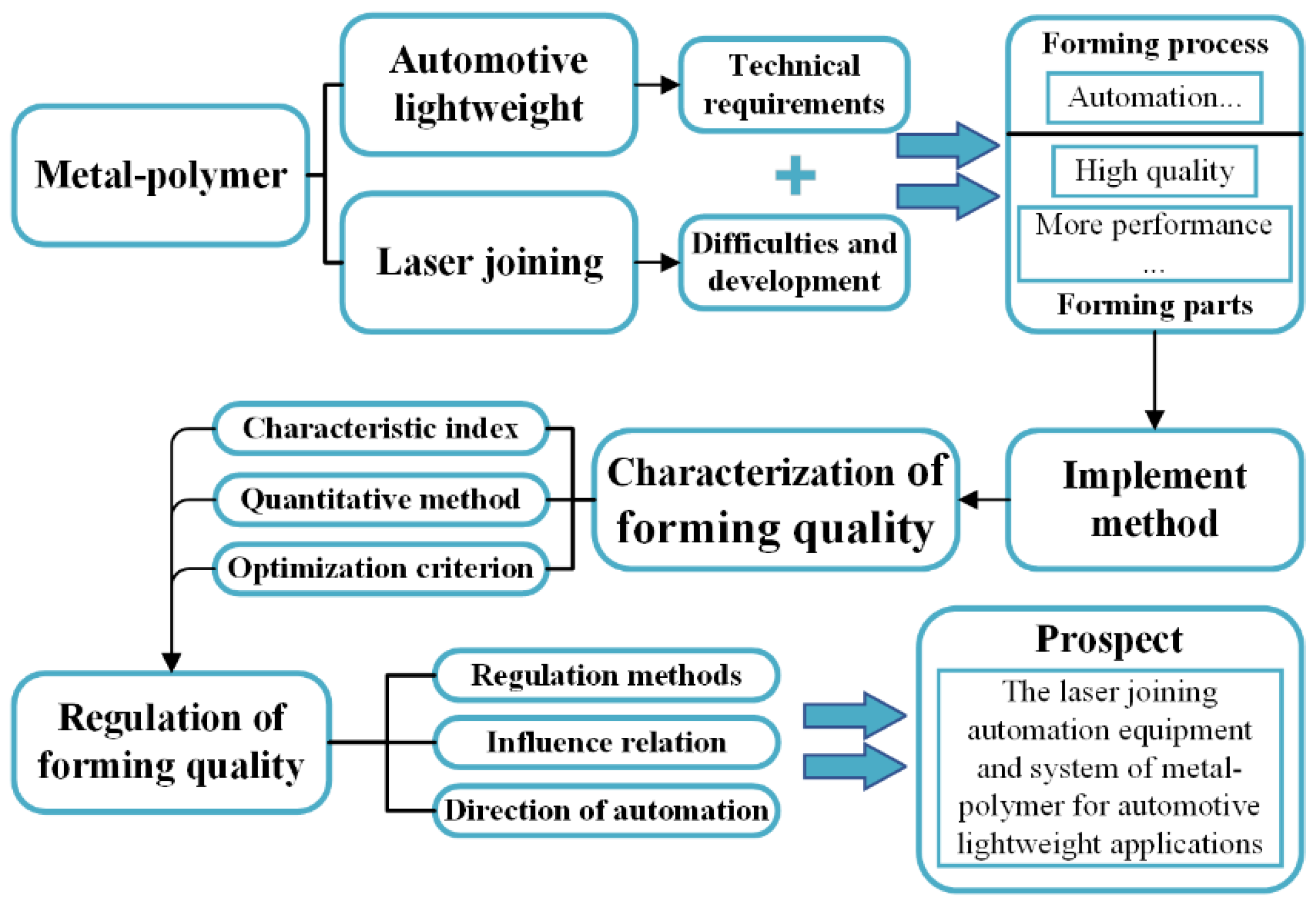

Research Progress on Characterization and Regulation of Forming Quality in Laser Joining of Metal and Polymer, and Development Trends of Lightweight Automotive Applications

