Texture Development in Aluminum Alloys with High Magnesium Content

Abstract

:1. Introduction

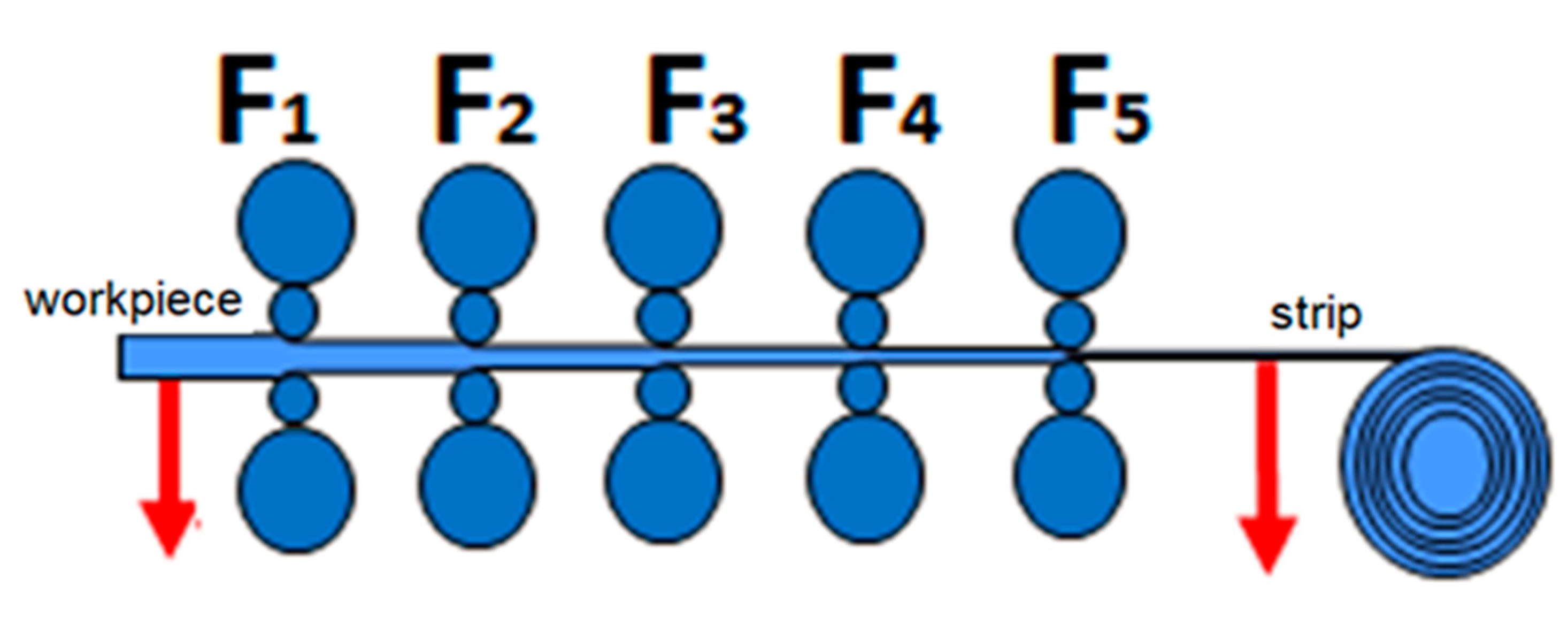

2. Materials and Methods

3. Results

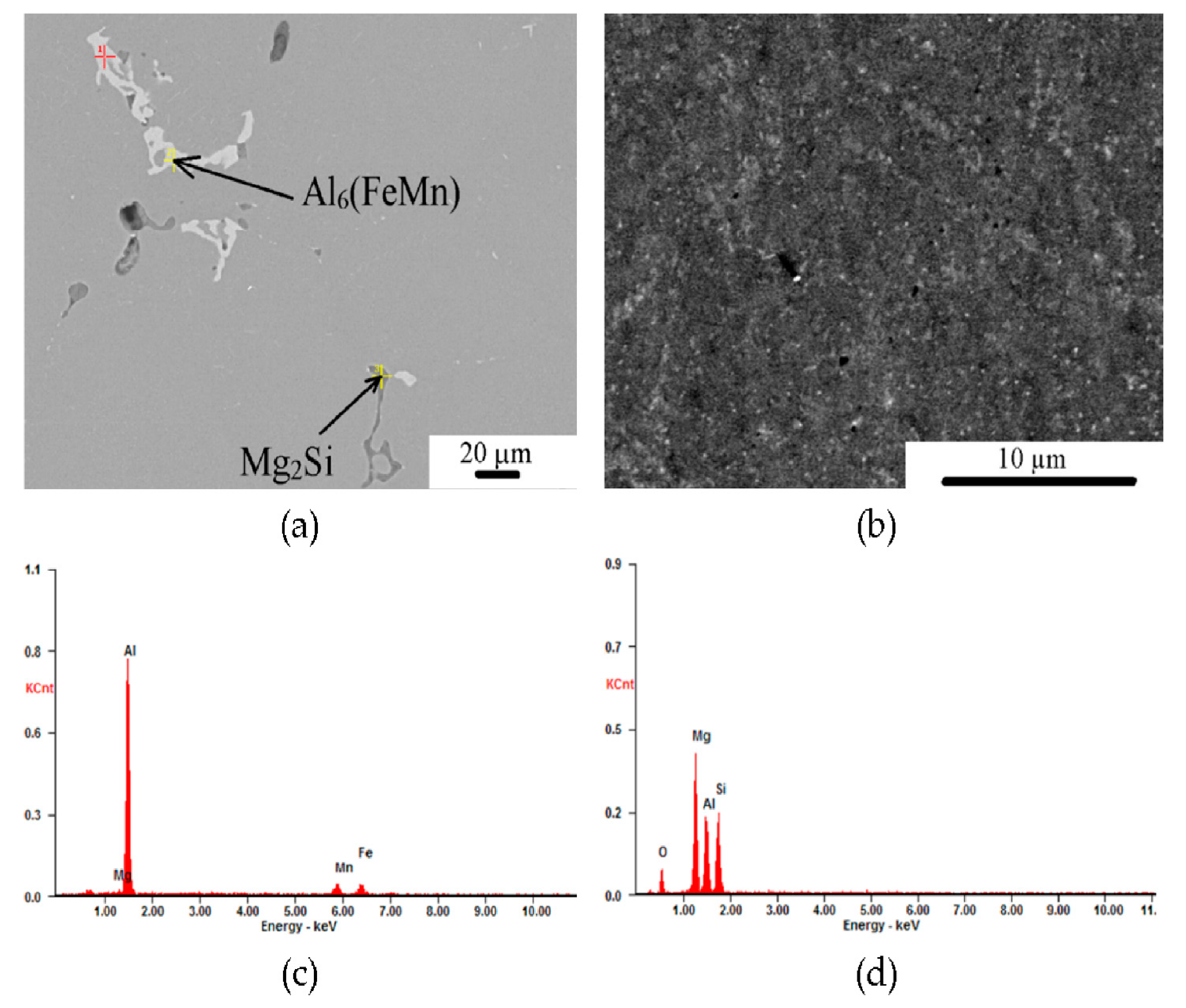

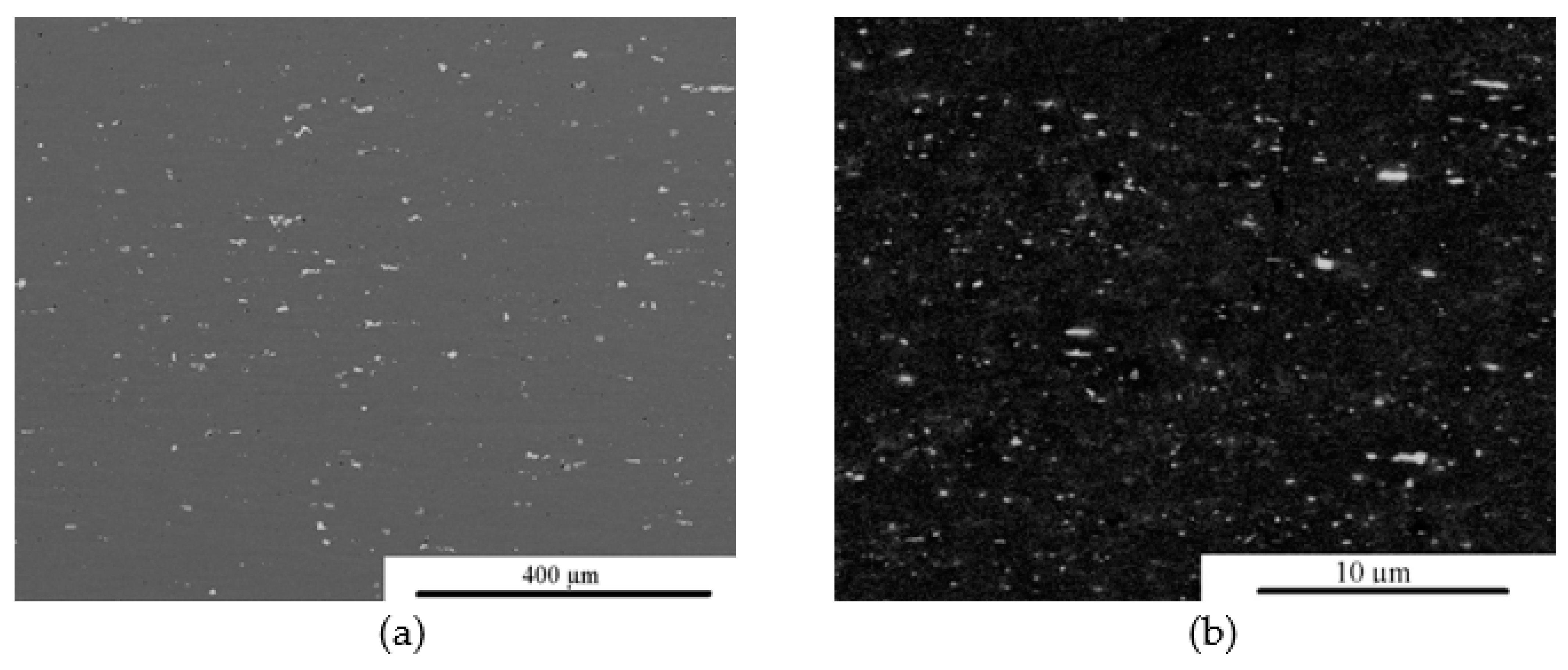

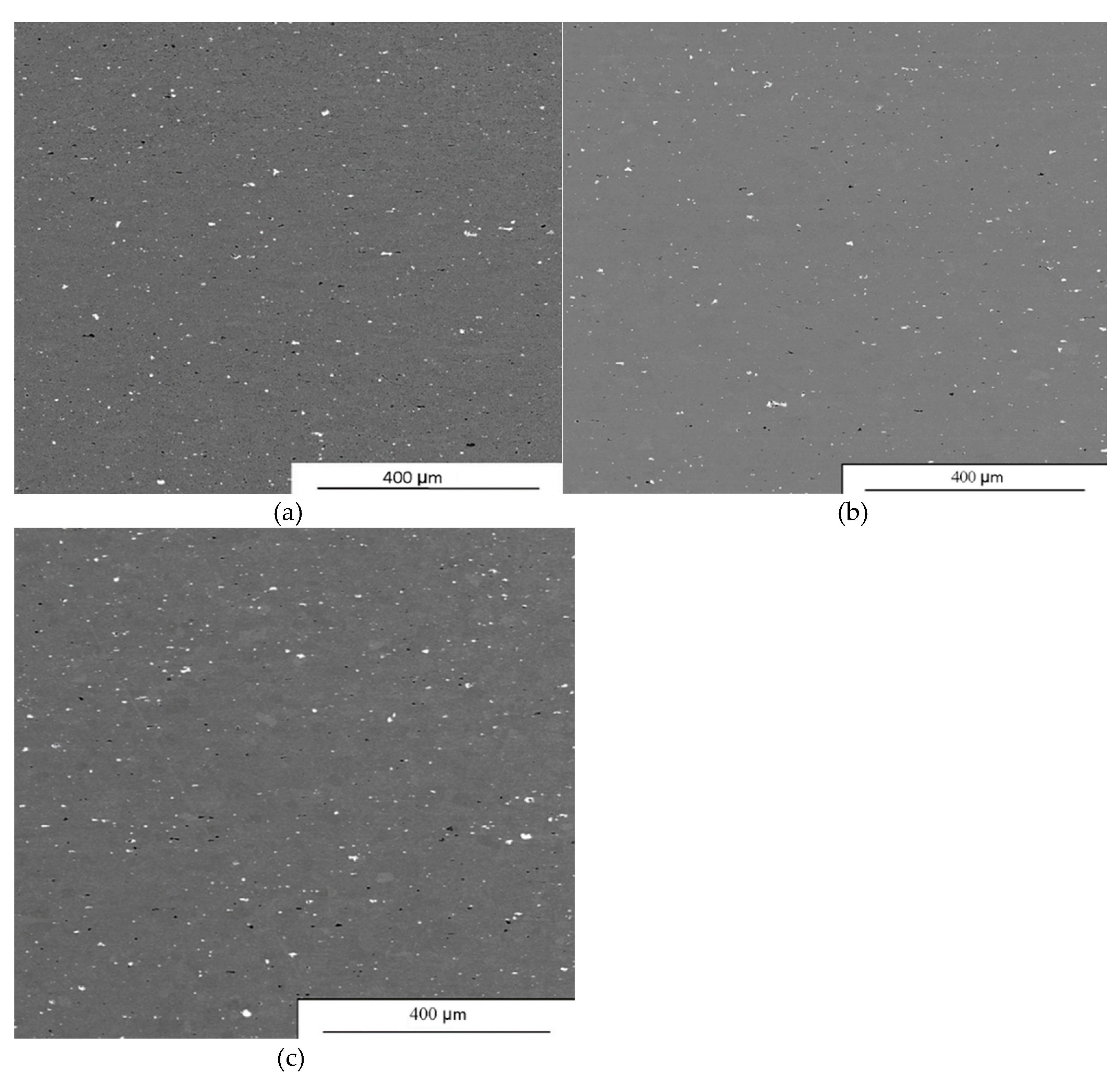

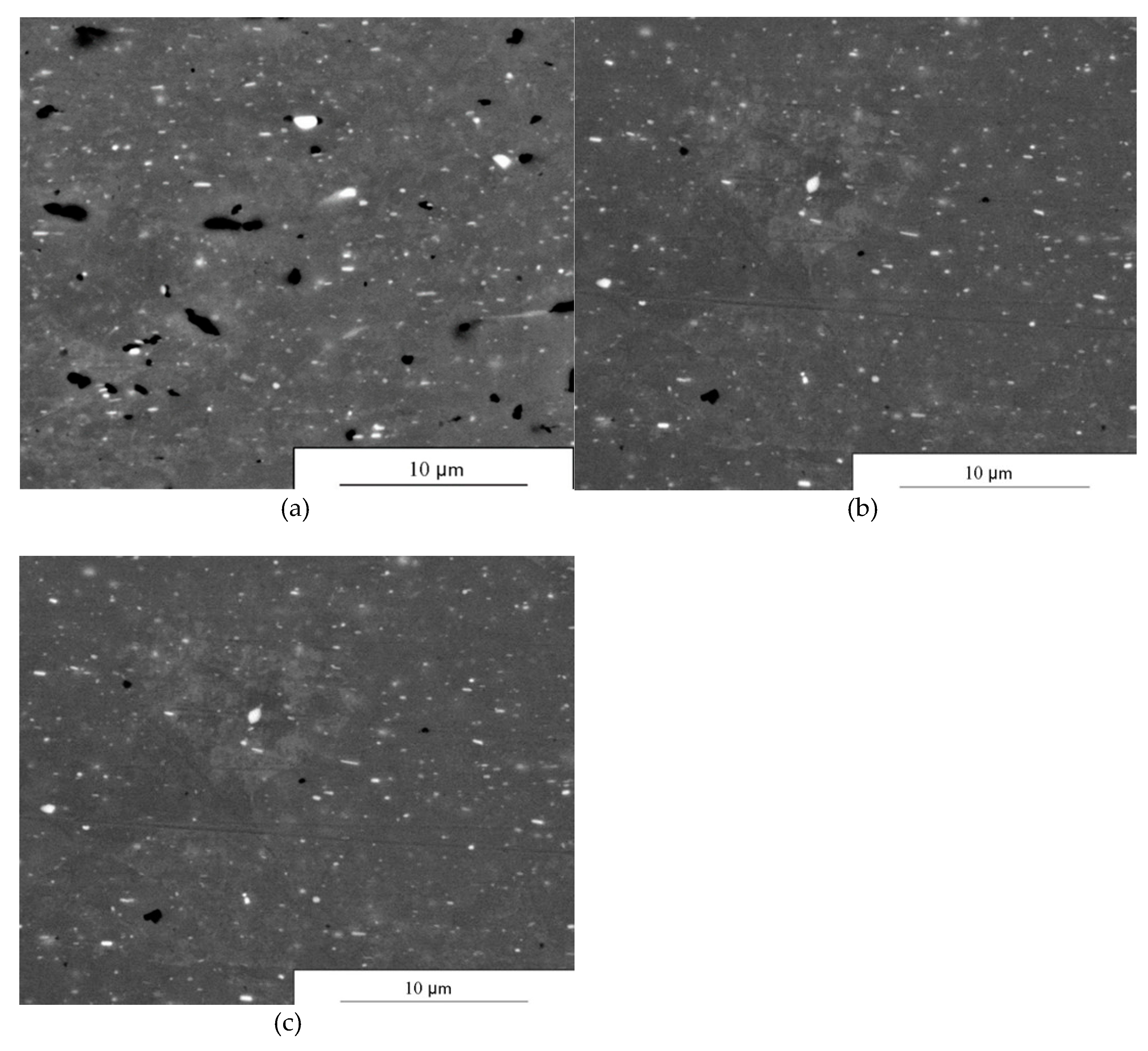

3.1. Evolution of Intermetallic Particles

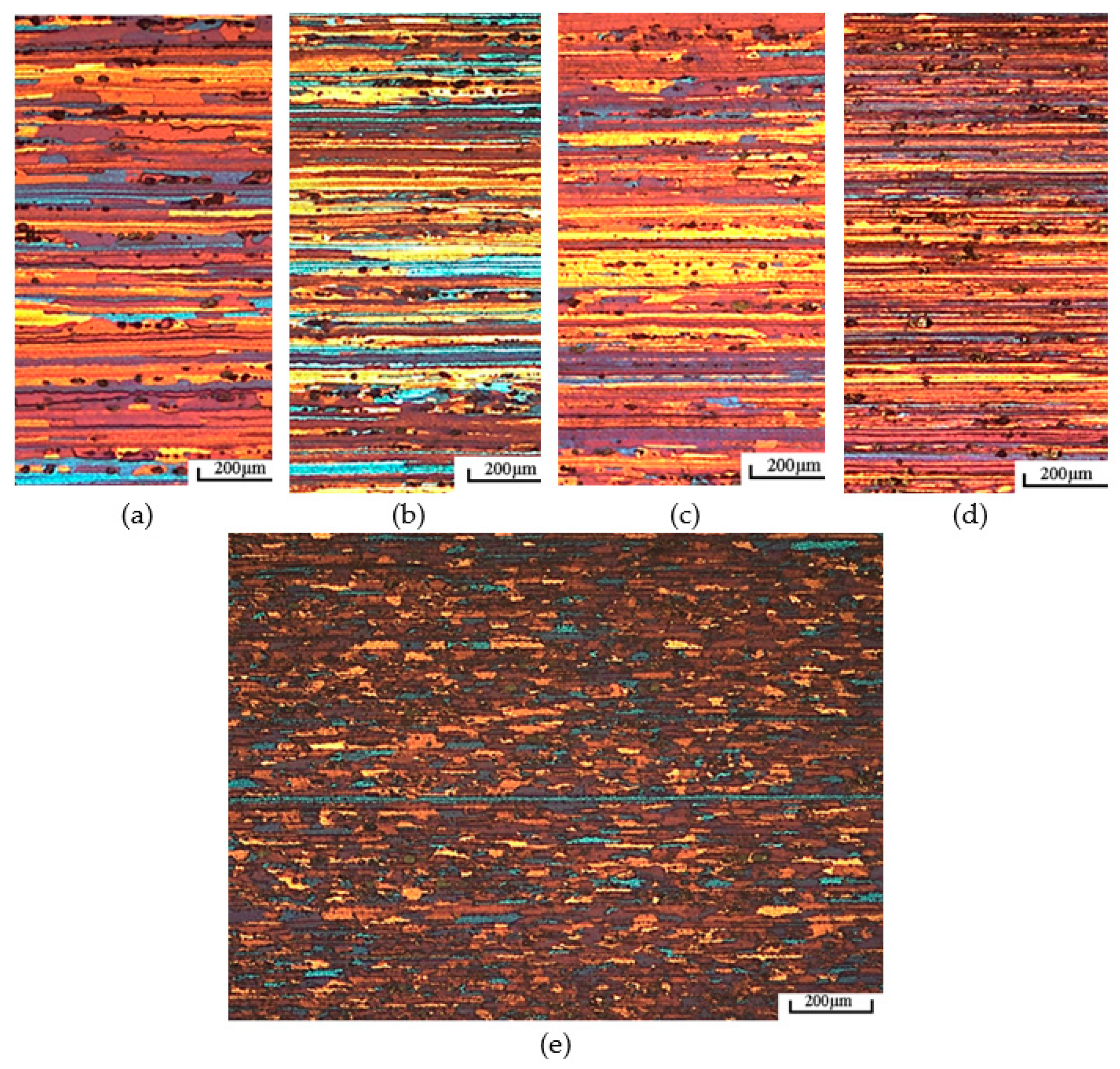

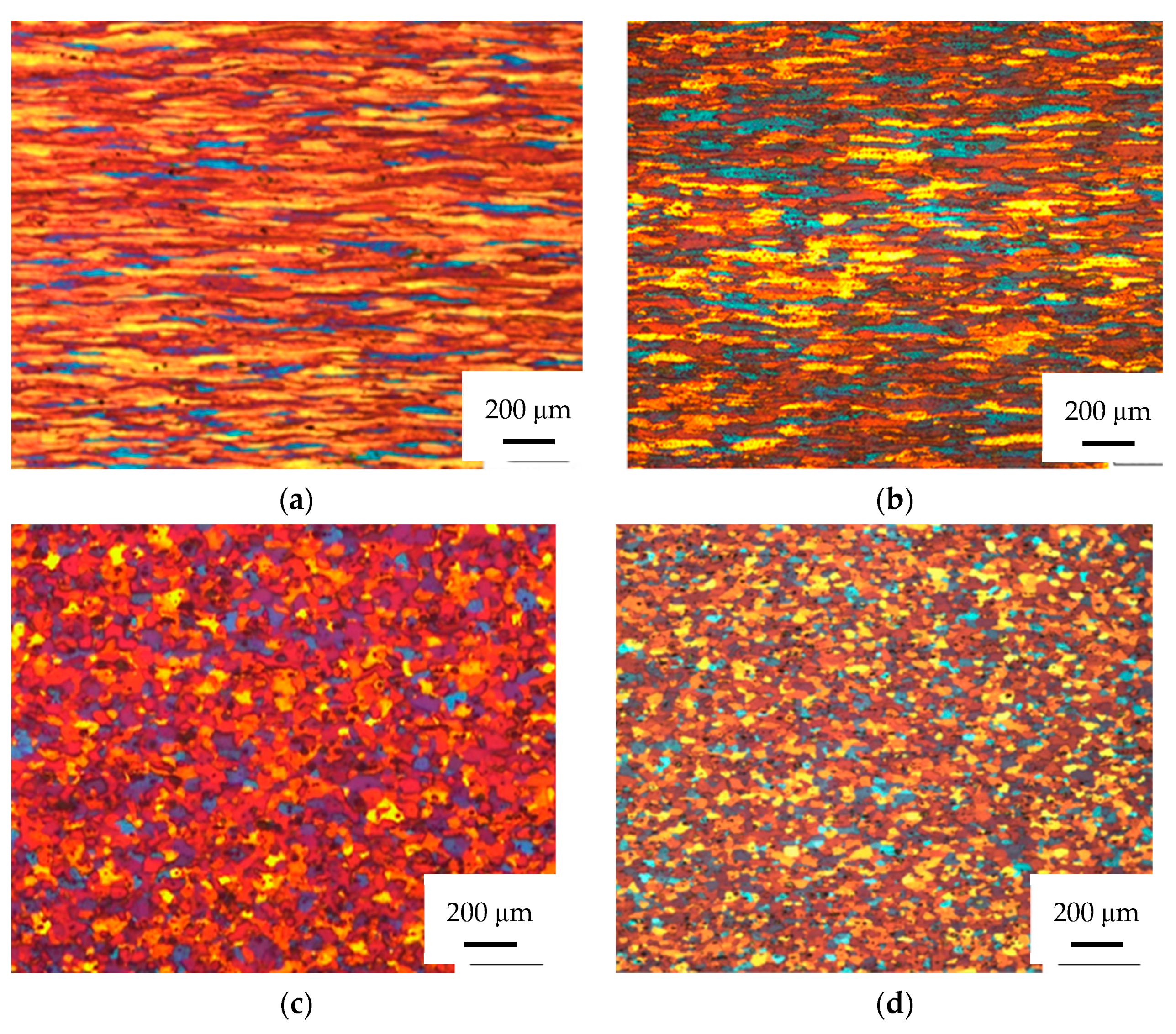

3.2. Grain Structure Evolution

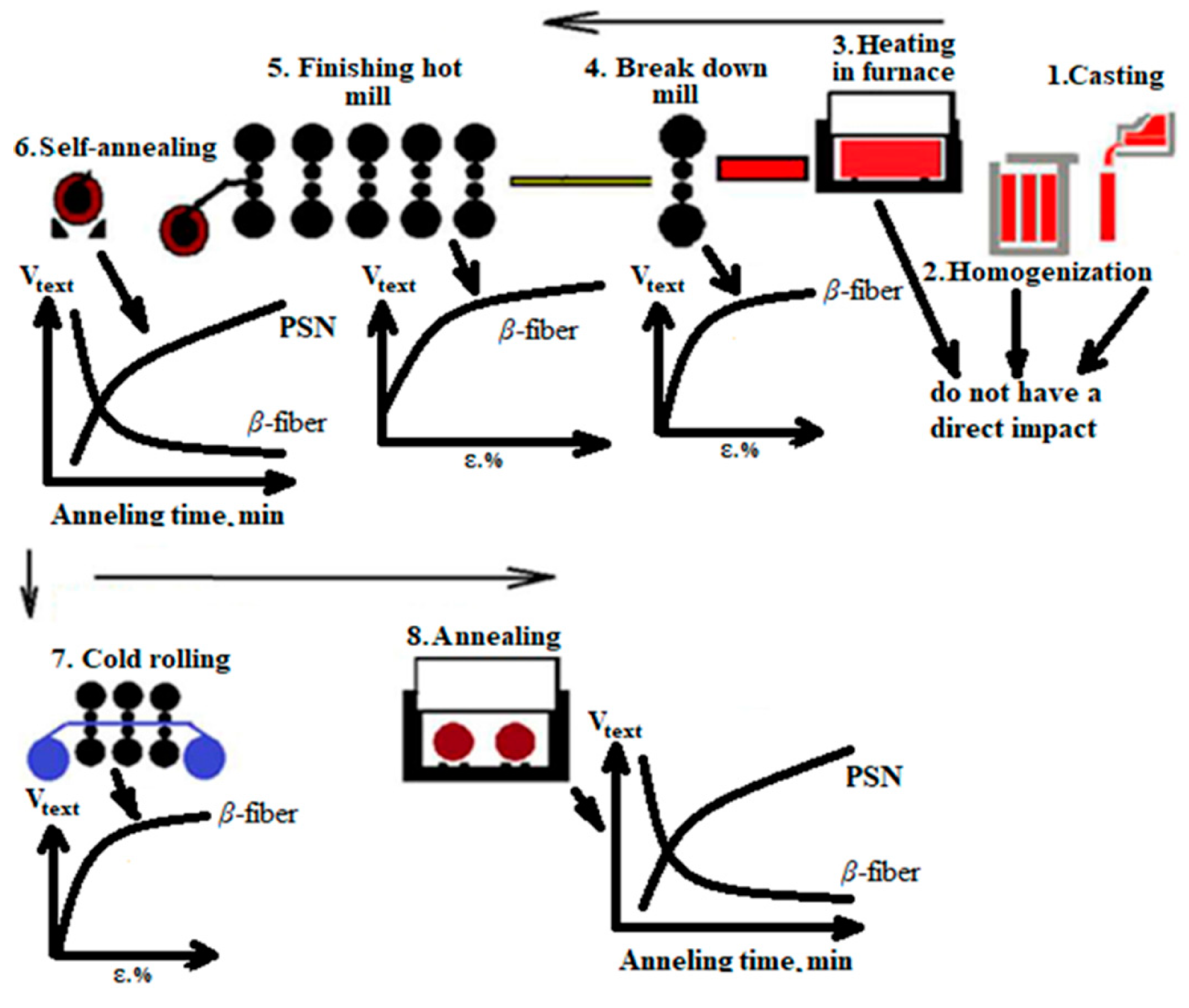

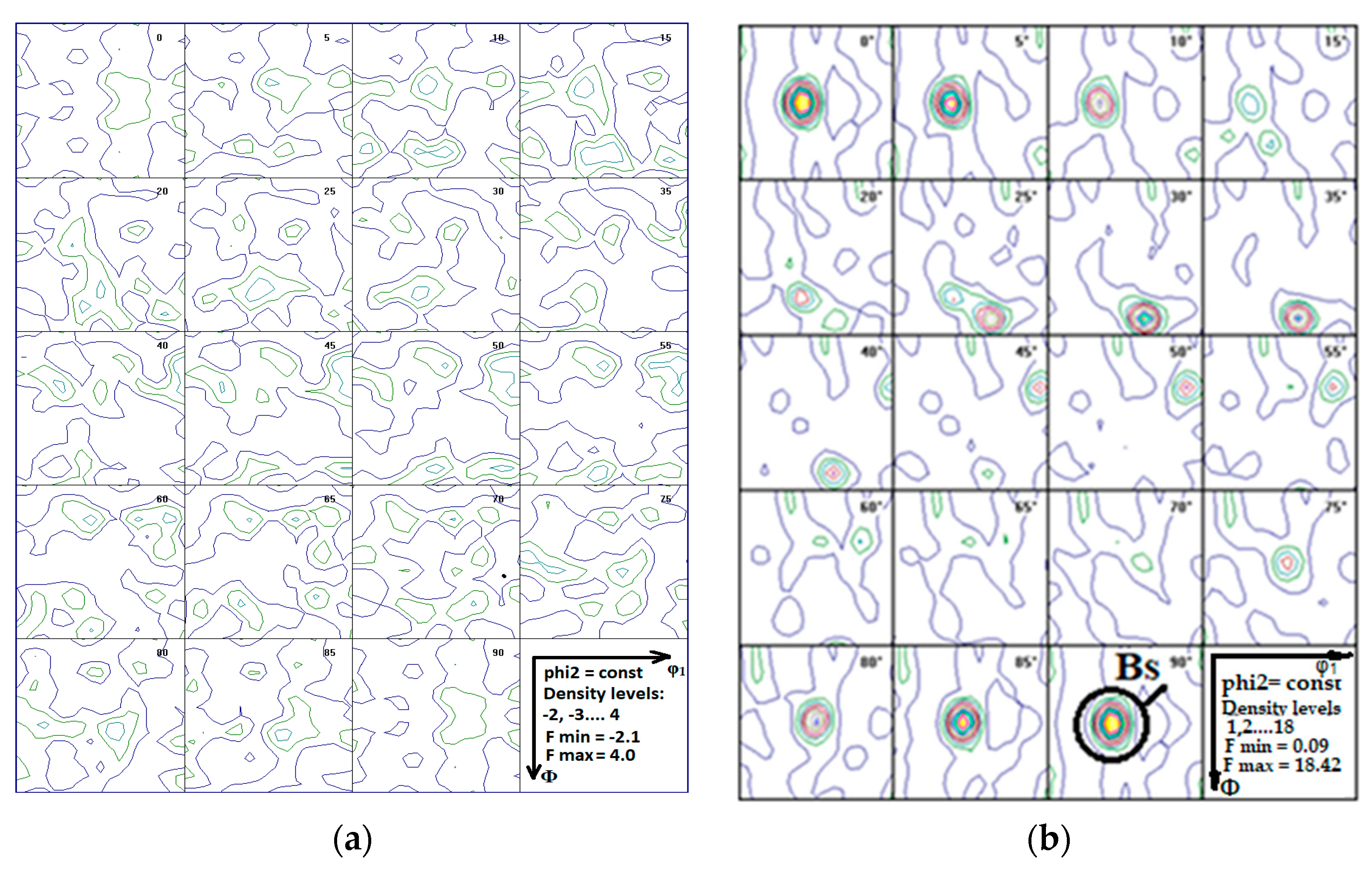

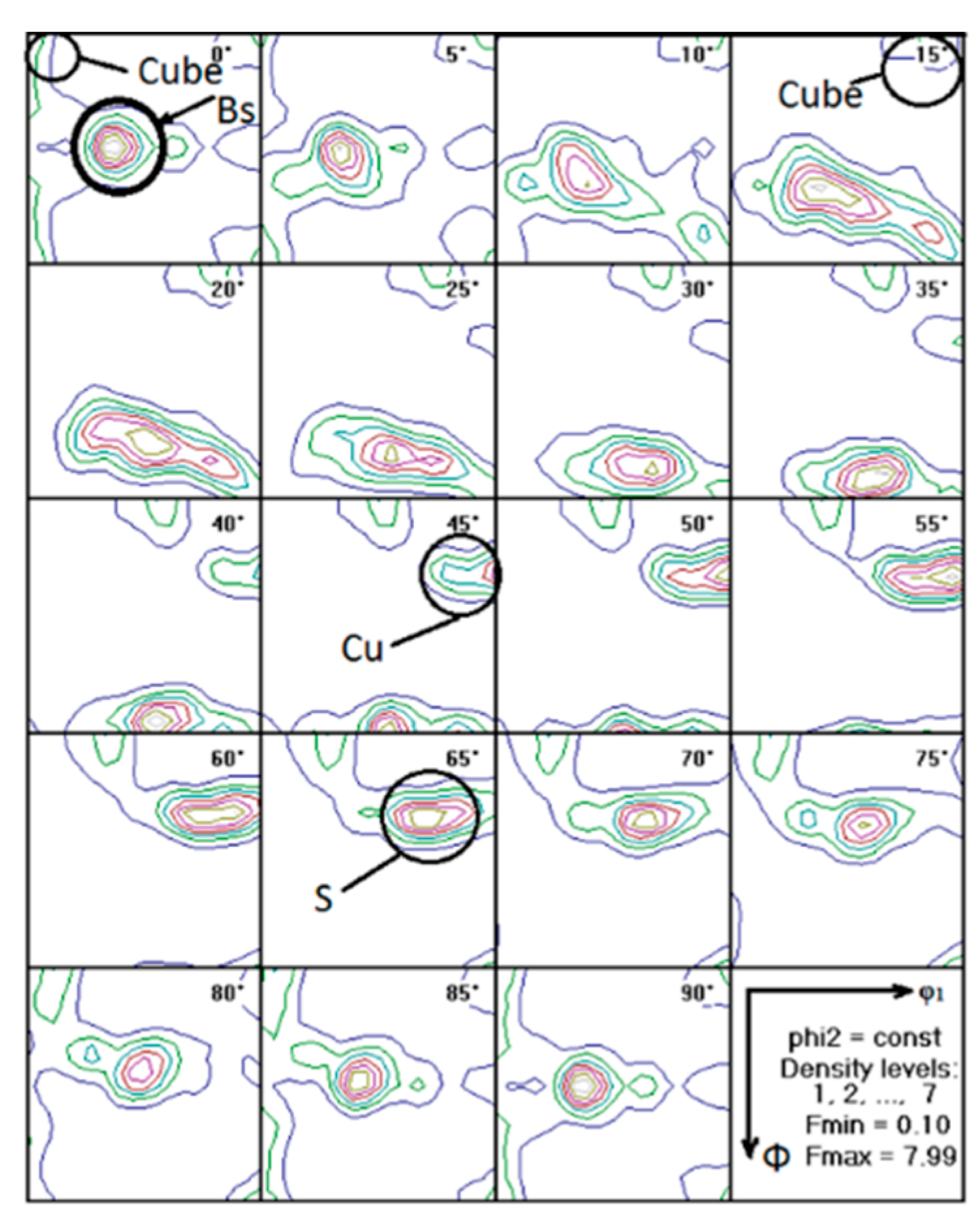

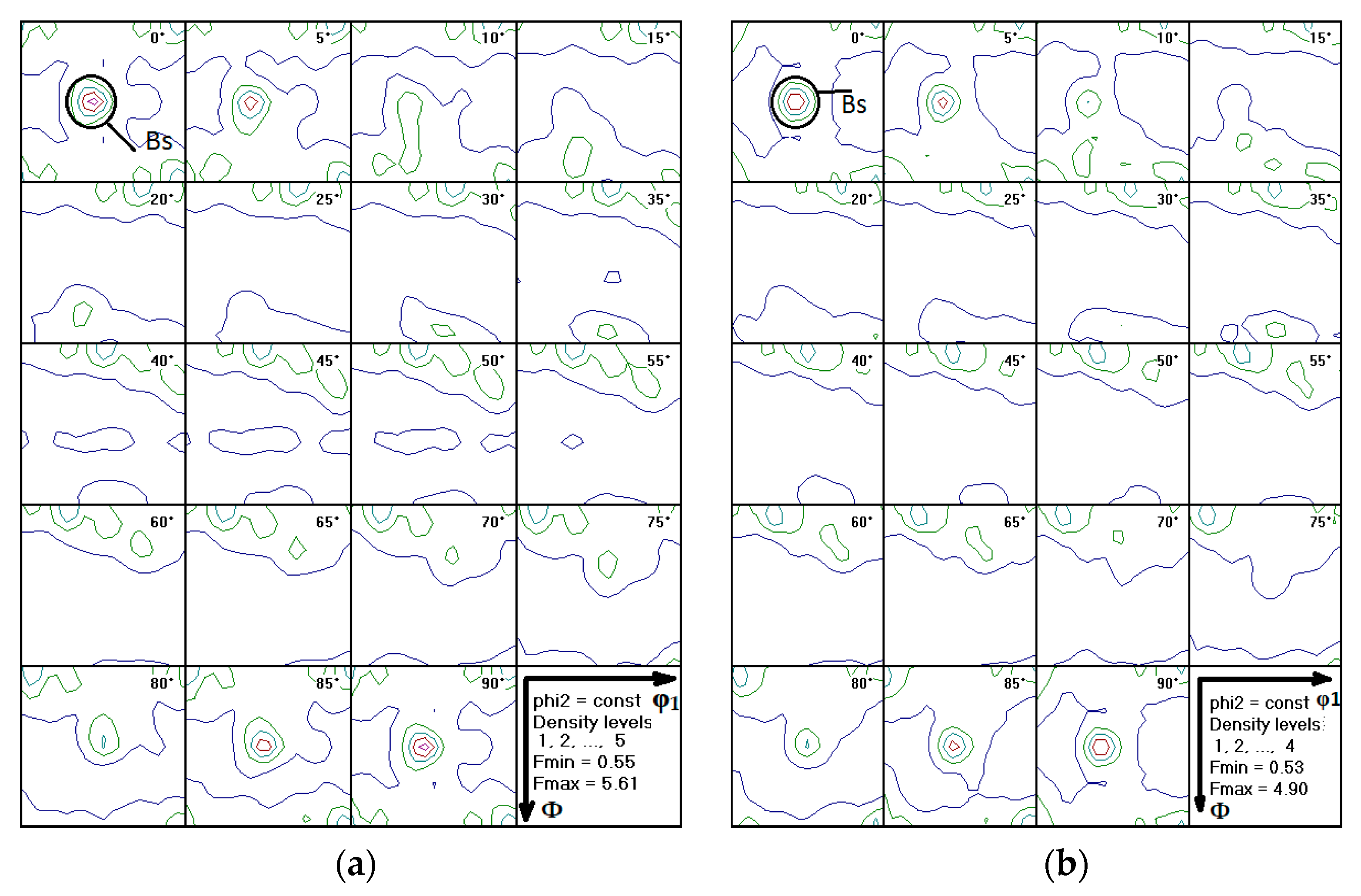

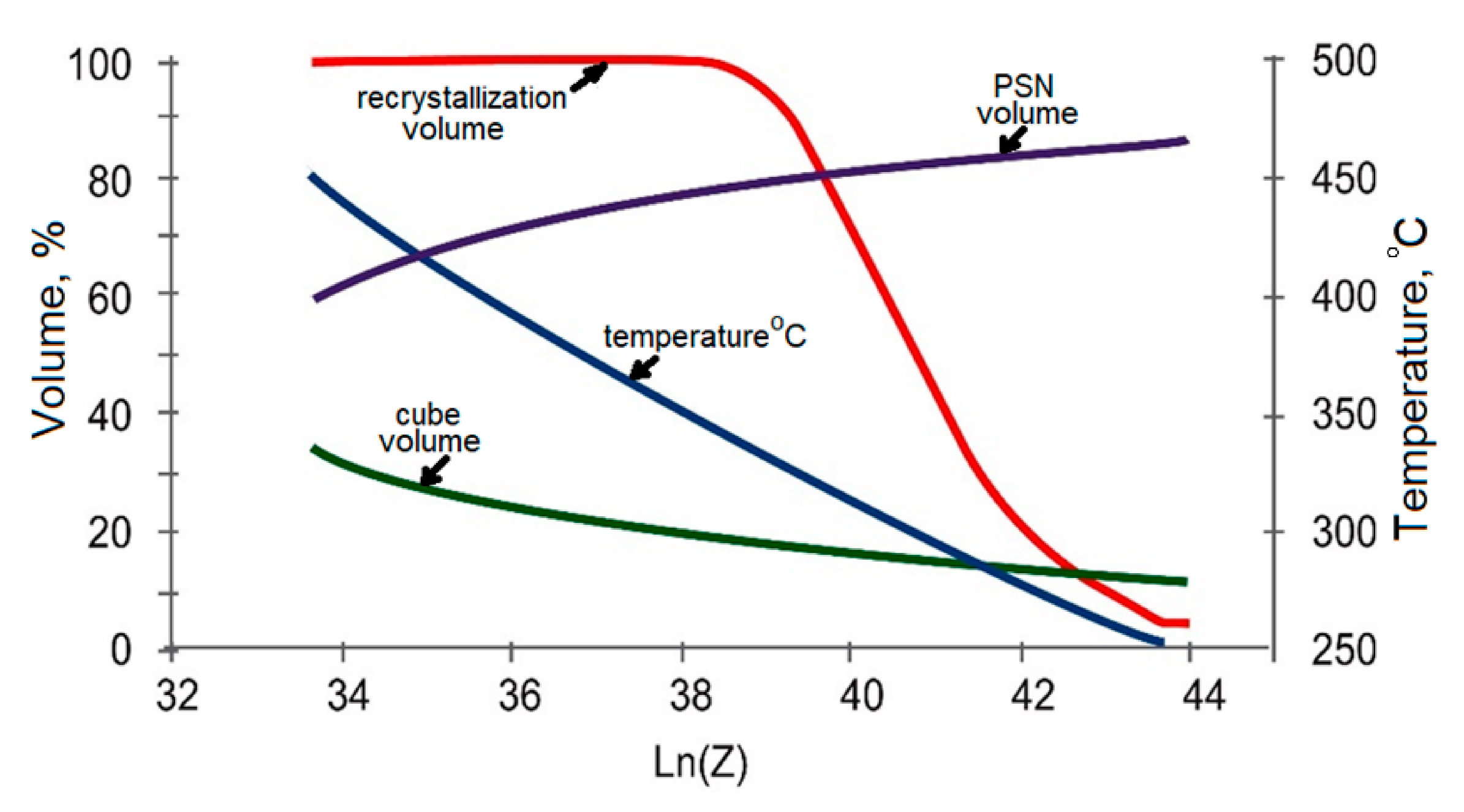

3.3. Texture Evolution

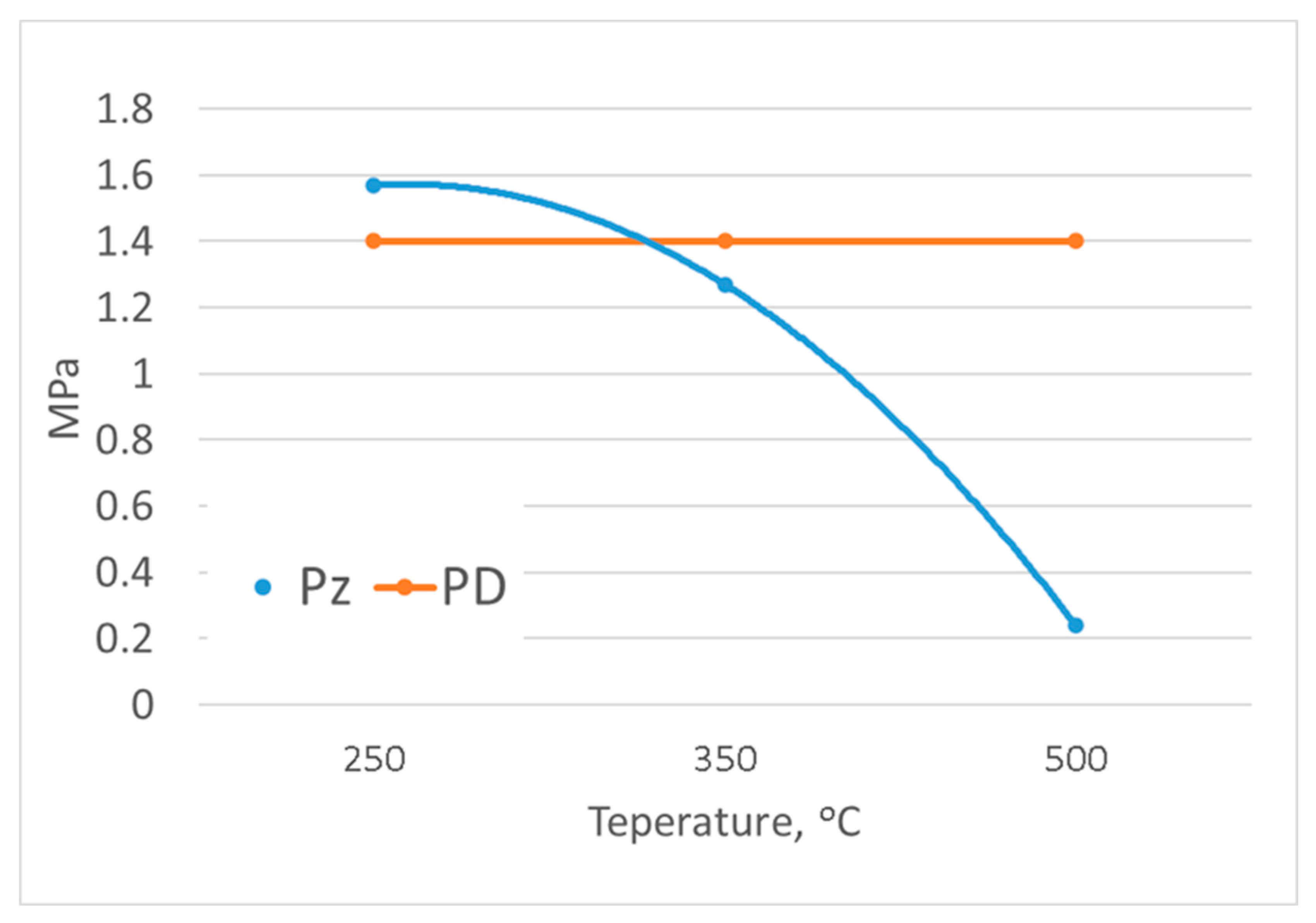

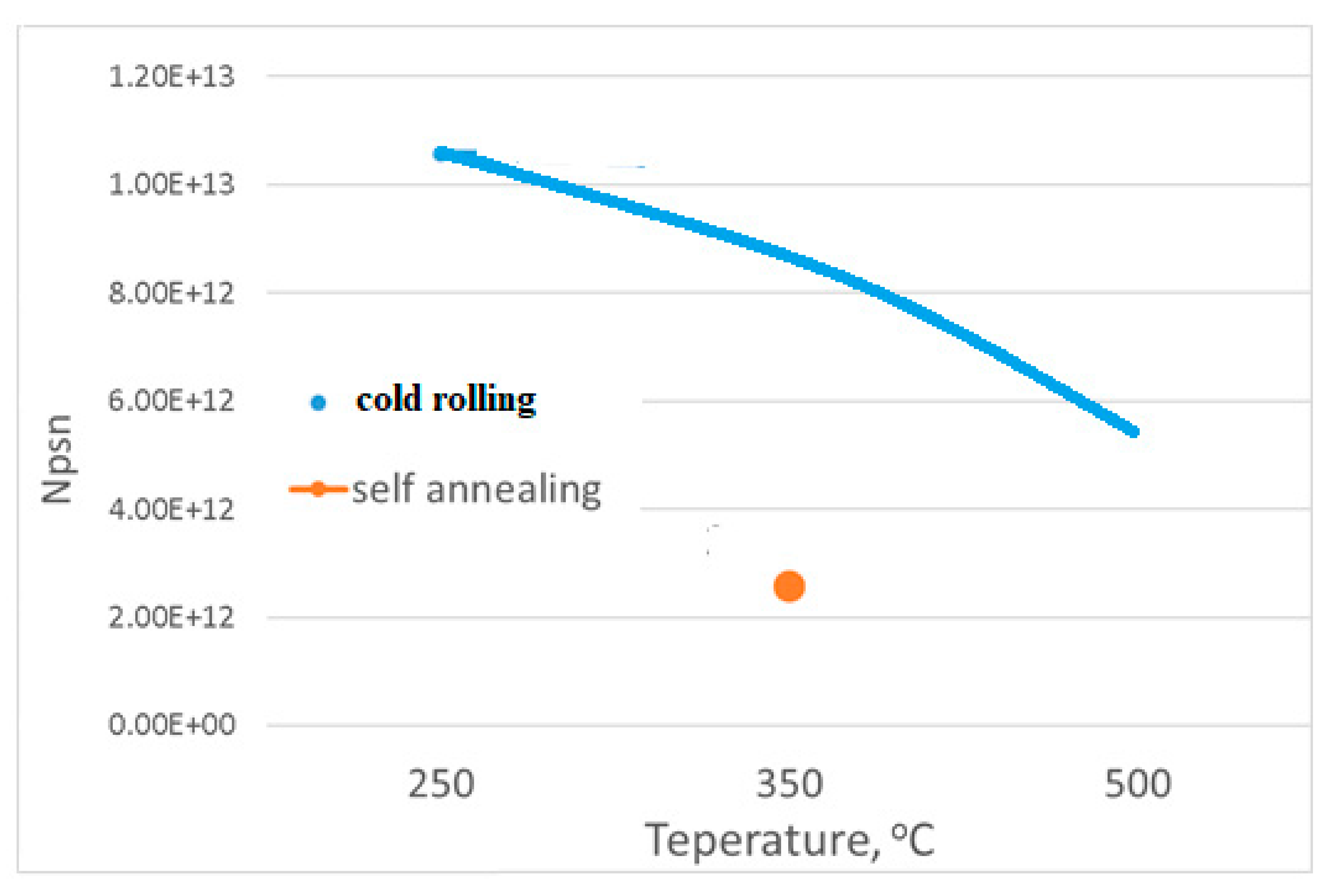

3.4. Computational Result

