Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations

Abstract

:1. Introduction

2. Lithium Battery Development

- Cost-efficient lithium-ion batteries with liquid electrolyte, graphite anode, and cathode material based mainly on iron and/or manganese and only small amounts of nickel and eventually cobalt. In addition to lithium-ion based batteries, also sodium-ion based batteries are under development, which could replace at least partly the named cost-efficient lithium-ion batteries [33,34].

- Solid-state lithium batteries with lithium or lithium-free anode structure (eventually graphite anode as intermediate stage) and solid-state electrolytes on the cathode side and as separator [35].

- Lithium sulfur batteries with lithium anode and a cathode made out of sulfur–carbon composites [36].

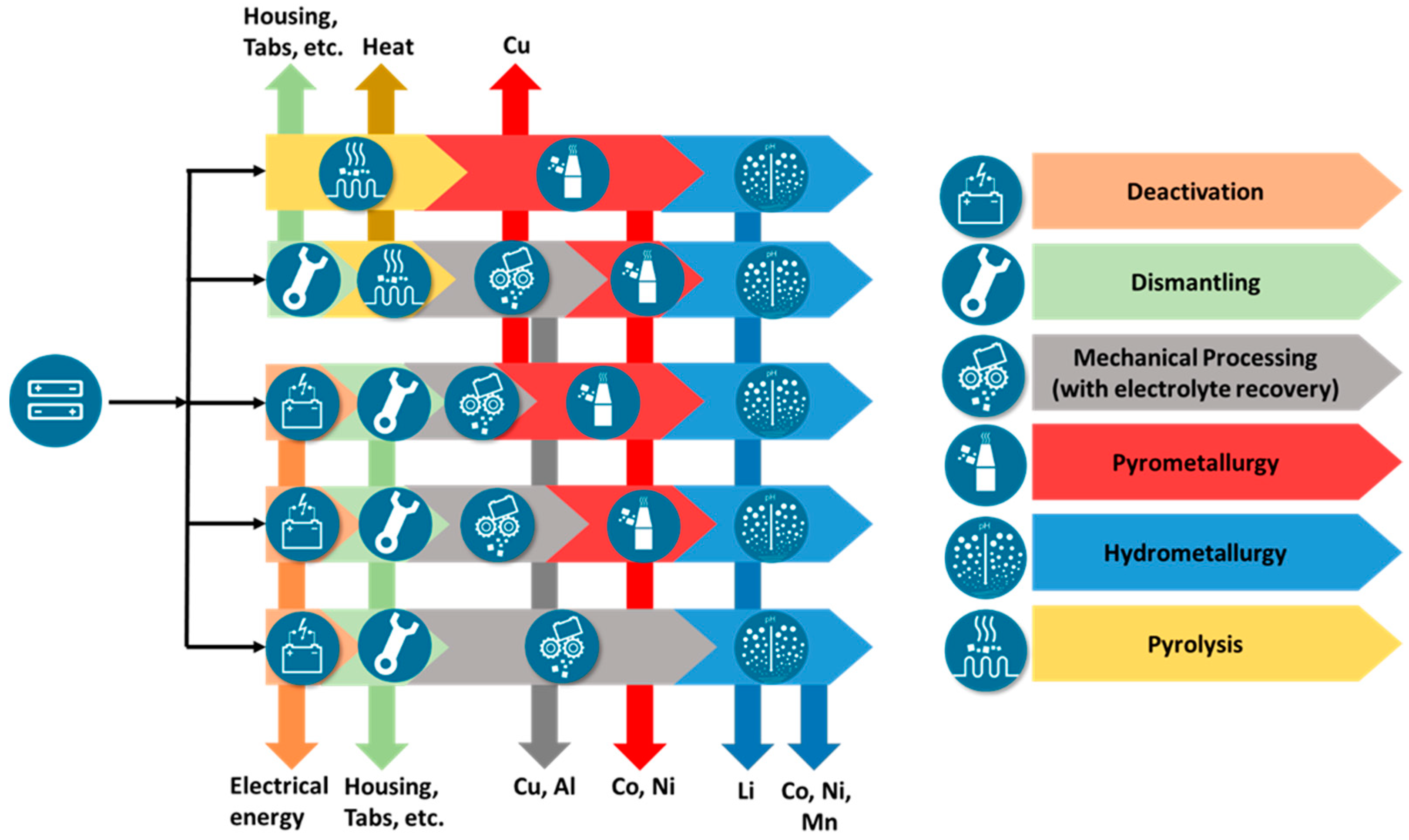

3. State of the Art Recycling Processes for Lithium-Ion Batteries

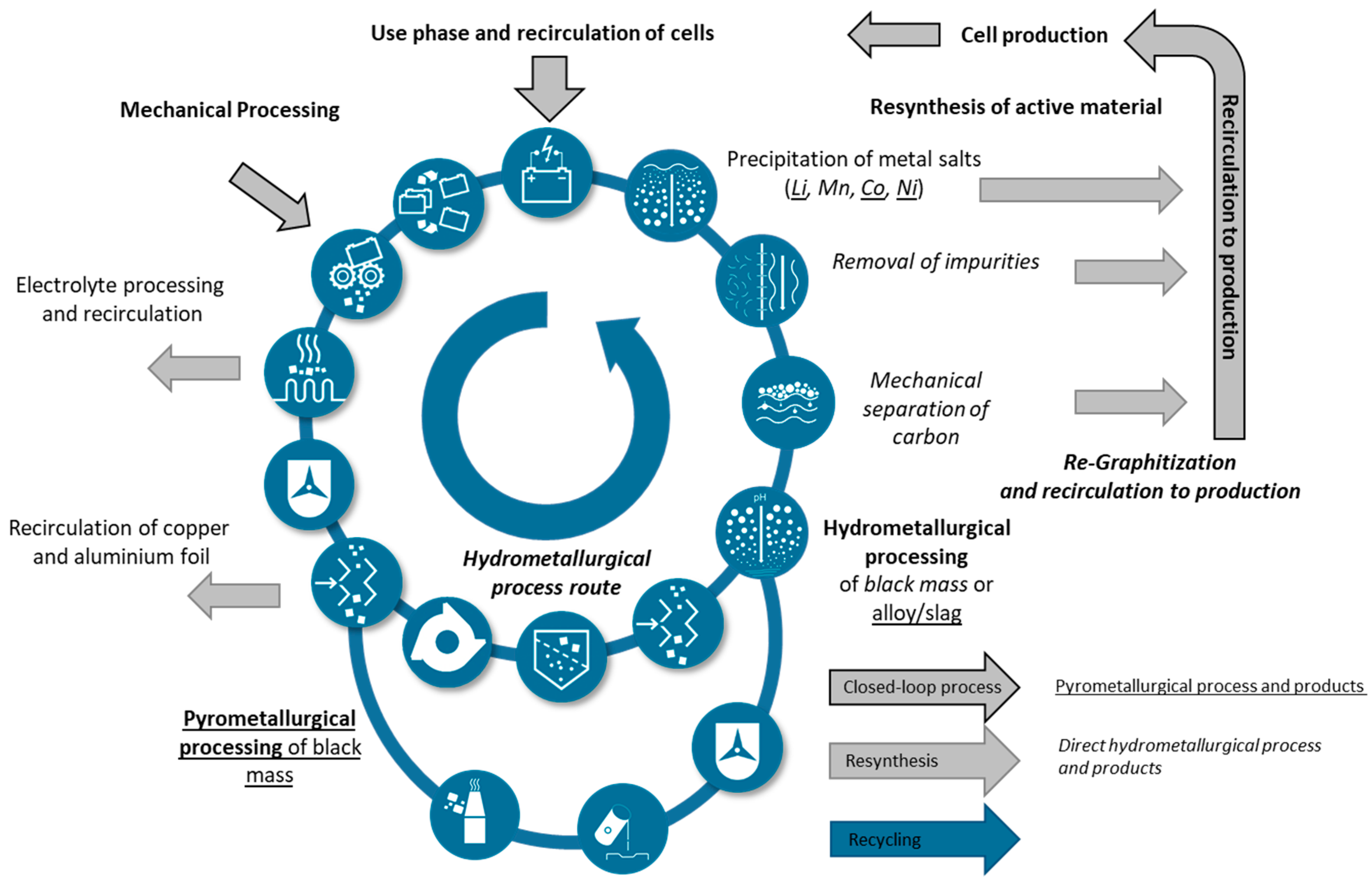

3.1. Mechanical–Hydrometallurgical Recycling Technology and Challenges

3.2. Pyrometallurgical Recycling Technology and Challenges

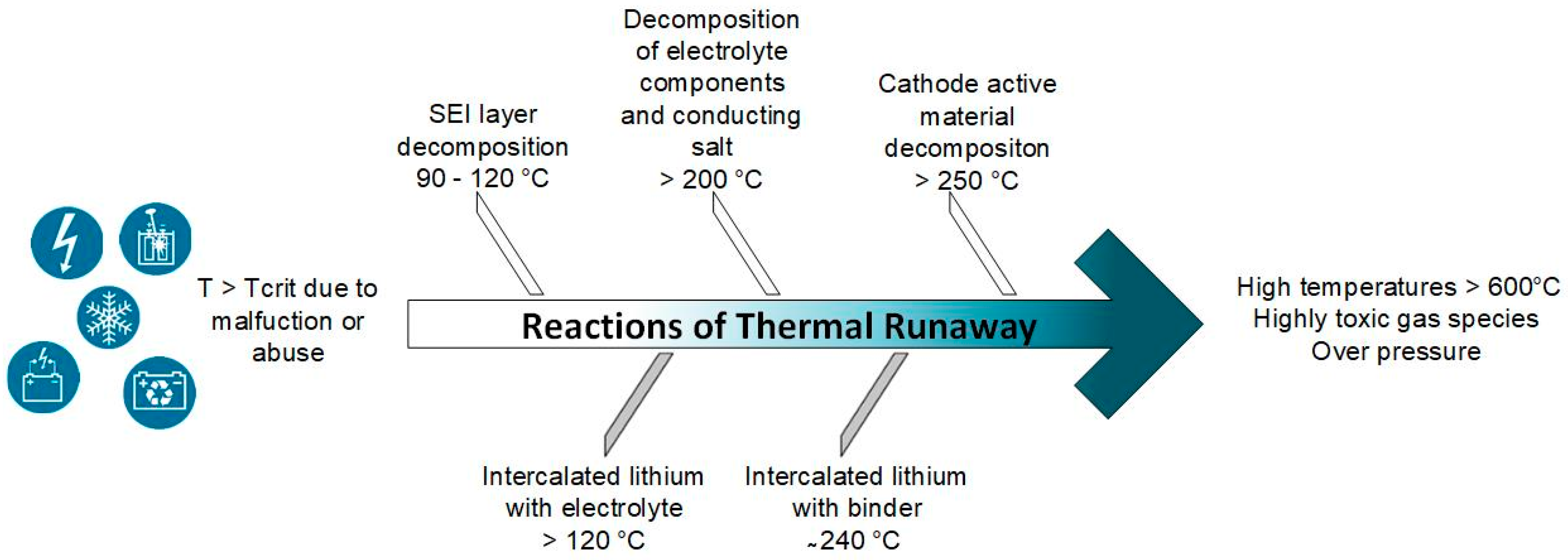

3.3. Potential Hazards of Lithium-Ion Batteries in Recycling Processes

- Direct electrical shock is one of the main types of hazard when handling batteries. A direct electric shock can cause severe skin burns at the point of entry and exit, depending on the current, voltage and type of current (AC/DC). In addition, the paralysis of muscles and, in the worst case, electrolysis of the blood may occur.

