Effect of CMT Welding Heat Input on Microstructure and Mechanical Properties of Different Groove Angles for Al-6061-T6 Alloy Joint

Abstract

1. Introduction

2. Methods

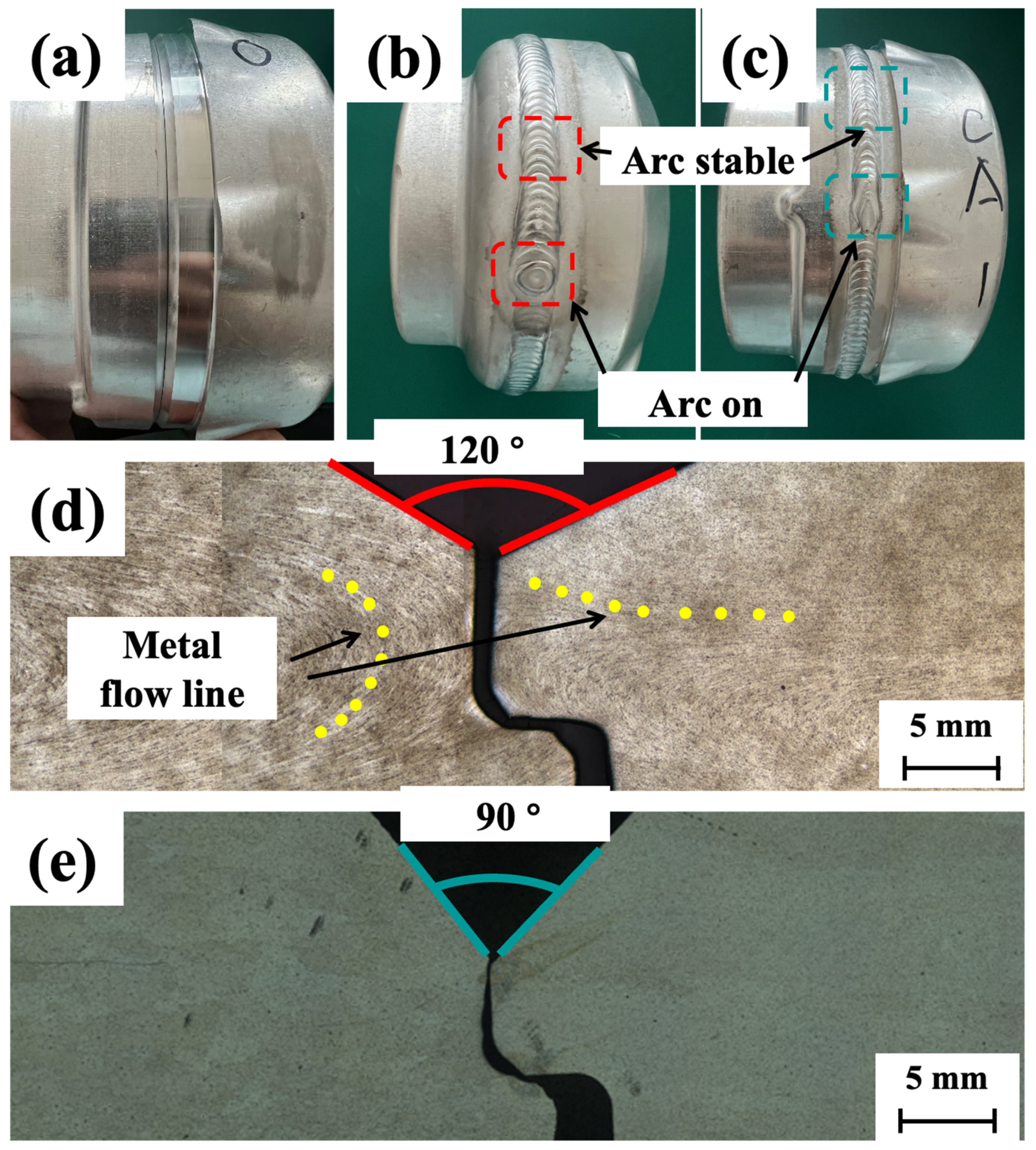

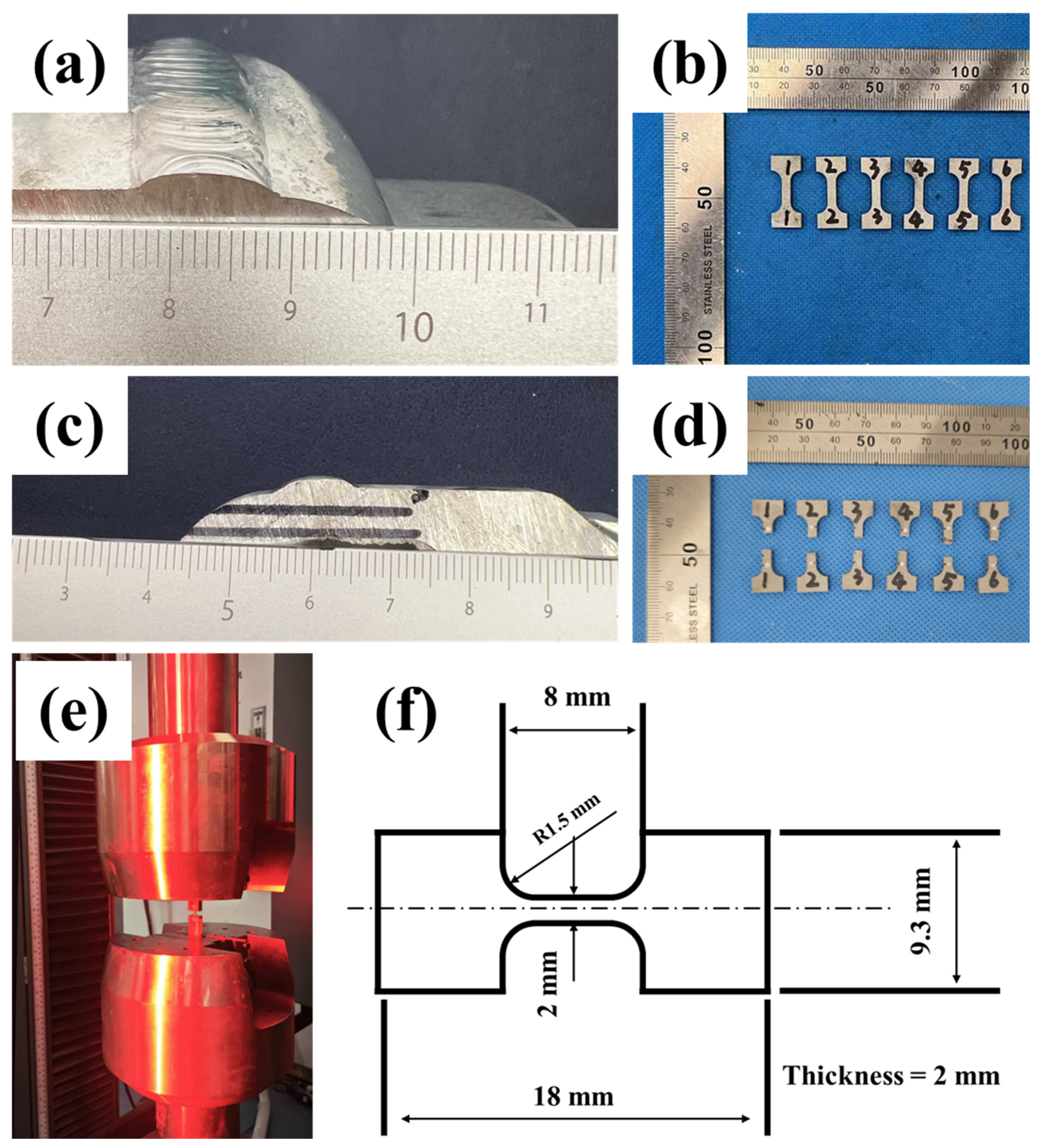

2.1. Manufacturing

2.2. Characterization and Mechanical Test

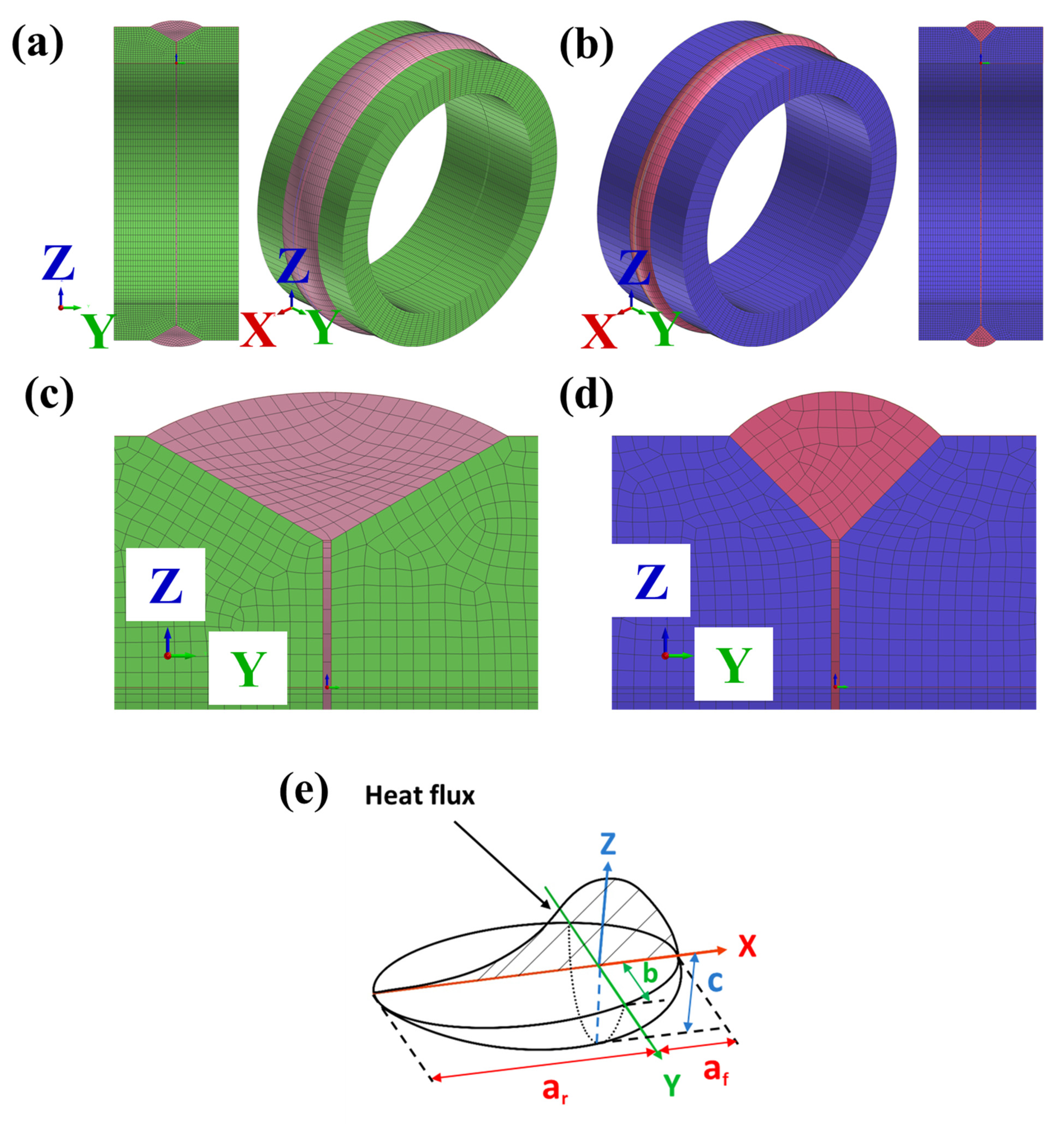

2.3. Thermal Analysis

- The initial temperature was 20 °C.

- Fluid flow within the molten pool was neglected.

- Heat exchange with the environment was modeled as convection and radiation from exposed surfaces to ambient air at 20 °C.

