Influence of Ball Burnishing Path Strategy on Surface Integrity and Performance of Laser-Cladded Inconel 718 Alloys

Abstract

1. Introduction

2. Materials and Methods

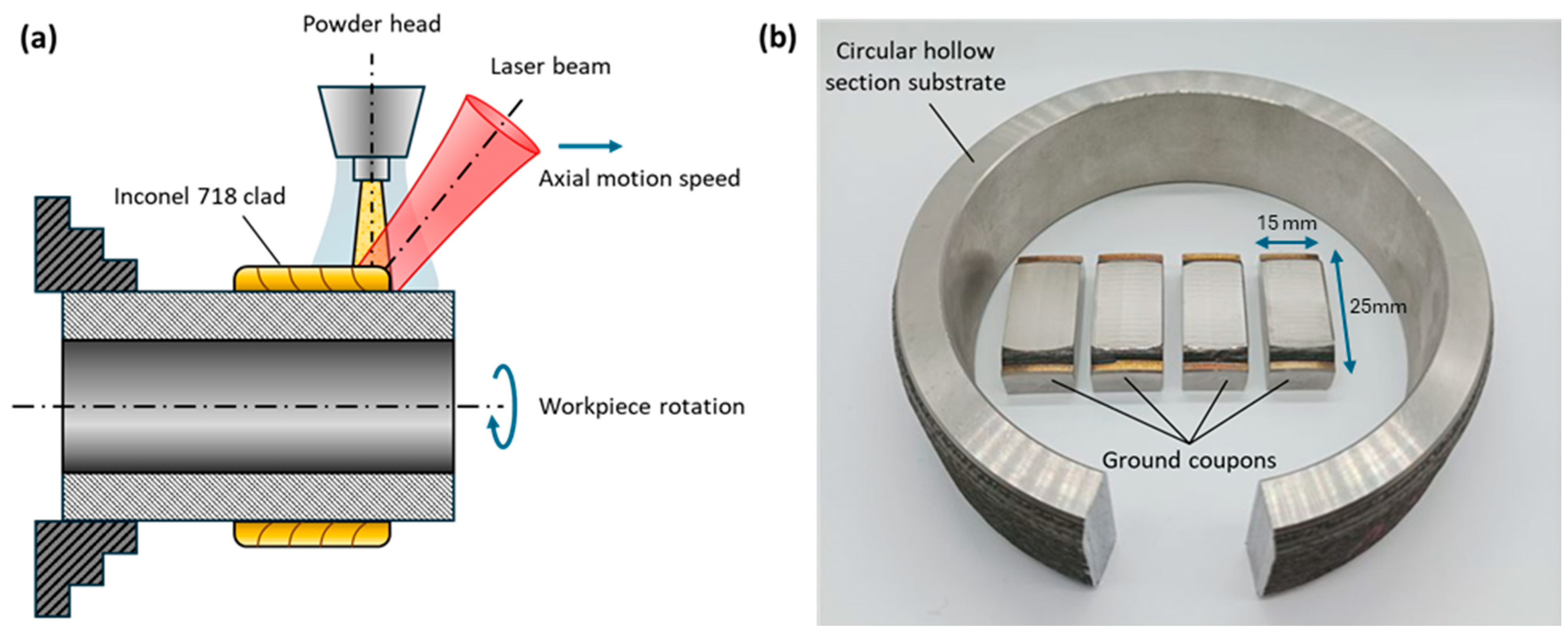

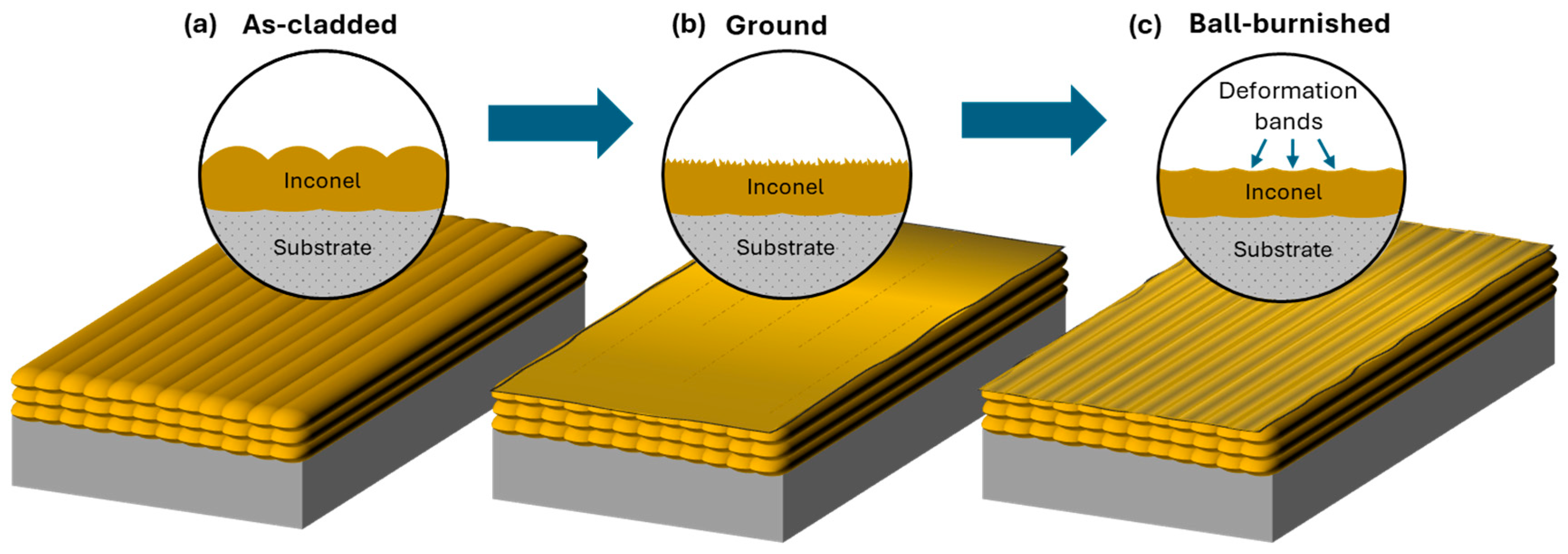

2.1. Laser Cladding and Sample Preparation

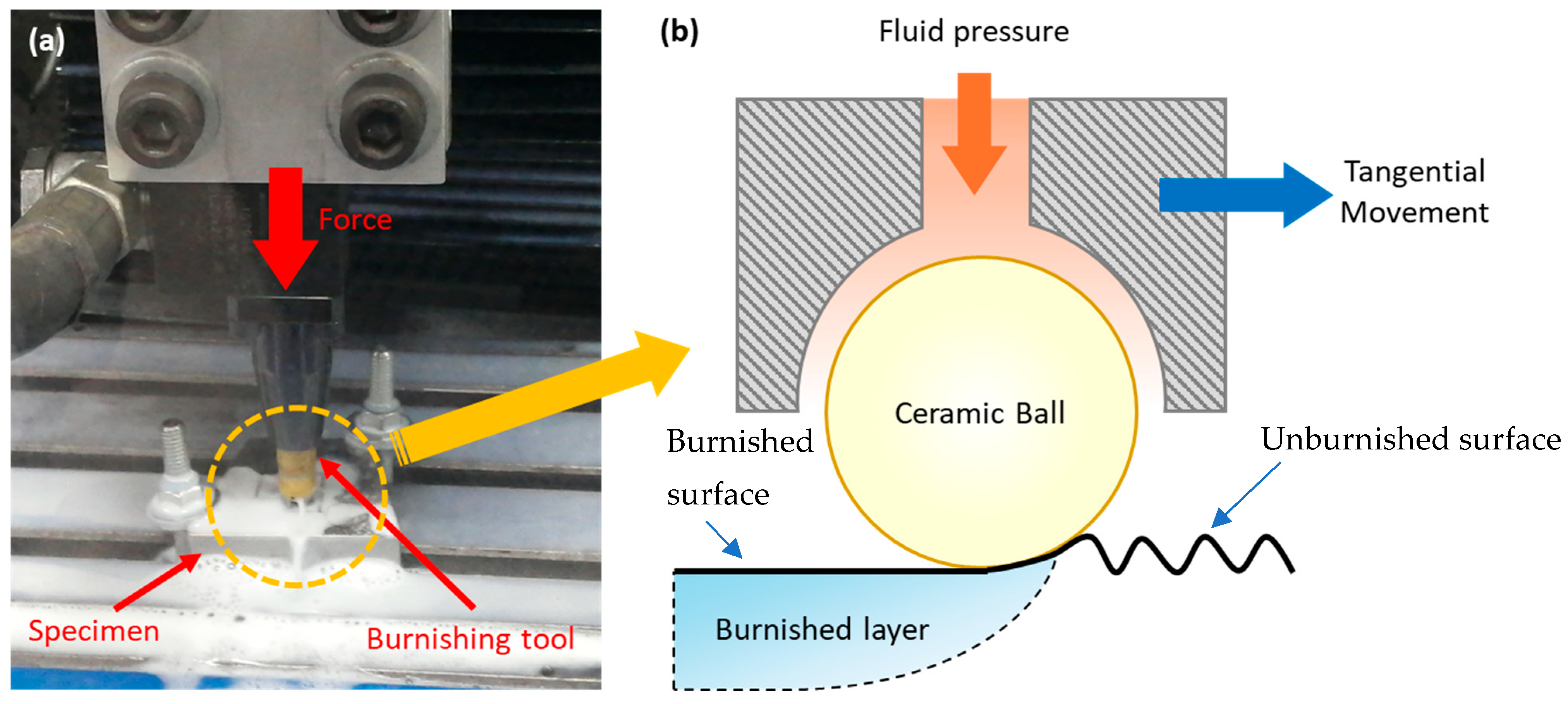

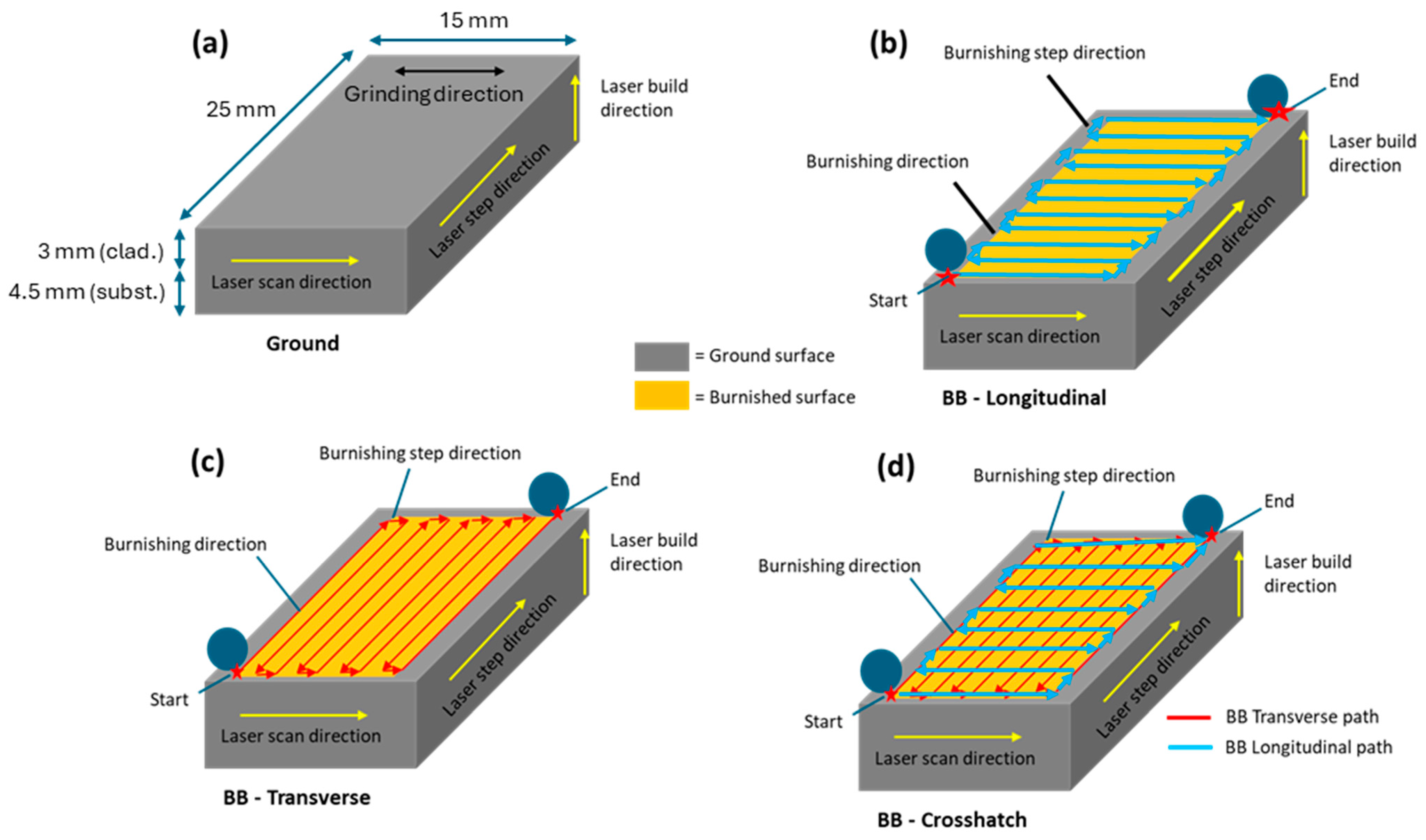

2.2. Ball Burnishing Experimental

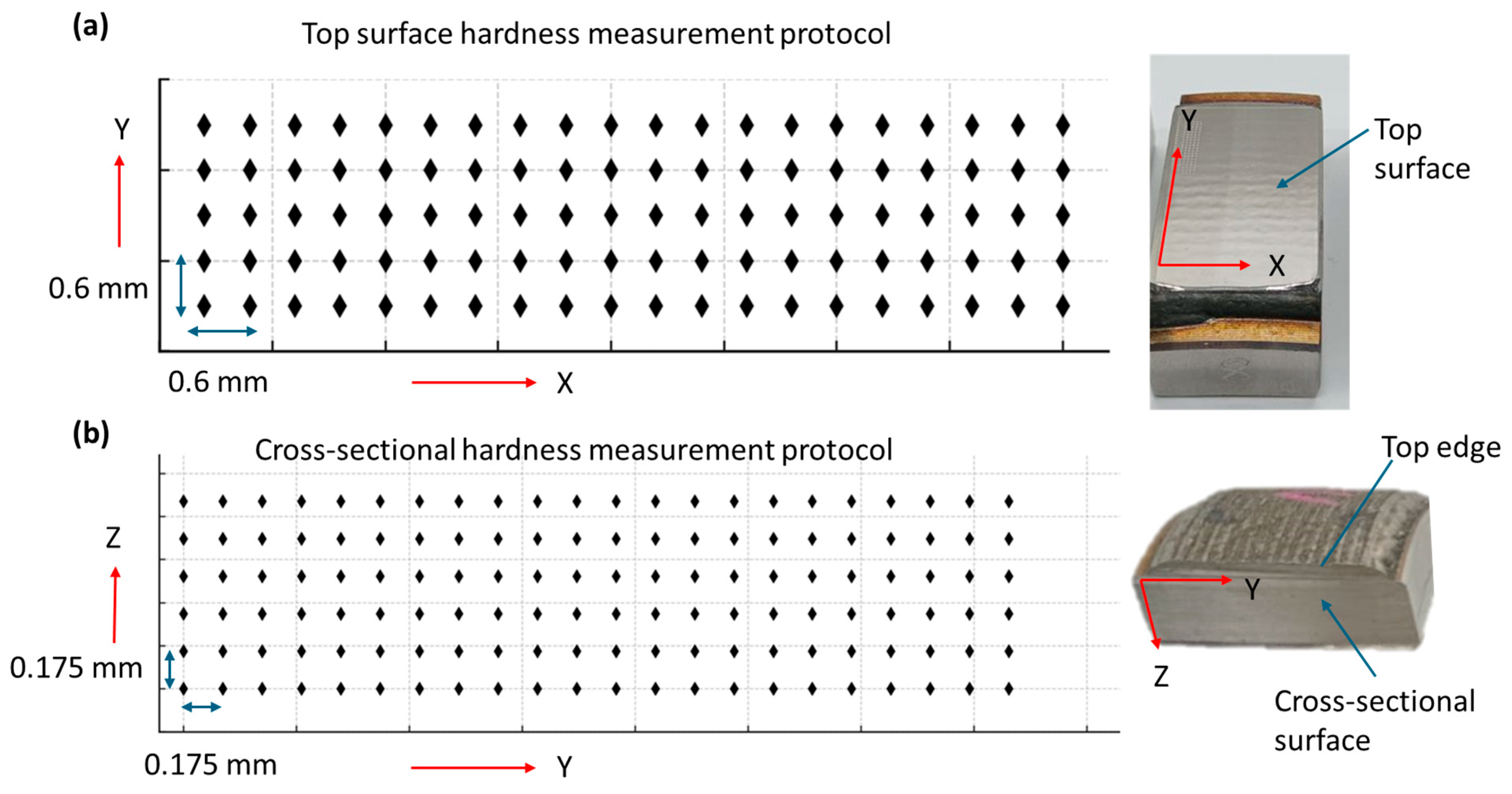

2.3. Material Characterization

2.4. Performance Assessment

3. Results and Discussions

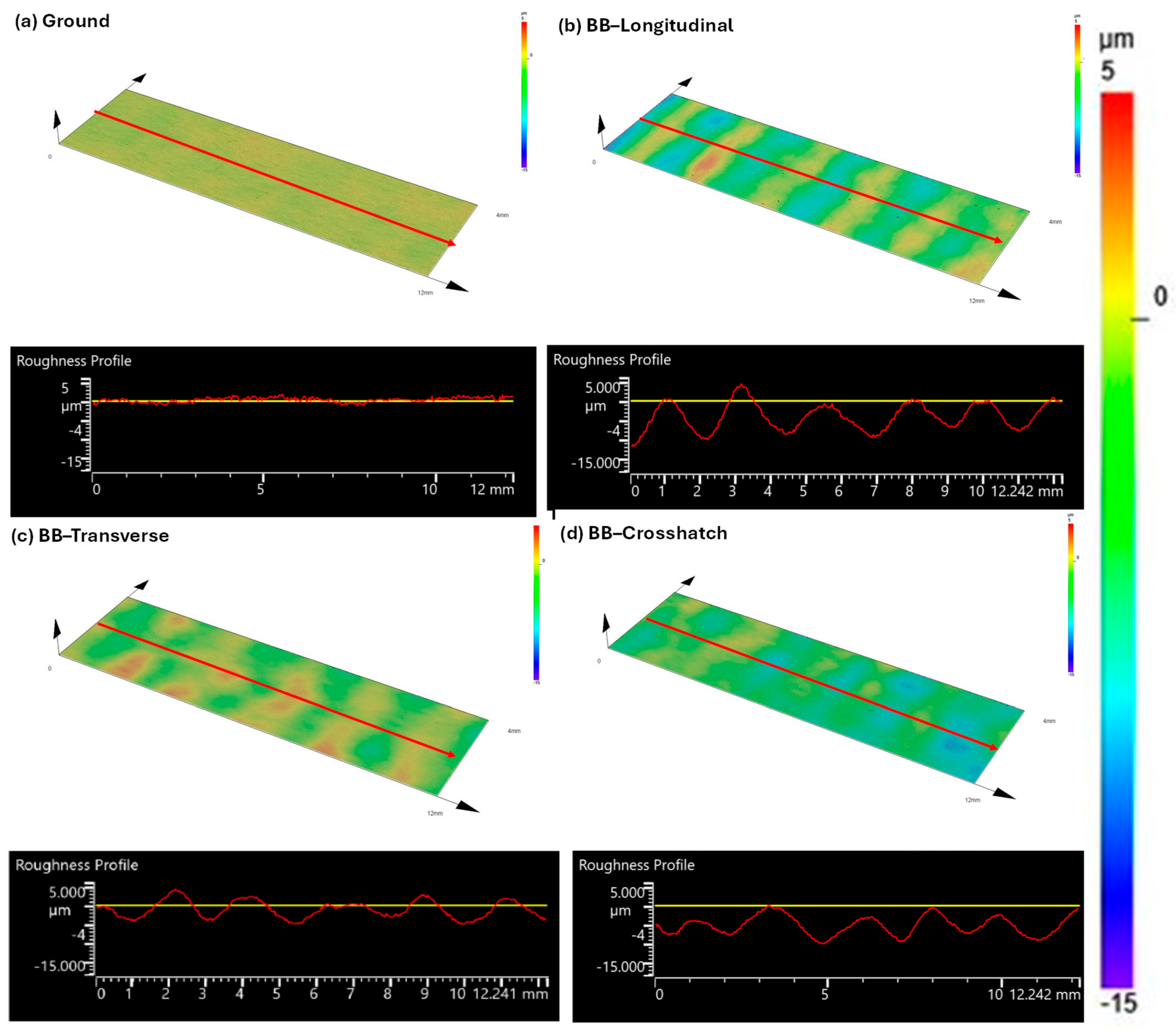

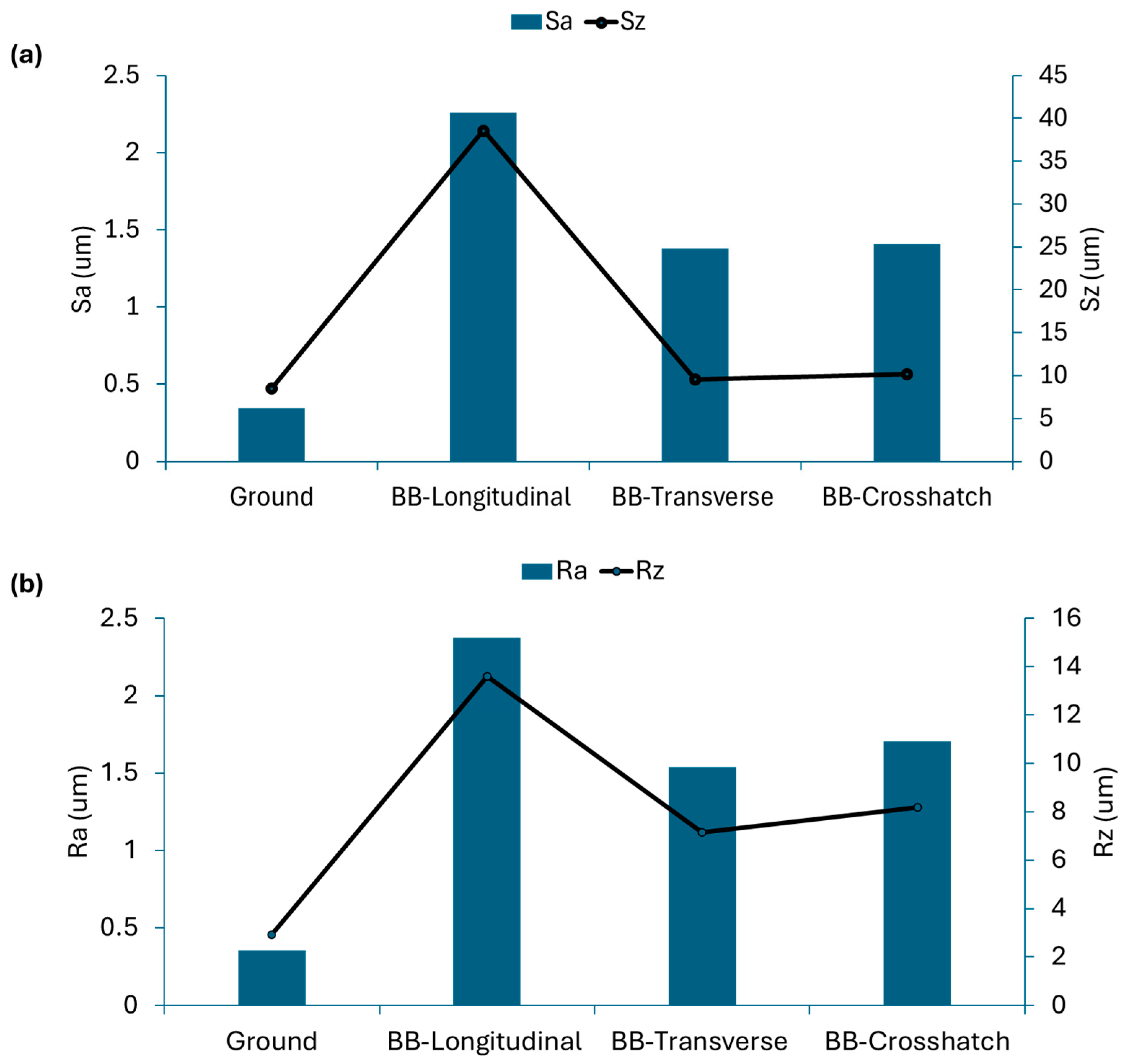

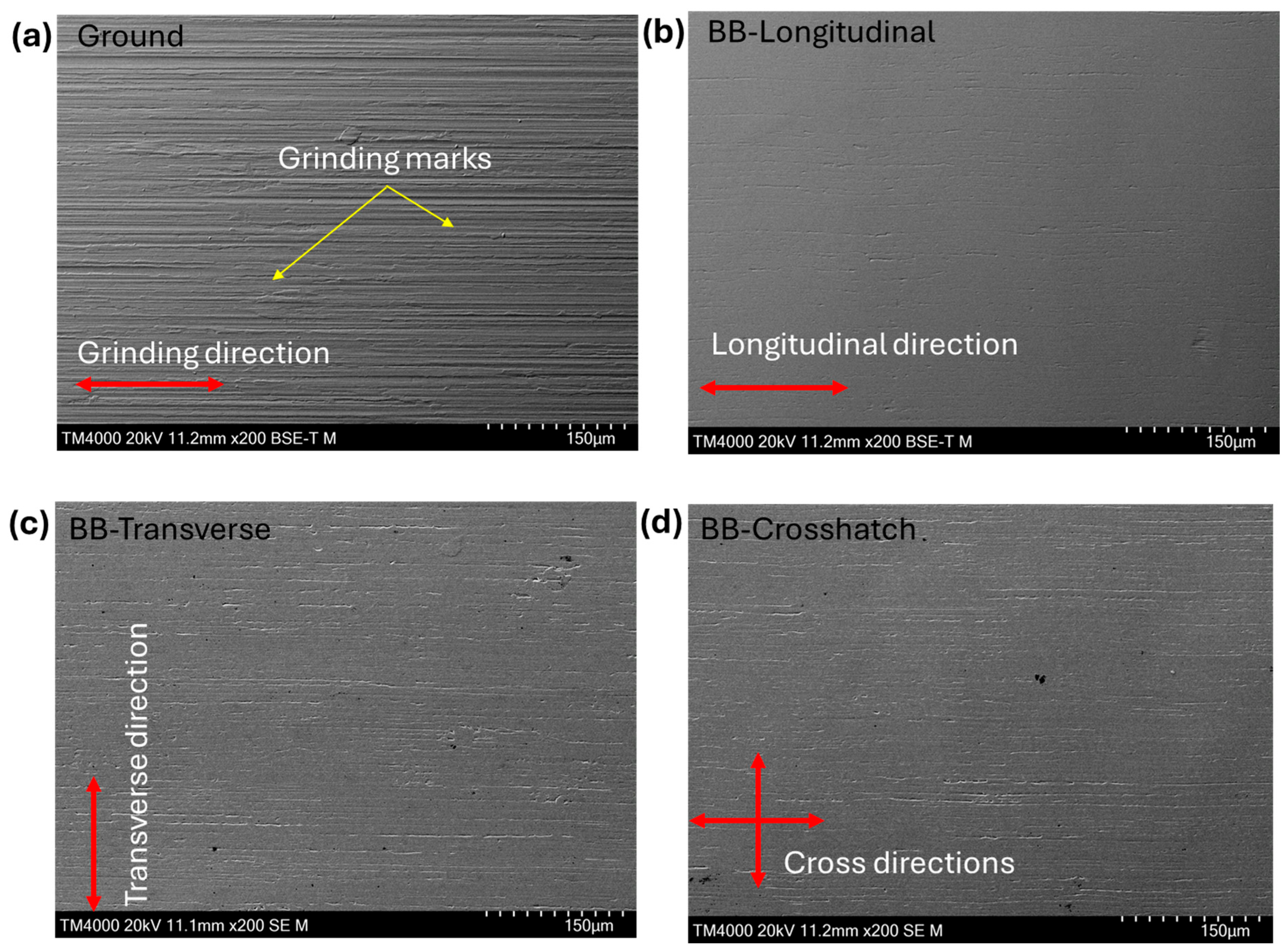

3.1. Surface Roughness and Topography Analysis

3.2. EBSD Microstructural Analysis

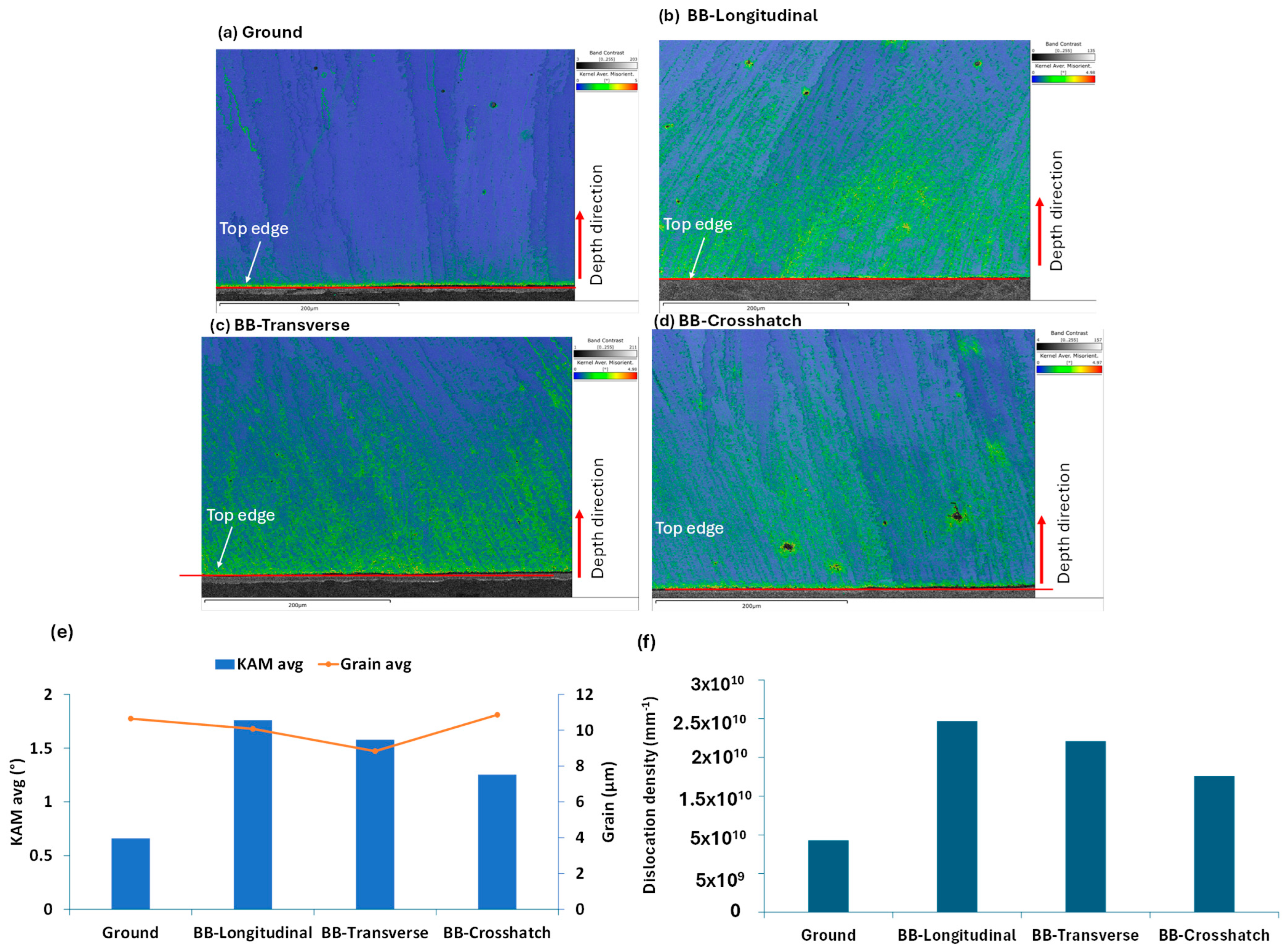

3.2.1. Kernel Average Misorientation (KAM) Analysis

3.2.2. Grain Boundary and Texture Analysis

3.3. Hardness Analysis

