Comparison of the Flow Field in a Slab Continuous Casting Mold between the Thicknesses of 180 mm and 250 mm by High Temperature Quantitative Measurement and Numerical Simulation

Abstract

:1. Introduction

2. Rod Deflection Method and Mathematical Models

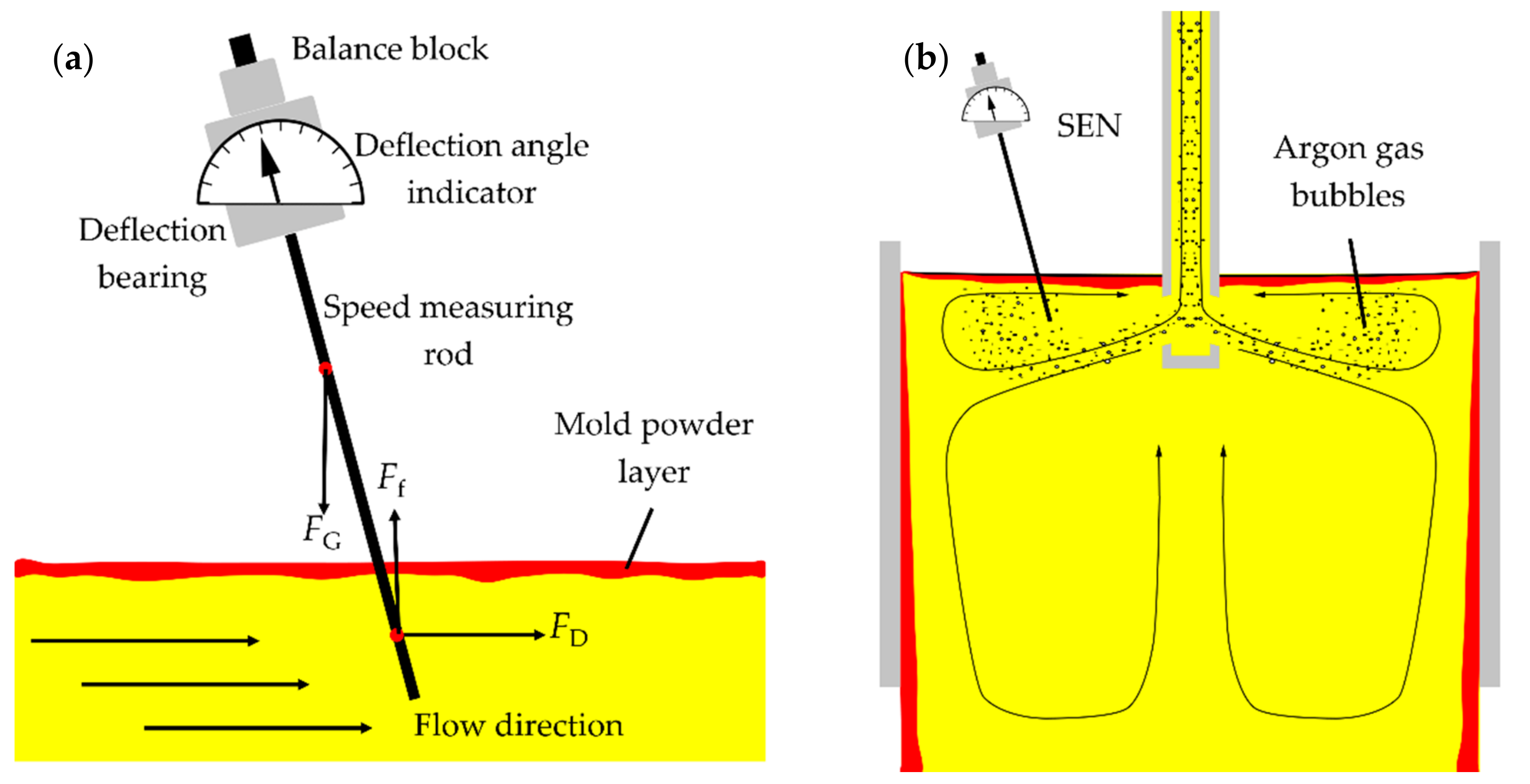

2.1. Rod Deflection Method for Measuring Velocities

2.2. Mathematical Models

2.2.1. Fluid-Phase Hydrodynamics

2.2.2. Lagrange Particle Dynamics for Modeling Argon Gas Bubbles

2.2.3. VOF Model for Tracking the Steel–Slag Interface

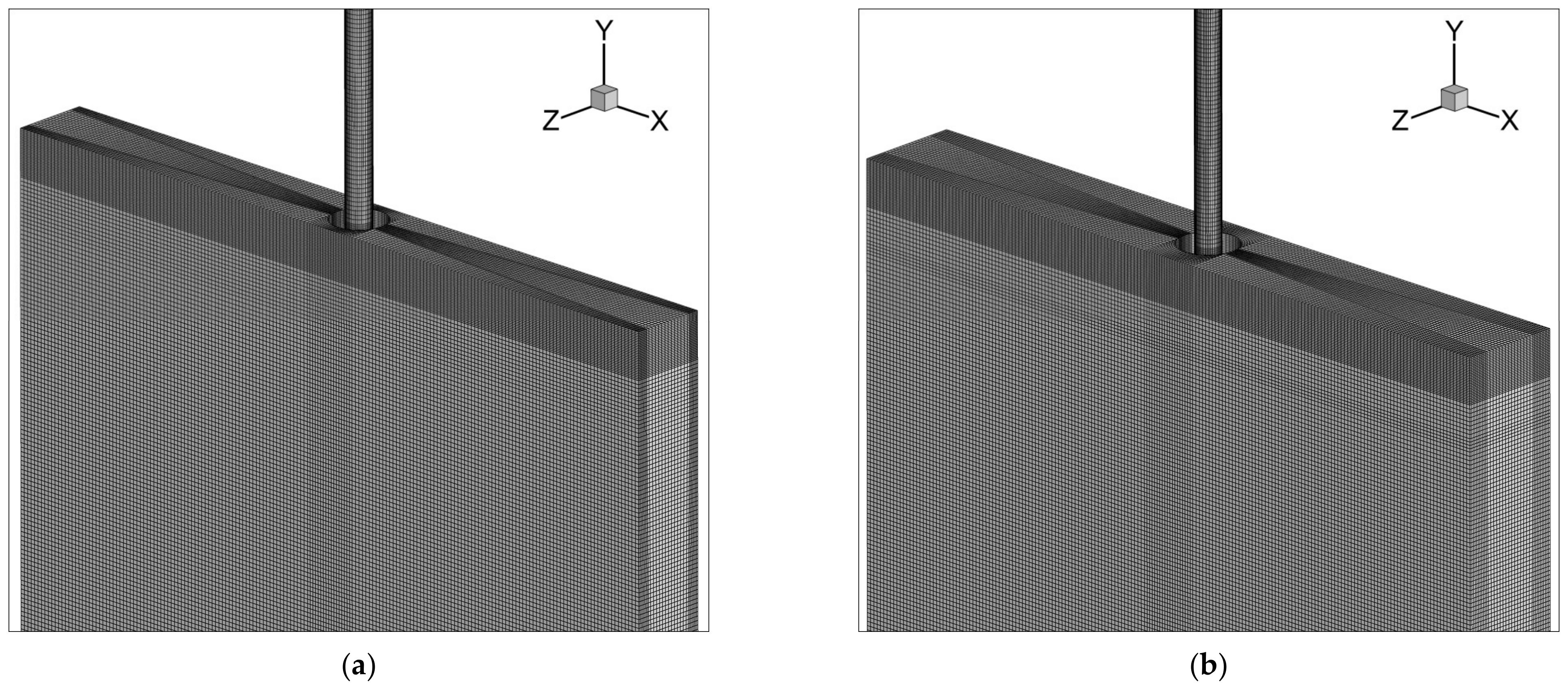

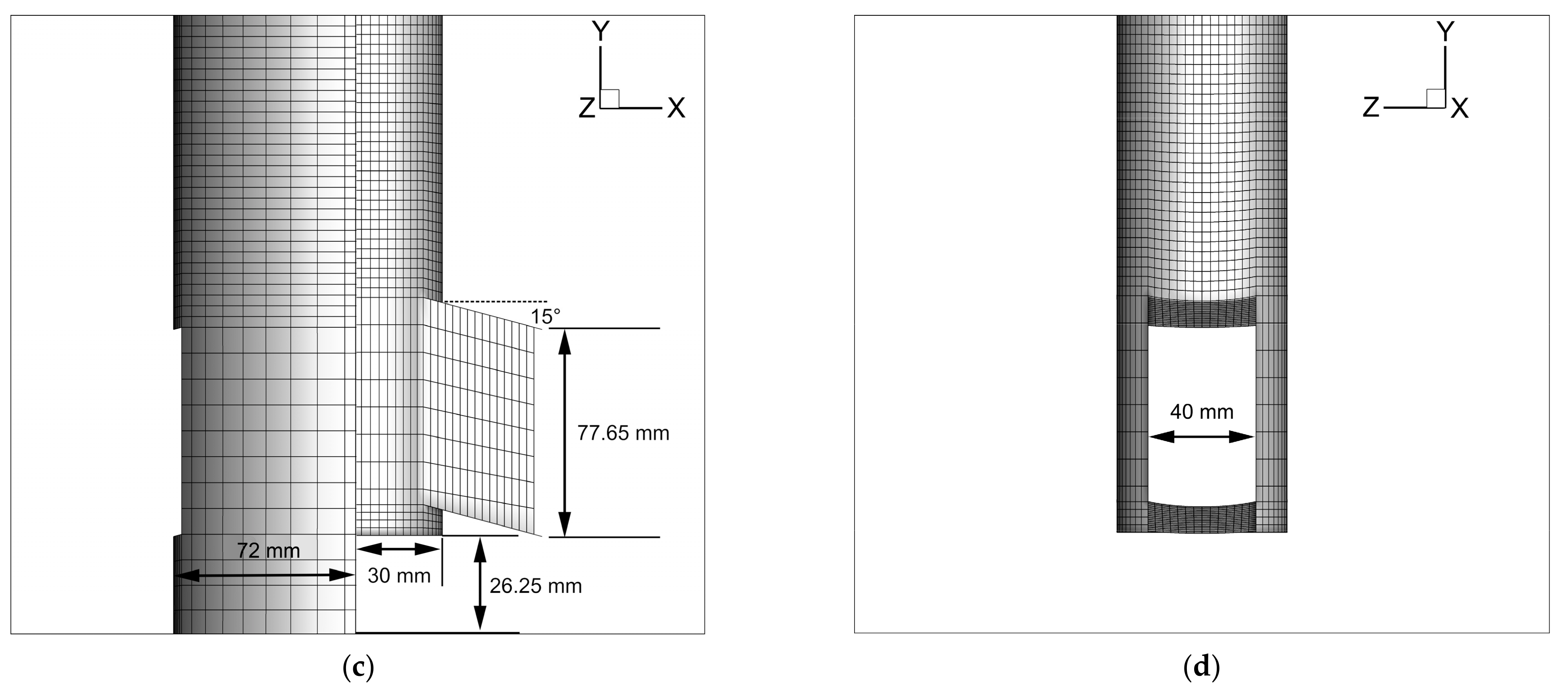

2.2.4. Detailed Parameters in Numerical Modeling

3. Results and Discussion

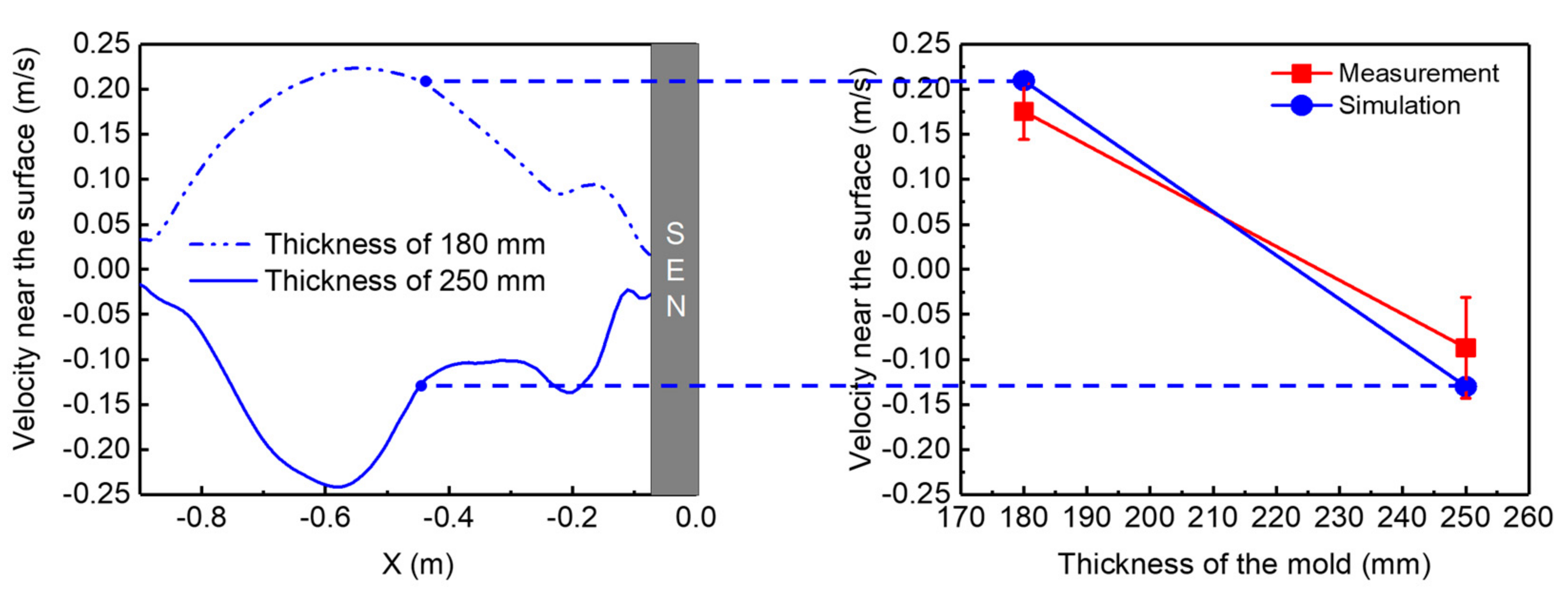

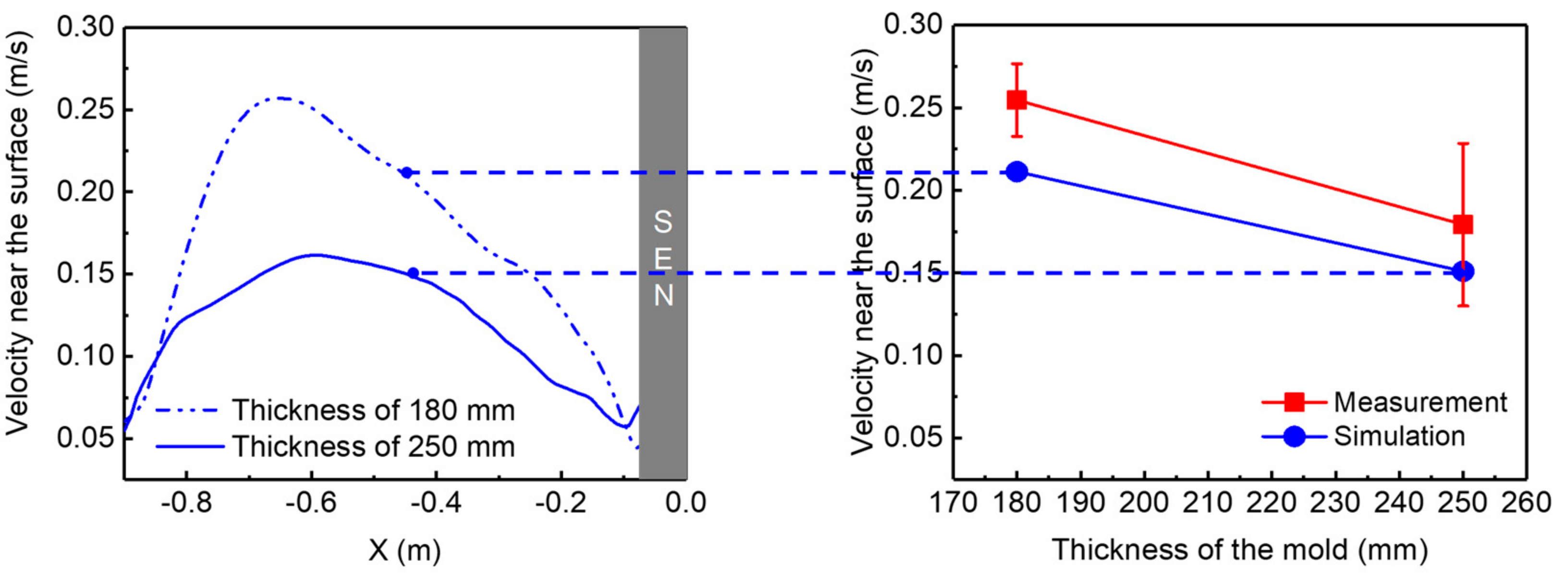

3.1. Comparison of High Temperature Quantitative Measurement and Numerical Simulation Results

