Rotary Friction Welding of Inconel 718 to Inconel 600

Abstract

1. Introduction

2. Experimental Techniques

3. Results and Discussion

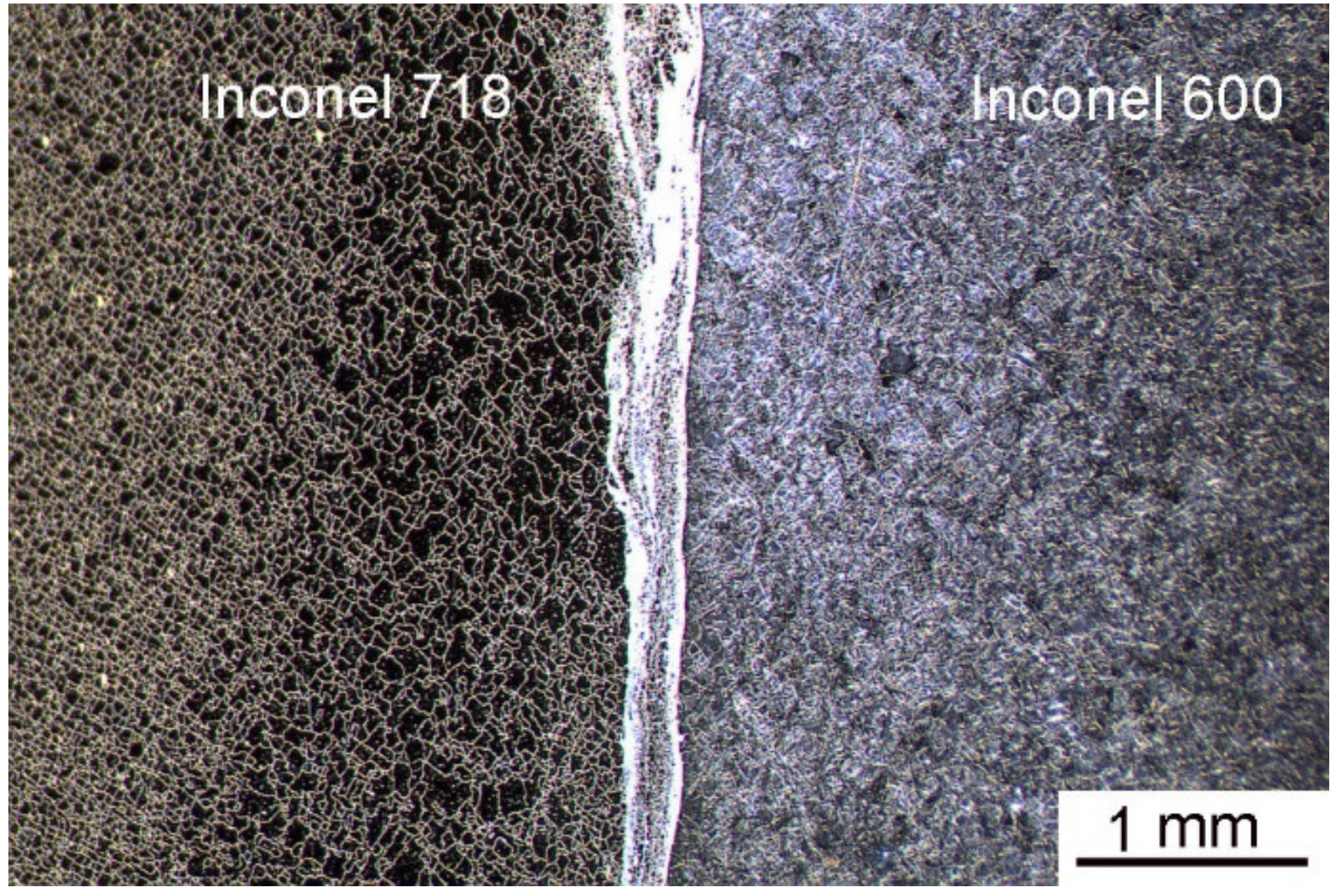

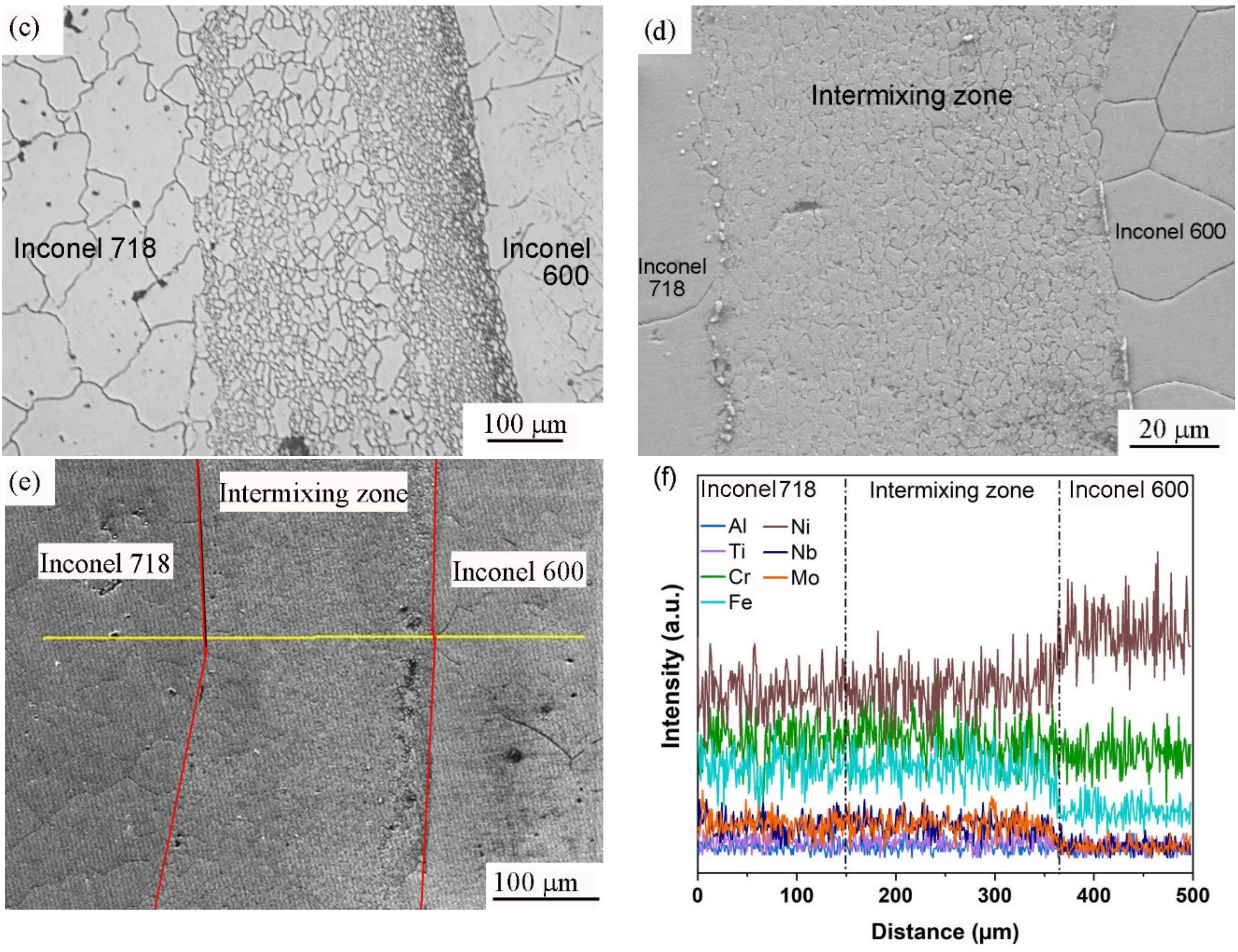