- The thermal hazards of a battery cell are mainly due to the electrolyte components used. The main components of the current electrolytes are a mixture of organic solvents (e.g., ethyl carbonate, EC; ethyl methyl carbonate, EMC; and others) and a conducting salt (lithium hexaflourophosphate, LiPF6). The carbonates used are highly flammable hydrocarbons. The reaction of LiPF6 with water can result in the highly toxic and corrosive hydrogen fluoride (HF) [59,60]. Partially high evaporation rates of electrolyte components in moderate temperature ranges and partially closed process rooms can lead to explosive mixtures in combination with an oxygen-containing atmosphere [61]. In addition, if higher temperatures have occurred, the reaction products of reactions of the different components of a battery cell can also lead to fire and explosions in the processes (hydrogen, methane, carbon monoxide).

- Chemical hazards of battery cells are mainly determined by the ingredients but also by accessible reaction products in case of failure. The materials and products have irritating, human-toxic, carcinogenic, respiratory, environmentally harmful, and water-damaging effects. Particularly noteworthy in this case is the active material of the cathode. The cathode active materials consist mainly of lithium transition metal oxides such as NMC and NCA or also lithium metal phosphates, especially lithium iron phosphate (LFP). Especially the significant amounts of the heavy metals nickel and cobalt are both known to be carcinogenic and toxic for mammals. In addition, the small particle size (10–15 µm) of these can increase the exposure through the human respiratory system.

4. Circular Economy in the Context of Battery Production

- Almost 100% of end-of-life batteries must be collected and recycled at the latest after any second-life application [73]. The expected lifetime of batteries in the automotive sector is at least 8 years, and, thus, in the mean, it tends to be more than 10 years. In the future, the lifetime will probably increase further. However, this value is highly dependent on the loads (fast charging, temperatures, etc.) [81]. Before recycling, it is important to check whether a second-life application can be reasonable.

- The condition of the batteries, especially the material composition, must be documented for the subsequent recycling process [82]. Alternatively, a uniform interface for reading out specific battery data could be implemented in the systems.

- With regard to the material composition of batteries, robust recycling processes must be developed and industrially implemented, especially with regard to future battery generations.

- The re-synthesis and eventual reconditioning of the active materials, such as Si-containing anode materials and cathode materials from lithium mixed oxides, has to function on a large scale without any loss of performance of the later battery. The synthesis processes should be as robust as possible against material contamination [83,84].

- The design of the battery cells should not only be based on requirements such as performance, cost, and safety, but also on sustainability and thus recyclability [85].

- The production of the battery cells themselves must be ecologically and economically sustainable [2].