Abstract

1. Introduction

2. Metal and Polymer Hybrid Structure for Automotive Lightweight Materials and Laser Joining

2.1. Research Status of Metal-Polymer Hybrid Structures in Automotive Lightweight

2.1.1. Automotive Body and Its Structural Parts

2.1.2. Other Body Components

2.2. Basic Characteristics of Metal-Polymer Hybrid Structure

2.3. The Fabrication Process of Metal-Polymer Components and the Advantages of Laser Joining

2.4. Basic Characteristics of Laser Joining Metal and Polymer

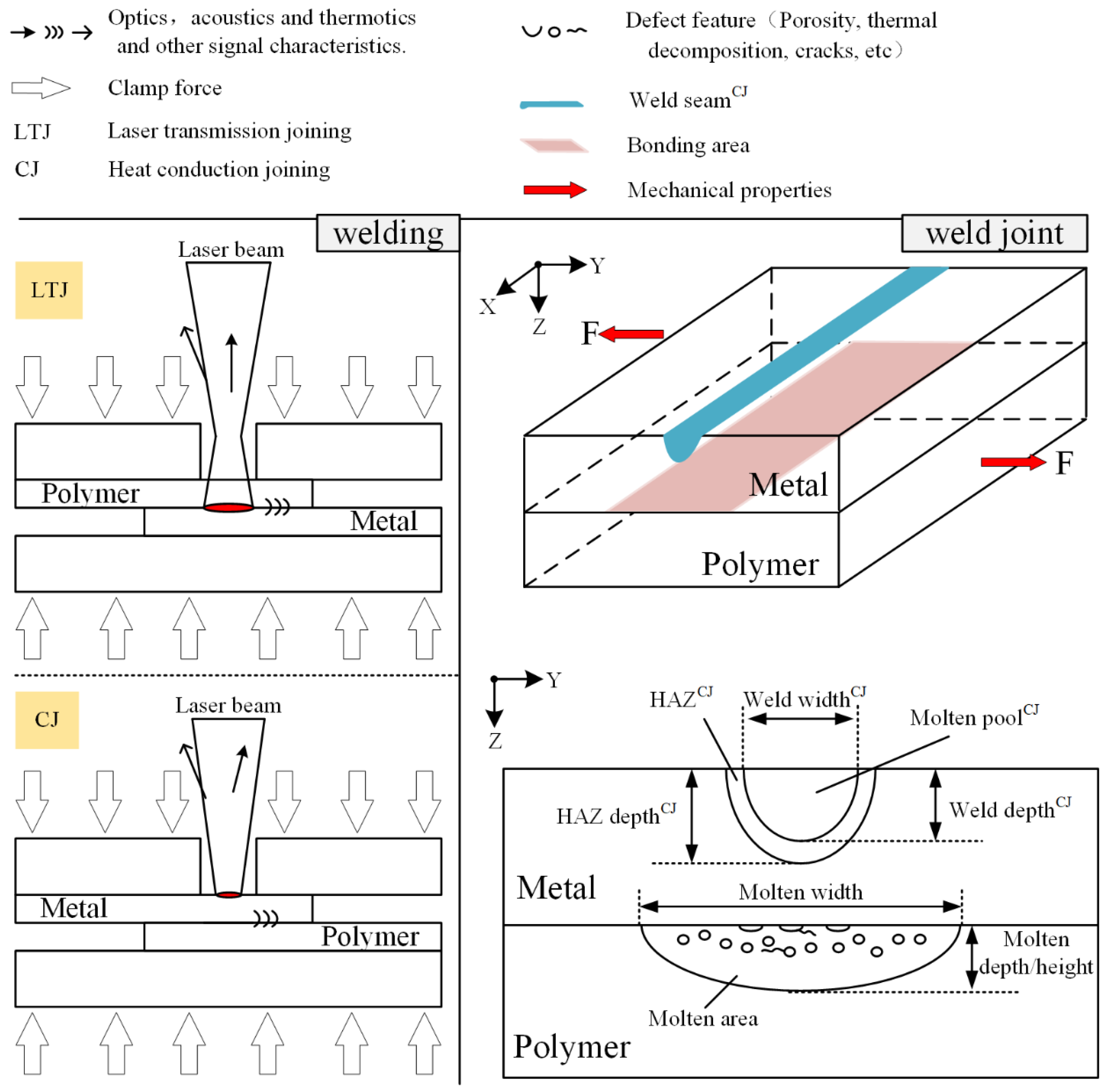

3. Forming Characterization of Metal–Polymer Hybrid Joints

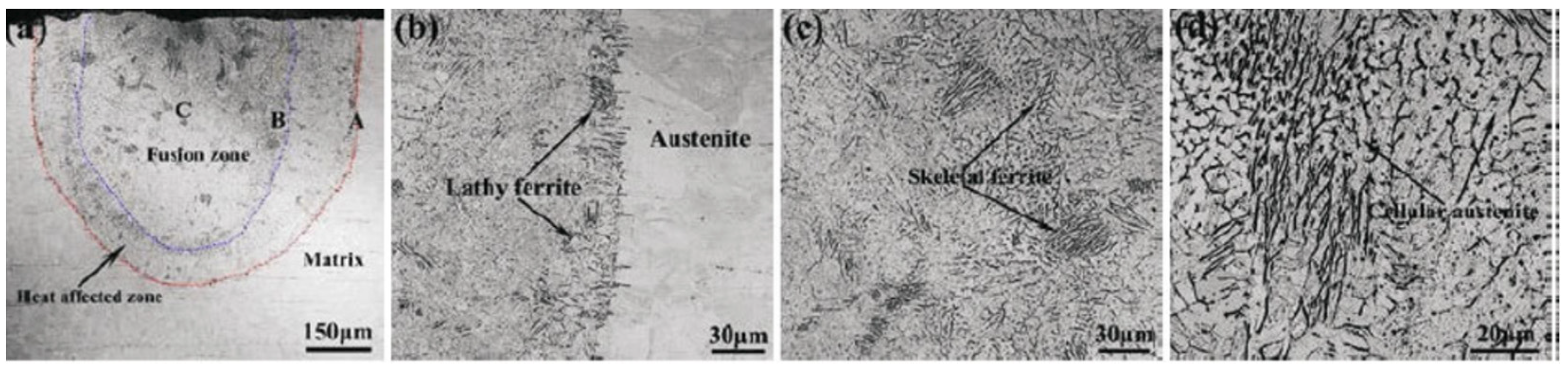

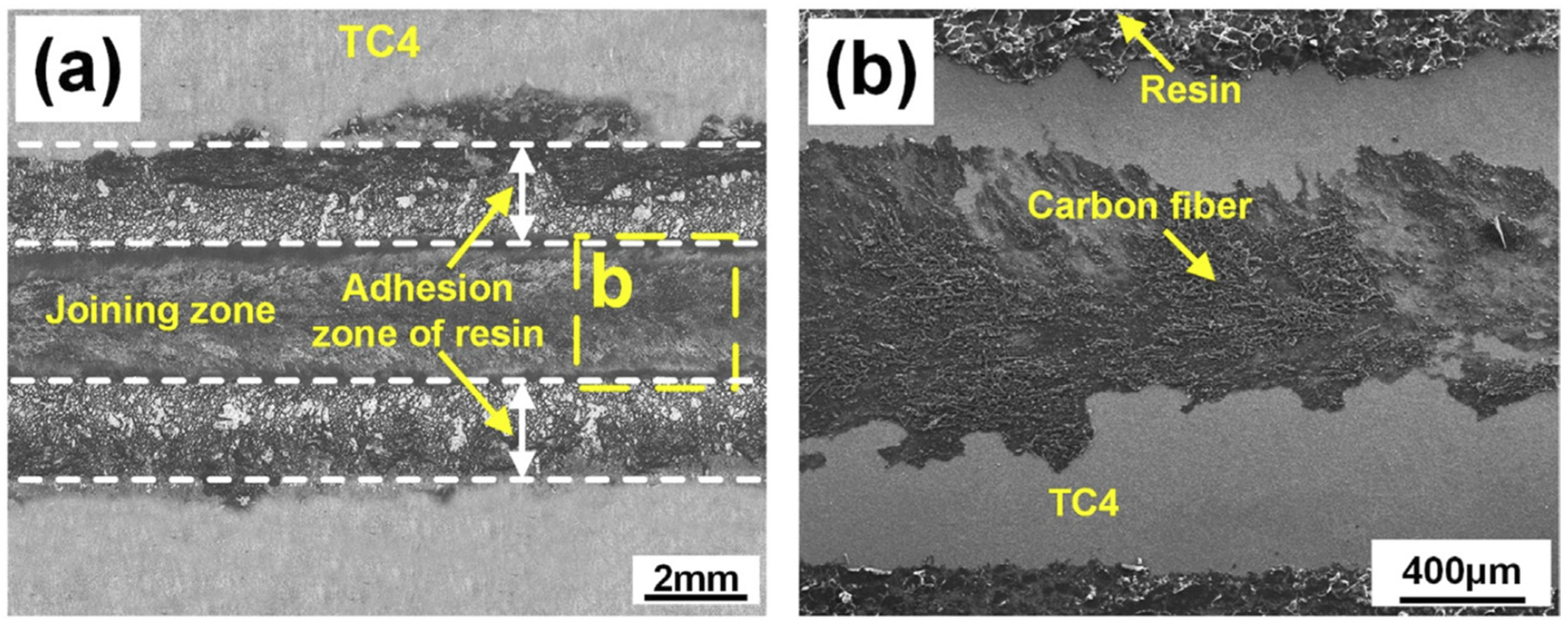

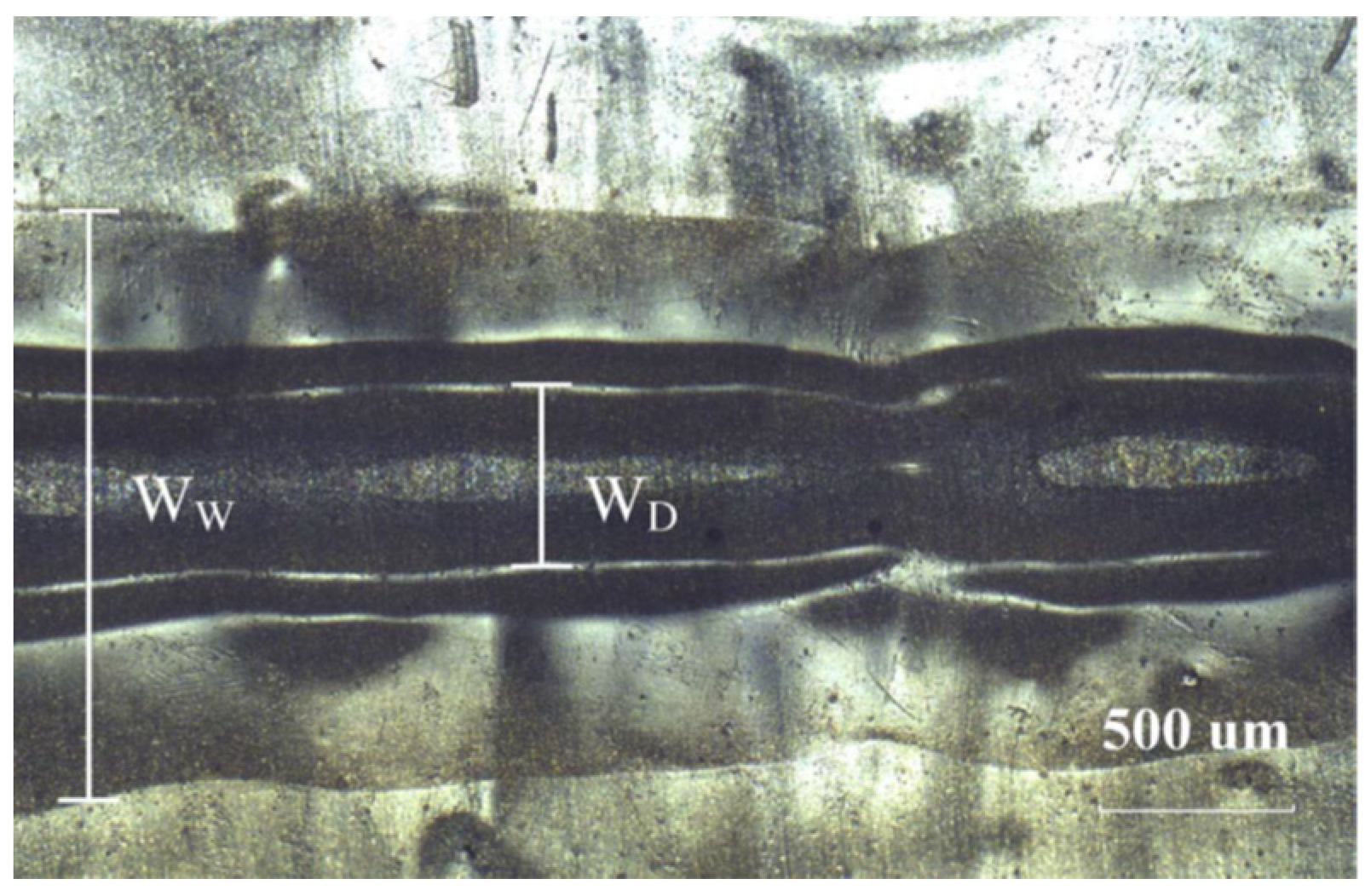

3.1. Weld Characteristics of Metal Surface

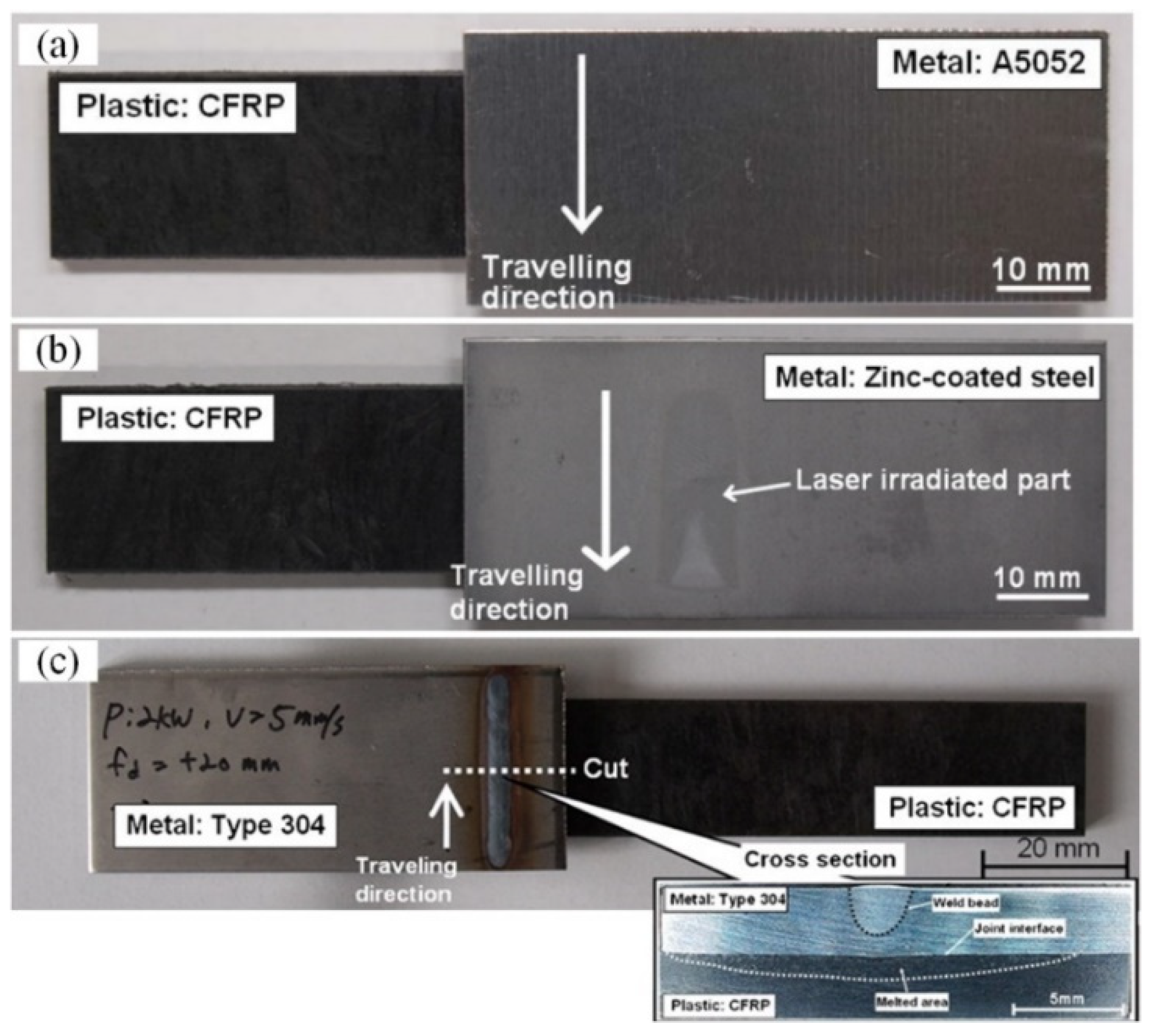

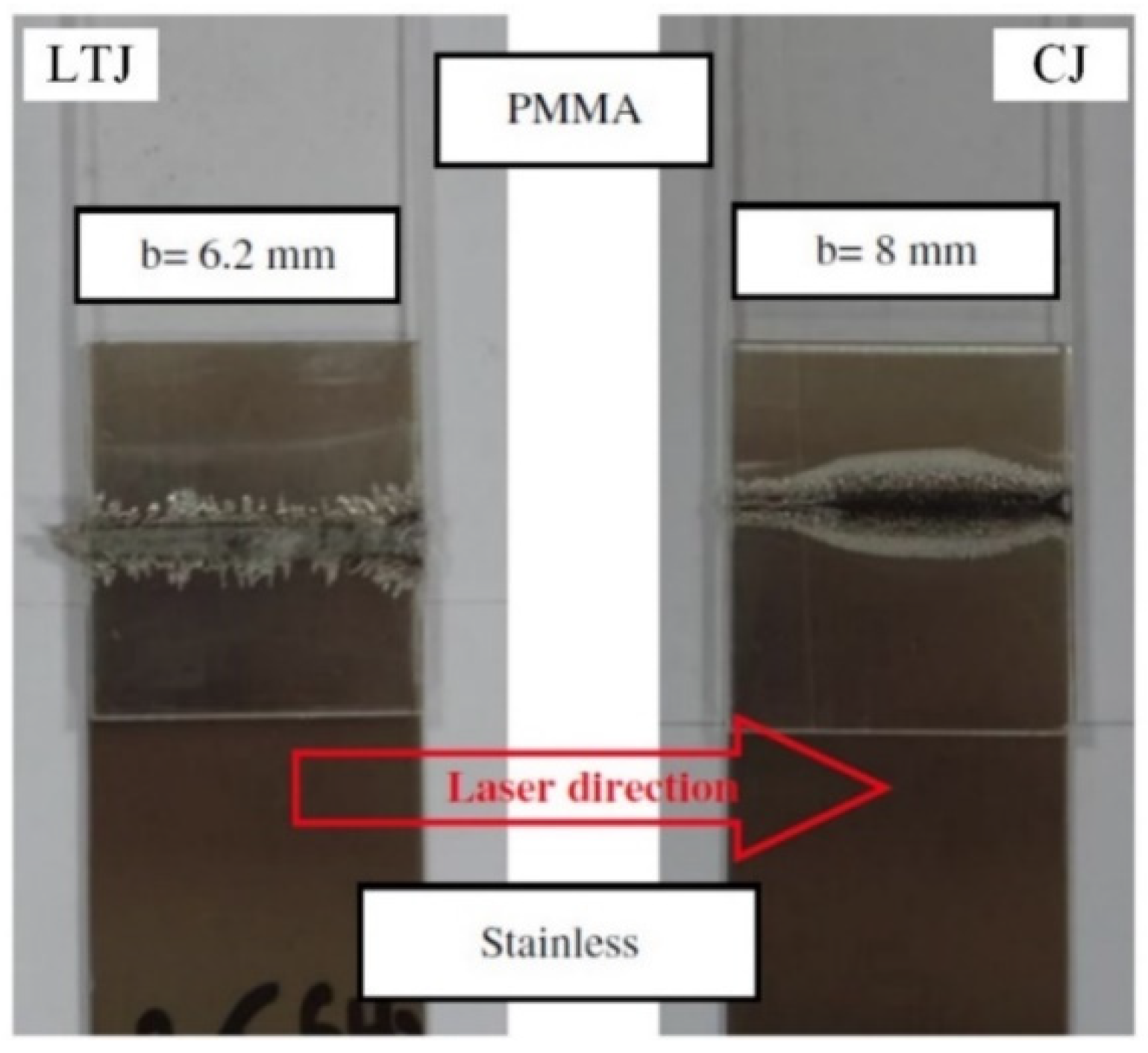

3.2. Weld Characteristics in Bonding Zone

3.2.1. Weld-Pool Depth (or Height) and Width

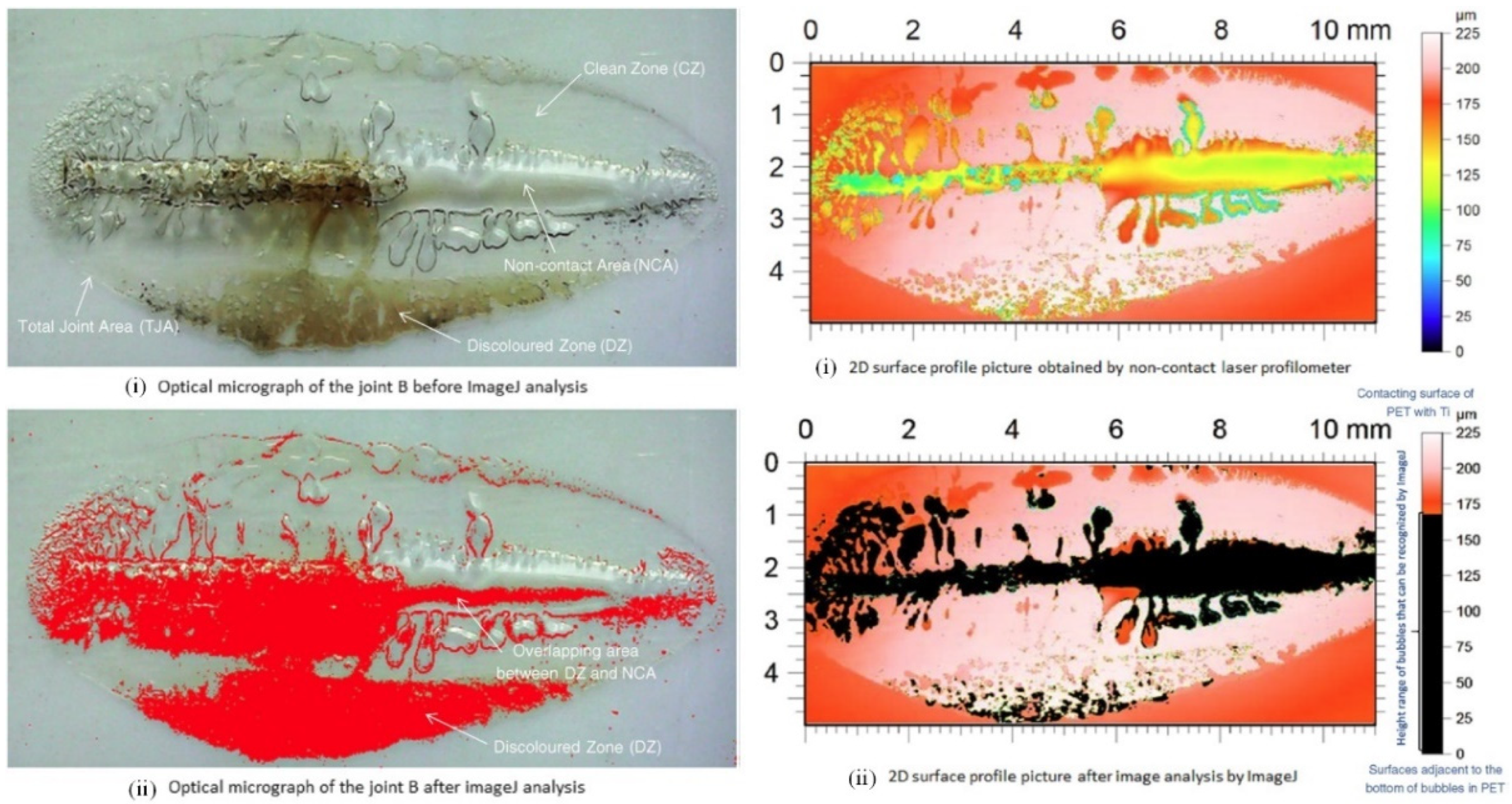

3.2.2. The Bonding Area

3.3. Mechanical Properties

3.3.1. Bonding Strength

3.3.2. Failure Mode

3.4. Defect Characteristics

3.5. Characteristics of Sensing Signals

4. Forming Quality Control of Metal–Polymer Laser Joining

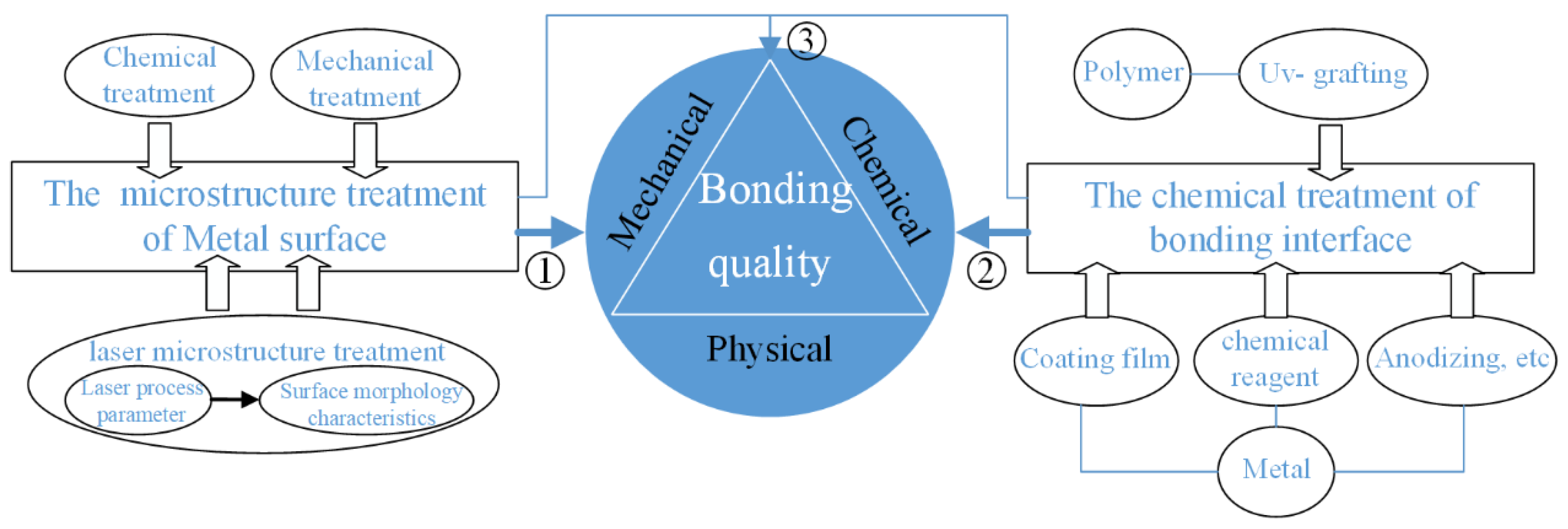

4.1. Surface Treatment of Bonding Interface

4.1.1. Microstructure Treatment of Metal Surface

4.1.2. Chemical Treatment of the Bonding Interface

4.2. Process Control of Laser Bonding Metal to Polymer Process

4.3. Process Parameter Optimization

5. Conclusions and Outlook

- Laser joining of metal and thermoplastic polymer has great application potential for automotive research. To realize the direct use of laser joining metal–polymer hybrid structures in lightweight automotive applications, it is necessary to conduct multi-objective optimization research on components, from the aspects of structural optimization, material optimization, and connection technology selection, based on the performance indexes and functional requirements of selected automotive components.

- In order to achieve high quality forming of metal and polymer laser joining, the forming quality of the structures can be characterized. The quality characterization indexes for laser joining of metal–polymer mainly include weld characteristics of the metal surface, weld characteristics of the bonding zone, mechanical properties, defect characteristics, and characteristics of sensing signals. In the process of laser connection, a good quality joint should have as few weld characteristics on the metal surface as possible, large weld size at the interface, high mechanical properties, ideal morphology, and low formation of defect characteristics.

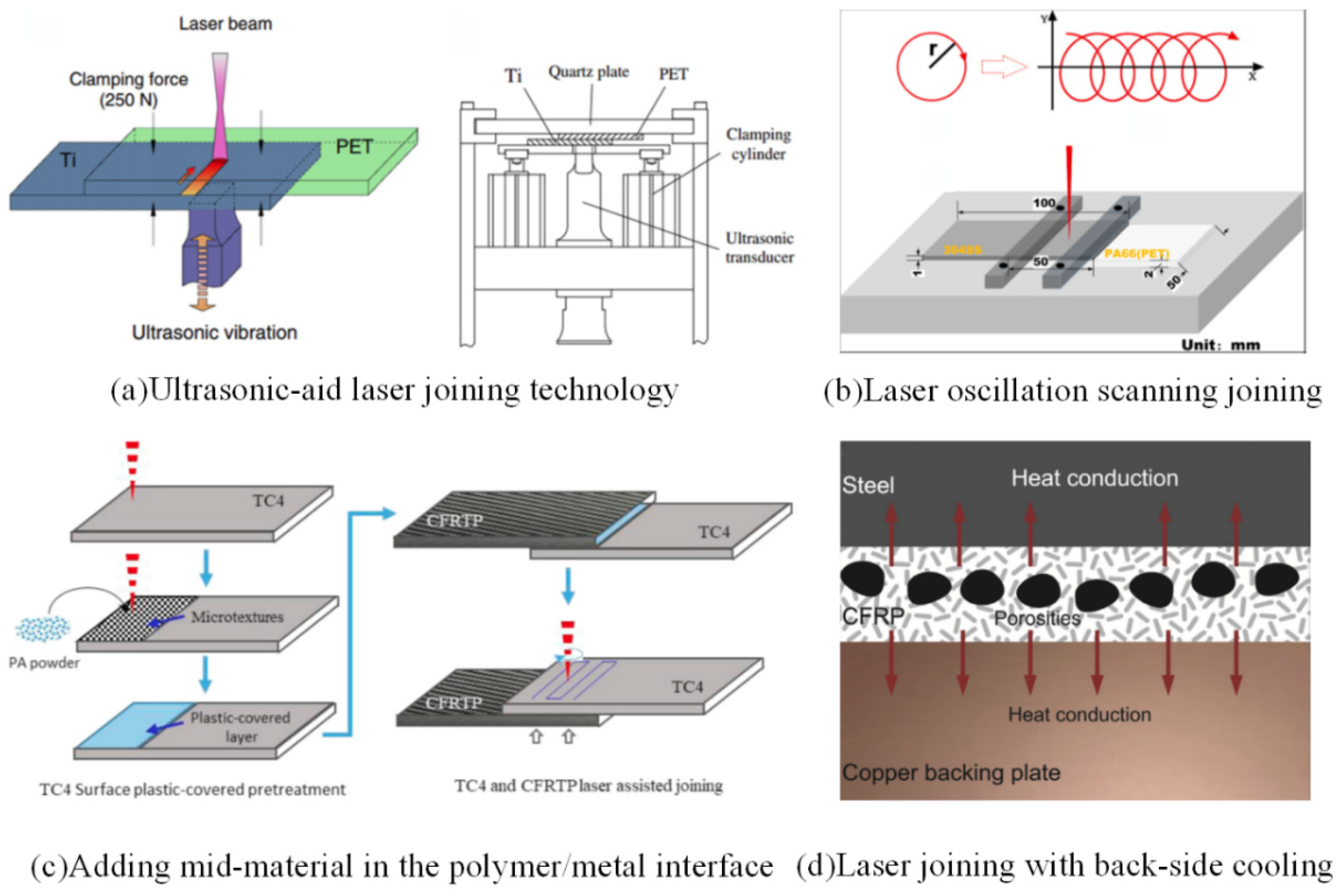