3.1. Microstructure

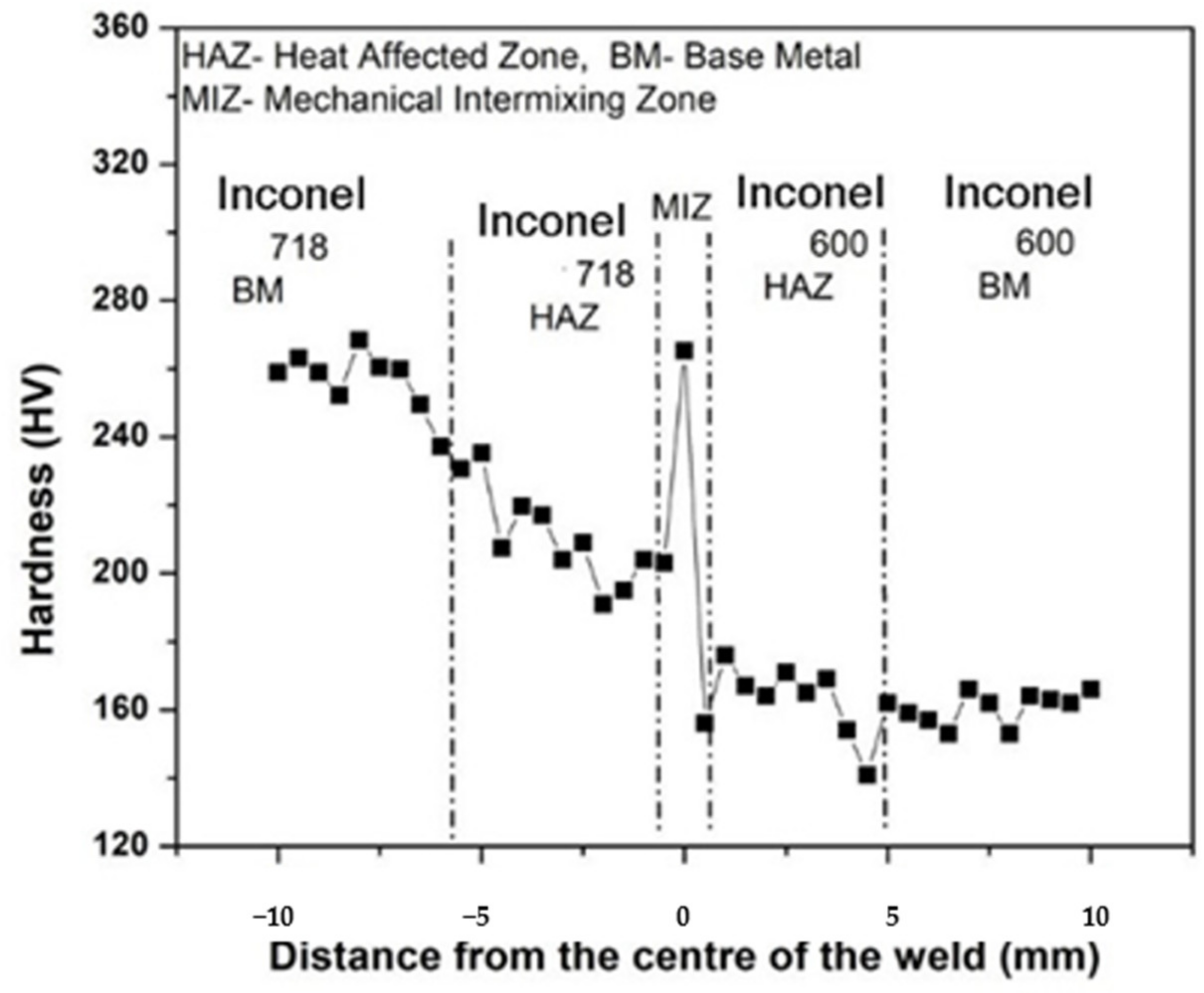

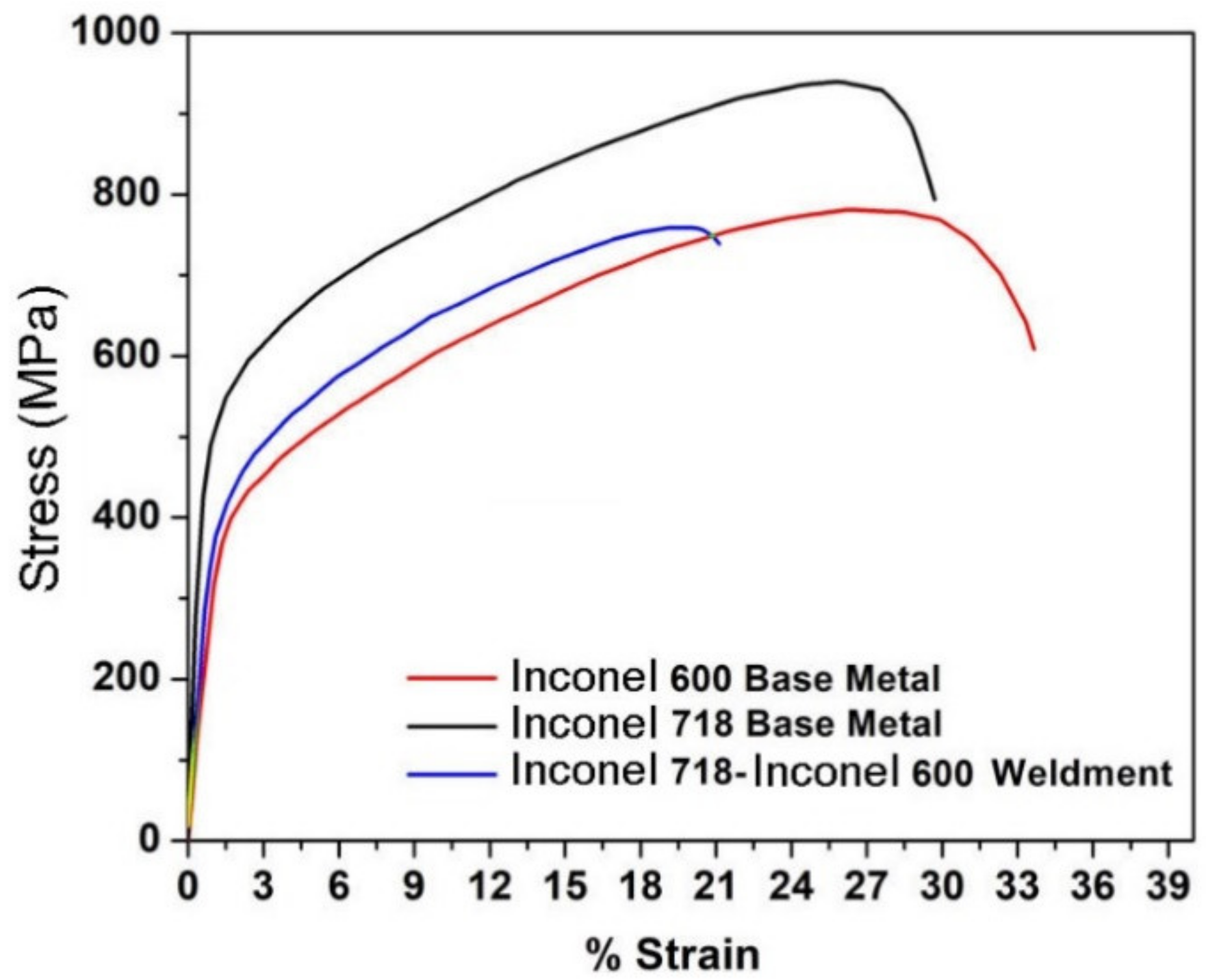

3.2. Mechanical Properties

4. Conclusions

- i.

- Friction welding can be readily used for joining Inconel 718 to Inconel 600. The welds did not suffer from major cracking problems. The welds were also free from undesirable elemental segregation and Laves formations.

- ii.

- No major undesirable microstructural changes took place in the HAZ of the Inconel 718 or Inconel 600 during friction welding. However, both of the alloys underwent some grain coarsening next to the weld interface.

- iii.

