Numerical Investigation of Flow Characteristics of Molten Steel in the Tundish with Channel Induction Heating

Abstract

1. Introduction

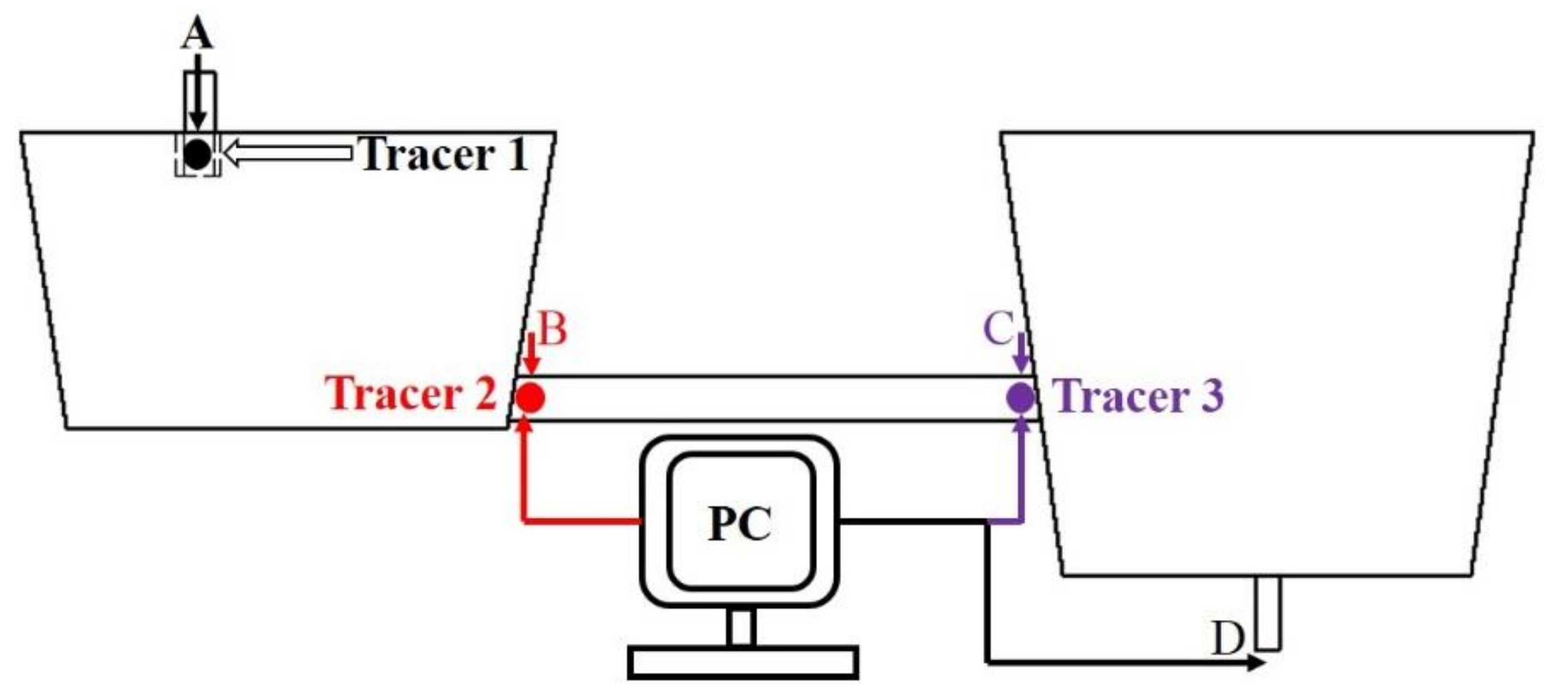

2. Model Development

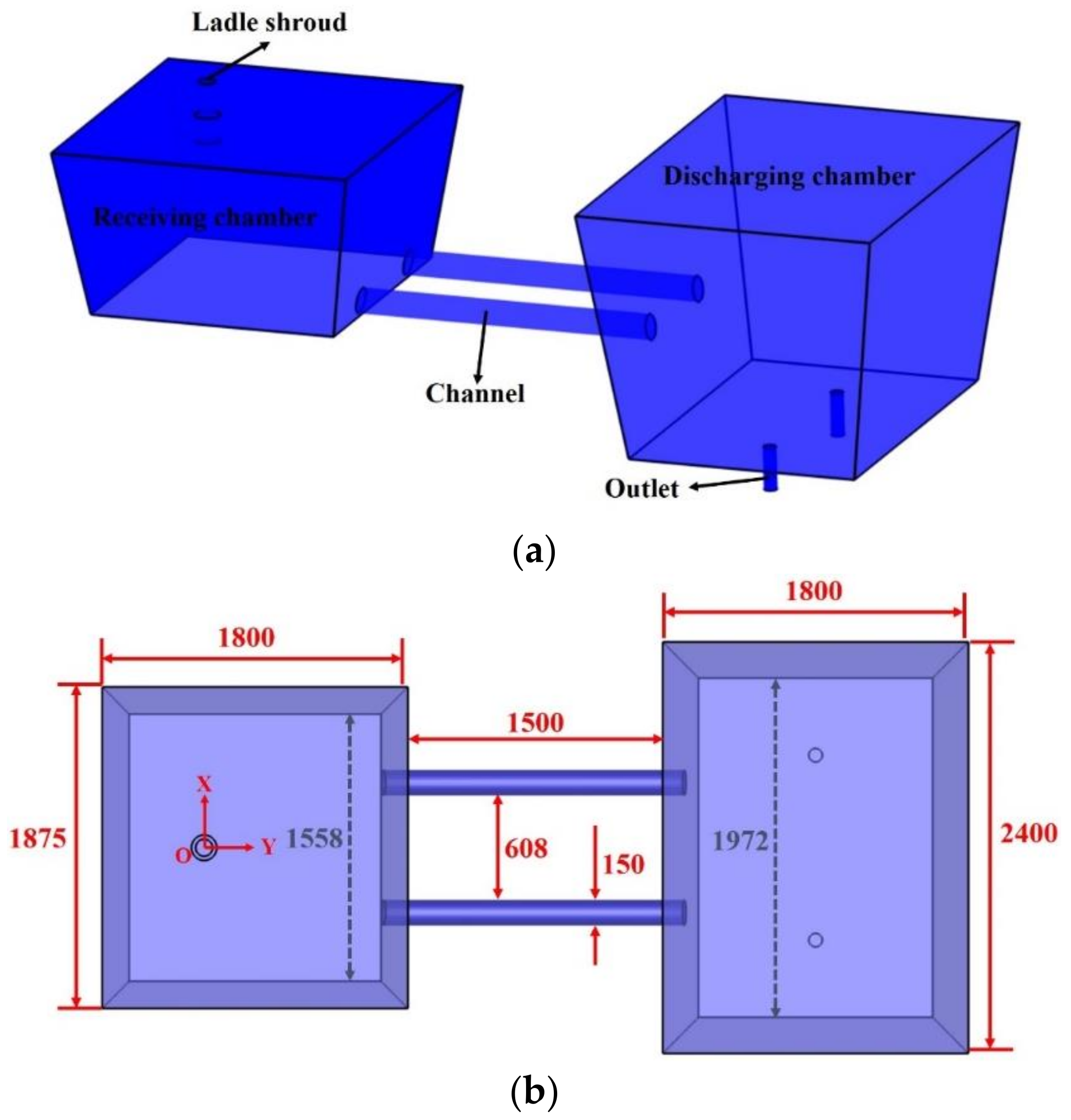

2.1. Geometrical Description

2.2. Governing Equations

2.3. Assumptions

- (1)

- The flow of molten steel in the tundish is at the steady state.

- (2)

- There is only the physical behavior in the tundish.

- (3)

- The physical parameter of the tracer is the same as molten steel in the tundish.

