Dynamic Study on Vanadium Extraction Process in Basic Oxygen Furnance: Modeling Based on Gibbs’ Free Energy Minimization

Abstract

1. Introduction

2. Model Formulation

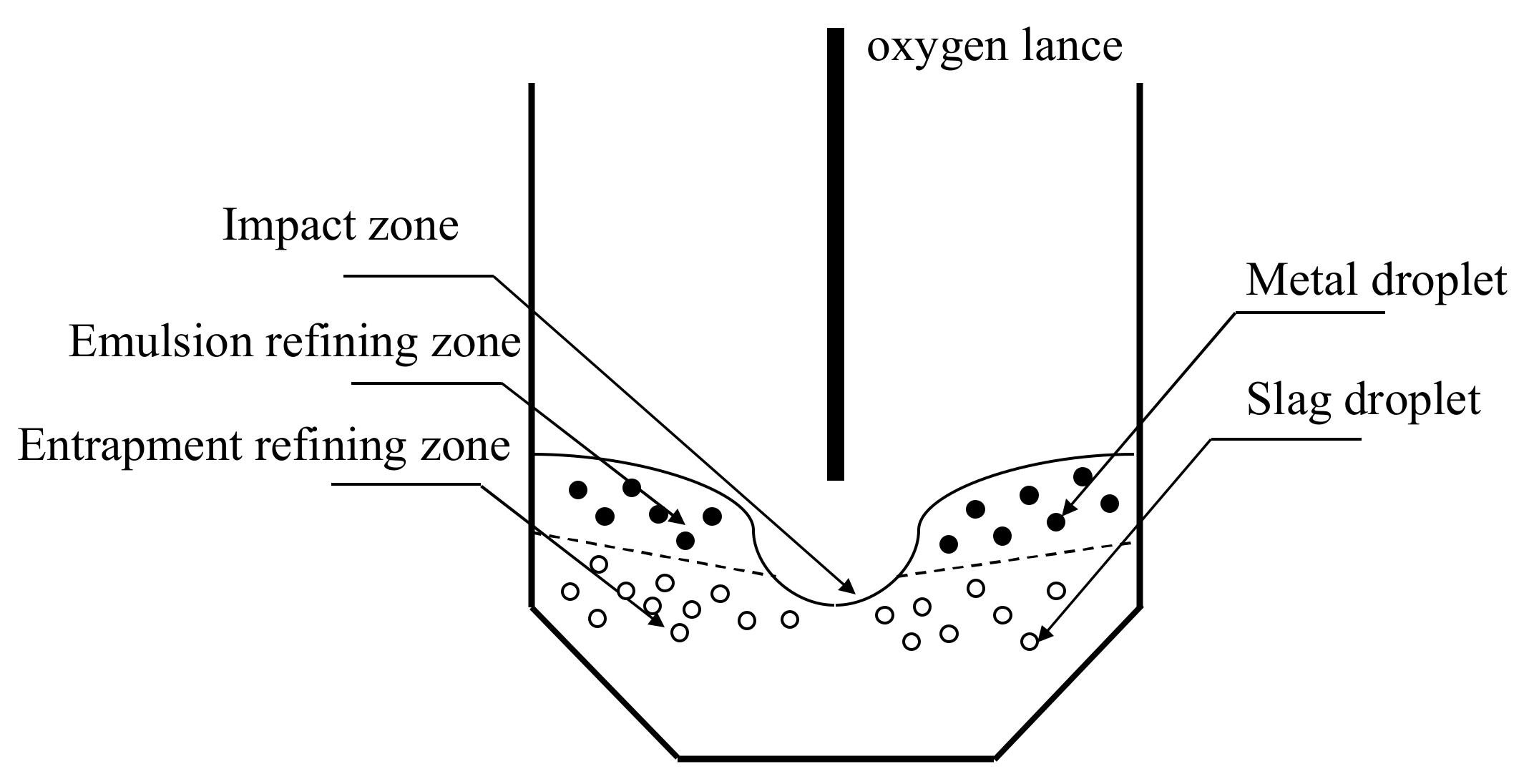

2.1. Refining Zone Definitions

2.2. Refining Mechanism of BOF Reactions

- a.

- Gaseous Oxygen O2 at the impact site reacts with a layer of metal, oxidizing all elements in it directly. The oxidation products are transferred to the slag phase, except for carbon oxides.

- b.