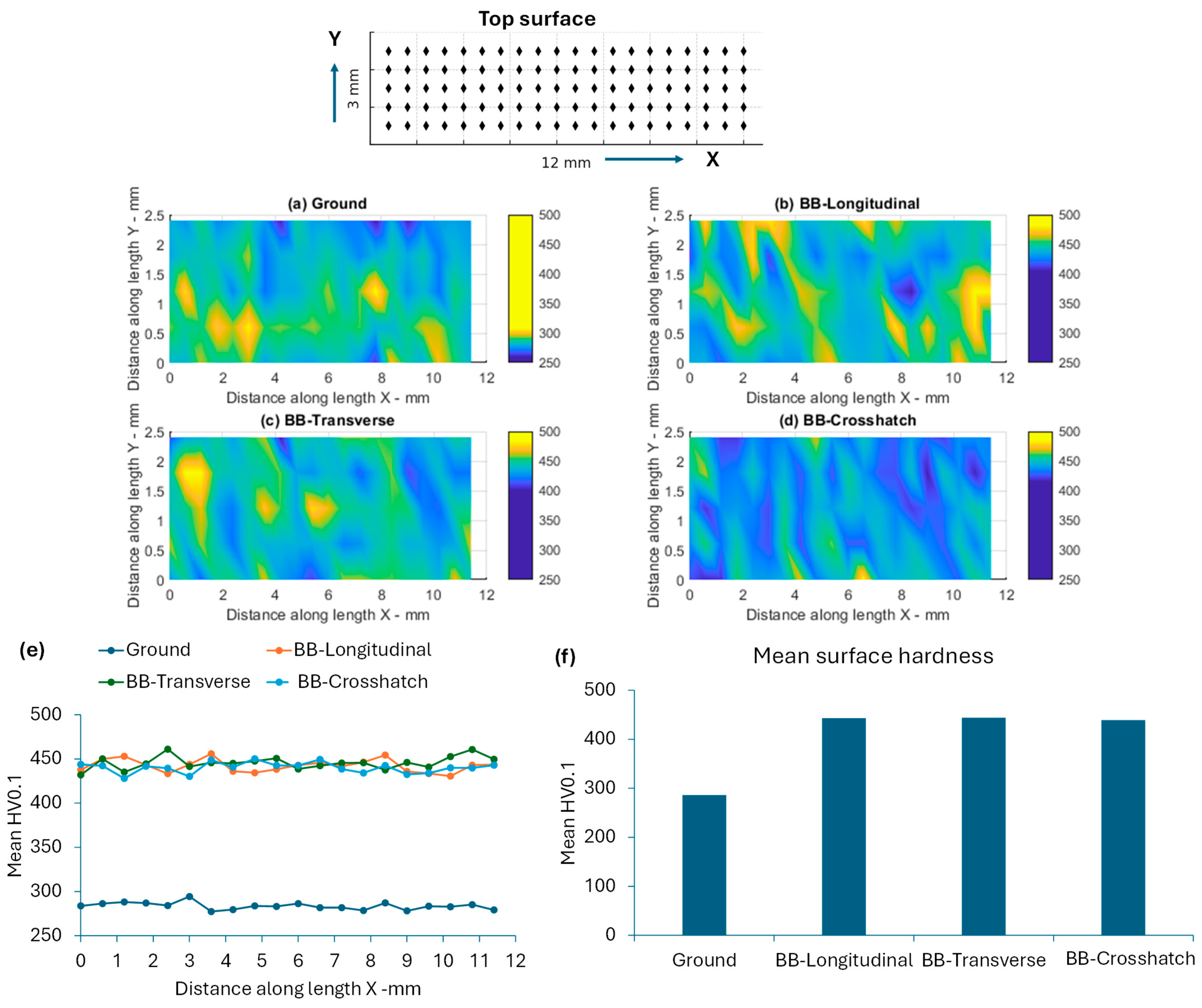

3.3.1. Surface Hardness Analysis

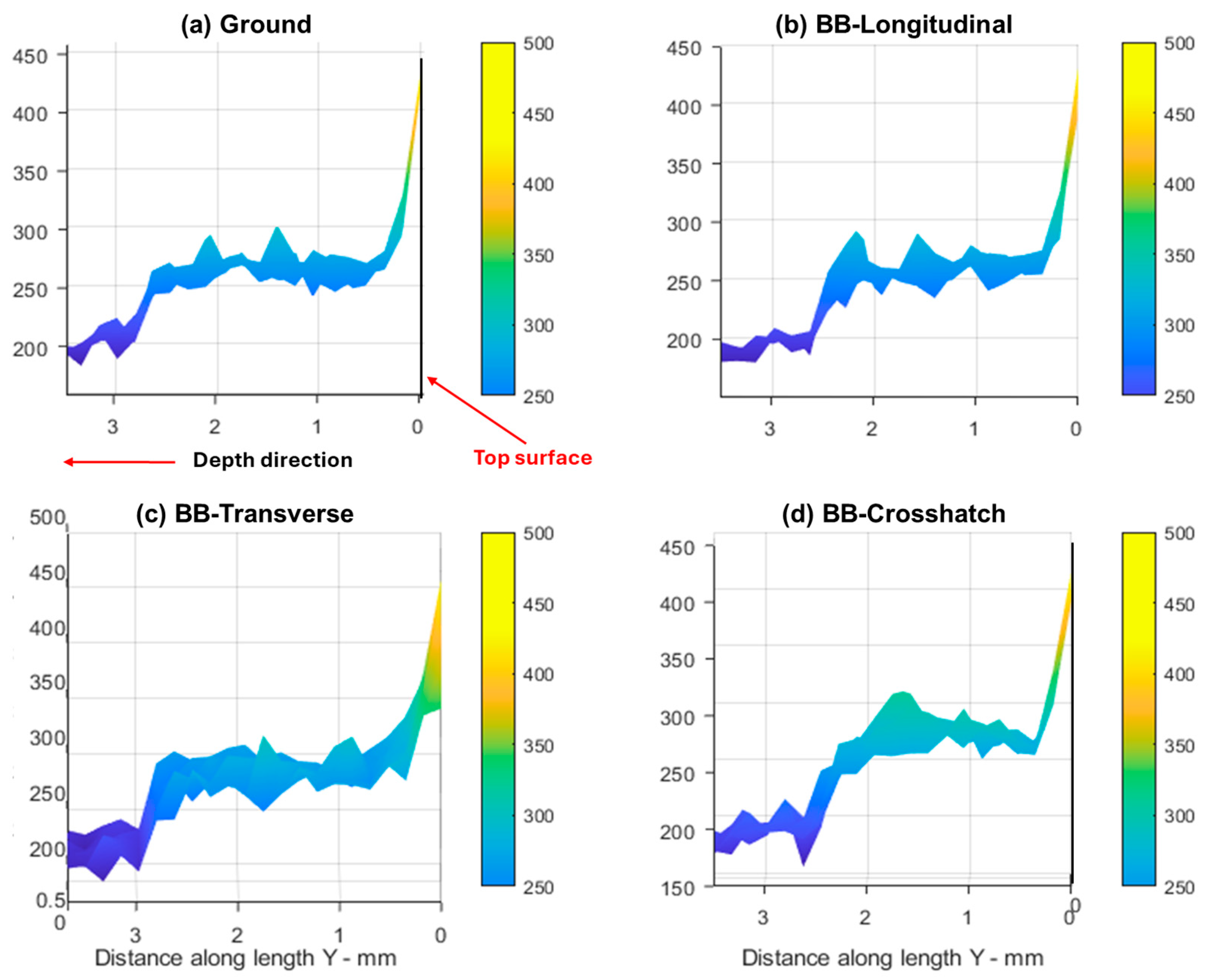

3.3.2. Cross-Section Hardness Analysis

3.4. Materials Performance

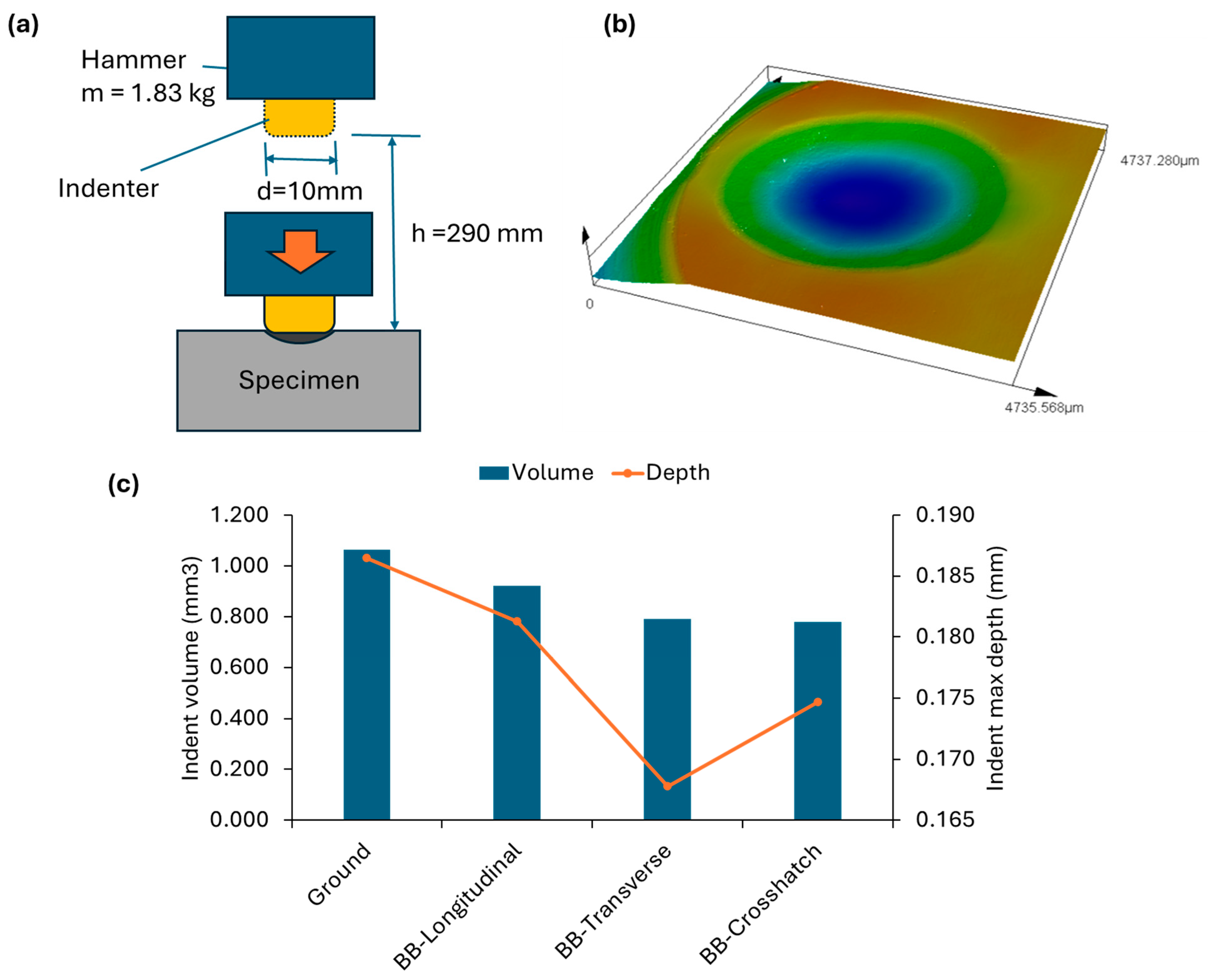

3.4.1. Impact Resistance

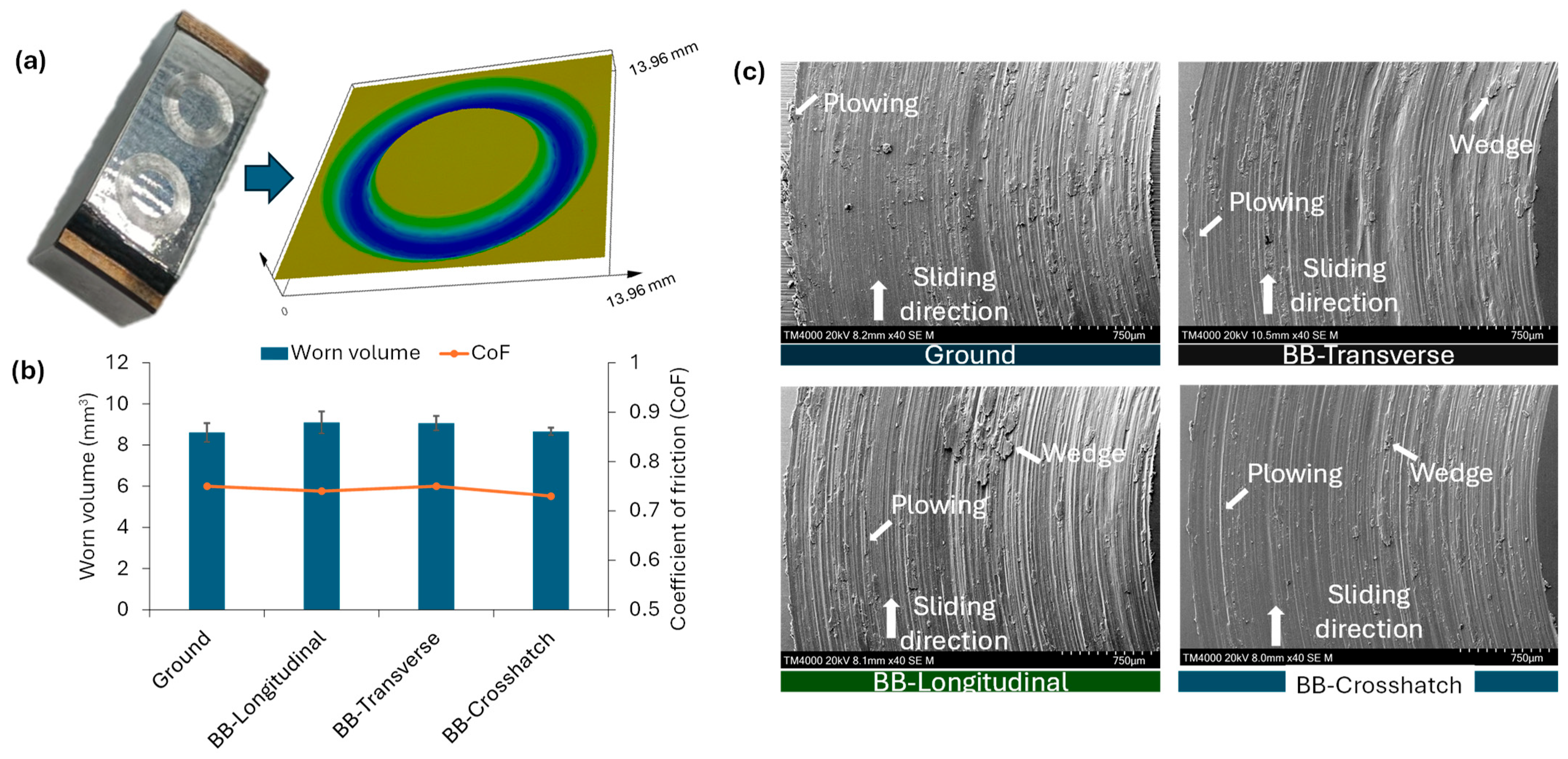

3.4.2. Sliding Wear Testing

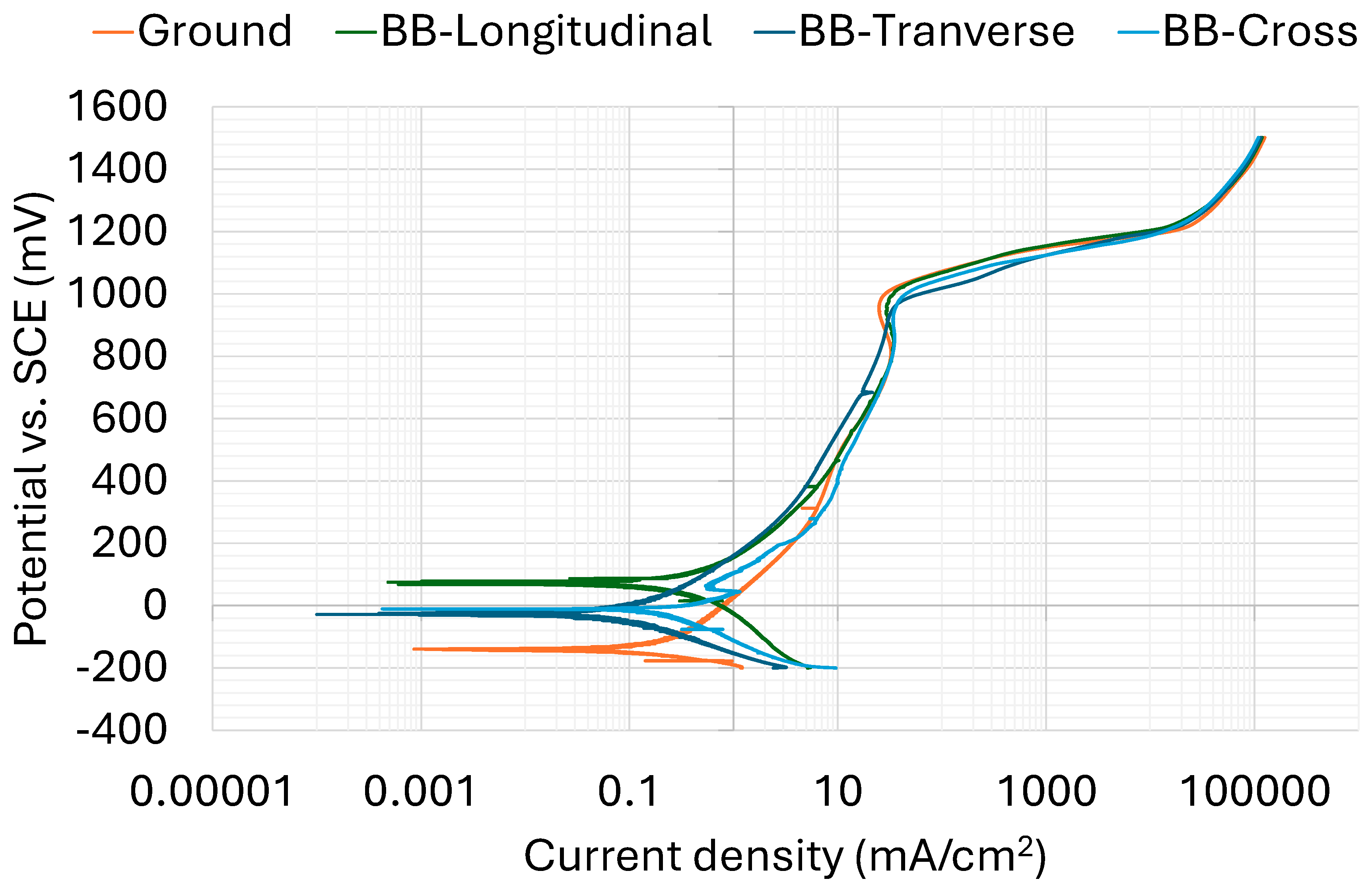

3.4.3. Electrochemical Corrosion Test

4. Conclusions

- Compared to the ground surface, the burnishing produced modulated surface profile, and this is more pronounced for BB-Longitudinal condition, while BB-Transverse and BB-Crosshatch exhibited moderate increase in profile and surface roughness. BB-Crosshatch may be selected if improved roughness is preferred.

- EBSD results showed that the burnishing induced the plastic straining in the cladded surface, as compared to the ground specimen. BB-Longitudinal and BB-Transverse showed