Creep-Fatigue Life Evaluation for Grade 91 Steels with Various Origins and Service Histories

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

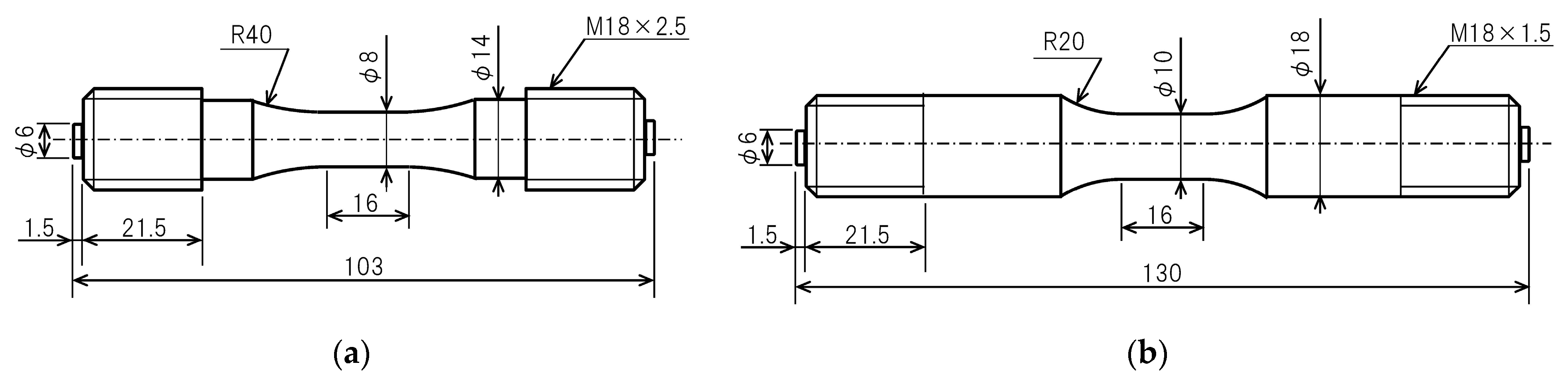

2.2. Tensile Test Method

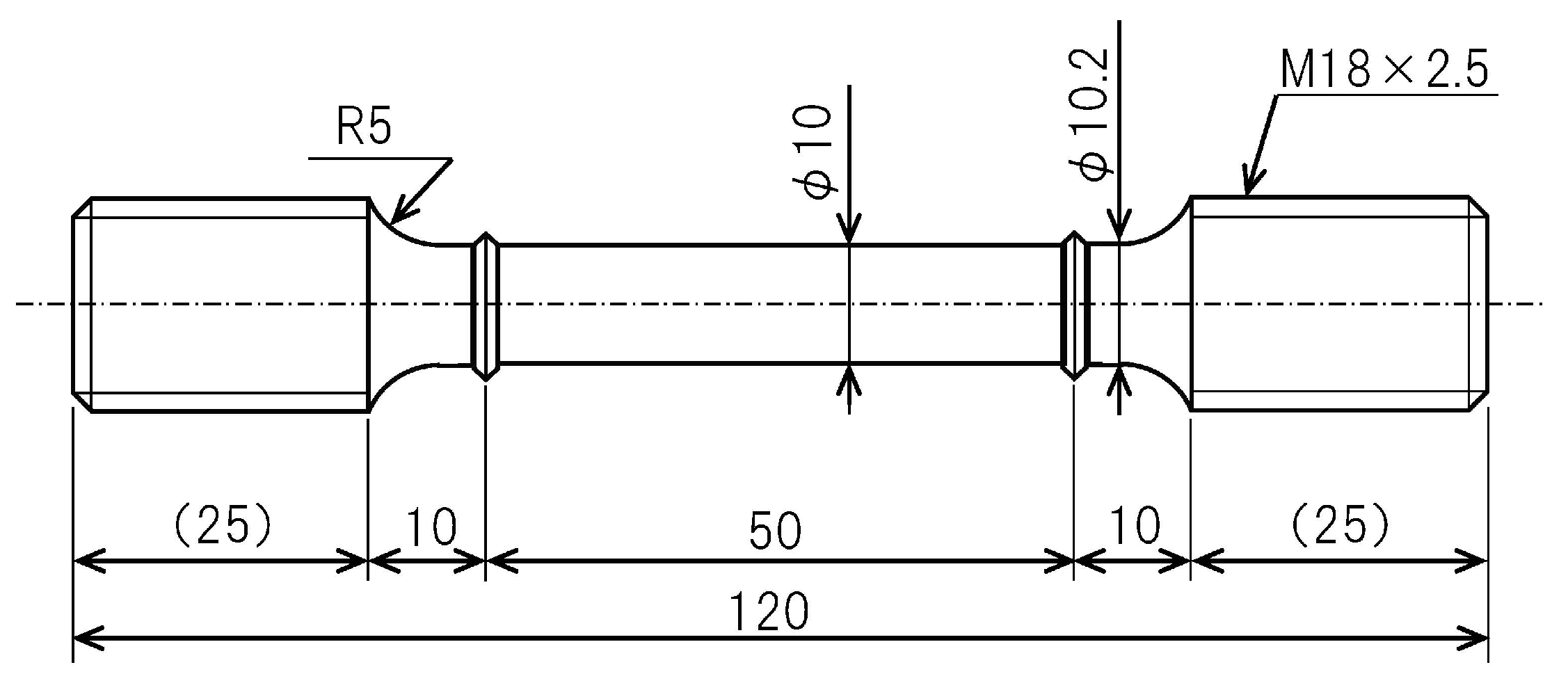

2.3. Creep Test Method

2.4. Fatigue and Creep-Fatigue Test Method

3. Results and Discussion

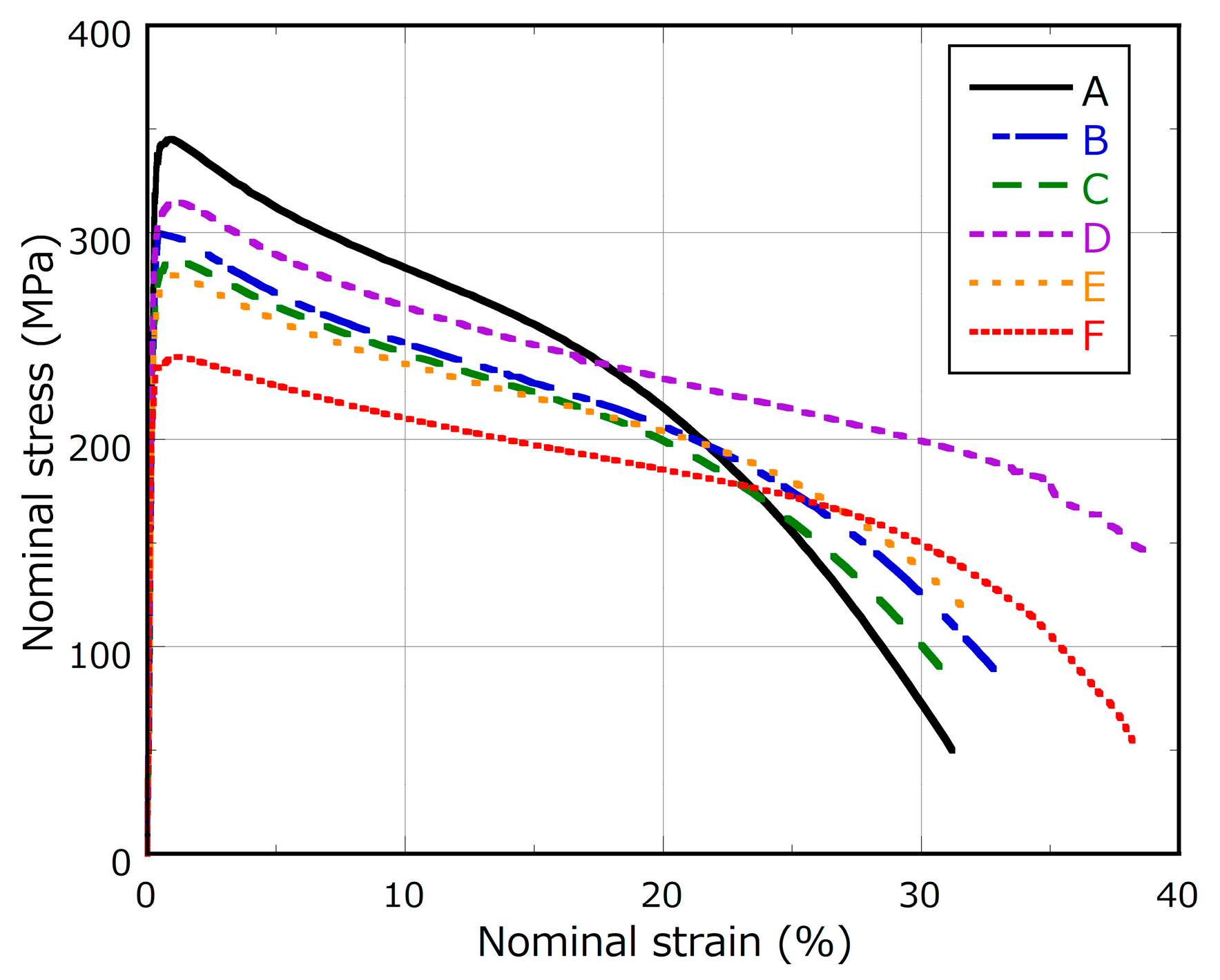

3.1. Tensile Properties

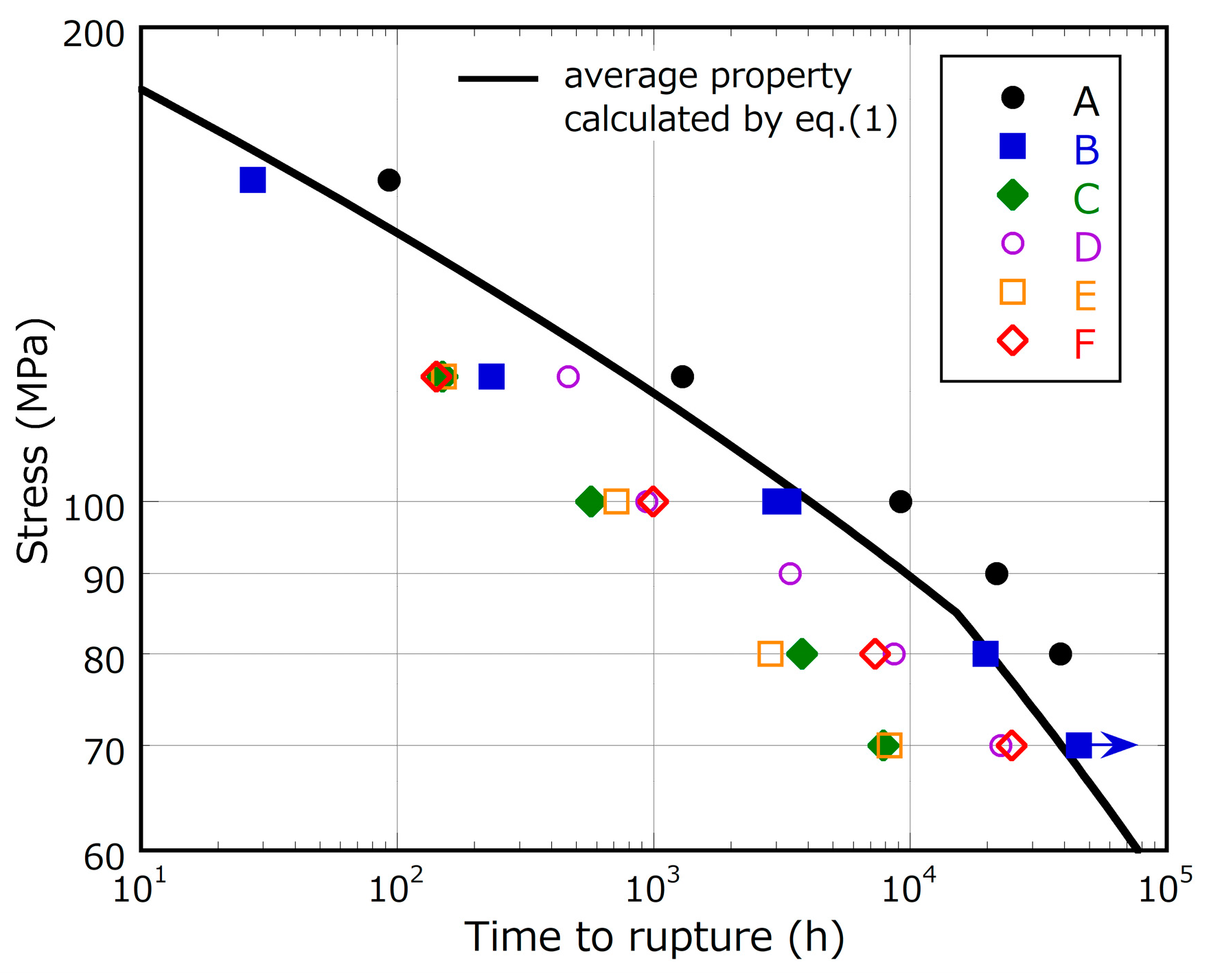

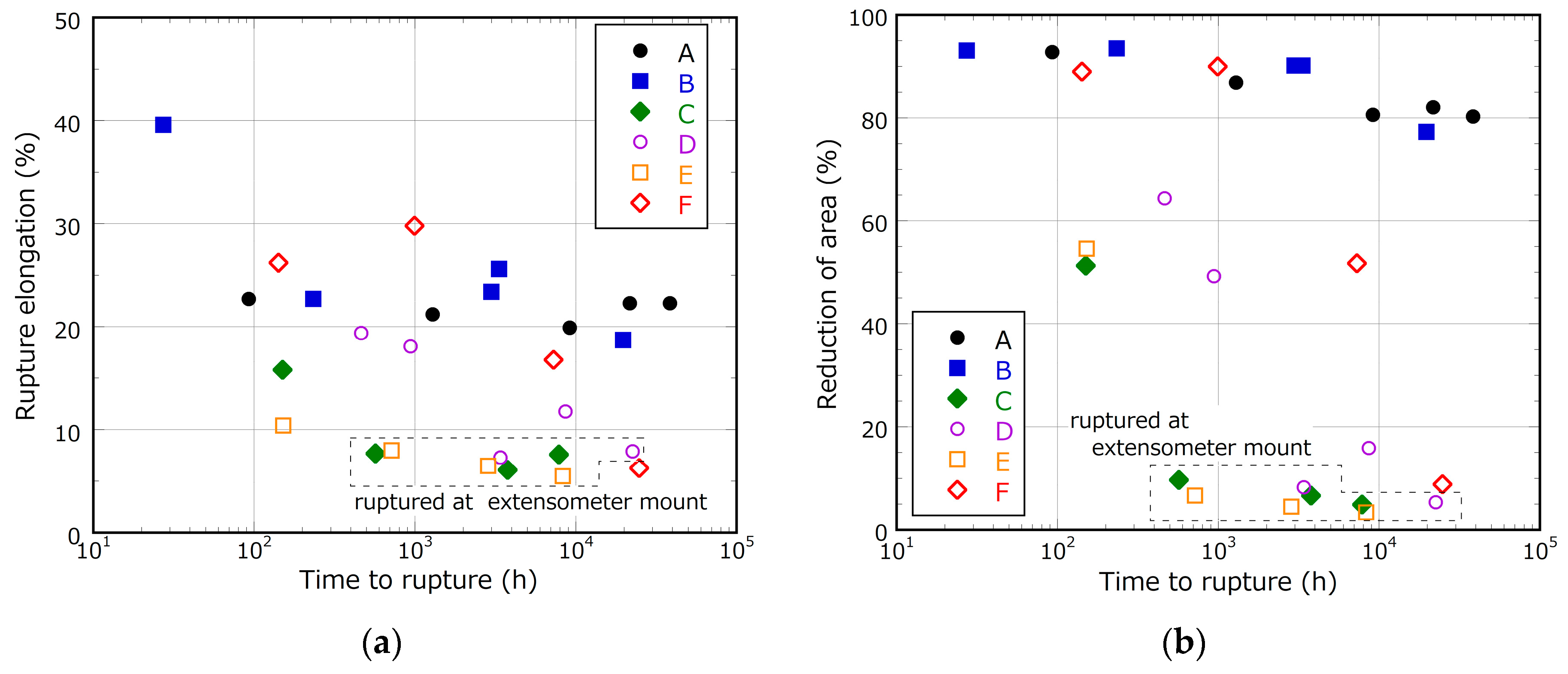

3.2. Creep Properties

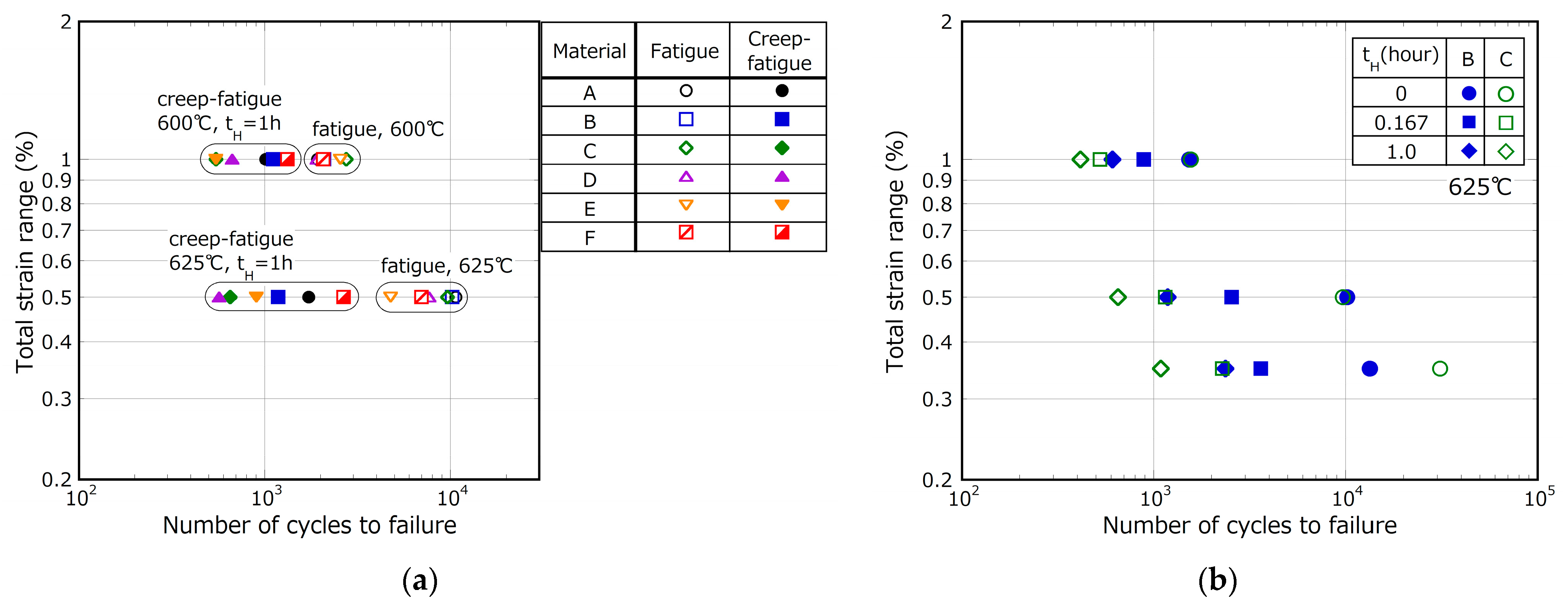

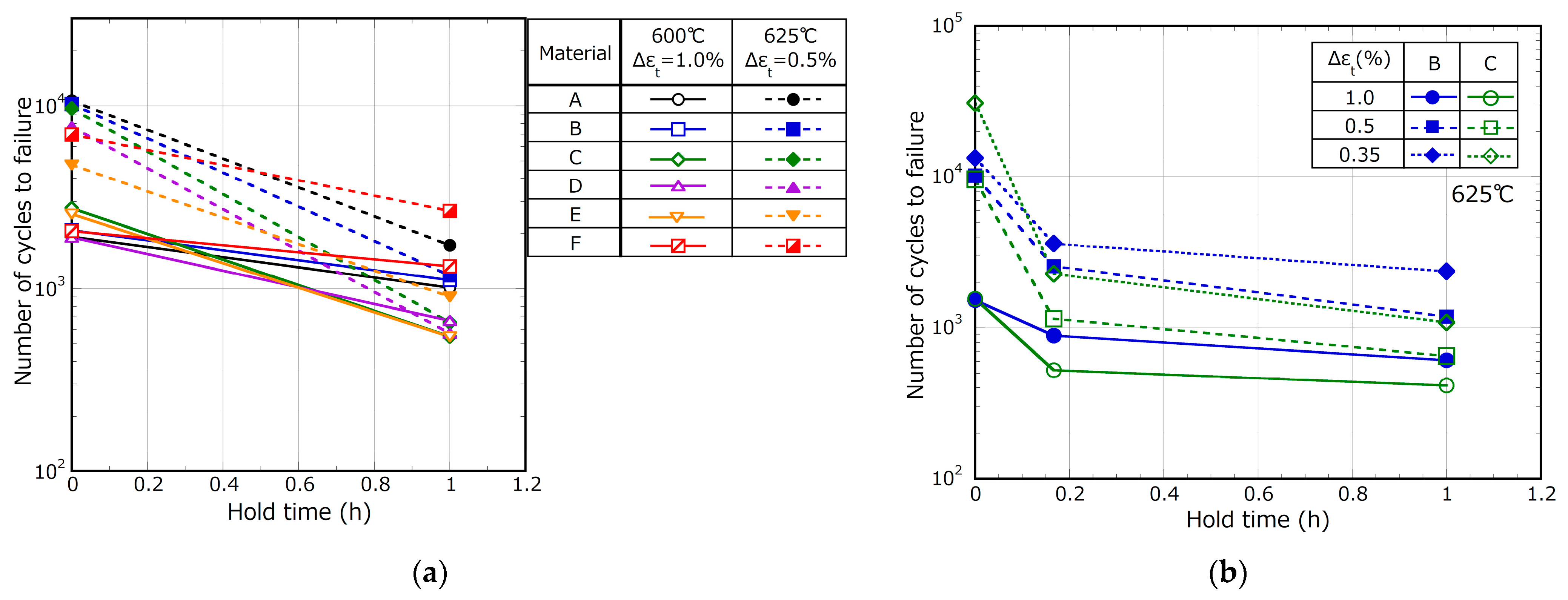

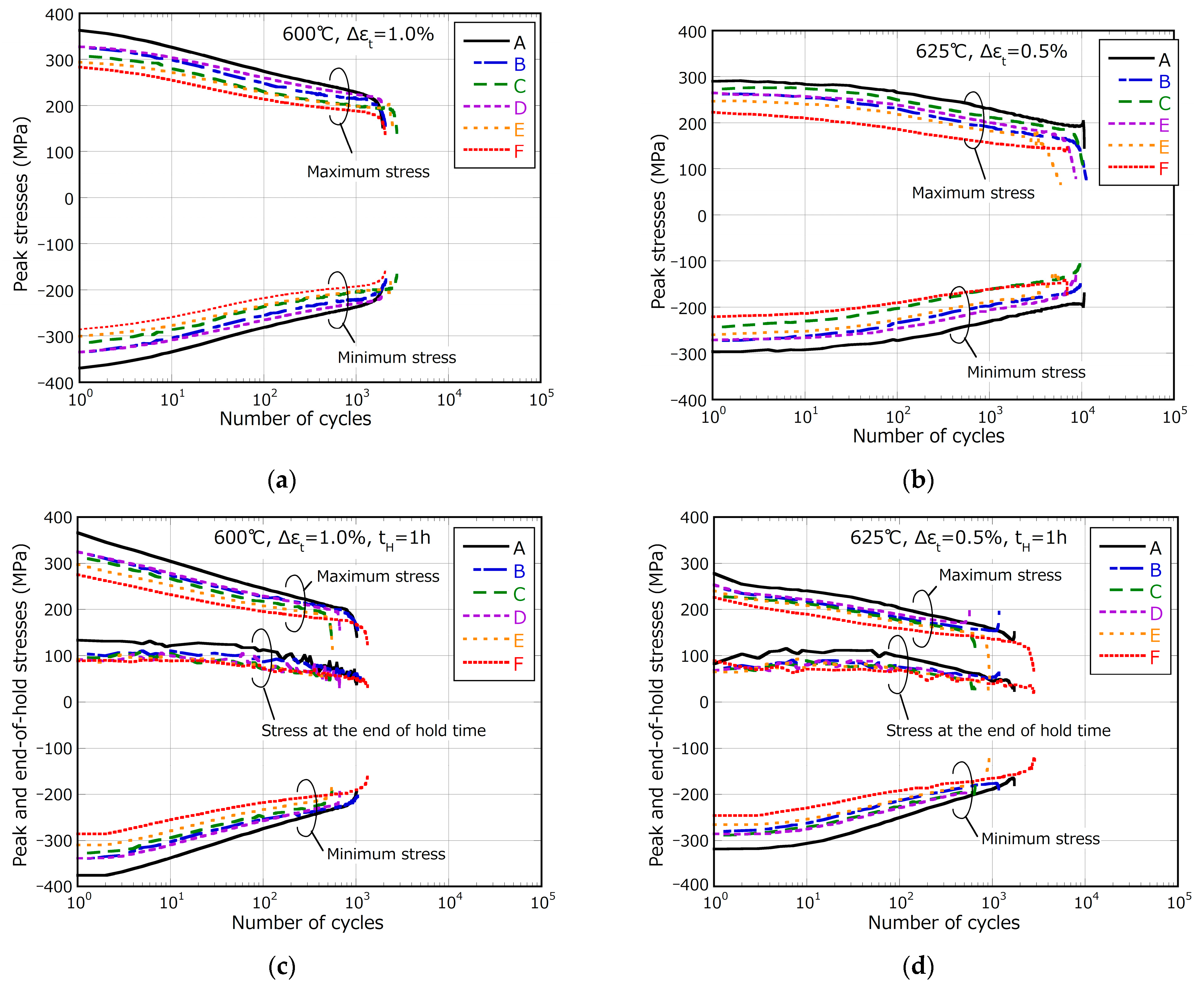

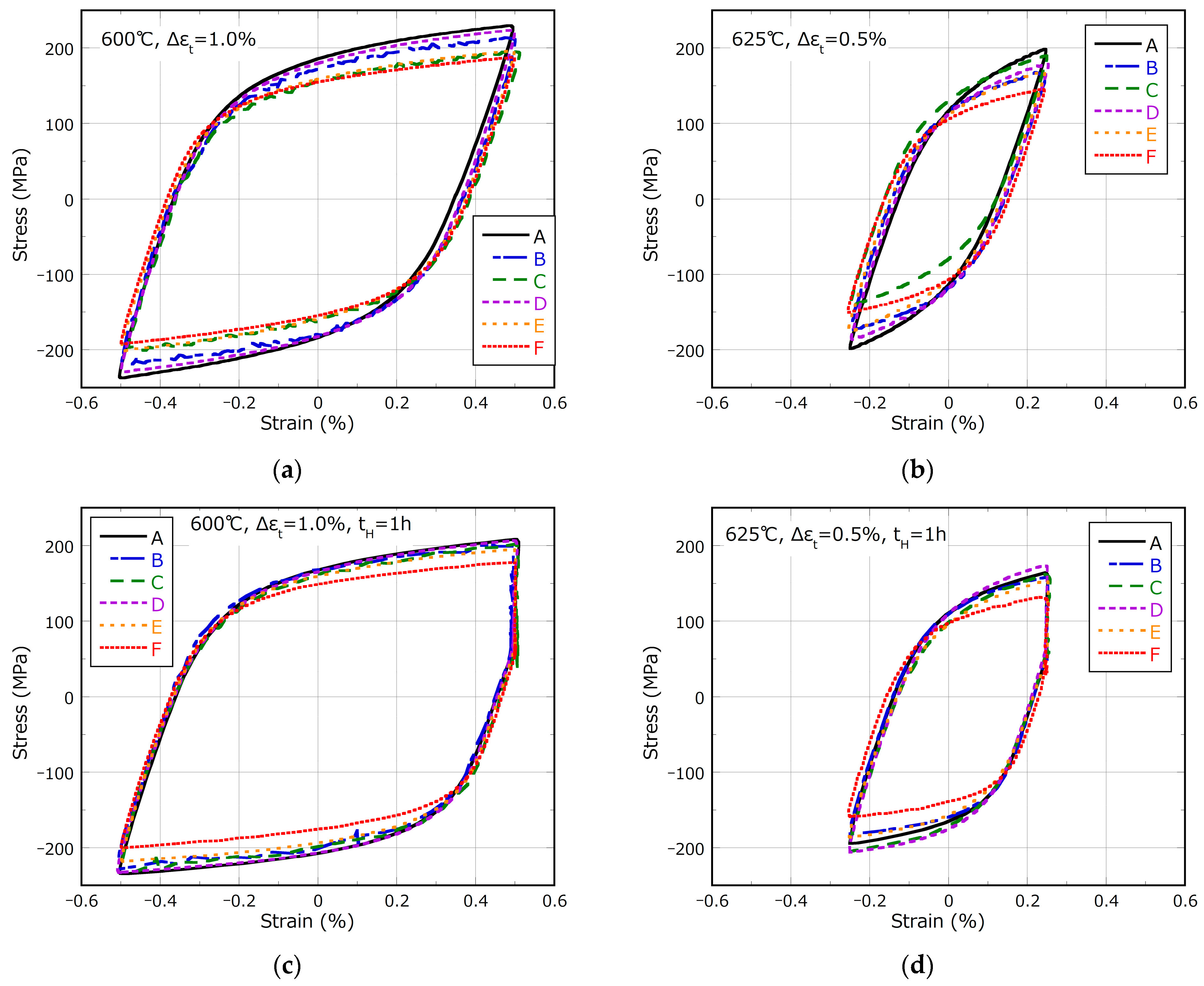

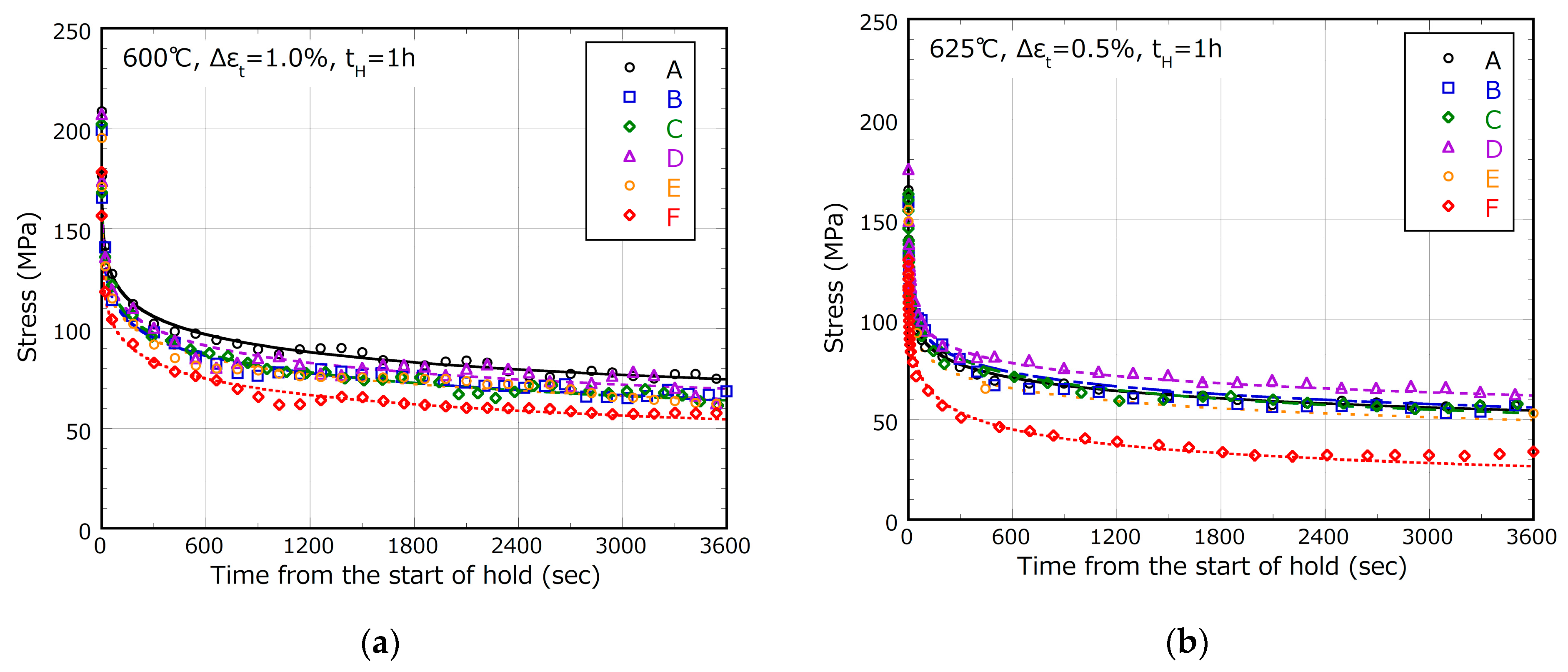

3.3. Fatigue and Creep-Fatige Properties

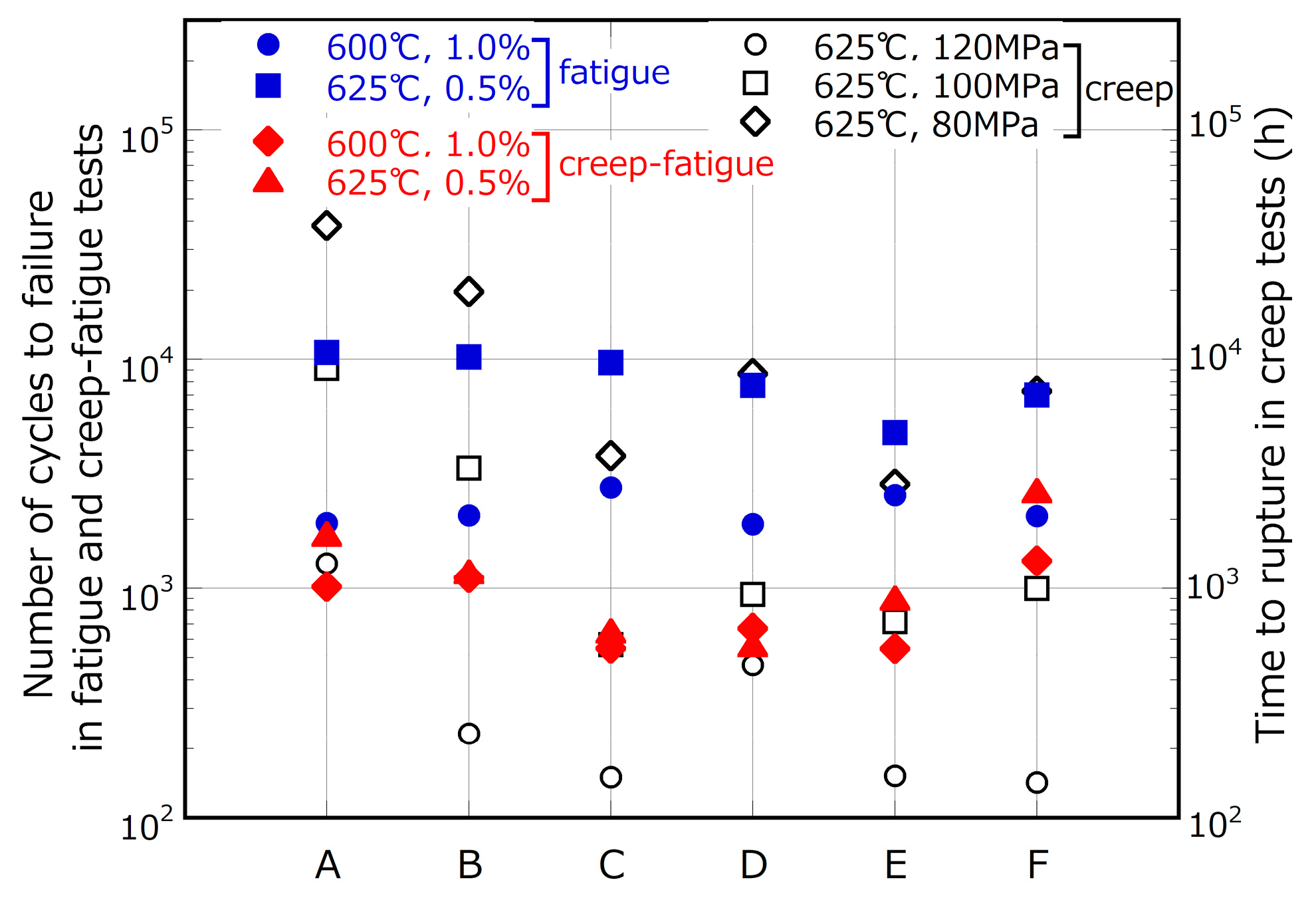

3.4. Variations in Creep, Fatigue, and Creep-Fatigue Lives

4. Evaluation of Creep-Fatigue Failure Lives