- For objective evaluation of the individual technologies, new software tools should be developed for an “as objective as possible” cost and environmental life cycle assessment of different battery cells and process technologies.

5. Perspective on Recycling and Circular Economy of Future Battery Generations

- The use of polymer electrolytes both in the cathode and in the separator results in a complex task of separation of the individual materials used. As it stands now, there are two options: On the one hand, the polymer electrolyte can be burned using thermal processes, and the materials exposed can be further processed in a similar way to classical LIB. However, the polymer-type solid electrolyte is lost. On the other hand, complex wet chemical processes can be chosen. Here, the electrolyte is dissolved in a suitable solvent, and the polymer can be recovered in the process, but it is not known today if this can be fulfilled with a sufficient quality or purity, respectively. However, the wet chemical route is not expected to be economically or environmentally viable, despite an associated increase in recycling yield.

- When using sulfidic solid electrolytes, the formation of toxic hydrogen sulfide compounds must be avoided during recycling. A mechanical separation of the solid sulfidic electrolyte from the active material is very difficult and probably not possible with the required purity or separation efficiency, respectively. Therefore, a reconditioning of the solid electrolyte and the active materials seems to be not possible from the today´s experience. In addition, the frequent use of other elements, such as germanium, makes it more difficult to recycle these substances in a pure form by hydrometallurgical processes. Therefore, complex hydrometallurgical processes are probably required to recover the different materials.

- If oxidic solid electrolytes are used in the separator and/or cathode, the electrolyte particles will be firmly sintered together. Thus, mechanical separation is associated with significantly higher costs, so that pyrometallurgical treatment of entire cells or at least larger cell fragments probably becomes more attractive compared to a mechanical/hydrometallurgical process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The European Dimension of Germany’s Energy Transition. Opportunities and Conflicts; Gawel, E.; Strunz, S.; Lehmann, P.; Purkus, A. (Eds.) Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-03374-3. [Google Scholar]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current status and challenges for automotive battery production technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Habib, K.; Hansdóttir, S.T.; Habib, H. Critical metals for electromobility: Global demand scenarios for passenger vehicles, 2015–2050. Resour. Conserv. Recycl. 2020, 154, 104603. [Google Scholar] [CrossRef]

- Behaviour of Lithium-Ion Batteries in Electric Vehicles. Battery Health, Performance, Safety, and Cost; Pistoia, G.; Liaw, B. (Eds.) Springer: Cham, Switzerland, 2018; ISBN 978-3-319-69950-9. [Google Scholar]

- Mohr, M.; Peters, J.F.; Baumann, M.; Weil, M. Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J. Ind. Ecol. 2020, 24, 1310–1322. [Google Scholar] [CrossRef]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef] [Green Version]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Zheng, Z.; Wang, Q.; Zhang, Y.; Ma, X.; Shen, C.; Xu, D.; Liu, J.; Liu, Y.; Gionet, P.; et al. Closed Loop Recycling of Electric Vehicle Batteries to Enable Ultra-high Quality Cathode Powder. Sci. Rep. 2019, 9, 173. [Google Scholar] [CrossRef] [PubMed]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef]

- Zeng, X.; Li, J.; Singh, N. Recycling of Spent Lithium-Ion Battery: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2014, 44, 1129–1165. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 437. [Google Scholar] [CrossRef]

- Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. 2020. Available online: https://ec.europa.eu/environment/waste/batteries/pdf/Proposal_for_a_Regulation_on_batteries_and_waste_batteries.pdf (accessed on 22 December 2020).

- Kwade, A.; Hagelüken, C.; Kohl, H.; Buchert, M.; Herrmann, C.; Vahle, T.; von Wittken, R.; Carrara, M.; Daelemans, S.; Ehrenberg, H.; et al. Ressourcenschonende Batteriekreisläufe—mit Circular Economy die Elektromobilität Antreiben; Acatech: München, Germany; London, UK, 2020; Available online: https://www.acatech.de/publikation/ressourcenschonende-batteriekreislaeufe/ (accessed on 22 December 2020).

- Siqi, Z.; Guangming, L.; Wenzhi, H.; Juwen, H.; Haochen, Z. Recovery methods and regulation status of waste lithium-ion batteries in China: A mini review. Waste Manag. Res. 2019, 37, 1142–1152. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO 4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Georgi-Maschler, T.; Friedrich, B.; Weyhe, R.; Heegn, H.; Rutz, M. Development of a recycling process for Li-ion batteries. J. Power Sources 2012, 207, 173–182. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Vonderstein, C.; Dertmann, C.; Klimko, J.; Oráč, D.; Miškufová, A.; Havlík, T.; Friedrich, B. A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 1: Production of Lithium Concentrates in an Electric Arc Furnace. Metals 2020, 10, 1069. [Google Scholar] [CrossRef]