higher KAM and dislocation density from the top edge. This is also aligned with the increase in LAGBs and reduction in HAGBs for both conditions. BB-Crosshatch seems to reduce these effects by neutralizing the straining due to second pass of burnishing direction perpendicular to first pass.

- The burnishing increased surface hardness by up to 64%, as compared to the ground surface, while the effect of BB path strategy on hardness is relatively small or marginal. However, BB-Transverse showed higher cross-sectional hardness with deeper modification layer up to about 400 µm, as opposed to BB-Longitudinal and BB-Crosshatch with improved hardness depth of about 250 µm. This is aligned with EBSD results.

- BB-Longitudinal and BB-Crosshatch conditions exhibited 35% reduction in indent volume and 11% reduction in indent depth compared to the ground sample. This enhancement was attributed to improved surface hardness introduced by ball burnishing, which enhanced the material’s yielding resistance to impact loading.

- BB-Longitudinal and BB-Transverse showed higher worn volume which can be due to high surface roughness, while BB-Crosshatch showed moderate resistance to wear. CoF followed the trend for worn volume for BB-treatment patterns. SEM analysis confirmed abrasion as the dominant wear mechanism for all cases.

- Compared to other treatments, BB-Longitudinal pattern enhanced corrosion resistance significantly, as evidenced by a higher corrosion potential (Ecorr). A slight increase in corrosion current density (icorr) indicated a marginally faster general corrosion rate. For all treated conditions, the pitting potential (Epit) remained consistent, demonstrating maintained resistance to localized corrosion. The discrepancy between SEM and confocal topography highlights the complex interplay between