Influence of Quenching and Partitioning Parameters on Phase Transformations and Mechanical Properties of Medium Manganese Steel for Press-Hardening Application

Abstract

:1. Introduction

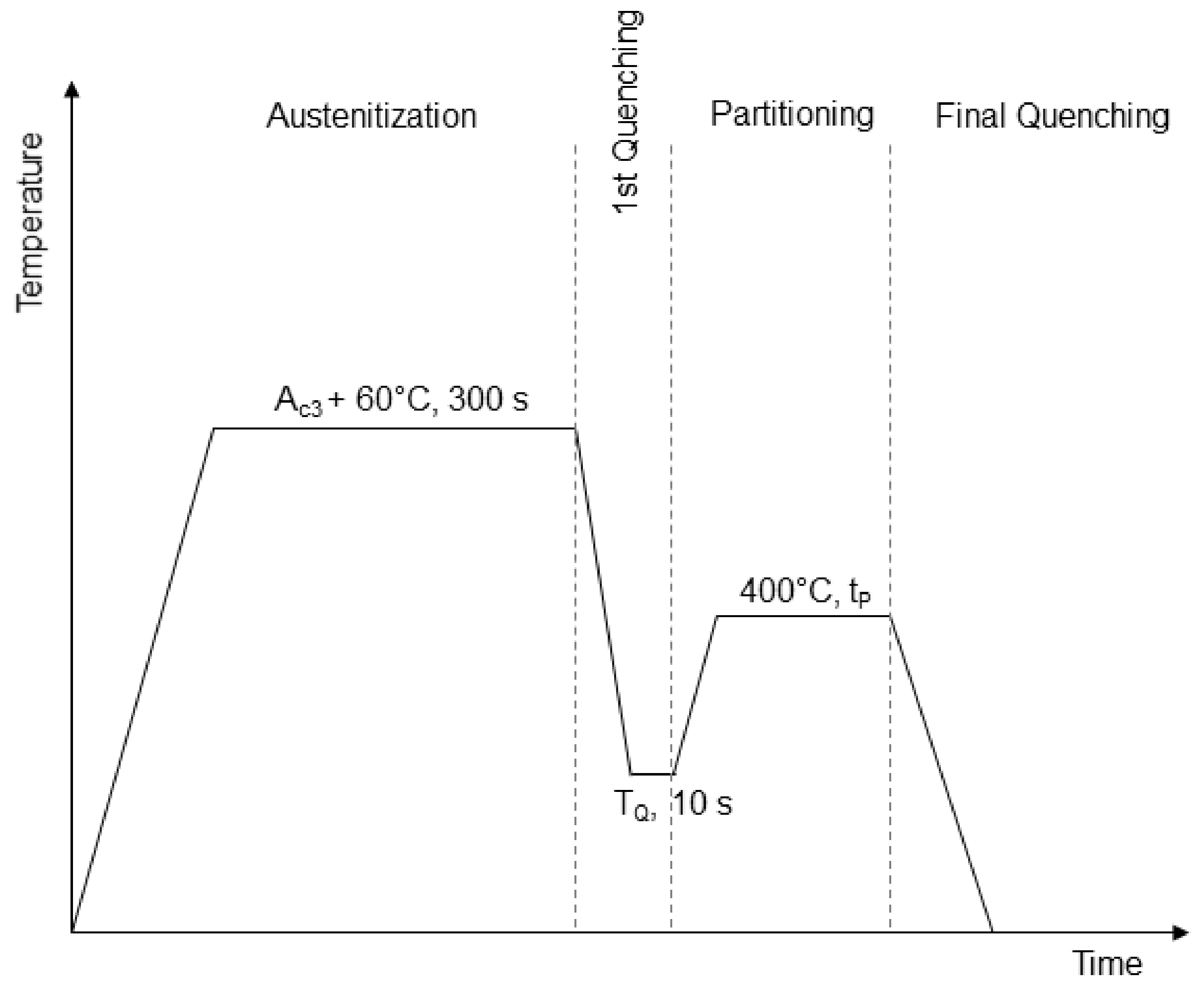

2. Materials and Methods

3. Results and Discussion

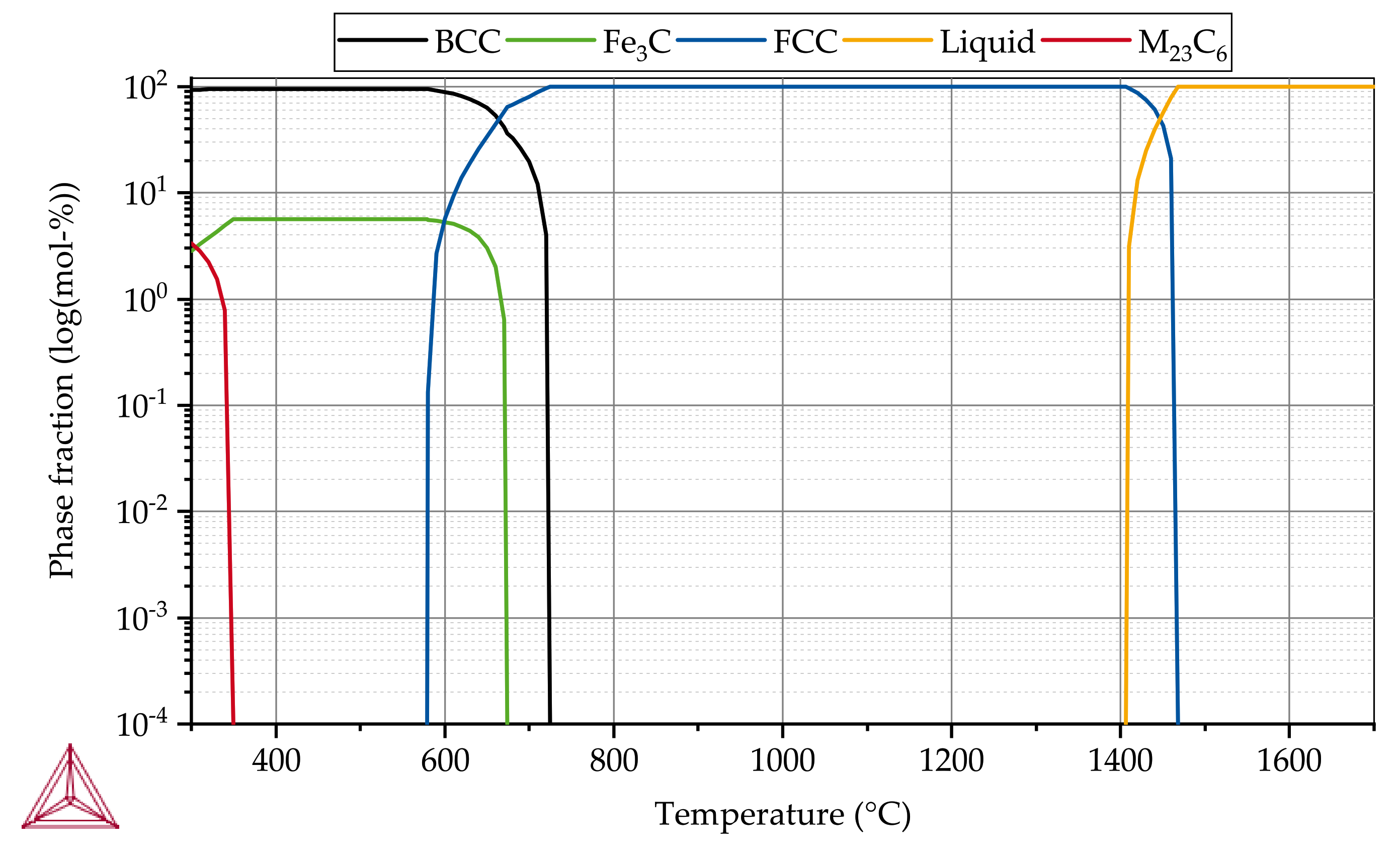