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chausov, M.G.; Berezin, V.B.; Pylypenko, A.P.; Hutsaylyuk, V.B. Strain field evolution on the surface of aluminum sheet alloys exposed to specific impact with oscillation loading. J. Strain Anal. Eng. Des. 2015, 50, 61–72. [Google Scholar] [CrossRef]

- Chausov, M.; Maruschak, P.; Zasimchuk, E.; Pypypenko, A.; Bishchak, R.; Burda, I. About physical aspects of increasing durability of aluminum alloys due to impact-oscillatory loading. In International Conference TRANSBALTICA: Transportation Science and Technology; Springer: Cham, Switzerland, 2021; pp. 572–580. [Google Scholar] [CrossRef]

- Savchenkov, S.; Kosov, Y.; Bazhin, V.; Krylov, K.; Kawalla, R. Microstructural Master Alloys Features of Aluminum–Erbium System. Crystals 2021, 11, 1353. [Google Scholar] [CrossRef]

- Kosov, Y.I.; Bazhin, V.Y.; Povarov, V.G. Interaction of Erbium Fluoride with Alkali Metal Chloride–Fluoride Melts in Synthesizing an Al–Er Master Alloy. Russ. Metall. (Metally) 2018, 6, 539–544. [Google Scholar] [CrossRef]