2.4. Boundary Conditions

2.5. Numerical Procedure

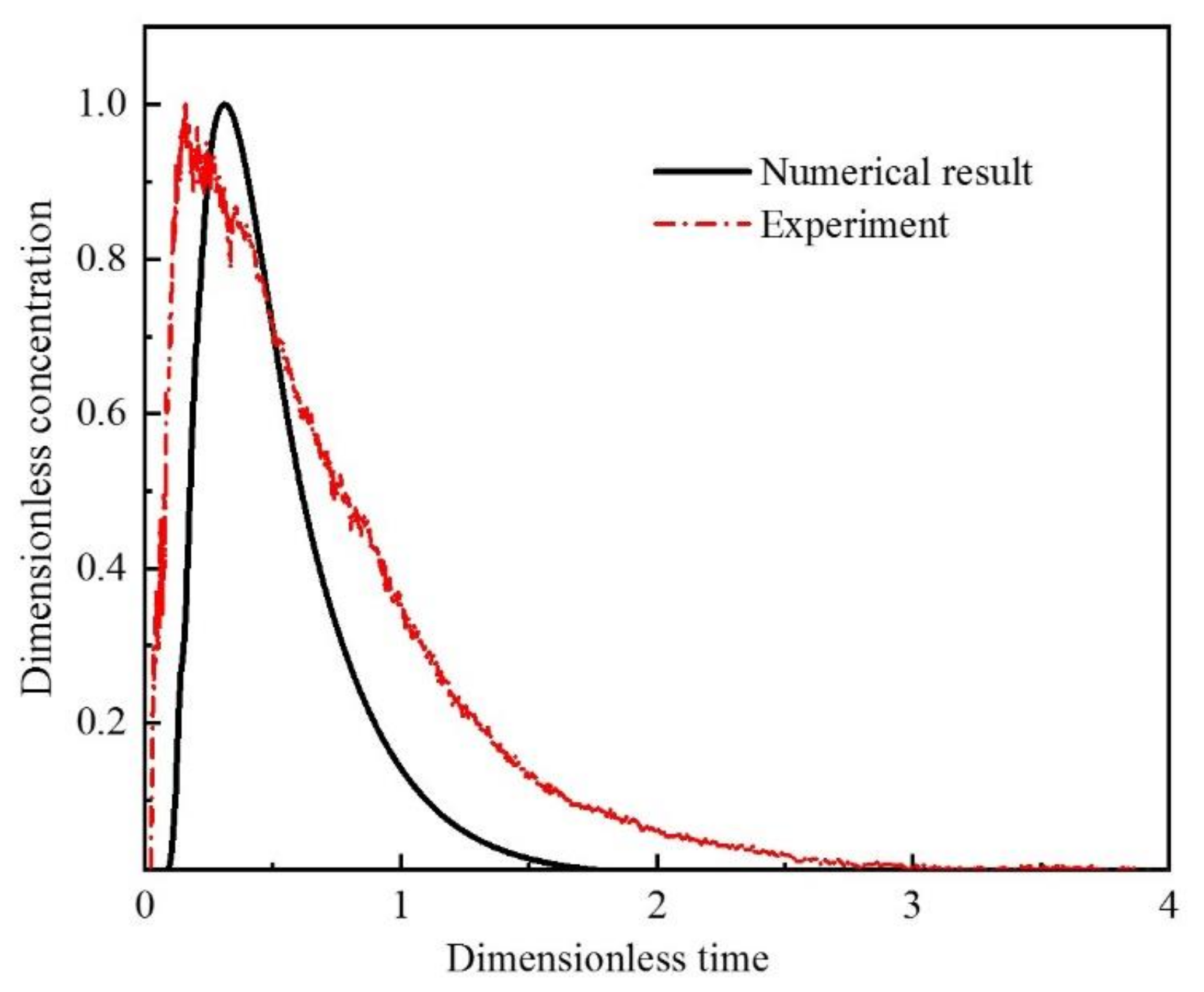

3. Validation of Numerical Results

3.1. Grid Independence

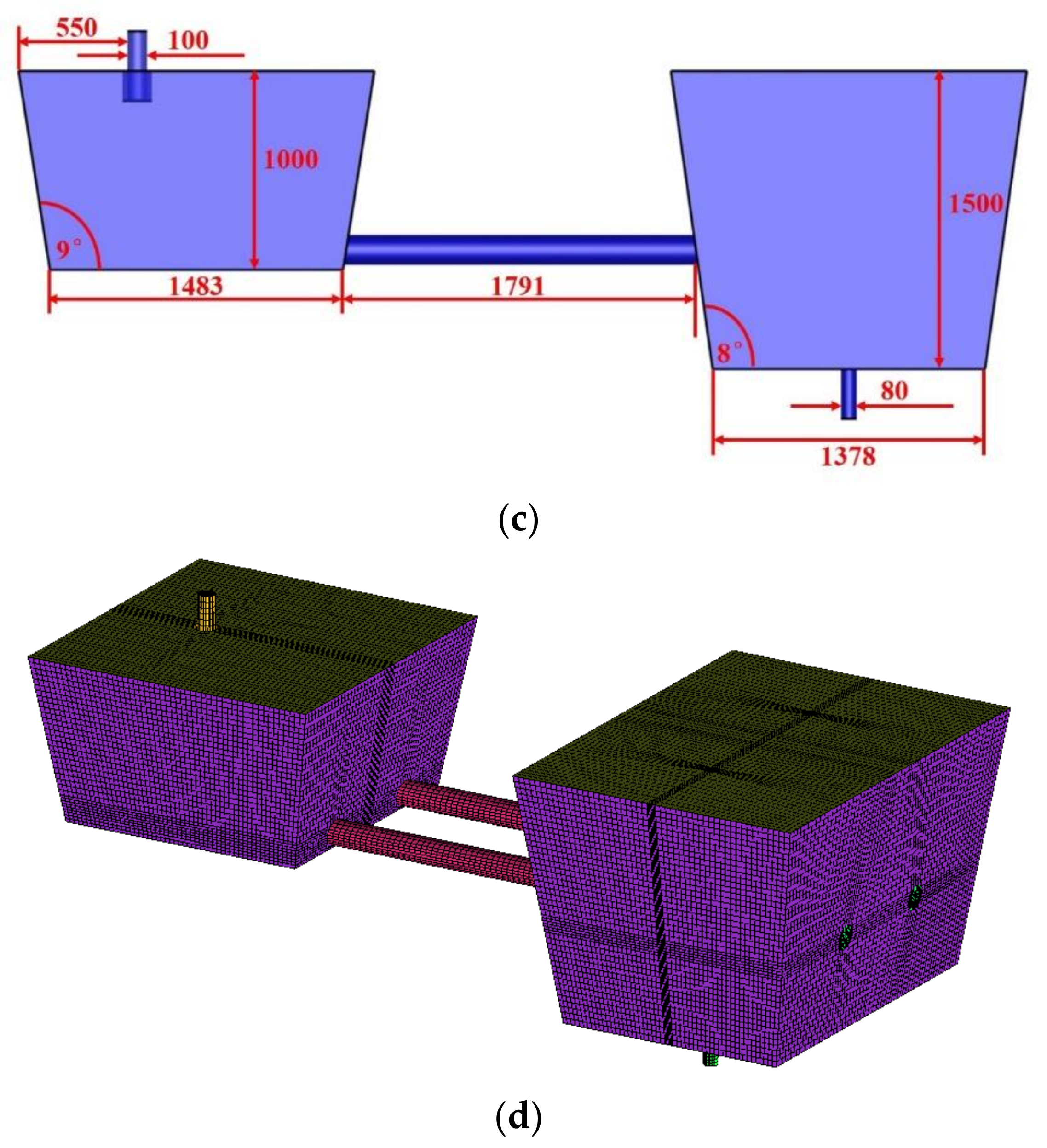

3.2. Model Validation