- Hanisch, C.; Loellhoeffel, T.; Diekmann, J.; Markley, K.J.; Haselrieder, W.; Kwade, A. Recycling of lithium-ion batteries: A novel method to separate coating and foil of electrodes. J. Clean. Prod. 2015, 108, 301–311. [Google Scholar] [CrossRef]

- Diekmann, J.; Hanisch, C.; Froböse, L.; Schälicke, G.; Loellhoeffel, T.; Fölster, A.-S.; Kwade, A. Ecological Recycling of Lithium-Ion Batteries from Electric Vehicles with Focus on Mechanical Processes. J. Electrochem. Soc. 2017, 164, A6184–A6191. [Google Scholar] [CrossRef]

- Chagnes, A.; Pospiech, B. A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J. Chem. Technol. Biotechnol. 2013, 88, 1191–1199. [Google Scholar] [CrossRef]

- Sommerville, R.; Shaw-Stewart, J.; Goodship, V.; Rowson, N.; Kendrick, E. A review of physical processes used in the safe recycling of lithium ion batteries. Sustain. Mater. Technol. 2020, 25, e00197. [Google Scholar] [CrossRef]

- Sojka, R.T. Safe Treatment of Lithium-based Batteries through Thermal Conditioning. In Recycling und Sekundärrohstoffe, Band 13; Thomé-Kozmiensky, E., Holm, O., Friedrich, B., Goldmann, D., Eds.; Thomé-Kozmiensky Verlag GmbH: Nietwerder, Germany, 2020; pp. 506–523. ISBN 3944310519. [Google Scholar]

- Hiskey, B. Metallurgy, Survey. In Encyclopedia of Chemical Technology; Kirk, R.E., Othmer, D.F., Eds.; Wiley: New York, NY, USA, 2003; ISBN 0471238961. [Google Scholar]

- Zhang, G.; Yuan, X.; He, Y.; Wang, H.; Zhang, T.; Xie, W. Recent advances in pretreating technology for recycling valuable metals from spent lithium-ion batteries. J. Hazard. Mater. 2020, 124332. [Google Scholar] [CrossRef]

- Träger, T.; Friedrich, B.; Weyhe, R. Recovery Concept of Value Metals from Automotive Lithium-Ion Batteries. Chem. Ing. Tech. 2015, 87, 1550–1557. [Google Scholar] [CrossRef]

- Diekmann, J.; Hanisch, C.; Loellhoeffel, T.; Schalicke, G.; Kwade, A. (Invited) Ecologically Friendly Recycling of Lithium-Ion Batteries—The LithoRec Process. ECS Trans. 2016, 73, 1–9. [Google Scholar] [CrossRef]

- Kwade, A.; Diekmann, J. Recycling of Lithium-Ion Batteries; Springer International Publishing: Cham, Germany, 2018; ISBN 978-3-319-70571-2. [Google Scholar]

- Dai, Q.; Spangenberger, J.; Ahmed, S.; Gaines, L.; Kelly, J.C.; Wang, M. EverBatt. A Closed-loop Battery Recycling Cost and Environmental Impacts Model; Argonne National Laboratory: Lemont, IL, USA, 2019. Available online: https://publications.anl.gov/anlpubs/2019/0-7/153050.pdf (accessed on 3 February 2021).

- Ciez, R.E.; Whitacre, J.F. Examining different recycling processes for lithium-ion batteries. Nat. Sustain. 2019, 2, 148–156. [Google Scholar] [CrossRef]

- Zhao, X.; Lehto, V.-P. Challenges and prospects of nanosized silicon anodes in lithium-ion batteries. Nanotechnology 2021, 32, 42002. [Google Scholar] [CrossRef]

- Heck, C.A.; Horstig, M.-W.; von Huttner, F.; Mayer, J.K.; Haselrieder, W.; Kwade, A. Review—Knowledge-Based Process Design for High Quality Production of NCM811 Cathodes. J. Electrochem. Soc. 2020, 167, 160521. [Google Scholar] [CrossRef]

- Cheruvally, G. Lithium Iron Phosphate. A Promising Cathode-Active Material for Lithium Secondary Batteries; Trans Tech Publishers: Zurich, Switzerland, 2008; ISBN 978-0-87849-477-4. [Google Scholar]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; van den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery—Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Manthiram, A.; Yu, X.; Wang, S. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2017, 2, 294. [Google Scholar] [CrossRef]

- Wild, M.; O’Neill, L.; Zhang, T.; Purkayastha, R.; Minton, G.; Marinescu, M.; Offer, G.J. Lithium sulfur batteries, a mechanistic review. Energy Environ. Sci. 2015, 8, 3477–3494. [Google Scholar] [CrossRef]

