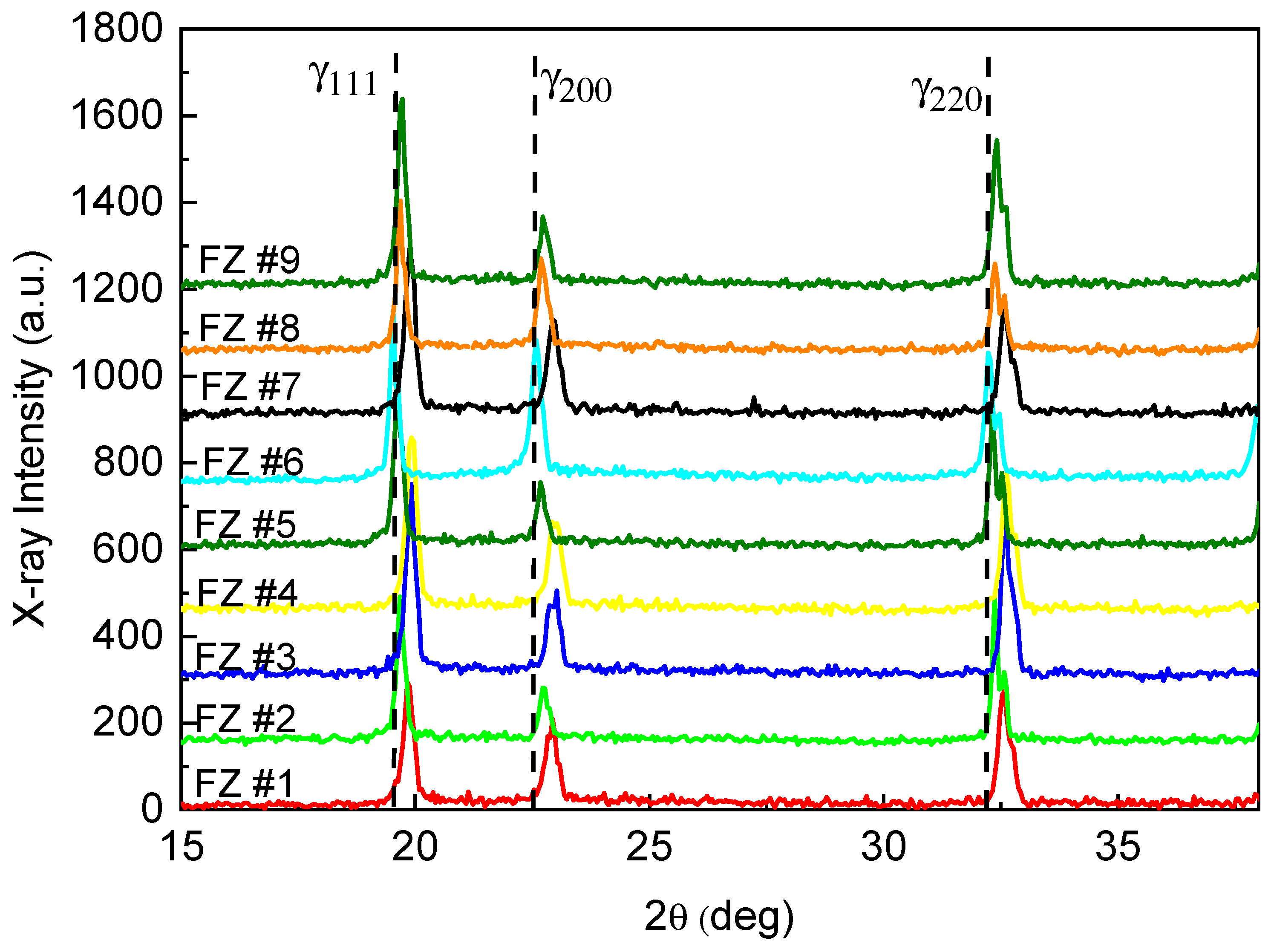

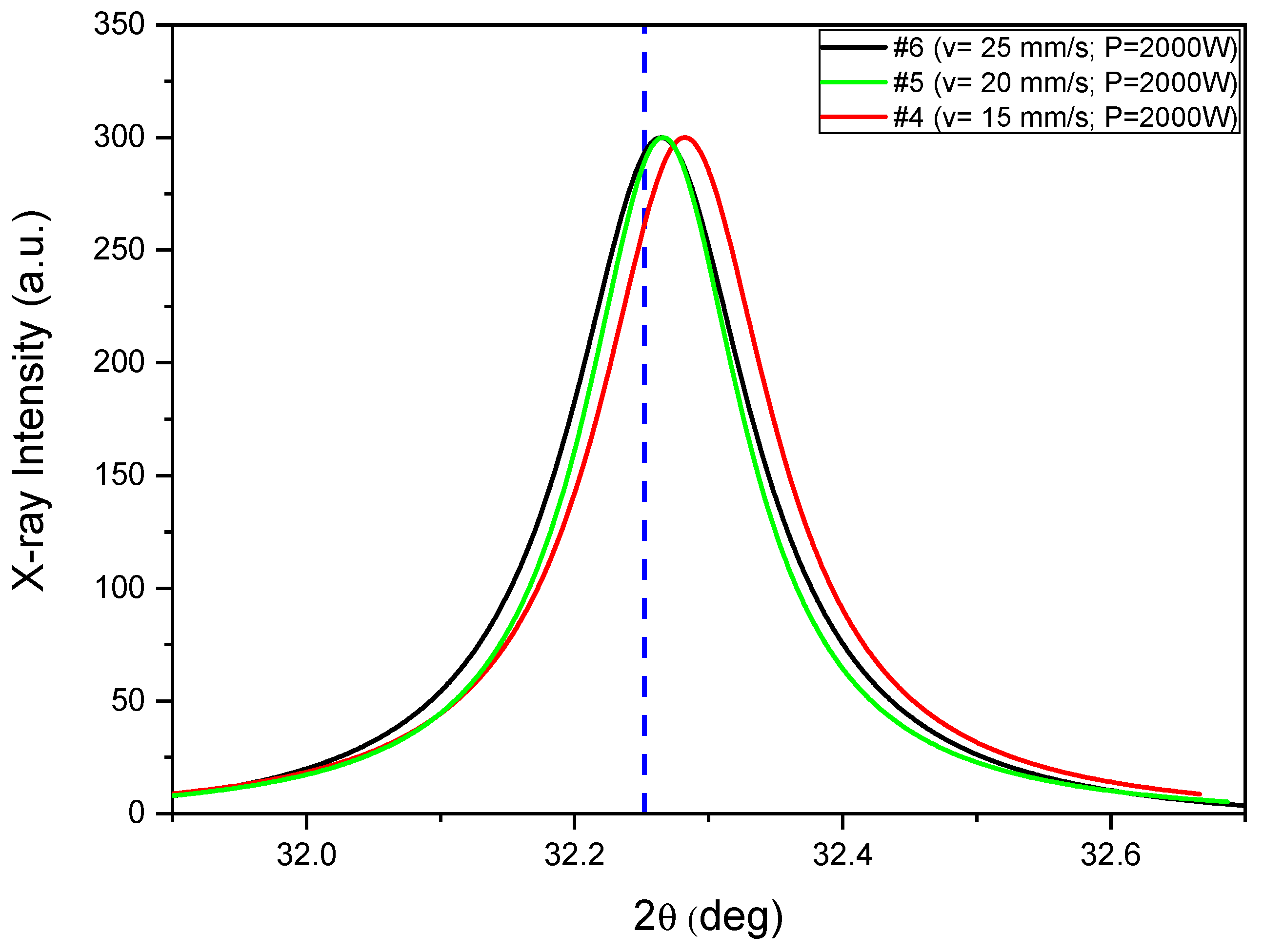

3.2.1. XRD Analysis

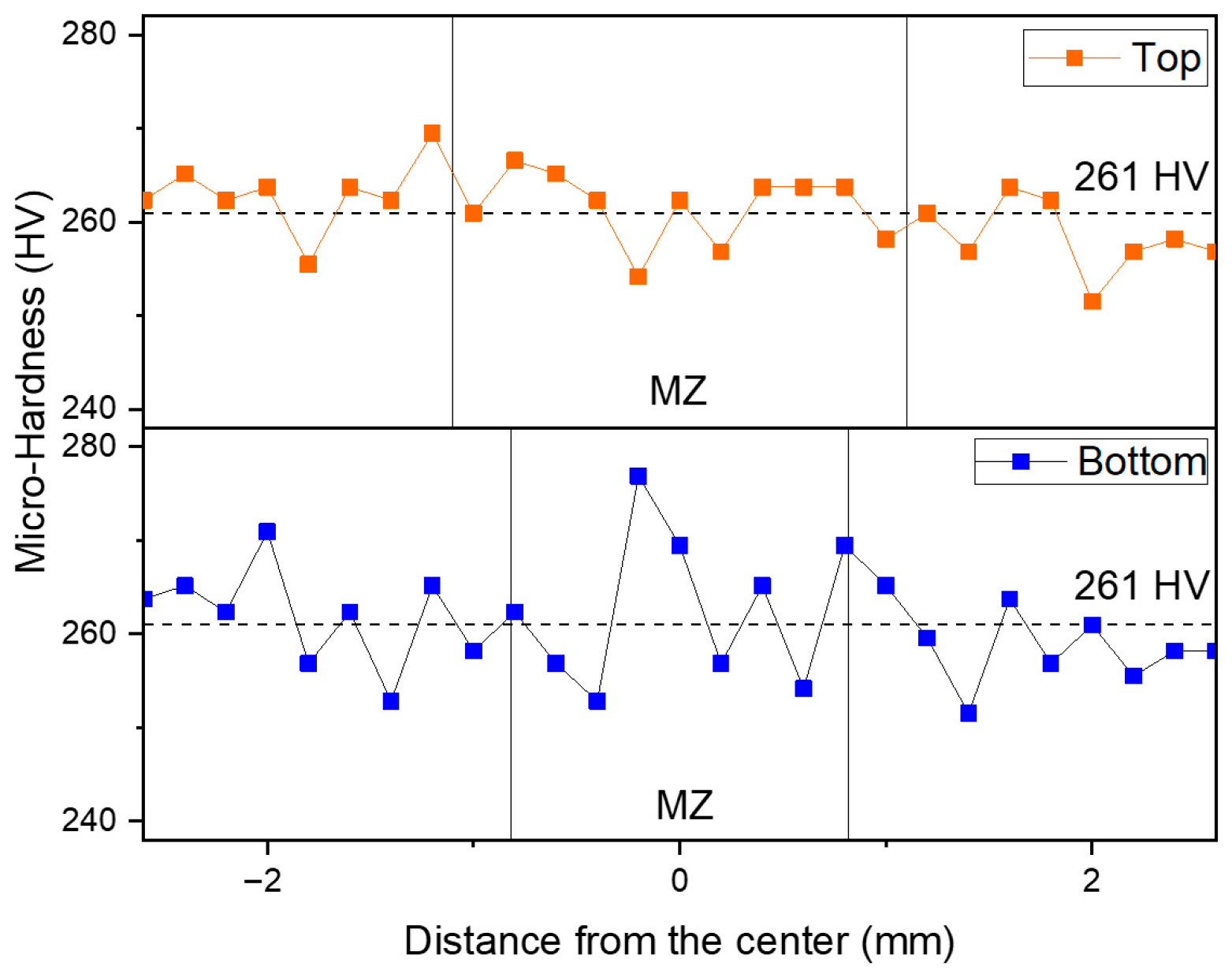

3.2.2. Micro-Hardness Testing

4. Discussion

5. Conclusions

- -

- Complete full penetration of 2.5 mm thick IN625 superalloy plates was obtained. All the welded seams were crack-free, indicating that the process parameters adopted in the research were appropriate;

