Technology Innovation for the Manual Laser Cladding of High-Alloy Tool Steels

Abstract

:1. Introduction

2. Materials and Methods

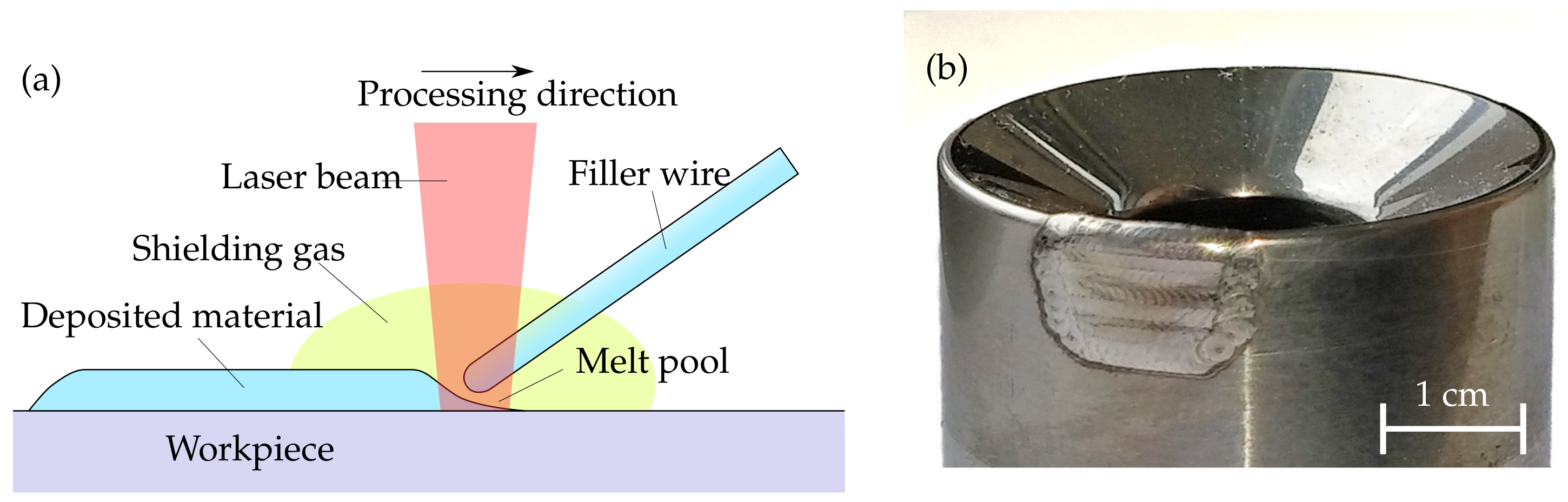

2.1. Experimental Setup

2.2. Materials Used

2.3. FE Simulation of the Preheating Process

2.4. FE Simulation of the Welding Process

3. Results and Discussion

3.1. Testing of a Suitable Coil Geometry

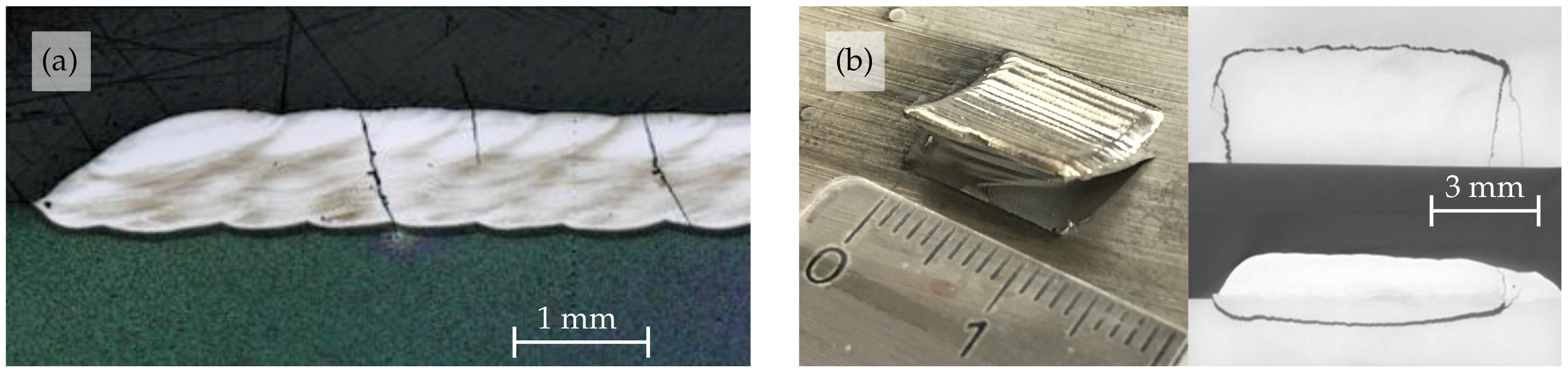

3.2. Welding Results with Preheating

3.3. Simulation Results of the Combined Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jhavar, S.; Paul, C.; Jain, N. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding, 1st ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Šturm, R.; Štefanikova, M.; Steiner Petrovič, D. Influence of pre-heating on the surface modification of powder-metallurgy processed cold-work tool steel during laser surface melting. Appl. Surf. Sci. 2015, 325, 203–210. [Google Scholar] [CrossRef]