4.1. Outline of Creep Damage Evaluation Methods

4.1.1. Time Fraction Approach

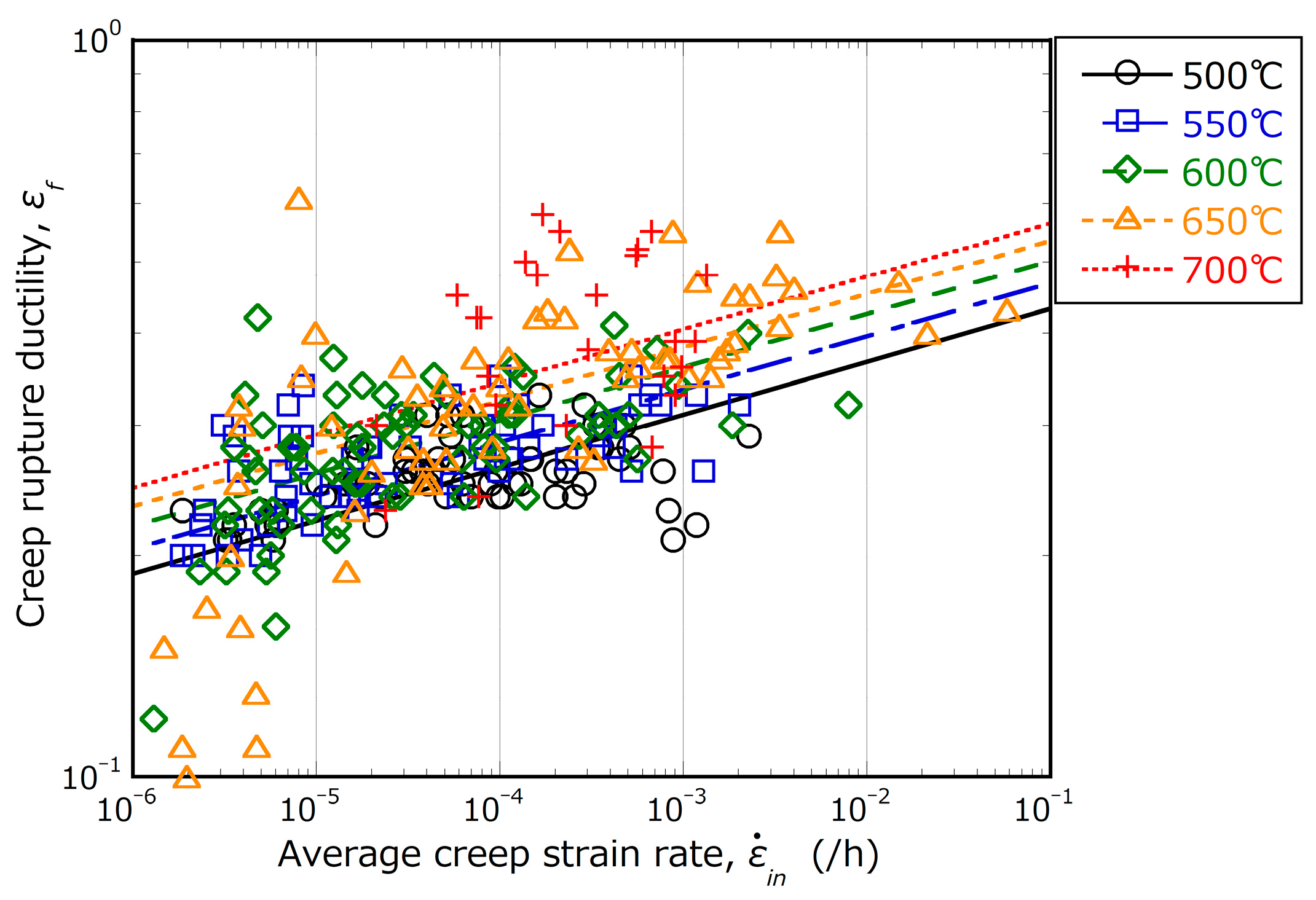

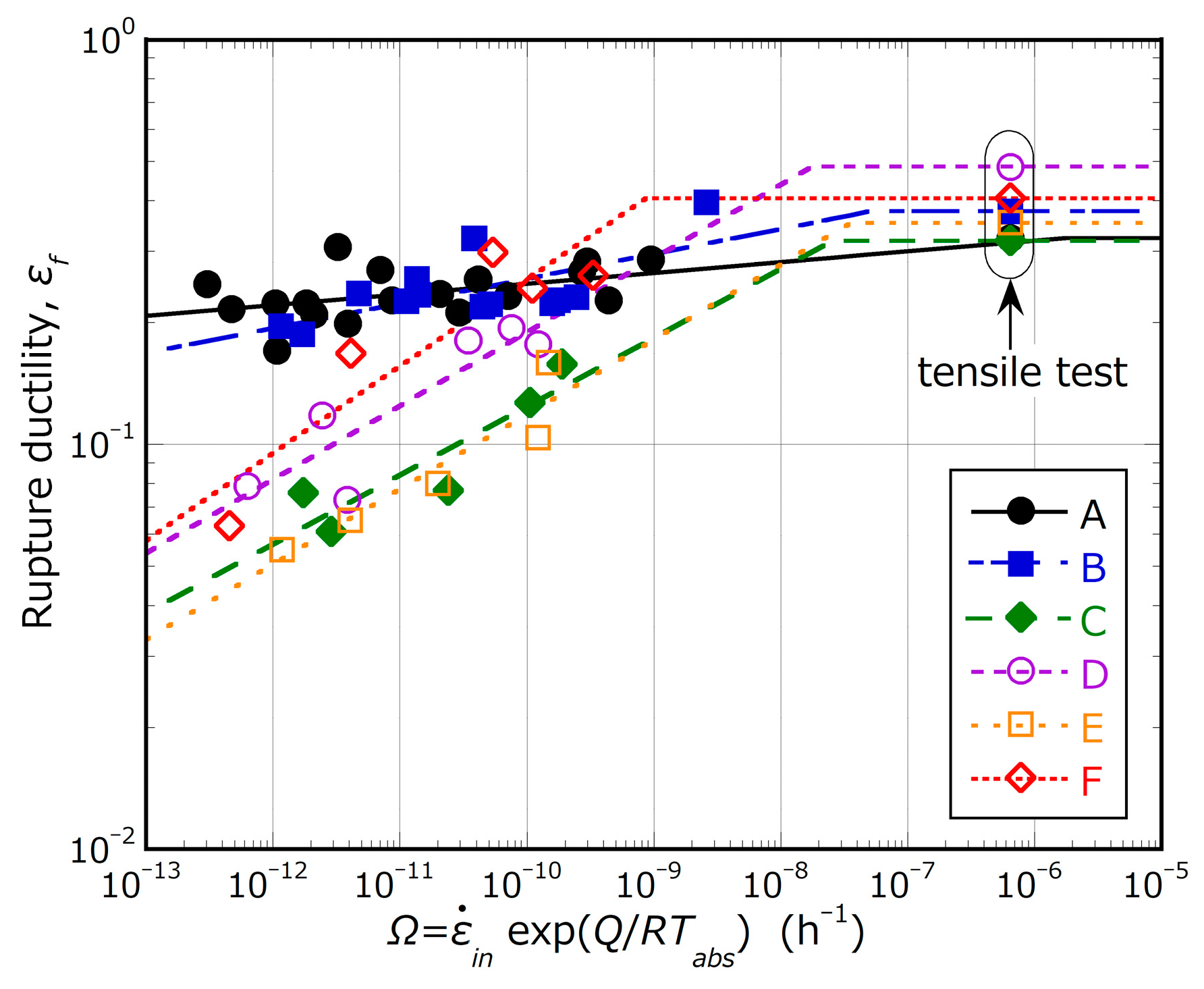

4.1.2. Ductility Exhaustion Approach

4.1.3. Modified Ductility Exhaustion Approach

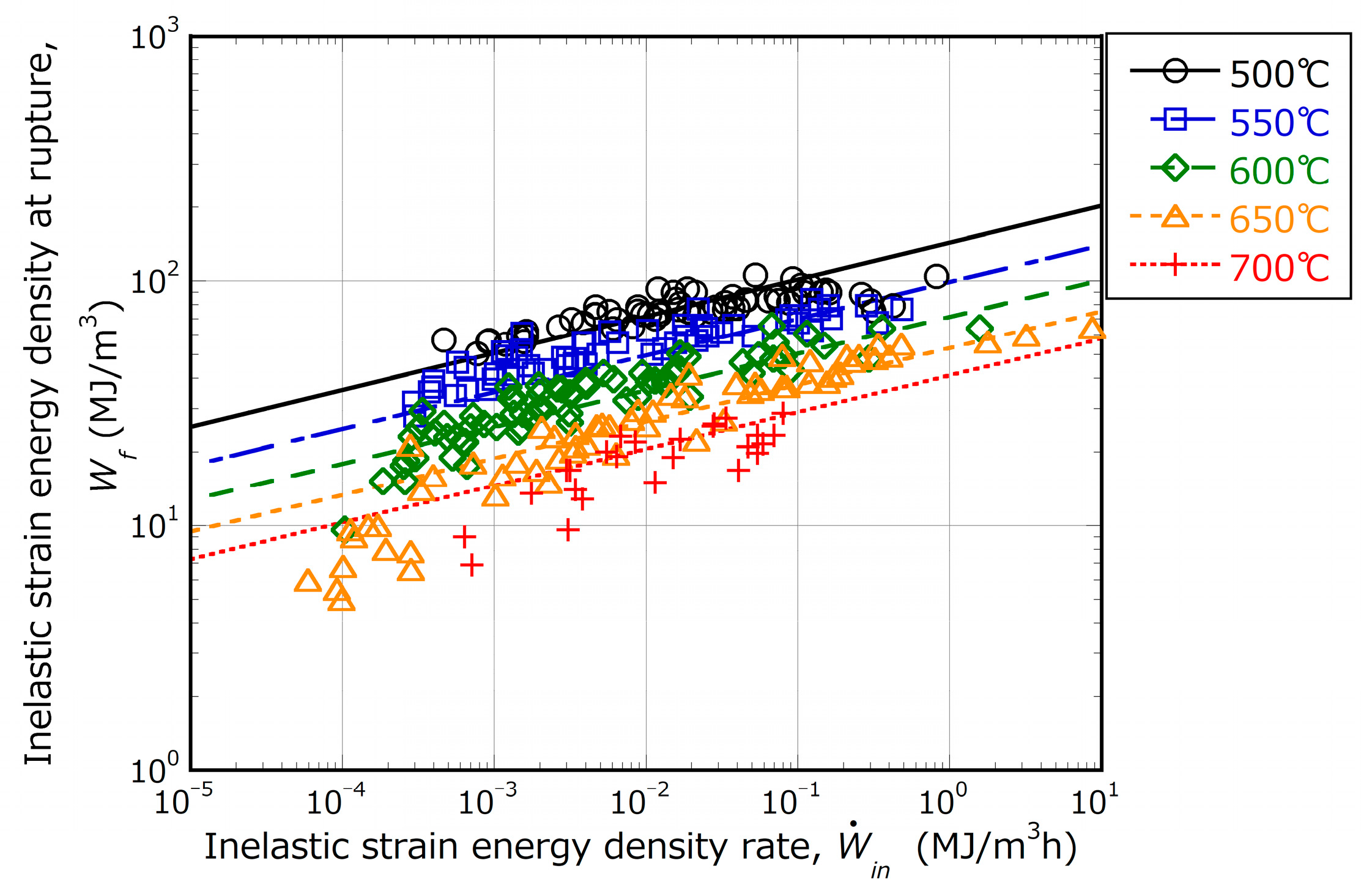

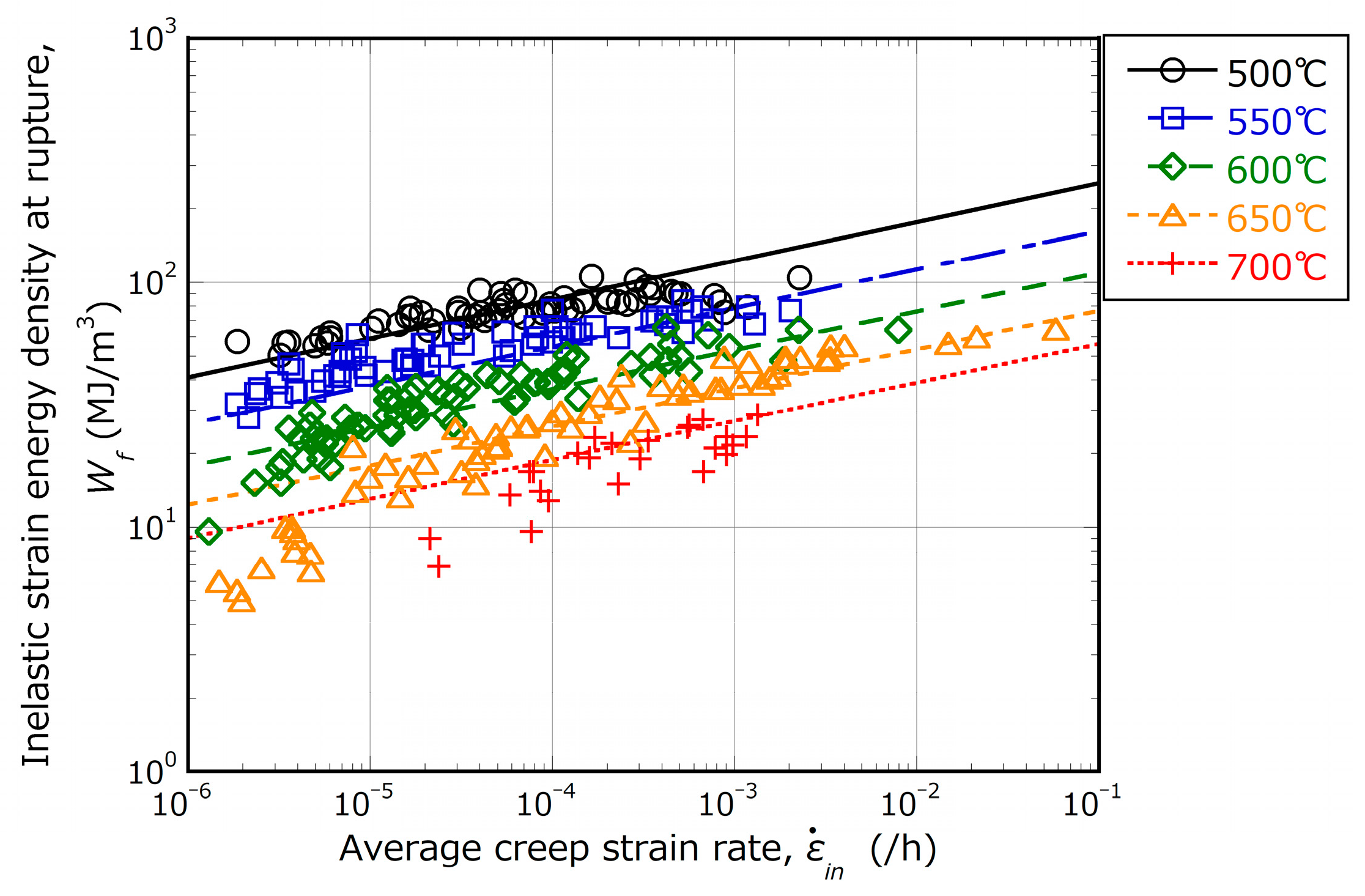

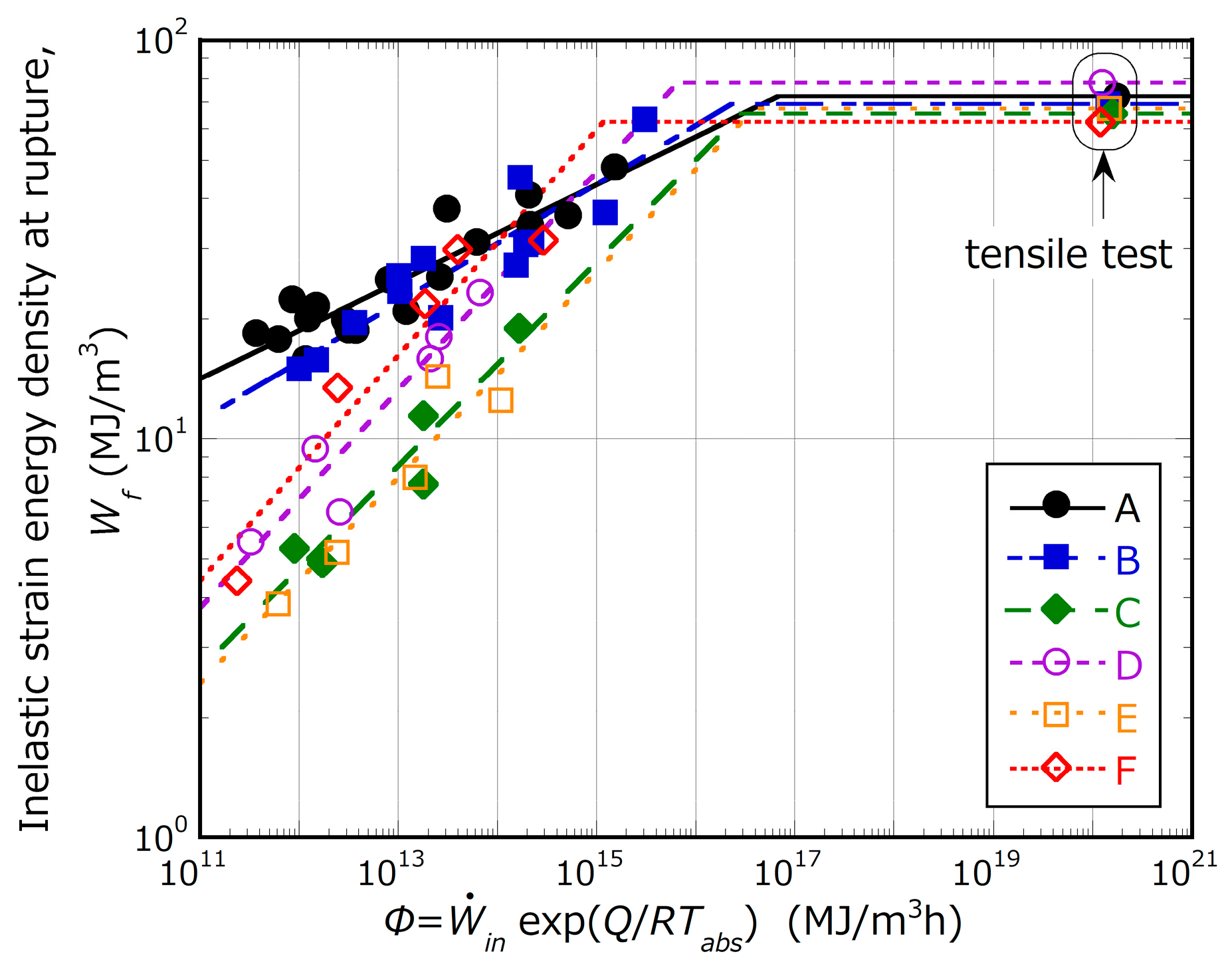

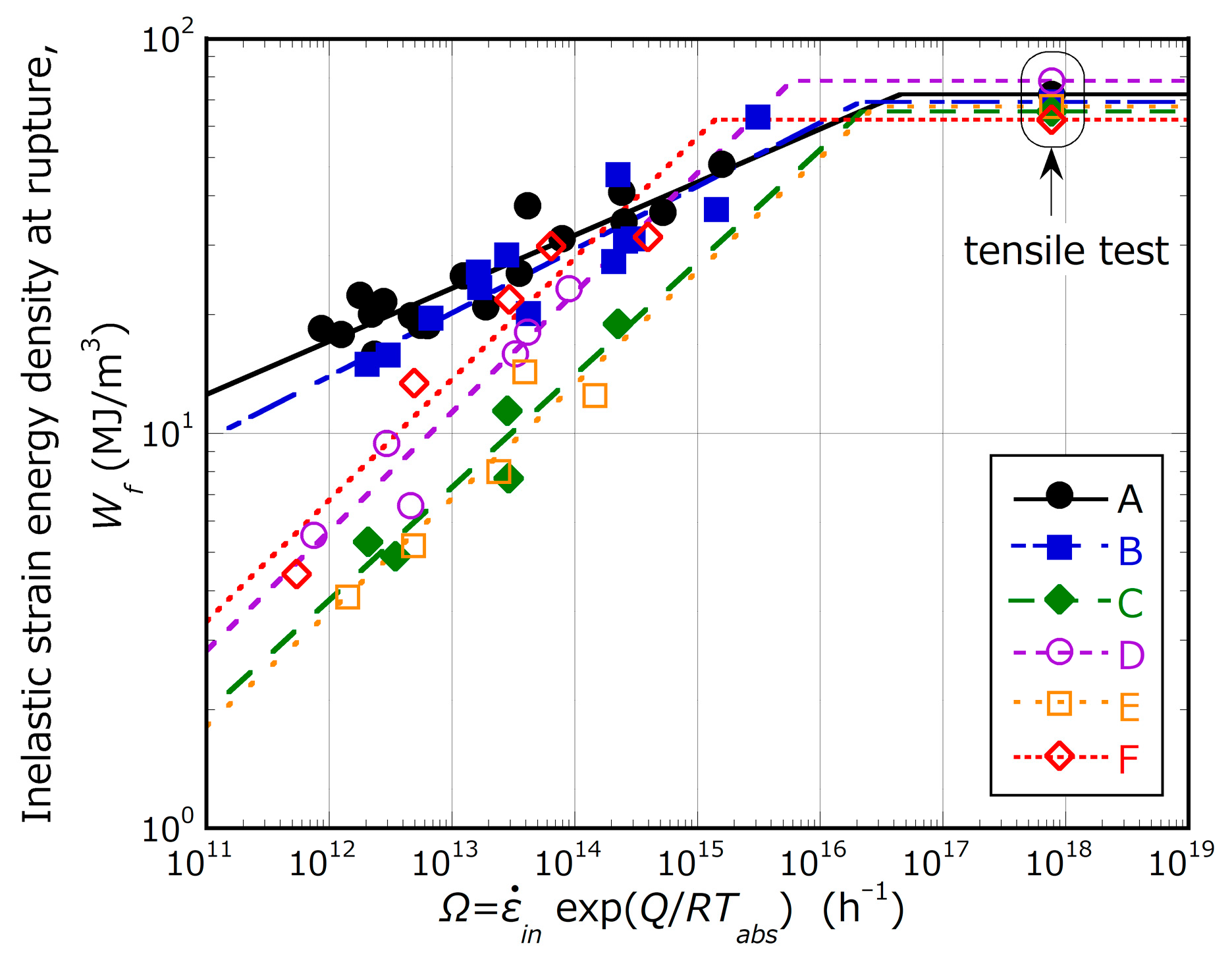

4.1.4. Energy-Based Approach

4.1.5. Hybrid Approach

4.2. Outline of Fatigue Damage Evaluation Method

4.3. Evaluation of Creep-Fatigue Failure Life

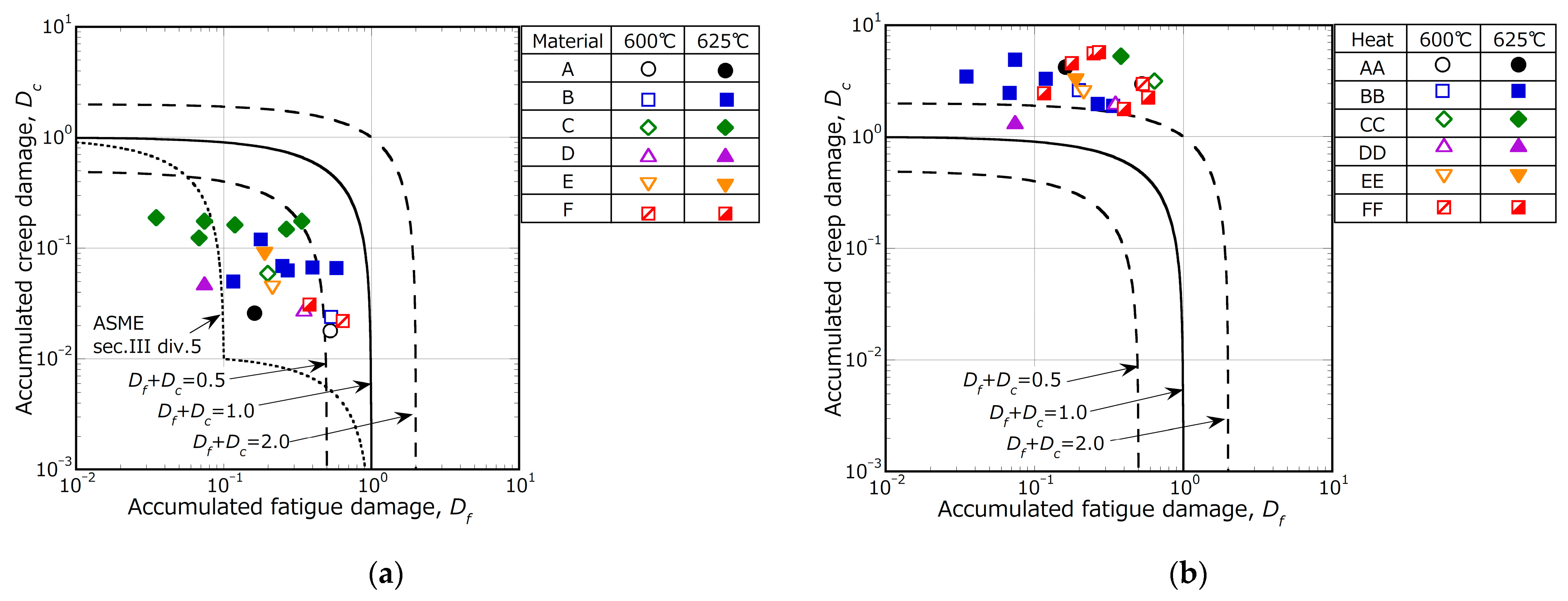

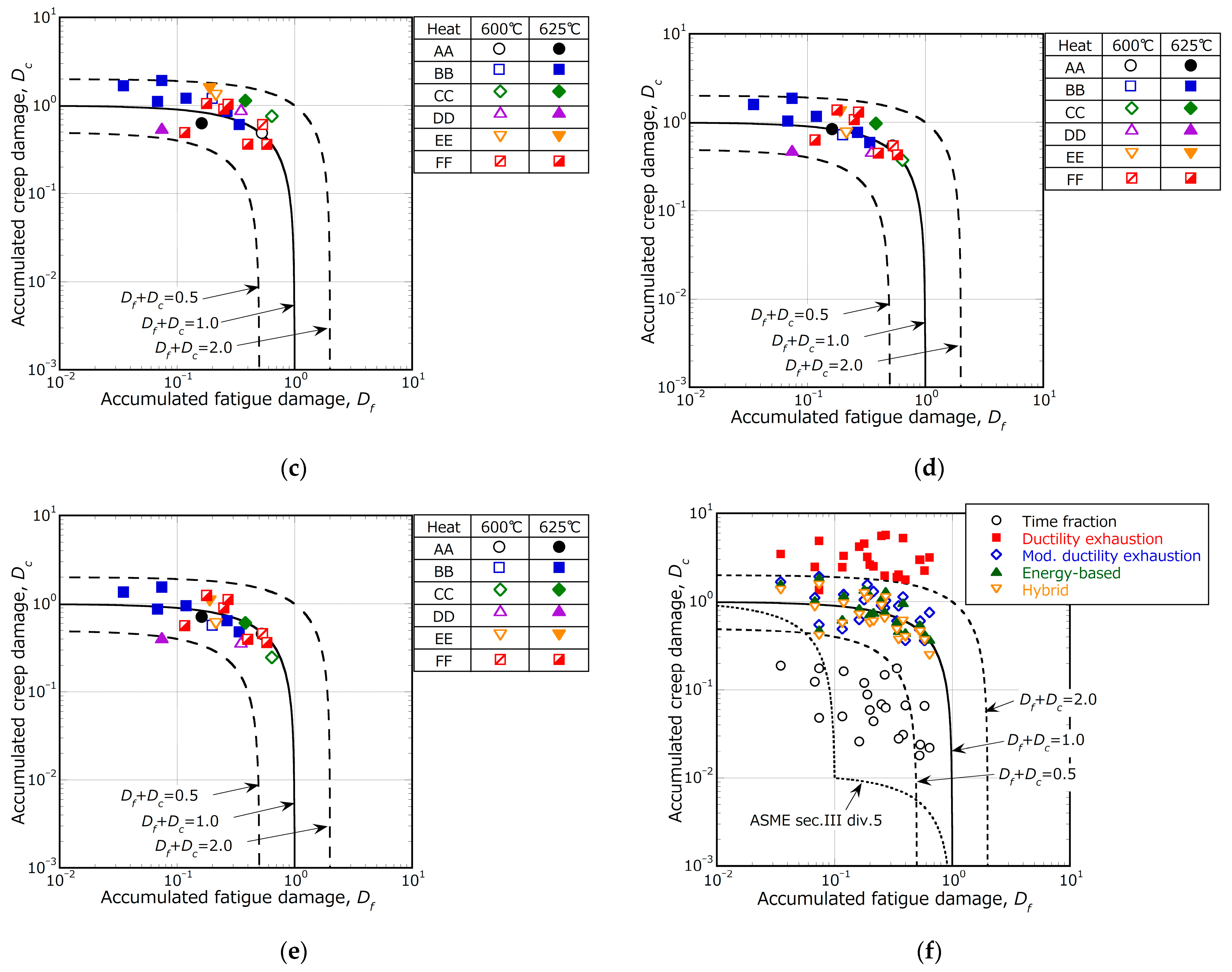

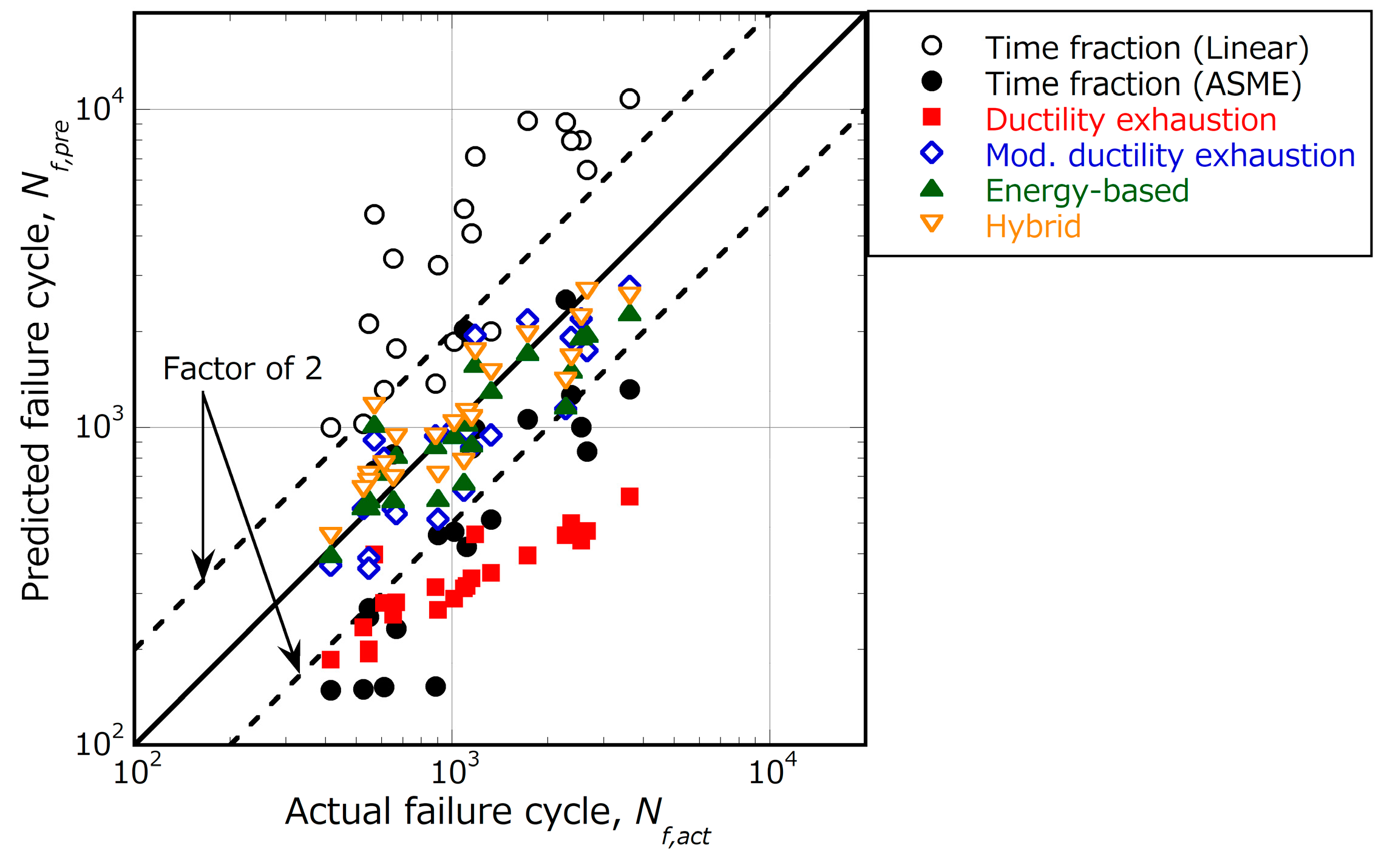

4.4. Results of Damage Calculation and Creep-Fatigue Life Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Equation/Approach | a0 | a1 | a2 |

|---|---|---|---|

| (1A)/Ductility Exhaustion | 6.26 × 10−1 | 7.19 × 10−2 | −8.35 × 103 |