surface smoothing and induced undulations. These features may influence corrosion potential through changes in surface strain and residual stress distribution, particularly when burnishing is aligned with the cladding direction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, P.; Jha, S.; Dewangan, S.; Agarwal, A. The Structure and Properties of Inconel 718 after Heat Treatment and Cooling in Various Media. J. Mater. Eng. Perform. 2024, 34, 16958–16973. [Google Scholar] [CrossRef]

- Ajay, P.; Dabhade, V.V. Heat Treatments of Inconel 718 Nickel-Based Superalloy: A Review. Met. Mater. Int. 2025, 31, 1204–1231. [Google Scholar] [CrossRef]

- Cano-Salinas, L.; Salem, M.; Moussaoui, K.; Le Roux, S.; Hor, A.; Zitoune, R. Laser Metal Deposition as Repair Technology for Inconel 718. Int. J. Adv. Manuf. Technol. 2025, 136, 2193–2208. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, L.; Li, Z.; Yu, M.; Gao, Y.; Liang, H. Microstructure and Properties of Inconel 718 Coatings with Different Laser Powers on the Surface of 316L Stainless Steel Substrate. Coatings 2023, 13, 1947. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Günen, A.; Ceritbinmez, F.; Bahador, A.; Nakano, T.; Çetin, M. Wire-EDM Performance and Surface Integrity of Inconel 718 with Unique Microstructural Features Fabricated by Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2024, 130, 4513–4528. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-Processing of the Inconel 718 Alloy Parts Fabricated by Selective Laser Melting: Effects of Mechanical Surface Treatments on Surface Topography, Porosity, Hardness and Residual Stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Banderas-Hernández, J.A.; Rubio-González, C.; Gómez-Ortega, A.; Flores-García, S.; Martínez-Pérez, C.E. Laser Shock Peening as a Post-Processing Technique for Inconel 718 Components Manufactured by Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2024, 132, 669–687. [Google Scholar] [CrossRef]

- Mebarek, A.M.; Bourebia, M.; Laouar, L.; Bouchelaghem, N. Effect of Ball Burnishing Process on Surface Roughness and Corrosion Behavior of S235JR Steel. Int. J. Adv. Manuf. Technol. 2024, 130, 3431–3444. [Google Scholar] [CrossRef]

- Uddin, M.; Santifoller, R.; Hall, C.; Schlaefer, T. A Grinding-Burnishing Approach to Enhancing Surface Integrity, Tribological, and Corrosion Behavior of Laser-Cladded AISI 431 Alloys. J. Manuf. Sci. Eng. 2022, 144, 71003. [Google Scholar] [CrossRef]

- Thit, M.; Rocissano, A.; Hatem, A.; Uddin, M.; Hall, C.; Schlaefer, T. Surface Integrity and High-Cycle Fatigue Life of Direct Laser Metal Deposited AISI 431 Alloys Modified by Plasticity Ball Burnishing. Int. J. Fatigue 2025, 190, 108614. [Google Scholar] [CrossRef]