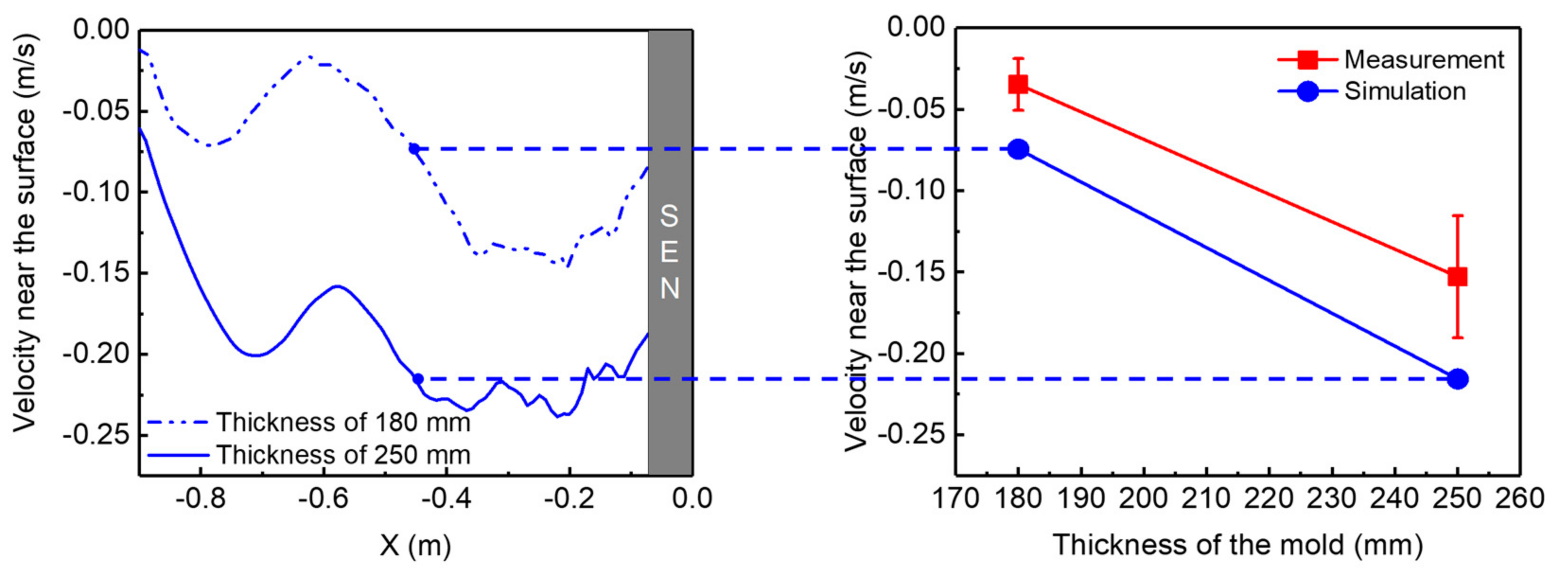

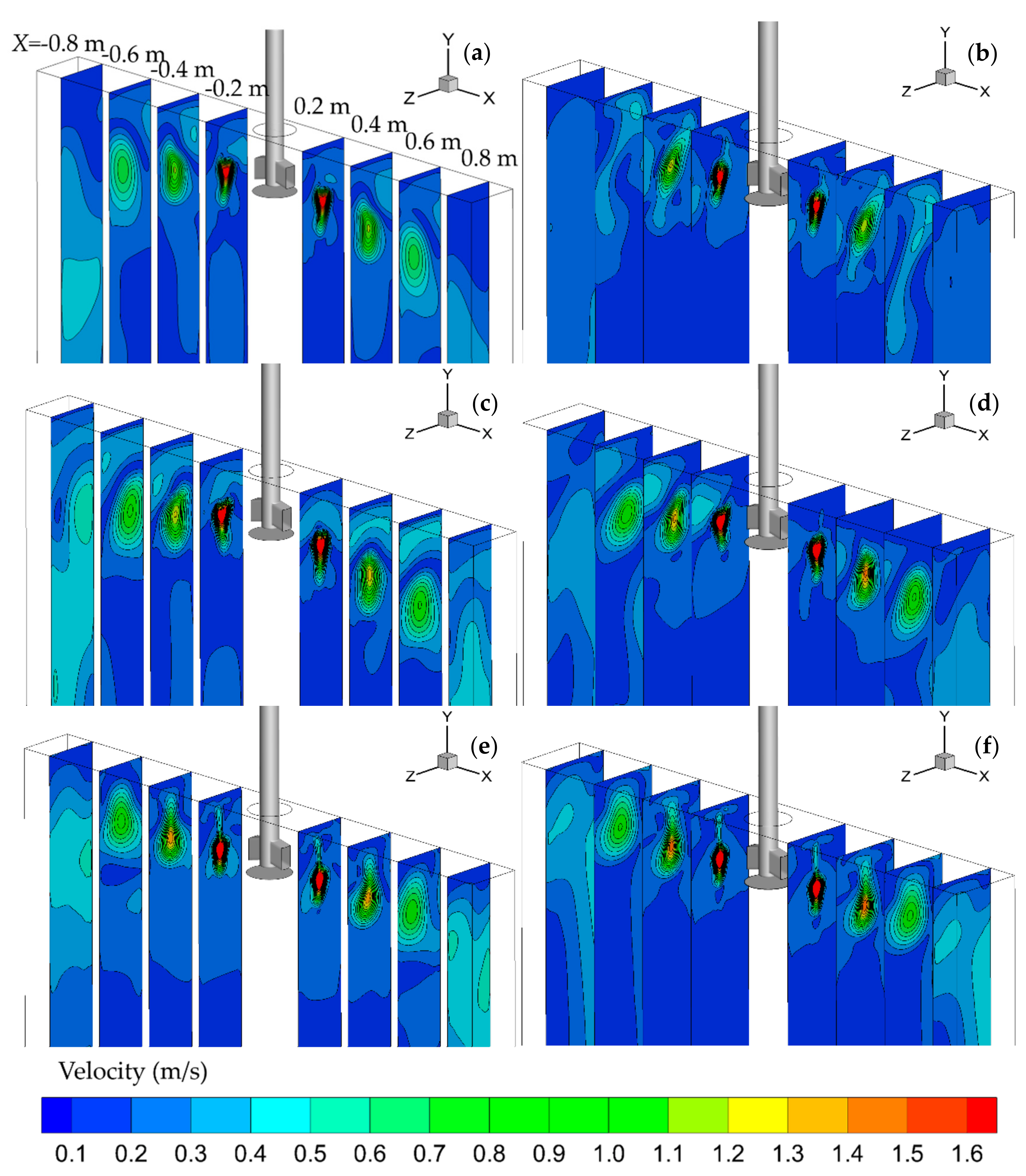

3.2. Velocity Distribution in the Mold

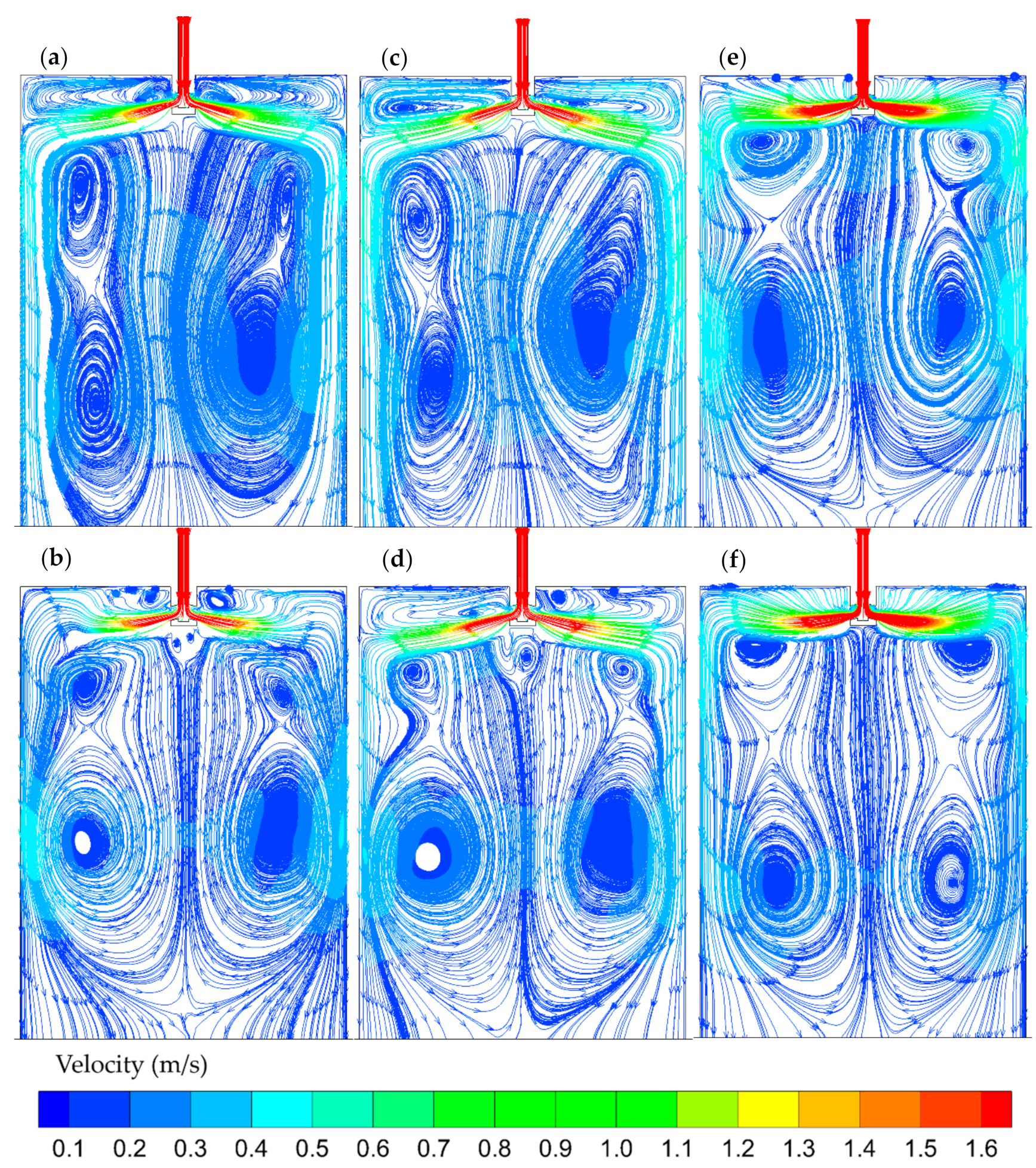

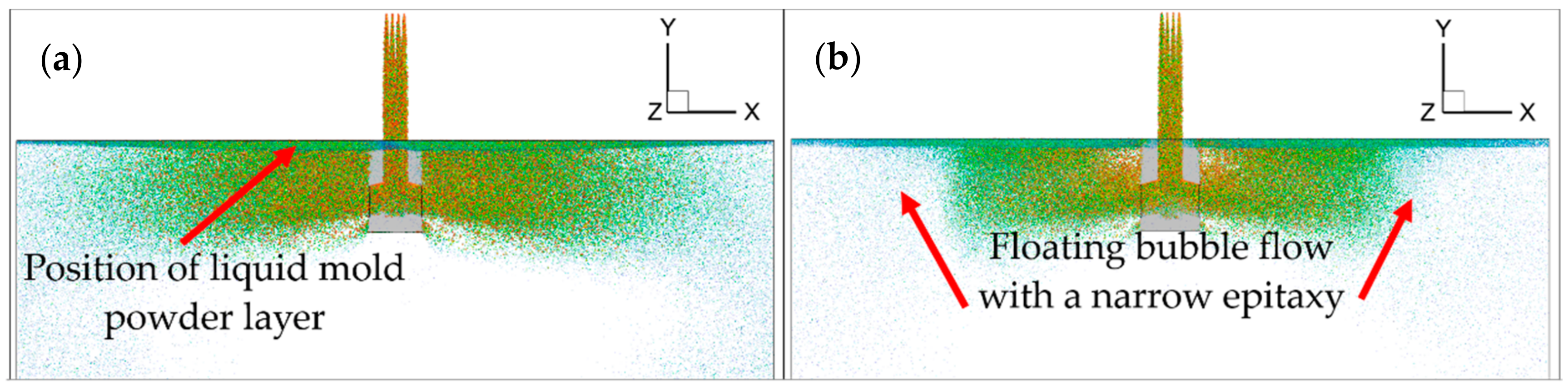

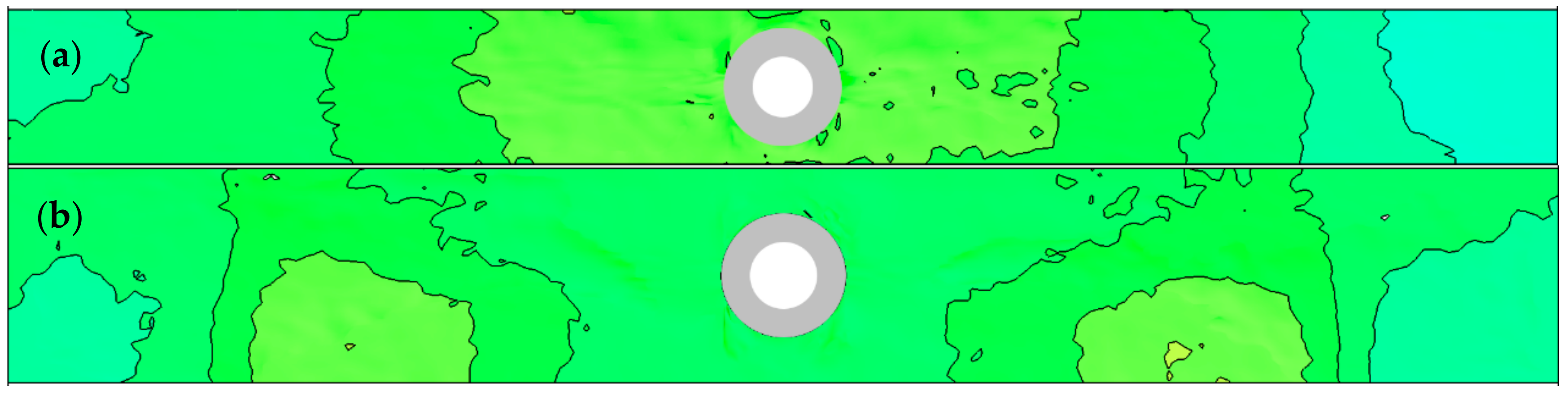

3.3. Argon Bubble Distribution

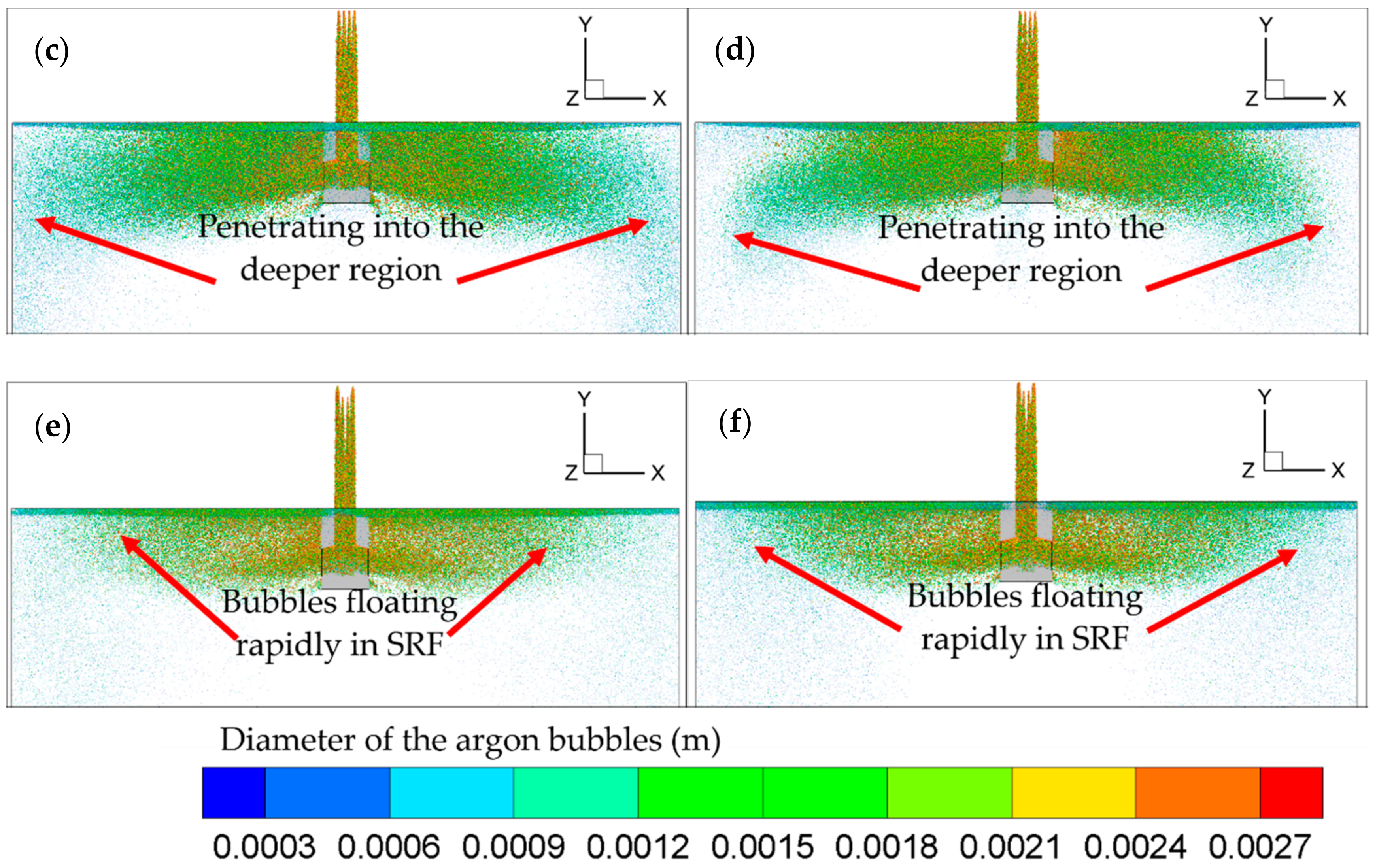

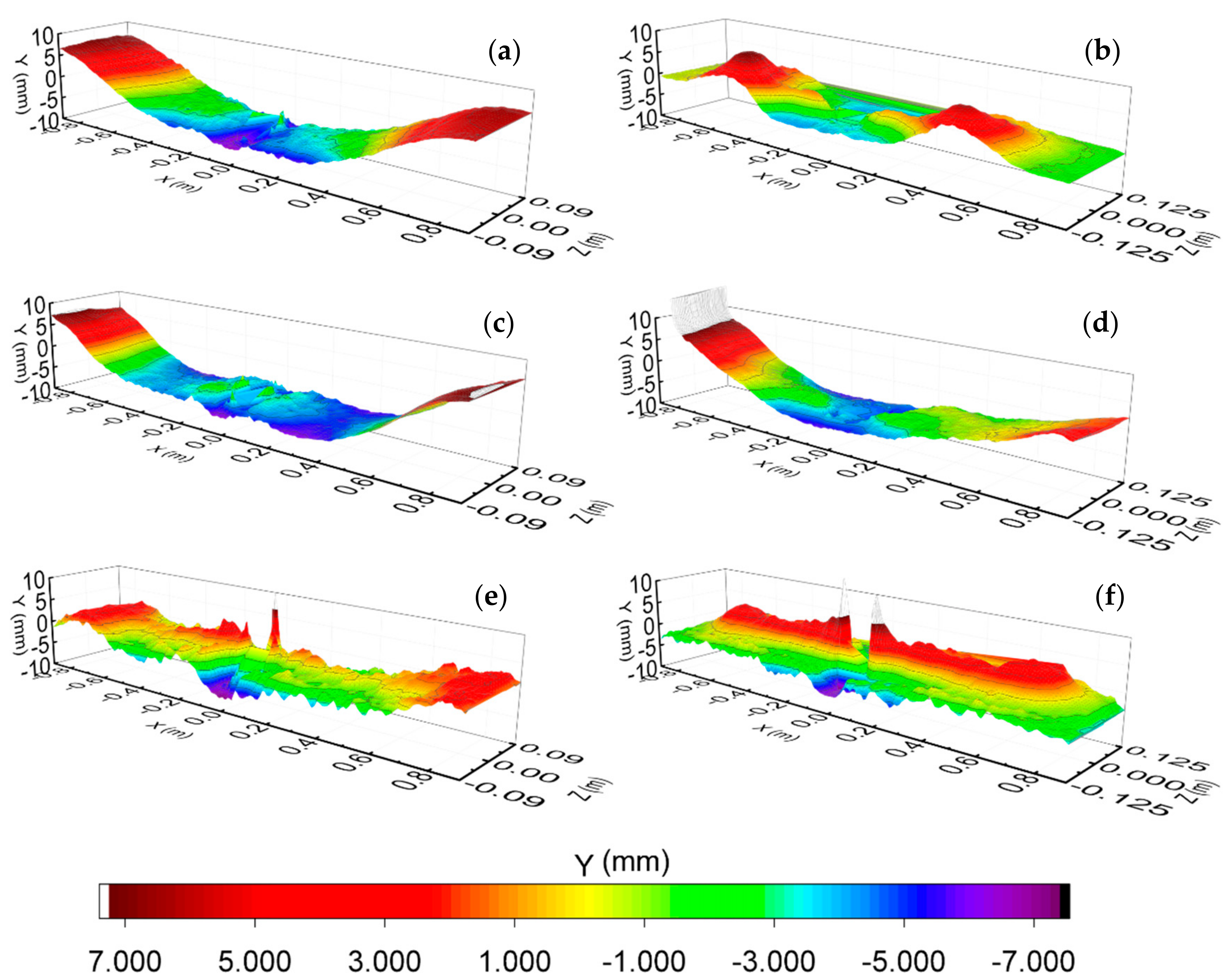

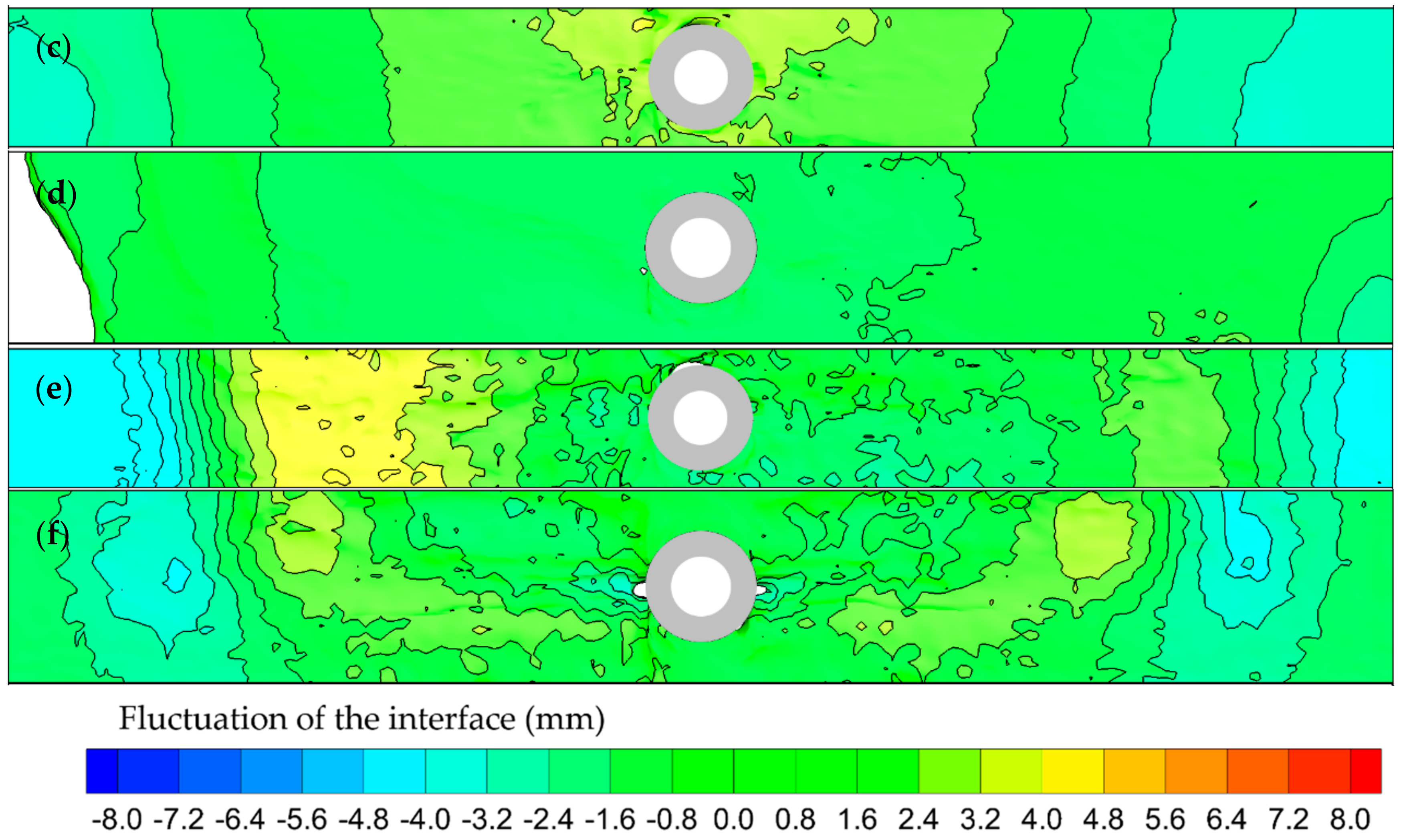

3.4. Profile and Fluctuation of Steel-Slag Interface

4. Conclusions

- (1)

- The results of the numerical simulation are in good agreement with those of high temperature quantitative measurement, which verifies the accuracy and reliability of the numerical simulation.

- (2)

- Under the same continuous casting conditions, the velocities near the surface of the mold with the thickness of 180 mm were slightly higher than those in the mold