- In the process of metal and polymer laser joining, surface treatment at the bonding interface, process control, and optimization of process parameters are effective means to achieve forming quality control. Hybrid joints with high binding strength, low stress concentration, and high forming quality can be obtained by the combination of metal surface microstructure, chemical modification of the binding interface, and reasonable optimization of process parameters. In addition, the solidification condition, fluidity, and spreading ability of the molten pool can be improved to inhibit the formation of defects during the forming process by applying ultrasonic auxiliary equipment, beam shaping, adding intermediate layers, and other processes control methods, which can lead to good control of the forming quality. Considering the influence of process parameters on forming quality, based on the above quantitative characteristics of forming quality, methods such as mathematical statistics, intelligent algorithms, and numerical simulation can be used to optimize the process parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fiber Reinforced Composites |

| HSS | High Strength Steel |

| PMH | Polymer Composite-Metal Hybrid Structure |

| GFRP | Glass Fiber Reinforced Composites |

| GLARE | Glass Fiber Reinforced Aluminum |

| PP | Polypropylene |

| EPDM | Ethylene Propylene Diene Monomer |

| LFT | Long Fiber reinforced Thermoplastics |

| TWB | Tailor Welded Blank |

| TRB | Tailor Rolling Blank |

| FRP | Fiber Reinforced Plastics |

| SMC | Sheet Molding Compound |

| NVH | Noise, Vibration and Harshness |

| BF | Basalt Fiber |

| PLA | Polylactic Acid |

| NFRP | Natural Fiber Reinforced Composites |

| PE | Polyethylene |

| PA | Polyamide |

| PEEK | Polyether Ether Ketone |

| PC | Polycarbonate |

| IM | Injection Molding |

| FDM | Fused Deposition Modeling |

| LTJ | Laser Transmission Joining |

| CJ | Heat Conduction Joining |

| LAMP | Laser Assisted Metal and Plastic |

| CFRTP | Carbon Fiber Reinforced Thermal Plastic |

| PET | Polyethylene Terephthalate |

| PMMA | Polymethyl Methacrylate |

| COP | Cyclic Olefin Polymer |

| UV | Ultraviolet |

| ABS | Acrylonitrile Butadiene Styrene Copolymer |

| UAL | Ultrasonic-aid Laser Joining |

| ARM | Adjustable Ring Mode |

| RSM | Response Surface Method |

References

- Nicoletti, L.; Romano, A.; Knig, A.; Khler, P.; Lienkamp, M. An Estimation of the Lightweight Potential of Battery Electric Vehicles. Energies 2021, 14, 4655. [Google Scholar] [CrossRef]

- Wang, Z.Y. Survey of Optimization Methods for BIW Lightweight Design. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 128, p. 05002. [Google Scholar]

- Zhao, H.W.; Zhang, R.B.; Bin, Z.Y. A Review of Automotive Lightweight Technology. Adv. Eng. Res. 2018, 149, 31–34. [Google Scholar]

- Zhao, J.Y.; Li, L.; Fan, Q.C.; Zhu, X.Y. Analysis on the Development of Light-Weight Automobile Body. In Proceedings of the 19th COTA International Conference of Transportation Professionals, Nanjing, China, 6–8 July 2019; pp. 4012–4022. [Google Scholar]