- Golubkov, A.W.; Fuchs, D.; Wagner, J.; Wiltsche, H.; Stangl, C.; Fauler, G.; Voitic, G.; Thaler, A.; Hacker, V. Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes. RSC Adv. 2014, 4, 3633–3642. [Google Scholar] [CrossRef] [Green Version]

- Olivetti, E.A.; Ceder, G.; Gaustad, G.G.; Fu, X. Lithium-Ion Battery Supply Chain Considerations: Analysis of Potential Bottlenecks in Critical Metals. Joule 2017, 1, 229–243. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.-G.; Fujiki, S.; Jung, C.; Suzuki, N.; Yashiro, N.; Omoda, R.; Ko, D.-S.; Shiratsuchi, T.; Sugimoto, T.; Ryu, S.; et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 2020, 5, 299–308. [Google Scholar] [CrossRef]

- Kato, Y.; Hori, S.; Saito, T.; Suzuki, K.; Hirayama, M.; Mitsui, A.; Yonemura, M.; Iba, H.; Kanno, R. High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 2016, 1, 652. [Google Scholar] [CrossRef]

- Wang, H.; Sheng, L.; Yasin, G.; Wang, L.; Xu, H.; He, X. Reviewing the current status and development of polymer electrolytes for solid-state lithium batteries. Energy Storage Mater. 2020, 33, 188–215. [Google Scholar] [CrossRef]

- Son, I.H.; Hwan Park, J.; Kwon, S.; Park, S.; Rümmeli, M.H.; Bachmatiuk, A.; Song, H.J.; Ku, J.; Choi, J.W.; Choi, J.-M.; et al. Silicon carbide-free graphene growth on silicon for lithium-ion battery with high volumetric energy density. Nat. Commun. 2015, 6, 7393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, T.; Cheng, H.; Choi, H.; Lee, J.-H.; Han, H.; Lee, D.H.; Yoo, D.S.; Kwon, M.-S.; Choi, J.-M.; Doo, S.G.; et al. Si/Ge double-layered nanotube array as a lithium ion battery anode. ACS Nano 2012, 6, 303–309. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Li, M.; Chen, R.; Wu, F.; Amine, K.; Lu, J. The Recycling of Spent Lithium-Ion Batteries: A Review of Current Processes and Technologies. Electrochem. Energ. Rev. 2018, 1, 461–482. [Google Scholar] [CrossRef]

- Zhang, T.; He, Y.; Ge, L.; Fu, R.; Zhang, X.; Huang, Y. Characteristics of wet and dry crushing methods in the recycling process of spent lithium-ion batteries. J. Power Sources 2013, 240, 766–771. [Google Scholar] [CrossRef]

- Zou, H.; Gratz, E.; Apelian, D.; Wang, Y. A novel method to recycle mixed cathode materials for lithium ion batteries. Green Chem. 2013, 15, 1183. [Google Scholar] [CrossRef]

- Larouche, F.; Tedjar, F.; Amouzegar, K.; Houlachi, G.; Bouchard, P.; Demopoulos, G.P.; Zaghib, K. Progress and Status of Hydrometallurgical and Direct Recycling of Li-Ion Batteries and Beyond. Materials 2020, 13, 801. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical Processes for Recycling Spent Lithium-Ion Batteries: A Critical Review. ACS Sustain. Chem. Eng. 2018, 6, 13611–13627. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, M.; Wang, Q.; Zhang, Y.; Ma, X.; Shen, C.; Xu, D.; Liu, J.; Liu, Y.; Gionet, P.; et al. High Performance Cathode Recovery from Different Electric Vehicle Recycling Streams. ACS Sustain. Chem. Eng. 2018, 6, 13977–13982. [Google Scholar] [CrossRef]

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 2019, 5, 402–416. [Google Scholar] [CrossRef]

- Sloop, S.; Crandon, L.; Allen, M.; Koetje, K.; Reed, L.; Gaines, L.; Sirisaksoontorn, W.; Lerner, M. A direct recycling case study from a lithium-ion battery recall. Sustain. Mater. Technol. 2020, 25, e00152. [Google Scholar] [CrossRef]

- Brückner, L.; Frank, J.; Elwert, T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals 2020, 10, 1107. [Google Scholar] [CrossRef]

- Xiao, S.; Ren, G.; Xie, M.; Pan, B.; Fan, Y.; Wang, F.; Xia, X. Recovery of Valuable Metals from Spent Lithium-Ion Batteries by Smelting Reduction Process Based on MnO–SiO2–Al2O3 Slag System. J. Sustain. Metall. 2017, 3, 703–710. [Google Scholar] [CrossRef]

- Assefi, M.; Maroufi, S.; Yamauchi, Y.; Sahajwalla, V. Pyrometallurgical recycling of Li-ion, Ni–Cd and Ni–MH batteries: A minireview. Curr. Opin. Green Sustain. Chem. 2020, 24, 26–31. [Google Scholar] [CrossRef]

