Effect of Heat Input on Microstructure and Corrosion Resistance of CP-Ti Laser Beam Welded Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Welding Parameters

2.2. Microstructure Observations and Mechanical Properties Testing

2.3. Electrochemical Measurements

3. Results

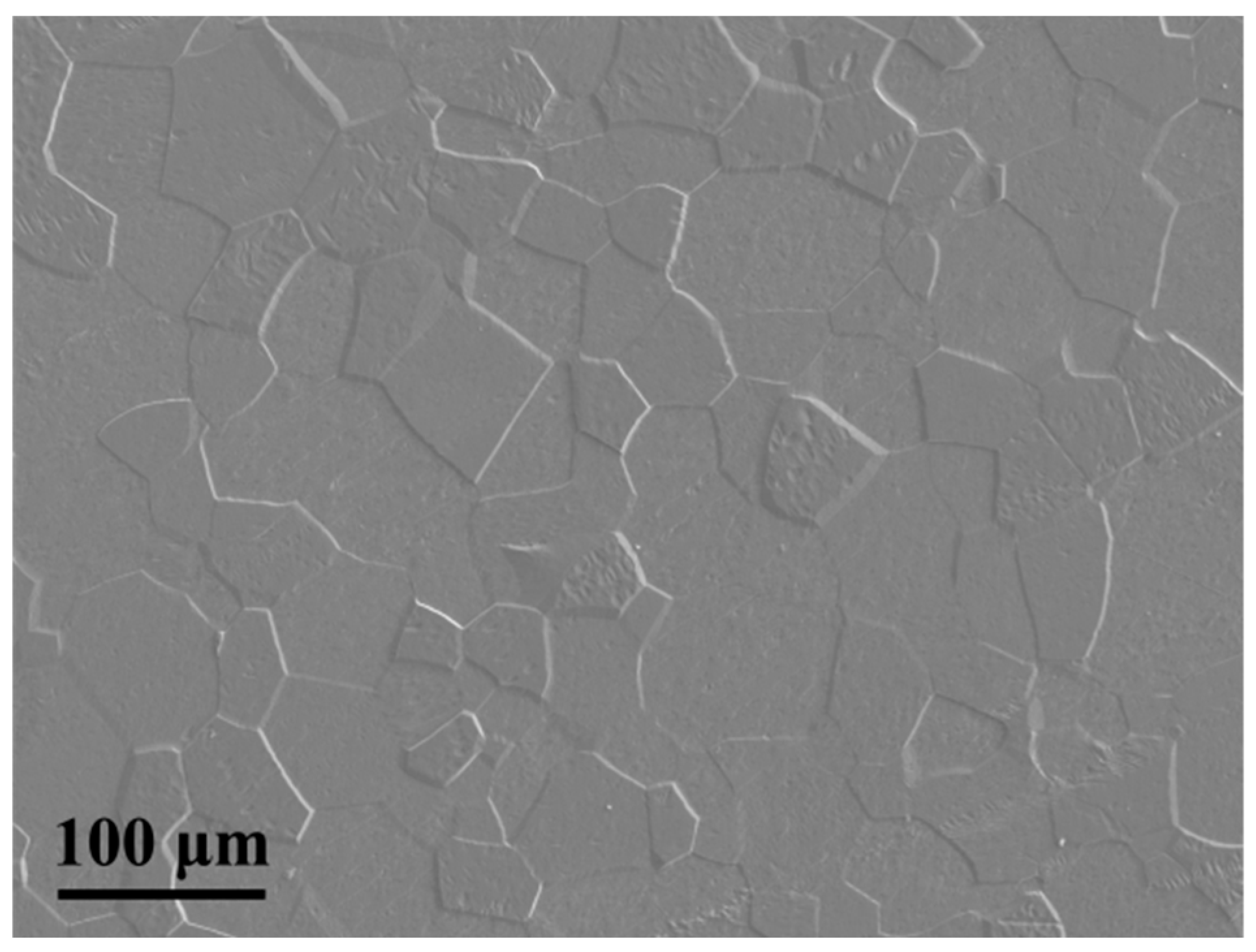

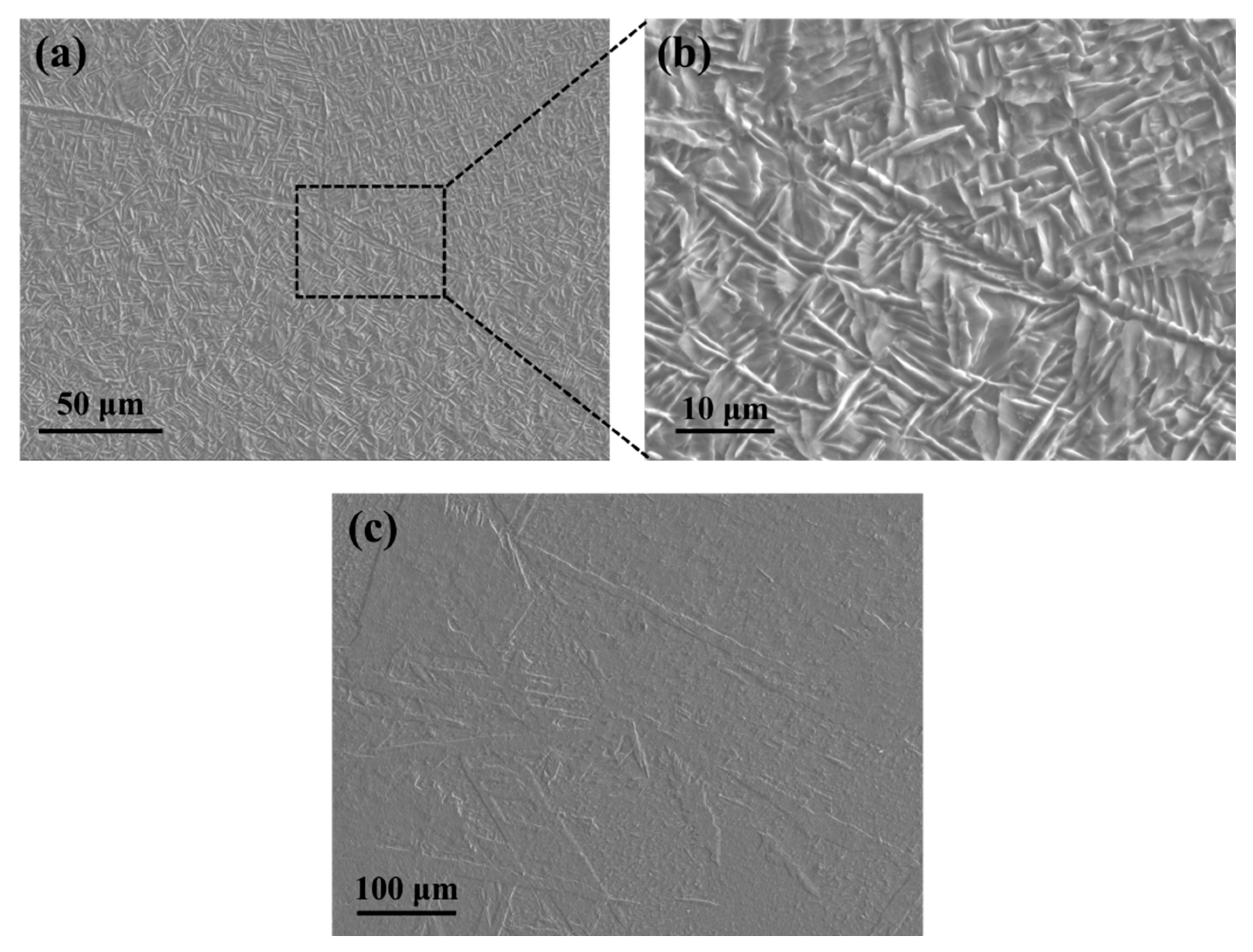

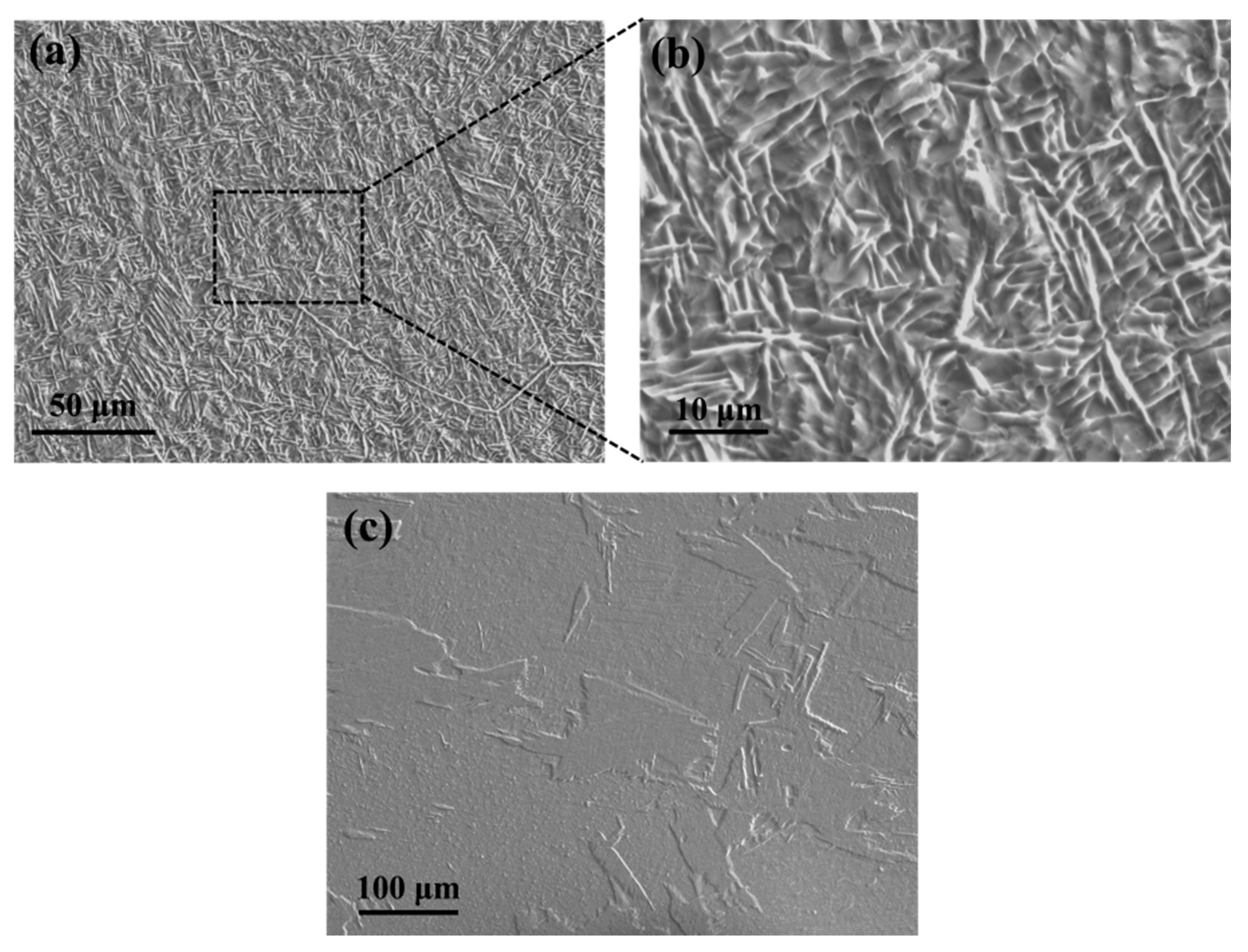

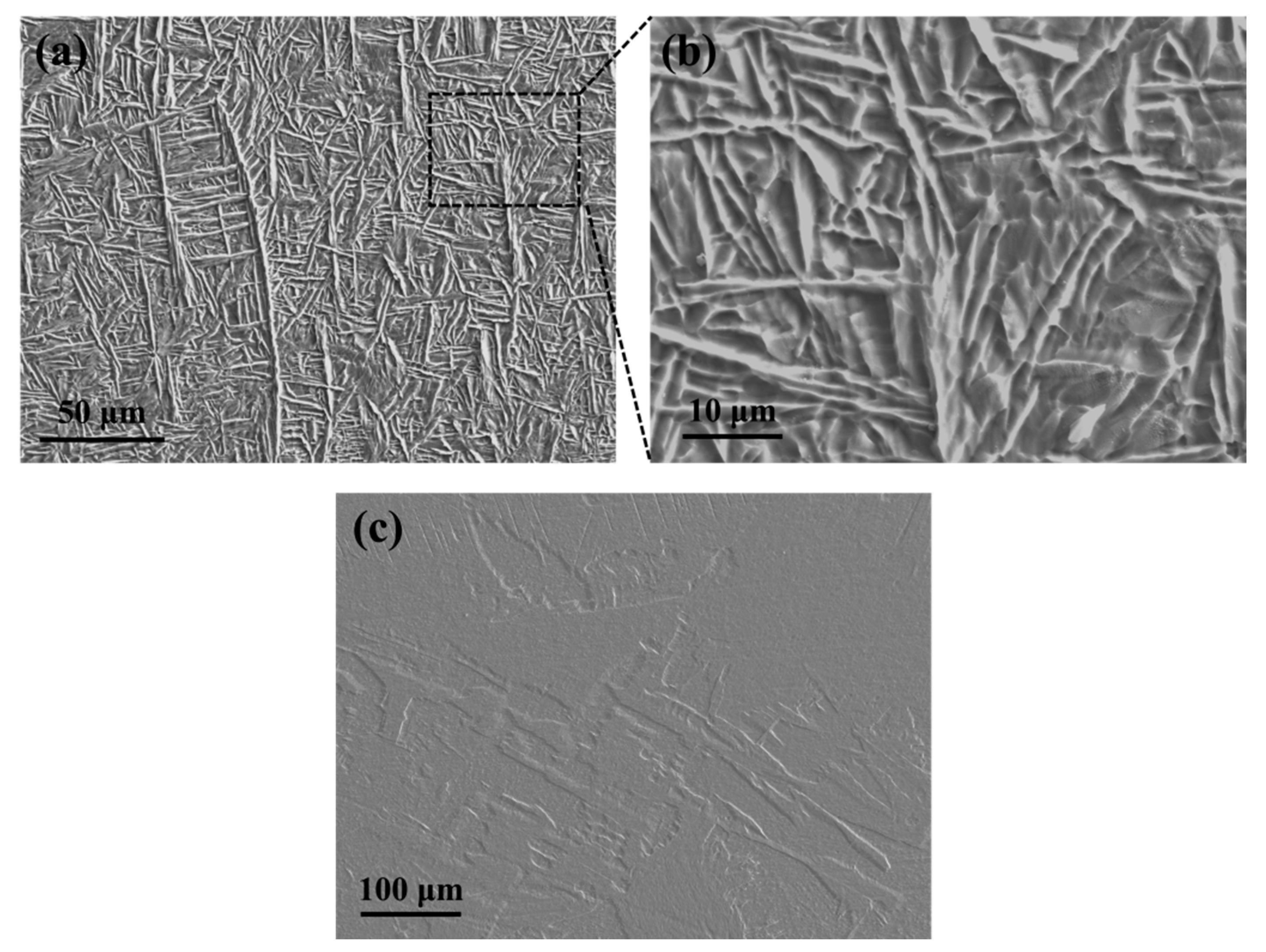

3.1. Microstructure Evolution