- The dissimilar weld was characterized by a narrow mechanical intermixing zone at the interface. In this zone, severe plastic deformation at high temperatures resulted in dynamic recrystallization leading to very fine equiaxed grains. Consequently, this zone displayed significantly higher hardness.

- iv.

- In an as-welded condition, Inconel 718/Inconel 600 dissimilar friction welds showed impressive room temperature tensile properties. The weld failed in the HAZ of the Inconel 718 due to significant grain coarsening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gorr, B.; Müller, F.; Azim, M.; Christ, H.J.; Müller, T.; Chen, H.; Kauffmann, A.; Heilmaier, M. High-Temperature Oxidation Behavior of Refractory High-Entropy Alloys: Effect of Alloy Composition. Oxid. Met. 2017, 88, 339–349. [Google Scholar] [CrossRef]

- Reed, R.C.; Rae, C.M.F. Physical Metallurgy of the Nickel-Based Superalloys, 5th ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 1, ISBN 9780444537713. [Google Scholar]

- Bamford, W.; Hall, J. A Review of Alloy 600 Cracking in Operating Nuclear Plants Including Alloy 82 and 182 Weld Behavior. In Proceedings of the 12th International Conference on Nuclear Engineering, ICONE12-49520, Arlington, VA, USA, 25–29 April 2004; pp. 1–9. [Google Scholar]

- Sato, Y.S.; Arkom, P.; Kokawa, H.; Nelson, T.W.; Steel, R.J. Effect of Microstructure on Properties of Friction Stir Welded Inconel Alloy 600. Mater. Sci. Eng. A 2008, 477, 250–258. [Google Scholar] [CrossRef]

- Wang, C.; Li, R. Effect of Double Aging Treatment on Structure in Inconel 718 Alloy. J. Mater. Sci. 2004, 39, 2593–2595. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; ISBN 9781118230701. [Google Scholar]

- Satyanarayana, V.V.; Reddy, G.M.; Mohandas, T. Dissimilar Metal Friction Welding of Austenitic-Ferritic Stainless Steels. J. Mater. Process. Technol. 2005, 160, 128–137. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Venugopal Reddy, A.; Prasad Rao, K.; Reddy, G.M.; Sarin Sundar, J.K. Microstructure and Tensile Properties of Inconel 718 Pulsed Nd-YAG Laser Welds. J. Mater. Process. Technol. 2005, 167, 73–82. [Google Scholar] [CrossRef]

- Huang, X.; Chaturvedi, M.C.; Richards, N.L. An Investigation of Microstructure and HAZ Microfissuring of Cast Alloy 718. In Proceedings of the Superalloys 718, 625, 706 and Various Derivatives, San Diego, CA, USA, 20–23 September 1994; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1994; pp. 871–880. [Google Scholar]

- Chamanfar, A.; Jahazi, M.; Cormier, J. A Review on Inertia and Linear Friction Welding of Ni-Based Superalloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 1639–1669. [Google Scholar] [CrossRef]

- Kong, Y.S.; Cheepu, M.; Kim, D.G. Microstructure and Mechanical Properties of Friction-Welded and Post-Heat-Treated Inconel 718. Trans. Indian Inst. Met. 2020, 73, 1449–1453. [Google Scholar] [CrossRef]

- Damodaram, R.; Raman, S.G.S.; Rao, K.P. Microstructure and Mechanical Properties of Friction Welded Alloy 718. Mater. Sci. Eng. A 2013, 560, 781–786. [Google Scholar] [CrossRef]

- Smith, M.; Bichler, L.; Gholipour, J.; Wanjara, P. Mechanical properties and microstructural evolution of in-service Inconel 718 superalloy repaired by linear friction welding. Int. J. Adv. Manuf. Technol. 2017, 90, 1931–1946. [Google Scholar] [CrossRef]

- Liu, F.C.; Nelson, T.W. Grain structure evolution, grain boundary sliding and material flow resistance in friction welding of Alloy 718. Mater. Sci. Eng. A 2018, 710, 280–288. [Google Scholar] [CrossRef]

- Gobu, N.; Mahadevan, K. Evaluation of Mechanical and Metallurgical Properties of Friction Welded Inconel 600 and Aisi 304L Austenitic Stainless Steel Dissimilar Joints. J. Manuf. Eng. 2016, 11, 171–177. Available online: http://smenec.org (accessed on 5 December 2020).