- Mayer, D.; Bein, T.; Buff, H.; Gotz, B.; Schwarzhaupt, O.; Spancken, D. Enhanced lightweight design by composites—Results of the EU project ENLIGHT. J. Reinf. Plast. Comp. 2018, 37, 1217–1224. [Google Scholar] [CrossRef]

- Liu, Y.C.; Zhao, H.Y.; Zhou, B.S.; Zhou, L.; Wang, P.; Yang, H.F.; Song, X.G. A Review on Friction-Based Metal/Polymer Joining Technologies. Acta Aeronaut. Et Astronaut. Sin. 2022, 43, 525016. (In Chinese) [Google Scholar]

- Lambiase, F.; Scipioni, S.I.; Lee, C.J.; Ko, D.C.; Liu, F. A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials 2021, 14, 1890. [Google Scholar] [CrossRef] [PubMed]

- Min, J.Y.; Hu, J.H.; Sun, C.C.; Wan, H.L.; Liao, P.X.; Teng, H.; Lin, J.P. Fabrication Processes of Metal-Fiber Reinforced Polymer Hybrid Components: A Review. Adv. Compos. Hybrid Mater. 2022, 5, 651–678. [Google Scholar] [CrossRef]

- Temesi, T.; Czigany, T. Integrated Structures from Dissimilar Materials: The Future Belongs to Aluminum–Polymer Joints. Adv. Eng. Mater. 2020, 22, 2000007. [Google Scholar] [CrossRef]

- Quazi, M.M.; Ishak, M.; Fazal, M.A.; Arslan, A.; Rubaiee, S.; Aiman, M.H.; Qaban, A.; Yusof, F.; Sultan, T.; Ali, M.M.; et al. A Comprehensive Assessment of Laser Welding of Biomedical Devices and Implant Materials: Recent Research, Development and Applications. Crit. Rev. Solid. State 2021, 46, 109–151. [Google Scholar] [CrossRef]

- Huang, Y.J.; Gao, X.D.; Zhang, Y.X.; Ma, B. Laser Joining Technology of Polymer-Metal Hybrid Structures—A Review. J. Manuf. Process 2022, 79, 934–961. [Google Scholar] [CrossRef]

- Xu, J.J.; Wang, D.; Xiao, S.R.; Huang, T. Laser Joining of Fiber Reinforced Thermoplastic Composites and Metal. Trans. China Weld. Inst. 2021, 42, 73–86. [Google Scholar]

- Tan, C.W.; Su, J.H.; Feng, Z.W.; Chen, B.; Song, X.G.; Feng, J.C. Research Status and Development on Laser Joining of Metal to Plastic. J. Mech. Eng. 2020, 56, 85–94. [Google Scholar]

- BMWBLOG. BMW 7 Seri’ Carbon Core More Important That You Might Think. 2015. Available online: https://www.bmwblog.com/2015/09/01/bmw-7-series-carbon-core-more-important-that-you-might-think/ (accessed on 15 December 2020).

- Jacob, A. Carbon fibre and cars—2013 in review. Reinf. Plast. 2014, 58, 18–19. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.S.; Zhang, Y.S.; Jacek, S.; Li, G.Y.; Ma, M.T. Current Research and Challenges in Innovative Technology of Joining Dissimilar Materials for Electric Vehicles. Mater. Rev. 2019, 33, 3853–3861. [Google Scholar]

- Lu, J.B.; Li, H.Q.; Wang, C. Overview of New Energy Vehicle Body Materials and Connecting Process. Auto Manuf. Eng. 2018, 8, 60–62. [Google Scholar]

- Kopp, G.; Beeh, E.; Schšll, R.; Kobilke, A.; Stra§burger, P.; Krieschera, M. New Lightweight Structures for Advanced Automotive Vehicles—Safe and Modular. Procedia-Soc. Behav. Sci. 2012, 48, 350–362. [Google Scholar] [CrossRef][Green Version]

- Li, J.X.; Wang, D.Y.; Tian, Y.; Pan, H.Q. Lightweight Design of Honda Energy-Saving Racing Single-Shell Body based on Carbon Fiber Material. J. Phys. Conf. Ser. 2020, 1622, 012113. [Google Scholar] [CrossRef]

- Zhu, G.H.; Wang, Z.; Cheng, A.G.; Li, G.Y. Design optimization of composite bumper beam with variable cross-sections for automotive vehicle. Int. J. Crashworthiness 2017, 22, 365–376. [Google Scholar] [CrossRef]

- Chu, Y.T.; Sun, L.Y.; Li, L.J. Lightweight Scheme Selection for Automotive Safety Structures Using a Quantifiable Multi-Objective Approach. J. Clean. Prod. 2019, 241, 118316. [Google Scholar] [CrossRef]

- Yang, Y.W.; Tian, Y.L.; Sun, Y.L. Study on Lightweight Design and Optimization of Composite Hood. Shanghai Plast. 2017, 178, 13–17. (In Chinese) [Google Scholar]

- Deepak, S.; Vigneshwaran, K.; Babu, N.V. Vibration Analysis of Metal–Polymer Sandwich Structure Incorporated in Car Bonnet. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 912, p. 022036. [Google Scholar]

- Park, S.W.; Choi, J.H.; Lee, B.C. Multi-Objective Optimization of an Automotive Body Component with Fiber-Reinforced Composites. Struct. Multidiscip. Optim. 2018, 58, 2203–2217. [Google Scholar] [CrossRef]

- Drössler, R.; Waffler, R.; Krahl, M.; Haider, D. Tool Technology for Lightweight Structures in 3-D Hybrid Designs. Lightweight Des. Worldw. 2018, 11, 42–47. [Google Scholar] [CrossRef]

- Lee, M.S.; Seo, H.Y.; Kang, C.G. Comparison of Collision Test Results for Center-pillar Reinforcements with TWB and CR420/CFRP Hybrid Composite Materials Using Experimental and Theoretical Methods. Compos. Struct. 2017, 168, 698–709. [Google Scholar] [CrossRef]

- Yang, Z.L.; Ning, H.M.; Hu, N.; Jing, M. Optimal Design of the Structure of CFRP-TRB Supper-Hybrid Composite B Pillar. J. Chongqing Univ. 2020, 43, 23–31. (In Chinese) [Google Scholar]

- Hoffmann, L.; Faißt, B.; Kose, K.; Eggers, F. Manufacturing and Characterisation of High-strength Plastic-metal Hybrids. Lightweight Des. Worldw. 2017, 10, 44–49. [Google Scholar] [CrossRef]

- Park, H.S.; Dang, X.P. Development of a Fiber-Reinforced Plastic Armrest Frame for Weight-Reduced Automobiles. Int. J Auto. Tech-Kor. 2011, 12, 83–92. [Google Scholar] [CrossRef]

- Fang, M.Q. Steel-Aluminum-Carbon Fiber Reinforced Plastic Hybrid Body Structure. Automob. New Powertrain 2019, 2, 28–30. (In Chinese) [Google Scholar]

- Wang, G.W. Research on Lightweight Design of Composite Battery Pack for Electric Vehicle. Master’s Thesis, Jilin University, Jilin, China, 2020. [Google Scholar]

- Ma, F.W.; Wang, G.W.; Yang, M.; Pu, Y.F.; Zhao, Y. Lightweight Design of CFRP Automobile Tailgate Based on Multi-Step Optimization; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019; Volume 1, p. 1103. [Google Scholar]

- Zhu, G.H.; Sun, G.Y.; Liu, Q.; Li, G.Y.; Li, Q. On Crushing Characteristics of Different Configurations of Metal-Composites Hybrid Tubes. Compos. Struct. 2017, 175, 58–69. [Google Scholar] [CrossRef]

- Bambach, M.R.; Jama, H.H.; Elchalakani, M. Axial Capacity and Design of Thin-Walled Steel SHS Strengthened With CFRP. Thin Wall. Struct. 2009, 47, 1112–1121. [Google Scholar] [CrossRef]

- Bambach, M.R. Axial Capacity and Crushing Behavior of Metal–Fiber Square Tubes—Steel, Stainless Steel and Aluminum with CFRP. Compos. Part B-Eng. 2010, 41, 550–559. [Google Scholar] [CrossRef]

- Ma, Q.H.; Sun, J.R.; Gan, X.H.; Sun, Z.Y. Experiment and Modified Model for CFRP/Steel Hybrid Tubes under the Quasi-Static Transverse Loading. Int. J. Crashworthines 2021, 26, 343–353. [Google Scholar] [CrossRef]

- Sun, J.R.; Ma, Q.H.; Gan, X.H.; Sun, Z.Y. Effect of Filament Winding Angle on Bending Performance of CFRP-Al Circular Tube. Aero. Mater. Tech. 2019, 49, 76–81. [Google Scholar]

- Sun, J.R. Optimization and Research of Composite/Metal Door Beam Based on Side Impact. Master’s Thesis, Shanghai University of Engineering Science, Shanghai, China, 2019. [Google Scholar]

- Kim, H.C.; Dong, K.S.; Lee, J.J. Characteristics of Aluminum/CFRP Short Square Hollow Section Beam under Transverse Quasi-Static Loading. Compos. Part B-Eng. 2013, 51, 345–358. [Google Scholar] [CrossRef]

- Schmerler, R.; Gebken, T.; Kalka, S.; Reincke, T. Multi-Functional Battery Housing for Electric Vehicles. Lightweight Des. Worldw. 2017, 10, 26–31. [Google Scholar] [CrossRef]

- Liu, S.L.; Xia, S.L.; Zhao, J.Z.; Zhang, B.X.; Chen, K.W. Lightweight Design of Electric Vehicle Battery Box. Automob. Appl. Techn. 2016, 11, 10–12. (In Chinese) [Google Scholar]

- Liu, Y.; Ma, Y.T.; Liu, Q. Performance of Short Carbon Fiber Reinforced Nylon Composite and it′s Application in Battery Pack. Compos. Sci. Eng. 2021, 9, 46–54. (In Chinese) [Google Scholar]

- Miklavec, M.; Klemenc, J.; Kostanjevec, A.; Fajdiga, M. Properties of a Metal-Nonmetal Hybrid Joint with an Improved Shape of the Metal Insert. Exp. Tech. 2015, 39, 69–76. [Google Scholar] [CrossRef]

- Yang, M.C. Design of Carbon Fiber Composite Drive Shaft for a Heavy Truck. Sci. Tech. Innov. 2017, 11, 25–26. (In Chinese) [Google Scholar]

- Lee, D.G.; Kim, H.S.; Kim, J.W.; Kim, J.K. Design and Manufacture of an Automotive Hybrid Aluminum/Composite Drive Shaft. Compos. Struct. 2004, 63, 87–99. [Google Scholar] [CrossRef]

- Catera, P.G.; Mundo, D.; Treviso, A.; Gagliardi, F.; Visrolia, A. On the Design and Simulation of Hybrid Metal-Composite Gears. Appl. Compos. Mater. 2019, 26, 817–833. [Google Scholar] [CrossRef]

- Stötzner, N. Scalable, Single-stage Manufacturing of Hybrid Components. Lightweight Des. Worldw. 2019, 12, 56–59. [Google Scholar] [CrossRef]

- New Carbon Prepreg Patch Technology Selected as Finalist in JEC Innovation Awards 2019. 2019. Available online: https://netcomposites.com/news/hexcels-new-carbon-prepreg-patch-technology-selected-as-finalist-in-jec-innovation-awards-2019/ (accessed on 23 December 2020).

- Zhang, K.M.; Li, M.; Gu, Y.Z.; Zhang, Z.G. Key Technology of Advanced Composite Materials from Aircraft to Automobile. Mater. China 2013, 11, 685–695. [Google Scholar]

- Li, L.Y.; Zhang, Y.; Jiang, G.H. Trial Manufacturing Method of Carbon Fiber Composite Wheel. Auto Ind. Res. 2018, 7, 22–25. (In Chinese) [Google Scholar]

- Automotive Weight Reduction Expo 2014 Part 2. 2014. Available online: https://www.marklines.com/cn/report_all/rep1261_201402 (accessed on 27 April 2021).

- Chen, S.X. Research on Bonding Strength Mechanism of Laser Treated Aluminum Alloy and Polylactic Acid for Automotive Lightweight. Ph.D. Thesis, Jilin University, Jilin, China, 2020. [Google Scholar]

- Ishak, N.M.; Malingam, S.D.; Mansor, M.R.; Mansor, M.R.; Razali, N.; Mustafa, Z.; Ghani, A.F.A. Investigation of Natural Fibre Metal Laminate as Car Front Hood. Mater. Res. Express 2021, 8, 025303. [Google Scholar] [CrossRef]

- Automotive Front-End Module Types and Material Selection Trends. Available online: https://www.qichecailiao.com/mall/show-99.html (accessed on 25 May 2020).