3.2. Mechanical Properties of Welded Joint

3.3. Corrosion Behaviors

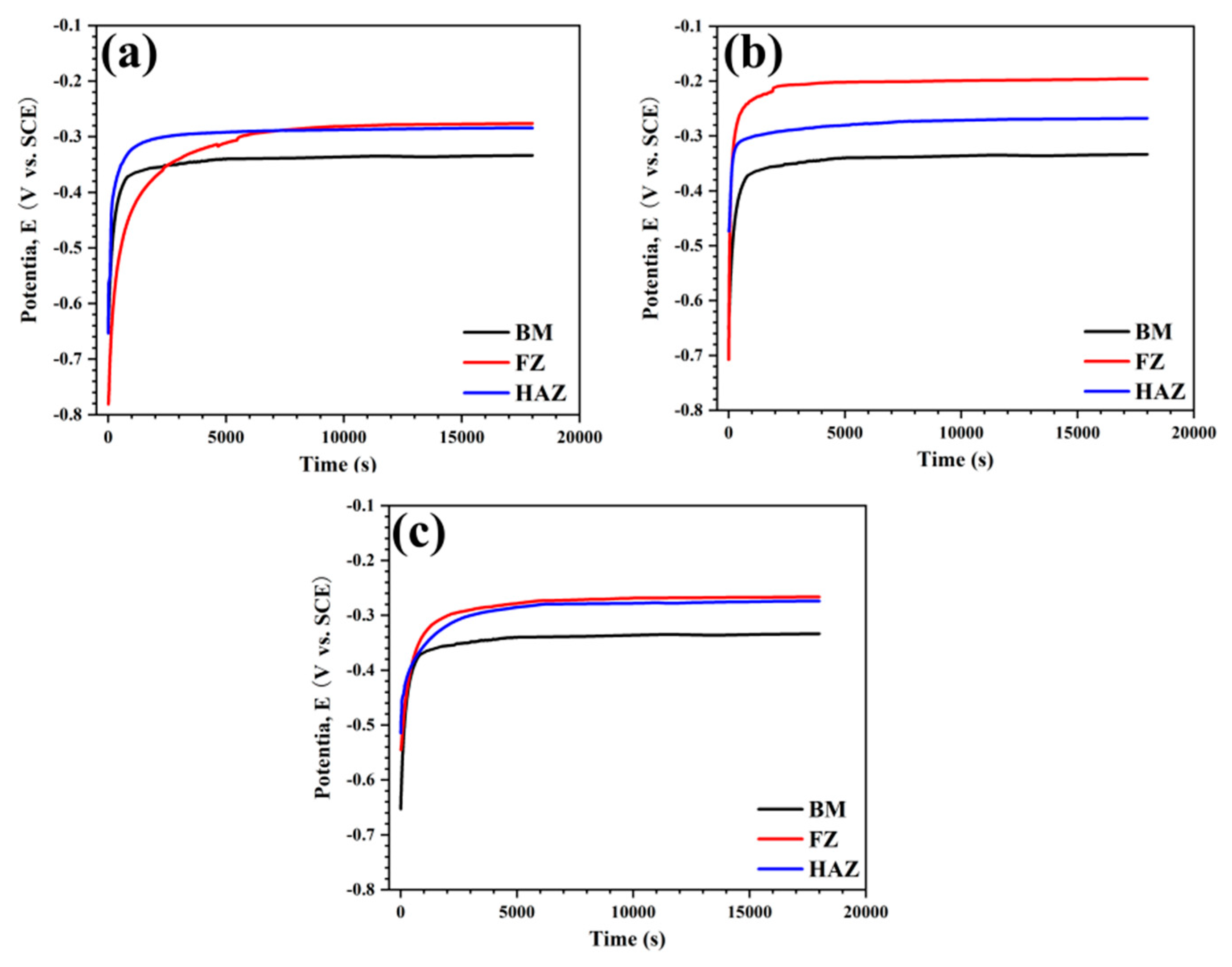

3.3.1. OCP

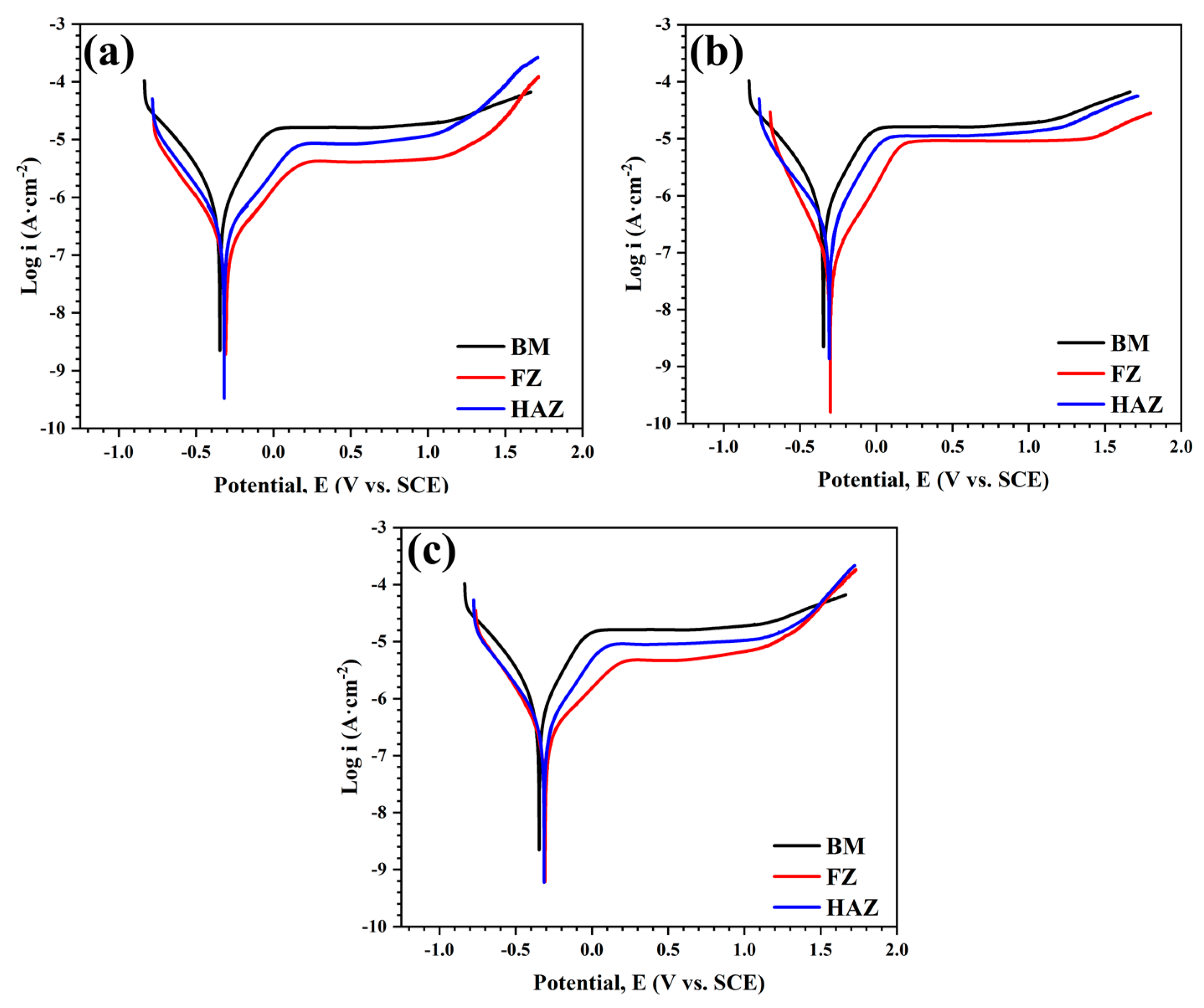

3.3.2. Potentiodynamic Polarization

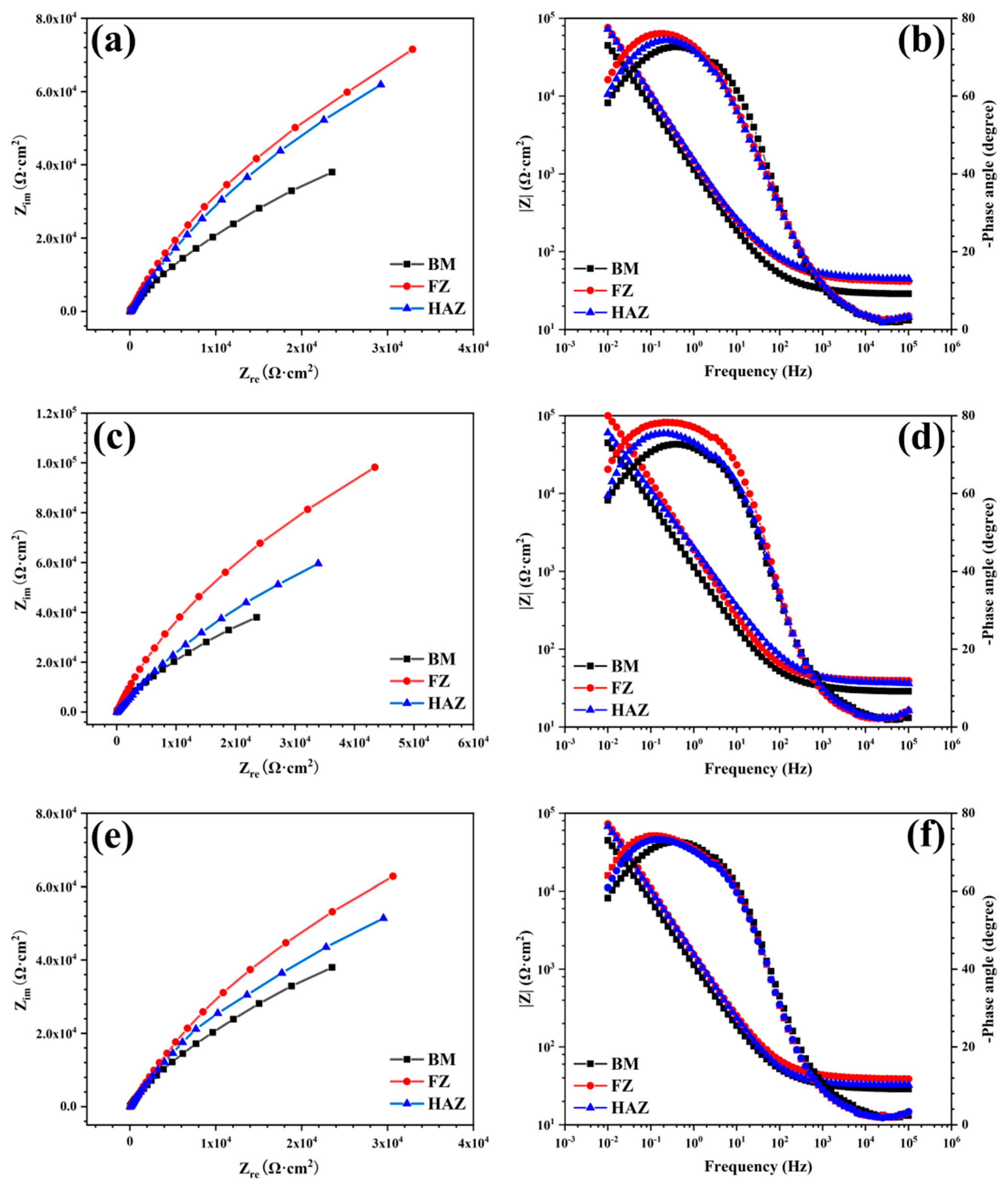