| (2A)/Energy-Based | −1.12 | 1.50 × 10−1 | 3.91 × 104 |

| (3A)/Hybrid | −1.45 | 1.59 × 10−1 | 4.73 × 104 |

Appendix B

| Test Conditions | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 625 °C, 120 MPa | 1289.7 | 233.3 | 150.3 | 463.2 | 152.0 | 142.1 |

| 625 °C, 100 MPa | 9159.1 | 3341.8 | 568.8 | 939.0 | 715.8 | 994.2 |

| 625 °C, 80 MPa | 38,440.0 | 19,703.0 | 3780.0 | 8642.8 | 2852.6 | 7291.5 |

| Test Conditions | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 1930 | 2090 | 2750 | 1910 | 2560 | 2070 | |

| 1010 | 1110 | 547 | 668 | 546 | 1320 |

| Test Conditions | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 10,700 | 10,200 | 9660 | 7690 | 4770 | 6980 | |

| 1730 | 1180 | 653 | 569 | 902 | 2660 |

References

- Kimura, K.; Sawada, K.; Kushima, H.; Toda, Y. Microstructural stability and long term creep strength of Grade 91 steel. Mater. Sci. Eng. Energy Syst. 2009, 4, 176–183. [Google Scholar] [CrossRef]

- Kimura, K.; Sawada, K.; Kushima, H.; Toda, Y. Influence of Chemical Composition and Heat Treatment on Long-term Creep Strength of Grade 91 Steel. Procedia Eng. 2013, 55, 2–9. [Google Scholar] [CrossRef]

- Parker, J.; Brett, S. Creep performance of a Grade 91 header. Int. J. Press. Vessel. Pip. 2013, 111–112, 82–88. [Google Scholar] [CrossRef]

- EPRI. The Benefits of Improved Control of Composition of Creep-Strength-Enhanced Ferritic Steel Grade 91; EPRI: Palo Alto, CA, USA, 2014; p. 3002003472. [Google Scholar]

- Sawada, K.; Kushima, H.; Hara, T.; Tabuchi, M.; Kimura, K. Heat-to-heat variation of creep strength and long-term stability of microstructure in Grade 91 steels. Mater. Sci. Eng. A 2014, 597, 164–170. [Google Scholar] [CrossRef]

- Maruyama, K.; Nakamura, J.; Sekido, N.; Yoshimi, K. Causes of heat-to-heat variation of creep strength in Grade 91 steel. Mater. Sci. Eng. A 2017, 696, 104–112. [Google Scholar] [CrossRef]