- Large numbers of metal droplets are generated at the impact zone, and they too splash into the slag zone in upper bath. Refining reactions of dissolved elements take place at the interface dictated by thermodynamics. Eventually, the droplets fall back to iron bath due to gravity. The two-phase reactions such as silicon take place directly with FeO:

- c.

- A number of slag droplets are entrapped in the lower bath. The refining reactions also take place at the interface that is similar to emulsion refining zone.

2.3. Assumptions of the Model

- a.

- According to the requirements of vanadium extraction process, the typical smelting time continues only about 6 min (360 s). The initial slag layer in bath is from addictive coolant before blowing and residual slag from previous heat. Slag compositions at this time are assumed from typical reported values from plant.

- b.

- Oxygen is partitioned among the elements based on their molar fraction available at the impact zone.

- c.

- Rates of refining reactions are assumed to be controlled only by mass transfer of FeO in the slag phase.

- d.

- Size distribution of metal droplets generated at the impact zone is heterogeneous. Sauter Mean Diameter is often used to describe it. A single size of metal droplets in emulsion is assumed for keeping the model simple. The size refers to Dogan’s [9].

- e.

- f.

- Necessary coolant for keeping reasonable thermodynamics [12] was added at 30th s, 90th s, and 150th s. The coolant consisted of FeO and Fe2O3, each 50%. Dissolving rate of addictive coolant depended on mass transfer of Fe2O3 to slag phase. Coolant meltage continued at 30 s equably.

2.4. Governing Equations

- a.

- Oxygen distribution at the impact zone

- b.

- Calculation of droplet generation rate

- c.

- Calculation slag–metal interface area

- d.

- Oxygen distribution at the slag–metal interface

2(FeO) + [Si] = (SiO2) + 2[Fe]

2(FeO) + [Ti] = (TiO2) + 2[Fe]

(FeO) + [Mn] = (MnO) + [Fe]

3(FeO) + 2[V] = (V2O3) + 3[Fe]