- Encyclopedia of Chemical Technology; Kirk, R.E.; Othmer, D.F. (Eds.) Wiley: New York, NY, USA, 2003; ISBN 0471238961. [Google Scholar]

- Werner, D.; Peuker, U.A.; Mütze, T. Recycling Chain for Spent Lithium-Ion Batteries. Metals 2020, 10, 316. [Google Scholar] [CrossRef] [Green Version]

- Iclodean, C.; Varga, B.; Burnete, N.; Cimerdean, D.; Jurchiş, B. Comparison of Different Battery Types for Electric Vehicles. Iop Conf. Ser. Mater. Sci. Eng. 2017, 252, 12058. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Tebbe, J.L.; Fuerst, T.F.; Musgrave, C.B. Mechanism of hydrofluoric acid formation in ethylene carbonate electrolytes with fluorine salt additives. J. Power Sources 2015, 297, 427–435. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Zhuang, G.V.; Ross, P.N. Thermal stability of LiPF6 salt and Li-ion battery electrolytes containing LiPF6. J. Power Sources 2006, 161, 573–579. [Google Scholar] [CrossRef] [Green Version]

- Nedjalkov, A.; Meyer, J.; Köhring, M.; Doering, A.; Angelmahr, M.; Dahle, S.; Sander, A.; Fischer, A.; Schade, W. Toxic Gas Emissions from Damaged Lithium Ion Batteries—Analysis and Safety Enhancement Solution. Batteries 2016, 2, 5. [Google Scholar] [CrossRef]

- Lamb, J.; Orendorff, C.J. Evaluation of mechanical abuse techniques in lithium ion batteries. J. Power Sources 2014, 247, 189–196. [Google Scholar] [CrossRef]

- Feng, X.; Sun, J.; Ouyang, M.; Wang, F.; He, X.; Lu, L.; Peng, H. Characterization of penetration induced thermal runaway propagation process within a large format lithium ion battery module. J. Power Sources 2015, 275, 261–273. [Google Scholar] [CrossRef]

- Diekmann, J.; Doose, S.; Weber, S.; Münch, S.; Haselrieder, W.; Kwade, A. Development of a New Procedure for Nail Penetration of Lithium-Ion Cells to Obtain Meaningful and Reproducible Results. J. Electrochem. Soc. 2020, 167, 90504. [Google Scholar] [CrossRef]

- Doose, S.; Haselrieder, W.; Kwade, A. Effects of the Nail Geometry and Humidity on the Nail Penetration of High-Energy Density Lithium Ion Batteries. Batteries 2021, 7, 6. [Google Scholar] [CrossRef]

- Yoon, T.; Milien, M.S.; Parimalam, B.S.; Lucht, B.L. Thermal Decomposition of the Solid Electrolyte Interphase (SEI) on Silicon Electrodes for Lithium Ion Batteries. Chem. Mater. 2017, 29, 3237–3245. [Google Scholar] [CrossRef]

- Campion, C.L.; Li, W.; Lucht, B.L. Thermal Decomposition of LiPF6-Based Electrolytes for Lithium-Ion Batteries. J. Electrochem. Soc. 2005, 152, A2327. [Google Scholar] [CrossRef]

- Diaz, F.; Wang, Y.; Weyhe, R.; Friedrich, B. Gas generation measurement and evaluation during mechanical processing and thermal treatment of spent Li-ion batteries. Waste Manag. 2019, 84, 102–111. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Grützke, M.; Mönnighoff, X.; Horsthemke, F.; Kraft, V.; Winter, M.; Nowak, S. Extraction of lithium-ion battery electrolytes with liquid and supercritical carbon dioxide and additional solvents. RSC Adv. 2015, 5, 43209–43217. [Google Scholar] [CrossRef] [Green Version]

- Nowak, S.; Winter, M. The Role of Sub- and Supercritical CO2 as “Processing Solvent” for the Recycling and Sample Preparation of Lithium Ion Battery Electrolytes. Molecules 2017, 22, 403. [Google Scholar] [CrossRef] [PubMed]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2020, 69, 37. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, e01866. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Richa, K.; Babbitt, C.W.; Gaustad, G. Eco-Efficiency Analysis of a Lithium-Ion Battery Waste Hierarchy Inspired by Circular Economy. J. Ind. Ecol. 2017, 21, 715–730. [Google Scholar] [CrossRef]

- Xie, Y.H.; Yu, H.J.; Ou, Y.N.; Li, C.D. Environmental impact assessment of recycling waste traction battery. Inorg. Chem. Ind. 2015, 47, 43–46. [Google Scholar]

- Heulens, J.; Van Horebeek, D.; Quix, M.; Brouwe, S. Process for smelting lithium-ion batteries. EP2015/067809, 8 March 2015. [Google Scholar]