- Takahashi, Y.; Shigeyama, H.; Siefert, J.; Parker, J. Effect of simulated heat affected zone thermal cycle on the creep deformation and damage response of Grade 91 steel including heat-to-heat variation. In Proceedings of the ASME 2018 Pressure Vessels and Piping Division Conference, Prague, Czech Republic, 15–20 July 2018; p. PVP2018-82105. [Google Scholar]

- Shigeyama, H.; Takahashi, Y.; Siefert, J.; Parker, J. Creep Deformation Analyses for Grade 91 Steels Considering Heat-to-Heat Variation. In Proceedings of the ASME 2018 Pressure Vessels and Piping Division Conference, Prague, Czech Republic, 15–20 July 2018; p. PVP2018-85058. [Google Scholar]

- Takahashi, Y.; Shigeyama, H.; Siefert, J.; Parker, J. A summary of 10 years research on Grade 91 and Grade 92 steel. In Joint EPRI-123HiMAT International Conference on Advances in High-Temperature Materials; Shingledecker, J., Takeyama, M., Eds.; ASM International: Materials Park, OH, USA, 2019; pp. 370–378. [Google Scholar]

- Siefert, J.A. The Influence of the Parent Metal Condition on the Cross-Weld Creep Performance in Grade 91 Steel. Ph.D. Thesis, Loughborough University, Loughborough, UK, July 2019. [Google Scholar]

- Sawada, K.; Sekido, K.; Kimura, K.; Arisue, K.; Honda, M.; Komai, N.; Fukuzawa, N.; Ueno, T.; Shimohata, N.; Nakatomi, H.; et al. Effect of Initial Microstructure on Creep Strength of ASME Grade T91 Steel. ISIJ Int. 2020, 60, 382–391. [Google Scholar] [CrossRef]

- Maruyama, K.; Dewees, D.; Abe, F.; Yoshimi, K. Examinations of equations for creep rupture life with a large creep database on Grade 91 steel. Int. J. Press. Vessel. Pip. 2022, 199, 104738. [Google Scholar] [CrossRef]

- ASME. ASME Boiler and Pressure Vessel Code-Code Cases: Boilers and Pressure Vessels; ASME: New York, NY, USA, 2017. [Google Scholar]

- ASME. ASME Boiler and Pressure Vessel Code Section III–Rules for Construction of Nuclear Facility Components-Division 5-High Temperature Reactors; ASME: New York, NY, USA, 2023. [Google Scholar]

- British Energy. Assessment Procedure R5, Issue 3. Assessment Procedure for the High Temperature Response of Structures; British Energy: London, UK, 2003. [Google Scholar]

- Takahashi, Y. Study on creep-fatigue evaluation procedures for high-chromium steels—Part I: Test results and life prediction based on measured stress relaxation. Int. J. Press. Vessel. Pip. 2008, 85, 406–422. [Google Scholar] [CrossRef]

- Wen, J.F.; Tu, S.T.; Xuan, F.Z.; Zhang, X.W.; Gao, X.L. Effects of Stress Level and Stress State on Creep Ductility: Evaluation of Different Models. J. Mater. Sci. Technol. 2016, 32, 695–704. [Google Scholar] [CrossRef]