- Preciado, W.T.; Bohorquez, C.E.N. Repair welding of polymer injection molds manufactured in AISI P20 and VP50IM steels. J. Mater. Process. Technol. 2006, 179, 244–250. [Google Scholar] [CrossRef]

- Cooper, K.P.; Slebodnick, P. Recent Developments in Laser Melt/Particle Injection Processing. J. Laser Appl. 1989, 1, 21–29. [Google Scholar] [CrossRef]

- Shi, R.R.; Chen, S.Y.; Peng, Y.G.; Zhang, Z. Effect of Preheating Temperature on Microstructure of Fe Based Alloy Coating by Laser Direct Metal Deposition. Key Eng. Mater. 2016, 703, 94–99. [Google Scholar] [CrossRef]

- Legesse, F.; Kapil, S.; Chabra, R.; Sharma, A.; Karunakaran, K.P. In-Situ Preheating in Hybrid Layered Manufacturing for Tooling Elements. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016; pp. 438–447. [Google Scholar]

- Alimardani, M.; Fallah, V.; Khajepour, A.; Toyserkani, E. The effect of localized dynamic surface preheating in laser cladding of Stellite 1. Surf. Coat. Technol. 2010, 204, 3911–3919. [Google Scholar] [CrossRef]

- Raj, D.; Das, B.; Maity, S.R. Preheating Path Selection through Numerical Analysis of Laser-Aided Direct Metal Deposition. In Recent Advances in Mechanical Engineering; Springer: Singapore, 2021; pp. 211–220. [Google Scholar] [CrossRef]

- Wang, D.; Hu, Q.; Zheng, Y.; Xie, Y.; Zeng, X. Study on deposition rate and laser energy efficiency of Laser-Induction Hybrid Cladding. Opt. Laser Technol. 2016, 77, 16–22. [Google Scholar] [CrossRef]

- Kotlan, V.; Hamar, R.; Pánek, D.; Doležel, I. Model of depositing layer on cylindrical surface produced by induction-assisted laser cladding process. Open Phys. 2017, 15, 971–978. [Google Scholar] [CrossRef] [Green Version]

- Tuominen, J.; Vuoristo, P. Induction heating unit equipped with closed-loop PID controller; versatile tool in laser cladding. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 29 October–1 November 2007; Laser Institute of America: Orlando, FL, USA, 2007. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Naumann, T.; Zieris, R.; Beyer, E. Laser based hybrid techniques for surface coating. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, Scottsdale, AZ, USA, 14–17 October 2002; Laser Institute of America: Orlando, FL, USA, 2002. [Google Scholar] [CrossRef]

- Capello, E.; Previtali, B. The influence of operator skills, process parameters and materials on clad shape in repair using laser cladding by wire. J. Mater. Process. Technol. 2006, 174, 223–232. [Google Scholar] [CrossRef]

- BÖHLER Edelstahl GmbH & Co KG. SCHWEISSEN IM WERKZEUGBAU—Anleitung zum Schweißen von Kaltarbeitsstählen, Warmarbeitsstählen, Schnellarbeitsstählen, Kunststoffformenstählen Einschließlich der PM-Hochleistungswerkstoffe; Bohler Edelstahl GmbH & Co KG: Kapfenberg, Austria, 2008; p. 24. [Google Scholar]

- Hu, L.; Huang, J.; Li, Z.; Wu, Y. Effects of preheating temperature on cold cracks, microstructures and properties of high power laser hybrid welded 10Ni3CrMoV steel. Mater. Des. 2011, 32, 1931–1939. [Google Scholar] [CrossRef]

- Fluxtrol Inc. Alphaform MF Data Sheet. Available online: https://fluxtrol.com/inc/pdf/AlphaForm-MF-Specs.pdf (accessed on 22 September 2021).

- Documentation of Simufact Welding 8; Simufact Engineering GmbH: Hamburg, Germany, 2019.

| C | Cr | Mn | Mo | V | Si | Fe |

|---|---|---|---|---|---|---|

| 1.7 | 18 | 0.3 | 1.0 | 3.0 | 0.8 | bal. |

| C | Cr | Mo | V | W | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|

| 1.0 | 4.0 | 8.3 | 1.8 | 1.9 | 0.4 | 0.4 | bal. |

| Radius | Depth | Gaussian Parameter | Speed | Power | Efficiency |

|---|---|---|---|---|---|

| 1.1 mm | 0.39 mm | 3.0 | 340 mm/min | 2800 W | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kimme, J.; Zeisig, J.; Fröhlich, A.; Kräusel, V. Technology Innovation for the Manual Laser Cladding of High-Alloy Tool Steels. Metals 2021, 11, 1820. https://doi.org/10.3390/met11111820

Kimme J, Zeisig J, Fröhlich A, Kräusel V. Technology Innovation for the Manual Laser Cladding of High-Alloy Tool Steels. Metals. 2021; 11(11):1820. https://doi.org/10.3390/met11111820

Chicago/Turabian StyleKimme, Jonas, Josephine Zeisig, Alexander Fröhlich, and Verena Kräusel. 2021. "Technology Innovation for the Manual Laser Cladding of High-Alloy Tool Steels" Metals 11, no. 11: 1820. https://doi.org/10.3390/met11111820

APA StyleKimme, J., Zeisig, J., Fröhlich, A., & Kräusel, V. (2021). Technology Innovation for the Manual Laser Cladding of High-Alloy Tool Steels. Metals, 11(11), 1820. https://doi.org/10.3390/met11111820