Buckling of Hydroformed Toroidal Pressure Hulls with Octagonal Cross-Sections

Abstract

:1. Introduction

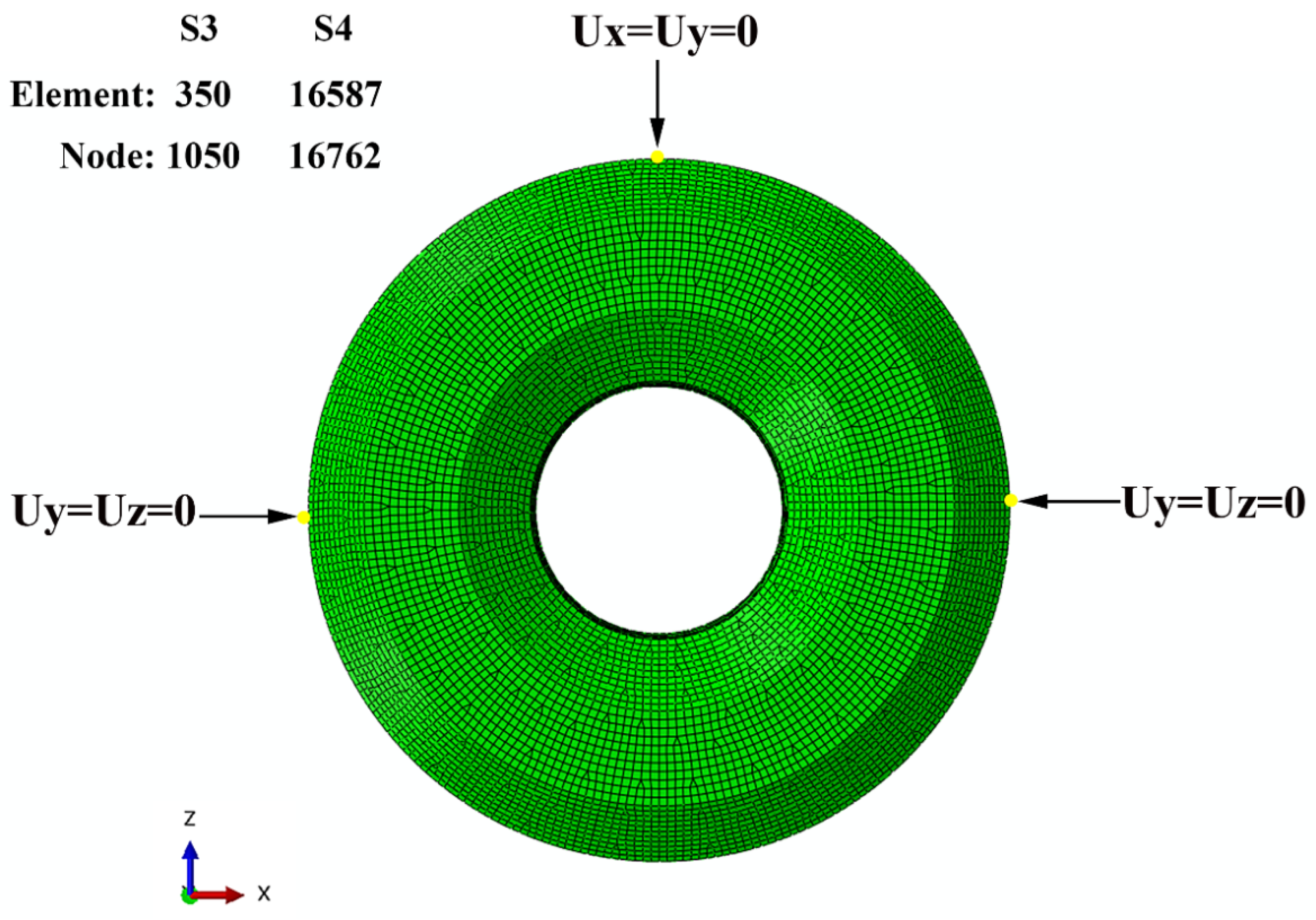

2. Numerical Study

2.1. Geometric Definition and Numerical Modeling

2.2. Numerical Results and Discussion

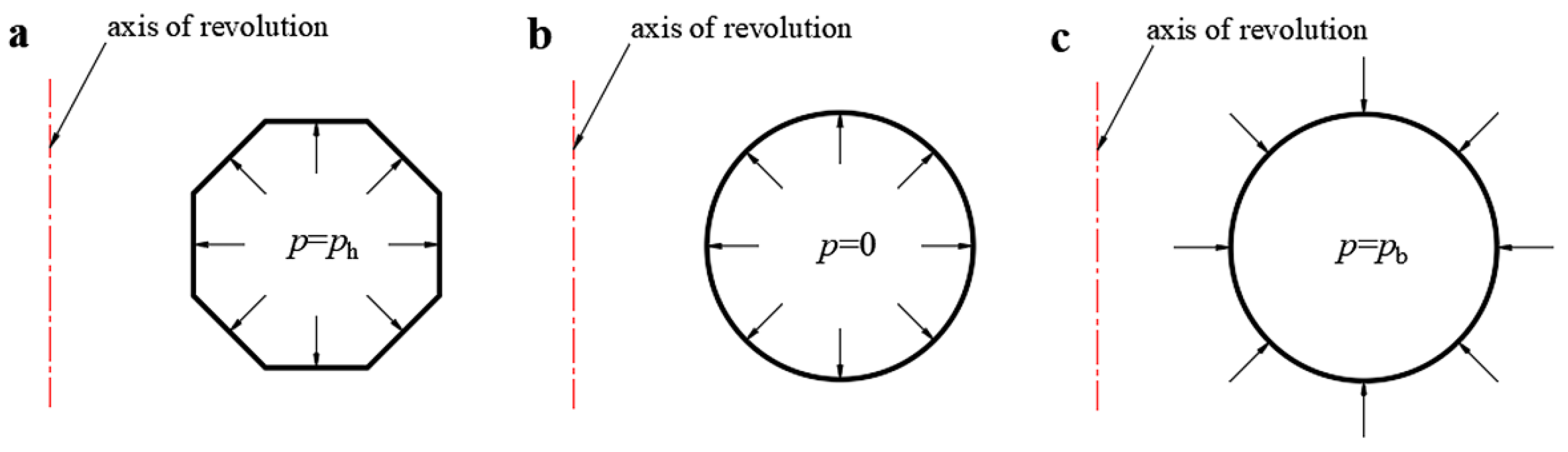

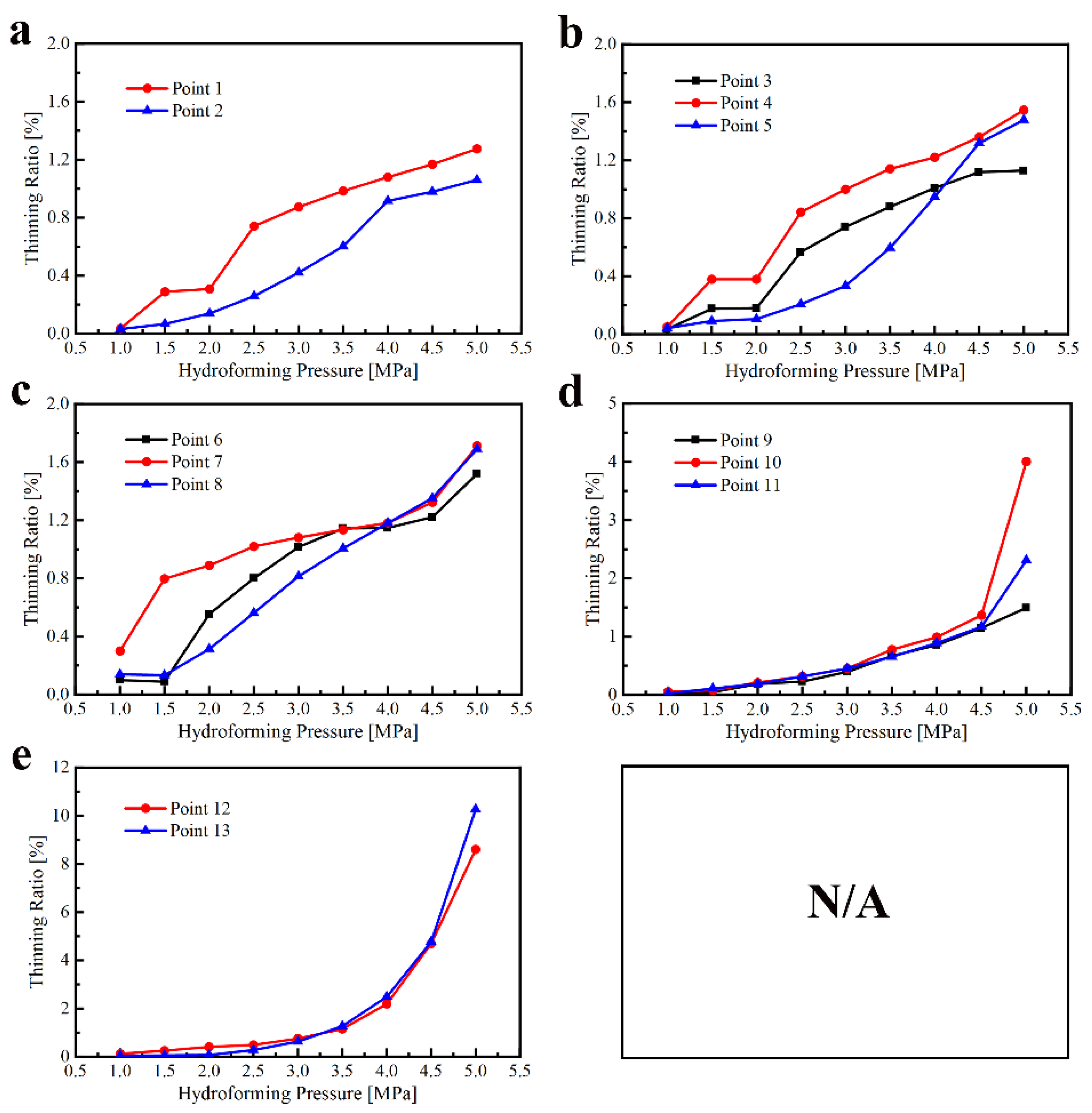

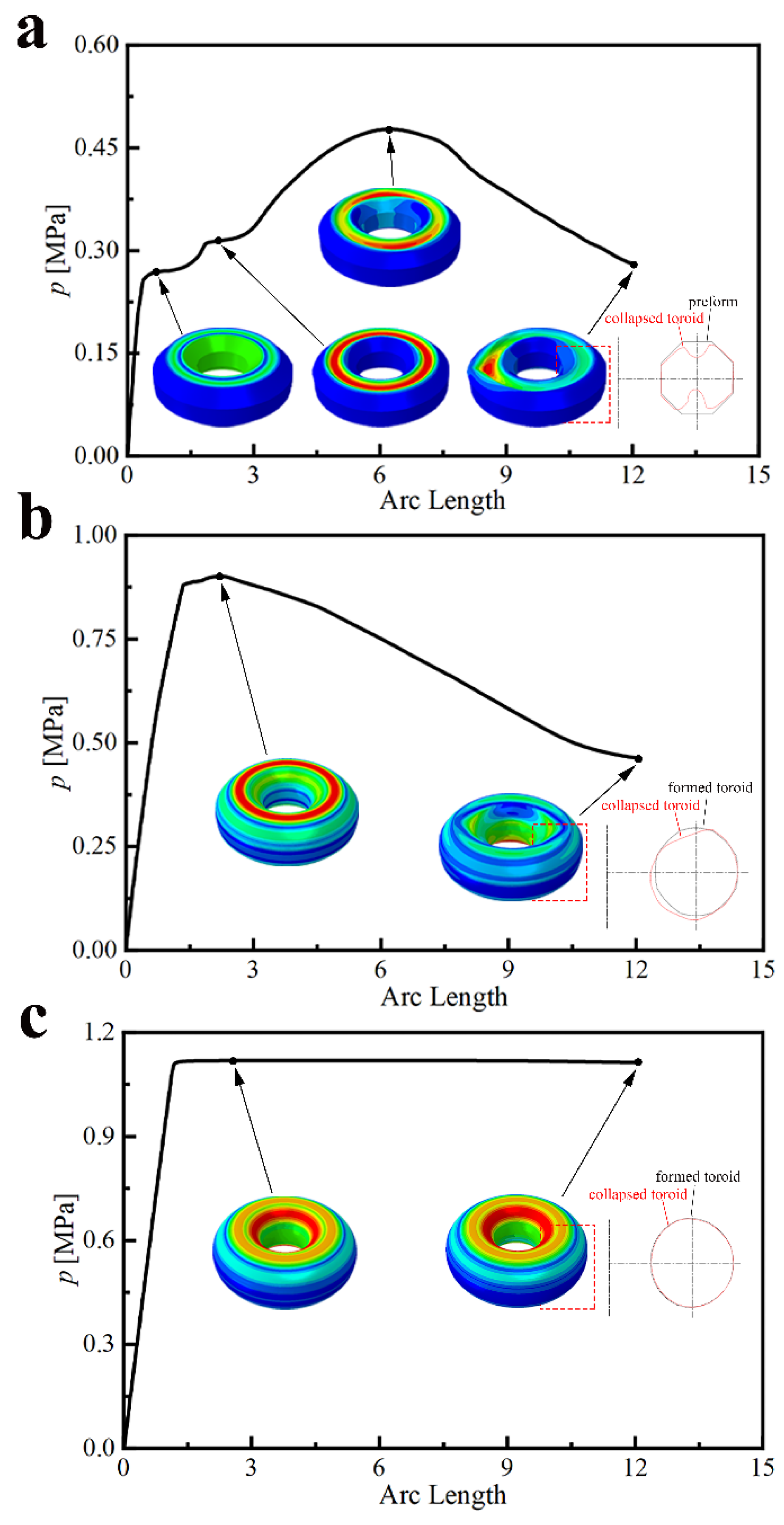

2.2.1. Hydroforming Analysis of Toroidal Pressure Hulls with Octagonal Cross-Sections

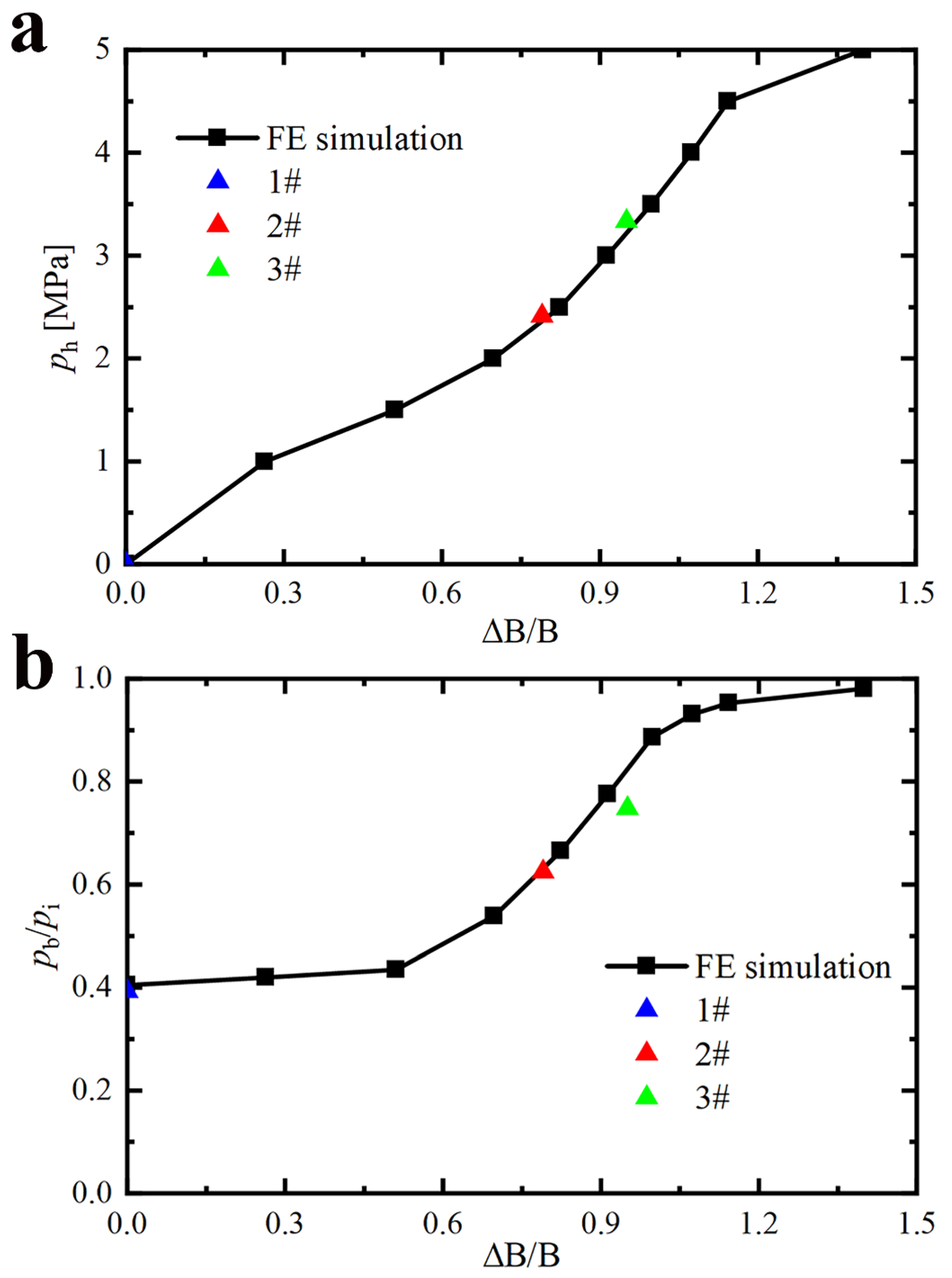

2.2.2. Buckling Analysis of Toroidal Pressure Hulls under Various Hydroforming Pressures