with the thickness of 250 mm. For the 180 mm thick mold, the critical throughput for the transition from SRF to DRF was smaller. The flow pattern in the 180 mm thick mold maintained DRF more easily than that in the 250 mm thick mold. The kinetic energy of the jet dissipated faster in the 250 mm thick mold. For the 250 mm thick mold, a larger throughput should be employed, which is beneficial to make up for the fast diffusion of kinetic energy and promotes the uniformity of velocity and temperature.

- (3)

- For the DRF, as the argon bubbles can be flushed into deeper regions under the influence of the strong jets on both sides, the argon bubbles distributed more widely in the mold. For the SRF, as the argon bubbles float up quickly after leaving the side holes, the bubble distribution was more concentrated in the width direction, which may cause violent interface fluctuation and slag entrainment.

- (4)

- Under the same continuous casting conditions, the fluctuation at the steel-slag interface in the mold with 180 mm thickness was greater than that in the mold with 250 mm thickness. Under the same steel throughput, DRF is easier to be form in the mold with 180 mm thickness than in the mold with 250 mm thickness. Therefore, a larger throughput can be adopted in the 250 mm thick mold to promote DRF formation while the surface fluctuation is still within a reasonable range.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| i, j, k | indices for different spatial coordinate directions |

| ρ, kg m−3 | density of continuous phase |

| u (ui, uj, uk), m s−1 | velocity of continuous phase |

| p, Pa | pressure |

| t, s | time |

| x (xi, xj, xk), m | location vector |