- -

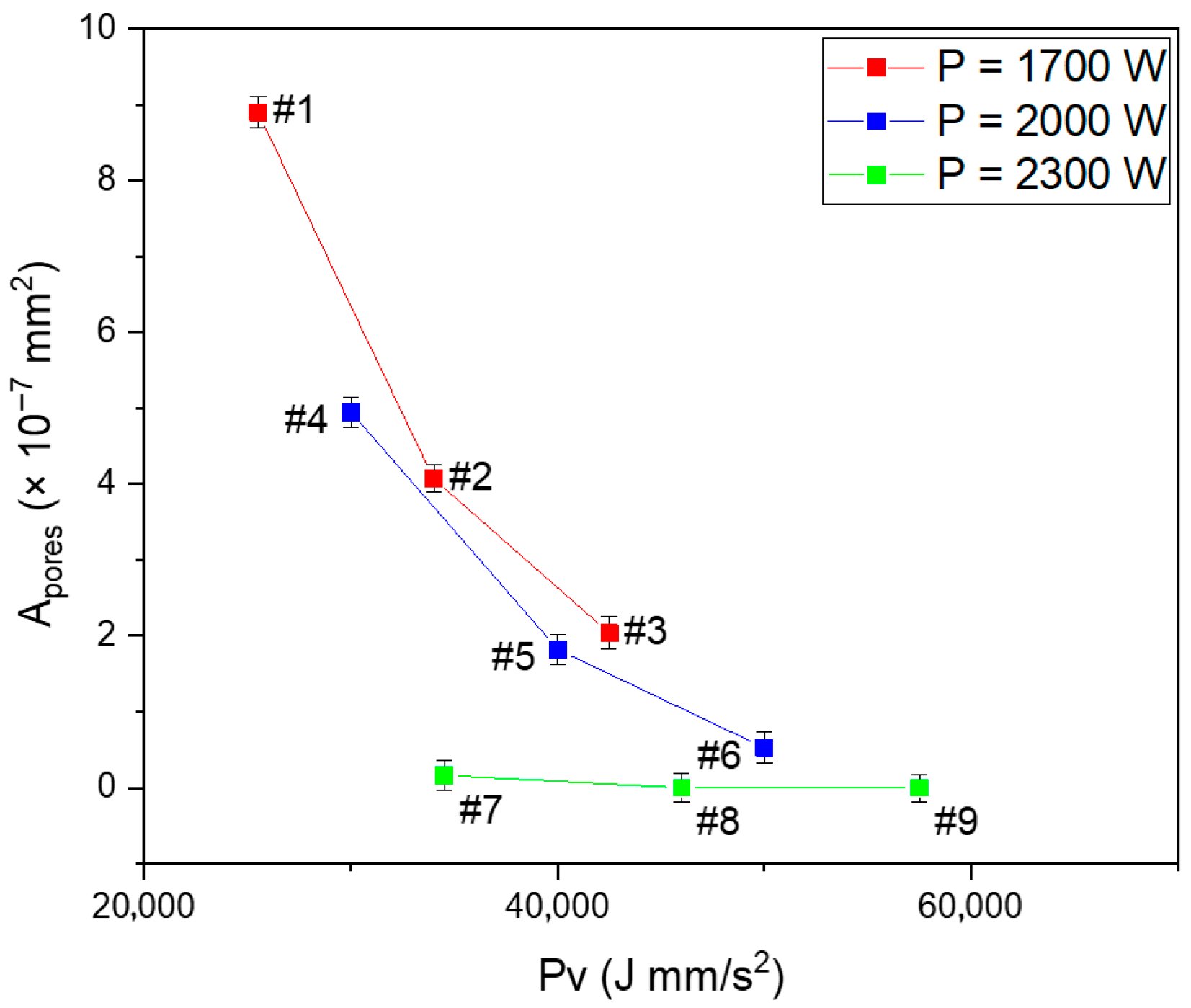

- Some micrometric pores (davg < 0.6 μm) were observed, and their average size decreases when P·v increases. In high-power regimes, the porosity tends to disappear completely due to a stronger agitation in the melt pool and, therefore, a higher bubble mobility;