- Skelton, R.P. Energy criterion for high temperature low cycle fatigue failure. Mater. Sci. Technol. 1991, 7, 427–440. [Google Scholar] [CrossRef]

- Takahashi, Y.; Dogan, B.; Gandy, D. Systematic evaluation of creep–fatigue life prediction methods for various alloys. J. Press. Vessel. Technol. 2013, 135, 061204. [Google Scholar] [CrossRef]

- Payten, W.M.; Dean, D.W.; Snowden, K.U. A strain energy density method for the prediction of creep–fatigue damage in high temperature components. Mater. Sci. Eng. A 2010, 527, 1920–1925. [Google Scholar] [CrossRef]

- Skelton, R.P. The energy density exhaustion method for assessing the creep–fatigue lives of specimens and components. Mater. High Temp. 2013, 30, 183–201. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhang, X.C.; Tu, S.T.; Zhu, S.P.; Zhang, C.C. A modified strain energy density exhaustion model for creep–fatigue life prediction. Int. J. Fatigue 2016, 90, 12–22. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhu, X.M.; Zhang, X.C.; Tu, S.T.; Gong, J.G.; Zhang, C.C. A generalized strain energy density exhaustion model allowing for compressive hold effect. Int. J. Fatigue 2017, 104, 61–71. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhang, X.C.; Gu, H.H.; Li, K.S.; Wen, J.F.; Miura, H.; Suzuki, K.; Tu, S.T. Oxidation-involved life prediction and damage assessment under generalized creep-fatigue loading conditions based on engineering damage mechanics. J. Mater. Res. Technol. 2023, 23, 114–130. [Google Scholar] [CrossRef]

- Li, K.S.; Wang, J.; Fan, Z.C.; Cheng, L.Y.; Yao, S.L.; Wang, R.Z.; Zhang, X.C.; Tu, S.T. A life prediction method and damage assessment for creep-fatigue combined with high-low cyclic loading. Int. J. Fatigue 2022, 161, 106923. [Google Scholar] [CrossRef]

- Song, K.W.D.; Zhao, L.; Xu, L.; Han, Y. An improved life prediction strategy at elevated temperature based on pure creep and fatigue data: Classical strain controlled and hybrid stress–strain controlled creep-fatigue test. Eng. Fract. Mech. 2023, 289, 109412. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.; Xia, X.; Jiang, Y.; Zhang, X.; Zhao, L.; Roy, A.; Gong, J.; Tu, S. A robust life prediction model for a range of materials under creep-fatigue interaction loading conditions. Int. J. Fatigue 2023, 176, 107904. [Google Scholar] [CrossRef]

- Takahashi, Y.; Parker, J.; Gandy, D. Creep-fatigue interaction in Grade 92 steel and its predictability. In Advances in Materials Technology for Fossil Power Plants: Proceedings from the Seventh International Conference, Waikoloa, HI, USA, 22–25 October 2013; Gandy, D., Shingledecker, J., Eds.; ASM International: Materials Park, OH, USA, 2014; pp. 667–678. [Google Scholar]

- Payten, W.M.; Dean, D.; Snowden, K.U. Analysis of creep ductility in a ferritic martensitic steel using a hybrid strain energy technique. Mater. Des. 2012, 33, 491–495. [Google Scholar] [CrossRef]

- EPRI. Review of Fabrication and In-Service Performance of a Grade 91 Header; EPRI: Palo Alto, CA, USA, 2013; p. 3002001831. [Google Scholar]

- Nitsche, A.; Mayr, P.; Allen, D. Damage Assessment of Creep Affected Weldments of a Grade 91 Header Component after Long-term High Temperature Service. Weld. World 2015, 59, 675–682. [Google Scholar] [CrossRef]

- ASME. ASME Boiler and Pressure Vessel Code Section II–Materials-Part A-Ferrous Materials Specifications; ASME: New York, NY, USA, 2019. [Google Scholar]

- Kimura, K.; Yaguchi, M. Re-Evaluation of Long-Term Creep Strength of Base Metal of ASME Grade 91 Type Steel. In Proceedings of the ASME 2016 Pressure Vessels and Piping Conference, British Columbia, VA, Canada, 17–21 July 2016; p. PVP2016-63355. [Google Scholar]

- NIMS. NIMS Creep Data Sheet No. 43A; NIMS: Tsukuba, Japan, 2014.

- Spindler, M.W. The prediction of creep damage in type 347 weld metal. Part I: The determination of material properties from creep and tensile tests. Int. J. Press. Vessel. Pip. 2005, 82, 175–184. [Google Scholar] [CrossRef]

- Takahashi, Y. Modelling of rupture ductility of metallic materials over wide ranges of temperatures and loading conditions, part II: Comparison with strain energy-based approach. Mater. High Temp. 2020, 37, 340–350. [Google Scholar] [CrossRef]

- Takahashi, Y. Modelling of rupture ductility of metallic materials over wide ranges of temperatures and loading conditions, part I: Development of basic model. Mater. High Temp. 2020, 37, 357–369. [Google Scholar] [CrossRef]

| Element | A | B | C/D | E | F | ASME SA-335 P91 | |

|---|---|---|---|---|---|---|---|

| Type 1 | Type 2 | ||||||

| C | 0.10 | 0.08 | 0.10 | 0.08 | 0.10 | 0.08~0.12 | |

| Mn | 0.44 | 0.45 | 0.41 | 0.41 | 0.40 | 0.30~0.60 | 0.30~0.50 |

| P | 0.003 | 0.015 | 0.009 | 0.012 | 0.012 | ≤0.020 | |

| S | 0.001 | <0.001 | 0.010 | 0.009 | 0.002 | ≤0.010 | ≤0.005 |

| Si | 0.26 | 0.24 | 0.41 | 0.14 | 0.33 | 0.20~0.50 | 0.20~0.40 |

| Cr | 8.94 | 8.43 | 8.77 | 8.88 | 8.30 | 8.0~9.5 | |

| Mo | 0.91 | 0.87 | 0.94 | 0.93 | 0.94 | 0.85~1.05 | |

| W | <0.002 | <0.002 | Not detected | <0.002 | Not detected | - | ≤0.05 |

| Ni | 0.04 | 0.11 | 0.12 | 0.14 | 0.19 | ≤0.40 | ≤0.20 |

| V | 0.21 | 0.20 | 0.21 | 0.21 | 0.21 | 0.18~0.25 | |

| Nb | 0.086 | 0.072 | 0.071 | 0.061 | 0.070 | 0.06~0.10 | |

| N | 0.0539 | 0.0429 | 0.0454 | 0.0447 | 0.0424 | 0.03~0.07 | 0.035~0.070 |

| Cu | 0.01 | 0.03 | 0.19 | 0.18 | 0.05 | - | ≤0.10 |

| Al | 0.013 | 0.010 | 0.040 | 0.034 | 0.020 | ≤0.02 | ≤0.020 |

| B | <0.0003 | 0.0003 | <0.0003 | <0.0010 | <0.0003 | - | ≤0.001 |

| Ti | 0.002 | 0.009 | <0.002 | 0.002 | <0.002 | ≤0.01 | |

| Zr | <0.002 | <0.002 | <0.002 | <0.002 | <0.002 | ≤0.01 | |

| As | 0.002 | 0.003 | 0.013 | 0.014 | 0.004 | - | ≤0.010 |

| Sn | 0.001 | <0.001 | 0.008 | 0.008 | 0.003 | - | ≤0.010 |

| Sb | <0.0001 | <0.0001 | 0.0023 | 0.0019 | 0.0006 | - | ≤0.003 |

| N/Al | 4.1 | 4.3 | 1.1 | 1.3 | 2.1 | - | ≥4.0 |

| Material | 0.2% Proof Stress (MPa) | Tensile Strength (MPa) | Elongation (%) | Reduction in Area (%) |

|---|---|---|---|---|

| A | 341 | 345 | 32 | 95 |

| B | 304 | 306 | 38 | 96 |

| C | 275 | 287 | 32 | 82 |

| D | 301 | 315 | 49 | 89 |

| E | 270 | 280 | 35 | 83 |

| F | 235 | 240 | 41 | 90 |

| Test Conditions | Coefficient of Variation | |

|---|---|---|

| Creep | 625 °C, 120 MPa | 1.015 |

| 625 °C, 100 MPa | 1.195 | |

| 625 °C, 80 MPa | 0.926 | |

| Fatigue | 600 °C, | 0.145 |

| 625 °C, | 0.249 | |

| Creep-Fatigue | 600 °C, , | 0.344 |

| 625 °C, , | 0.566 | |

| Constants | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 1.70 | 7.20 × 10−1 | 1.70 × 10−1 | 5.00 × 10−1 | 1.70 × 10−1 | 4.00 × 10−1 | |

| 3.24 × 10−1 | 3.76 × 10−1 | 3.19 × 10−1 | 4.85 × 10−1 | 3.53 × 10−1 | 4.06 × 10−1 | |

| 4.61 × 10−1 | 1.06 | 6.22 | 1.25 × 101 | 8.46 | 3.63 × 101 | |

| 2.66 × 10−2 | 6.14 × 10−2 | 1.70 × 10−1 | 1.82 × 10−1 | 1.85 × 10−1 | 2.15 × 10−1 | |

| 7.23 × 101 | 6.91 × 101 | 6.54 × 101 | 7.81 × 101 | 6.73 × 101 | 6.23 × 101 | |

| 6.57 × 10−1 | 2.61 × 10−1 | 4.06 × 10−3 | 3.73 × 10−3 | 3.60 × 10−3 | 3.45 × 10−3 | |

| 1.21 × 10−1 | 1.48 × 10−1 | 2.56 × 10−1 | 2.73 × 10−1 | 2.58 × 10−1 | 2.83 × 10−1 | |

| 4.17 × 10−1 | 1.65 × 10−1 | 1.45 × 10−3 | 1.34 × 10−3 | 1.23 × 10−3 | 1.41 × 10−3 | |

| 1.35 × 10−1 | 1.61 × 10−1 | 2.85 × 10−1 | 3.02 × 10−1 | 2.88 × 10−1 | 3.07 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shigeyama, H.; Takahashi, Y.; Siefert, J.; Parker, J. Creep-Fatigue Life Evaluation for Grade 91 Steels with Various Origins and Service Histories. Metals 2024, 14, 148. https://doi.org/10.3390/met14020148

Shigeyama H, Takahashi Y, Siefert J, Parker J. Creep-Fatigue Life Evaluation for Grade 91 Steels with Various Origins and Service Histories. Metals. 2024; 14(2):148. https://doi.org/10.3390/met14020148

Chicago/Turabian StyleShigeyama, Haruhisa, Yukio Takahashi, John Siefert, and Jonathan Parker. 2024. "Creep-Fatigue Life Evaluation for Grade 91 Steels with Various Origins and Service Histories" Metals 14, no. 2: 148. https://doi.org/10.3390/met14020148

APA StyleShigeyama, H., Takahashi, Y., Siefert, J., & Parker, J. (2024). Creep-Fatigue Life Evaluation for Grade 91 Steels with Various Origins and Service Histories. Metals, 14(2), 148. https://doi.org/10.3390/met14020148