- Sequera, A.; Fu, C.H.; Guo, Y.B.; Wei, X.T. Surface Integrity of Inconel 718 by Ball Burnishing. J. Mater. Eng. Perform. 2014, 23, 3347–3353. [Google Scholar] [CrossRef]

- Okada, M.; Nakagawa, H.; Nikawa, M.; Kitagawa, S. Texture Formation and Surface Characteristics in an Intermittent Burnishing Process Utilizing Plastic Flow of Surface Material. Nanomanuf. Metrol. 2025, 8, 19. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; Figueras, J. Evaluation of the Mechanical Properties of Inconel 718 Components Built by Laser Cladding. Int. J. Mach. Tools Manuf. 2011, 51, 465–470. [Google Scholar] [CrossRef]

- Xu, Z.; Yuan, J.; Wu, M.; Arif, A.F.M.; Li, D. Effect of Laser Cladding Parameters on Inconel 718 Coating Performance and Multi-Parameter Optimization. Opt. Laser Technol. 2023, 158, 108850. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Background and Basic Overview. In Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004; ISBN 978-0-429-12189-0. [Google Scholar]

- Dwivedi, A.; Khurana, M.K.; Bala, Y.G. A Comparative Study of Porosity Rate Measurement Methods and Influence of Energy Density in Inconel 718 Produced by Laser Powder Bed Fusion Additive Manufacturing Process. Int. J. Interact. Des. Manuf. IJIDeM 2025, 19, 2645–2658. [Google Scholar] [CrossRef]

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM G99-23; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Tang, Y.; Shen, X.; Qiao, Y.; Yang, L.; Chen, J.; Lu, D.; Zhang, Z. Corrosion Behavior of a Selective Laser Melted Inconel 718 Alloy in a 3.5 Wt.% NaCl Solution. J. Mater. Eng. Perform. 2021, 30, 5506–5514. [Google Scholar] [CrossRef]

- Konijnenberg, P.J.; Zaefferer, S.; Raabe, D. Assessment of Geometrically Necessary Dislocation Levels Derived by 3D EBSD. Acta Mater. 2015, 99, 402–414. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z.; Yi, J.; Tang, A. Studies on the Microstructural Evolution and Mechanical Properties of Superalloy Inconel 718 Induced by Low Plasticity Burnishing Coupled with Turning. Materials 2022, 15, 3740. [Google Scholar] [CrossRef]

- Li, F.; Jiang, W.; Lu, J.; Cheng, X.; Wang, J.; Zhang, Y.; Zhang, Z. In Situ EBSD Study of Formation and Propagation of Deformation Bands in a Single-Crystal Superalloy during Tensile Deformation. J. Mater. Sci. 2023, 58, 10764–10781. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Bolmaro, R.E.; Jorge, A.M.; Zhilyaev, A.; Cabrera, J.M. Prediction of Generation of High- and Low-Angle Grain Boundaries (HAGB and LAGB) During Severe Plastic Deformation. Metall. Mater. Trans. A 2020, 51, 4674–4684. [Google Scholar] [CrossRef]

- Langdon, T.G. Grain Boundary Sliding Revisited: Developments in Sliding over Four Decades. J. Mater. Sci. 2006, 41, 597–609. [Google Scholar] [CrossRef]

- Varpe, N.J.; Tajane, R. Overview of Burnishing Process as a Surface Improvement Technique. Manuf. Strateg. Syst. 2025, 234–266. [Google Scholar]

- Cui, P.; Liu, Z.; Yao, X.; Cai, Y. Effect of Ball Burnishing Pressure on Surface Roughness by Low Plasticity Burnishing Inconel 718 Pre-Turned Surface. Materials 2022, 15, 8067. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Sánchez, J.A.; Arana, J.L. The Effect of Ball Burnishing on Heat-Treated Steel and Inconel 718 Milled Surfaces. Int. J. Adv. Manuf. Technol. 2007, 32, 958–968. [Google Scholar] [CrossRef]

- Yaman, N.; Sunay, N.; Kaya, M.; Kaynak, Y. Enhancing Surface Integrity of Additively Manufactured Inconel 718 by Roller Burnishing Process. Procedia CIRP 2022, 108, 681–686. [Google Scholar] [CrossRef]

- Uddin, M.; Rech, J.; Hall, C.; Schlaefer, T. Directional Effect of Plasticity Ball Burnishing on Surface Finish, Microstructure, Residual Stress and Hardness of Laser Direct Energy Deposited Stellite 21 Alloy. Materials 2025, 18, 2971. [Google Scholar] [CrossRef]

- Shen, X.; Gong, X.; Wang, B.; He, J.; Xu, C.; Su, G. Surface Properties Enhancement of Inconel 718 Alloy by Ultrasonic Roller Burnishing Coupled with Heat Treatment. Arch. Civ. Mech. Eng. 2021, 21, 122. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Han, E.-H.; Ke, W. Corrosion Behavior for Alloy 690 and Alloy 800 Tubes in Simulated Primary Water. Corros. Sci. 2013, 67, 169–178. [Google Scholar] [CrossRef]

- Kornienko, E.; Ossenbrink, R.; Michailov, V. Electrochemical Corrosion Characteristic of Structured Low Carbon Steel DC04 and Stainless Steel 304 Sheets in Sodium Chloride Solution. Adv. Mater. Res. 2012, 396, 1736–1743. [Google Scholar] [CrossRef]

- Hubschmid, C.; Landolt, D. Formation Conditions, Chloride Content, and Stability of Passive Films on an Iron-Chromium Alloy. J. Electrochem. Soc. 1993, 140, 1898. [Google Scholar] [CrossRef]

- Li, L.; Sagues, A.A. Chloride Corrosion Threshold of Reinforcing Steel in Alkaline Solutions—Effect of Specimen Size. Corrosion 2004, 60, 195–202. [Google Scholar] [CrossRef]

| Material | Chemical Composition (wt.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Mo | Ni | Ti | Al | Nb | B | Fe | |

| Inconel 718 Powder Feedstock | 0.02 | 18 | 3 | Bal. | 0.95 | 0.5 | 5 | 0.003 | 18.5 |

| Specimen | Corrosion Potential, Ecorr (mV vs. SCE) | Corrosion Density, Icorr (mA/cm2) | Pitting Potential, Epit (mV vs. SCE) | Polarization Resistance, Rp (MΩ·cm2) | Open Circuit Potential, OCP (mV vs. SCE) |

|---|---|---|---|---|---|

| Ground | −109 ± 43 | 0.017 ± 0.001 | 1164 ± 16 | 1.05 ± 0.2 | −61 ± 35 |

| BB-Longitudinal | 13 ± 88 | 0.021 ± 0.003 | 1165 ± 8 | 0.63 ± 0.2 | 14 ± 30 |

| BB-Transverse | −73 ± 63 | 0.015 ± 0.007 | 1158 ± 11 | 1.23 ± 0.01 | −77 ± 82 |

| BB-Crosshatch | −43 ± 45 | 0.020 ± 0.004 | 1145 ± 16 | 0.53 ± 0.2 | −35 ± 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, G.; Hatem, A.; Roccisano, A.; Uddin, M.; Hall, C.; Schlaefer, T. Influence of Ball Burnishing Path Strategy on Surface Integrity and Performance of Laser-Cladded Inconel 718 Alloys. Metals 2025, 15, 1190. https://doi.org/10.3390/met15111190

Fernandes G, Hatem A, Roccisano A, Uddin M, Hall C, Schlaefer T. Influence of Ball Burnishing Path Strategy on Surface Integrity and Performance of Laser-Cladded Inconel 718 Alloys. Metals. 2025; 15(11):1190. https://doi.org/10.3390/met15111190

Chicago/Turabian StyleFernandes, Gustavo, Andre Hatem, Anthony Roccisano, Mohammad Uddin, Colin Hall, and Thomas Schlaefer. 2025. "Influence of Ball Burnishing Path Strategy on Surface Integrity and Performance of Laser-Cladded Inconel 718 Alloys" Metals 15, no. 11: 1190. https://doi.org/10.3390/met15111190

APA StyleFernandes, G., Hatem, A., Roccisano, A., Uddin, M., Hall, C., & Schlaefer, T. (2025). Influence of Ball Burnishing Path Strategy on Surface Integrity and Performance of Laser-Cladded Inconel 718 Alloys. Metals, 15(11), 1190. https://doi.org/10.3390/met15111190