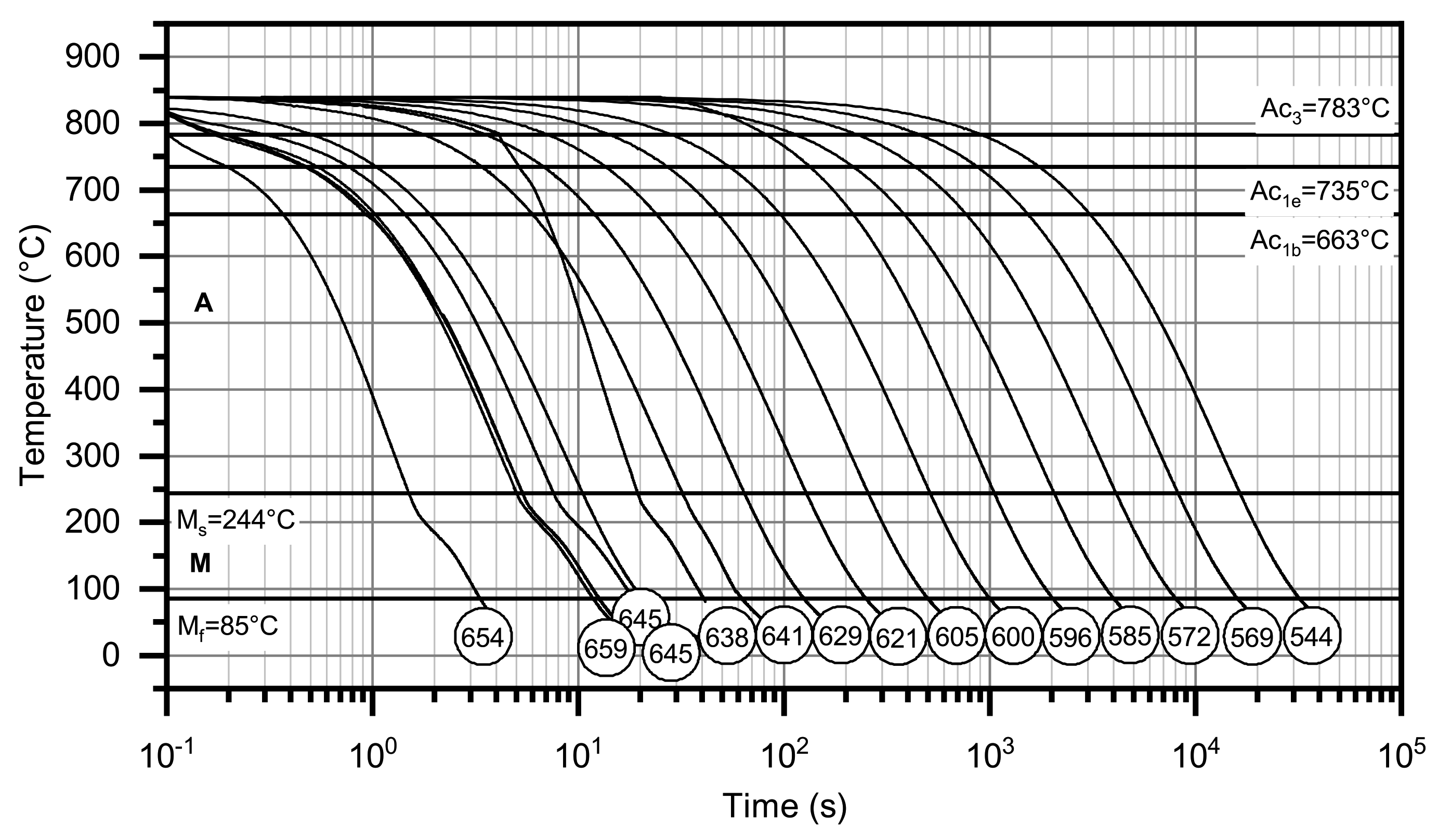

3.1. Phase Transformations and Initial State

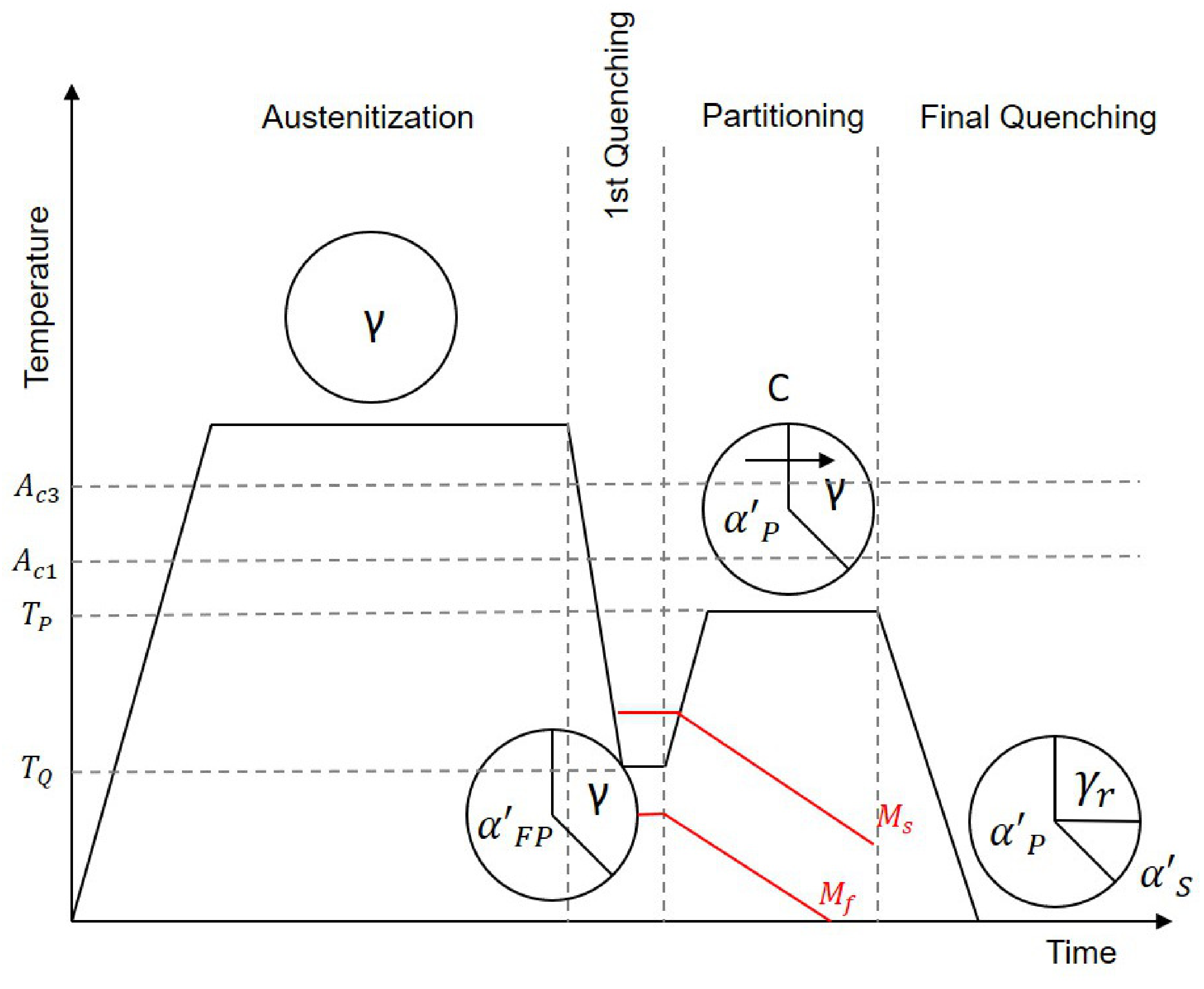

3.2. Quenching & Partitioning