4. Results and Discussion

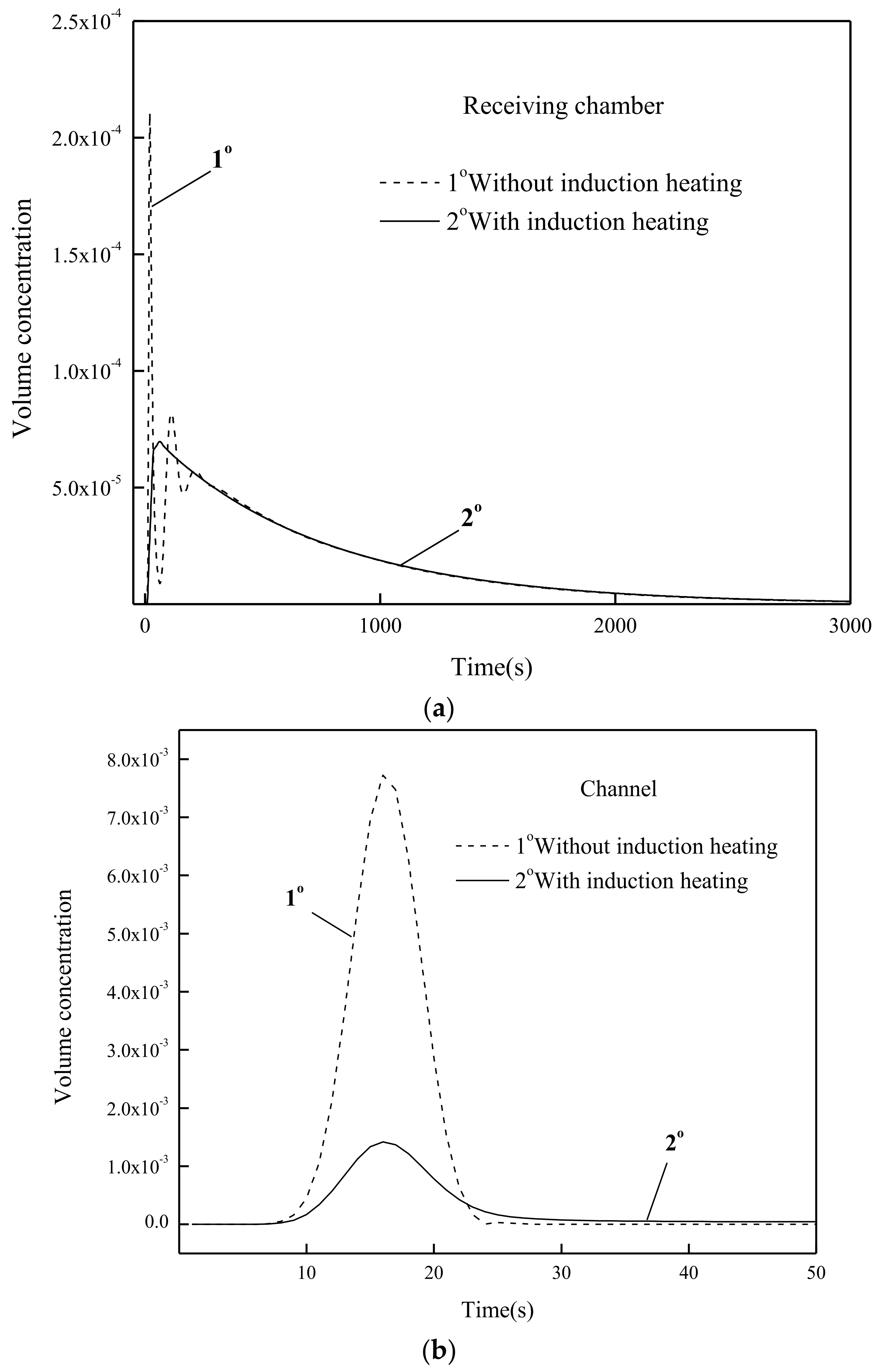

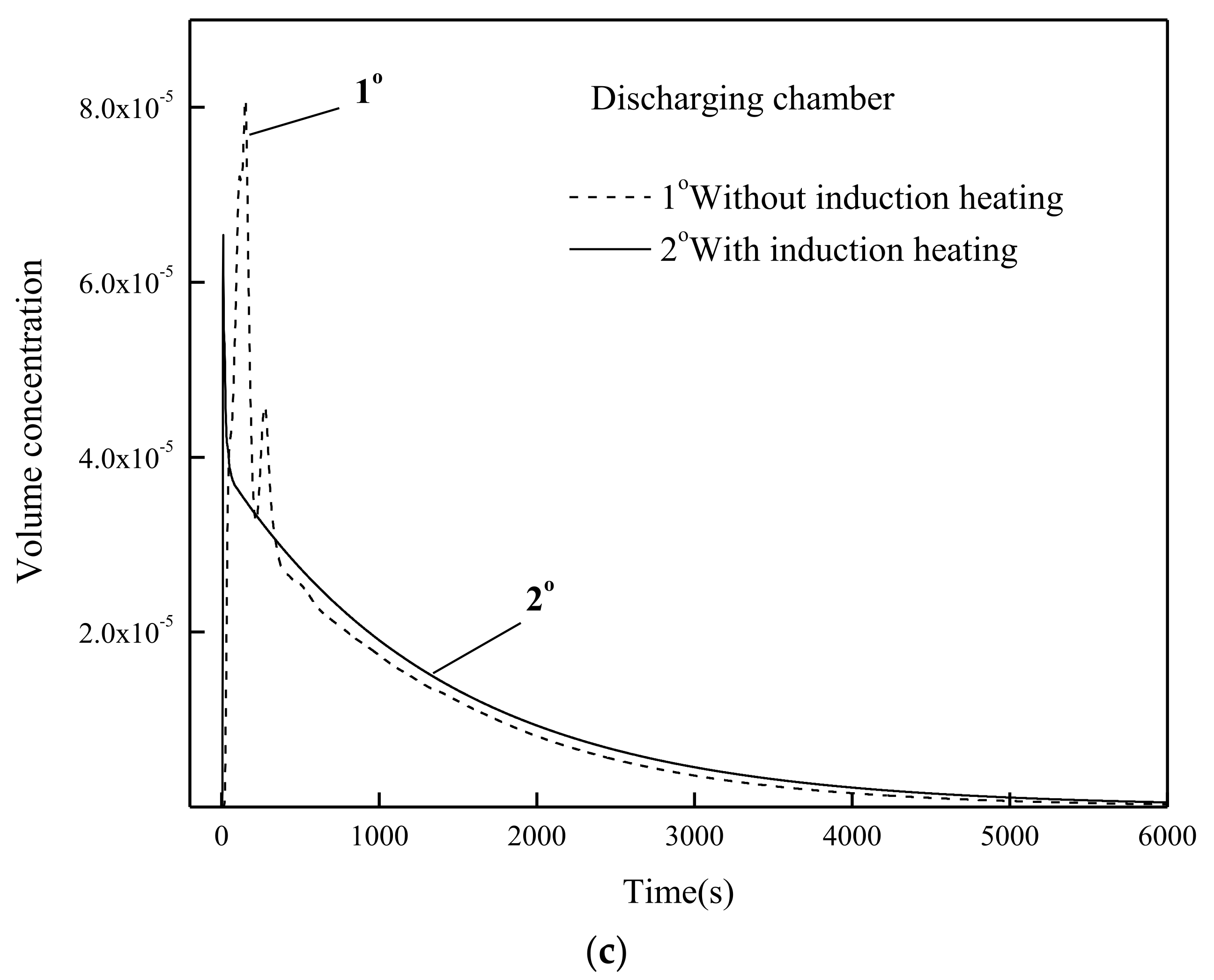

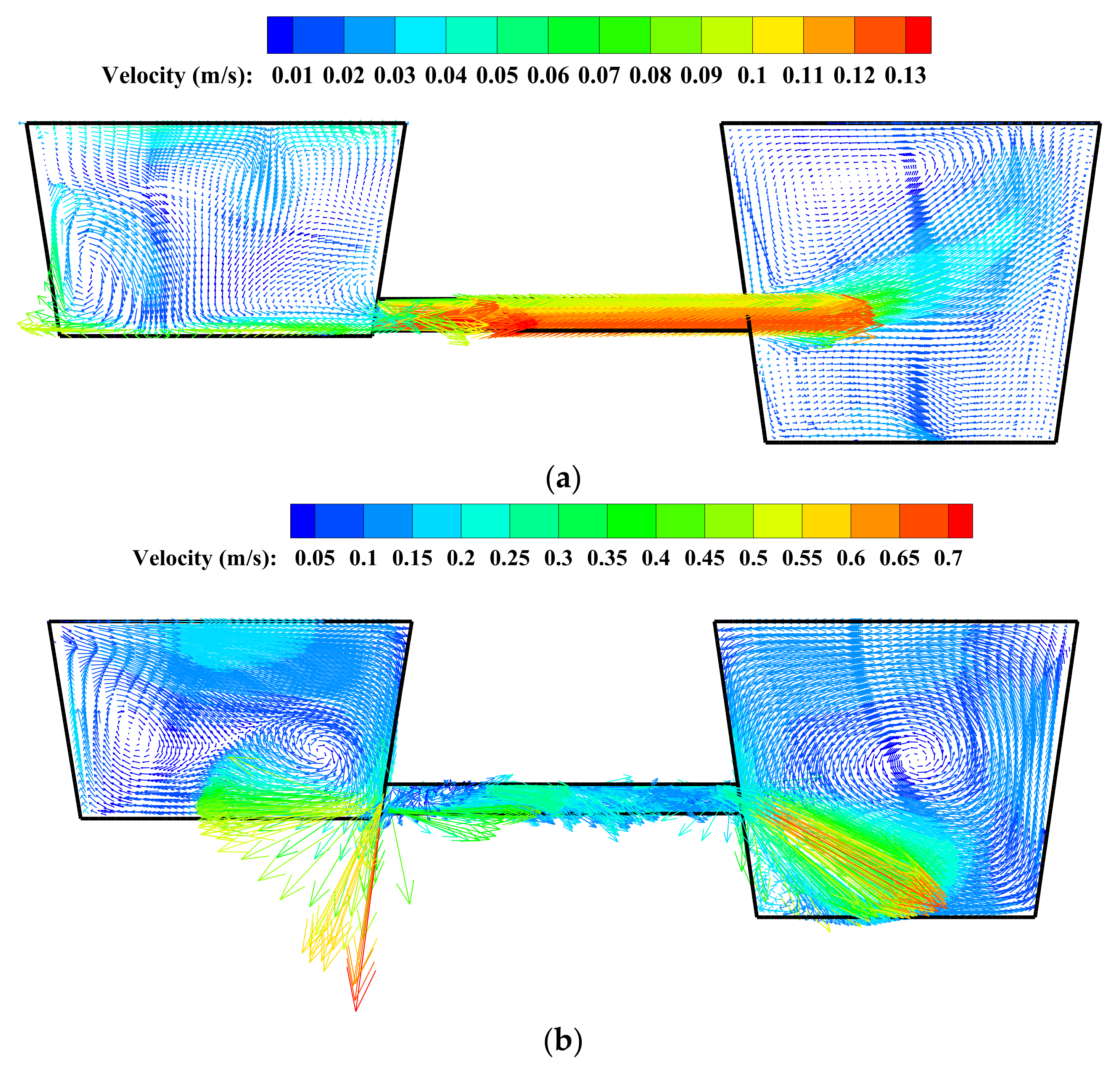

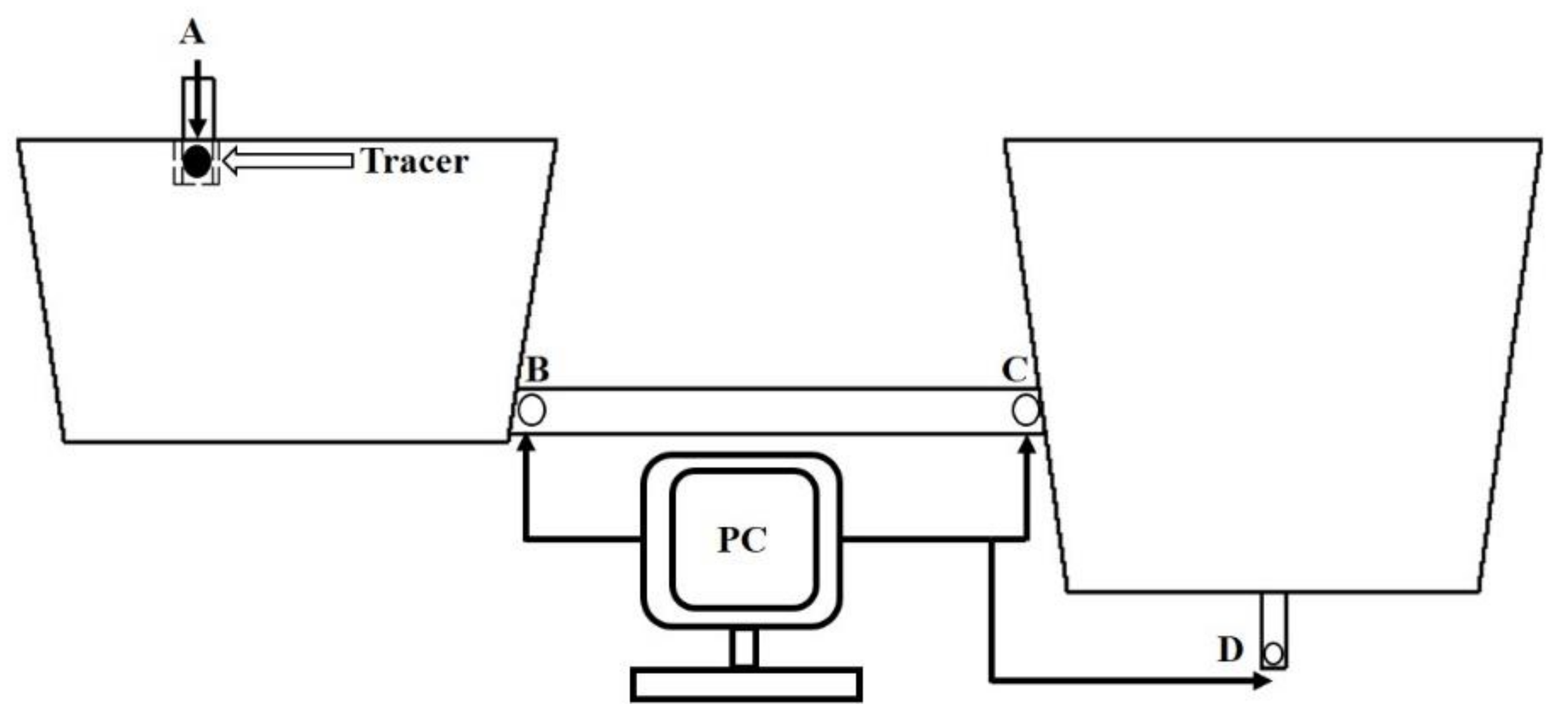