3. Experimental Study

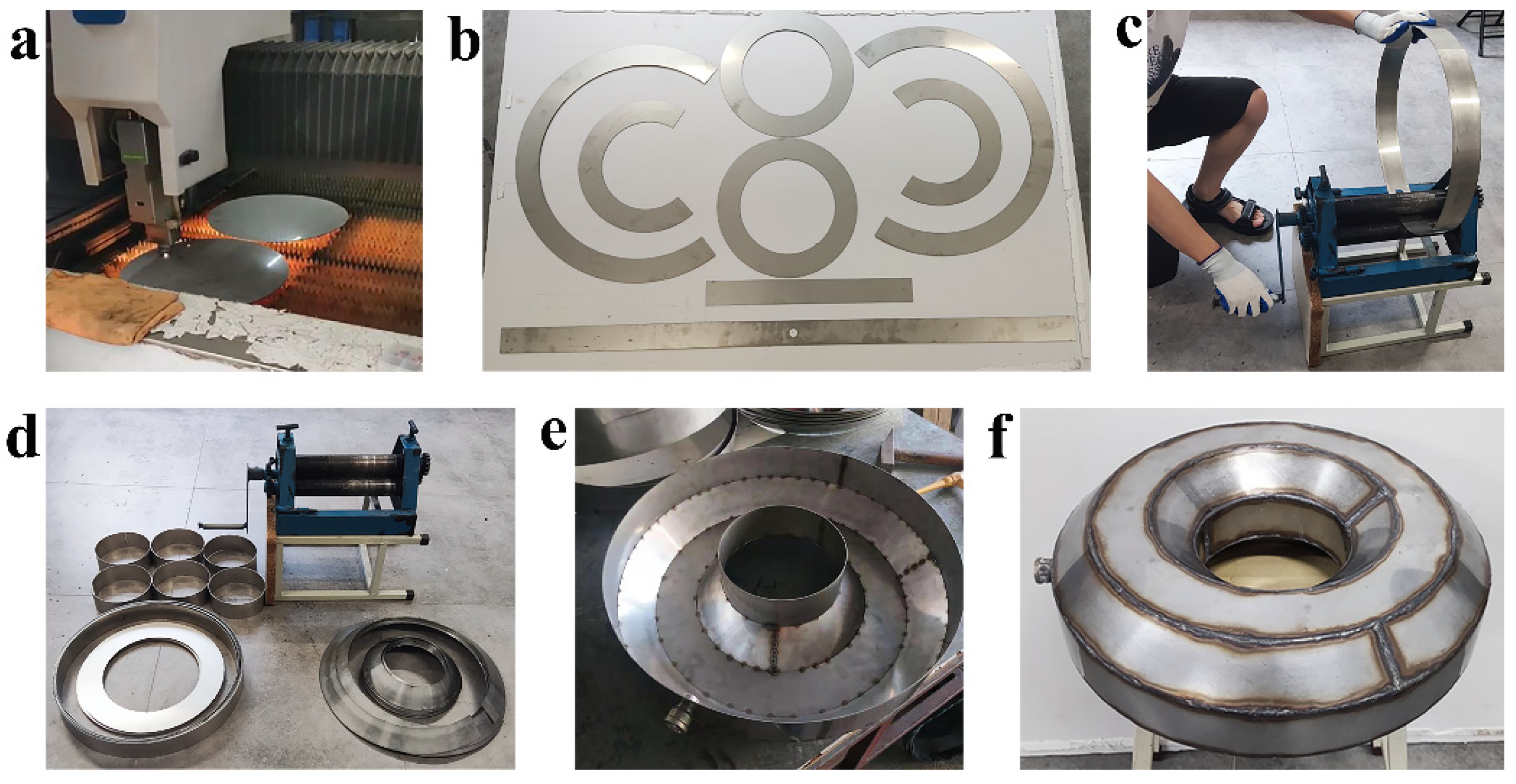

3.1. Preform Manufacture and Experimental Methodology

3.2. Experimental Results and Discussion

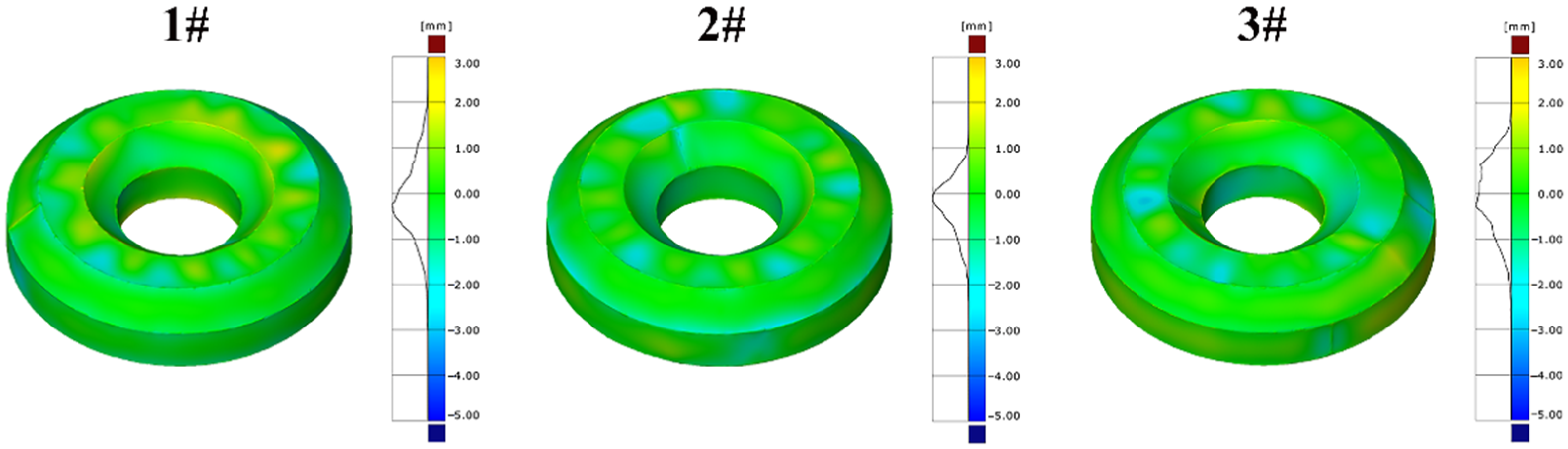

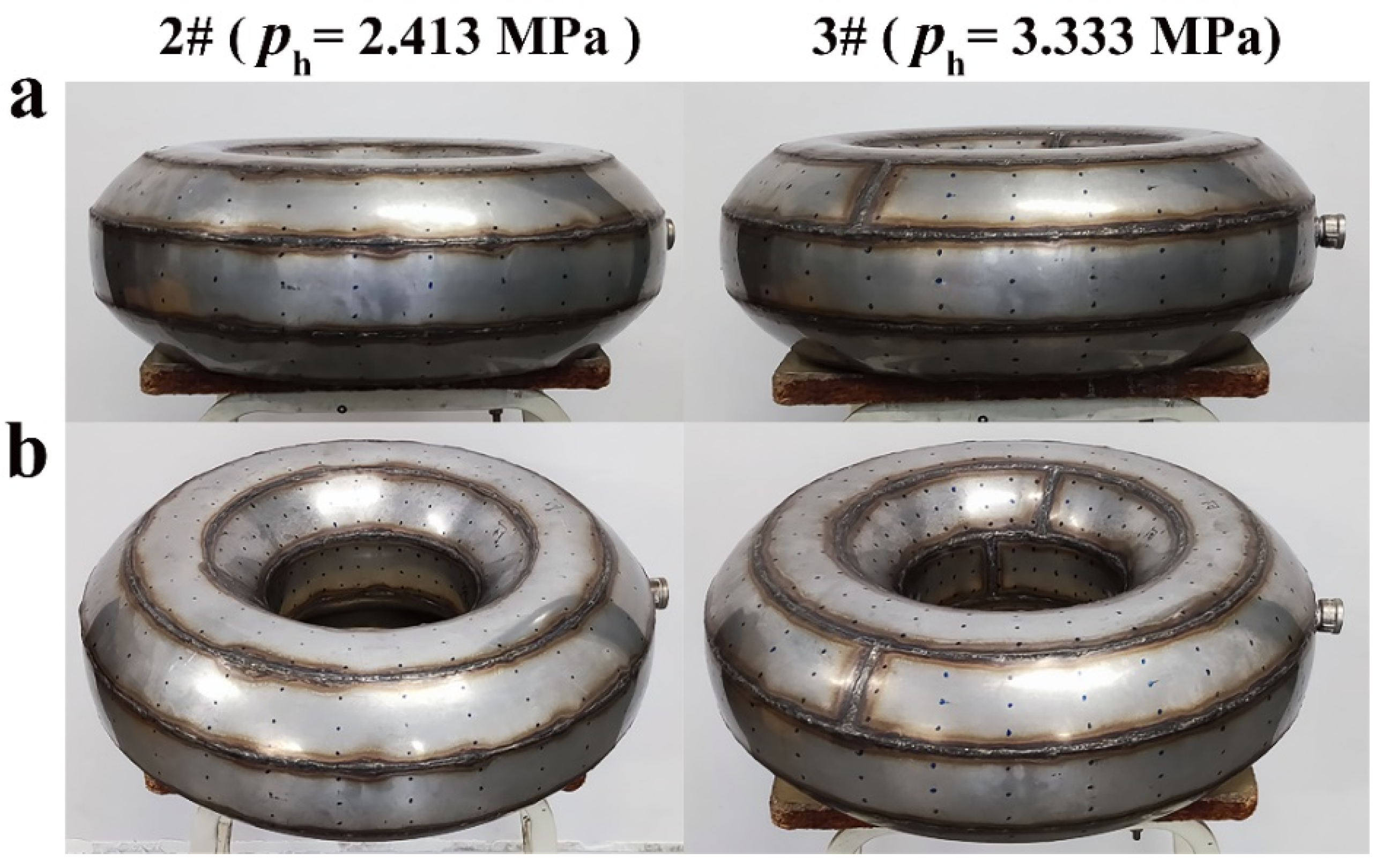

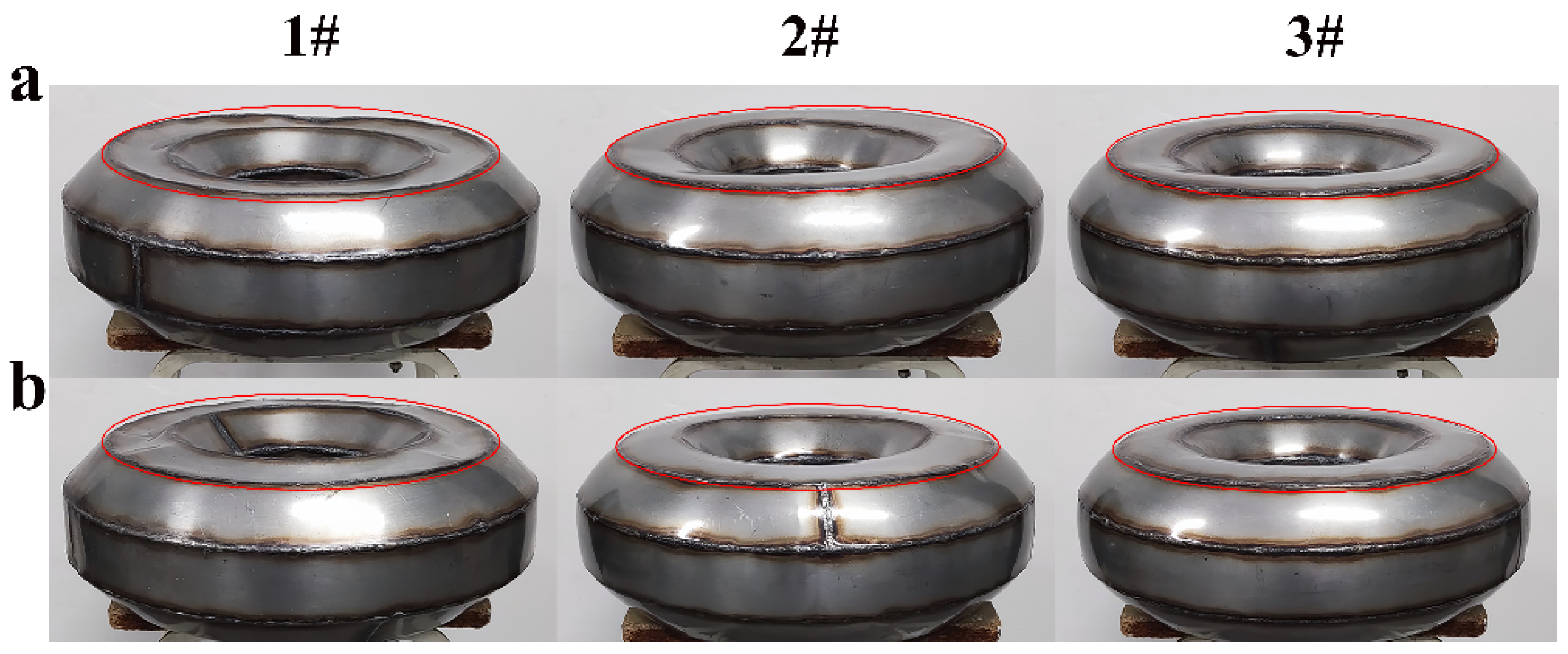

3.2.1. Geometrical Analysis of Three Manufactured Toroid Pressure Hulls

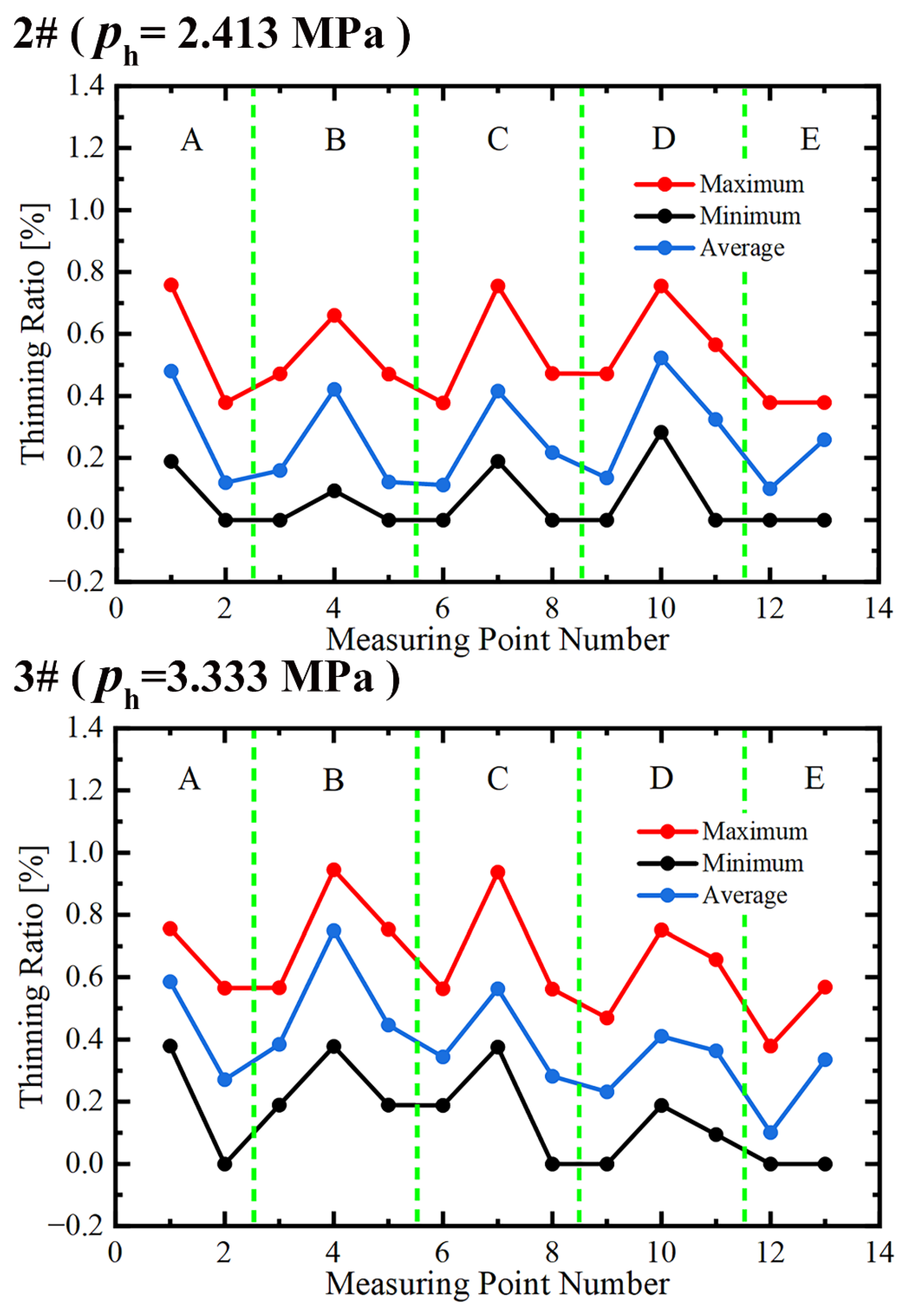

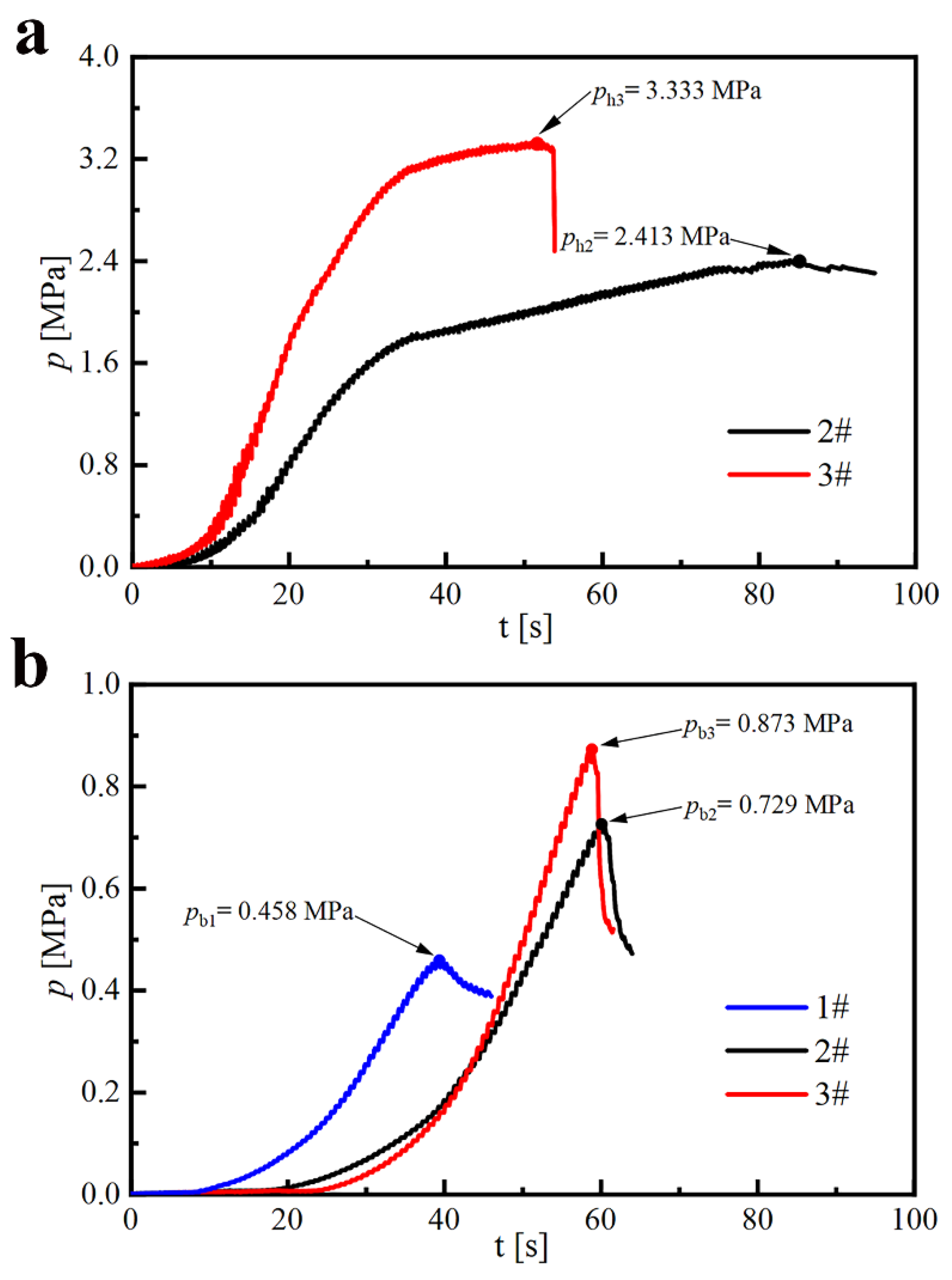

3.2.2. Mechanical Analysis of Three Manufactured Toroid Pressure Hulls

4. Conclusions

- (1)