- -

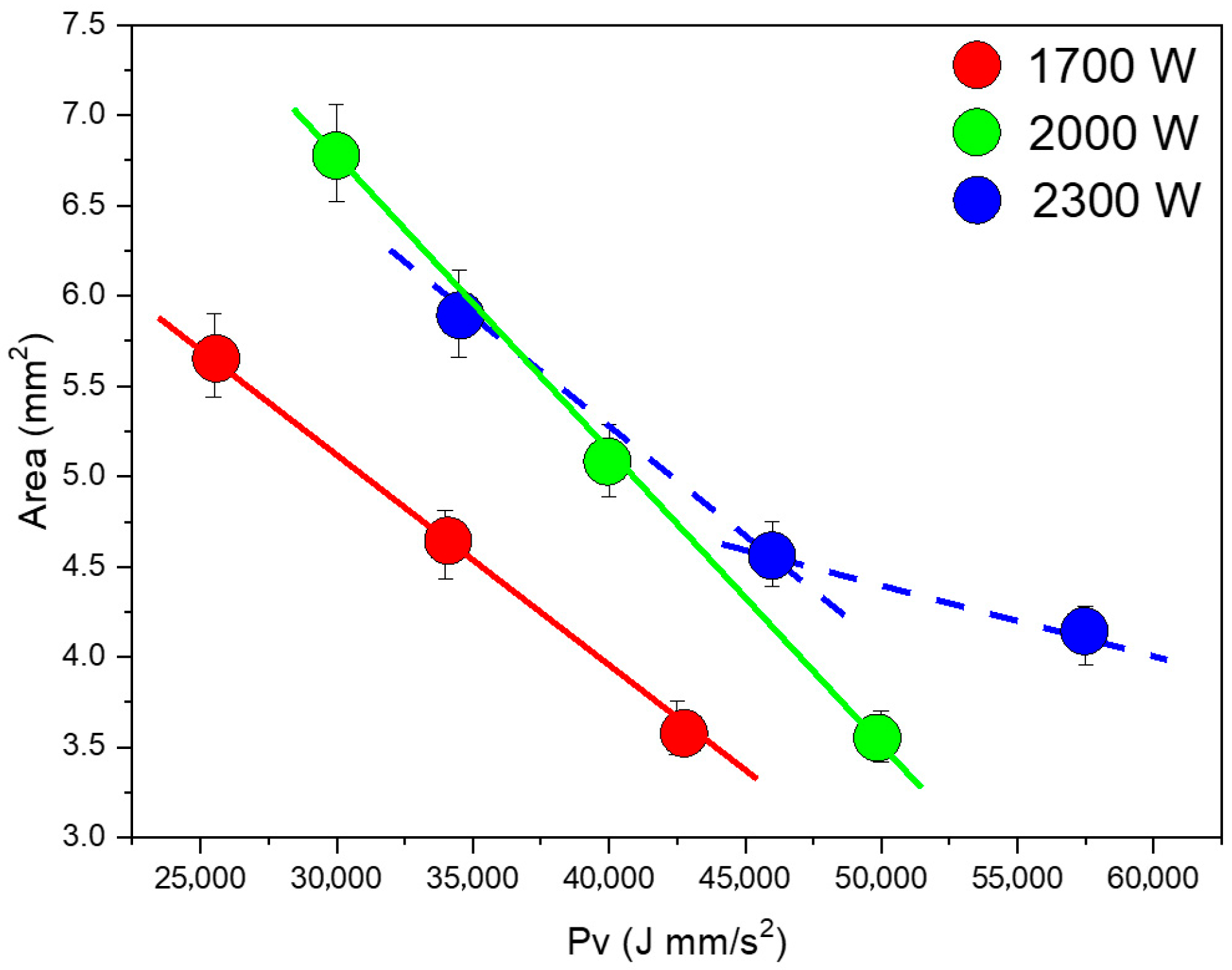

- The amount of volume affected by the welding process is mainly affected by the welding speed. It decreases as v increases, and the lowest value (A = 3.56 mm2) was obtained for seam #6;