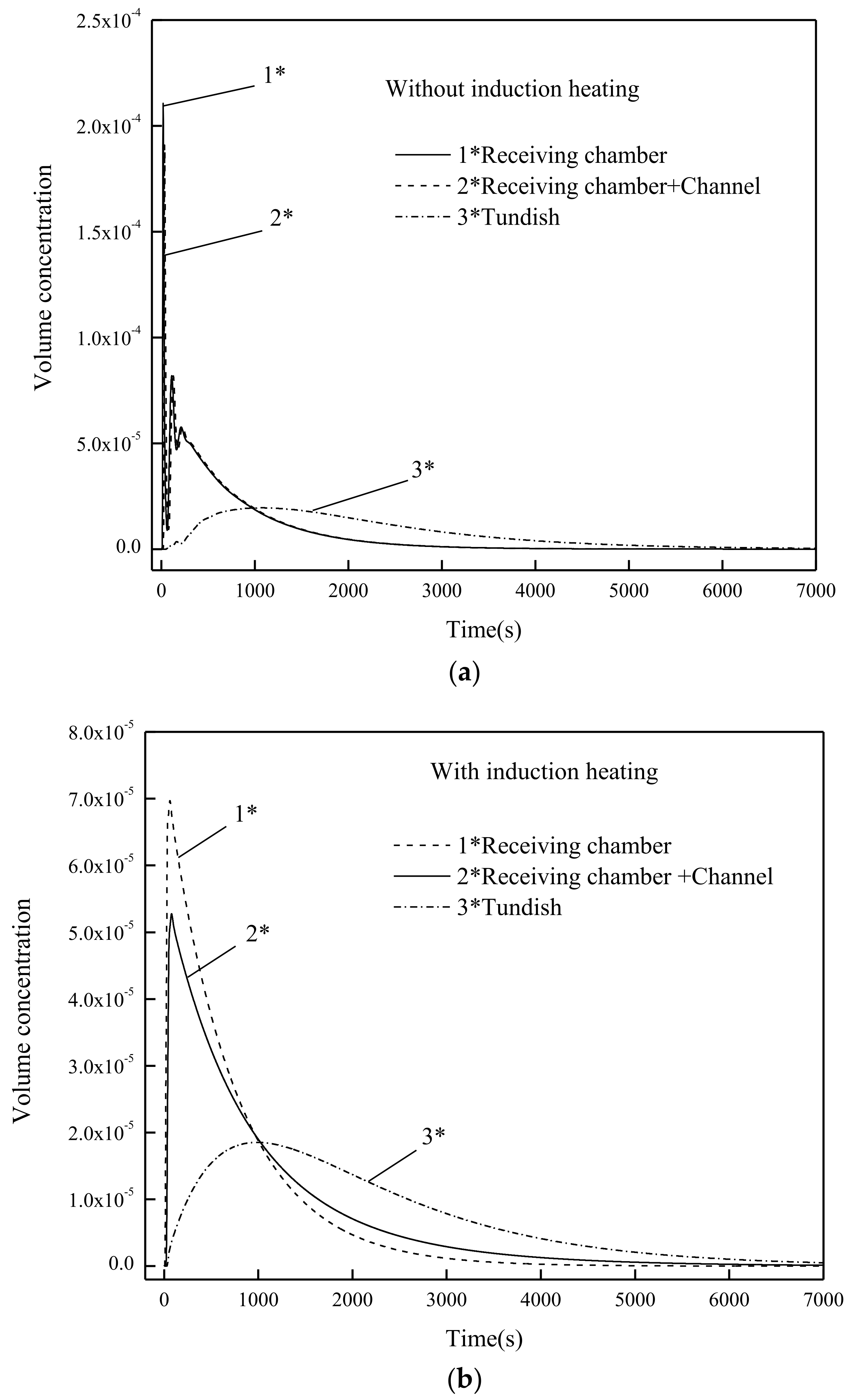

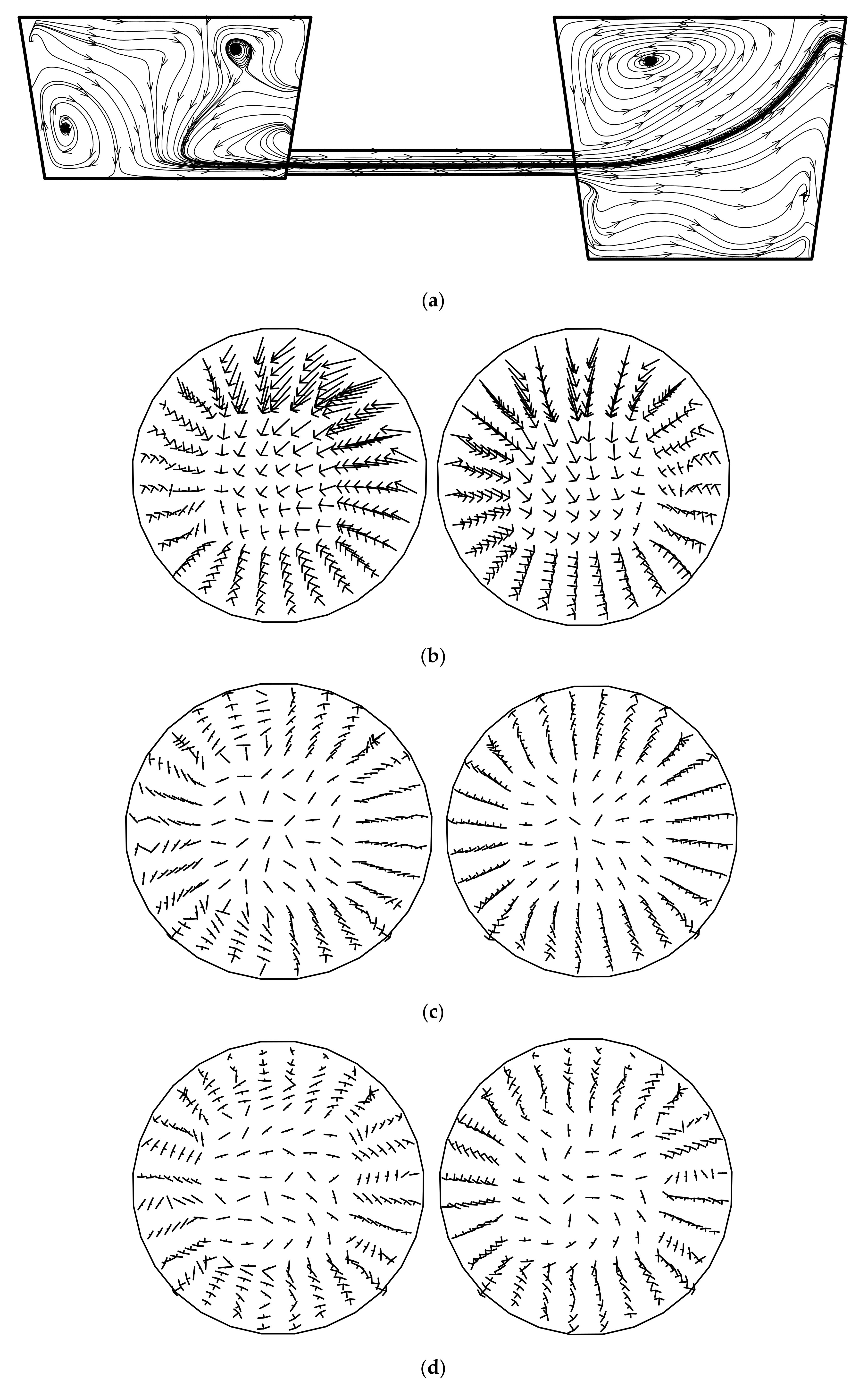

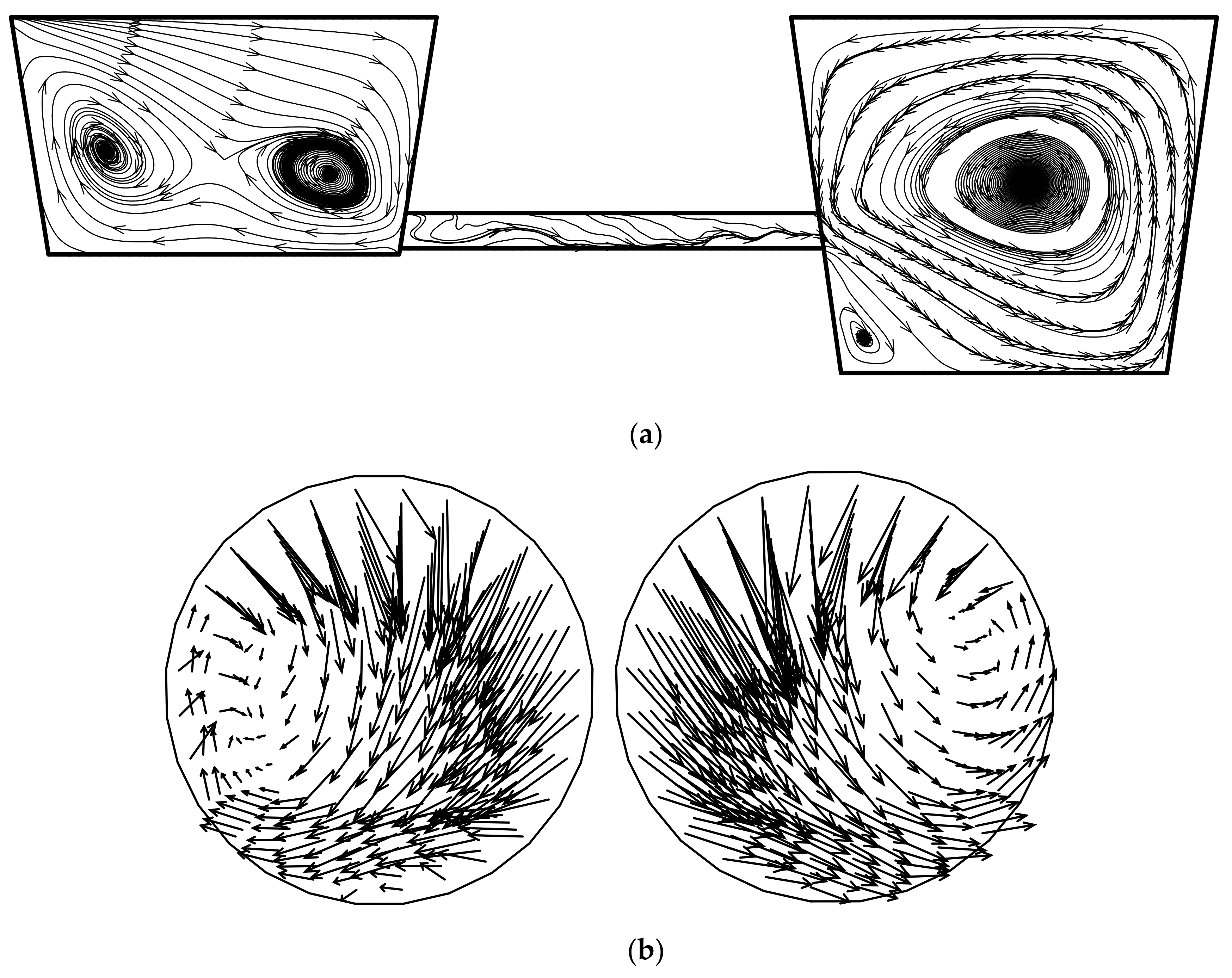

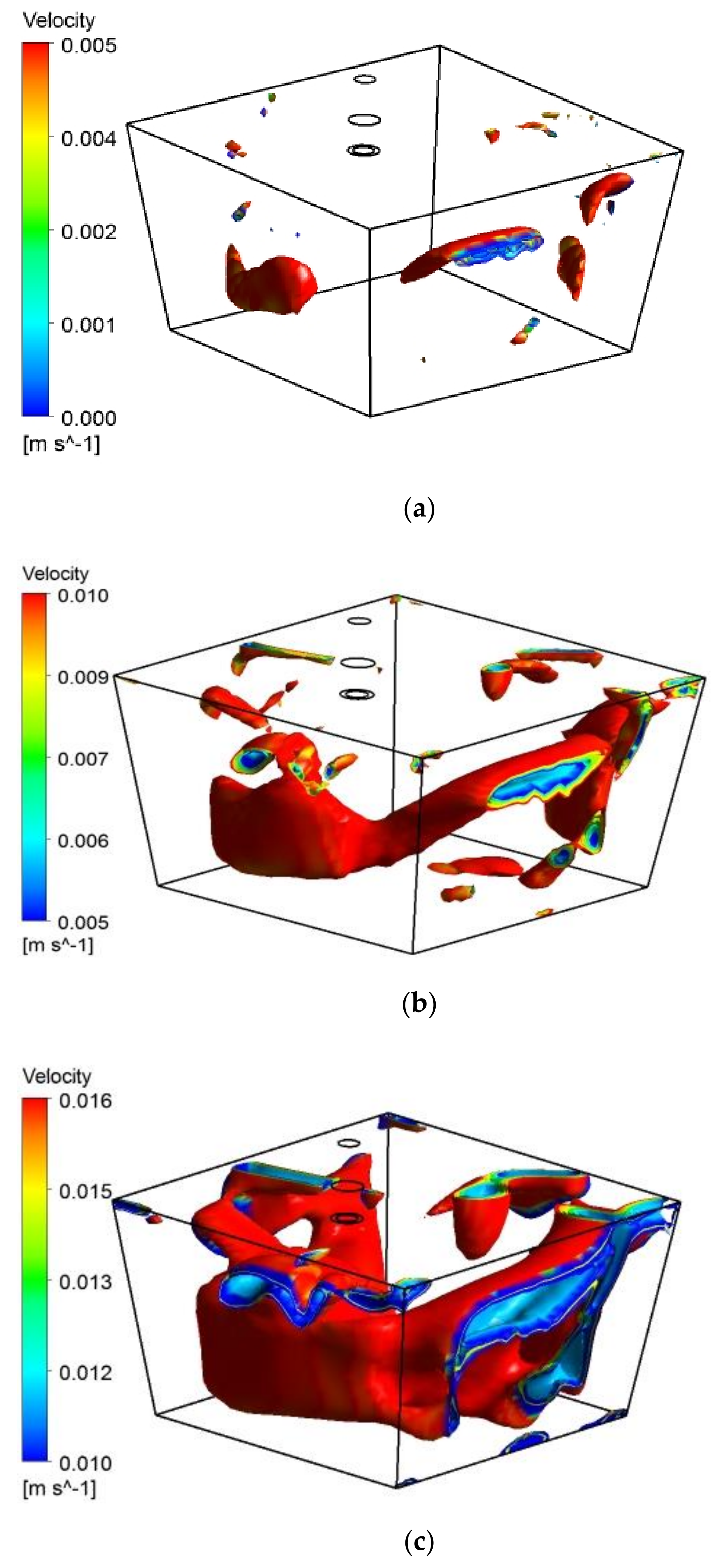

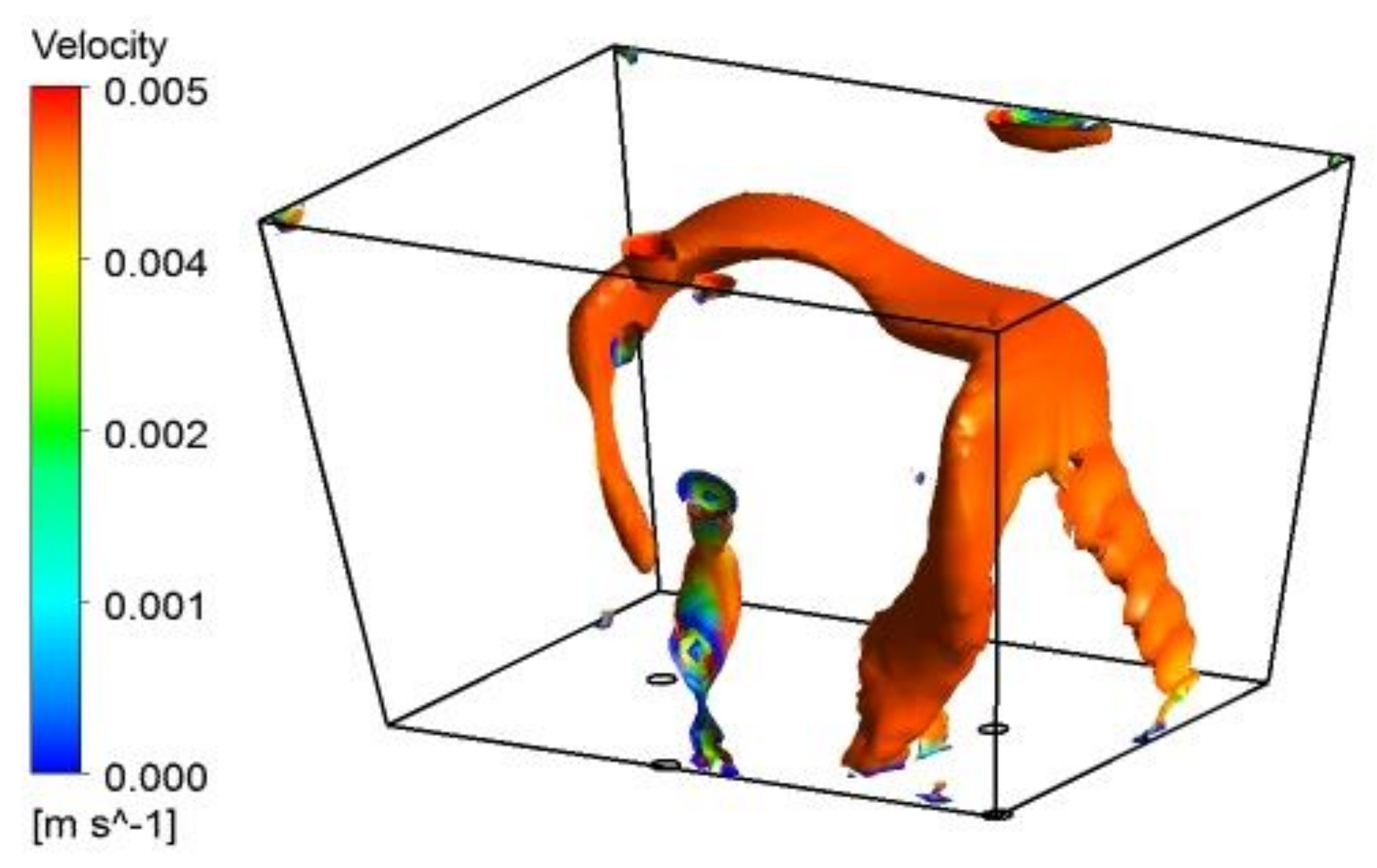