- Belov, N.A.; Alabin, A.N.; Sannikov, A.V.; Deev, V.B. Primary crystallization in the Al-Fe-Mn-Ni-Si system as applied to casting alloys based on aluminum-nickel eutectic. Russ. J. Non-Ferr. Met. 2014, 55, 356–364. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Korotkova, N.O.; Timofeev, V.N.; Shurkin, P.K. Effect of cold rolling and annealing temperature on structure, hardness and electrical conductivity of rapidly solidified alloy of Al–Cu–Mn–Zr system. Mater. Lett. 2021, 300, 130199. [Google Scholar] [CrossRef]

- Engler, O.; Kalz, S. Simulation of earing profiles from texture data by means of a visco-plastic self-consistent polycrystal plasticity approach. Mater. Sci. Eng. A 2004, 373, 350–362. [Google Scholar] [CrossRef]

- Engler, O. Modeling of texture and texture-related properties during the thermo-mechanical processing of aluminum sheets. Mater. Sci. Forum 2003, 426, 3655–3660. [Google Scholar] [CrossRef]

- Hutchinson, W.B.; Oscarsson, A.; Karlsson, Å. Control of microstructure and earing behaviour in aluminium alloy AA 3004 hot bands. Mater. Sci. Technol. 1989, 5, 1118–1127. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J. Polycrystal-plasticity simulation of six and eight ears in deep-drawn aluminum cups. Mater. Sci. Eng. A 2007, 452, 640–651. [Google Scholar] [CrossRef]

- Engler, O. Control of texture and earing in aluminium alloy AA 3105 sheet for packaging applications. Mater. Sci. Eng. A 2012, 538, 69–80. [Google Scholar] [CrossRef]

- Aryshenskii, E.V.; Hirsch, J.; Konovalov, S.V.; Prahl, U. Specific features of microstructural evolution during hot rolling of the as-cast magnesium-rich aluminum alloys with added transition metal elements. Metall. Mater. Trans. A 2019, 50, 5782–5799. [Google Scholar] [CrossRef]

- Aryshenskii, E.V.; Aryshenskii, V.Y.; Beglov, E.D.; Chitnaeva, E.S.; Konovalov, S.V. Investigation of subgrain and fine intermetallic participles size impact on grain boundary mobility in aluminum alloys with transitional metal addition. Mater. Today Proc. 2019, 19, 2183–2188. [Google Scholar] [CrossRef]