3. Results

3.1. Chemical Composition

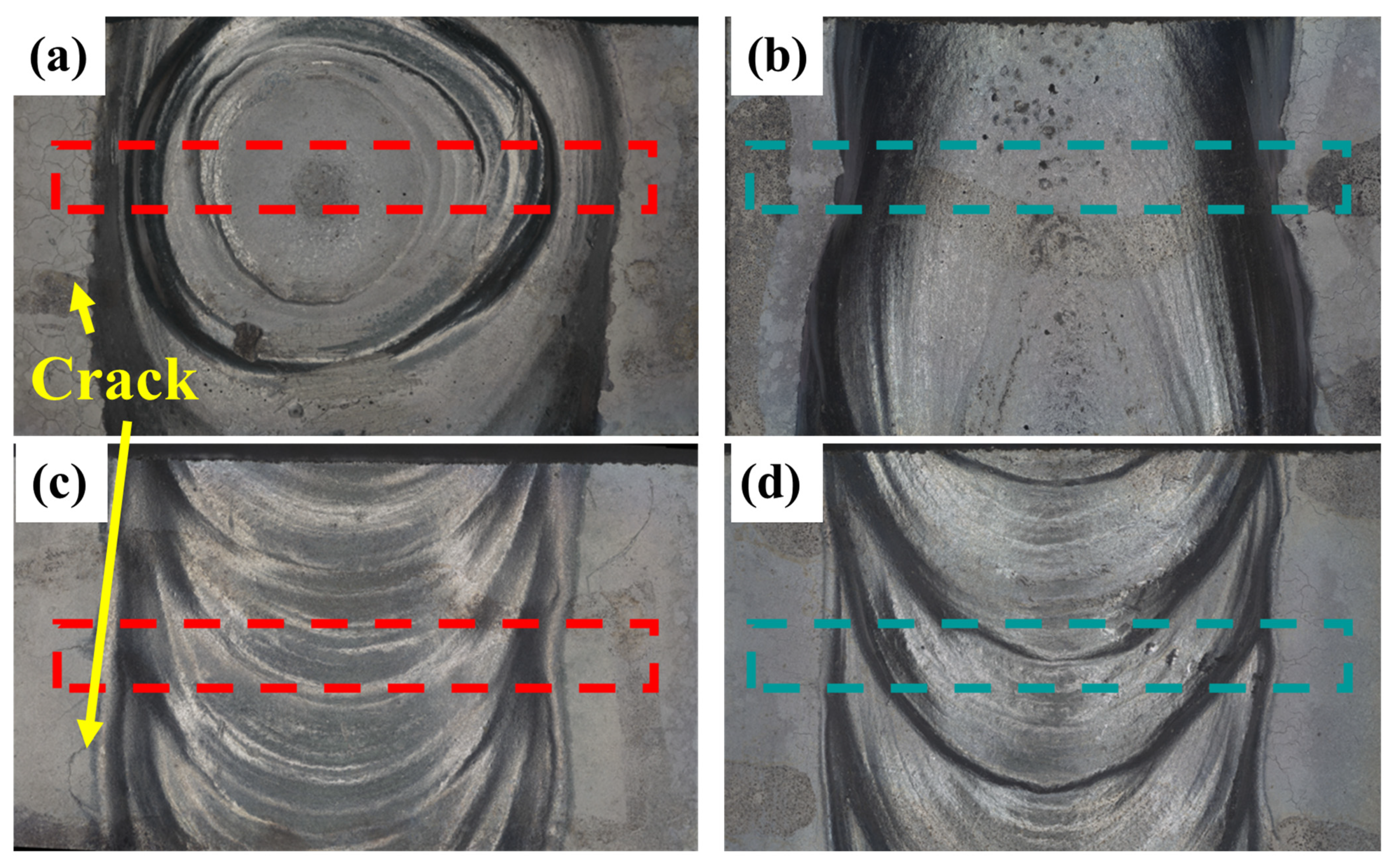

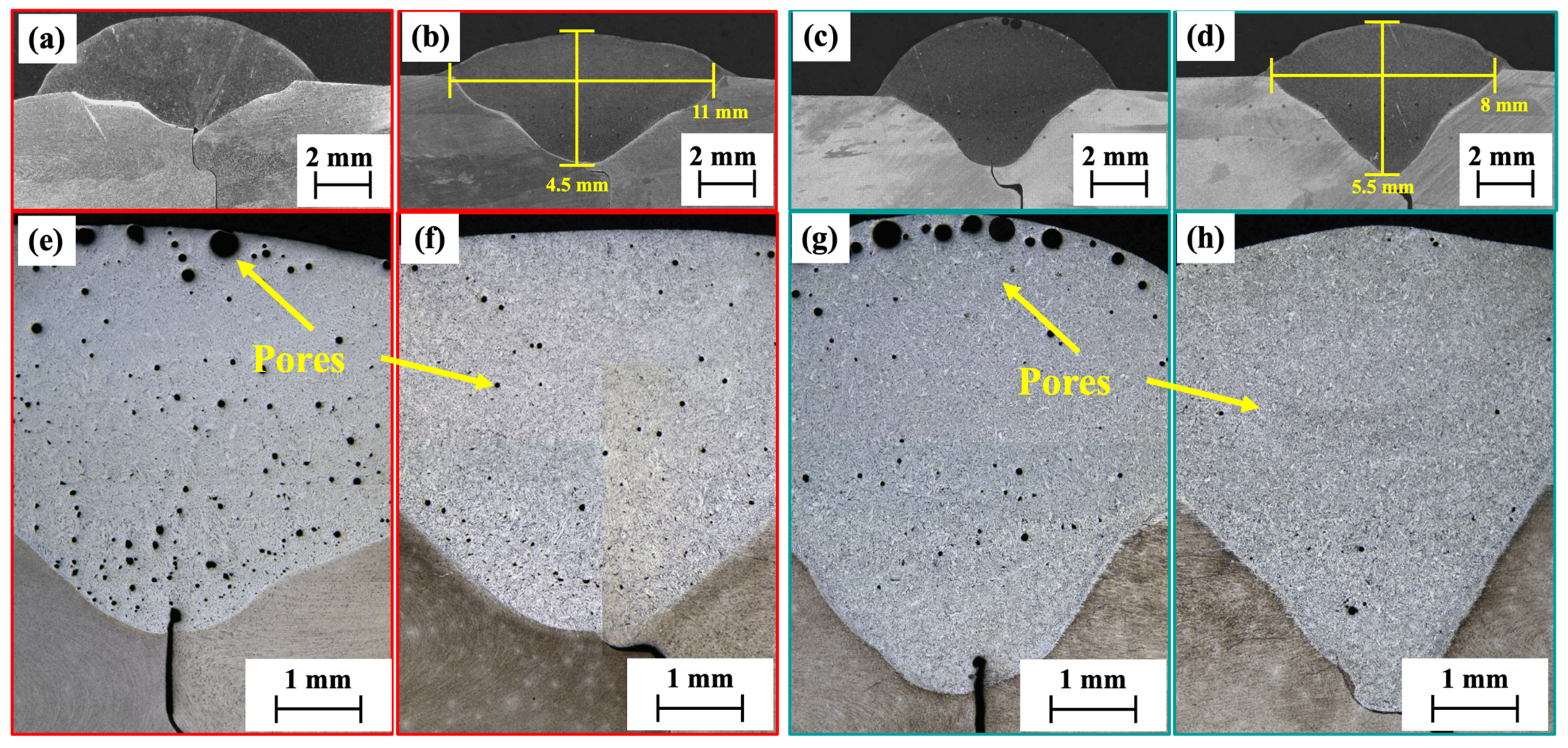

3.2. Macrostructure

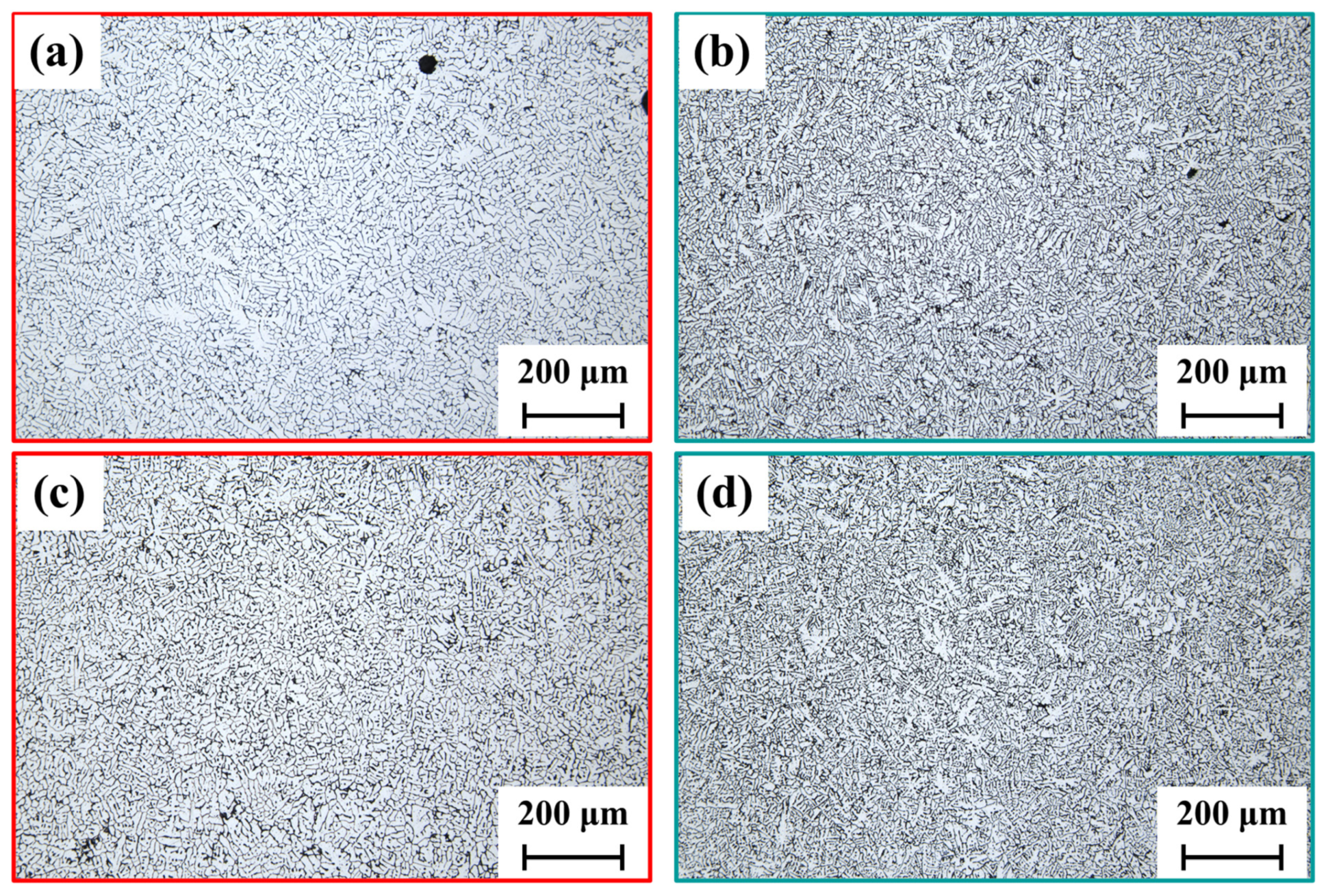

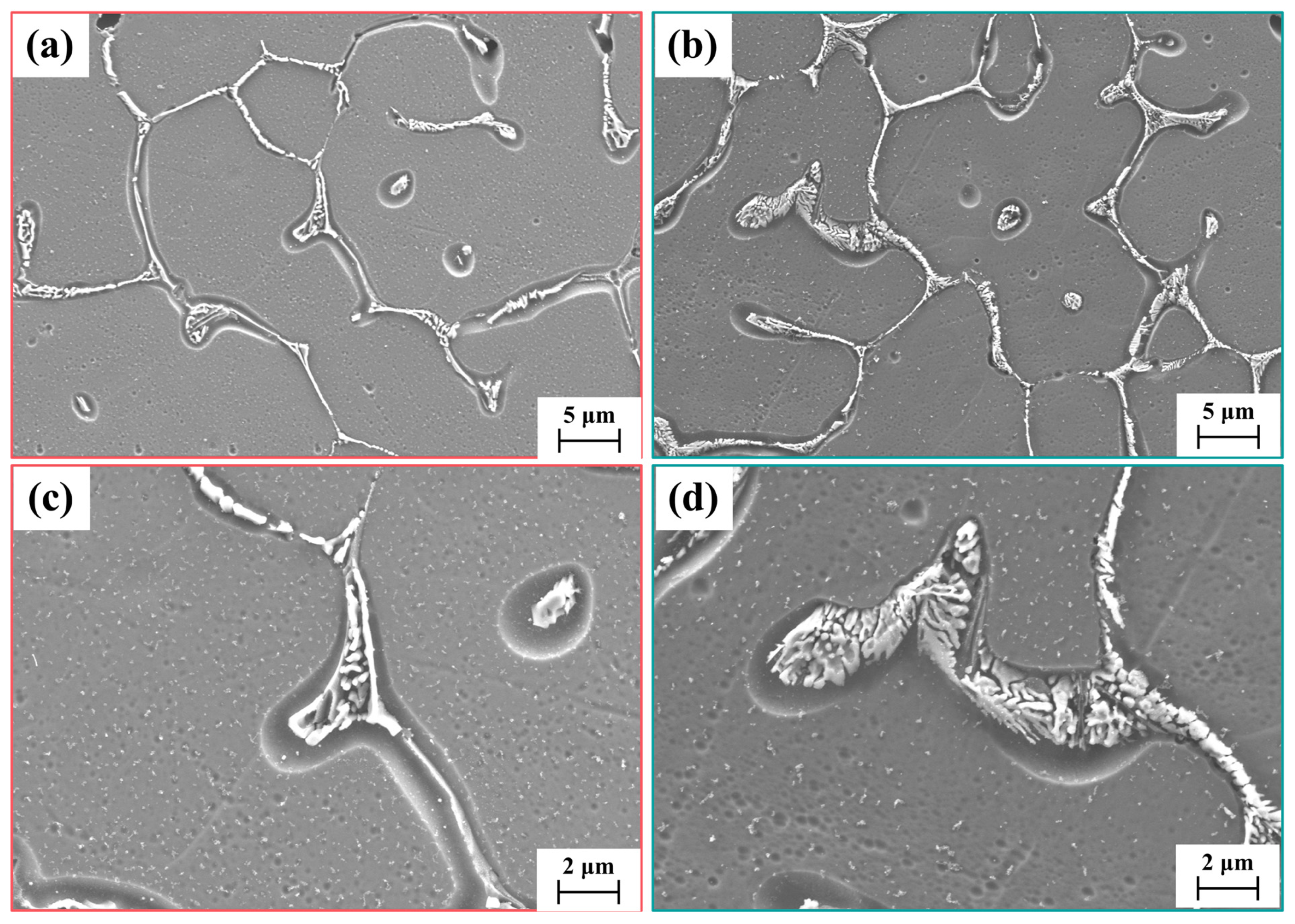

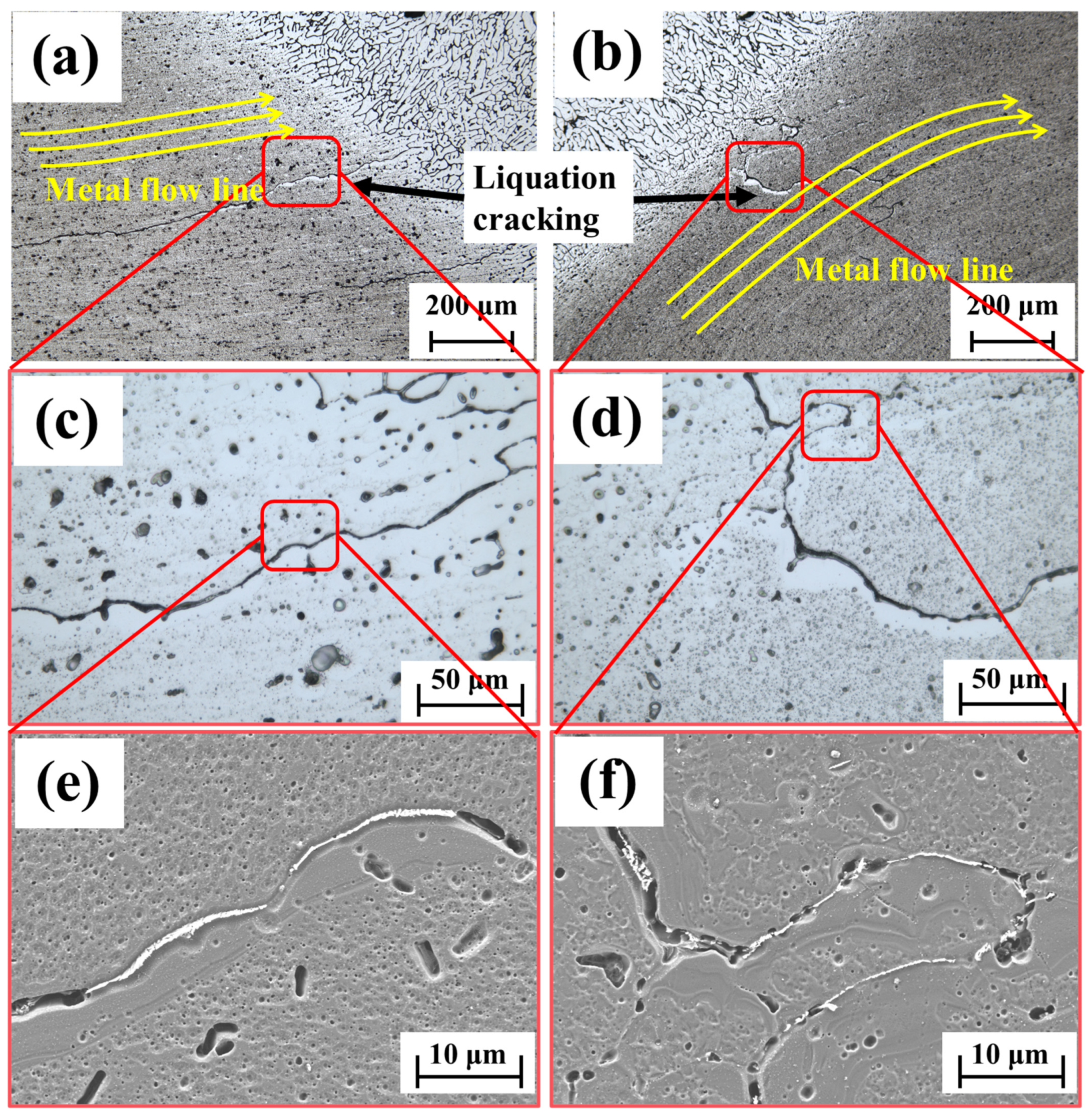

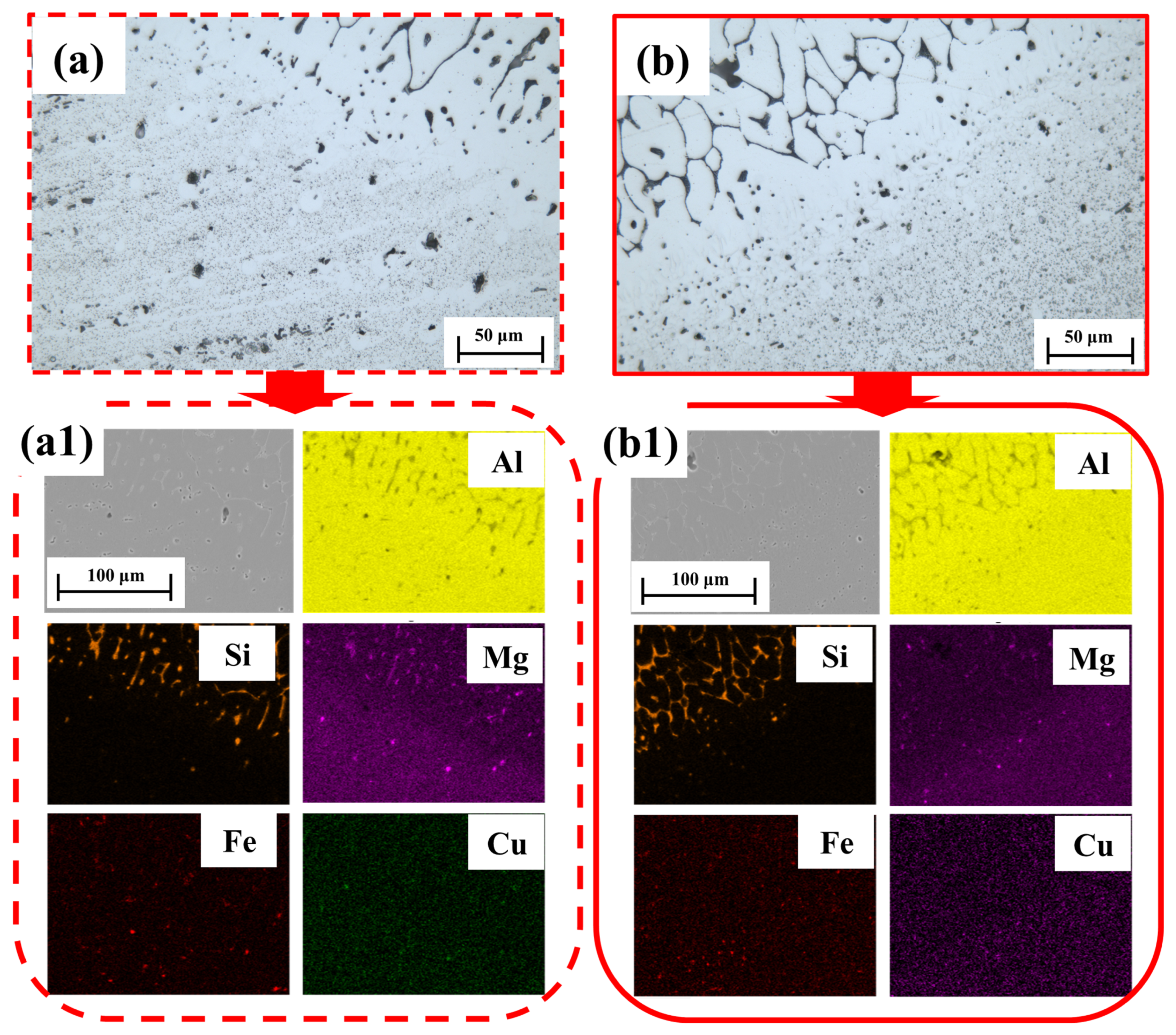