4.1. Investigation of the Fluid Flow Characteristics by Individual Unit Method

4.2. Investigation of the Fluid Flow Characteristics by Volume Subtraction Model

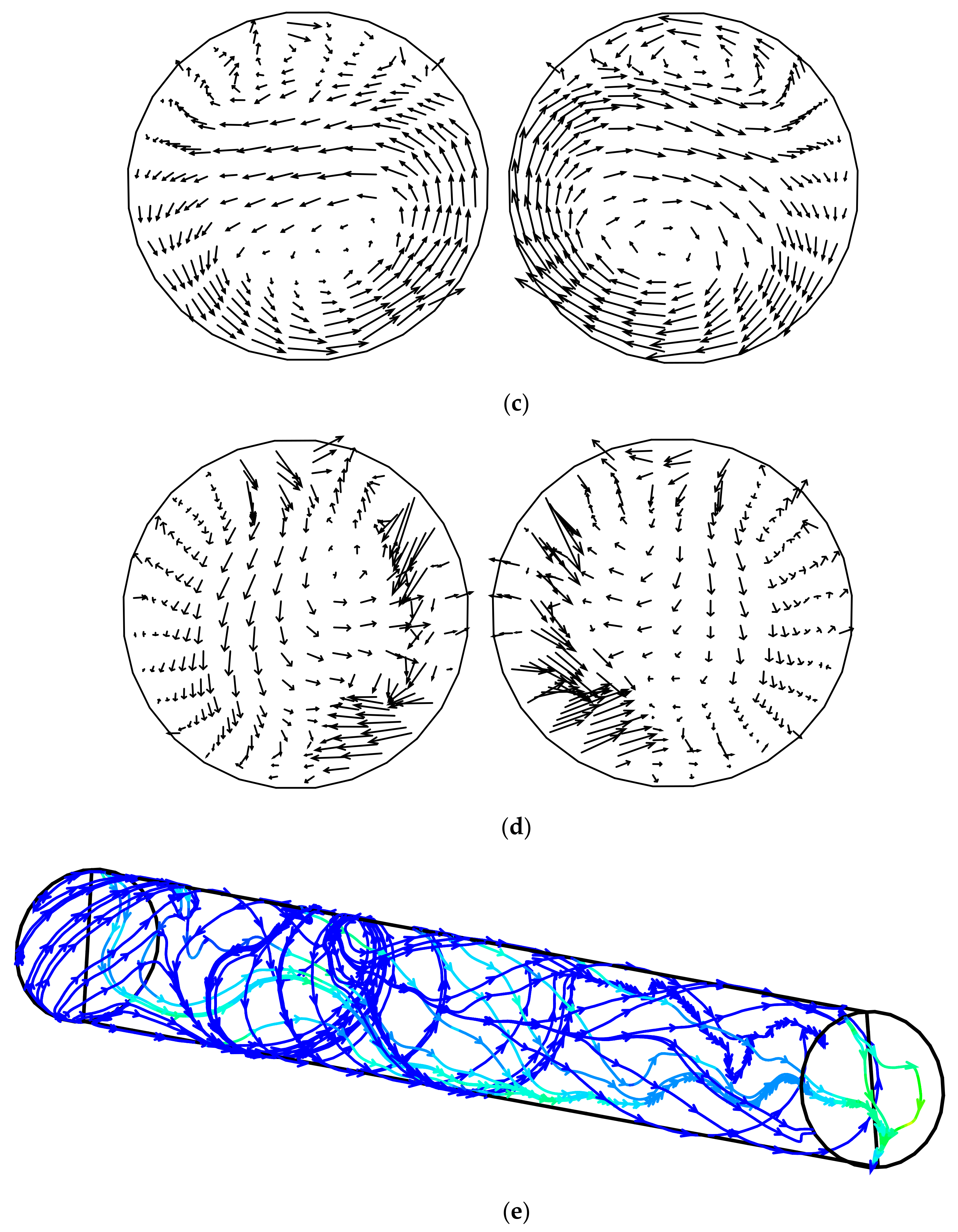

4.3. Investigation of the Flow Characteristics in the Tundish with Channel Induction Heating

5. Conclusions

- (1)

- In the receiving chamber with and without induction heating, the main flow behavior of molten steel is mixed flow.