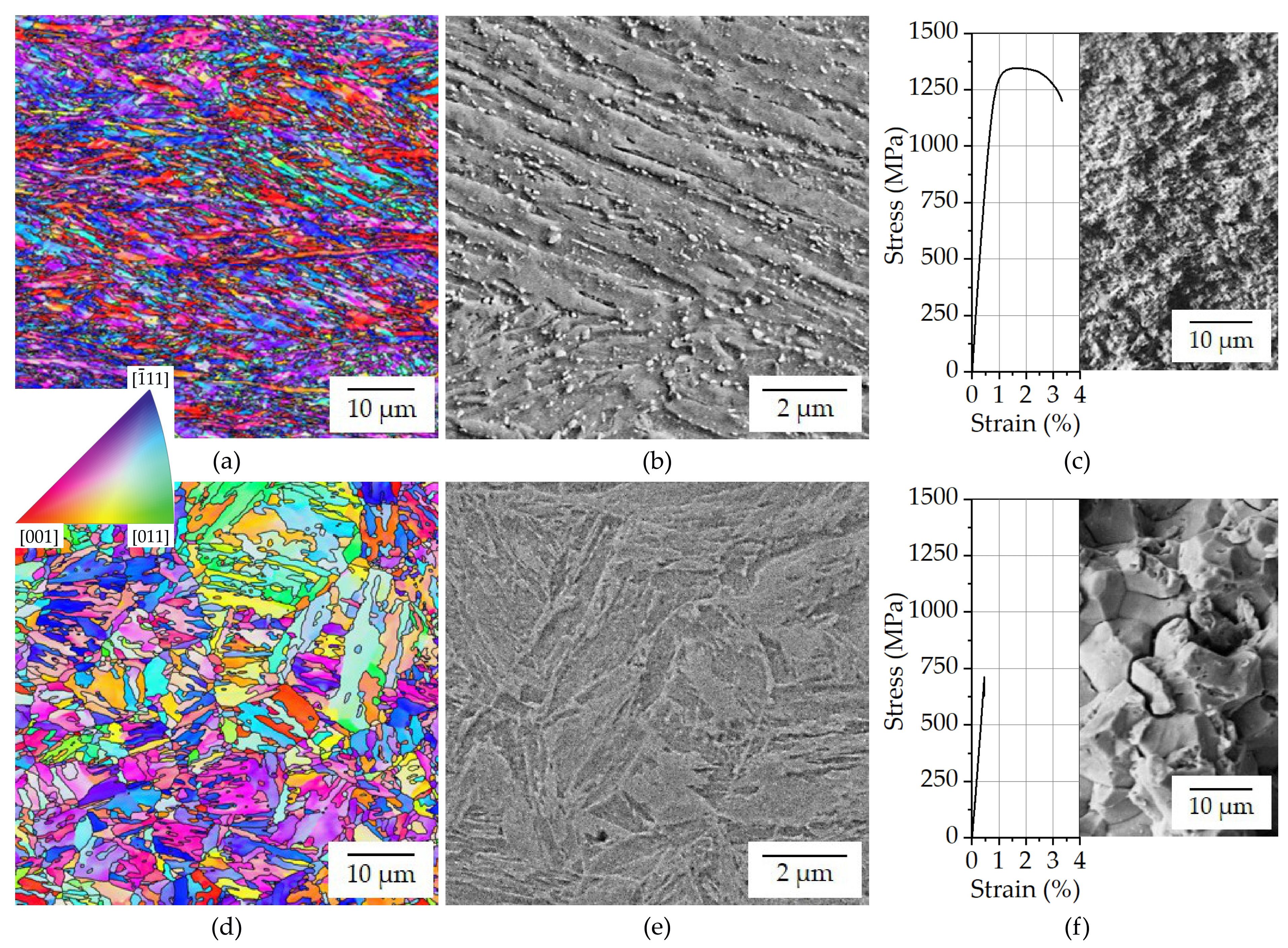

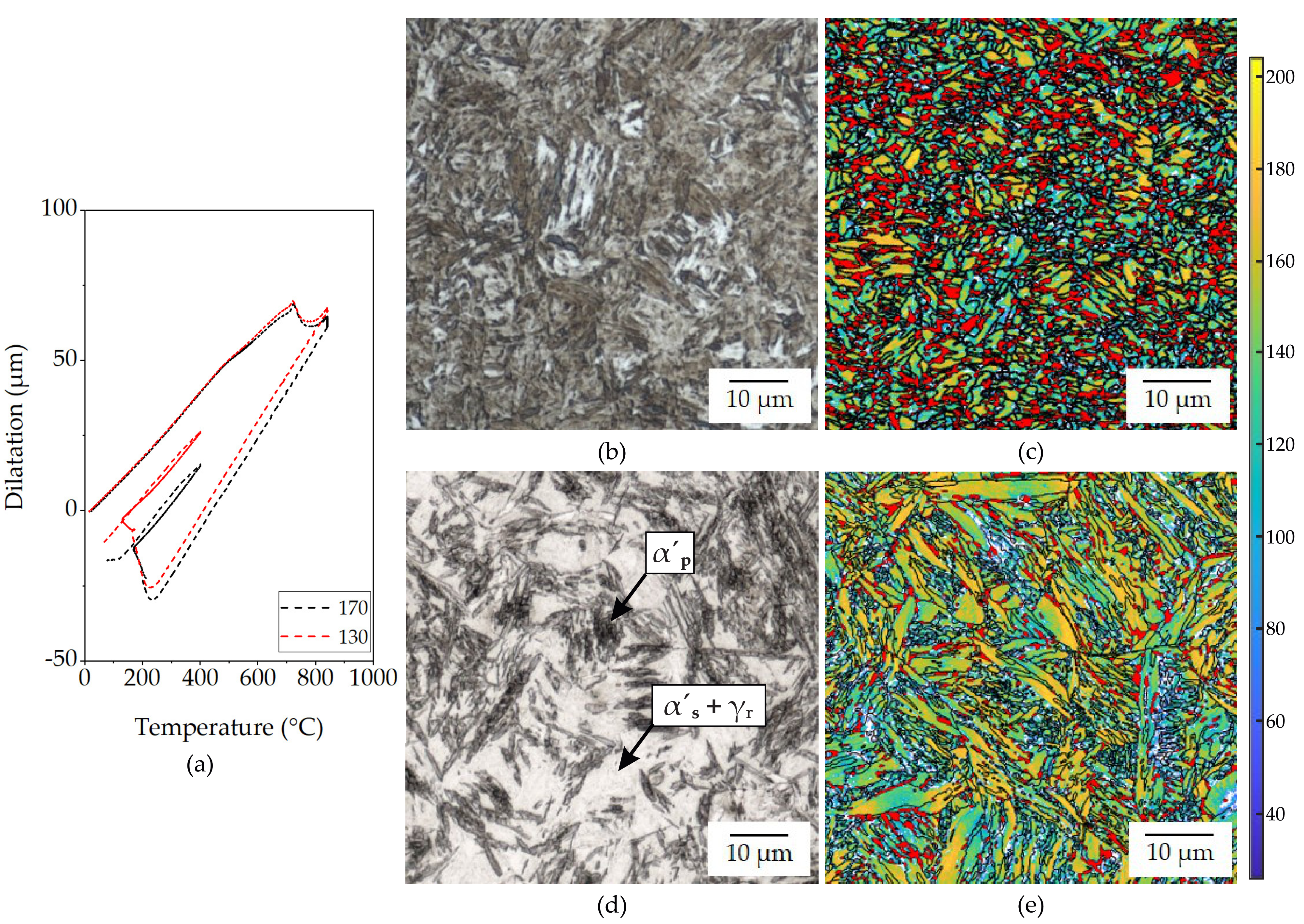

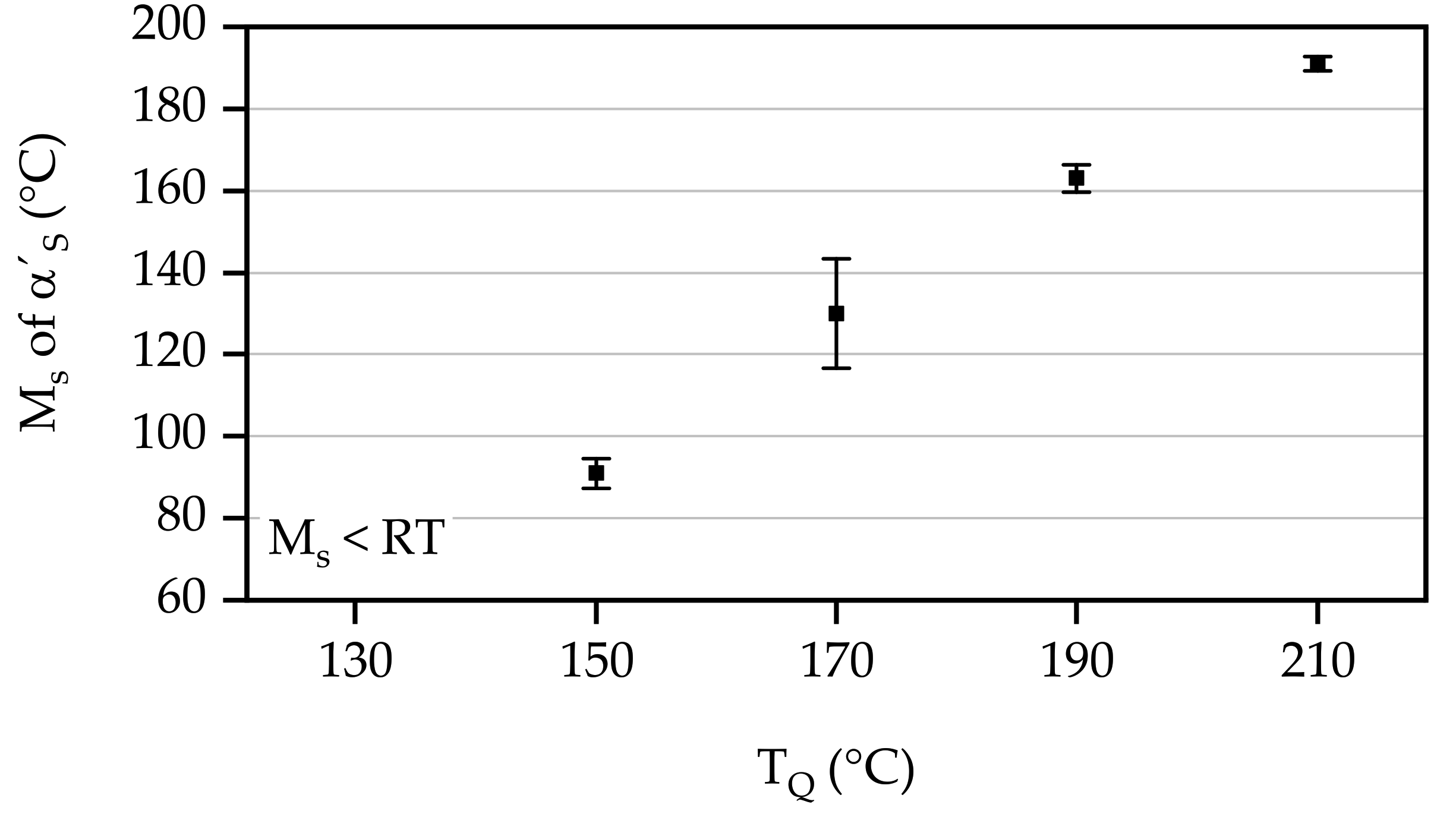

3.2.1. Influence of TQ

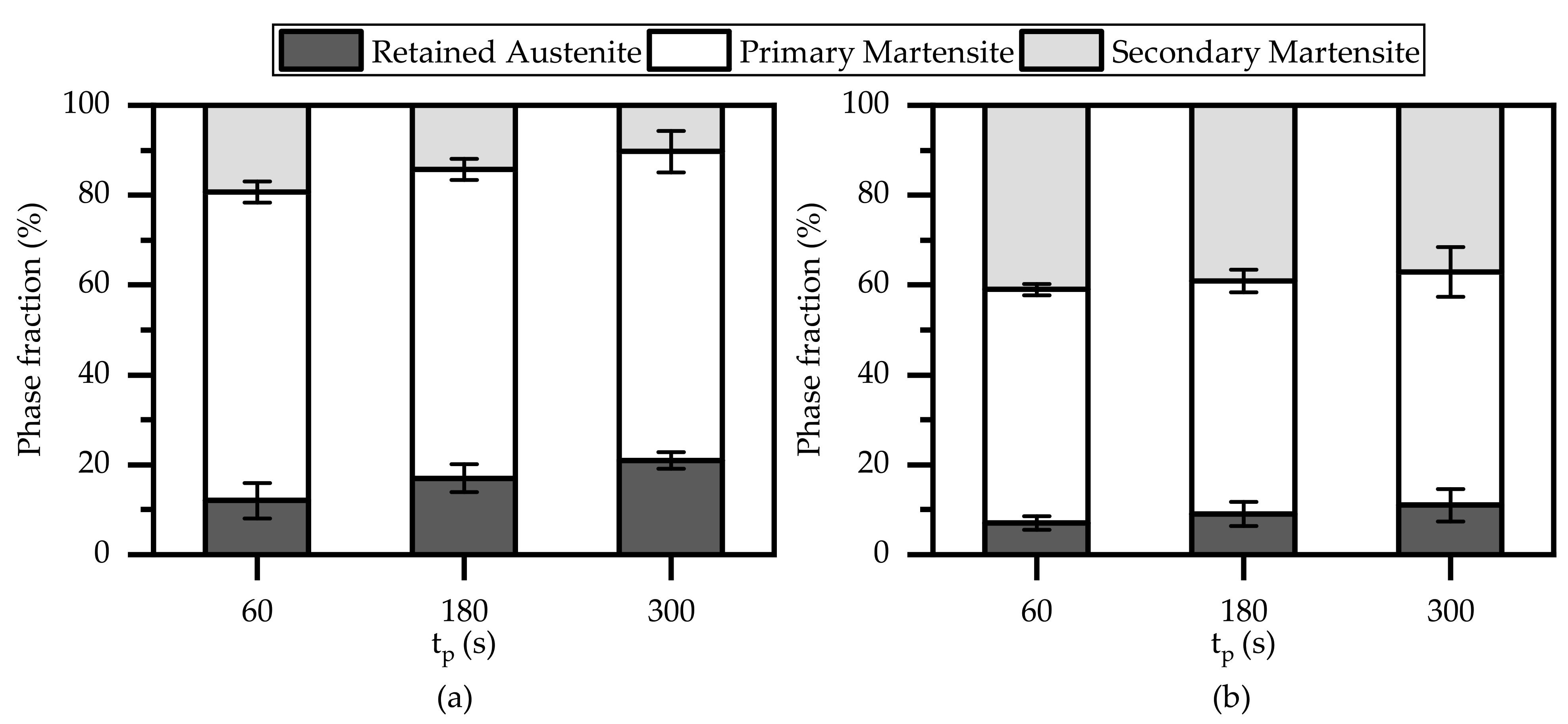