3.3.3. EIS

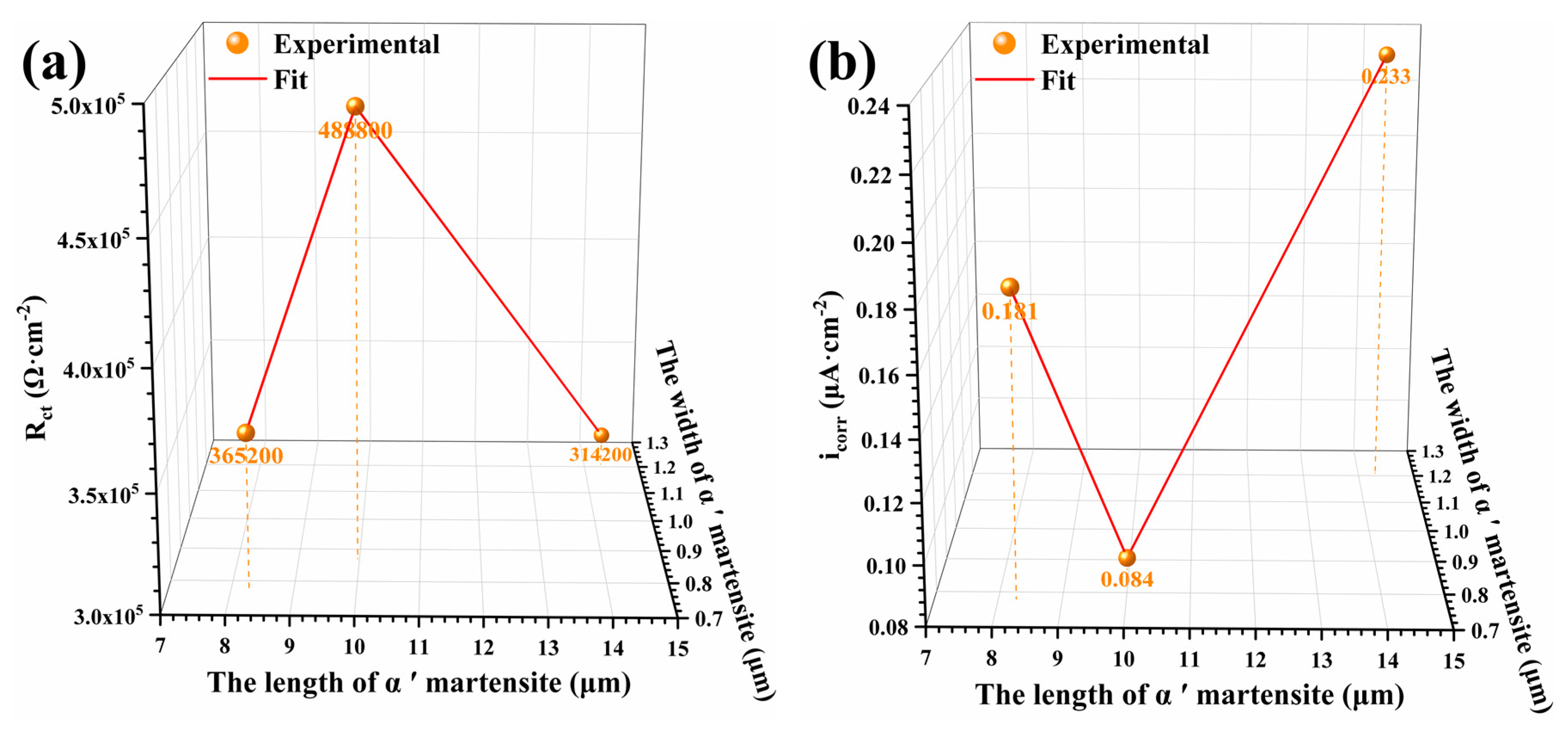

4. Discussion

5. Conclusions

- (1)

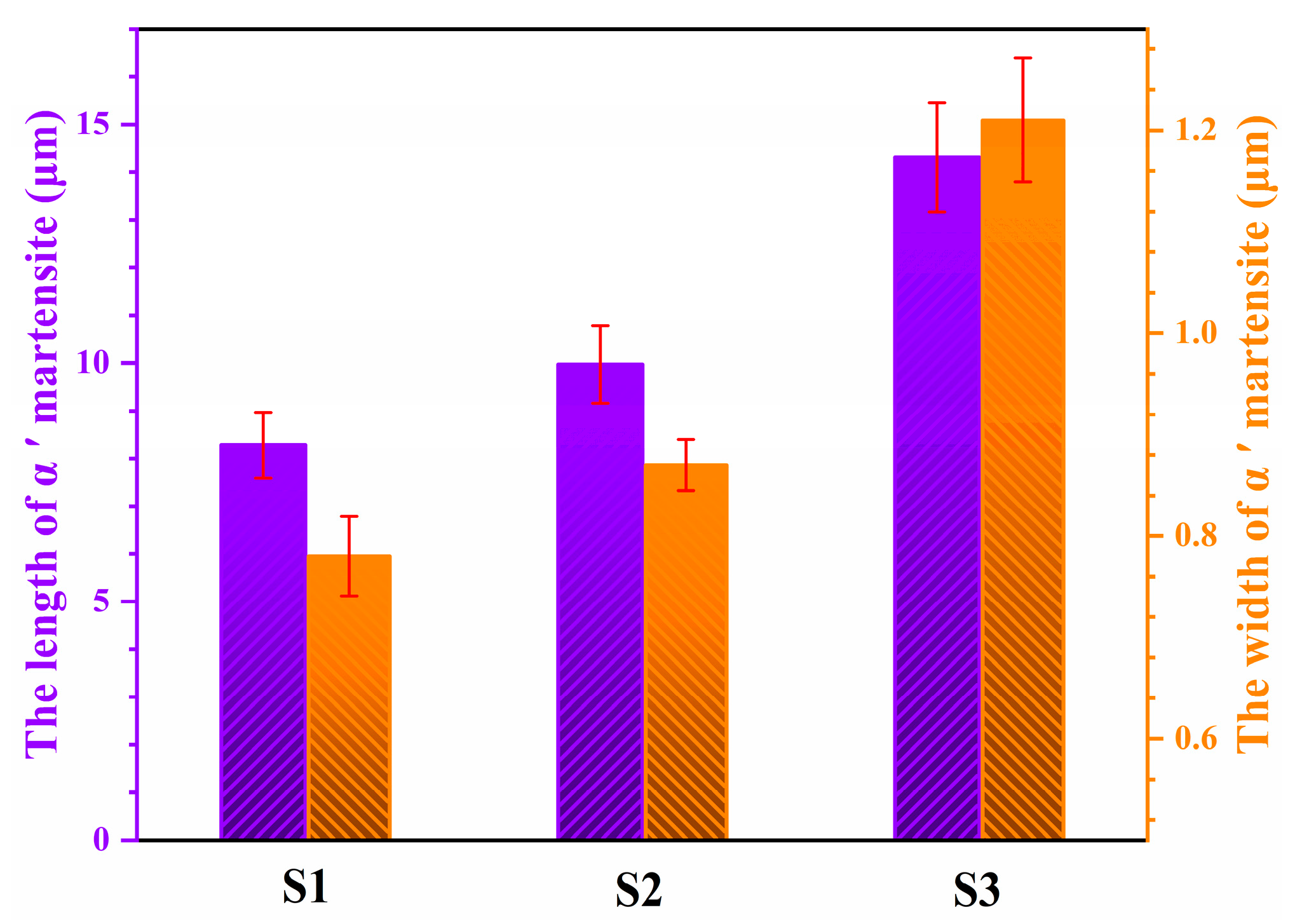

- The microstructure of FZ is needle-like α′ martensite. The volume fraction of needle-like α′ martensite decreases, the distribution is relatively chaotic, and the grain size increases with the increase of heat input. The microstructure of HAZ is zigzag α phase and the change of heat input does not significantly change its shape and size.