- Yan, Z.; Xu, X.Y.; Li, N.W.; Li, Y.X. Structural Analysis of Continuous Carbon Fiber Reinforced Composite B-Pillar Reinforcement. Automob. Tech. 2020, 45, 120–123. [Google Scholar]

- Yu, K.H.; Kim, H.G. Analysis on Life Prediction for Different Materials in Vehicle Door Hinge Lightweight Design. J. Korean Soc. Manuf. Tech. Eng. 2013, 22, 693–699. [Google Scholar]

- Liu, F.C.; Dong, P.; Lu, W.; Sun, K. On Formation of Al-O-C Bonds at Aluminum/Polyamide Joint Interface. Appl. Surf. Sci. 2019, 466, 202–209. [Google Scholar] [CrossRef]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. Part B-Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Dave, F.; Ali, M.M.; Sherlock, R.; Kandasami, A.; David, T. Laser Transmission Welding of Semi-Crystalline Polymers and Their Composites: A Critical Review. Polymers 2021, 13, 675. [Google Scholar] [CrossRef]

- Prasad, N.E.; Wanhill, R.J.H. Aerospace Materials and Material Technologies; Indian Institute of Metals: Kolkata, India, 2017; pp. 291–342. [Google Scholar]

- Luca, Q.; Kim, D.W.; Jang, C.S.; Kim, N.; Hong, S. Impact Resistance of Metal Skin-Carbon Fiber Reinforced Polymer Laminate Structures for the Production of Lightweight Vehicles Body Frame. J. Phys. Conf. Ser. 2017, 843, 012017. [Google Scholar]

- Andure, M.W.; Jirapure, S.C.; Dhamande, L.P. Advance Automobile Material for Light Weight Future–A Review. In Proceedings of the IJCA, International Conference on Benchmarks in Engineering Science and Technology 2012, Maharashtra, India, 7–8 October 2012; Foundation of Computer Science (FCS): New York, NY, USA, 2012. [Google Scholar]

- Ryu, J.B.; Lyu, M.Y. A Study on the Mechanical Property and 3D Fiber Distribution in Injection Molded Glass Fiber Reinforced PA66. Int. Polym. Proc. 2014, 39, 389–401. [Google Scholar] [CrossRef]

- Lee, M.; Lyu, M.Y. A Study on the Part Shrinkage in Injection Molded Annular Shaped Product for Glass Reinforced Polycarbonate. Elastom. Compos. 2013, 48, 300–305. [Google Scholar] [CrossRef][Green Version]

- Kim, K.S.; Bae, K.M.; Oh, S.Y.; Seo, M.K.; Kang, C.G.; Park, S.J. Trend of Carbon Fiber-Reinforced Composites for Lightweight Vehicles. Elastom. Compos. 2012, 47, 65–74. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Laser Transmission Welding of Polycarbonates: Experiments, Modeling, and Sensitivity Analysis. Int. J. Adv. Manuf. Tech. 2015, 78, 853–861. [Google Scholar] [CrossRef]

- Kinvi-Dossou, G.; Matadi, B.R.; Bonfoh, N.; Garzon-Hernandez, S.; GarciaGonzalez, D.; Gerard, P.; Arias, A. Innovative Acrylic Thermoplastic Composites Versus Conventional Composites: Improving the Impact Performances. Compos. Struct. 2019, 217, 1–13. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Rahimzadeh, A.; Barletta, M. An Artificial Neural Network Model for Laser Transmission Welding of Biodegradable Polyethylene Terephthalate/Polyethylene Vinyl-Acetate (PET/PEVA) Blends. Int. J. Adv. Manuf. Tech. 2019, 102, 1497–1507. [Google Scholar] [CrossRef]

- Shanmugam, L.; Kazemi, M.E.; Rao, Z.; Lu, D.; Wang, X.; Wang, B.; Yang, L.; Yang, J. Enhanced Mode I Fracture Toughness of UHMWPE Fabric/Thermoplastic Laminates with Combined Surface Treatments of Polydopamine and Functionalized Carbon Nanotubes. Compos. Part B-Eng. 2019, 178, 107450. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Chen, S.J.; Lei, L.; Li, J.B.; Ren, J. Several Kinds of Modified Bio-based Plastics and Application in Automobile. Mod. Plast. Process. Appl. 2018, 4, 56–59. (In Chinese) [Google Scholar]

- Babu, R.P.; Kevin, O.C.; Seeram, R. Current Progress on Bio-Based Polymers and Their Future Trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef]

- Fischer, T.; Grubenmann, M.; Harhash, M.; Hua, W.; Heingärtner, J.; Hora, P.; Palkowski, H.; Ziegmann, G. Experimental and Numerical Investigations on the Quasi-Static Structural Properties of Fibre Metal Laminates Processed by Thermoforming. Compos. Struct. 2020, 258, 113418. [Google Scholar] [CrossRef]

- Blala, H.; Lang, L.; Khan, S.; Li, L. A Comparative Study on the GLARE Stamp Forming Behavior Using Cured and Non-Cured Preparation Followed by Hot-Pressing. Int. J. Adv. Manuf. Tech. 2021, 115, 1461–1473. [Google Scholar] [CrossRef]

- Kadoya, S.; Kimura, F.; Kajihara, Y. PBT–Anodized Aluminum Alloy Direct Joining: Characteristic Injection Speed Dependence of Injected Polymer Replicated into Nanostructures. Poly. Test. 2019, 75, 127–132. [Google Scholar] [CrossRef]

- Altan, M.; Yavuz, B. A Novel Method for Manufacturing Polymer/Metal Hybrid Structures. Acta Phys. Pol. A 2016, 129, 639–641. [Google Scholar] [CrossRef]

- Falck, R.; Goushegir, S.M.; Santos, J.D.; Amancio-Filho, S.T. Add Joining: A Novel Additive Manufacturing Approach for Layered Metal-Polymer Hybrid Structures. Mater. Lett. 2018, 217, 211–214. [Google Scholar] [CrossRef]

- Gresham, J.; Cantwell, W.; Cardew-Hall, M.J.; Compston, P.; Kalyanasundaram, S. Drawing Behaviour of Metal–Composite Sandwich Structures. Compos. Struct. 2006, 75, 305–312. [Google Scholar] [CrossRef]

- Mennecart, T.; Werner, H.; Khalifa, N.B.; Weidenmann, K.A. Developments and Analyses of Alternative Processes for the Manufacturing of Fiber Metal Laminates. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18 October 2018. [Google Scholar]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of Carbon Fibre Reinforced Polymer (CFRP) Composites and Aluminium Alloys–A Review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Wang, H.; Kai, Y.; Liu, L. The Analysis of Welding and Riveting Hybrid Bonding Joint of Aluminum Alloy and Polyether-Ether-Ketone Composites. J. Manuf. Process. 2018, 36, 301–308. [Google Scholar] [CrossRef]

- Mariam, M.; Afendi, M.; Abdul, M.; Ridzuan, M.J.M.; Gibson, A.G. Tensile and Fatigue Properties of Single Lap Joints of Aluminium Alloy/Glass Fibre Reinforced Composites Fabricated with Different Joining Methods. Compos. Struct. 2018, 200, 647–658. [Google Scholar] [CrossRef]

- Galvez, P.; Abenojar, J.; Martinez, M.A. Durability of Steel-CFRP Structural Adhesive Joints with Polyurethane Adhesives. Compos. Part B-Eng. 2019, 165, 1–9. [Google Scholar] [CrossRef]

- Jin, Q.H.; Chen, J.; Peng, L.M.; Li, Z.Y.; Yan, X.; Li, C.X.; Hou, C.C.; Yuan, M.Y. Research Progress in Joining of Carbon Fiber-Reinforced Polymer Composites and Aluminum/Magnesium Alloys. J. Mater. Eng. 2022, 50, 15–24. (In Chinese) [Google Scholar]

- Johnson, D. Adhesion and Adhesives Technology: An Introduction; American Society for Testing Materials: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Streitferdt, A.; Rudolph, N.; Taha, I. Co-Curing of CFRP-Steel Hybrid Joints Using the Vacuum Assisted Resin Infusion Process. Appl. Compos. Mater. 2017, 24, 1137–1149. [Google Scholar] [CrossRef]

- Mandolfino, C.; Lertora, E.; Genna, S.; Leone, C.; Gambaro, C. Effect of Laser and Plasma Surface Cleaning on Mechanical Properties of Adhesive Bonded Joints. Procedia CIRP 2015, 33, 458–463. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, J.P.; Zheng, R.; Wu, Y.R. Investigation of Strength Degradation of Adhesive-Bonded Aluminum Joints Exposed to Corrosive Environment Using Electrochemical Methods. J. Adhes. Sci. Tech. 2018, 32, 642–655. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive Bonding of Aircraft Structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Karatas, M.A.; Gokkaya, H. A Review on Machinability of Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) Composite Materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of Mechanical Properties and Fracture Mode of Additively Manufactured Carbon Fiber and Glass Fiber Reinforced Thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Liu, D.F.; Tang, Y.; Cong, W.L. A Review of Mechanical Drilling gor Composite Laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Lionetto, F.; Mele, C.; Leo, P.; D’Ostuni, S.; Balle, F.; Maffezzoli, A. Ultrasonic Spot Welding of Carbon Fiber Reinforced Epoxy Composites to Aluminum: Mechanical and Electrochemical Characterization. Compos. Part B Eng. 2018, 144, 134–142. [Google Scholar] [CrossRef]

- Lionetto, F.; Balle, F.; Maffezzoli, A. Hybrid Ultrasonic Spot Welding of Aluminum to Carbon Fiber Reinforced Epoxy Composites. J. Mater. Process. Technol. 2017, 247, 289–295. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Elyasi, M. The Influence of Process Parameters in Friction Stir Welding of Al-Mg Alloy and Polycarbonate. J. Manuf. Process. 2018, 35, 88–98. [Google Scholar] [CrossRef]

- Goushegir, S.M.; Dos-Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of Aluminum AA2024/Carbon-Fiber Reinforced Poly (Phenylene Sulfide) Composite Single Lap Joints: Microstructure and Mechanical Performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Mitschang, P.; Velthuis, R.; Emrich, S.; Kopnarski, M. Erratum: Induction Heated Joining of Aluminum and Carbon Fiber Reinforced Nylon 66. J. Thermoplast. Compos. 2009, 22, 767–801. [Google Scholar] [CrossRef]

- Bayerl, T.; Duhovic, M.; Mitschang, P.; Bhattacharyya, D. The Heating of Polymer Composites by Electromagnetic Induction–A Review. Compos. Part A-Appl. S. 2014, 57, 27–40. [Google Scholar] [CrossRef]

- Liu, G.Q.; Gao, X.D.; Peng, C.; Liu, X.H.; You, D.Y. Tensile Resistance, Microstructures of Intermetallic Compounds, and Fracture Modes of Welded Steel/Aluminum Joints Produced Using Laser Lap Welding. Trans. Nonferrous Met. Soc. China 2020, 30, 2639–2649. [Google Scholar] [CrossRef]

- Liu, G.Q.; Gao, X.D.; You, D.Y.; Zhang, N.F. Prediction of High-Power Laser Welding Status Based on PCA and SVM Classification of Multiple Sensors. J. Intell. Manuf. 2019, 30, 821–832. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Latest Progress in Performance and Understanding of Laser Welding. Phys. Procedia 2012, 39, 8–16. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Li, S.C.; Gao, X.D. Numerical Modeling of Thermal Behavior of Melt Pool in Laser Additive Manufacturing of Ni-Based Diamond Tools. Ceram. Int. 2022, 48, 14876–14890. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y. Laser Direct Joining of Metal and Plastic. Scr. Mater. 2008, 59, 1247–1250. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yue, T.M.; Guo, Z.N. A New Laser Joining Technology for Direct-Bonding of Metals and Plastics. Mater. Des. 2016, 110, 775–781. [Google Scholar] [CrossRef]

- Acherjee, B. Laser Transmission Welding of Polymers-A Review on Process Fundamentals, Material Attributes, Weldability, and Welding Techniques. J. Manuf. Process. 2020, 60, 227–246. [Google Scholar] [CrossRef]

- Acherjee, B. Laser Transmission Welding of Polymers—A Review on Welding Parameters, Quality Attributes, Process Monitoring, and Applications. J. Manuf. Process. 2021, 64, 421–443. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, A.Y.; Takahashi, M.; Katayama, S. Laser Direct Joining of Carbon Fiber Reinforced Plastic to Aluminum Alloy. J. Laser Appl. 2013, 25, 530–533. [Google Scholar] [CrossRef]

- Ma, F.W.; Chen, S.X.; Han, L.; Wang, Z.J.; Pu, Y.F. Experimental and Numerical Investigation on the Strength of Polymer-Metal Hybrid with Laser Assisted Metal Surface Treatment. J. Adhes. Sci. Technol. 2019, 33, 1112–1129. [Google Scholar] [CrossRef]

- Saborowski, E.; Dittes, A.; Steinert, P.; Lindner, T.; Lampke, T. Effect of Metal Surface Topography on the Interlaminar Shear and Tensile Strength of Aluminum/Polyamide 6 Polymer-Metal-Hybrids. Materials 2019, 12, 2963. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Lai, C.; Xu, Z.F.; Jiao, J.K. Effect of the Surface Texture on Laser Joining of a Carbon Fiber-Reinforced Thermosetting Plastic and Stainless Steel. Strength Mater. 2019, 51, 122–129. [Google Scholar] [CrossRef]

- Georgiev, G.L.; Baird, R.J.; Mccullen, E.F.; Newaz, G.; Auner, G.; Patwa, R.; Herfurth, H. Chemical Bond Formation During Laser Bonding of Teflon® FEP and Titanium. Appl. Surf. Sci. 2009, 255, 7078–7083. [Google Scholar] [CrossRef]