3.2.2. Influence of tP

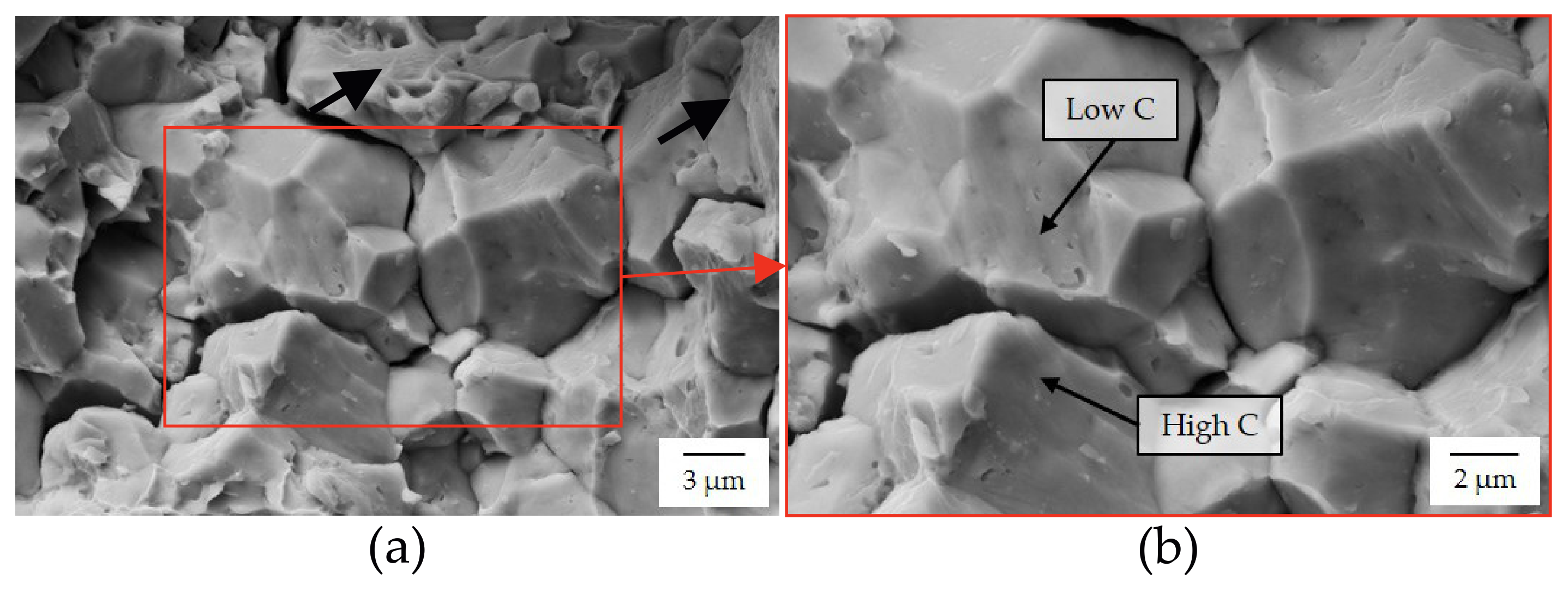

3.2.3. Role of Secondary Martensite on Ductility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmitt, J.H.; Iung, T. New developments of advanced high-strength steels for automotive applications. Comptes Rendus Phys. 2018, 19, 641–656. [Google Scholar] [CrossRef]