- (2)

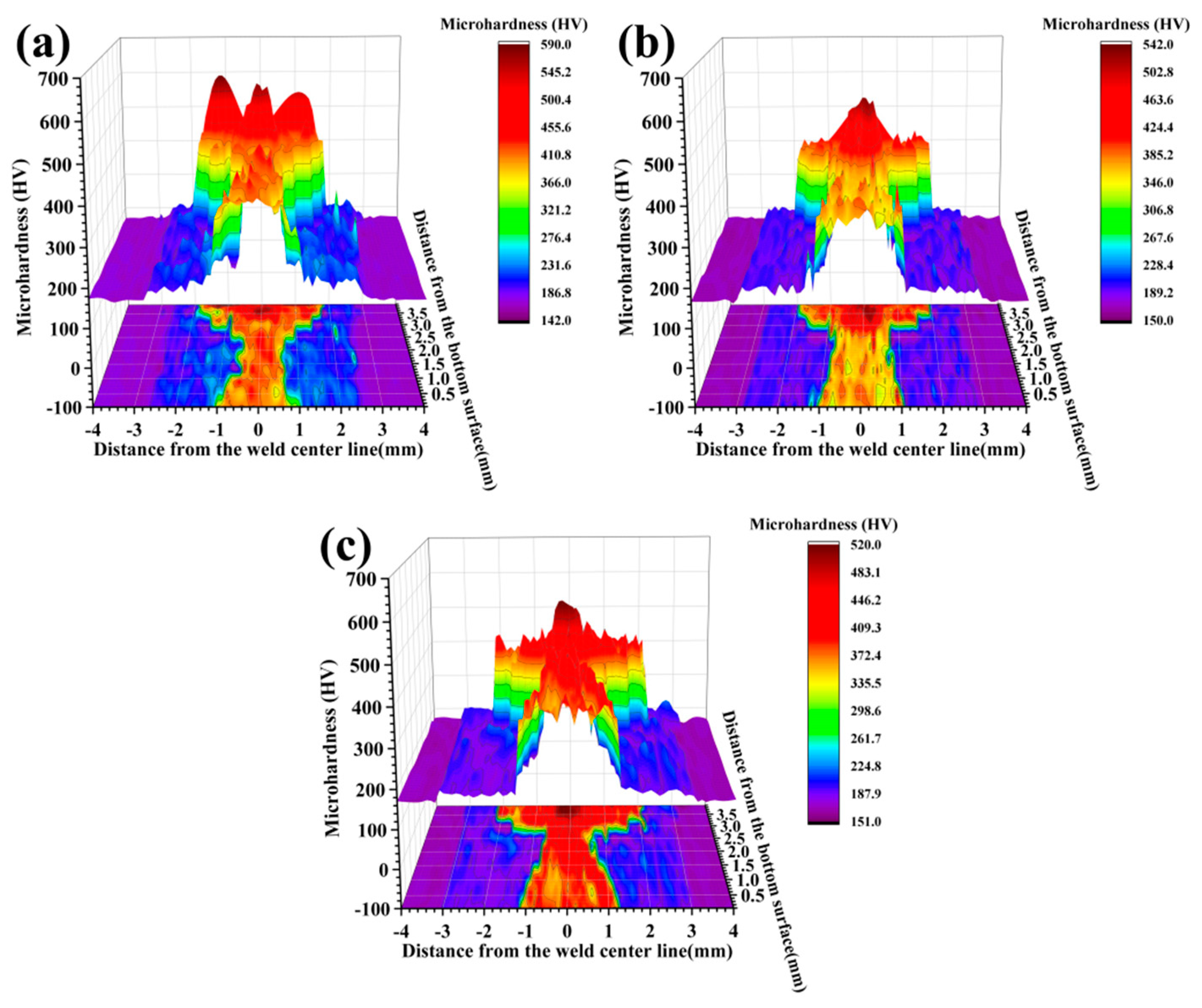

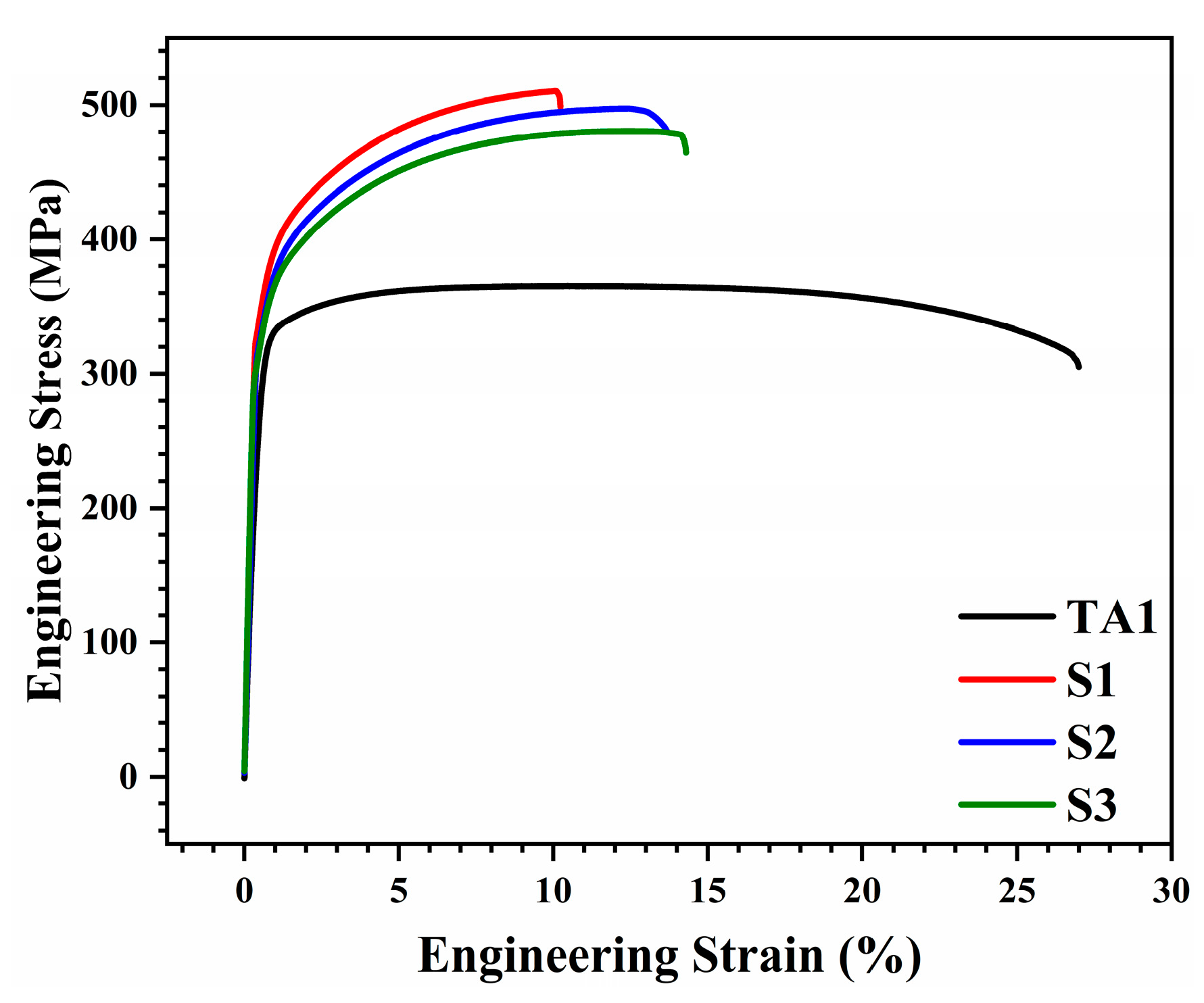

- With the increase of heat input, the elongation increases, while microhardness and tensile strength decrease. In addition, the microhardness of welded joints gradually increases from BM to FZ.