- (2)

- In the channel with and without induction heating, the main flow behavior of molten steel is plug flow, and the dead volume can be considered as zero due to the developed pipe flow and spiral flow.

- (3)

- In the discharging chamber with and without induction heating, the main flow pattern of molten steel is mixed flow, and the minor flow pattern is plug flow. The discharging chamber is dominated by these two flow patterns.

- (4)

- The method of comparing the RTD curve and the flow behavior of the flow field is used to evaluate the complex flow in the combined metallurgical reactor, which is a good research idea.

- (5)

- The certain critical velocity and are defined in the receiving chamber and discharging chamber respectively, and the dead area in the tundish can be observed clearly by mathematical derivation and CFD-POST statistics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazumdar, D. Review, Analysis, and Modeling of Continuous Casting Tundish Systems. Steel Res. Int. 2018, 90, 1800279. [Google Scholar] [CrossRef]

- Mazumdar, D. Tundish Metallurgy: Towards Increased Productivity and Clean Steel. Trans. Indian Inst. Met. 2013, 66, 597–610. [Google Scholar] [CrossRef]

- Sahai, Y. Tundish Technology for Casting Clean Steel: A Review. Met. Mater. Trans. A 2016, 47, 2095–2106. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Y.; Huang, A.; Yan, W.; Gu, H.; Li, G. CFD Investigation of Effect of Multi-hole Ceramic Filter on Inclusion Removal in a Two-Strand Tundish. Met. Mater. Trans. A 2019, 51, 276–292. [Google Scholar] [CrossRef]

- Raghavendra, K.; Sarkar, S.; Ajmani, S.; Denys, M.; Singh, M. Mathematical modelling of single and multi-strand tundish for inclusion analysis. Appl. Math. Model. 2013, 37, 6284–6300. [Google Scholar] [CrossRef]

- Ling, H.; Zhang, L. Numerical Simulation of the Growth and Removal of Inclusions in the Molten Steel of a Two-Strand Tundish. JOM 2013, 65, 1155–1163. [Google Scholar] [CrossRef]

- Joo, S.; Guthrie, R.I.L. Inclusion behavior and heat-transfer phenomena in steelmaking tundish operations: Part I. Aqueous modeling. Met. Mater. Trans. A 1993, 24, 755–765. [Google Scholar] [CrossRef]

- Joo, S.; Han, J.W.; Guthrie, R.I.L. Inclusion behavior and heat-transfer phenomena in steelmaking tundish operations: Part II. Mathematical model for liquid steel in tundishes. Met. Mater. Trans. A 1993, 24, 767–777. [Google Scholar] [CrossRef]

- Zhang, L.; Taniguchi, S.; Cai, K. Fluid flow and inclusion removal in continuous casting tundish. Met. Mater. Trans. A 2000, 31, 253–266. [Google Scholar] [CrossRef]

- Miki, Y.; Thomas, B.G. Modeling of inclusion removal in a tundish. Metall. Mater. Trans. B 1999, 30, 639–654. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Physical and Mathematical Modelling of Inert Gas Shrouding in a Tundish. ISIJ Int. 2011, 51, 573–580. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Physical and Mathematical Modelling of Steelmaking Tundish Operations: A Review of the Last Decade (1999–2009). ISIJ Int. 2010, 50, 331–348. [Google Scholar] [CrossRef]

- Warzecha, M.; Merder, T.; Warzecha, P.; Stradomski, G. Experimental and Numerical Investigations on Non-metallic Inclusions Distribution in Billets Casted at a Multi-strand Continuous Casting Tundish. ISIJ Int. 2013, 53, 1983–1992. [Google Scholar] [CrossRef]

- Warzecha, M.; Merder, T.; Pfeifer, H.; Pieprzyca, J. Investigation of Flow Characteristics in a Six-Strand CC Tundish Combining Plant Measurements, Physical and Mathematical Modeling. Steel Res. Int. 2010, 81, 987–993. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. The Physical and Mathematical Modelling of Continuous Casting Tundish System. ISIJ Int. 1999, 39, 524–547. [Google Scholar] [CrossRef]

- Pardeshi, R.; Basak, S.; Singh, A.K.; Basu, B.; Mahashabde, V.; Roy, S.K.; Kumar, S. Mathematical Modeling of the Tundish of a Single-Strand Slab Caster. ISIJ Int. 2004, 44, 1534–1540. [Google Scholar] [CrossRef]

- Cwudziński, A. Numerical and Physical Modeling of Liquid Steel Active Flow in Tundish with Subflux Turbulence Controller and Dam. Steel Res. Int. 2013, 85, 902–917. [Google Scholar] [CrossRef]

- Cwudziński, A. Numerical, Physical, and Industrial Experiments of Liquid Steel Mixture in One Strand Slab Tundish with Flow Control Devices. Steel Res. Int. 2013, 85, 623–631. [Google Scholar] [CrossRef]

- Cwudziński, A. Numerical, Physical, and Industrial Studies of Liquid Steel Chemical Homogenization in One Strand Tundish with Subflux Turbulence Controller. Steel Res. Int. 2014, 86, 972–983. [Google Scholar] [CrossRef]

- Tripathi, A.; Ajmani, S.K. Effect of Shape and Flow Control Devices on the Fluid Flow Characteristics in Three Different Industrial Six Strand Billet Caster Tundish. ISIJ Int. 2011, 51, 1647–1656. [Google Scholar] [CrossRef][Green Version]

- Tripathi, A.; Ajmani, S.K. Numerical Investigation of Fluid Flow Phenomenon in a Curved Shape Tundish of Billet Caster. ISIJ Int. 2005, 45, 1616–1625. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Effect of flow modifiers on liquid metal cleanliness in four-strand delta shaped billet caster tundish. Ironmak. Steelmak. 2012, 39, 454–462. [Google Scholar] [CrossRef]

- Neves, L.; Tavares, R.P. Analysis of the mathematical model of the gas bubbling curtain injection on the bottom and the walls of a continuous casting tundish. Ironmak. Steelmak. 2016, 44, 559–567. [Google Scholar] [CrossRef]

- Lopez-Ramirez, S.; Palafox-Ramos, J.; Morales, R.D.; Barreto, J.D.J.; Zacharias, D. Modeling study of the influence of turbulence inhibitors on the molten steel flow, tracer dispersion, and inclusion trajectories in tundishes. Met. Mater. Trans. A 2001, 32, 615–627. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sahai, Y. Effect of holding time and surface cover in ladles on liquid steel flow in continuous casting tundishes. Met. Mater. Trans. A 1992, 23, 153–167. [Google Scholar] [CrossRef]

- Palafox-Ramos, J.; Barreto, J.D.J.; Lopez-Ramirez, S.; Morales, R. Melt flow optimisation using turbulence inhibitors in large volume tundishes. Ironmak. Steelmak. 2001, 28, 101–109. [Google Scholar] [CrossRef]

- Ni, P.; Jonsson, L.T.I.; Ersson, M.; Jönsson, P.G. Non-Metallic Inclusion Behaviors in a New Tundish and SEN Design Using a Swirling Flow during Continuous Casting of Steel. Steel Res. Int. 2016, 88, 1600155. [Google Scholar] [CrossRef]

- Tkadlečková, M.; Walek, J.; Michalek, K.; Huczala, T. Numerical Analysis of RTD Curves and Inclusions Removal in a Multi-Strand Asymmetric Tundish with Different Configuration of Impact Pad. Metals 2020, 10, 849. [Google Scholar] [CrossRef]