- Bleck, W.; Brühl, F.; Ma, Y.; Sasse, C. Materials and Processes for the Third-generation Advanced High-strength Steels. BHM Berg- Hüttenmännische Monatshefte 2019, 164, 466–474. [Google Scholar] [CrossRef]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press hardening—An innovative and challenging technology. Arch. Civ. Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Järvinen, H.; Isakov, M.; Nyyssönen, T.; Järvenpää, M.; Peura, P. The effect of initial microstructure on the final properties of press hardened 22MnB5 steels. Mater. Sci. Eng. A 2016, 676, 109–120. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Lenze, F.-J.; Sikora, S. Device and Method for the Forming of Blanks from High and Very High Strength Steels. U.S. Patent US9,068,239 B2, 30 June 2015. [Google Scholar]

- Ademaj, A. Method and Device for Producing a Press-Hardened Metal Component. European Patent EP2864506B1, 11 July 2018. [Google Scholar]

- Wang, C.; Li, X.; Han, S.; Zhang, L.; Chang, Y.; Cao, W.; Dong, H. Warm Stamping Technology of the Medium Manganese Steel. Steel Res. Int. 2018, 89, 1700360. [Google Scholar] [CrossRef]

- Rana, R.; Carson, C.H.; Speer, J. Ductile Ultra High Strength Medium Manganese Steel Produced through Continuous Annealing and Hot Stamping. U.S. Patent Application Publication US2016/0312323 A1, 27 October 2016. [Google Scholar]

- Oh, J.-K.; Lee, K.-Y.; Cho, Y.-R.; Choi, E.-Y.; Kim, K.-S. Steel Sheet for Warm Press Forming, Warm Press Formed Parts and Method for Manufacturing Thereof. European Patent Application Publication EP2778247 A1, 17 September 2014. [Google Scholar]

- Wang, Z.; Zhang, Y.; Zhu, B.; Wang, Y.; Ding, H.; Cai, M. Hot stamped parts with desirable properties in medium Mn TRIP steels. Procedia Eng. 2017, 207, 699–704. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Xu, Y.; Wang, Y.; Zhang, Y. Hot Stamping of High Strength Steel with Tailored Properties by Two Methods. Procedia Eng. 2014, 81, 1725–1730. [Google Scholar] [CrossRef] [Green Version]

- Merklein, M.; Franke, J.M.; Geiger, M.; Schmidt, M. (Eds.) Ein Ansatz zur Herstellung von Pressgehärteten Karosseriekomponenten mit Maßgeschneiderten Mechanischen Eigenschaften: Temperierte Umformwerkzeuge. Prozessfenster, Prozesssimulation und Funktionale Untersuchung; Fertigungstechnik–Erlangen, Meisenbach: Bamberg, Germany, 2012; Volume Bd.226. [Google Scholar]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Tong, C.; Rong, Q.; Yardley, V.A.; Li, X.; Luo, J.; Zhu, G.; Shi, Z. New Developments and Future Trends in Low-Temperature Hot Stamping Technologies: A Review. Metals 2020, 1652, 1652. [Google Scholar] [CrossRef]

- Meza-García, E.; Rautenstrauch, A.; Bräunig, M.; Kräusel, V.; Landgrebe, D. Energetic evaluation of press hardening processes. Procedia Manuf. 2019, 33, 367–374. [Google Scholar] [CrossRef]

- Chang, Y.; Wang, C.Y.; Zhao, K.M.; Dong, H.; Yan, J.W. An introduction to medium-Mn steel: Metallurgy, mechanical properties and warm stamping process. Mater. Des. 2016, 94, 424–432. [Google Scholar] [CrossRef]

- Speer, J.; Rana, R.; Matlock, D.; Glover, A.; Thomas, G.; de Moor, E. Processing Variants in Medium-Mn Steels. Metals 2019, 9, 771. [Google Scholar] [CrossRef] [Green Version]

- Seo, E.J.; Cho, L.; de Cooman, B.C. Application of Quenching and Partitioning (Q&P) Processing to Press Hardening Steel. Metall. Mater. Trans. A 2014, 45, 4022–4037. [Google Scholar] [CrossRef]

- de Cooman, B.C.; Lee, S.J.; Shin, S.; Seo, E.J.; Speer, J.G. Combined Intercritical Annealing and Q&P Processing of Medium Mn Steel. Metall. Mater. Trans. A 2017, 48, 39–45. [Google Scholar] [CrossRef]

- de Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Effect of Carbon and Manganese on the Quenching and Partitioning Response of CMnSi Steels. ISIJ Int. 2011, 51, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Koistinen, D.P.; Marburger, R.E. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Gramlich, A.; van der Linde, C.; Ackermann, M.; Bleck, W. Effect of aluminum, molybdenum and boron on the phase transformation in 4 wt.-% manganese steels. Results Mater. 2020, 8, 100–147. [Google Scholar]

- Sackl, S.; Clemens, H.; Primig, S. Investigation of the Self Tempering Effect of Martensite by Means of Atom Probe Tomography. Pract. Metallogr. 2015, 52, 374–383. [Google Scholar] [CrossRef]

- Andrews, K.W. Empirical formulae for calculation of some transformation temperatures. J. Iron Steel Inst. 1965, 203, 721–727. [Google Scholar]

- Seo, E.J.; Cho, L.; de Cooman, B.C. Modified Methodology for the Quench Temperature Selection in Quenching and Partitioning (Q&P) Processing of Steels. Metall. Mater. Trans. A 2016, 47, 3797–3802. [Google Scholar] [CrossRef]