- The cross-sections of hydroformed toroidal pressure hulls change gradually from a discrete octagon into a continuous circle as the hydroforming pressure increases. The wall thickness varies slightly, suggesting a nearly uniform distribution of hydroforming.

- (2)

- For the first two hydroforming cases and the last three hydroforming cases, the numerical collapse strength keeps constant. For the remaining hydroforming cases, the numerical collapse strength increases linearly and considerably with an increase in the hydroforming amplitude.

- (3)

- The experimental collapse strength is 0.458 MPa for preformed toroids and 0.729 MPa and 0.837 MPa for hydroformed toroids. Compared to the preformed toroids, the loading capacity of the hydroformed toroids increased by as much as 1.59–1.83 times.

- (4)

- The collapse modes of the tested toroids belong to the deformation of pole plates along the axis of revolution. The deformation is nearly axisymmetric around the axis of revolution, which is consistent with the numerical observations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiammeepreecha, W.; Chucheepsakul, S. Nonlinear Static Analysis of an Underwater Elastic Semi-Toroidal Shell. Thin-Walled Struct. 2017, 116, 12–18. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Tang, W.; Wang, F.; Yin, B. Experimental and Numerical Buckling Analysis of Toroidal Shell Segments under Uniform External Pressure. Thin-Walled Struct. 2020, 150, 106689. [Google Scholar] [CrossRef]

- Pietraszkiewicz, W.; Konopińska, V. Junctions in Shell Structures: A Review. Thin-Walled Struct. 2015, 95, 310–334. [Google Scholar] [CrossRef]

- Wang, Z.R.; Hu, W.L.; Yuan, S.J.; Wang, X.S. Engineering Plasticity-Theory and Applications in Metal Forming; Higher Education Press: Beijing, China; John Wiley & Sons Singapore Pte., Ltd.: Singapore, 2018; pp. 355–356. [Google Scholar]

- Zhan, H.J.; Redekop, D. Vibration, Buckling and Collapse of Ovaloid Toroidal Tanks. Thin-Walled Struct. 2008, 46, 380–389. [Google Scholar] [CrossRef]

- Zhan, H.J.; Redekop, D. Static and Dynamic Loading of an Ovaloid Toroidal Tank. Thin-Walled Struct. 2009, 47, 760–767. [Google Scholar] [CrossRef]

- Lubis, A.; Su’Udi, A. Ring Stability of Underground Toroidal Tanks. AIP Conf. Proc. 2017, 1855, 040003. [Google Scholar] [CrossRef]