- -

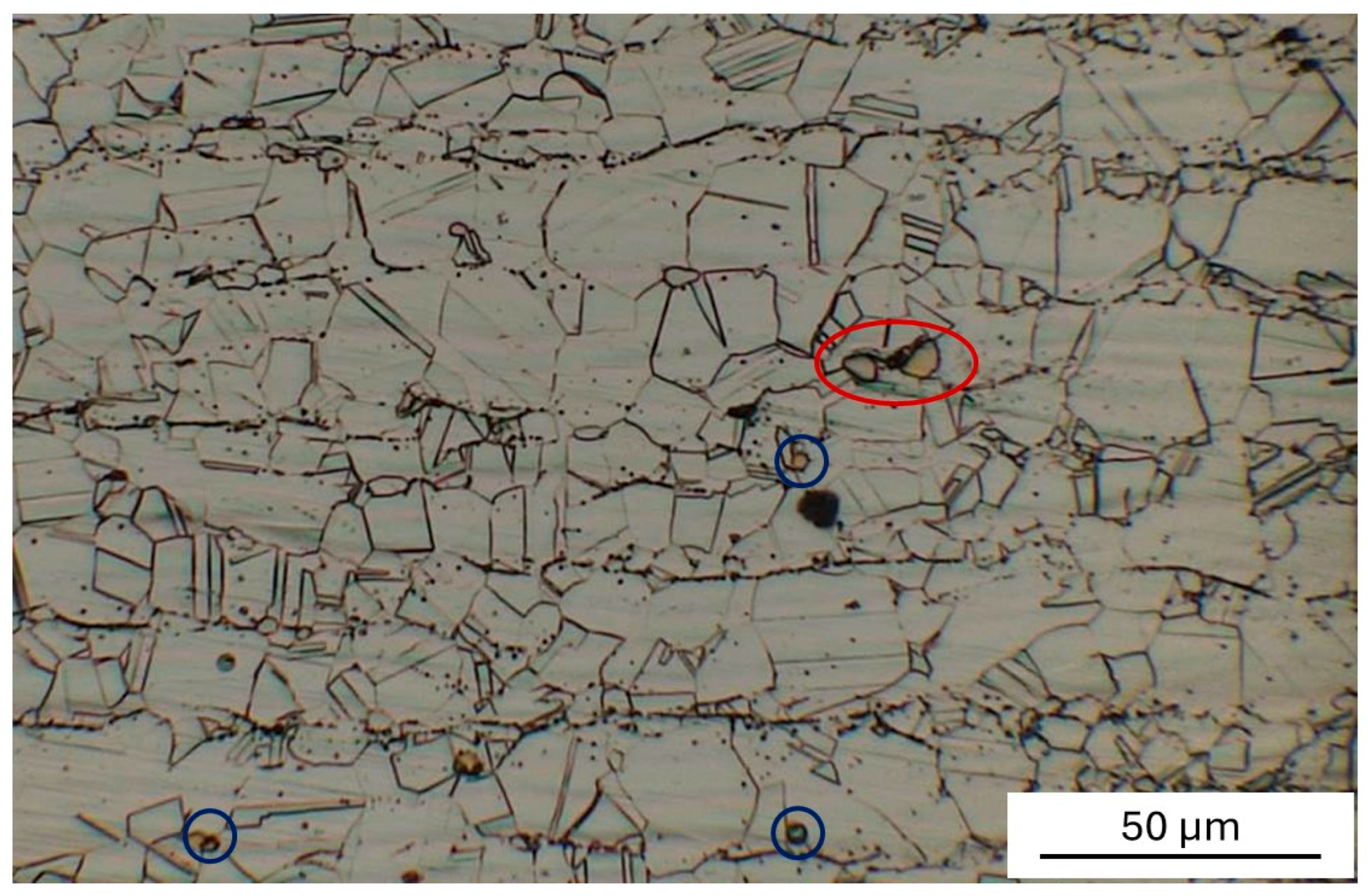

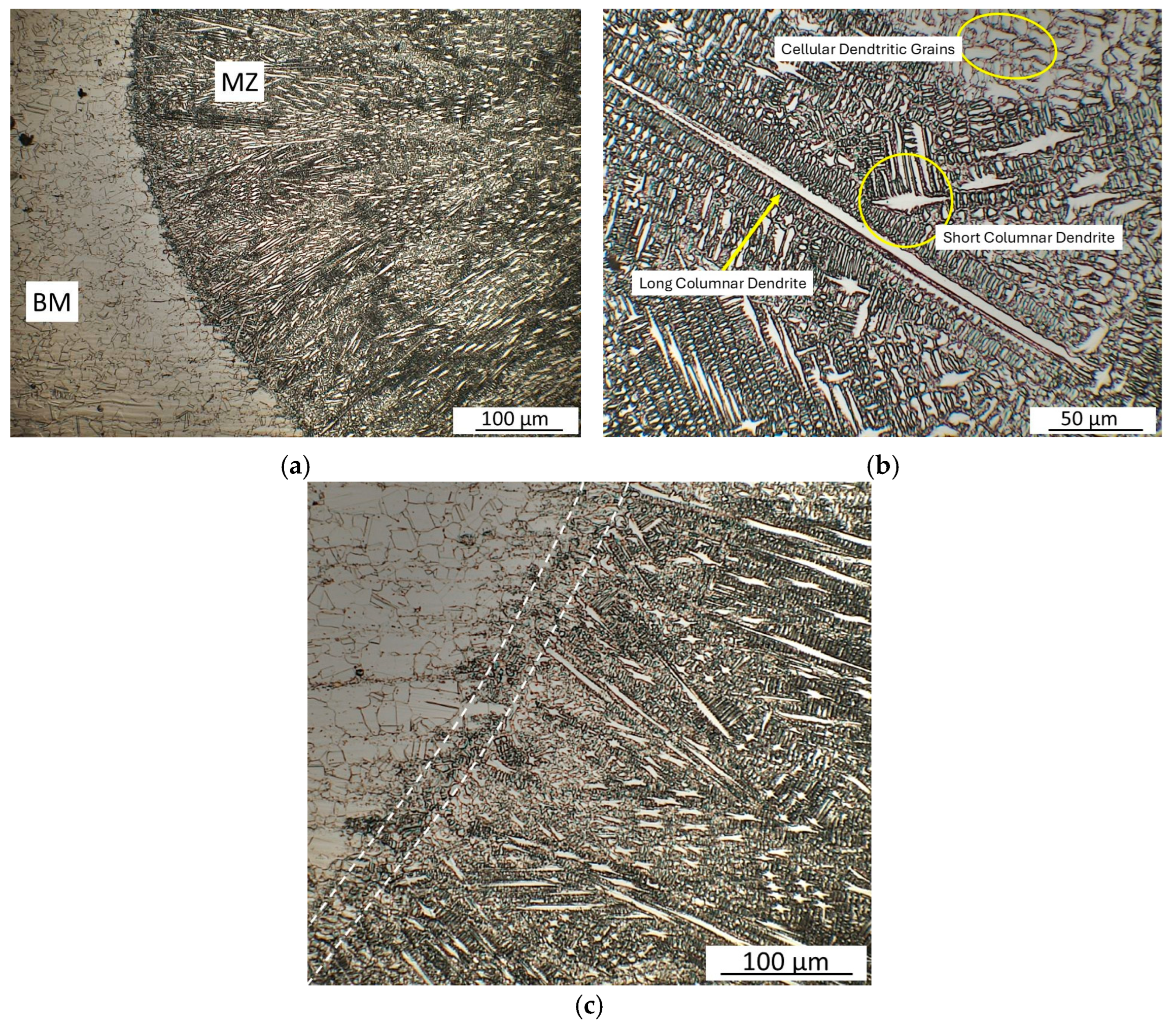

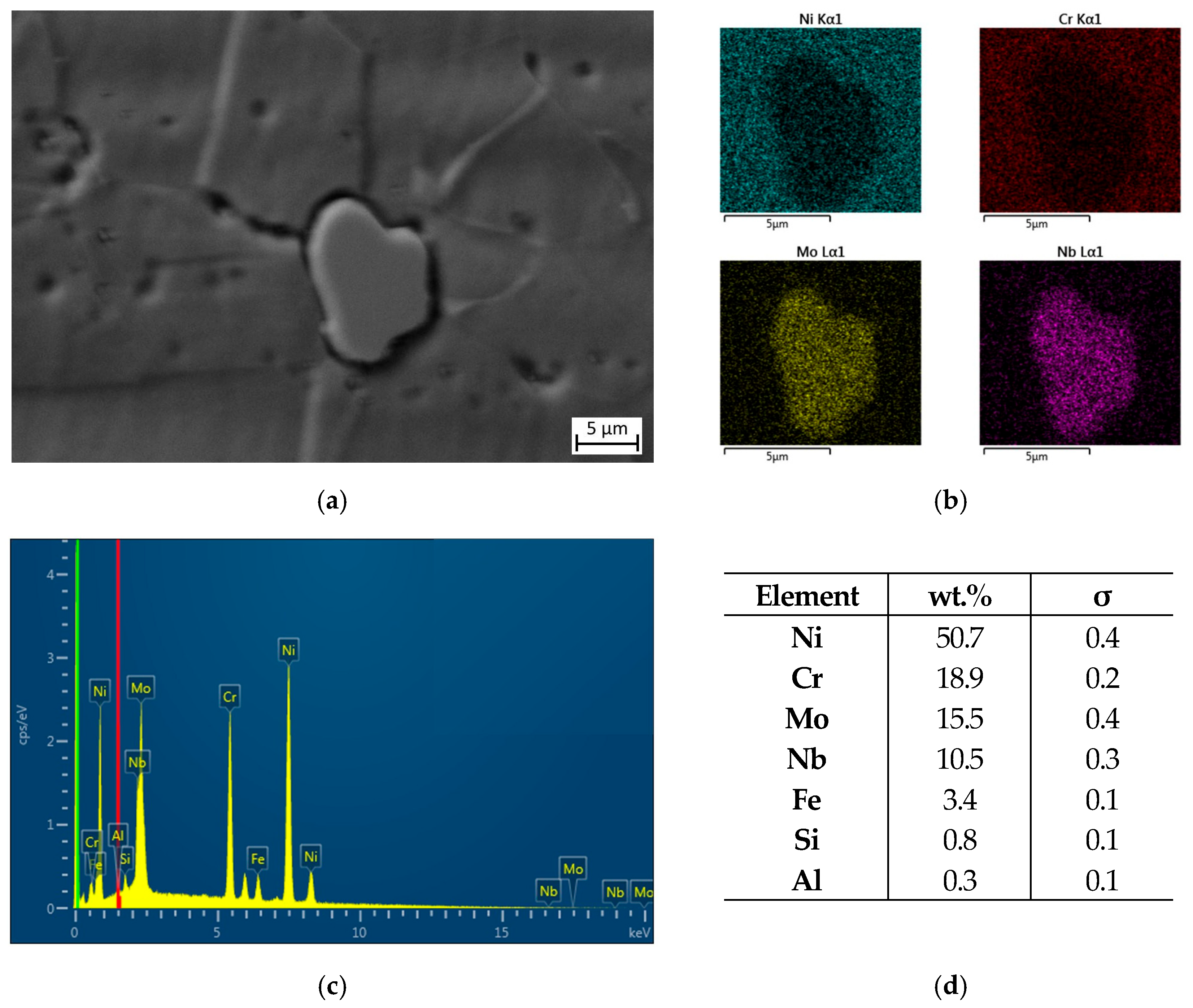

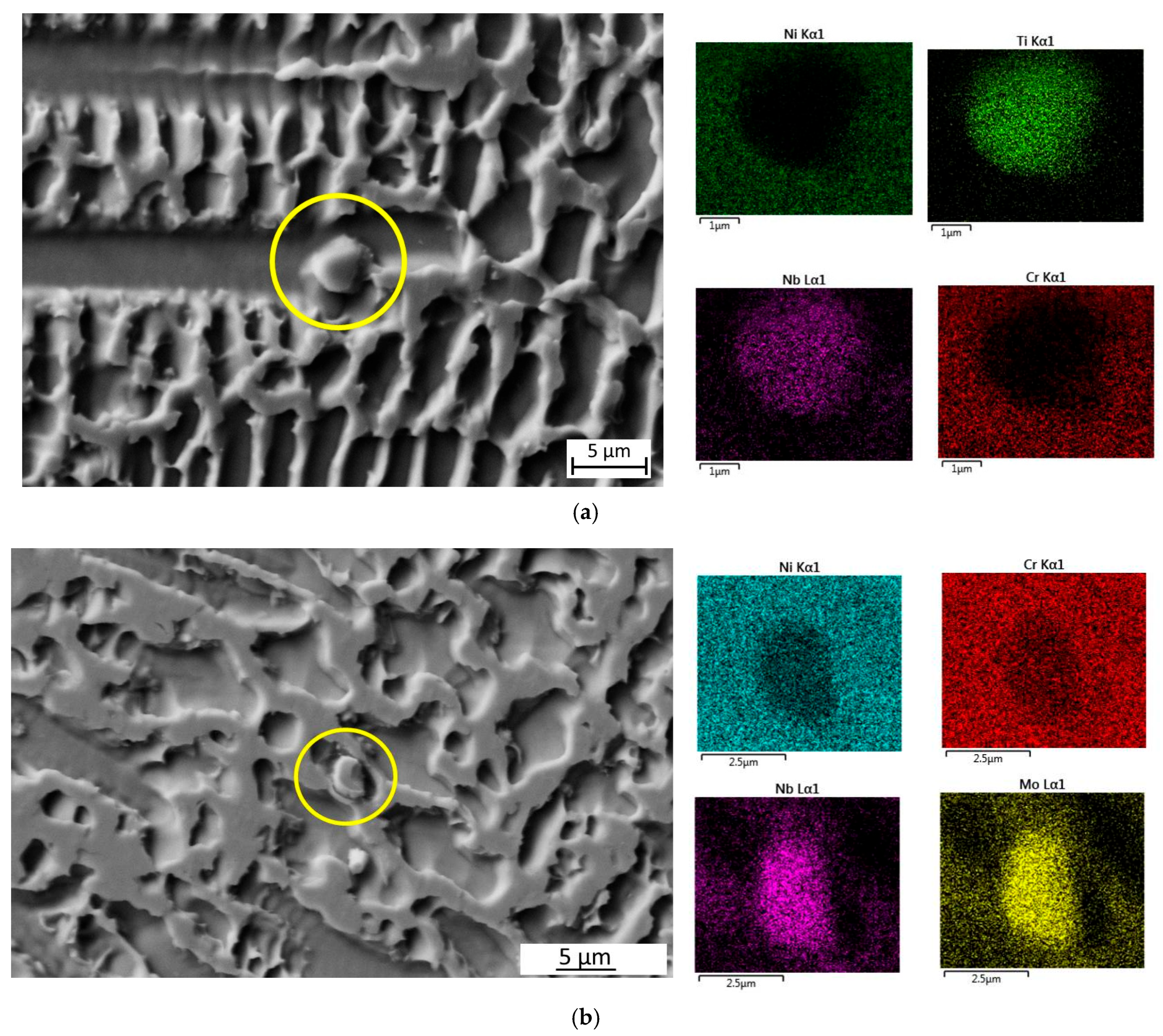

- The base metal structure consists of equiaxed grains, with an average size of d = 15 ± 5 μm, and several twins. Precipitates of the (Nb, Mo, Ti)C type of larger size (7 ± 1 μm) are present alongside a finer dispersion of smaller ones (<1 μm) at the grain boundaries;

- -

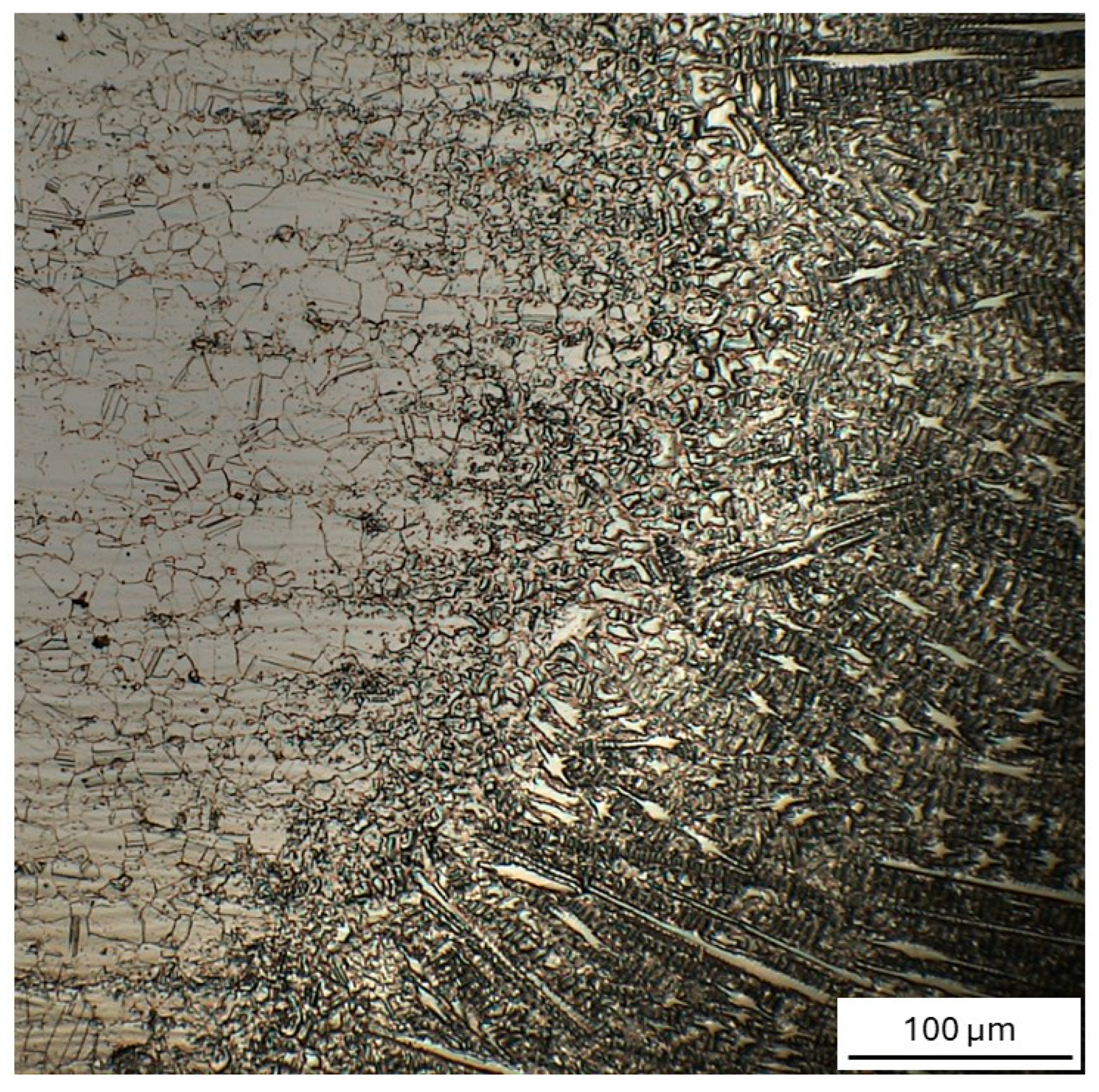