- (3)

- The increase of heat input does not change the corrosion resistance law of each zone of the welded joint as FZ > HAZ > BM. The corrosion resistance of FZ and HAZ increased first and then decreased with the increase of heat input.

- (4)

- The mathematical model between grain size and corrosion resistance in FZ was established by multivariate linear fitting method, it is found that the width of α′ martensite is the main factor affecting the corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Okazaki, Y. A new Ti–15Zr–4Nb–4Ta alloy for medical applications. Curr. Opin. Solid State Mater. Sci. 2001, 5, 45–53. [Google Scholar] [CrossRef]

- Tanaka, Y.; Nakai, M.; Akahori, T.; Niinomi, M.; Tsutsumi, Y.; Doi, H.; Hanawa, T. Characterization of air-formed surface oxide film on Ti–29Nb–13Ta–4.6Zr alloy surface using XPS and AES. Corros. Sci. 2008, 50, 2111–2116. [Google Scholar] [CrossRef]

- Mareci, D.; Chelariu, R.; Gordin, D.M.; Ungureanu, G.; Gloriant, T. Comparative corrosion study of Ti-Ta alloys for dental applications. Acta Biomater. 2009, 5, 3625–3639. [Google Scholar] [CrossRef] [PubMed]

- Rao, S.; Ushida, T.; Tateishi, T.; Okazaki, Y.; Asao, S. Effect of Ti, Al, and V ions on the relative growth rate of fibroblasts (L929) and osteoblasts (MC3T3-E1) cells. Bio-Med. Mater. Eng. 1996, 6, 79–86. [Google Scholar] [CrossRef]

- Walker, P.R.; LeBlanc, J.; Sikorska, M. Effects of aluminum and other cations on the structure of brain and liver chromatin. Biochemistry 1989, 28, 3911–3915. [Google Scholar] [CrossRef]

- Yumoto, S.; Ohashi, H.; Nagai, H.; Kakimi, S.; Ogawa, Y.; Iwata, Y.; Ishii, K. Aluminum neurotoxicity in the rat brain. Int. J. PIXE 1992, 2, 493–504. [Google Scholar] [CrossRef]

- Aparicio, C.; Gil, F.J.; Fonseca, C.; Barbosa, M.; Planell, J.A. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials 2003, 24, 263–273. [Google Scholar] [CrossRef]

- Kahraman, N. The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater. Des. 2007, 28, 420–427. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Muvvala, G.; Sarkar, S.; Racherla, V.; Nath, A.K. Effect of laser shock peening on microstructural, mechanical and corrosion properties of laser beam welded commercially pure titanium. Opt. Laser Technol. 2021, 133, 106527. [Google Scholar] [CrossRef]

- Fomin, F.; Froend, M.; Ventzke, V.; Alvarez, P.; Bauer, S.; Kashaev, N. Metallurgical aspects of joining commercially pure titanium to Ti-6Al-4V alloy in a T-joint configuration by laser beam welding. Int. J. Adv. Manuf. Technol. 2018, 97, 2019–2031. [Google Scholar] [CrossRef] [Green Version]

- Squillace, A.; Prisco, U.; Ciliberto, S.; Astarita, A. Effect of welding parameters on morphology and mechanical properties of Ti-6Al-4V laser beam welded butt joints. J. Mater. Process. Tech. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Fomichev, V.; Fomin, F.; Riekehr, S. Effect of Nd:YAG laser beam welding on weld morphology and mechanical properties of Ti-6Al-4V butt joints and T-joints. Opt. Lasers Eng. 2016, 86, 172–180. [Google Scholar] [CrossRef]

- Kumar, B.; Bag, S.; Paul, C.P.; Das, C.R.; Ravikumar, R.; Bindra, K.S. Influence of the mode of laser welding parameters on microstructural morphology in thin sheet Ti6Al4V alloy. Opt. Laser Technol. 2020, 131, 106456. [Google Scholar] [CrossRef]

- Fu, Y.; Guo, N.; Zhu, B.; Shi, X.; Feng, J. Microstructure and properties of underwater laser welding of TC4 titanium alloy. J. Mater. Process. Technol. 2020, 275, 116372. [Google Scholar] [CrossRef]

- Kumar, C.; Das, M.; Paul, C.P.; Bindra, K.S. Comparison of bead shape, microstructure and mechanical properties of fiber laser beam welding of 2 mm thick plates of Ti-6Al-4V alloy. Opt. Laser Technol. 2018, 105, 306–321. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, D.; Geng, S.; Fan, Y.; Liu, M.; Wang, Q.; Wang, F. Mechanical properties, corrosion behavior and cytotoxicity of Ti-6Al-4V alloy fabricated by laser metal deposition. Mater. Charact. 2021, 179, 111302. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Li, S.; Cuiuri, D.; Ding, D.; Li, H. The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution. Corros. Sci. 2018, 137, 176–183. [Google Scholar] [CrossRef]

- Emre, H.E. The corrosion behaviour of as-welded and post-weld heat treated Ti6Al4V alloy in simulated body fluid. Mater. Lett. 2019, 254, 162–166. [Google Scholar] [CrossRef]

- Han, Z.; Zhao, H.; Chen, X.; Lin, H. Corrosion behavior of Ti-6Al-4V alloy welded by scanning electron beam. Mater. Sci. Eng. A 2000, 277, 38–45. [Google Scholar] [CrossRef]

- Atapour, M.; Fathi, M.H.; Shamanian, M. Corrosion behavior of Ti-6Al-4V alloy weldment in hydrochloric acid. Mater. Corros. 2012, 63, 134–139. [Google Scholar] [CrossRef]

- Wang, L.M.; Lin, H.C. The characterization of corrosion resistance in the Ti-6Al-4V alloy fusion zone using a gas tungsten arc welding process. J. Mater. Res. 2011, 24, 3680–3688. [Google Scholar] [CrossRef]

- Lu, W.; Shi, Y.; Lei, Y.; Li, X. Effect of electron beam welding on the microstructures and mechanical properties of thick TC4-DT alloy. Mater. Des. 2012, 34, 509–515. [Google Scholar] [CrossRef]

- Luo, S.; Yan, P.; Liu, M.; Xue, Y.; Song, W. Electrochemical Corrosion Behavior of TA2 Titanium Alloy Welded Joint in Cl-Containing Solutions. Int. J. Electrochem. Sci. 2021, 16, 21096. [Google Scholar] [CrossRef]

- Jorcin, J.-B.; Orazem, M.E.; Pébère, N.; Tribollet, B. CPE analysis by local electrochemical impedance spectroscopy. Electrochim. Acta 2006, 51, 1473–1479. [Google Scholar] [CrossRef]

- Gong, X.; Cui, Y.; Wei, D.; Liu, B.; Liu, R.; Nie, Y.; Li, Y. Building direction dependence of corrosion resistance property of Ti–6Al–4V alloy fabricated by electron beam melting. Corros. Sci. 2017, 127, 101–109. [Google Scholar] [CrossRef]