| g (gi, gj, gk), m s−2 | gravity acceleration vector |

| μl, Pa s | liquid viscosity |

| μt, Pa s | turbulent viscosity |

| F, N m−3 | momentum exchange caused by the inter phase force traction |

| K, m2 s−2 | turbulent kinetic energy |

| ε, m2 s−3 | turbulent energy dissipation rate |

| ui,j, m s−1 | velocity perpendicular to the i,j plane |

| mb, kg | bubble mass |

| ub, m s−1 | bubble velocity |

| ρb, kg m−3 | bubble density |

| db, m | bubble diameter |

| FD, N | drag force |

| FP, N | pressure gradient force |

| Ff, N | buoyancy |

| FV, N | virtual mass force |

| Fg, N | gravity force |

| FL, N | lift force |

| αsteel, 1 | volume fraction of molten steel |

| αslag, 1 | volume fraction of liquid mold powder |

| ρsteel, kg m−3 | density of molten steel |

| ρslag, kg m−3 | density of liquid mold powder |

| μsteel, Pa s | viscosity of molten steel |

| μslag, Pa s | viscosity of liquid mold powder |

| σ, N∙m−1 | interface tension coefficient |

| R1, R2, m | principal radii of curvature at the two-phase interface in orthogonal directions |

| p1, p2, Pa | pressure on both sides of the two-phase interface |

| k, m−2 | interface curvature |

| , m−1 | unit normal vector of the interface |

| n, m−1 | normal vector of the interface |

| Fvol, N m−3 | interface tension volume force |

References

- Liu, X.F.; Zhang, J.Y.; Du, W.D.; Zhai, Q.J.; Li, Q. Analysis of flow field and temperature distribution in compact strip production casting process. Ironmak. Steelmak. 2007, 34, 491–500. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Tao, H.; Zhang, H. Numerical analysis of local heat flux and thin-slab solidification in a CSP funnel-type mold with electromagnetic braking. Metall. Res. Technol. 2020, 6, 602. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Qi, F.S.; Li, B.K.; Jiang, M.F. Vortex flow pattern in a slab continuous casting mold with argon gas injection. J. Iron Steel Res. Int. 2014, 21, 1081–1089. [Google Scholar] [CrossRef]

- Yu, H.Q.; Zhu, M.Y.; Wang, J. Interfacial fluctuation behavior of steel/slag in medium-thin slab continuous casting mold with argon gas injection. J. Iron Steel Res. Int. 2010, 17, 5–11. [Google Scholar] [CrossRef]

- Gutierrez-Montiel, Y.S.; Morales, R.D. Control of meniscus stability in medium thickness-straight walls slab mould. ISIJ Int. 2013, 53, 230–239. [Google Scholar] [CrossRef]

- Liu, K.; Ji, C.X.; Wang, S.D.; Sun, Q.S.; Tian, Z.H.; Li, H.B. Numerical simulation of fluid flow in funnel-type mold of 110 mm thin slab in MCCR process. J. Iron Steel Res. Int. 2021, 33, 143–148. [Google Scholar]