- Xu, P.; Dai, Q.; Gao, H.; Liu, H.; Zhang, M.; Li, M.; Chen, Y.; An, K.; Meng, Y.S.; Liu, P.; et al. Efficient Direct Recycling of Lithium-Ion Battery Cathodes by Targeted Healing. Joule 2020, 4, 2609–2626. [Google Scholar] [CrossRef]

- Gao, H.; Yan, Q.; Xu, P.; Liu, H.; Li, M.; Liu, P.; Luo, J.; Chen, Z. Efficient Direct Recycling of Degraded LiMn2O4 Cathodes by One-Step Hydrothermal Relithiation. ACS Appl. Mater. Interfaces 2020, 12, 51546–51554. [Google Scholar] [CrossRef]

- Wang, T.; Luo, H.; Bai, Y.; Li, J.; Belharouak, I.; Dai, S. Direct Recycling of Spent NCM Cathodes through Ionothermal Lithiation. Adv. Energy Mater. 2020, 10, 2001204. [Google Scholar] [CrossRef]

- Hanisch, C.; Schunemann, J.-H.; Diekmann, J.; Westphal, B.; Loellhoeffel, T.; Prziwara, P.F.; Haselrieder, W.; Kwade, A. In-Production Recycling of Active Materials from Lithium-Ion Battery Scraps. ECS Trans. 2015, 64, 131–145. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Bai, Y.; Muralidharan, N.; Sun, Y.-K.; Passerini, S.; Stanley Whittingham, M.; Belharouak, I. Energy and environmental aspects in recycling lithium-ion batteries: Concept of Battery Identity Global Passport. Mater. Today 2020, 41, 304–315. [Google Scholar] [CrossRef]

- Krüger, S.; Hanisch, C.; Kwade, A.; Winter, M.; Nowak, S. Effect of impurities caused by a recycling process on the electrochemical performance of Li[Ni0.33Co0.33Mn0.33]O2. J. Electroanal. Chem. 2014, 726, 91–96. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, Y.; Yao, Z.; Vanaphuti, P.; Ma, X.; Bong, S.; Chen, M.; Liu, Y.; Cheng, F.; Yang, Z.; et al. Systematic Study of Al Impurity for NCM622 Cathode Materials. ACS Sustain. Chem. Eng. 2020, 8, 9875–9884. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Rothermel, S.; Evertz, M.; Kasnatscheew, J.; Qi, X.; Grützke, M.; Winter, M.; Nowak, S. Graphite Recycling from Spent Lithium-Ion Batteries. ChemSusChem 2016, 9, 3473–3484. [Google Scholar] [CrossRef] [PubMed]

| Amounts of Materials in Each Battery Type (%) | Type I (High Ni-NMC) [37,38] (%) | Type II (e.g., LFP) [37,38] (%) | Type III (SSB) [39] (%) | Type IV (LiS) (%) |

|---|---|---|---|---|

| Housing | 22 (cylindrical) | 27 (cylindrical) | 27 (pouch) | 34 (pouch) |

| Cathode current collector | 7 (Al) | 6 (Al) | 4 (Al) | 5 (Al) |

| Cathode active material | 26 (high Ni content, i.e., NMC 811) | 25 (e.g., Fe content, i.e., LFP) | 42 (high Ni content, i.e., NMC 90505) | 21 (S-C composite) |

| Anode current collector | 17 (Cu) | 10 (Cu) | 10 (stainless steel) | 14 (Cu) |

| Anode active material | 15 (C/Si) | 13 (C) | 3 (Ag-C composite) | 7 (Li) |

| Electrolyte | 10 (liquid) | 16 (liquid) | 13 (solid, Li6PS5Cl) | 19 (solid, Li6PS5Cl) |

| Separator | 3 | 3 |

| Classic Electrolyte | Oxides | Sulfides | Polymeres | |

|---|---|---|---|---|

| Aggregate state | liquid | solid | solid | solid |

| Conducting salt | 1M LiPF6 | LiTFSI | ||

| Liquid organic solvents | EC, EMC, DMC, PC | |||

| Solid electrolyte compounds | LLZO, LATP | e.g., Li3PS4, Li6PS5Cl, Li10SnP2S12 [40] | e.g., PEO, PC, PS, and variations [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doose, S.; Mayer, J.K.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291. https://doi.org/10.3390/met11020291

Doose S, Mayer JK, Michalowski P, Kwade A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals. 2021; 11(2):291. https://doi.org/10.3390/met11020291

Chicago/Turabian StyleDoose, Stefan, Julian K. Mayer, Peter Michalowski, and Arno Kwade. 2021. "Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations" Metals 11, no. 2: 291. https://doi.org/10.3390/met11020291

APA StyleDoose, S., Mayer, J. K., Michalowski, P., & Kwade, A. (2021). Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals, 11(2), 291. https://doi.org/10.3390/met11020291