- Cantrell, J.H. Determination of Absolute Bond Strength from Hydroxyl Groups at Oxidized Aluminum-Epoxy Interfaces by Angle Beam Ultrasonic Spectroscopy. J. Appl. Phys. 2004, 96, 3775–3781. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Takahashi, M.; Katayama, S. Laser Direct Joining of Carbon Fiber Reinforced Plastic to Zinc-Coated Steel. Mater. Des. 2013, 47, 179–188. [Google Scholar] [CrossRef]

- Huang, Y.J.; Gao, X.D.; Ma, B.; Liu, G.Q.; Zhang, N.F.; Zhang, Y.X.; You, D.Y. Optimization of Weld Strength for Laser Welding of Steel to PMMA Using Taguchi Design Method. Opt. Laser Technol. 2021, 136, 106726. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, J.; Shan, J.; Yang, S.; Ren, J. Characteristics and Formation Mechanism of Porosities in CFRP During Laser Joining of CFRP and Steel. Compos. Part B Eng. 2015, 70, 35–43. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Laser-Assisted Direct Joining of AISI304 Stainless Steel with Polycarbonate Sheets: Thermal Analysis, Mechanical Characterization, and Bonds Morphology. Opt. Laser Technol. 2017, 88, 205–214. [Google Scholar] [CrossRef]

- Gower, H.L.; Pieters, R.; Richardson, I.M. Pulsed Laser Welding of Metal-Polymer Sandwich Materials Using Pulse Shaping. J. Laser Appl. 2006, 18, 35–41. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Jiao, J.K.; Lai, C. Assessment of the Microstructure and Mechanical Properties of a Laser-Joined Carbon Fiber-Reinforced Thermosetting Plastic and Stainless Steel. Strength Mater. 2018, 50, 752–763. [Google Scholar] [CrossRef]

- Jiao, J.K.; Ye, Y.Y.; Jia, S.H.; Xu, Z.F.; Ouyang, W.T.; Zhang, W.W. CFRTP—Al Alloy Laser Assisted Joining with a High Speed Rotational Welding Technology. Opt. Laser Technol. 2020, 127, 106187. [Google Scholar] [CrossRef]

- Jiao, J.K.; Xu, Z.F.; Wang, Q.; Sheng, L.Y.; Zhang, W.W. CFRTP and Stainless Steel Laser Joining: Thermal Defects Analysis and Joining Parameters Optimization. Opt. Laser Technol. 2018, 103, 170–176. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Katayama, S. Laser Direct Joining of Carbon Fibre Reinforced Plastic to Stainless Steel. Sci. Technol. Weld. Join. 2011, 16, 676–680. [Google Scholar] [CrossRef]

- Pagano, N.; Campana, G.; Fiorini, M.; Morelli, R. Laser Transmission Welding of Polylactide to Aluminum Thin Films for Applications in the Food-Packaging Industry. Opt. Laser Technol. 2017, 91, 80–84. [Google Scholar] [CrossRef]

- Taha, Z.A.; Roy, G.G.; Hajim, K.I.; Manna, I. Mathematical Modeling of Laser-Assisted Transmission Lap Welding of Polymers. Scr. Mater. 2009, 60, 663–666. [Google Scholar] [CrossRef]

- Yusof, F.; Yukio, M.; Yoshiharu, M.; Shukor, M. Effect of Anodizing on Pulsed Nd:YAG Laser Joining of Polyethylene Terephthalate (PET) and Aluminium Alloy (A5052). Mater. Des. 2012, 37, 410–415. [Google Scholar] [CrossRef]

- Yusof, F.; Mutoh, Y.; Miyashita, Y. Effect of Pre-Oxidized CuO Layer in Joining Between Polyethylene Terephalate (PET) and Copper (Cu) by Using Pulsed Nd:YAG Laser. Adv. Mat. Res. 2010, 129, 714–718. [Google Scholar] [CrossRef]

- Ai, Y.W.; Zheng, K.; Shin, Y.C.; Wu, B.X. Analysis of Weld Geometry and Liquid Flow in Laser Transmission Welding between Polyethylene Terephthalate (PET) and Ti6Al4V Based on Numerical Simulation. Opt. Laser Technol. 2018, 103, 99–108. [Google Scholar] [CrossRef]

- Acherjee, B.; Misra, D.; Bose, D.; Venkadeshwaran, K. Prediction of Weld Strength and Seam Width for Laser Transmission Welding of Thermoplastic Using Response Surface Methodology. Opt. Laser Technol. 2009, 41, 956–967. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D.; Acharyya, S. Experimental Investigation on Laser Transmission Welding of PMMA to ABS via Response Surface Modeling. Opt. Laser Technol. 2012, 44, 1372–1383. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Application of Grey-Based Taguchi Method for Simultaneous Optimizationof Multiple Quality Characteristics in Laser Transmission Welding Process of Thermoplastics. Int. J. Adv. Manuf. Technol. 2011, 56, 995–1006. [Google Scholar] [CrossRef]

- Hussein, F.I.; Akman, E.; Oztoprak, B.G.; Gunes, M.; Gundogdu, O.; Kacar, E.; Hajim, K.I.; Demir, A. Evaluation of PMMA Joining to Stainless Steel 304 Using Pulsed Nd:YAG Laser. Opt. Laser Technol. 2013, 49, 143–152. [Google Scholar] [CrossRef]

- Tan, C.W.; Su, J.H.; Zhu, B.H.; Li, X.T.; Wu, L.J.; Che, B.; Song, X.G.; Feng, J.C. Effect of Scanning Speed on Laser Joining of Carbon Fiber Reinforced PEEK to Titanium Alloy. Opt. Laser Technol. 2020, 129, 106273. [Google Scholar] [CrossRef]

- Su, J.H.; Tan, C.W.; Wu, Z.L.; Wu, L.J.; Gong, X.T.; Chen, B.; Song, X.G.; Feng, J.C. Influence of Defocus Distance on Laser Joining of CFRP to Titanium Alloy. Opt. Laser Technol. 2020, 124, 106006. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Stambke, M. Potential of Laser-manufactured Polymer-metal hybrid Joints. Phys. Procedia 2012, 39, 84–91. [Google Scholar] [CrossRef]

- Huang, Y.J.; Gao, X.D.; Ma, B.; Zhang, Y.X. Interface Formation and Bonding Mechanisms of Laser Welding of PMMA Plastic and 304 Austenic Stainless Steel. Metals 2021, 11, 1495. [Google Scholar] [CrossRef]

- Chan, C.W.; Smith, G.C. Fibre Laser Joining of Highly Dissimilar Materials: Commercially Pure Ti and PET Hybrid Joint for Medical Device Applications. Mater. Des. 2016, 103, 278–292. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yue, T.M.; Guo, Z.N. Fatigue Behavior of Titanium/PET Joints Formed by Ultrasound-Aided Laser Welding. J. Manuf. Process. 2018, 31, 356–363. [Google Scholar] [CrossRef]

- Jia, L.; Yang, H.; Wang, Y.; Zhang, B.; Hao, J. Direct Bonding of Copper Foil and Liquid Crystal Polymer by Laser Etching and Welding. Opt. Lasers Eng. 2021, 139, 106509. [Google Scholar] [CrossRef]

- Amanat, N.; Chaminade, C.; Grace, J.; McKenzie, D.R.; James, N.L. Transmission Laser Welding of Amorphous and Semi-Crystalline Poly-Ether–Ether–Ketone for Applications in the Medical Device Industry. Mater. Des. 2010, 31, 4823–4830. [Google Scholar] [CrossRef]

- Arai, S.; Kawahito, Y.; Katayama, S. Effect of Surface Modification on Laser Direct Joining of Cyclic Olefin Polymer and Stainless Steel. Mater. Des. 2014, 59, 448–453. [Google Scholar] [CrossRef]

- Al-Sayyad, A.; Lama, P.; Bardon, J.; Hirchenhahn, P.; Houssiau, L.; Plapper, P. Laser Joining of Titanium Alloy to Polyamide: Influence of Process Parameters on the Joint Strength and Quality. Int. J. Adv. Manuf. Tech. 2020, 107, 2917–2925. [Google Scholar] [CrossRef]

- Wang, X.; Guo, D.; Che, G.; Jiang, H.; Meng, D.; Yan, Z.; Liu, H.X. Thermal Degradation of PA66 During Laser Transmission Welding. Opt. Laser Technol. 2016, 83, 35–42. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Seol, J.B.; Lee, Y.S.; Lee, M.; Kim, J.H. Interfacial Structure and Bonding Mechanism of AZ31/Carbon-Fiber-Reinforced Plastic Composites Fabricated by Thermal Laser Joining. Compos. Part B-Eng. 2019, 167, 71–82. [Google Scholar] [CrossRef]

- Jiao, J.K.; Wang, Q.; Wang, F.Y.; Zan, S.P.; Zhang, W.W. Numerical and Experimental Investigation on Joining CFRTP and Stainless-Steel Using Fiber Lasers. J. Mater. Process. Tech. 2016, 240, 362–369. [Google Scholar] [CrossRef]

- Miyashita, Y.; Takahashi, M.; Takemi, M.; Oyama, K.; Mutoh, Y.; Tanaka, H. Dissimilar Materials Micro Welding Between Stainless Steel and Plastics by Using Pulse YAG Laser. J. Solid. Mech. Mater. Eng. 2009, 3, 409–415. [Google Scholar] [CrossRef]

- Cheon, J.; Na, S.J. Relation of Joint Strength and Polymer Molecular Structure in Laser Assisted Metal and Polymer Joining. Sci. Technol. Weld. Join. 2014, 19, 631–637. [Google Scholar] [CrossRef]

- Zhou, Z.; Tan, X.H.; Jing, Z.; Shan, J.G. Suppression of Shrinkage Porosity in Laser-Joining of CFRP and Steel Using a Laser Surface Modification Process “Surfi-Sculpt”. Int. J. Adhes. Adhes. 2018, 85, 184–192. [Google Scholar]

- Schricker, K.; Diller, S.; Bergmann, J.P. Bubble Formation in Thermal Joining of Plastics with Metals. Procedia CIRP 2018, 74, 518–523. [Google Scholar] [CrossRef]

- Tamrin, K.F.; Nukman, Y.; Zakariyah, S.S. Laser Lap Joining of Dissimilar Materials—A Review of Factors Affecting Joint Strength. Mater. Manuf. Process. 2013, 28, 857–871. [Google Scholar] [CrossRef]

- Wahba, M.; Kawahito, Y.; Katayama, S. Laser Direct Joining of AZ91D Thixomolded Mg Alloy and Amorphous Polyethylene Terephthalate. J. Mater. Process. Tech. 2011, 211, 1166–1174. [Google Scholar] [CrossRef]

- Tan, X.; Shan, J.; Ren, J. Effects of Cr Plating Layer on Shear Strength and Interface Bonding Characteristics of Mild Steel/CFRP Joint by Laser Heating. Acta Metall. Sin. 2013, 49, 751–756. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, J.; Shan, J.; Yang, S.; Ren, J. The damage characteristics and mechanism of CFRP during laser joining of CFRP/mild steel dissimilar joint. In Proceedings of the 32th International Congress on Applications of Lasers and Electro-Optics, Miami, FL, USA, 6–10 October 2013; Laser Institute of America: Miami, FL, USA, 2013. [Google Scholar]

- Fortunato, A.; Cuccolini, G.; Ascari, A.; Orazi, L.; Campana, G.; Tani, G. Hybrid Metal-Plastic Joining by Means of Laser. Int. J. Mater. Form. 2010, 3, 1131–1134. [Google Scholar] [CrossRef]

- Acherjee, B. Laser Transmission Welding of Dissimilar Plastics:3-D FE Modeling and Experimental Validation. Weld. World 2021, 65, 1429–1440. [Google Scholar]

- Lambiase, F.; Genna, S. Homogenization of Temperature Distribution at Metal-Polymer Interface During Laser Direct Joining. Opt. Laser Technol. 2020, 128, 106226. [Google Scholar] [CrossRef]

- Gao, X.D.; Ding, D.K.; Bai, T.X.; Katayama, S. Weld-Pool Image Centroid Algorithm for Seam Tracking Vision Model in Arc-Welding Process. IET Image Process 2011, 5, 410–419. [Google Scholar] [CrossRef]

- Schricker, K.; Bergmann, J.P.; Hopfeld, M.; Spieß, L. Effect of Thermoplastic Morphology on Mechanical Properties in Laser-Assisted Joining of Polyamide 6 with Aluminum. Weld. World 2021, 65, 699–711. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Experimental Analysis of Laser Assisted Joining of Al-Mg Aluminium Alloy with Polyetheretherketone (PEEK). Int. J. Adhes. Adhes. 2018, 84, 265–274. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Laser Assisted Joining of AA5053 Aluminum Alloy with Polyvinyl Chloride (PVC). Opt. Laser Technol. 2018, 107, 80–88. [Google Scholar] [CrossRef]

- Schricker, K.; Ganß, M.; Könke, C.; Bergmann, J.P. Feasibility Study of Using Integrated Fiber Optical Sensors to Monitor Laser-Assisted Metal–Polymer Joining. Weld. World 2020, 64, 1565–1578. [Google Scholar] [CrossRef]