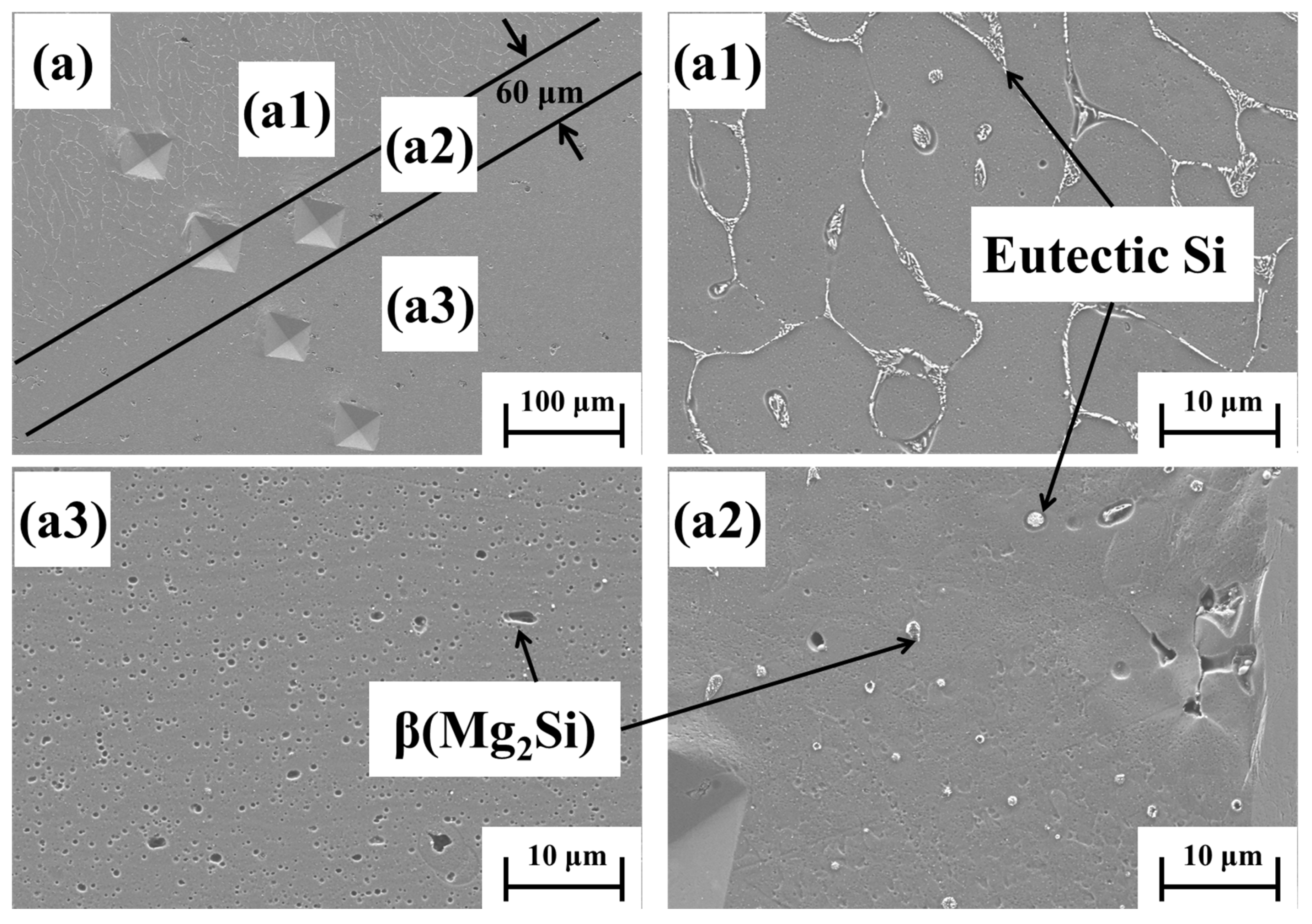

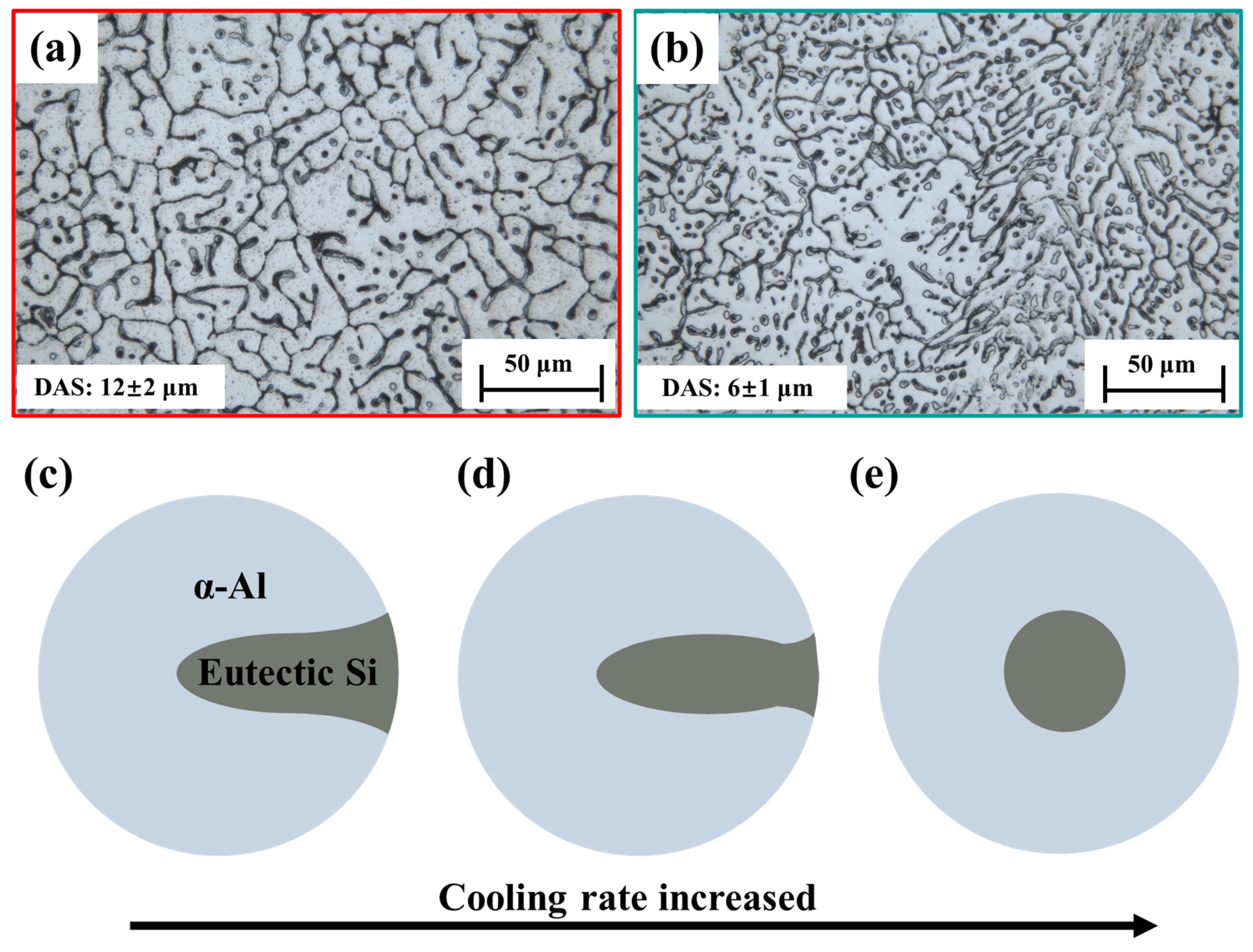

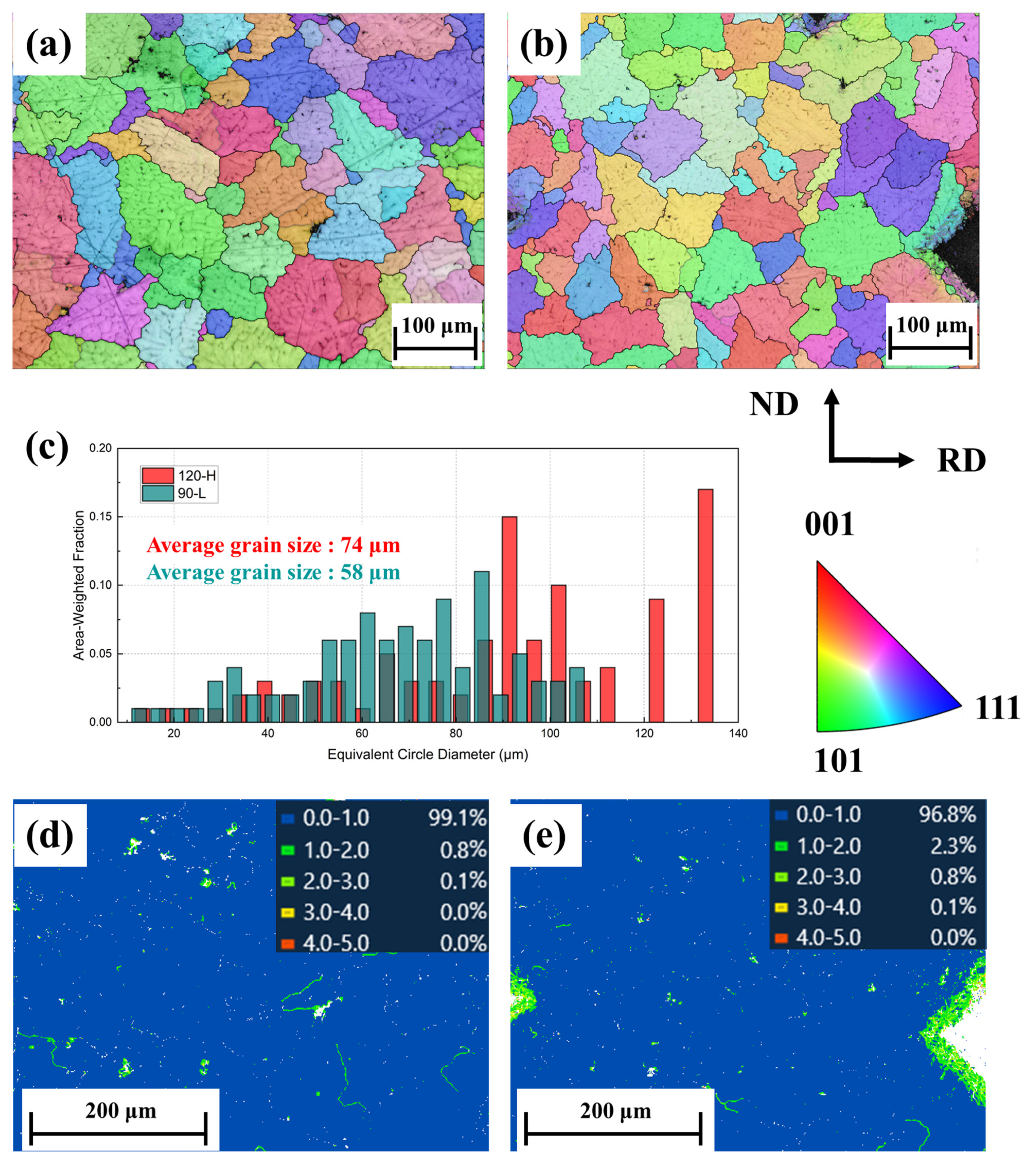

3.3. Microstructure

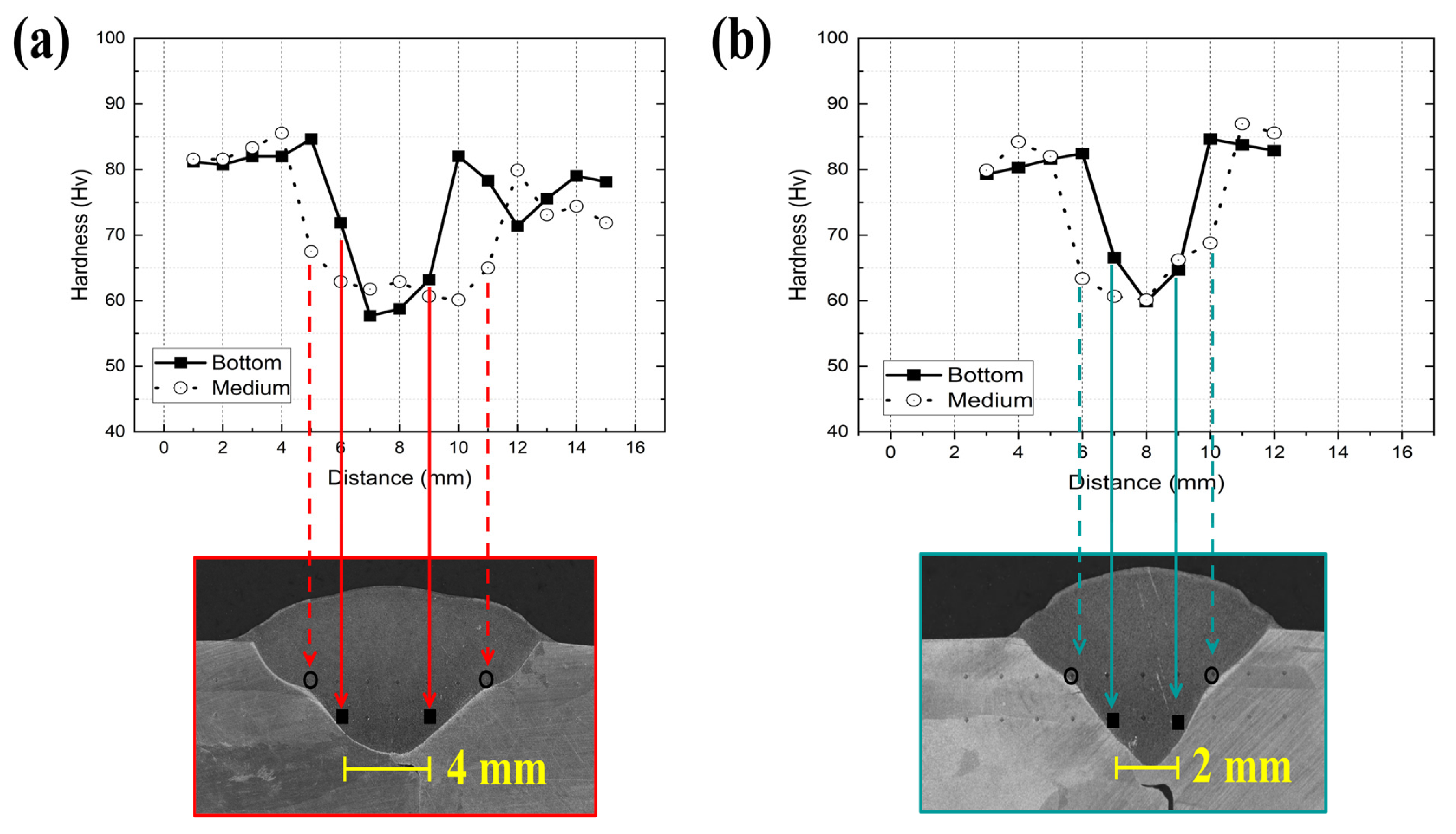

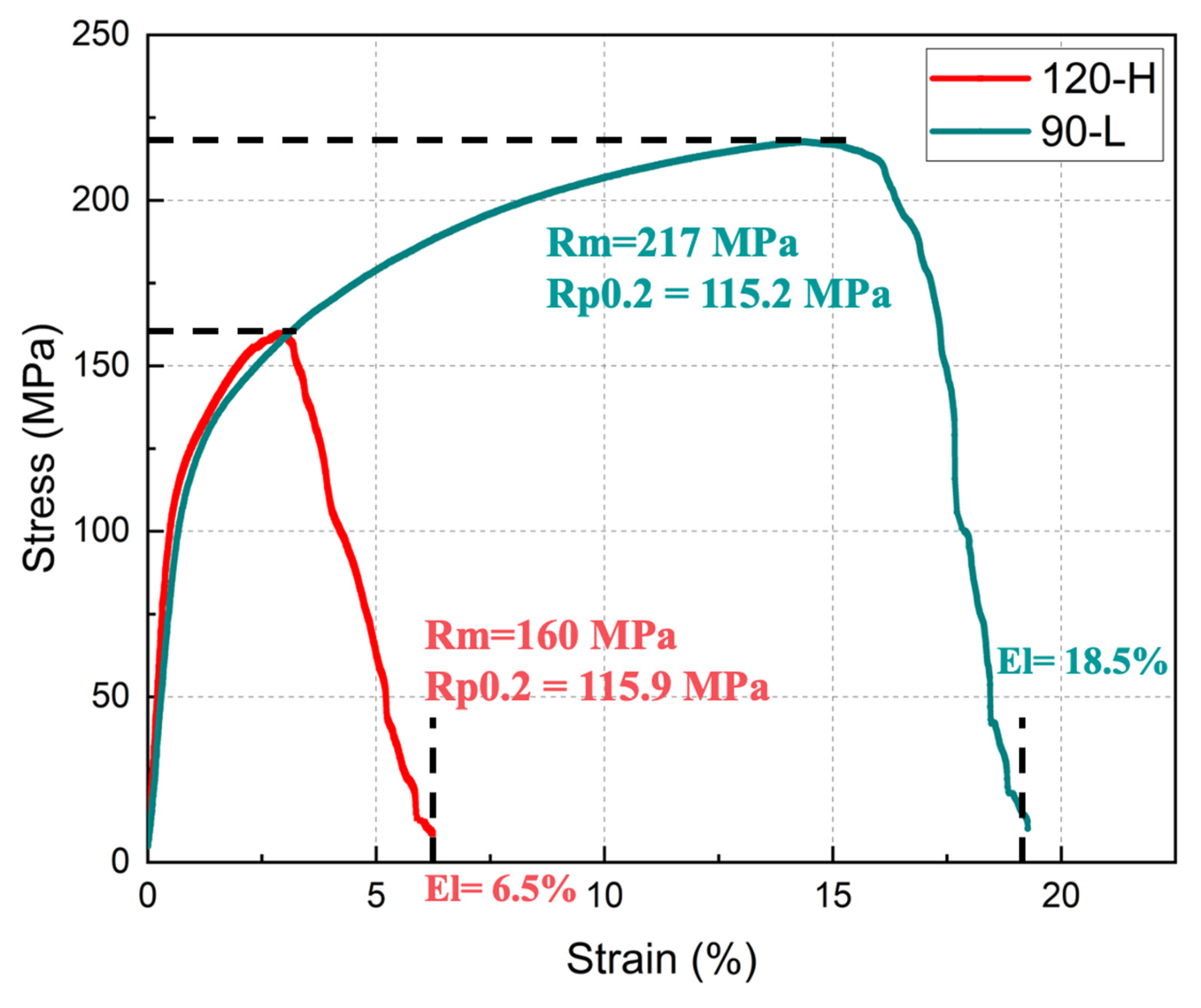

3.4. Hardness and Tensile Test