3. Results and Discussion

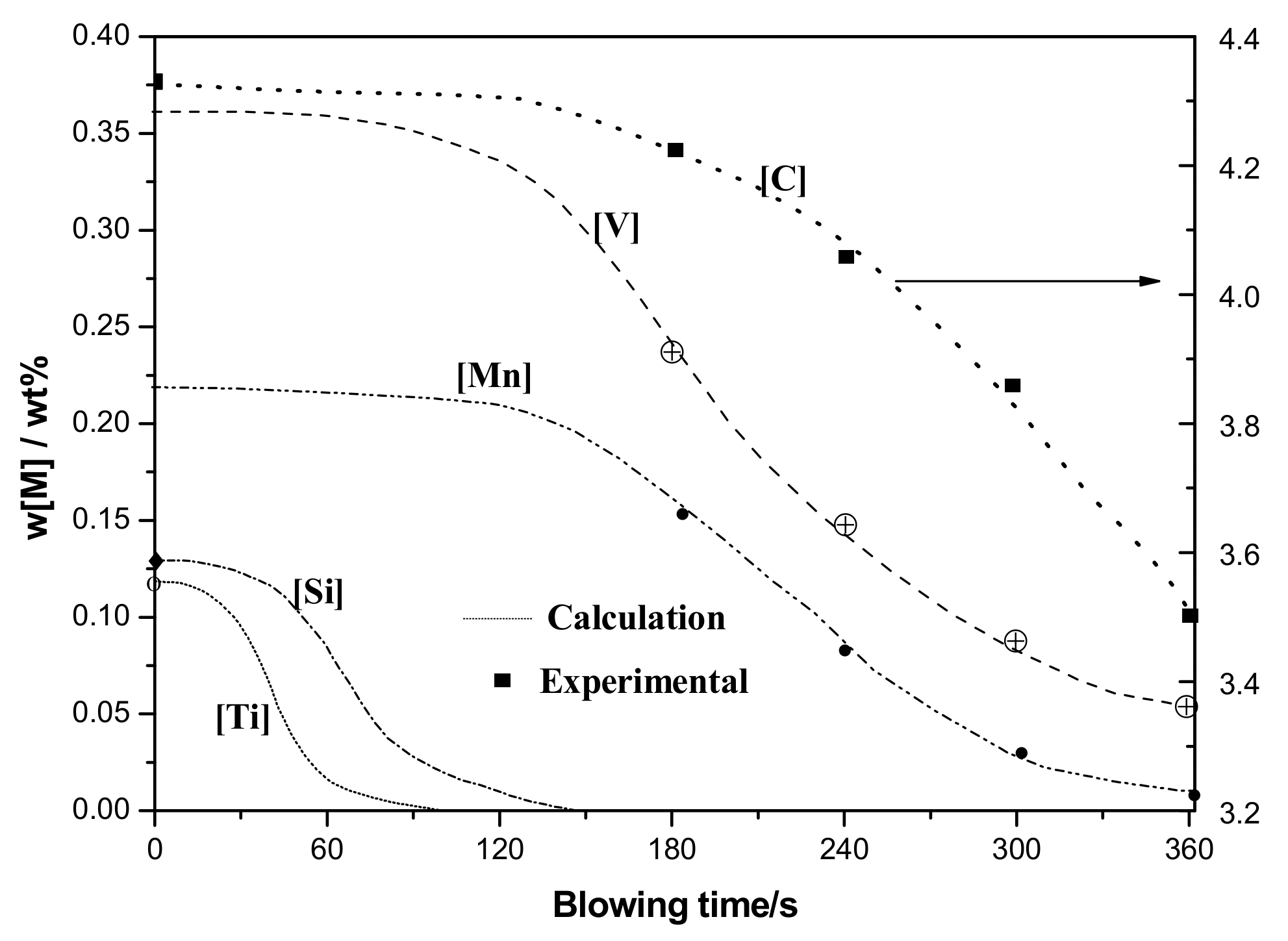

3.1. Description of Vanadium Extraction Process

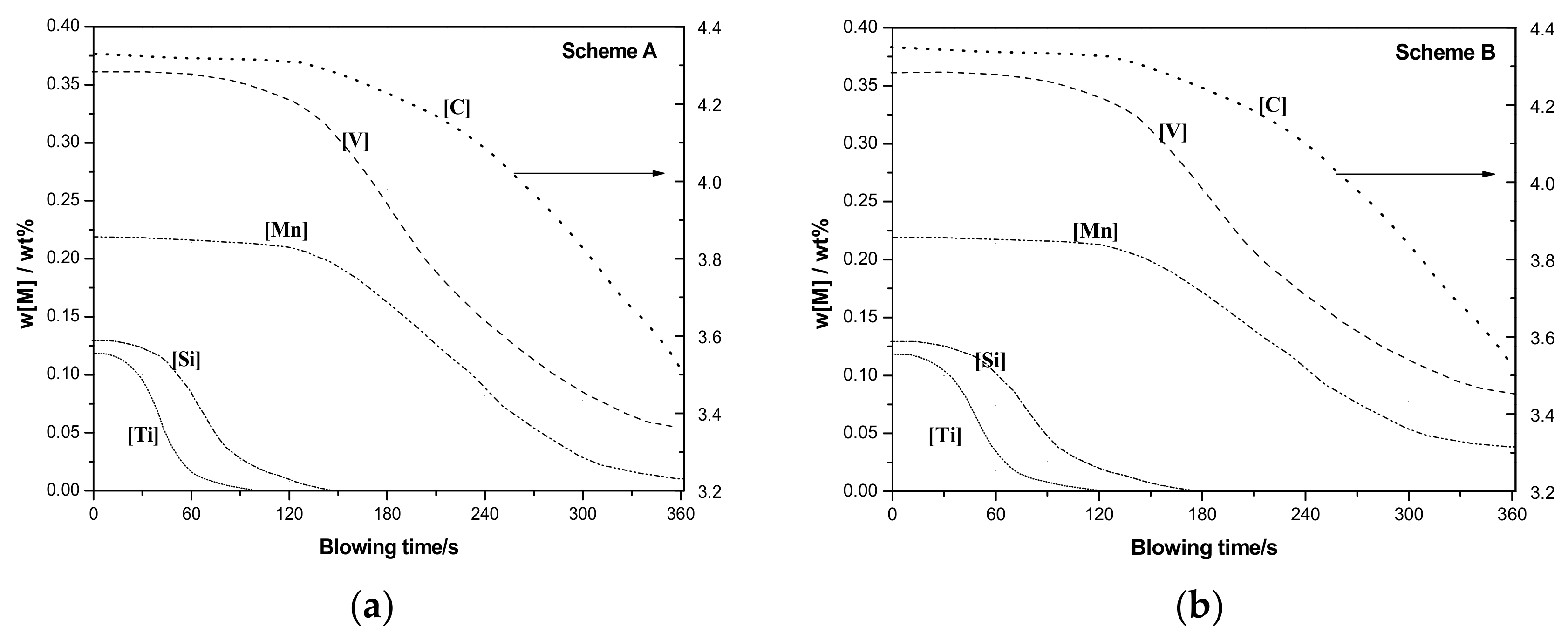

3.2. Effect of Coolant Addition

3.3. Effect of Oxygen Flow Rate

4. Conclusions

- (1)