- Zaidi, M.A.; Sheppard, T. Development of microstructure throughout roll gap during rolling of aluminium alloys. Met. Sci. 1982, 16, 229–238. [Google Scholar] [CrossRef]

- Vatne, H.E.; Wells, M.A. Modelling of the recrystallization behaviour of AA5XXX aluminum alloys after hot deformation. Can. Metall. Q 2003, 42, 79–88. [Google Scholar] [CrossRef]

- Aryshenskii, E.; Kawalla, R.; Hirsch, J. Development of new fast algorithms for calculation of texture evolution during hot continuous rolling of Al–Fe alloys. Steel Res. Int. 2017, 88, 1700053. [Google Scholar] [CrossRef]

- Evgenii, A.; Erkin, B.; Hirsch, J.; Vladimir, A.; Segrey, K. Development of the new fast approach for calculation of texture evolution during hot deformation of aluminum alloys. Procedia Manuf. 2019, 37, 492–499. [Google Scholar] [CrossRef]

- Aryshenskii, E.; Hirsch, J.; Konovalov, S.; Aryshenskii, V.; Drits, A. Influence of mg content on texture development during hot plain-strain deformation of aluminum alloys. Metals 2021, 11, 865. [Google Scholar] [CrossRef]

- Engler, O.; Miller-Jupp, S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloy. Compd. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Engler, O.; Kuhnke, K.; Hasenclever, J. Development of intermetallic particles during solidification and homogenization of two AA 5xxx series Al-Mg alloys with different Mg contents. J. Alloy. Compd. 2017, 728, 669–681. [Google Scholar] [CrossRef]

- Tepterev, M.S.; Aryshenskii, E.V.; Guk, S.V.; Bazhenov, V.E.; Drits, A.M.; Kavalla, R. Effect of annealing conditions on the evolution of the grain structure and intermetallic phases in the cold-rolled strip of aluminum–magnesium alloy. Phys. Met. Metallogr. 2020, 121, 906–913. [Google Scholar] [CrossRef]

- Gottstein, G. Grain Boundary Migration in Metals: Thermodynamics, Kinetics, Applications; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Maire, E.; Grenier, J.C.; Daniel, D.; Baldacci, A.; Klöcker, H.; Bigot, A. Quantitative 3D characterization of intermetallic phases in an Al–Mg industrial alloy by X-ray microtomography. Scr. Mater. 2006, 55, 123–126. [Google Scholar] [CrossRef]

- Moulin, N.; Parra-Denis, E.; Jeulin, D.; Ducottet, C.; Bigot, A.; Boller, E.; Klöcker, H. Constituent Particle Break-Up During Hot Rolling of AA 5182. Adv. Eng. Mater. 2010, 12, 20–29. [Google Scholar] [CrossRef] [Green Version]

- Aryshenskii, E.; Hirsch, J.; Konovalov, S. Investigation of the intermetallic compounds fragmentation impact on the formation of texture during the as cast structure thermomechanical treatment of aluminum alloys. Metals 2021, 11, 507. [Google Scholar] [CrossRef]

- Humphreys, F.J. The nucleation of recrystallization at second phase particles in deformed aluminium. Acta Metall. 1977, 25, 1323–1344. [Google Scholar] [CrossRef]