- Wang, Q.; Qi, F.; Li, B.; Tsukihashi, F. Behavior of Non-metallic Inclusions in a Continuous Casting Tundish with Channel Type Induction Heating. ISIJ Int. 2014, 54, 2796–2805. [Google Scholar] [CrossRef]

- Yue, Q.; Zhang, C.B.; Pei, X.H. Magnetohydrodynamic flows and heat transfer in a twin-channel induction heating tundish. Ironmak. Steelmak. 2016, 44, 227–236. [Google Scholar] [CrossRef]

- Xing, F.; Zheng, S.; Zhu, M. Motion and Removal of Inclusions in New Induction Heating Tundish. Steel Res. Int. 2018, 89, 1700542. [Google Scholar] [CrossRef]

- Lei, H.; Yang, B.; Bi, Q.; Xiao, Y.; Chen, S.; Ding, C. Numerical Simulation of Collision-Coalescence and Removal of Inclusion in Tundish with Channel Type Induction Heating. ISIJ Int. 2019, 59, 1811–1819. [Google Scholar] [CrossRef]

- Xing, F.; Zheng, S.; Liu, Z.; Zhu, M. Flow Field, Temperature Field, and Inclusion Removal in a New Induction Heating Tundish with Bent Channels. Metals 2019, 9, 561. [Google Scholar] [CrossRef]

- Yang, B.; Lei, H.; Bi, Q.; Jiang, J.; Zhang, H.; Zhao, Y.; Zhou, J.-A. Electromagnetic Conditions in a Tundish with Channel Type Induction Heating. Steel Res. Int. 2018, 89, 1800145. [Google Scholar] [CrossRef]

- Yang, B.; Lei, H.; Bi, Q.; Jiang, J.; Zhang, H.; Zhao, Y.; Zhou, J.-A. Fluid Flow and Heat Transfer in a Tundish with Channel Type Induction Heating. Steel Res. Int. 2018, 89, 1800173. [Google Scholar] [CrossRef]

- Tang, H.; Guo, L.; Wu, G.; Xiao, H.; Yao, H.; Zhang, J. Hydrodynamic Modeling and Mathematical Simulation on Flow Field and Inclusion Removal in a Seven-Strand Continuous Casting Tundish with Channel Type Induction Heating. Metals 2018, 8, 374. [Google Scholar] [CrossRef]

- Yue, Q.; Pei, X.; Zhang, C.; Wang, X. Magnetohydrodynamics Calculation on Double-loop Channel Induction Tundish. Arch. Metall. Mater. 2018, 63, 329–336. [Google Scholar] [CrossRef]

- Sahai, Y.; Emi, T. Melt Flow Characterization in Continuous Casting Tundishes. ISIJ Int. 1996, 36, 667–672. [Google Scholar] [CrossRef]

- Sahai, Y.; Ahuja, R. Steel Flow and Mixing of Melt in Steelmaking Tundishes. Ironmak. Steelmak. 1986, 13, 241–247. [Google Scholar]

- Lei, H. New Insight into Combined Model and Revised Model for RTD Curves in a Multi-strand Tundish. Met. Mater. Trans. A 2015, 46, 2408–2413. [Google Scholar] [CrossRef]

| Parameters | Value | Units |

|---|---|---|

| Strands | 2 | - |

| Volumetric flow rate at the ladle shroud | 14 | |

| Volume of receiving chamber | 2.826 | |

| Volume of channel | 0.062 | |

| Volume of discharging chamber | 5.243 | |

| Submergence depth of shroud | 150 | mm |

| Relative permeability of molten steel | 1 | - |

| Relative permeability of iron core | 1000 | - |

| Resistivity of molten steel | 1.4 × 10−6 | |

| Relative permeability of copper coil | 1 | - |

| Relative permeability of air | 1 | - |

| Thermal conductivity of molten steel | 41 | |

| Heat capacity of molten steel | 750 | |

| Density of molten steel | (8523–0.8358T) | |

| Relative permeability of molten steel | 1 | - |

| Relative permeability of iron core | 1000 | - |

| Parameters | Combined Model |

|---|---|

| Mean residence time | |

| Dimensionless time | |

| Theoretical residence time | |

| Dead volume fraction | |

| Plug volume fraction | |

| Well-mixed volume fraction |

| Parameter | Value | Units |

|---|---|---|

| Heat loss of free surface | 8000 | W/m2 |

| Heat loss of bottom | 1800 | W/m2 |

| Heat loss of wide wall | 4000 | W/m2 |

| Heat loss of narrow wall | 4200 | W/m2 |

| Heat loss of channel wall | 1100 | W/m2 |

| Velocity of ladle shroud | 0.5 | m/s |

| Temperature of ladle shroud | 1800 | K |

| Grid Numbers | 196,156 | 248,300 | 300,318 | 324,848 | 350,580 |

|---|---|---|---|---|---|

| Test point | M | M | M | M | M |

| Velocity () | 0.125271 | 0.126333 | 0.126674 | 0.1258324 | 0.125795 |

| Cases | |||

|---|---|---|---|

| Numerical calculate | 33.05% | 9.55% | 57.40% |

| Water model | 33.72% | 9.48% | 56.80% |

| Metallurgical Containers | Addition Position | Monitor Position | Tracer |

|---|---|---|---|

| Receiving chamber | A | B | 1 |

| Channel | B | C | 2 |

| Discharging chamber | C | D | 3 |

| Cases | Residence Time (s) | Volume (m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 544.4 | 16.2 | 907.4 | 0.063 | 0.051 | 0.345 | 2.075 | 0.013 | 3.218 | 0.688 | −0.003 | 1.70 |

| 2 | 547.2 | 17.5 | 996.8 | 0.145 | 0.051 | 0.035 | 2.004 | 0.017 | 3.879 | 0.677 | −0.007 | 1.33 |

| Addition Point | Monitor Point | Volume | Notes |

|---|---|---|---|

| A | B | - | |

| A | C | ||

| A | D |

| Cases | Residence Time (s) | Volume (m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Without induction heating | 544.4 | 563.7 | 1850.1 | 19.3 | 1286.4 | 0.0628 | 0.1217 | 2.24 | 0.0589 | 2.118 |

| With induction heating | 547.2 | 623.5 | 1812.1 | 76.3 | 1188.6 | 0.1461 | 0.2070 | 2.03 | 0.0609 | 1.822 |

| Cases | ||||||||||

| Without induction heating | 2.075 | 2.092 | 5.025 | 0.017 | 2.933 | 0.688 | 0.670 | 0.866 | −0.018 | 0.1957 |

| With induction heating | 2.004 | 2.240 | 5.080 | 0.236 | 2.840 | 0.677 | 0.436 | 1.015 | −0.241 | 0.5791 |

| 0.001 | 0.000312 | 0.011 |

| 0.002 | 0.002860 | 0.101 |

| 0.003 | 0.008170 | 0.289 |

| 0.004 | 0.016300 | 0.577 |

| 0.005 | 0.029300 | 1.037 |

| 0.006 | 0.0462 | 1.635 |

| 0.007 | 0.0695 | 2.460 |

| 0.008 | 0.1020 | 3.609 |

| 0.009 | 0.1410 | 4.990 |

| 0.010 | 0.1900 | 6.723 |

| 0.011 | 0.2440 | 8.634 |

| 0.012 | 0.3140 | 11.11 |

| 0.013 | 0.3930 | 13.907 |

| 0.014 | 0.4860 | 17.197 |

| 0.015 | 0.5800 | 20.523 |

| 0.016 | 0.6880 | 24.345 |

| 0.001 | 0.00162 | 0.0309 |

| 0.002 | 0.0111 | 0.212 |

| 0.003 | 0.043 | 0.820 |

| 0.004 | 0.101 | 1.926 |

| 0.004736 | 0.178 | 3.395 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Lei, H.; Xu, Y.; Liu, K.; Han, P. Numerical Investigation of Flow Characteristics of Molten Steel in the Tundish with Channel Induction Heating. Metals 2021, 11, 1937. https://doi.org/10.3390/met11121937

Yang B, Lei H, Xu Y, Liu K, Han P. Numerical Investigation of Flow Characteristics of Molten Steel in the Tundish with Channel Induction Heating. Metals. 2021; 11(12):1937. https://doi.org/10.3390/met11121937

Chicago/Turabian StyleYang, Bin, Hong Lei, Yingshi Xu, Kun Liu, and Peng Han. 2021. "Numerical Investigation of Flow Characteristics of Molten Steel in the Tundish with Channel Induction Heating" Metals 11, no. 12: 1937. https://doi.org/10.3390/met11121937

APA StyleYang, B., Lei, H., Xu, Y., Liu, K., & Han, P. (2021). Numerical Investigation of Flow Characteristics of Molten Steel in the Tundish with Channel Induction Heating. Metals, 11(12), 1937. https://doi.org/10.3390/met11121937