- van Bohemen, S.; Sietsma, J. Martensite Formation in Partially and Fully Austenitic Plain Carbon Steels. Metall. Mater. Trans. A 2009, 40, 1059–1068. [Google Scholar] [CrossRef] [Green Version]

- Xiao, L.; Fan, Z.; Jinxu, Z.; Mingxing, Z.; Mokuang, Z.; Zhenqi, G. Lattice-parameter variation with carbon content of martensite. I. X-ray-diffraction experimental study. Phys. Rev. B Condens. Matter 1995, 52, 9970–9978. [Google Scholar] [CrossRef]

- Nasim, M.; Edwards, B.C.; Wilson, E.A. A study of grain boundary embrittlement in an Fe–8%Mn alloy. Mater. Sci. Eng. A 2000, 281, 56–67. [Google Scholar] [CrossRef]

- Han, J.; Da Silva, A.K.; Ponge, D.; Raabe, D.; Lee, S.M.; Lee, Y.K.; Lee, S.I.; Hwang, B. The effects of prior austenite grain boundaries and microstructural morphology on the impact toughness of intercritically annealed medium Mn steel. Acta Mater. 2017, 122, 199–206. [Google Scholar] [CrossRef]

- Kuzmina, M.; Ponge, D.; Raabe, D. Grain boundary segregation engineering and austenite reversion turn embrittlement into toughness: Example of a 9 wt.% medium Mn steel. Acta Mater. 2015, 86, 182–192. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; de Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Toji, Y.; Matsuda, H.; Herbig, M.; Choi, P.P.; Raabe, D. Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 2014, 65, 215–228. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Petrov, R.; Kwakernaak, C.; Sloof, W.G.; Sietsma, J. Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel. Acta Mater. 2011, 59, 6059–6068. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Petrov, R.H.; Zhao, L.; Sietsma, J. Microstructural analysis of martensite constituents in quenching and partitioning steels. Mater. Charact. 2014, 92, 91–95. [Google Scholar] [CrossRef]

- Qi, X.; Du, L.; Hu, J.; Misra, R.D.K. Effect of austenite stability on toughness, ductility, and work-hardening of medium-Mn steel. Mater. Sci. Technol. 2019, 35, 2134–2142. [Google Scholar] [CrossRef]

- Paravicini Bagliani, E.; Santofimia, M.J.; Zhao, L.; Sietsma, J.; Anelli, E. Microstructure, tensile and toughness properties after quenching and partitioning treatments of a medium-carbon steel. Mater. Sci. Eng. A 2013, 559, 486–495. [Google Scholar] [CrossRef]

- Arlazarov, A.; Bouaziz, O.; Masse, J.P.; Kegel, F. Characterization and modeling of mechanical behavior of quenching and partitioning steels. Mater. Sci. Eng. A 2015, 620, 293–300. [Google Scholar] [CrossRef]

- HajyAkbary, F.; Sietsma, J.; Petrov, R.H.; Miyamoto, G.; Furuhara, T.; Santofimia, M.J. A quantitative investigation of the effect of Mn segregation on microstructural properties of quenching and partitioning steels. Scr. Mater. 2017, 137, 27–30. [Google Scholar] [CrossRef]

- de Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L.A. Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Wang, M.M.; Hell, J.C.; Tasan, C.C. Martensite size effects on damage in quenching and partitioning steels. Scr. Mater. 2017, 138, 1–5. [Google Scholar] [CrossRef]

- Celada-Casero, C.; Kwakernaak, C.; Sietsma, J.; Santofimia, M.J. The influence of the austenite grain size on the microstructural development during quenching and partitioning processing of a low-carbon steel. Mater. Des. 2019, 178, 107847. [Google Scholar] [CrossRef]

| Fe | C | Mn | Si | Al | Cr | P | S | N |

|---|---|---|---|---|---|---|---|---|

| bal. | 0.30 | 4.99 | 1.55 | 0.004 | 0.04 | 0.005 | 0.003 | 0.004 |

| TQ (°C) | tP (s) | Rp0.2 (MPa) | Rm (MPa) | Ag (%) | Ax (%) |

|---|---|---|---|---|---|

| 150 | 60 | 923 | 1634 | 13.0 | 16.3 |

| 180 | 950 | 1648 | 15.3 | 18.8 | |

| 300 | 946 | 1640 | 15.0 | 18.8 | |

| 170 | 60 | 912 | 1515 | 3.8 | 3.8 |

| 180 | 892 | 1508 | 5.0 | 5.0 | |

| 300 | 878 | 1471 | 3.7 | 3.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blankart, C.; Wesselmecking, S.; Krupp, U. Influence of Quenching and Partitioning Parameters on Phase Transformations and Mechanical Properties of Medium Manganese Steel for Press-Hardening Application. Metals 2021, 11, 1879. https://doi.org/10.3390/met11111879

Blankart C, Wesselmecking S, Krupp U. Influence of Quenching and Partitioning Parameters on Phase Transformations and Mechanical Properties of Medium Manganese Steel for Press-Hardening Application. Metals. 2021; 11(11):1879. https://doi.org/10.3390/met11111879

Chicago/Turabian StyleBlankart, Charline, Sebastian Wesselmecking, and Ulrich Krupp. 2021. "Influence of Quenching and Partitioning Parameters on Phase Transformations and Mechanical Properties of Medium Manganese Steel for Press-Hardening Application" Metals 11, no. 11: 1879. https://doi.org/10.3390/met11111879

APA StyleBlankart, C., Wesselmecking, S., & Krupp, U. (2021). Influence of Quenching and Partitioning Parameters on Phase Transformations and Mechanical Properties of Medium Manganese Steel for Press-Hardening Application. Metals, 11(11), 1879. https://doi.org/10.3390/met11111879