- In the melt zone, microstructure is characterized by columnar dendrites that evolve from long dendrite arms toward a cellular dendritic structure as a result of the different temperature gradients and solidification rates within the melted material;

- -

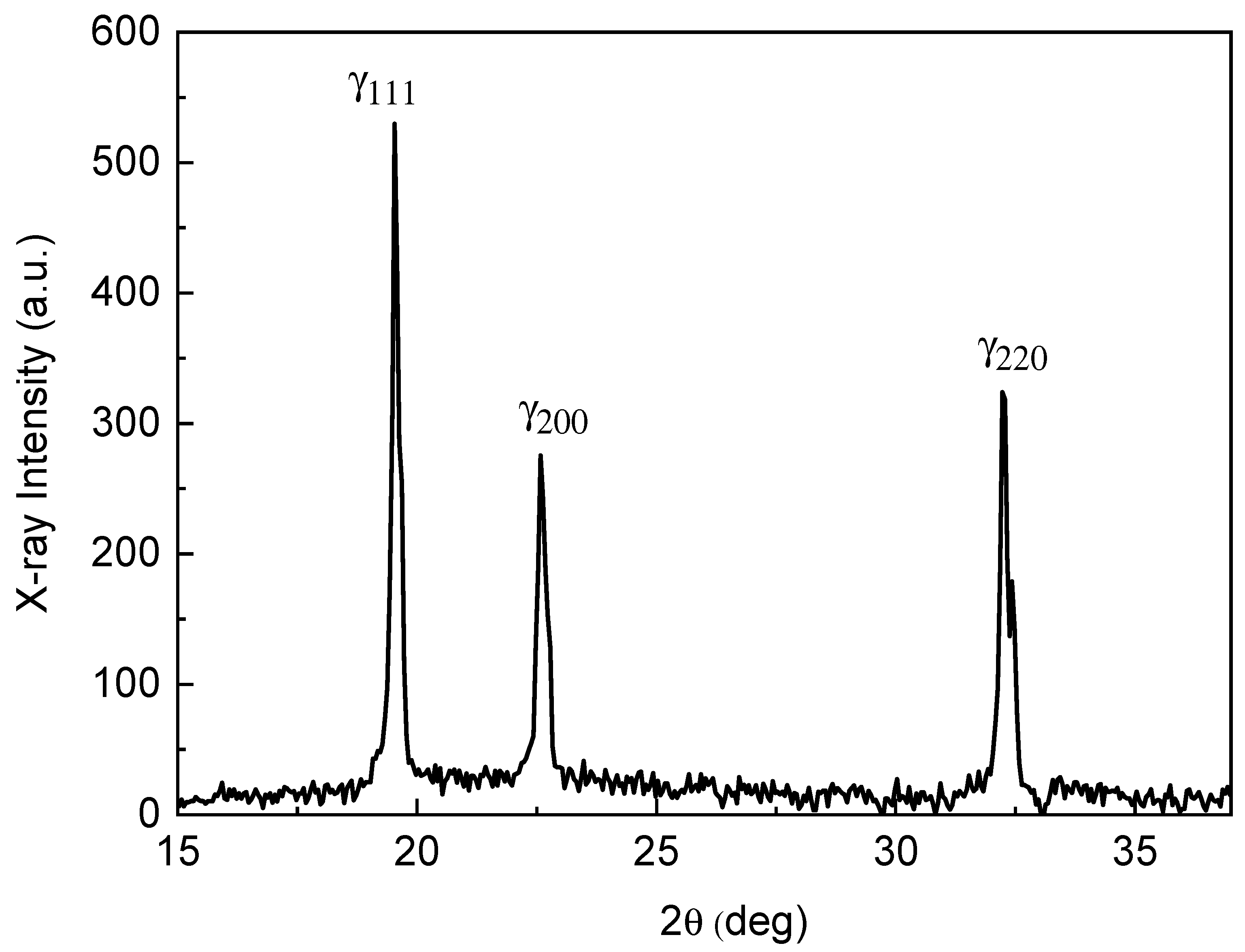

- The BM exhibits a preferred grain orientation of grains with a strong [110] component: the I(220)/I(111) ratio is 0.60, while it is 0.21 for Ni with randomly oriented grains. After welding, the preferred orientation of grains is still present;