- The three-part model, including the impact zone, emulsion zone, and entrapment zone, has been developed to model the vanadium extraction process in BOF. The concept of Gibbs’ free energy minimization at the slag–metal interface has been adopted to model the refining reactions.

- (2)

- Simulation results predicting variations of dissolved elements have shown good uniformity with plant experimental data. The present model describes the vanadium extraction process in BOF qualitatively well.

- (3)

- The effects of coolant addition and oxygen flow rate have been studied. The lack of coolant will reduce (FeO) content and elevate the molten bath temperature, harming deep vanadium removal, resulting in less carbon loss in semi-steel. Excessive oxygen flow rate has little affect on residual [V] but results in more carbon loss because of higher (FeO) content and molten bath temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.H.; Zhang, W.; Xue, Z.L. An environment-friendly process featuring calcified roasting and precipitation purification to prepare vanadium pentoxide from the converter vanadium slag. Metals 2019, 9, 21. [Google Scholar] [CrossRef]

- Lidiane, M.A.; Heide, M.; Gaebler, D.J.; Silva, W.E.; Belian, M.F.; Lira, E.C. Acute toxicity evaluation of non-innocent oxidovanadium(V) schiff base complex. Inorganics 2021, 9, 42. [Google Scholar] [CrossRef]

- Hong, Y.; Peng, J.; Sun, Z.; Yu, Z.; Wang, A.; Wang, Y.; Liu, Y.-Y.; Xu, F.; Sun, L.-X. Transition metal oxodiperoxo complex modified metal-organic frameworks as catalysts for the selective oxidation of cyclohexane. Materials 2020, 13, 829. [Google Scholar] [CrossRef] [PubMed]

- Condruz, M.R.; Matache, G.; Paraschiv, A.; Badea, T.; Badilita, V. High temperature oxidation behavior of selective laser melting manufactured IN 625. Metals 2020, 10, 668. [Google Scholar] [CrossRef]

- Huang, Q.Y. Basic Research on the Related Technology of High Efficient Extraction of Vanadium from Hot Metal by BOF. Ph.D. Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Shukla, A.K.; Deo, B.; Millman, S.; Snoeijer, B.; Overbosch, A.; Kapilashrami, A. An insight into the mechanism and kinetics of reactions in BOF steel-making: Theory vs practice. Steel Res. Int. 2010, 81, 940–948. [Google Scholar] [CrossRef]

- Pahlevani, F.; Kitamura, S.; Shibata, H.; Maruoka, N. Simulation of Steel Refining Process in Converter. Steel Res. Int. 2010, 81, 617–622. [Google Scholar] [CrossRef]

- Taylor, P.R.; Shuey, S.A.; Vidal, E.E.; Gomez, J.C. Extractive metallurgy of vanadium-containing titaniferous magnetite ores: A review. Miner. Metall. Process. 2006, 23, 80–86. [Google Scholar] [CrossRef]

- Dogan, N.; Brooks, G.; Rhamdhani, M.A. Analysis of droplet generation in oxygen steel-making. ISIJ Int. 2009, 49, 24–28. [Google Scholar] [CrossRef][Green Version]

- Brooks, G.A.; Pan, Y.; Subagyo, H.; Coley, K.S. Modeling of trajectory and residence time of metal droplets in slag–metal-gas emulsions in oxygen steel-making. Metall. Mater. Trans. B 2005, 36, 525–535. [Google Scholar] [CrossRef]

- Sarkar, R.; Gupta, P.; Basu, S.; Ballal, N.B. Dynamic modeling of LD converter steelmaking: Reaction modeling using Gibbs’ free energy minimization. Met. Mater. Trans. A 2015, 46, 961–976. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Tang, P. Optimization on temperature strategy of BOF vanadium extraction to enhance vanadium yield with minimum carbon loss. Metals 2021, 11, 906. [Google Scholar] [CrossRef]