- Hirsch, J.; Karhausen, K.; Kopp, R. Microstructure simulation during hot rolling of Al-Mg alloys. In Proceedings of the 4th International 1994 Conference on Aluminium Alloys (ICAA4), Atlanta, GA, USA, 11–16 September 1994. [Google Scholar]

- Hirsch, J. Thermomechanical control in aluminium sheet production. Mater. Sci. Forum 2003, 426, 185–194. [Google Scholar] [CrossRef]

- Hirsch, J.; Aryshesnkij, E.; Konovalov, S. Slip System Selection and Taylor Factor Evolution in FCC Metals. 2020, p. 3618715. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3618715 (accessed on 13 March 2022). [CrossRef]

- Aryshenskii, E.V.; Aryshenskii, V.Y.; Grechnikova, A.F.; Beglov, E.D. Evolution of texture and microstructure in the production of sheets and ribbons from aluminum alloy 5182 in modern rolling facilities. Met. Sci. Heat Treat. 2014, 56, 347–352. [Google Scholar] [CrossRef]

- Wells, M.A.; Samarasekera, I.V.; Brimacombe, J.K.; Hawbolt, E.B.; Lloyd, D.J. Modeling the microstructural changes during hot tandem rolling of AA5XXX aluminum alloys: Part I. Microstructural evolution. Metall. Mater. Trans. B 1998, 29, 611–620. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Randle, V.; Engler, O. Introduction to Texture Analysis: Macrotexture, Microtexture and Orientation Mapping; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Liu, W.C.; Zhai, T.; Morris, J.G. Comparison of recrystallization and recrystallization textures in cold-rolled DC and CC AA 5182 aluminum alloys. Mater. Sci. Eng. A 2003, 358, 84–93. [Google Scholar] [CrossRef]

- Engler, O. Through-process modelling of the impact of intermediate annealing on texture evolution in aluminium alloy AA 5182. Model. Simul. Mater. Sci. Eng. 2003, 11, 863. [Google Scholar] [CrossRef]

- Hirsch, J. Texture evolution during rolling of aluminum alloys. In Light Metals-Warrendale-Proceedings; TMS: Pittsburgh, PA, USA, 2008; p. 1071. [Google Scholar]

- Rushchits, S.V.; Aryshenskii, E.V.; Kawalla, R.; Serebryany, V. Investigation of texture structure and mechanical properties evolution during hot deformation of 1565 aluminum alloy. Mater. Sci. Forum 2016, 854, 73–78. [Google Scholar] [CrossRef] [Green Version]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J.; Lücke, K. Texture development in Al-1.8 wt% Cu depending on the precipitation state—II. Recrystallization textures. Acta Metall. Mater. 1995, 43, 121–138. [Google Scholar]

- Yashin, V.; Aryshenskii, E.; Hirsch, J.; Konovalov, S.; Latushkin, I. Study of recrystallization kinetics in AA5182 aluminium alloy after deformation of the as-cast structure. Mater. Res. Express 2019, 6, 066552. [Google Scholar] [CrossRef]

| Content of Chemical Elements, wt.% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr |

| 1565 ch | base | 0.12 | 0.22 | 0.05 | 0.80 | 5.6 | 0.06 | 0.50 | 0.07 | 0.10 |

| Passnumber | Input Thickness, mm | Output Thickness, mm | Linear Speed of the Work Roll | Deformation Temperature, °C | Strain Rate, s−1 | Rolling Force, Tc | Zener Parameter Logarithm |

|---|---|---|---|---|---|---|---|

| 1 | 400 | 390 | 57 | 460 | 0.35 | 2407 | 12.74 |

| 2 | 390 | 375 | 85 | 459 | 0.66 | 2350 | 13.03 |

| 3 | 375 | 355 | 85 | 459 | 0.79 | 2493 | 13.11 |

| 4 | 355 | 335 | 85 | 459 | 0.84 | 2432 | 13.13 |

| 5 | 335 | 310 | 85 | 459 | 0.99 | 2526 | 13.21 |

| 6 | 310 | 285 | 85 | 459 | 1.07 | 2447 | 13.24 |

| 7 | 285 | 255 | 85 | 459 | 1.28 | 2517 | 13.31 |

| 8 | 255 | 225 | 85 | 460 | 1.43 | 2436 | 13.35 |

| 9 | 225 | 190 | 85 | 460 | 1.74 | 2532 | 13.43 |

| 10 | 190 | 160 | 85 | 461 | 1.91 | 2325 | 13.46 |

| 11 | 160 | 130 | 85 | 460 | 2.26 | 2345 | 13.54 |

| 12 | 130 | 100 | 85 | 460 | 2.77 | 2457 | 13.63 |

| 13 | 100 | 75 | 85 | 460 | 3.28 | 2393 | 13.70 |

| 14 | 75 | 55 | 113 | 459 | 3.91 | 2351 | 13.80 |

| 15 | 55 | 40 | 113 | 455 | 6.15 | 2352 | 14.07 |

| 16 | 40 | 30 | 113 | 451 | 6.93 | 2233 | 14.19 |

| Alloy | TMP Parameters | Entering a Continuous Group | Stand No F1 | Stand No F2 | Stand No F3 | Stand No F4 | Stand No F5 |

|---|---|---|---|---|---|---|---|

| 1565 ch | Thickness, mm | 35 | 23 | 18 | 13.5 | 10 | 6.80 |

| Rolls rotation rate, m/min | - | 33 | 48 | 65 | 92 | 128 | |

| Temperature | 460 °C | - | - | - | - | 355 °C | |

| Interdeformation pause, s | 10.9 | 6.4 | 4.1 | 2.433 | - |

| Alloy | Sample Thickness, mm | Volume Fraction of Intermetallic Compounds, % | Average Diameter of Intermetallic Compounds, µm | Maximum Diameter of Intermetallic Compounds, µm | Volume Fraction of Dispersoids, 10−3% | Average Diameter of Dispersoids, μm | Maximum Diameter of Dispersoids, μm |

|---|---|---|---|---|---|---|---|

| 1565 ch | In-cast | 4.9 | 10.3 | 13.96 | - | - | - |

| Hom. | 3.3 | 8.66 | 9.9 | 8.2 | 0.42 | 0.48 | |

| Reverse | 3.2 | 6 | 6.52 | 8.4 | 0.4 | 0.45 | |

| Continuous | 3.0 | 5 | 5.38 | 8.7 | 0.33 | 0.38 | |

| Coldrolled | 2.2 | 2.5 | 5.22 | 10.7 | 0.51 | 0.58 |

| Direction to RD | A% | n | Δr | ||

|---|---|---|---|---|---|

| 0° | 160 ± 2 | 320 ± 3 | 24 ± 1 | 0.26 ± 0 | 0.87 |

| 45° | 158 ± 4 | 321 ± 3 | 25 ± 1 | 0.26 ± 0 | |

| 90° | 156 ± 4 | 321 ± 4 | 24 ± 1 | 0.25 ± 0 |

| Component | Miller Indices {hkl}〈uvw〉 | Euler Angles | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | ||

| Cube | {001}〈100〉 | 0 | 0 | 0°/90 |

| Bs | {011}〈211〉 | 35° | 45° | 0°/90° |

| Cu | {112}〈111〉 | 90° | 30° | 45° |

| S | {123}〈634〉 | 60° | 35° | 65° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aryshenskii, E.; Hirsch, J.; Drits, A.; Konovalov, S.; Aryshenskii, V.; Tepterev, M. Texture Development in Aluminum Alloys with High Magnesium Content. Metals 2022, 12, 723. https://doi.org/10.3390/met12050723

Aryshenskii E, Hirsch J, Drits A, Konovalov S, Aryshenskii V, Tepterev M. Texture Development in Aluminum Alloys with High Magnesium Content. Metals. 2022; 12(5):723. https://doi.org/10.3390/met12050723

Chicago/Turabian StyleAryshenskii, Evgenii, Jurgen Hirsch, Alexander Drits, Sergey Konovalov, Vladimir Aryshenskii, and Maksim Tepterev. 2022. "Texture Development in Aluminum Alloys with High Magnesium Content" Metals 12, no. 5: 723. https://doi.org/10.3390/met12050723

APA StyleAryshenskii, E., Hirsch, J., Drits, A., Konovalov, S., Aryshenskii, V., & Tepterev, M. (2022). Texture Development in Aluminum Alloys with High Magnesium Content. Metals, 12(5), 723. https://doi.org/10.3390/met12050723