- -

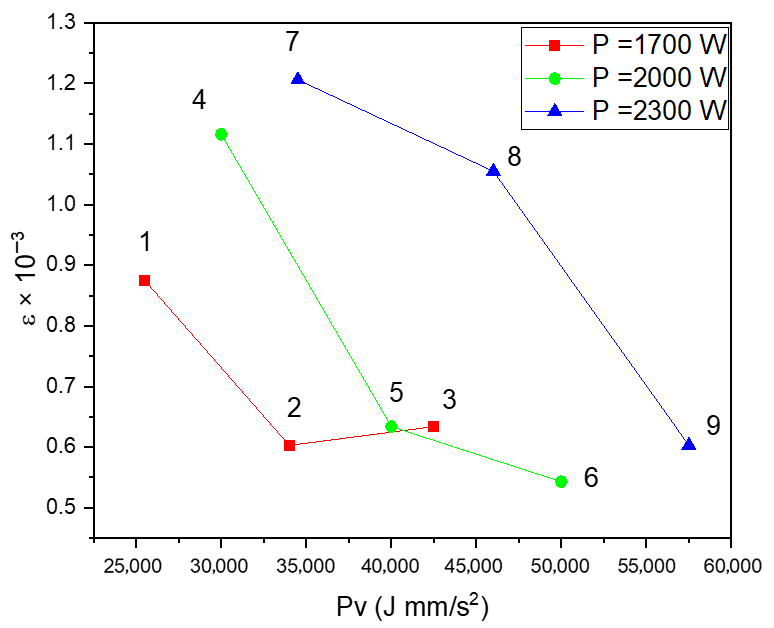

- Residual stresses, caused by the welding process, are always below the yield stress. The elastic distortion increases with the HI and can be reduced by increasing the laser speed.

- -

- Power modulation has a positive indirect influence: it allows employment of higher laser speed compared to the ones required in continuous mode, with a consequent reduction in melted volume, porosity, and residual stresses;

- -

- The MZ hardness slightly increases compared to the BM for all the seams, and no influence of process parameters has been observed. Moreover, the difference between the BM and MZ is within the experimental error, and no post-process treatments are needed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Su, R.; Hao, D.; He, P.; Wu, D.; Wang, Q.; Dong, H.; Ma, H. Effect of Co on creep and stress rupture properties of nickel-based superalloys—A review. J. Alloys Compd. 2023, 967, 171744. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys, Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Cottrell, A.H.; Bilby, B.A. Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. Sect. A 1949, 62, 49–62. [Google Scholar] [CrossRef]

- Goodfellow, A.J. Strengthening mechanisms in polycrystalline nickel-based superalloys. Mater. Sci. Technol. 2018, 34, 1793–1808. [Google Scholar] [CrossRef]

- AL-Nafeay, R.H.; AL-Roubaiy, A.O.; Omidvar, H. Overview of Joining and Repairing Techniques of Ni-Based Superalloy for Industrial Gas Turbine Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012141. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, P.; Wen, Z.; Xu, Z.; He, P.; Yue, Z. Study on creep properties of nickel-based superalloy blades based on microstructure characteristics. J. Alloys Compd. 2022, 890, 161710. [Google Scholar] [CrossRef]

- Wu, Y.; Li, C.; Xia, X.; Liang, H.; Qi, Q.; Liu, Y. Precipitate coarsening and its effects on the hot deformation behavior of the recently developed γ′-strengthened superalloys. J. Mater. Sci. Technol. 2021, 67, 95–104. [Google Scholar] [CrossRef]

- Thellaputta, G.R.; Chandra, P.S.; Rao, C.S.P. Machinability of Nickel Based Superalloys: A Review. Mater. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Sundaramali, G.; Dev, S.J.; Swathish, R.S.; Karthikeyan, R.; Vishaal, K.E.V.; Paramasivam, V. Recent Advancements in the Field of Ni-Based Superalloys. Adv. Mater. Sci. Eng. 2021, 2021, 9723450. [Google Scholar] [CrossRef]

- Donnini, R.; Varone, A.; Palombi, A.; Spiller, S.; Ferro, P.; Angella, G. High Energy Density Welding of Ni-Based Superalloys: An Overview. Metals 2025, 15, 30. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, M.; Gao, K.; Shen, X. Polycrystal modeling and micromechanical simulation of nickel-based superalloy electron beam welded joint. Mater. Sci. Eng. A 2023, 883, 145507. [Google Scholar] [CrossRef]

- Barbieri, G.; Cognini, F.; Fava, A.; Kaciulis, S.; Mezzi, A.; Moncada, M.; Montanari, R.; Palombi, A.; Richetta, M.; Varone, A. Segregation and Crack Formation in Laser Welded IN792 Equiaxed Superalloy. Surf. Interface Anal. 2025, 57, 485–491. [Google Scholar] [CrossRef]

- Wang, H.-S.; Huang, C.-Y.; Ho, K.-S.; Deng, S.-J. Microstructure evolution of laser repair welded René 77 nickel-based superalloy cast. Mater. Trans. 2011, 52, 2197–2204. [Google Scholar] [CrossRef]

- Kim, K.M.; Lee, U.; Lee, H.; Seo, S.M.; Chun, F.J. Quantifying Susceptibility to Solidification Cracking in Oscillated CM247LC Superalloy Welds via Varestraint Testing. Met. Mater. Int. 2023, 29, 777–794. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Patterson, T.; Hochanadel, J.; Sutton, S.; Panton, B.; Lippold, J. A review of high energy density beam processes for welding and additive manufacturing applications. Weld. World 2021, 65, 1235–1306. [Google Scholar] [CrossRef]

- Saurabh, S.K.; Chand, P.; Yadav, U.S. Study of the effect of laser beam welding on joint of Nimonic 80A superalloy: An experimental approach. Int. J. Adv. Manuf. Technol. 2024, 133, 5501–5513. [Google Scholar] [CrossRef]

- Siddharth, P.N.; Narayanan, C.S. A review on Electron Beam Welding process. J. Phys. Conf. Ser. 2020, 1706, 012208. [Google Scholar] [CrossRef]

- Thejasree, P.; Manikandan, N.; Binoj, J.S.; Varaprasad, K.C.; Palanisamy, D.; Raju, R. Numerical simulation and experimental investigation on laser beam welding of Inconel 625. Mater. Today Proc. 2020, 39, 268–273. [Google Scholar] [CrossRef]

- Choudhury, B.; Singh, V.; Selvarajan, L.; Goel, S.; Chandrasekaran, M. Synergic investigation of microstructure, precipitation, and micro-segregation on Inconel 825 weldments: A comparative study between GTAW and EBW. Mater. Chem. Phys. 2024, 318, 129249. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.K.; Guan, Z.W.; Liu, Y.J.; Qi, D.K.; Wang, Q.Y. Electron beam welding of Nimonic 80A: Integrity and microstructure evaluation. Vacuum 2018, 151, 266–274. [Google Scholar] [CrossRef]

- Vemanaboina, H.; Gundabattini, E.; Akella, S.; Rao, A.C.U.M.; Buddu, R.K.; Ferro, P.; Berto, F. Mechanical and metallurgical properties of co2 laser beam inconel 625 welded joints. Appl. Sci. 2021, 11, 7002. [Google Scholar] [CrossRef]

- Saurabh, S.K.; Chand, P.; Yadav, U.S. Multi-objective optimization and fracture analysis of laser weld joints of Ni-Cr superalloy 80 A for gas turbine components. J. Mech. Sci. Technol. 2024, 38, 4867–4876. [Google Scholar] [CrossRef]