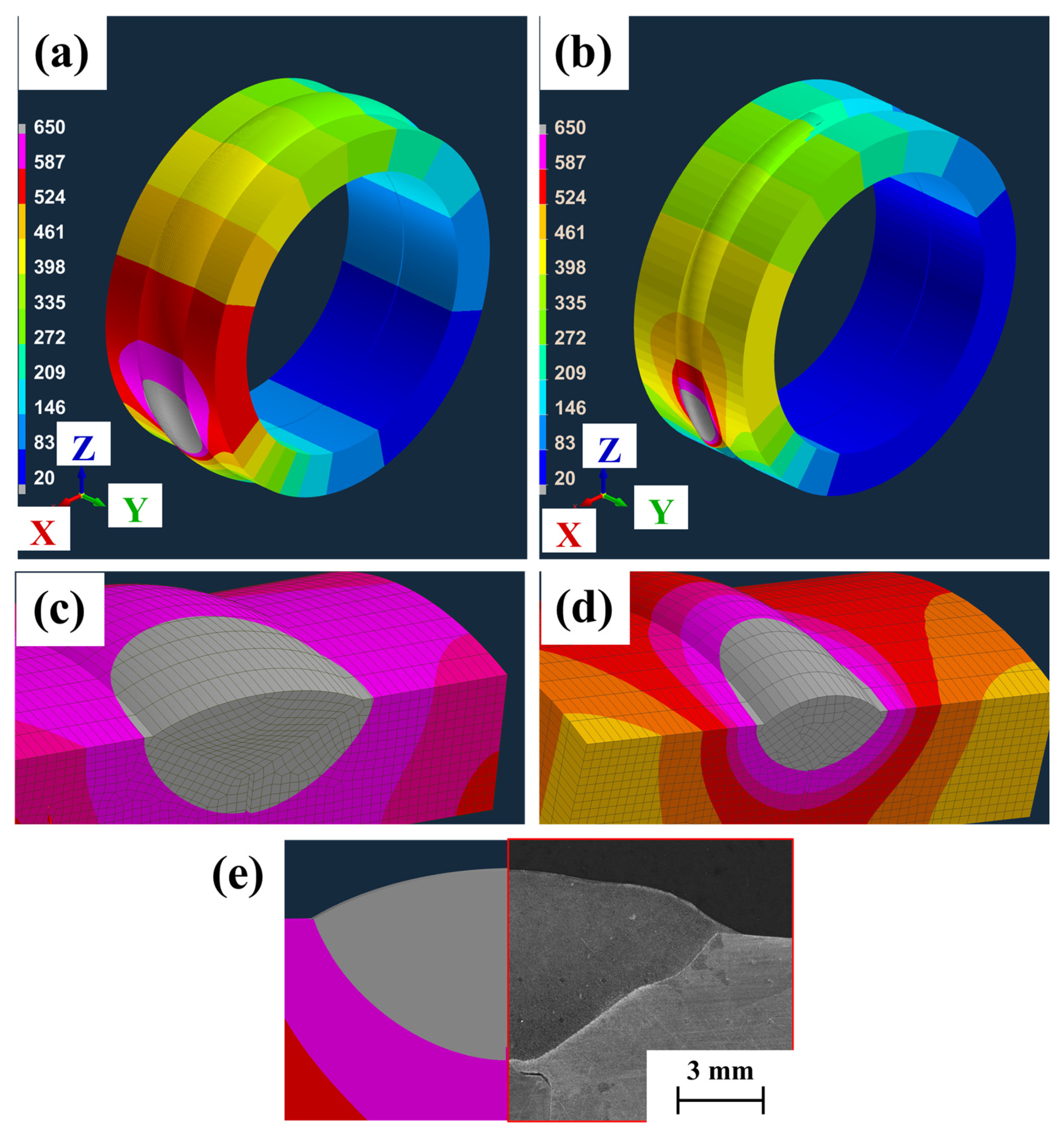

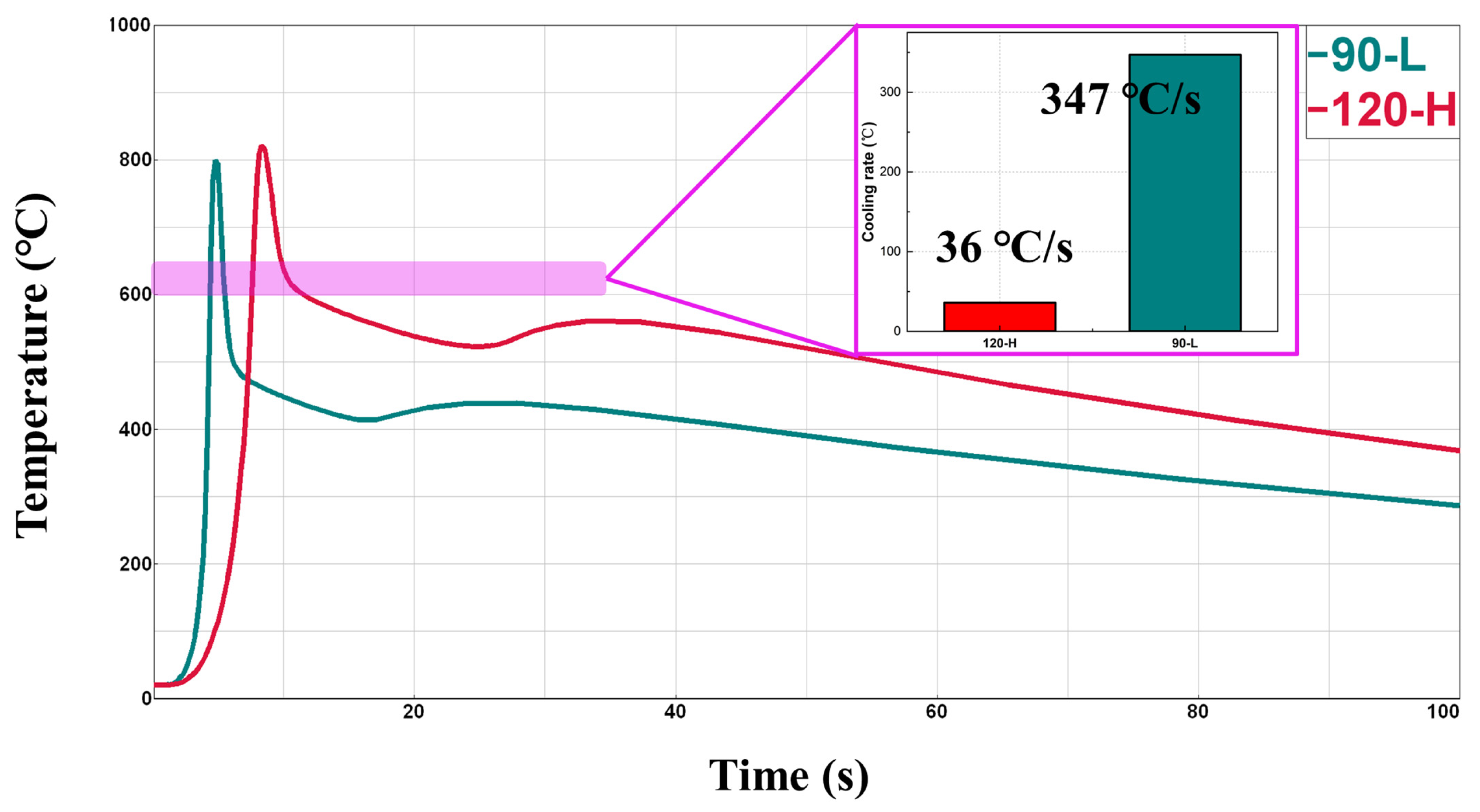

3.5. Numerical Simulation Results

4. Discussion

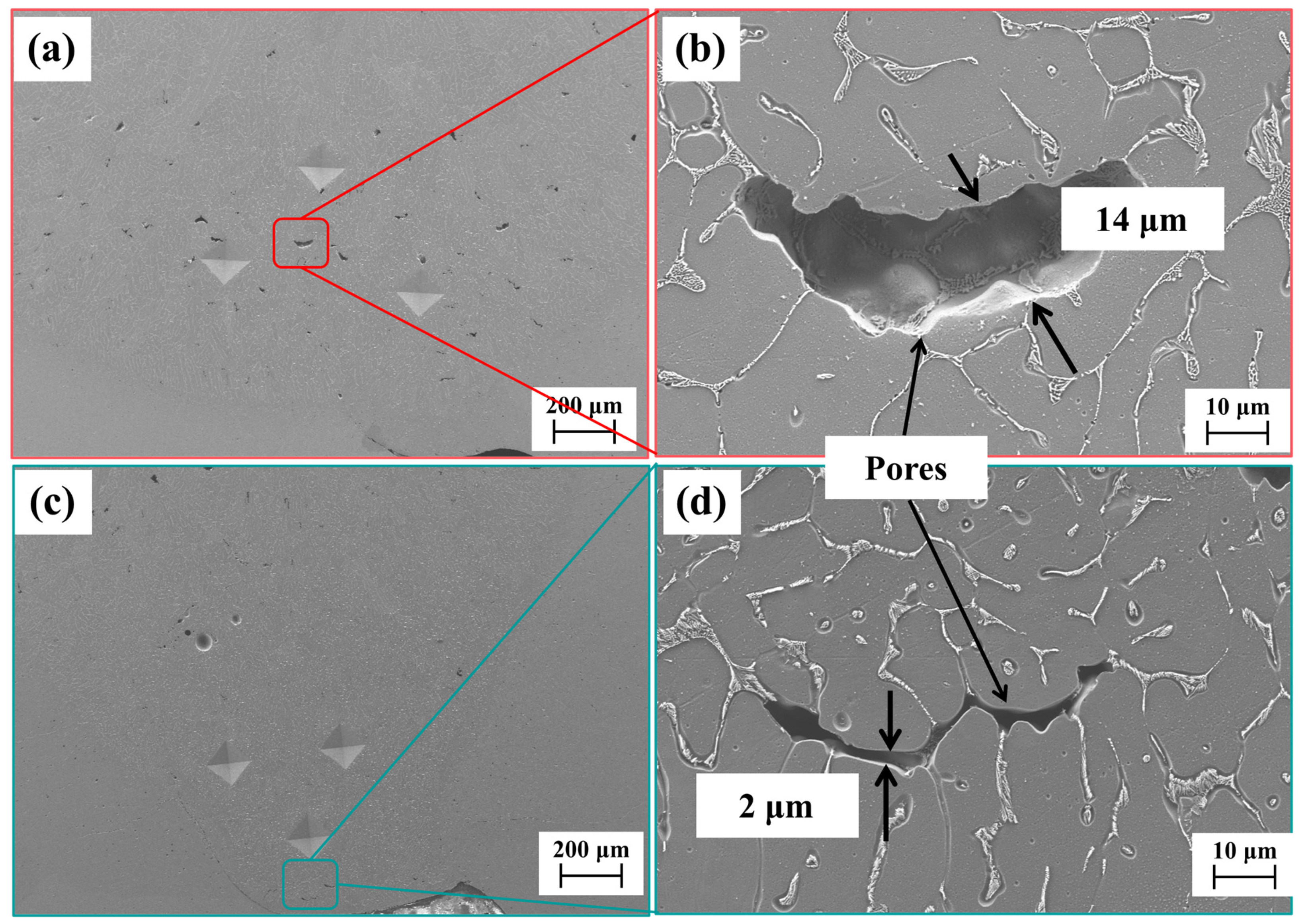

4.1. Effect of Heat Input on Liquation Crack and Porosity

4.2. Effect of Heat Input on Microstructure and Mechanical Property

5. Conclusions

- Porosity concentrates in the arc start transient relative to the steady-state region for both 120-H and 90-L, identifying arc initiation as a critical weak link. This underscores the need to optimize ignition energy, shielding stability, and welding parameters.

- Relative to low heat input (90-L), high heat input (120-H) produces higher porosity and a less favorable microstructure, leading to inferior mechanical performance. Within the present process window, a 90° groove is preferred unless substantial improvements are implemented for the 120° groove.

- Faster cooling under 90-L reduces dendrite arm spacing (DAS), shifts eutectic Si morphology from coarse plate/needle-like to finer, more discontinuous forms, and measurably refines the α-Al grain structure. While these grains are not readily resolved by optical microscopy, EBSD orientation mapping delineates the refinement.