- Subagyo; Brooks, G.A.; Coley, K.S.; Irons, G.A. Generation of Droplets in Slag–metal Emulsions Through Top Gas Blowing. ISIJ Int. 2003, 43, 983–989. [Google Scholar] [CrossRef]

- He, Q.L.; Standish, N. A model study of droplet generation in the BOF steelmaking. ISIJ Int. 1990, 30, 305–309. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Tang, P.; Hou, Z.B.; Wen, G.H. Investigation of the end-point temperature control based on the critical temperature of vanadium oxidation during the vanadium extraction process in BOF. Trans. Indian Inst. Met. 2018, 71, 1957. [Google Scholar] [CrossRef]

- Zhou, C.G.; Li, J.; Wu, H. Dependence of Temperature and slag composition on dephosphorization at the first deslagging in BOF steelmaking process. High Temp. Mater. Process. 2016, 35, 433–440. [Google Scholar] [CrossRef]

| Quantity | Unit | Value |

|---|---|---|

| Initial hot metal condition | − | 1573 K (1300 °C), 200,000 kg, and 4.3%C-0.13%Si-0.22%Mn-0.36%V-0.12%Ti |

| Initial slag condition | − | 1573 K (1300 °C), 3000 kg, and 94%FeO-3%SiO2-3%TiO2 |

| Coolant condition | − | 50%FeO-50%Fe2O3, 1800 kg (30th s), 1800 kg (90th s), and 1800 kg (150th s) |

| Density of steel | kg/m3 | 6900 |

| Density of slag | kg/m3 | 3200 |

| Density of gas | kg/m3 | 1.25 |

| Viscosity of slag | Pa.s | 1.82 |

| Surface tension of steel | N/m | 1.7 |

| Mass transfer coefficient of FeO in slag phase | m/s | 3.4 × 10−6 |

| Average diameter of metal droplets [9] | mm | 15 |

| Average residual time of metal droplets | s | 30 |

| i | j | ||||

|---|---|---|---|---|---|

| C | Si | Mn | V | Ti | |

| C | 0.1659 | 0.0948 | −0.0142 | −0.0913 | −0.045 |

| Si | 0.2133 | 0.1304 | 0.0024 | 0.0296 | 0.0367 |

| Mn | −0.083 | 0.0024 | 0.0000 | 0.0000 | 0.0051 |

| V | −0.4029 | 0.0498 | 0.0000 | 0.0178 | 0.0000 |

| Ti | −0.1955 | 0.0593 | 0.0051 | 0.0000 | 0.0154 |

| Quantity | Value/mm.s−1 | Quantity | Value/mm.s−1 |

|---|---|---|---|

| kC | 0.003 | kFeO | 0.0034 |

| kV | 0.035 | kMnO | 0.000034 |

| kSi | 0.019 | kSiO2 | 0.00005 |

| kMn | 0.0265 | kV2O3 | 0.000032 |

| kTi | 0.024 | kTiO2 | 0.00007 |

| kO | 0.005 |

| Scheme | 60 s Before Blowing | 30th s | 90th s | 150th s |

|---|---|---|---|---|

| A | 3000 kg | 1800 kg | 1800 kg | 1800 kg |

| B | 3000 kg | 1000 kg | 1000 kg | 1000 kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Luo, C. Dynamic Study on Vanadium Extraction Process in Basic Oxygen Furnance: Modeling Based on Gibbs’ Free Energy Minimization. Metals 2022, 12, 612. https://doi.org/10.3390/met12040612

Zhou Z, Luo C. Dynamic Study on Vanadium Extraction Process in Basic Oxygen Furnance: Modeling Based on Gibbs’ Free Energy Minimization. Metals. 2022; 12(4):612. https://doi.org/10.3390/met12040612

Chicago/Turabian StyleZhou, Zhenyu, and Cong Luo. 2022. "Dynamic Study on Vanadium Extraction Process in Basic Oxygen Furnance: Modeling Based on Gibbs’ Free Energy Minimization" Metals 12, no. 4: 612. https://doi.org/10.3390/met12040612

APA StyleZhou, Z., & Luo, C. (2022). Dynamic Study on Vanadium Extraction Process in Basic Oxygen Furnance: Modeling Based on Gibbs’ Free Energy Minimization. Metals, 12(4), 612. https://doi.org/10.3390/met12040612