- Aqeel, M.; Gautam, J.P.; Shariff, S.M. Comparative study on autogenous diode laser, CO2 laser-MIG hybrid and multi-pass TIG welding of 10-mm thick Inconel 617 superalloy. Mater. Sci. Eng. A 2022, 856, 143967. [Google Scholar] [CrossRef]

- Tlili, I.; Baleanu, D.; Mohammad Sajadi, S.; Ghaemi, F.; Fagiry, M.A. Numerical and experimental analysis of temperature distribution and melt flow in fiber laser welding of Inconel 625. Int. J. Adv. Manuf. Technol. 2022, 121, 765–784. [Google Scholar] [CrossRef]

- Norouzian, M.; Amne Elahi, M.; Plapper, P. A review: Suppression of the solidification cracks in the laser welding process by controlling the grain structure and chemical compositions. J. Adv. Join. Process. 2023, 7, 100139. [Google Scholar] [CrossRef]

- Yan, S.; Meng, Z.; Chen, B.; Tan, C.; Song, X.; Wang, G. Experimental study on the grain evolution induced by thermal characteristics during oscillation laser welding of IN718. Mater. Lett. 2022, 323, 132581. [Google Scholar] [CrossRef]

- Sun, W.; Wang, S.; Tan, G.; Xin, J.; Hong, M.; Wu, M.; Chen, Y. Microstructure and mechanical properties of Inconel713C Ni3Al-based superalloy joint welded by electron beam feeding wire welding technology. J. Manuf. Process 2023, 89, 50–63. [Google Scholar] [CrossRef]

- Choudhury, B.; Chandrasekaran, M. Microstructural Investigation and Integrated Optimization of Weld Bead Characteristics in Electron Beam Welding of Inconel 825. Trans. Indian Inst. Met. 2021, 74, 2681–2701. [Google Scholar] [CrossRef]

- Li, J.; Yao, J.; Zhao, G.; Li, H.; Li, Y.; Liu, J. The Influence of Different Focusing Currents on the Microstructure Evolution and Wear Properties of a Scanning Electron Beam Modified Inconel 625 Nickel Base Alloy Surface. Crystals 2023, 13, 325. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A.; Barbieri, G.; Soltani, P.; Mezzi, A.; Kaciulis, S. Welding of IN792 DS superalloy by electron beam. Surf. Interface Anal. 2016, 48, 483–487. [Google Scholar] [CrossRef]

- Angella, G.; Barbieri, G.; Donnini, R.; Montanari, R.; Richetta, M.; Varone, A. Electron Beam Welding of IN792 DS: Effects of Pass Speed and PWHT on Microstructure and Hardness. Materials 2017, 10, 1033. [Google Scholar] [CrossRef] [PubMed]

- Spiller, S.; Varone, A.; Angella, G.; Cognini, F.; Fabrizi, A.; Bonollo, F.; Ferro, P. Hot Cracking in Laser Welding of Equiaxed and Directionally Solidified Nickel-Based Alloy IN792: Experimental and Numerical Study. Mater. Des. 2025, 257, 114413. [Google Scholar] [CrossRef]

- Barbieri, G.; Cognini, F.; de Crescenzo, C.; Fava, A.; Moncada, M.; Montanari, R.; Richetta, M.; Varone, A. Process Optimization in Laser Welding of IN792 DS Superalloy. Metals 2024, 14, 124. [Google Scholar] [CrossRef]

- Shankar, V.; Bhanu Sankara Rao, K.; Mannan, S.L. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Shoemaker, L.E. Alloys 625 and 725: Trends properties and applications. In Proceedings of the Superalloys 718, 625, 706 and Various Derivatives, Pittsburgh, PA, USA, 2–5 October 2005; pp. 409–418. [Google Scholar]

- Gessinger, G.H.; Bomford, M. Powder metallurgy of superalloys. Int. Metall. Rev. 1974, 19, 51–76. [Google Scholar] [CrossRef]

- Special Metals Corporation Products. INCONEL® Alloy 625 (Technical Bulletins). Available online: https://www.specialmetals.com/products/ (accessed on 10 December 2024).

- Quist, W.E.; Taggart, R.; Polonis, D.H. The influence of iron and aluminum on the precipitation of metastable Ni3Nb phases in the Ni-Nb system. Metall. Trans. 1971, 2, 825–832. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Precipitation of the δ-Ni3Nb phase in two nickel base superalloys. Metall. Trans. A 1988, 19, 453–465. [Google Scholar] [CrossRef]

- Kohl, H.; Peng, K. Thermal stability of the superalloys Inconel 625 and Nimonic 86. J. Nucl. Mater. 1981, 101, 243–250. [Google Scholar] [CrossRef]

- Muzyka, D.R. The Superalloys; John Wiley & Sons: New York, NY, USA, 1972. [Google Scholar]

- Jelokhani-Niaraki, M.R.; Arab, N.B.M.; Naffakh-Moosavy, H.; Ghoreishi, M. The systematic parameter optimization in the Nd:YAG laser beam welding of Inconel 625. Int. J. Adv. Manuf. Technol. 2016, 84, 2537–2546. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Cardaropoli, F.; Sergi, V. Investigation on edge joints of Inconel 625 sheets processed with laser welding. Opt. Laser Technol. 2017, 93, 180–186. [Google Scholar] [CrossRef]

- Tom Saju, M. Velu, Review on welding and fracture of nickel based superalloys. Mater. Today Proc. 2021, 46, 7161–7169. [Google Scholar] [CrossRef]

- Kumar, P.; Farah, J.; Akram, J.; Teng, C.; Ginn, J.; Misra, M. Influence of laser processing parameters on porosity in Inconel 718 during additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 103, 1497–1507. [Google Scholar] [CrossRef]

- Odabaşı, A.; Ünlü, N.; Göller, G.; Eruslu, M.N. A Study on Laser Beam Welding (LBW) Technique: Effect of Heat Input on the Microstructural Evolution of Superalloy Inconel 718. Metall. Mater. Trans. A 2010, 41, 2357–2365. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B. Comparative study between CW and PW emissions in selective laser melting. J. Laser Appl. 2018, 30, 032305. [Google Scholar] [CrossRef]

- Ariaseta, A.; Pick, D.; Andersson, J.; Ojo, O. Study of Pulsed Laser Beam Welding of Nickel-Based Superalloy G27. In Ebook Volume 52: Sustainable Production Through Advanced Manufacturing, Intelligent Automation and Work Integrated Learning; Advances in Transdisciplinary Engineering; IOS Press: Amsterdam, The Netherlands, 2024; pp. 39–49. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Chen, Y.; Su, Z.; Shan, J.; Wu, A.; Sato, Y.S.; Gu, H.; Tang, X. The role of the pulsed-wave laser characteristics on restraining hot cracking in laser cladding non-weldable nickel-based superalloy. Mater. Des. 2021, 198, 109346. [Google Scholar] [CrossRef]

- Jiang, Z.; Tao, W.; Yu, K.; Tan, C.; Chen, Y.; Li, L.; Li, Z. Comparative study on fiber laser welding of GH3535 superalloy in continuous and pulsed waves. Mater. Des. 2016, 110, 728–739. [Google Scholar] [CrossRef]

- Kuo, T.-Y. Effects of pulsed and continuous Nd–YAG laser beam waves on welding of Inconel alloy. Sci. Technol. Weld. Join. 2005, 10, 557–565. [Google Scholar] [CrossRef]

- Kuo, T.-Y.; Lin, Y.-D. Effects of Different Shielding Gases and Power Waveforms on Penetration Characteristics and Porosity Formation in Laser Welding of Inconel 690 Alloy. Mater. Trans. 2007, 48, 219–226. [Google Scholar] [CrossRef]

- Hensel, J.; Köhler, M.; Uhlenberg, L.; e Castro, J.D.; Dilger, K.; Faß, M.; Baumgartner, J. Laser welding of 16MnCr5 butt welds with gap: Resulting weld quality and fatigue strength assessment. Weld. World 2022, 66, 1867–1881. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Huang, T.-Y.; Cheng, C.-W.; Lee, A.-C.; Chang, T.-W.; Tsai, M.-C. Influence of Wobble-Based Scanning Strategy on Surface Morphology of Laser Powder Bed-Fabricated Permalloy. Materials 2023, 16, 2062. [Google Scholar] [CrossRef]

- Unocic, R.R.; DuPont, J.N. Process Efficiency Measurements in the Laser Engineered Net Shaping Process. Metall. Mater. Trans. B 2004, 35, 143–152. [Google Scholar] [CrossRef]

- JCPDS-International Centre for Diffraction Data, Newtown Square, PA 19073, USA. Available online: https://www.icdd.com/ (accessed on 10 November 2025).