- Liquation cracks exhibit preferential growth along forging metal flow lines in the base metal, and their interaction with groove geometry degrades joint performance. Co-optimization of flow line orientation and groove/root geometry, combined with low heat input strategies, is recommended to mitigate cracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nie, Y.; Zhang, P.; Wu, X.; Li, G.; Yan, H.; Yu, Z. Rapid Prototyping of 4043 Al-Alloy Parts by Cold Metal Transfer. Sci. Technol. Weld. Join. 2018, 23, 527–535. [Google Scholar] [CrossRef]

- Kazmi, K.H.; Das, A.K.; Sharma, S.K.; Mandal, A.; Shukla, A.K. Wire Arc Additive Manufacturing of ER-4043 Aluminum Alloy: Evaluation of Bead Profile, Microstructure, and Wear Behavior. Weld. World 2023, 67, 2187–2200. [Google Scholar] [CrossRef]

- Ahmed, M.; Javidani, M.; Maltais, A.; Chen, X.-G. Microstructure and Mechanical Properties of High-Strength AA6011 Aluminum Alloy Welding with Novel 4xxx Filler Metals. Materials 2024, 17, 380. [Google Scholar] [CrossRef]

- Ortega, A.G.; Corona Galvan, L.; Salem, M.; Moussaoui, K.; Segonds, S.; Rouquette, S.; Deschaux-Beaume, F. Characterisation of 4043 Aluminium Alloy Deposits Obtained by Wire and Arc Additive Manufacturing Using a Cold Metal Transfer Process. Sci. Technol. Weld. Join. 2019, 24, 538–547. [Google Scholar] [CrossRef]

- Nur Azida, C.L.; Ibrahim, M.F.A.; Jalar, A.; Sharif, J.; Othman, N.K.; Rashdi, N.M. The Effect of Filler ER4043 and ER5356 on Porosity Distribution of Welded AA6061 Aluminum Alloy. Adv. Mater. Res. 2010, 146–147, 987–990. [Google Scholar] [CrossRef]

- Liang, Y.; Shen, J.; Hu, S.; Wang, H.; Pang, J. Effect of TIG current on microstructural and mechanical properties of 6061-T6 aluminium alloy joints by TIG–CMT hybrid welding. J. Mater. Process. Technol. 2018, 255, 161–174. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of Cold Metal Transfer (CMT) Process for Welding Aluminium Alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and Mechanical Property Considerations in Additive Manufacturing of Aluminum Alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Kah, P.; Martikainen, J.; Hiltunen, E.; Brhane, F.; Karkhin, V. Hot Cracking Susceptibility of Wrought 6005 and 6082 Aluminium Alloys. In Hot Cracking Phenomena in Welds III; Lippold, J., Böllinghaus, T., Cross, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 59–69. [Google Scholar]

- Vargas, J.A.; Torres, J.E.; Pacheco, J.A.; Hernandez, R.J. Analysis of Heat Input Effect on the Mechanical Properties of Al-6061-T6 Alloy Weld Joints. Mater. Des. 2013, 52, 556–564. [Google Scholar] [CrossRef]

- Gulshan, F.; Ahsan, Q. Effect of Heat Input on the Structure and Properties of Aluminium Weldment TIG Welded with 4043 Filler Rod. Chem. Mater. Eng. 2014, 2, 25–32. [Google Scholar] [CrossRef]

- Dorta-Almenara, M.; Capace, M.C. Microstructure and Mechanical Properties of GTAW Welded Joints of AA6105 Aluminum Alloy. Rev. Facultad Ingeniería 2016, 25, 7–19. [Google Scholar] [CrossRef]

- Knapp, G.L.; Gussev, M.; Shyam, A.; Feldhausen, T.; Plotkowski, A. Microstructure, Deformation and Fracture Mechanisms in Al-4043 Alloy Produced by Laser Hot-Wire Additive Manufacturing. Addit. Manuf. 2022, 59, 103150. [Google Scholar] [CrossRef]

- Dada, M.; Popoola, P. Recent Advances in Joining Technologies of Aluminum Alloys: A Review. Discov. Mater. 2024, 4, 86. [Google Scholar] [CrossRef]

- Habibi, I.; Triyono; Muhayat, N. A Review on Aluminum Arc Welding and Its Problems. In Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials, Surakarta, Indonesia, 16–17 October 2019; Sabino, U., Imaduddin, F., Prabowo, A.R., Eds.; Springer: Singapore, 2020; pp. 819–826. [Google Scholar]

- Nunes, R.; Faes, K.; De Waele, W.; Simar, A.; Verlinde, W.; Lezaack, M.; Sneyers, W.; Arnhold, J. A Review on the Weldability of Additively Manufactured Aluminium Parts by Fusion and Solid-State Welding Processes. Metals 2023, 13, 1724. [Google Scholar] [CrossRef]

- Henry, S.; Minghetti, T.; Rappaz, M. Dendrite Growth Morphologies in Aluminium Alloys. Acta Mater. 1998, 46, 6431–6443. [Google Scholar] [CrossRef]

- Shankar, S.; Riddle, Y.W.; Makhlouf, M.M. Eutectic Solidification of Aluminum–Silicon Alloys. Metall. Mater. Trans. A 2004, 35, 3038–3043. [Google Scholar] [CrossRef]

- Rosa, D.M.; Spinelli, J.E.; Garcia, A. Tertiary Dendrite Arm Spacing during Downward Transient Solidification of Al–Cu and Al–Si Alloys. Mater. Lett. 2006, 60, 1871–1874. [Google Scholar] [CrossRef]

- Coniglio, N.; Cross, C.E.; Dörfel, I.; Österle, W. Phase Formation in 6060/4043 Aluminum Weld Solidification. Mater. Sci. Eng. A 2009, 517, 321–327. [Google Scholar] [CrossRef]

- Ujjwal, K.; Anand Kumar, K.; Anand, M.; Singh Raman, R.K.; Das, A.K. Effect of Current Waveforms during Directed Energy Deposition of 4043 Aluminum Alloy on Microstructure, Hardness, and Wear of Alloy. Materials 2023, 16, 6716. [Google Scholar] [CrossRef]

- Kelly, S.M. Thermal and Microstructure Modeling of Metal Deposition Processes with Application to Ti-6Al-4V. Ph.D. Thesis, Virginia Polytechnic Institute & State University, Blacksburg, VA, USA, 2004. [Google Scholar]

- Fu, R.; Tang, S.; Lu, J.; Cui, Y.; Li, Z.; Zhang, H.; Xu, T.; Chen, Z.; Liu, C. Hot-Wire Arc Additive Manufacturing of Aluminum Alloy with Reduced Porosity and High Deposition Rate. Mater. Des. 2021, 199, 109419. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Wang, B.B.; Xie, G.M.; Wu, L.H.; Xue, P.; Ni, D.R.; Xiao, B.L.; Liu, Y.D.; Ma, Z.Y. Grain Size Effect on Tensile Deformation Behaviors of Pure Aluminum. Mater. Sci. Eng. A 2021, 820, 141504. [Google Scholar] [CrossRef]

- Schempp, P.; Cross, C.E.; Häcker, R.; Pittner, A.; Rethmeier, M. Influence of Grain Size on Mechanical Properties of Aluminium GTA Weld Metal. Weld. World 2013, 57, 245–254. [Google Scholar] [CrossRef]

- Yuan, T.; Kou, S.; Luo, Z. Grain Refining by Ultrasonic Stirring of the Weld Pool. Acta Mater. 2016, 106, 144–154. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.; Zheng, Y.; Fraser, H.; StJohn, D.; Easton, M. Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mg | Mn | Zn | Cr | Ti | V | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 4043 | Filler metal | 6 | 0.8 | 0.3 | 0.05 | 0.05 | 0.1 | 0 | 0.2 | - |

| 120-H | Base metal | 0.69 | 0.38 | 0.28 | 1.04 | 0.11 | 0.016 | 0.14 | 0.05 | 0.015 |

| 90-L | Base metal | 0.7 | 0.155 | 0.24 | 1.01 | 0.08 | 0.009 | 0.09 | 0.08 | 0.024 |

| Feed Rate (m/min) | Voltage (V) | Current (A) | Welding Speed (cm/min) | Q (J) | Heat Input (J/mm) | |

|---|---|---|---|---|---|---|

| 120-H | 5.9 | 17.9 | 135 | 39 | 2416.5 | 223 |

| 90-L | 6.3 | 18.4 | 143 | 64 | 2631.2 | 149 |

| Model Parameters | 120-H | 90-L |

|---|---|---|

| Material (base metals) | 6061 | |

| Material (weld metals) | AlMgSi | |

| Density (kg/m3) | 2.7 | |

| Specific heat (J/kg·K) | 900 | |

| Thermal conductivity (W/m·K) | 560 | |

| Ambient temperature (°C) | 20 | |

| Element size (mm3) | ~0.4 | |

| Heat source parameter (af + ar) | 10 mm | 10 mm |

| Heat source parameter (b) | 9 mm | 5 mm |

| Heat source parameter (c) | 2 mm | 2 mm |

| Arc type | MIG | |

| Arc efficiency | 60% | |

| Si | Fe | Cu | Mg | Mn | Zn | Cr | Ti | V | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 120-H | Base metal | 0.69 | 0.38 | 0.28 | 1.04 | 0.11 | 0.016 | 0.14 | 0.05 | 0.015 |

| 120-H | Weld metal | 3.1 | 0.21 | 0.148 | 0.44 | 0.05 | 0.016 | 0.08 | 0.05 | 0.014 |

| 90-L | Base metal | 0.7 | 0.155 | 0.24 | 1.01 | 0.08 | 0.009 | 0.09 | 0.08 | 0.024 |

| 90-L | Weld metal | 3.07 | 0.12 | 0.12 | 0.48 | 0.05 | 0.013 | 0.05 | 0.05 | 0.016 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xian, G.; Gao, Z.; Fu, Y.; Ding, Z.; Que, X.; Pan, J. Effect of CMT Welding Heat Input on Microstructure and Mechanical Properties of Different Groove Angles for Al-6061-T6 Alloy Joint. Metals 2025, 15, 1290. https://doi.org/10.3390/met15121290

Xian G, Gao Z, Fu Y, Ding Z, Que X, Pan J. Effect of CMT Welding Heat Input on Microstructure and Mechanical Properties of Different Groove Angles for Al-6061-T6 Alloy Joint. Metals. 2025; 15(12):1290. https://doi.org/10.3390/met15121290

Chicago/Turabian StyleXian, Guo, Zhen Gao, Yunfeng Fu, Zhao Ding, Xianshu Que, and Jingbang Pan. 2025. "Effect of CMT Welding Heat Input on Microstructure and Mechanical Properties of Different Groove Angles for Al-6061-T6 Alloy Joint" Metals 15, no. 12: 1290. https://doi.org/10.3390/met15121290

APA StyleXian, G., Gao, Z., Fu, Y., Ding, Z., Que, X., & Pan, J. (2025). Effect of CMT Welding Heat Input on Microstructure and Mechanical Properties of Different Groove Angles for Al-6061-T6 Alloy Joint. Metals, 15(12), 1290. https://doi.org/10.3390/met15121290