- Hwang, J.Y.; Cho, M.J.; Thomas, B.G.; Cho, S.M. Numerical simulation of turbulent steel CEM® mold under high mass flow condition. In Proceedings of the 9th International Symposium on Electromagnetic Processing of Materials (EPM2018), Awaji Island, Hyogo, Japan, 14–18 October 2018. [Google Scholar]

- Zheng, S.G.; Zhu, M.Y. Physical modeling of gas-liquid interfacial fluctuation in a thick slab continuous casting mold with argon blowing. Int. J. Miner. Metall. Mater. 2010, 17, 704–708. [Google Scholar] [CrossRef]

- Yang, B.; Jing, L.; Zhang, L.W.; Zhang, Y.; Cui, Y.; Xu, C.J. Simulation analysis on flow field and temperature field in mould of special thick slab caster. Teh. Vjesn. 2019, 26, 566–570. [Google Scholar]

- Xie, X.; Chen, D.F.; Long, M.J.; Zhang, L.L.; Shen, J.L.; Ma, Y.G. Numerical analysis of coupled fluid flow, heat transfer and solidification in ultra-thick slab continuous casting mold. In Materials Processing Fundamentals; Springer: Cham, Switzerland, 2013; pp. 63–71. [Google Scholar]

- Shen, J.L.; Chen, D.F.; Xie, X.; Zhang, L.L.; Dong, Z.H.; Long, M.J.; Ruan, X.B. Influences of SEN structures on flow characters, temperature field and shell distribution in 420 mm continuous casting mould. Ironmak. Steelmak. 2013, 40, 263–275. [Google Scholar] [CrossRef]

- Liu, X.F.; Zhang, J.Y.; Zhai, Q.J.; Li, Q. Comparison of four methods to evaluate flow fields in CSP casting mould. Ironmak. Steelmak. 2007, 34, 501–505. [Google Scholar] [CrossRef]

- Rietow, B.; Thomas, B.G. Using nail board experiments to quantify surface velocity in the CC mold. In Proceedings of the AISTech 2008 Steelmaking Conference Proceedings, Pittsburgh, PA, USA, 5–8 May 2008; Volume 1. [Google Scholar]

- Ren, L.; Zhang, L.F.; Wang, Q.Q. Nail board experiments to investigate level characteristic in slab continuous casting mold. Iron Steel 2016, 51, 49–54. [Google Scholar]

- Jiang, P.; Yang, J.; Zhang, T.; Xu, G.J.; Liu, H.J.; Zhou, J.J.; Qin, W. Optimization of flow field in slab continuous casting mold with medium width using high temperature measurement and numerical simulation for automobile exposed panel production. Metals 2020, 10, 9. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Yang, J.; Xu, G.J.; Liu, H.J.; Zhou, J.J.; Qin, W. Effects of operating parameters on the flow field in slab continuous casting molds with narrow widths. Int. J. Miner. Metall. Mater. 2021, 28, 238–248. [Google Scholar] [CrossRef]

- Ma, C.; He, W.Y.; Qiao, H.S.; Zhao, C.L.; Liu, Y.B.; Yang, J. Flow field in slab continuous casting mold with large width optimized with high temperature quantitative measurement and numerical calculation. Metals 2021, 11, 261. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, J.; Jiang, P. Measurement of molten steel velocity near the surface and modeling for transient fluid flow in the continuous casting mold. Metals 2019, 9, 36. [Google Scholar] [CrossRef] [Green Version]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Lu, H.B.; Cheng, C.G.; Li, Y.; Yang, M.L.; Jin, Y. Distribution of argon bubble and fluctuation behavior of steel/slag interface in continuous casting mold. Iron Steel 2018, 53, 27–36. [Google Scholar]

| C | Si | Mn | P | S | Als | Nb | Ti |

|---|---|---|---|---|---|---|---|

| 0.0015 | 0.0057 | 0.15 | 0.0126 | 0.0105 | 0.044 | 0.012 | 0.0417 |

| Material | Density (kg/m3) | Viscosity (Pa∙s) | Interfacial Tension Coefficient (N/m) | Interfacial Tension Coefficient (N/m) |

|---|---|---|---|---|

| Liquid mold powder | 2600 | 0.5 | 1.192 | - |

| Molten steel | 7020 | 0.0062 | 1.5 | |

| Argon gas | 0.27 | 2.13 × 10−5 | - |

| Boundary Name | Flow Field Boundary Condition | Boundary Condition for Lagrangian Particles |

|---|---|---|

| Inlet | Velocity inlet | Escape |

| SEN | Non-slip wall | Reflect |

| Mold surface | Free-slip Wall | Escape |

| Wide face | Non-slip wall | Trap |

| Narrow face | Non-slip wall | Trap |

| Outlet | Pressure outlet | Escape |

| Case Number | Mold Width (mm) | Mold Thickness (mm) | Throughput (t/min) | Argon Gas Flow Rate (L/min) | Flow Pattern |

|---|---|---|---|---|---|

| 1 | 1800 | 180 | 2.38 | 3 | DRF |

| 2 | 1800 | 250 | 2.38 | 3 | SRF |

| 3 | 1800 | 180 | 2.65 | 3 | DRF |

| 4 | 1800 | 250 | 2.65 | 3 | DRF |

| 5 | 1800 | 180 | 2.65 | 10 | SRF |

| 6 | 1800 | 250 | 2.65 | 10 | SRF |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Yang, J.; Huang, F.; Zhu, K.; Liu, F.; Gong, J. Comparison of the Flow Field in a Slab Continuous Casting Mold between the Thicknesses of 180 mm and 250 mm by High Temperature Quantitative Measurement and Numerical Simulation. Metals 2021, 11, 1886. https://doi.org/10.3390/met11121886

Liu Y, Yang J, Huang F, Zhu K, Liu F, Gong J. Comparison of the Flow Field in a Slab Continuous Casting Mold between the Thicknesses of 180 mm and 250 mm by High Temperature Quantitative Measurement and Numerical Simulation. Metals. 2021; 11(12):1886. https://doi.org/10.3390/met11121886

Chicago/Turabian StyleLiu, Yibo, Jian Yang, Fuxiang Huang, Keran Zhu, Fenggang Liu, and Jian Gong. 2021. "Comparison of the Flow Field in a Slab Continuous Casting Mold between the Thicknesses of 180 mm and 250 mm by High Temperature Quantitative Measurement and Numerical Simulation" Metals 11, no. 12: 1886. https://doi.org/10.3390/met11121886

APA StyleLiu, Y., Yang, J., Huang, F., Zhu, K., Liu, F., & Gong, J. (2021). Comparison of the Flow Field in a Slab Continuous Casting Mold between the Thicknesses of 180 mm and 250 mm by High Temperature Quantitative Measurement and Numerical Simulation. Metals, 11(12), 1886. https://doi.org/10.3390/met11121886