- Zingoni, A. Liquid-Containment Shells of Revolution: A Review of Recent Studies on Strength, Stability and Dynamics. Thin-Walled Struct. 2015, 87, 102–114. [Google Scholar] [CrossRef]

- Zingoni, A.; Enoma, N.; Govender, N. Equatorial Bending of an Elliptic Toroidal Shell. Thin-Walled Struct. 2015, 96, 286–294. [Google Scholar] [CrossRef]

- Zhang, J.; Di, C.; Wang, F.; Tang, W. Buckling of Segmented Toroids under External Pressure. Ocean Eng. 2021, 239, 109921. [Google Scholar] [CrossRef]

- Ross, C.T.F. A Conceptual Design of an Underwater Vehicle. Ocean Eng. 2006, 33, 2087–2104. [Google Scholar] [CrossRef]

- Ross, C.T.F. A Conceptual Design of an Underwater Missile Launcher. Ocean Eng. 2005, 32, 85–99. [Google Scholar] [CrossRef]

- Du, Q.; Cui, W.; Zhang, B. Buckling Characteristics of a Circular Toroidal Shell with Stiffened Ribs. Ocean Eng. 2015, 108, 325–335. [Google Scholar] [CrossRef]

- Du, Q.; Zou, G.; Zhang, B.; Wan, Z. Simplified Theoretical Solution of Circular Toroidal Shell with Ribs under Uniform External Pressure. Thin-Walled Struct. 2015, 96, 49–55. [Google Scholar] [CrossRef]

- Błachut, J. Buckling and First Ply Failure of Composite Toroidal Pressure Hull. Comput. Struct. 2004, 82, 1981–1992. [Google Scholar] [CrossRef]

- Galletly, G.D.; Blachut, J. Stability of Complete Circular and Non-Circular Toroidal Shells. J. Mech. Eng. Sci. 1995, 209, 245–255. [Google Scholar]

- Zou, G.; Peng, X.N.; Du, Q.H. Theoretical Solution and Essential Research of the Ring-Stiffened Toroidal Shell. J. Ship Mech. 2012, 16, 83–92. [Google Scholar]

- Du, Q.H.; Cui, W.C.; Wan, Z.Q. Nonlinear Finite Element Analysis of a Toroidal Shell with Ring-Stiffened RIBS. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Shanghai, China, 6–11 June 2010; Volume 2, pp. 759–765. [Google Scholar]

- Alves, L.M.; Martins, P.A.F. Forming of Thin-Walled Tubes into Toroidal Shells. J. Mater. Process. Technol. 2010, 210, 689–695. [Google Scholar] [CrossRef]

- Micari, F.; Ambrogio, G.; Filice, L. Shape and Dimensional Accuracy in Single Point Incremental Forming: State of the Art and Future Trends. J. Mater. Process. Technol. 2007, 191, 390–395. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, W.W.; Yuan, S.J. Research on Hydro-Forming of Spherical Shells with Different Preform Types. Int. J. Adv. Manuf. Technol. 2017, 92, 2631–2638. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Z.R. Shape Improvement of a Dieless Hydro-Bulged Sphere Made of Hexagonal and Pentagonal Shaped Panels. J. Mater. Process. Technol. 2015, 220, 87–95. [Google Scholar] [CrossRef]

- Zhang, W.W.; Yuan, S.J. Reverse Geometric Modeling for Pre-Form Shape of Prolate Ellipsoid before Hydro-Forming. Int. J. Adv. Manuf. Technol. 2016, 88, 1903–1909. [Google Scholar] [CrossRef]

- Zhang, W.W.; Yuan, S.J. Research on Hydro-Forming of Combined Prolate Ellipsoidal Shell with Double Generating Lines. Int. J. Adv. Manuf. Technol. 2015, 82, 595–603. [Google Scholar] [CrossRef]

- Yuan, S.J.; Zhang, W.W.; Teng, B.G. Research on Hydro-Forming of Combined Ellipsoidal Shells with Two Axis Length Ratios. J. Mater. Process. Technol. 2015, 219, 124–132. [Google Scholar] [CrossRef]

- Zhang, W.W.; Teng, B.G.; Yuan, S. J Research on Deformation and Stress in Hydroforming Process of an Ellipsoidal Shell without Constraint. Int. J. Adv. Manuf. Technol. 2015, 76, 1555–1562. [Google Scholar] [CrossRef]

- Ruan, S.; Lang, L.; Ge, Y. Hydroforming Process for an Ultrasmall Bending Radius Elbow. Adv. Mater. Sci. Eng. 2018, 2018, 7634708. [Google Scholar] [CrossRef]

- Wang, Z.R. Shell and Tube Hydroforming: Mechanics of Dieless Closed Shell Hydro-Bulging; Higher Education Press: Beijing, China, 2018; pp. 343–364. [Google Scholar]

- Yuan, S.; Teng, B.; Wang, Z.R. A New Hydroforming Process for Large Elbow Pipes. J. Mater. Process. Technol. 2001, 117, 28–31. [Google Scholar] [CrossRef]

- Yuan, S.J.; Xu, Z.; Wang, Z.R.; Hai, W. The Integrally Hydro-Forming Process of Pipe Elbows. Int. J. Press. Vessel. Pip. 1998, 75, 7–9. [Google Scholar] [CrossRef]

- Yuan, S.; Wang, Z.R.; He, Q. Finite Element Analysis of Hydro-Forming Process of a Toroidal Shell. Int. J. Mach. Tools Manuf. 1999, 39, 1439–1450. [Google Scholar] [CrossRef]

- Teng, B.G.; Yuan, S.J.; Wang, Z.R. Effect of the Initial Structure on the Hydro-Forming of Toroidal Shells. J. Mater. Process. Technol. 2002, 123, 18–21. [Google Scholar] [CrossRef]

- Teng, B.G.; Yuan, S.J.; Wang, Z.R. Experiment and Numerical Simulation of Hydro-Forming Toroidal Shells with Different Initial Structure. Int. J. Press. Vessel. Pip. 2001, 78, 31–34. [Google Scholar] [CrossRef]

- Soni, A.; Vimal, J.; Sharma, A.K. Finite Element Analysis of Component Developed by Tube Hydro Forming. Int. J. Res. Eng. Appl. Sci. 2014, 1, 35–43. [Google Scholar]

- Zhang, J.; Dai, M.; Wang, F.; Tang, W.; Zhao, X. Buckling Performance of Egg-Shaped Shells Fabricated through Free Hydroforming. Int. J. Press. Vessel. Pip. 2021, 193, 104435. [Google Scholar] [CrossRef]

- Zhang, J.; Dai, M.; Wang, F.; Tang, W.; Zhao, X. Theoretical and Experimental Study of the Free Hydroforming of Egg-Shaped Shell. Ships Offshore Struct. 2022, 17, 257–267. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, P.; Wang, F.; Tang, W.; Zhao, X. Hydroforming and Buckling of an Egg-Shaped Shell Based on a Petal-Shaped Preform. Ocean Eng. 2022, 250, 111057. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, F.; Wang, F.; Zhao, X.; Tang, W.; Chen, F. Buckling Properties of Bulged Barrels under External Pressure. Thin-Walled Struct. 2021, 168, 108226. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Tang, W.; Wang, F.; Zhao, X.; Zhang, J.; Tang, L. Collapse of Barreled Frustums under External Hydrostatic Pressure. Mar. Struct. 2022, 84, 103218. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Zhan, M.; Wang, F.; Zhao, X. Hydroforming and buckling of toroids with polyhedral sections. Ships Offshore Struct. 2022; 1–11, in press. [Google Scholar] [CrossRef]

- ISO 6892-1; Metallic Materials, Tensile Testing-Part-1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2009; Volume 2009.