- Yang, J.; Yang, H.; Yu, H.; Wang, Z.; Zeng, X. Corrosion Behavior of Additive Manufactured Ti-6Al-4V Alloy in NaCl Solution. Metall. Mater. Trans. A 2017, 48, 3583–3593. [Google Scholar] [CrossRef]

- Oh, M.; Lee, J.-Y.; Park, J.K. Continuous cooling β-to-α transformation behaviors of extra-pure and commercially pure Ti. Metall. Mater. Trans. A 2004, 35, 3071–3077. [Google Scholar] [CrossRef]

- Pilchak, A.L.; Broderick, T.F. Evidence of a Massive Transformation in a Ti-6Al-4V Solid-State Weld? Jom 2013, 65, 636–642. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.K. In-situ measurement of continuous cooling β→α transformation behavior of CP-Ti. Metall. Mater. Trans. A 2002, 33, 1051–1056. [Google Scholar] [CrossRef]

- Banerjee, S.; Mukhopadhyay, P. Phase Transformations: Examples from Titanium and Zirconium Alloys; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Xu, M.; Chen, Y.; Zhang, T.; Xie, J.; Wang, S.; Yin, L.; He, P. Microstructure evolution and mechanical properties of wrought/wire arc additive manufactured Ti-6Al-4V joints by electron beam welding. Mater. Charact. 2022, 190, 112090. [Google Scholar] [CrossRef]

- Ji, X.; Emura, S.; Liu, T.; Suzuta, K.; Min, X.; Tsuchiya, K. Effect of oxygen addition on microstructures and mechanical properties of Ti-7.5Mo alloy. J. Alloys Compd. 2018, 737, 221–229. [Google Scholar] [CrossRef]

- Shao, X.H.; Jin, Q.Q.; Zhou, Y.T.; Yang, H.J.; Zheng, S.J.; Zhang, B.; Chen, Q.; Ma, X.L. Basal shearing of twinned stacking faults and its effect on mechanical properties in an Mg–Zn–Y alloy with LPSO phase. Mater. Sci. Eng. A 2020, 779, 139109. [Google Scholar] [CrossRef]

- Wu, D.; Liu, L.; Zhang, L.; Wang, W.; Zhou, K. Tensile deformation mechanism and micro-void nucleation of Ti-55531 alloy with bimodal microstructure. J. Mater. Res. Technol. 2020, 9, 15442–15453. [Google Scholar] [CrossRef]

- Ye, R.R.; Li, H.Y.; Ding, R.G.; Doel, T.J.A.; Bray, S.; Walpole, A.; Bowen, P. Microstructure and microhardness of dissimilar weldment of Ni-based superalloys IN718-IN713LC. Mater. Sci. Eng. A 2020, 774, 138894. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Balyanov, A.; Kutnyakova, J.; Amirkhanova, N.; Stolyarov, V.; Valiev, R.; Liao, X.; Zhao, Y.; Jiang, Y.; Xu, H.; Lowe, T. Corrosion resistance of ultra fine-grained Ti. Scr. Mater. 2004, 51, 225–229. [Google Scholar] [CrossRef]

| Sample | Power/P (W) | Welding Rate/v (mm/s) | Heat Input/E (J/mm) |

|---|---|---|---|

| S1 | 2000 | 15 | 133.3 |

| S2 | 2400 | 15 | 160 |

| S3 | 2800 | 15 | 186.6 |

| NaCl | KCl | CaCl2·2H2O | Na2HPO4·2H2O | Na2S·2H2O | CH4N2O | Distilled Water |

|---|---|---|---|---|---|---|

| 0.4 g | 0.4 g | 0.795 g | 0.78 g | 0.005 g | 1 g | 1 L |

| Sample | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| BM | 365.4 | 298.1 | 26.9 |

| S1 | 510.5 | 343.6 | 10.2 |

| S2 | 497.4 | 341.5 | 13.7 |

| S3 | 480.5 | 317.2 | 14.3 |

| Samples | Ecorr (mV) | icorr (μA cm−2) | βa (mV dec−1) | −βc (mV dec−1) | |

|---|---|---|---|---|---|

| BM | −346.2 | 0.649 | 200.5 | 231.7 | |

| S1 | FZ | −309.3 | 0.181 | 289.9 | 251.5 |

| HAZ | −318.6 | 0.318 | 299.3 | 264.6 | |

| S2 | FZ | −301.1 | 0.084 | 222.6 | 183.0 |

| HAZ | −308.7 | 0.303 | 196.9 | 265.2 | |

| S3 | FZ | −302.4 | 0.233 | 361.5 | 230.9 |

| HAZ | −313.8 | 0.339 | 257.7 | 262.8 | |

| Samples | Rs (Ω·cm2) | Qf | Rf (Ω·cm−2) | Qdl | Rct (Ω·cm−2) | |||

|---|---|---|---|---|---|---|---|---|

| Y0 (Ω−1·cm−2·Sn) | nsl | Y0 (Ω−1·cm−2·Sn) | nsl | |||||

| BM | 29.09 | 9.011 × 10−5 | 0.8248 | 35.02 | 1.036 × 10−4 | 0.8168 | 1.506 × 105 | |

| S1 | FZ | 43.2 | 6.585 × 10−5 | 0.8383 | 133 | 7.394 × 10−5 | 0.8689 | 3.652 × 105 |

| HAZ | 36.09 | 6.726 × 10−5 | 0.8293 | 65.34 | 7.337 × 10−5 | 0.8603 | 2.59 × 105 | |

| S2 | FZ | 40.02 | 5.849 × 10−5 | 0.8839 | 141.5 | 4.538 × 10−5 | 0.8731 | 4.888 × 105 |

| HAZ | 39.54 | 7.583 × 10−5 | 0.85 | 68.27 | 5.815 × 10−5 | 0.8418 | 2.815 × 105 | |

| S3 | FZ | 31.97 | 1.216 × 10−4 | 0.8329 | 94.75 | 8.93 × 10−5 | 0.8194 | 3.142 × 105 |

| HAZ | 34.24 | 8.575 × 10−5 | 0.8414 | 46.15 | 4.874 × 10−5 | 0.8288 | 2.254 × 105 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhao, W.; Yu, K.; Guo, N.; Gao, S. Effect of Heat Input on Microstructure and Corrosion Resistance of CP-Ti Laser Beam Welded Joints. Metals 2022, 12, 1570. https://doi.org/10.3390/met12101570

Li Z, Zhao W, Yu K, Guo N, Gao S. Effect of Heat Input on Microstructure and Corrosion Resistance of CP-Ti Laser Beam Welded Joints. Metals. 2022; 12(10):1570. https://doi.org/10.3390/met12101570

Chicago/Turabian StyleLi, Zhen, Wei Zhao, Kedong Yu, Ning Guo, and Song Gao. 2022. "Effect of Heat Input on Microstructure and Corrosion Resistance of CP-Ti Laser Beam Welded Joints" Metals 12, no. 10: 1570. https://doi.org/10.3390/met12101570

APA StyleLi, Z., Zhao, W., Yu, K., Guo, N., & Gao, S. (2022). Effect of Heat Input on Microstructure and Corrosion Resistance of CP-Ti Laser Beam Welded Joints. Metals, 12(10), 1570. https://doi.org/10.3390/met12101570