- Available online: https://www.espimetals.com/index.php/technical-data/89-inconel-625#:~:text=Density:%208.44%20g/cm3,Resistivity:%201290%20n%CE%A9%20%E2%8B%85%20m (accessed on 10 November 2025).

- Montanari, R.; Varone, A. Flat-top cylinder indenter for mechanical characterization: A report of industrial applications. Materials 2021, 14, 1742. [Google Scholar] [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Dear, J.P.; Davies, C.M. Optimisation of process parameters and weld shape of high power Yb-fibre laser welded 2024-T3 aluminium alloy. J. Manuf. Process. 2018, 34, 70–85. [Google Scholar] [CrossRef]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F.; Alarifi, I.M. Effect of Nd:YAG laser welding on microstructure and mechanical properties of Incoloy alloy 800. Opt. Laser Technol. 2021, 140, 107039. [Google Scholar] [CrossRef]

- Sharma, S.K.; Biswas, K.; Nath, A.K.; Manna, I.; Dutta Majumdar, J. Microstructural change during laser welding of Inconel 718. Optik 2020, 218, 165029. [Google Scholar] [CrossRef]

- Saha, D.; Pal, S. Study of mechanical behaviour and microsegregation in interdendritic region of a single-pass plasma arc welding of thick IN625 plate. Arch. Civ. Mech. Eng. 2025, 25, 105. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Yang, D.; Li, H.; Peng, Y.; Wang, K. Multi-scale simulation of grain growth during laser beam welding of nickel-based superalloy. J. Mater. Res. Technol. 2020, 9, 15034–15044. [Google Scholar] [CrossRef]

- Yue, N.; Pei, L.; Xu, P.; Jiang, Z.; Lin, T.; Zhou, L.; Liang, Y. Porosity suppression of nickel-based superalloy by modulated base temperature in laser welding and mechanism analysis. J. Mater. Res. Technol. 2024, 30, 4725–4738. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Mulimani, S.S.; Ankit, K.; Kothari, A.; Ganguly, S. Effect of grain boundary precipitation on the mechanical integrity of EBW joints of Inconel 625. Mater. Sci. Eng. A. 2021, 808, 140926. [Google Scholar] [CrossRef]

- Hong, M.; Wang, S.; Sun, W.; Geng, Z.; Xin, J.; Ke, L. Effect of welding speed on microstructure and mechanical properties of selective laser melting Inconel 625 alloy laser welded joint. J. Mater. Res. Technol. 2022, 19, 2093–2103. [Google Scholar] [CrossRef]

- Tenner, F.; Brock, C.; Klämpfl, F.; Schmidt, M. Analysis of the correlation between plasma plume and keyhole behavior in laser metal welding for the modeling of the keyhole geometry. Opt. Lasers Eng. 2015, 64, 32–41. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Hu, M.; Guo, L.; Wang, Z.; Zeng, X. Characteristics of plasma plume in fiber laser welding of aluminum alloy. Appl. Surf. Sci. 2015, 326, 181–186. [Google Scholar] [CrossRef]

- Xu, J.; Luo, Y.; Zhu, L.; Han, J.; Zhang, C.; Chen, D. Effect of shielding gas on the plasma plume in pulsed laser welding. Measurement 2019, 134, 25–32. [Google Scholar] [CrossRef]

| Cr | Fe | Mo | Nb | Co | Mn | Al | Ti | Ta | Si | S + P | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.26 | 4.54 | 8.33 | 3.43 | 0.04 | 0.35 | 0.22 | 0.20 | 0.01 | 0.24 | <0.01 | 0.04 | balance |

| Welding | P (W) | Pmax (W) | Pmin (W) | ΔP (W) | v (mm/s) | Γ | HI (J/mm) | P·v (J mm/s2) |

|---|---|---|---|---|---|---|---|---|

| #1 | 1700 | 2125 | 1275 | 850 | 15 | 0.6 | 113 | 25,500 |

| #2 | 1700 | 1889 | 1511 | 378 | 20 | 0.8 | 85 | 34,000 |

| #3 | 1700 | 1700 | 1700 | 0 | 25 | 1 | 68 | 42,500 |

| #4 | 2000 | 2222 | 1778 | 444 | 15 | 0.8 | 133 | 30,000 |

| #5 | 2000 | 2000 | 2000 | 0 | 20 | 1 | 100 | 40,000 |

| #6 | 2000 | 2500 | 1500 | 1000 | 25 | 0.6 | 80 | 50,000 |

| #7 | 2300 | 2300 | 2300 | 0 | 15 | 1 | 153 | 34,500 |

| #8 | 2300 | 2875 | 1725 | 1150 | 20 | 0.6 | 115 | 46,000 |

| #9 | 2300 | 2556 | 2044 | 512 | 25 | 0.8 | 92 | 57,500 |

| Sample | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

|---|---|---|---|---|---|---|---|---|---|

| A (mm2) | 5.67 | 4.62 | 3.61 | 6.79 | 5.09 | 3.56 | 5.90 | 4.57 | 4.12 |

| #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 | |

|---|---|---|---|---|---|---|---|---|---|

| davg (μm) | 0.37 | 0.29 | 0.51 | 0.56 | 0.20 | 0.17 | 0.10 | - | - |

| Apores (×10−7 mm2) | 8.92 | 4.07 | 2.04 | 4.95 | 1.82 | 0.53 | 0.082 | - | - |

| 111 | 200 | 220 | I200/I111 | I220/I111 | |

|---|---|---|---|---|---|

| BM | 100 | 52 | 60 | 0.52 | 0.60 |

| JCPDS 4-850 | 100 | 42 | 21 | 0.42 | 0.21 |

| 111 | 200 | 220 | I220/I111 | |

|---|---|---|---|---|

| #1 | 100 | 58 | 67 | 0.67 |

| #2 | 100 | 39 | 99 | 0.99 |

| #3 | 100 | 46 | 80 | 0.80 |

| #4 | 100 | 52 | 80 | 0.80 |

| #5 | 100 | 36 | 74 | 0.74 |

| #6 | 100 | 83 | 76 | 0.76 |

| #7 | 100 | 71 | 93 | 0.93 |

| #8 | 100 | 52 | 59 | 0.59 |

| #9 | 100 | 38 | 78 | 0.78 |

| Sample | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

|---|---|---|---|---|---|---|---|---|---|

| ε (× 10−3) | 0.875 | 0.603 | 0.634 | 1.116 | 0.634 | 0.543 | 1.206 | 1.055 | 0.603 |

| (σX + σY) (MPa) | 603.5 | 416.3 | 437.1 | 769.8 | 437.1 | 374.7 | 832.1 | 728.2 | 416.3 |

| HI (J/mm) | 113 | 85 | 68 | 133 | 100 | 80 | 153 | 115 | 92 |

| Sample | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

|---|---|---|---|---|---|---|---|---|---|

| HV in MZ | 264 ± 3 | 263 ± 6 | 266 ± 5 | 264 ± 4 | 263 ± 6 | 263 ± 8 | 264 ± 4 | 260 ± 4 | 264 ± 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angella, G.; Bergamini, F.; Cognini, F.; Fava, A.; Ferro, P.; Palombi, A.; Richetta, M.; Varone, A. Laser Beam Welding of IN625 Alloy with Equiaxed Grains: Influence of Process Parameters. Metals 2025, 15, 1296. https://doi.org/10.3390/met15121296

Angella G, Bergamini F, Cognini F, Fava A, Ferro P, Palombi A, Richetta M, Varone A. Laser Beam Welding of IN625 Alloy with Equiaxed Grains: Influence of Process Parameters. Metals. 2025; 15(12):1296. https://doi.org/10.3390/met15121296

Chicago/Turabian StyleAngella, Giuliano, Fabio Bergamini, Francesco Cognini, Alessandra Fava, Paolo Ferro, Alessandra Palombi, Maria Richetta, and Alessandra Varone. 2025. "Laser Beam Welding of IN625 Alloy with Equiaxed Grains: Influence of Process Parameters" Metals 15, no. 12: 1296. https://doi.org/10.3390/met15121296

APA StyleAngella, G., Bergamini, F., Cognini, F., Fava, A., Ferro, P., Palombi, A., Richetta, M., & Varone, A. (2025). Laser Beam Welding of IN625 Alloy with Equiaxed Grains: Influence of Process Parameters. Metals, 15(12), 1296. https://doi.org/10.3390/met15121296