- Rehman, A.U.; Babu, N.K.; Talari, M.K.; Usmani, Y.S.; Al-Khalefah, H. Microstructure and Mechanical properties of Dissimilar Friction Welding Ti-6Al-4V Alloy to Nitinol. Metals 2021, 11, 109. [Google Scholar] [CrossRef]

- Sims, C.T.; Stoloff, N.S.; Hagel, W.C. Superalloys II: High Temperature Materials for Aerospace and Industrial Power; Wiley Sons: Hoboken, NJ, USA, 1987. [Google Scholar]

- Knap, I.; Krawczyk, R. Temperature Measurement on the Interface of a Friction-Welded Joint. Weld. Int. 2000, 14, 964–969. [Google Scholar] [CrossRef]

- Devaux, A.; Nazé, L.; Molins, R.; Pineau, A.; Organista, A.; Guédou, J.Y.; Uginet, J.F.; Héritier, P. Gamma Double Prime Precipitation Kinetic in Alloy 718. Mater. Sci. Eng. A 2008, 486, 117–122. [Google Scholar] [CrossRef]

- Murr, L.E.; Liu, G.; McClure, J.C. Dynamic Recrystallization in Friction-Stir Welding of Aluminium Alloy 1100. J. Mater. Sci. Lett. 1997, 16, 1801–1803. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of Friction Stir Welding Speed on Mechanical Properties and Microstructure of Nickel Based Super Alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Anbarasan, N.; Gupta, B.K.; Prakash, S.; Muthukumar, P.; Oyyaravelu, R.; Kumar, R.J.F.; Jerome, S. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Inconel 718. Mater. Today Proc. 2018, 5, 7716–7724. [Google Scholar] [CrossRef]

- Vincent, R. Precipitation around Welds in the Nickel-Base Superalloy, Inconel 718. Acta Metall. 1985, 33, 1205–1216. [Google Scholar] [CrossRef]

| Alloy/wt.% | Ni | Cr | Nb | Mo | Ti | Al | C | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 52.5 | 19 | 5.7 | 3 | 0.9 | 0.5 | 0.08 | Bal. | 0.18 Cu |

| Inconel 600 | 72 | 16 | - | - | - | - | 0.15 | Bal. | 0.2 Cu, 0.15 Si, 0.5 Mn |

| Friction Pressure (MPa) | Friction Time (s) | Welding Speed (rpm) | Upset Pressure (MPa) | Upset Time (s) |

|---|---|---|---|---|

| 60 | 3 | 1500 | 80 | 6 |

| Sample | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Inconel 718 base metal | 485 ± 7 | 940 ± 2 | 30 ± 2 |

| Inconel 600 base metal | 390 ± 8 | 780 ± 5 | 34 ± 1 |

| Inconel 718/600 dissimilar friction weld | 416 ± 10 | 759 ± 11 | 21 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, A.U.; Usmani, Y.; Al-Samhan, A.M.; Anwar, S. Rotary Friction Welding of Inconel 718 to Inconel 600. Metals 2021, 11, 244. https://doi.org/10.3390/met11020244

Rehman AU, Usmani Y, Al-Samhan AM, Anwar S. Rotary Friction Welding of Inconel 718 to Inconel 600. Metals. 2021; 11(2):244. https://doi.org/10.3390/met11020244

Chicago/Turabian StyleRehman, Ateekh Ur, Yusuf Usmani, Ali M. Al-Samhan, and Saqib Anwar. 2021. "Rotary Friction Welding of Inconel 718 to Inconel 600" Metals 11, no. 2: 244. https://doi.org/10.3390/met11020244

APA StyleRehman, A. U., Usmani, Y., Al-Samhan, A. M., & Anwar, S. (2021). Rotary Friction Welding of Inconel 718 to Inconel 600. Metals, 11(2), 244. https://doi.org/10.3390/met11020244