- Zhang, J.; Hua, Z.; Tang, W.; Wang, F.; Wang, S. Buckling of Externally Pressurised Egg-Shaped Shells with Variable and Constant Wall Thicknesses. Thin-Walled Struct. 2018, 132, 111–119. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Tang, W.; Wang, F.; Zhu, Y. Non-Linear Collapse Behavior of Externally Pressurized Resin Toroidal and Cylindrical Shells: Numerical and Experimental Studies. Ships Offshore Struct. 2021, 16, 529–545. [Google Scholar] [CrossRef]

- Wang, Z.R.; Zeng, Y.S.; Yuan, S.J.; Zhang, S.H. The Research on the Plastic Deformation of the Hydrobulge Forming of Ellipsoidal Shells. Acta Mech. Solida Sin. 1998, 19, 259–264. [Google Scholar]

- Wang, Z.R.; Wang, T.; Kang, D.C.; Zhang, S.H.; Yi, F. The Technology of the Hydro-Bulging of Whole Spherical Vessels and Experimental Analysis. J. Mech. Work. Technol. 1989, 18, 85–94. [Google Scholar] [CrossRef]

- CCS. Rules for Construction and Classification of Diving Systems and Submersibles; China Classification Society: Beijing, China, 2013. [Google Scholar]

- Tang, W.; Wang, W.; Zhang, J.; Wang, S. Buckling of Cassini Oval Pressure Hulls Subjected to External Pressure. China Ocean Eng. 2019, 33, 503–508. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Wang, W.; Tang, W. Linear and Nonlinear Elastic Buckling of Stereolithography Resin Egg-Shaped Shells Subjected to External Pressure. Thin-Walled Struct. 2018, 127, 516–522. [Google Scholar] [CrossRef]

- Zhang, W.W.; Yuan, S.J. Pre-Form Design for Hydro-Forming Process of Combined Ellipsoidal Shells by Response Surface Methodology. Int. J. Adv. Manuf. Technol. 2015, 81, 1977–1986. [Google Scholar] [CrossRef]

- Rathinam, N.; Prabu, B.; Anbazhaghan, N. Buckling Analysis of Ring Stiffened Thin Cylindrical Shell under External Pressure. J. Ocean Eng. Sci. 2021, 6, 360–366. [Google Scholar] [CrossRef]

- Foryś, P. Optimization of Cylindrical Shells Stiffened by Rings under External Pressure Including Their Post-Buckling Behaviour. Thin-Walled Struct. 2015, 95, 231–243. [Google Scholar] [CrossRef]

- Yu, M.H.; Wang, R.H.; Li, L.B. Research on the Ultimate Strength of Pressure Spherical Shell with Openings in Manned Deep-sea Submersible. Shipbuild. China 2005, 46, 92–96. [Google Scholar]

| 57.4 | 75 | 150 | 1.058 |

| Sample | ||||

|---|---|---|---|---|

| SC1 | 198.2 | 0.29 | 250 | 1566.3 |

| SC2 | 197.5 | 0.30 | 252 | 1518.7 |

| SC3 | 197.8 | 0.30 | 240 | 1578.9 |

| AVE | 197.8 | 0.30 | 247 | 1554.6 |

| 0 | 0 | 0.472 | 0 | 0 | 0.405 |

| 1 | 0.889 | 0.489 | 1.026 | 0.264 | 0.419 |

| 1.5 | 1.719 | 0.508 | 1.048 | 0.511 | 0.435 |

| 2 | 2.349 | 0.629 | 1.060 | 0.698 | 0.539 |

| 2.5 | 2.774 | 0.776 | 1.071 | 0.824 | 0.665 |

| 3 | 3.074 | 0.905 | 1.074 | 0.913 | 0.775 |

| 3.5 | 3.358 | 1.035 | 1.071 | 0.998 | 0.887 |

| 4 | 3.617 | 1.086 | 1.069 | 1.075 | 0.931 |

| 4.5 | 3.850 | 1.112 | 1.068 | 1.043 | 0.953 |

| 5 | 4.712 | 1.144 | 1.065 | 1.399 | 0.981 |

| Measuring Point Number | |||

|---|---|---|---|

| 1# | 2# | 3# | |

| 1 | 1.054 (N/A) | 1.057 (0.481) | 1.056 (0.586) |

| 2 | 1.054 (N/A) | 1.058 (0.120) | 1.055 (0.274) |

| 3 | 1.060 (N/A) | 1.058 (0.138) | 1.053 (0.384) |

| 4 | 1.060 (N/A) | 1.058 (0.422) | 1.052 (0.749) |

| 5 | 1.060 (N/A) | 1.058 (0.122) | 1.052 (0.447) |

| 6 | 1.060 (N/A) | 1.058 (0.113) | 1.059 (0.345) |

| 7 | 1.060 (N/A) | 1.058 (0.416) | 1.058 (0.564) |

| 8 | 1.060 (N/A) | 1.058 (0.217) | 1.059 (0.282) |

| 9 | 1.062 (N/A) | 1.059 (0.122) | 1.058 (0.232) |

| 10 | 1.062 (N/A) | 1.060 (0.523) | 1.058 (0.410) |

| 11 | 1.062 (N/A) | 1.060 (0.324) | 1.058 (0.363) |

| 12 | 1.056 (N/A) | 1.054 (0.101) | 1.055 (0.101) |

| 13 | 1.056 (N/A) | 1.055 (0.259) | 1.054 (0.335) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, J.; Di, C.; Zhan, M.; Wang, F. Buckling of Hydroformed Toroidal Pressure Hulls with Octagonal Cross-Sections. Metals 2022, 12, 1475. https://doi.org/10.3390/met12091475

Liu X, Zhang J, Di C, Zhan M, Wang F. Buckling of Hydroformed Toroidal Pressure Hulls with Octagonal Cross-Sections. Metals. 2022; 12(9):1475. https://doi.org/10.3390/met12091475

Chicago/Turabian StyleLiu, Xiaobin, Jian Zhang, Chenyang Di, Ming Zhan, and Fang Wang. 2022. "Buckling of Hydroformed Toroidal Pressure Hulls with Octagonal Cross-Sections" Metals 12, no. 9: 1475. https://doi.org/10.3390/met12091475

APA StyleLiu, X., Zhang, J., Di, C., Zhan, M., & Wang, F. (2022). Buckling of Hydroformed Toroidal Pressure Hulls with Octagonal Cross-Sections. Metals, 12(9), 1475. https://doi.org/10.3390/met12091475