- Wang, H.Z.; Kawahito, Y.; Koji, N. A Laser Joining System for Titanium and Polyethylene Terephthalate Plastic Controlled by Multiple Signal Sources. IEEE T. Ind. Electron. 2018, 66, 1255–1263. [Google Scholar] [CrossRef]

- Schmitt, R.; Mallmann, G.; Ackermann, P.; Bergmann, J.P.; Stambke, M.; Schricker, K. 3D Weld Seam Characterization Based on Optical Coherence Tomography for Laser-Based Thermal Joining of Thermoplastics to Metals. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 22–25 June 2015. [Google Scholar]

- Chen, Z.Q.; Gao, X.D. Detection of Weld Pool Width Using Infrared Imaging During High-Power Fiber Laser Welding of Type 304 Austenitic Stainless Steel. Int. J. Adv. Manuf. Technol. 2014, 74, 1247–1254. [Google Scholar] [CrossRef]

- Franz, C.; Abels, P.; Merz, M.; Singpiel, H.; Trein, J. Real-Time Process Control by Machine Vision. In Proceedings of the 30th International Congress on Laser Materials Processing, Laser Microprocessing and Nanomanufacturing, Orlando, FL, USA, 23–27 October 2011; pp. 104–109. [Google Scholar]

- You, D.Y.; Gao, X.D.; Katayama, S. Multi-Sensor Fusion System for Monitoring High-Power Disk Laser Welding Using Support Vector Machine. IEEE Trans. Ind. Informat. 2014, 10, 1285–1295. [Google Scholar]

- Song, L.; Huang, W.; Han, X.; Mazumder, J. Real-Time Composition Monitoring Using Support Vector Regression of Laser-Induced Plasma for Laser Additive Manufacturing. IEEE Trans. Ind. Electron. 2017, 64, 633–642. [Google Scholar] [CrossRef]

- Gao, X.D.; Zhang, Y.X. Monitoring of Welding Status by Molten Pool Morphology During High-Power Disk Laser Welding. Opt.-Int. J. Light Electron Opt. 2015, 126, 1797–1802. [Google Scholar] [CrossRef]

- Braunreuther, S.; Hammerstingl, V.; Schweier, M.; Theodossiadis, G.; Reinhart, G.; Zaeh, M.F. Welding Joint Detection by Calibrated Mosaicking with Laser Scanner Systems. CIRP J. Manuf. Sci. Technol. 2015, 10, 16–23. [Google Scholar] [CrossRef]

- Chen, J.Q.; Wang, T.; Gao, X.D.; Li, W. Real-Time Monitoring of High-Power Disk Laser Welding Based on Support Vector Machine. Comput. Ind. 2018, 94, 75–81. [Google Scholar] [CrossRef]

- Lott, P.; Schleifenbaum, H.; Meiners, W.; Wissenbach, K.; Hinke, C.; Bültmann, J. Design of an Optical System for the in Situ Process Monitoring of Selective Laser Melting (SLM). Phys. Procedia 2011, 12, 683–690. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.D.; Katayama, S.; Jin, X.L. Study of Dynamic Features of Surface Plasma in High-Power Disk Laser Welding. Plasma Sci. Technol. 2012, 14, 245–251. [Google Scholar] [CrossRef]

- Wang, C.Y.; Gao, X.D.; Ma, N.J.; Liu, G.Q.; Zhang, Y.X. Multiangle Excited MOI and Image Processing Strategies Specified for Detection of Orthogonal Weld Defects. Opt. Express 2022, 30, 1280–1292. [Google Scholar] [CrossRef]

- Gao, X.D.; Ma, N.J.; Du, L.L. Magneto-Optical Imaging Characteristics of Weld Defects under Alternating Magnetic Field Excitation. Opt. Express 2018, 26, 9972–9983. [Google Scholar] [CrossRef]

- Vithanage, R.; Mohseni, E.; Qiu, Z.; Macleod, C.; Gachagan, A. A Phased Array Ultrasound Roller Probe for Automated In-Process/Interpass Inspection of Multipass Welds. IEEE T. Ind. Electron. 2021, 68, 12781–12790. [Google Scholar] [CrossRef]

- Cenigaonaindia, A.; Liébana, F.; Lamikiz, A.; Echegoyen, Z. Novel Strategies for Laser Joining of Polyamide and AISI 304. Phys. Procedia 2012, 39, 92–99. [Google Scholar] [CrossRef][Green Version]

- Liu, Y.; Su, J.; Tan, C.; Feng, Z.W.; Zhang, H.; Wu, L.J.; Chen, B.; Song, X.G. Effect of Laser Texturing on Mechanical Strength and Microstructural Properties of Hot-Pressing Joining of Carbon Fiber Reinforced Plastic to Ti6Al4V. J. Manuf. Process. 2021, 65, 30–41. [Google Scholar] [CrossRef]

- Xu, R.; Xie, Y.; Li, R.L.; Zhang, J.H.; Zhou, T. Direct Bonding of Polymer and Metal with an Ultra-High-Strength: Laser Treatment and Mechanical Interlocking. Adv. Eng. Mater. 2021, 23, 2001288. [Google Scholar] [CrossRef]

- Schricker, K.; Stambke, M.; Bergmann, J.P.; Bräutigam, K.; Henckell, P. Macroscopic Surface Structures for Polymer-metal Hybrid Joints Manufactured by Laser Based Thermal Joining. Phys. Procedia 2014, 56, 782–790. [Google Scholar] [CrossRef][Green Version]

- Rodríguez-Vidal, E.; Sanz, C.; Soriano, C.; Leunda, J.; Verhaeghe, G. Effect of Metal Micro-Structuring on the Mechanical Behavior of Polymer–Metal Laser T-Joints. J. Mater. Process. Technol. 2016, 229, 668–677. [Google Scholar] [CrossRef]

- Rodríguez-Vidal, E.; Sanz, C.; Lambarri, J.; Quintana, I. Experimental Investigation into Metal Micro-Patterning by Laser on Polymer-Metal Hybrid Joining. Opt. Laser Technol. 2018, 104, 73–82. [Google Scholar] [CrossRef]

- Amend, P.; Pfindel, S.; Schmidt, M. Thermal Joining of Thermoplastic Metal Hybrids by Means of Mono- and Polychromatic Radiation. Phys. Procedia 2013, 41, 98–105. [Google Scholar] [CrossRef]

- Jiao, J.K.; Jia, S.H.; Xu, Z.F.; Ye, Y.Y.; Sheng, L.Y.; Zhang, W.W. Laser Direct Joining of CFRTP and Aluminium Alloy with a Hybrid Surface Pre-Treating Method. Compos. B-Eng. 2019, 173, 106911. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.G.; Tan, X.H.; Zhang, J. Improvement of the Laser Joining of CFRP and Aluminum via Laser Pre-Treatment. INT J. Adv. Manuf. Tech. 2016, 90, 3465–3472. [Google Scholar] [CrossRef]

- Henrottin, A.; Patars, J.; Ramos-De-Campos, J.A. New Approach for Assembling Dissimilar Materials: Laser Technology. J. Laser Micro Nanoeng. 2018, 13, 296–300. [Google Scholar]

- Kira VD, S.; Burkhardt, I.; Olowinsky, A.; Gillner, A. Laser-induced Self-organizing Microstructures on Steel for Joining with Polymers. Phys. Procedia 2016, 83, 1137–1144. [Google Scholar]

- Heckert, A.; Zaeh, M.F. Laser Surface Pre-treatment of Aluminium for Hybrid Joints with Glass Fibre Reinforced Thermoplastics. Phys. Procedia 2014, 56, 1171–1181. [Google Scholar] [CrossRef]

- Kawahito, Y.; Tange, A.; Kubota, S.; Katayama, S. Development of Direct Laser Joining for Metal and Plastic. In ICALEO; Laser Institute of America: Orlando, FL, USA, 2006; p. 604. [Google Scholar]

- Zhang, Z.; Shan, J.G.; Tan, X.H. Evaluation of The CFRP Grafting and Its Influence on the Laser Joining CFRP to Aluminum Alloy. J. Adhes. Sci. Technol. 2018, 32, 390–406. [Google Scholar] [CrossRef]

- Jung, D.; Cheon, J.; Na, S. Effect of Surface Pre-Oxidation on Laser Assisted Joining of Acrylonitrile Butadiene Styrene (ABS) and Zinc-Coated Steel. Mater. Des. 2016, 99, 1–9. [Google Scholar] [CrossRef]

- Pan, L.; Hu, J.L.; Lv, Y.F.; Ma, W.L.; Ding, W.Y.; Wang, Y.F.; Zhang, A.A.; Wang, F.; Pang, X.F.; Tao, J. Modification of Ti-6Al-4 V Plates with Schiff Base Complex and Adhesive Performance of Ti-6Al-4V/PEEK. Mater. Des. 2018, 144, 271–280. [Google Scholar] [CrossRef]

- Hino, M.; Mitooka, Y.; Murakami, K.; Kanadani, T. Laser Joining of Metal and Plastic Using Insert Materials. Trans. Tech. Publ. 2012, 706, 2956–2961. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.G.; Tan, X.H.; Zhang, J. Effect of Anodizing Pretreatment on Laser Joining CFRP to Aluminum Alloy A6061. Int. J. Adhes. Adhes. 2016, 70, 142–151. [Google Scholar] [CrossRef]

- Pan, Y.C.; Wu, X.; Huang, Z.; Wu, G.Q.; Sun, S.Q.; Ye, H.J.; Zhang, Z.K. A New Approach to Enhancing Interlaminar Strength and Galvanic Corrosion Resistance of CFRP/Mg Laminates. Compos. Part A Appl. Sci. Manuf. 2018, 105, 78–86. [Google Scholar] [CrossRef]

- Pan, Y.C.; Wu, G.Q.; Huang, Z.; Zhang, Z.K.; Ye, H.J.; Li, M.Y.; Ji, S.D. Improvement in Interlaminar Strength and Galvanic Corrosion Resistance of CFRP/Mg Laminates by Laser Ablation. Mater. Lett. 2017, 207, 4–7. [Google Scholar] [CrossRef]

- Su, J.H. Research on Laser Joining of Titanium Alloy and Carbon Fiber Reinforced Thermoplastic Composite via Surface Dual Scale Reinforcement. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Qu, L.J. Structure and Properties of Ultrasond Micro-Arc Oxidation Biocoatings on Magnesium Alloy. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Gao, M.; Liao, W.; Chen, C. Improving the Interfacial Bonding Strength of Dissimilar Pa66 Plastic and 304 Stainless Steel by Oscillating Laser Beam. Opt. Laser Technol. 2021, 138, 106869. [Google Scholar] [CrossRef]

- Jiao, J.K.; Qi, Z.; Ye, Y.Y.; Xu, Z.F.; Sheng, L.Y. Carbon Fiber Reinforced Thermoplastic Composites and TC4 Alloy Laser Assisted Joining with the Metal Surface Laser Plastic-Covered Method. Compos. Part B Eng. 2021, 213, 108738. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yue, T.M.; Guo, Z.N. Laser Joining of Metals to Plastics with Ultrasonic Vibration. J. Mater. Process. Tech. 2017, 249, 441–451. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yue, T.M.; Guo, Z.N. Combined Effects of Temperature Field and Ultrasonic Vibration on Bubble Motion in Laser Joining of Plastic to Metal. J. Mater. Process. Technol. 2021, 288, 116848. [Google Scholar] [CrossRef]

- Liu, J.; Cui, W.F.; Shi, Y.; Zhu, H.Y.; Li, Z. Effect of Surface Texture and Ultrasonic on Tensile Property Of 316L/PET Dissimilar Joints. J. Manuf. Process. 2020, 50, 430–439. [Google Scholar] [CrossRef]

- Xia, H.B.; Wang, T.; Li, L.Q.; Tan, C.W.; Zhang, K.P.; Ma, N.S. Effect of Laser Beam Models on Laser Welding–Brazing Al to Steel. Opt. Laser Technol. 2019, 122, 105845. [Google Scholar] [CrossRef]

- Cui, L.; Chen, B.X.; Chen, L.; He, D.Y. Dual Beam Laser Keyhole Welding of Steel/Aluminum Lapped Joints. J. Mater. Process. Technol. 2018, 256, 87–97. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.Y.; Zhang, C.; Gao, M. Effect of Beam Oscillating Pattern on Weld Characterization of Laser Welding of AA6061-T6 Aluminum Alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Hao, K.D.; Liao, W.; Zhang, T.D.; Gao, M. Interface Formation and Bonding Mechanisms of Laser Transmission Welded Composite Structure of Pet on Austenitic Steel via Beam Oscillation. Compos. Struct. 2020, 235, 111752. [Google Scholar] [CrossRef]

- Bu, H.; Li, Y.; Yang, H.; Wang, L.L.; Zhan, X.H. Investigation of Laser Joining Process of CFRTP and Aluminum Alloy. Mater. Manuf. Process. 2020, 35, 1251–1258. [Google Scholar] [CrossRef]

- Wang, L.; Gao, X.D.; Kong, F.R. Keyhole Dynamic Status and Spatter Behavior During Welding of Stainless Steel with Adjustable-Ring Mode Laser Beam. J. Manuf. Process. 2022, 74, 201–219. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Jiao, J.K.; Du, B.N.; Wang, F.Y.; Wang, Q. Influence of Processing Parameters on Laser Direct Joining of CFRTP and Stainless Steel. Adv. Mater. Sci. Eng. 2018, 2018, 2530521. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Wang, F.Y.; Wang, Q.; Jiao, J.K. Shear Strength Optimization of Laser-Joined Polyphenylene Sulfide-Based CFRTP and Stainless Steel. Strength Mater. 2018, 50, 824–831. [Google Scholar] [CrossRef]

- Huang, Y.J.; Gao, X.D.; Zheng, Q.Q. Laser Welding Test of Polymethyl Methacrylate and 304 Stainless Steel. Trans. China Weld. Inst. 2014, 76, 67–70. [Google Scholar]

- Jiao, J.K.; Xu, Z.F.; Wang, Q.; Zan, S.P.; Zhang, W.W. Research on Carbon Fiber Reinforced Thermal Polymer/Stainless Steel Laser Direct Joining. J. Laser Appl. 2018, 30, 032419. [Google Scholar] [CrossRef]

- Wang, H.P.; Chen, Y.; Guo, Z.Y.; Guan, Y.C. Porosity Elimination in Modified Direct Laser Joining of Ti6Al4V and Thermoplastics Composites. Appl. Sci. 2019, 9, 411. [Google Scholar] [CrossRef]

- Wang, L.; Gao, X.D.; Chen, Z.Q. Status Analysis of Keyhole Bottom in Laser-MAG Hybrid Welding Process. Opt. Express 2018, 26, 347–355. [Google Scholar] [CrossRef]

- Farazila, Y.; Miyashita, Y.; Hua, W.; Mutoh, Y.; Otsuka, Y. YAG Laser Spot Welding of Pet and Metallic Materials. J. Laser Micro/Nanoeng. 2011, 6, 0015. [Google Scholar] [CrossRef]

- Wang, D.; Xu, J.J.; Huang, T.; Jing, R.M.; Zhang, J.Q.; Xiao, R.S. Effect of Beam Shaping on Laser Joining of CFRP and Al-Li Alloy. Opt. Laser Technol. 2021, 143, 107336. [Google Scholar] [CrossRef]

- Huang, Y.J.; Gao, X.D.; Zheng, Q.Q. PMMA and 304 Stainless Steel Laser Welding. Trans. China Weld. Inst. 2018, 39, 67–70. [Google Scholar]

- Tamrin, K.F.; Nukrnan, Y.; Sheikh, N.A.; Harizam, M.Z. Determination of Optimum Parameters Using Grey Relational Analysis for Multi-Performance Characteristics in CO2 Laser Joining of Dissimilar Materials. Opt. Laser. Eng. 2014, 57, 40–47. [Google Scholar] [CrossRef]

- Acherjee, B.; Mondal, S.; Tudu, B.; Misra, D. Application of Artificial Neural Network for Predicting Weld Quality in Laser Transmission Welding of Thermoplastics. Appl. Soft Comput. J. 2011, 11, 2548–2555. [Google Scholar] [CrossRef]

- Huang, Y.J. Study on the Welding Process of Dissimilar Materials Stainless Steel 304 and Polyethylene Methacrylate (PMMA). Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Ai, Y.W.; Shao, X.Y.; Jang, P.; Li, P.G.; Liu, Y.; Liu, W. Welded Joints Integrity Analysis and Optimization for Fiber Laser Welding of Dissimilar Materials. Opt. Laser. Eng. 2016, 86, 62–74. [Google Scholar] [CrossRef]

- Ai, Y.W.; Shao, X.Y.; Jang, P.; Li, P.G.; Liu, Y.; Chen, Y. Process Modeling and Parameter Optimization Using Radial Basis Function Neural Network and Genetic Algorithm for Laser Welding of Dissimilar Materials. Appl. Phys. A Mater. 2015, 121, 555. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Parvizi, A.; Moradi, M. Multi-Objective Topology Optimization of Deep Drawing Dissimilar Tailor Laser Welded Blanks; Experimental and Finite Element Investigation. Opt. Laser Technol. 2020, 125, 106029. [Google Scholar] [CrossRef]

- Yu, T.B.; Lin, Y.; Zhao, Y.; Sun, J.Y.; Li, B.C. Experimental Research and Multi-Response Multi-Parameter Optimization of Laser Cladding Fe313. Opt. Laser Technol. 2018, 108, 321–332. [Google Scholar] [CrossRef]

- Li, S.C.; Mo, B.; Xu, W.; Xiao, G.; Deng, Z.H. Research on Nonlinear Prediction Model of Weld Forming Quality During Hot-Wire Laser Welding. Opt. Laser Technol. 2020, 131, 106436. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Kant, R. Optimization of Laser-Assisted Joining Through an Integrated Experimental-Simulation Approach. Int. J. Adv. Manuf. Tech. 2018, 97, 2655–2666. [Google Scholar] [CrossRef]

- Rodríguez-Vidal, E.; Lambarri, J.; Soriano, C.; Sanz, C.; Verhaeghe, G. A Combined Experimental and Numerical Approach to the Laser Joining of Hybrid Polymer-Metal Parts. Phys. Procedia 2014, 56, 835–844. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.; Mitra, S.; Misra, D. Modeling and Analysis of Simultaneous Laser Transmission Welding of Polycarbonates Using an FEM and RSM Combined Approach. Opt. Laser Technol. 2012, 44, 995–1006. [Google Scholar] [CrossRef]

- Liu, H.; Wang, K.; Li, P.; Zhang, C.; Du, D.Z.; Hu, Y.; Wang, X. Modeling and Prediction of Transmission Laser Bonding Process Between Titanium Coated Glass and PET Based on Response Surface Methodology. Opt. Lasers Eng. 2012, 50, 440–448. [Google Scholar] [CrossRef]

- Wang, X.; Song, X.H.; Jiang, M.F.; Li, P.; Hu, Y.; Wang, K.; Liu, H.X. Modeling and Optimization of Laser Transmission Joining Process Between PET and 316L Stainless Steel Using Response Surface Methodology. Opt. Laser Technol. 2012, 44, 656–663. [Google Scholar] [CrossRef]

- Katayama, S. Handbook of Laser Welding Technologies; Woodhead: Sawston, UK, 2013. [Google Scholar]

- Schricker, K.; Stambke, M.; Bergmann, J.P. Experimental Investigations and Modeling of The Melting Layer in Polymer-Metal Hybrid Structures. Weld. World 2015, 59, 407–412. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Han, S.W.; Cheon, J.; Na, S.J.; Gao, X.D. Effect of Joint Gap on Bead Formation in Laser Butt Welding of Stainless Steel. J. Mater. Process. Technol. 2017, 249, 274–284. [Google Scholar] [CrossRef]

| Applications | Sources | Materials and Structures | Connection Process |

|---|---|---|---|

| Body frame | BMW 7 series [8,14] | Steel–Aluminum–CFRP | — |

| BMW-i3 [15] | CFRP cockpit + Aluminum alloy chassis | Adhesive bonding and bolted connection | |

| QIANTU-K50 [17] | Aluminum alloy body frame + CFRP outer covering | Adhesive bonding and bolted connection | |

| Li et al. [19] | Sandwich: Carbon fiber + Al honeycomb + Carbon fiber | Adhesive bonding | |

| Bumper | Chu et al. [21] | HSS-DP590+PA66-GF35 hybrid structure | Injection molding |

| GLARE (die casting) beam + Aluminum alloy collision box | Adhesive bonding | ||

| Hood | Ishak [53] | NFRP (PP)+5052 Aluminum alloy laminate | Adhesive bonding |

| Yang [22] | Outer panel PP+EPDM, Inner panel LFT (PP), Steel widgets | Adhesive bonding | |

| Deepak et al. [23] | Three kinds of sandwich structure: Steel–polyurethane foam–steel, aluminum–polyurethane foam–aluminum, aluminum–polyurethane foam–steel | Adhesive bonding | |

| Front-end module | Park et al. [24] | PA6-GF30+ High strength steel side panel | Mechanical fastening |

| Audi A3 [54] | Steel plate +GFRP (PA6-GF30) | Injection molding | |

| Town&Country [54] | GFRP + Steel plate | Riveting and adhesive bonding | |

| A pillar | Porsche 911 [8] | Fiberglass mesh, honeycomb structure short FRP and high strength steel composite | Adhesive bonding |

| Drössler et al. [25] | Steel–FRP | Injection molding | |

| B pillar | Drössler et al. [25] | Steel–FRP | Injection molding |

| BMW-7 series [27] | Steel–CFRP | Molded connection | |

| Lee et al. [26] | CR420 steel + CFRP (thermosetting) composite | Thermal curing | |

| Yan et al. [55] | Sheet metal parts + continuous CFRP (epoxy resin) | Adhesive bonding | |

| Cockpit beam | Hoffmann et al. [28] | PA6-GF60+Al | Injection molding |

| Door hinge | Yu and Kim [56] | CFRP and 6061 aluminum alloy combined with steel | — |

| Armrest | Park and Dang [29] | Short GFRP(PP) handrail frame + Metal pin | Injection molding |

| Coaming | Audi A8 [30] | CFRP rear coaming + Aluminum body | Bolted connection |

| Car floor | Nio ES6 [31] | CFRP rear floor (embedded in all-aluminum body) | — |

| Rear door | Ma et al. [32] | SUV CFRP rear door + Steel widgets | Adhesive bonding and bolted connection |

| Thin-walled tubes | Zhu et al. [33] | Al (outer)–CFRP (inner, epoxy resin as matrix) | Pressure heat curing |

| Bambach et al. [34,35] | Carbon fiber wound metal (steel/carbon fiber, aluminum/carbon fiber) epoxy resin composite | Fiber winding and adhesive bonding | |

| Ma et al. [36] | CFRP (epoxy resin) + Steel | Adhesive bonding | |

| Sun et al. [37,38] | CFRP (epoxy resin) + Aluminum | Adhesive bonding | |

| Kim et al. [39] | CFRP (epoxy resin) + Aluminum | Co-curing | |

| Battery box | Schmerler et al. [40] | Upper cover: GFRP (PA6) + Al foam + Solid Al | Heat curing |

| Wang et al. [31] | Upper SMC+ Lower CFRP + Aluminum alloy reinforced stent | Adhesive bonding and riveting | |

| Brake pedal | Miklavec et al. [43] | Steel (main frame) + PA6 | Injection molding |

| Drive shaft | Yang et al. [44] | CFRP drive shaft tube + Metal shaft head | Bolted connection |

| Lee et al. [45] | Aluminum + (carbon + glass) FRP (epoxy) | Co-curing | |

| Car gear | Catera et al. [46] | CFRP (epoxy resin) + Steel | Adhesive bonding |

| Control arm | Stötzner [47] | High strength steel plate (DP800) + GFRP (PA6) | Adhesive bonding |

| Subframe | Hexcel [48] | Aluminum alloy +FRP | Curing |

| Wheel | DYMAG [49] | Carbon fiber wheel net + Magnesium brake disc | Mechanical joining |

| Li et al. [50] | Split structure: CFRP shell + Cast aluminum alloy mandrel | Adhesive bonding | |

| Interior part | Chen [52] | Control unit housing: BFRP (PLA) + Aluminum alloy | Heat pressing molding |

| Mechanism | Description | Appearance | Inference | Details |

|---|---|---|---|---|

| Interfacial | Interfacial failure |  | Bond strength ≪ substrate strength | Interfacial failure at bond. Least desirable result. |

| Substrate (Type I) | Bulk substrate failure |  | Bond strength ≫ substrate strength | Substrate results in tensile yield and breakage. This implies that the joint is as strong as possible, and the substrate will fail first. Most desirable result. |

| Substrate (Type II) | Near interfacial substrate failure |  | Bond strength > substrate strength | Failure within the substrate, but near the interracial region and the bond remains intact. |

| Mixed (Type I) | Substrate and interfacial |  | Bond strength ≈ substrate strength | Failure partially within the substrate and at the bond interface. |

| Mixed (Type II) | Interfacial and some substrate |  | Bond strength < substrate strength | Failure mostly interfacial, but with some substrate failure, e.g., in the form of plastic deformation. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Gao, X.; Zhang, Y. Research Progress on Characterization and Regulation of Forming Quality in Laser Joining of Metal and Polymer, and Development Trends of Lightweight Automotive Applications. Metals 2022, 12, 1666. https://doi.org/10.3390/met12101666

Zhou Z, Gao X, Zhang Y. Research Progress on Characterization and Regulation of Forming Quality in Laser Joining of Metal and Polymer, and Development Trends of Lightweight Automotive Applications. Metals. 2022; 12(10):1666. https://doi.org/10.3390/met12101666

Chicago/Turabian StyleZhou, Zhenhong, Xiangdong Gao, and Yanxi Zhang. 2022. "Research Progress on Characterization and Regulation of Forming Quality in Laser Joining of Metal and Polymer, and Development Trends of Lightweight Automotive Applications" Metals 12, no. 10: 1666. https://doi.org/10.3390/met12101666

APA StyleZhou, Z., Gao, X., & Zhang, Y. (2022). Research Progress on Characterization and Regulation of Forming Quality in Laser Joining of Metal and Polymer, and Development Trends of Lightweight Automotive Applications. Metals, 12(10), 1666. https://doi.org/10.3390/met12101666