An Effective Strengthening Strategy of Nano Carbide Precipitation and Cellular Microstructure Refinement in a Superalloy Fabricated by Selective Laser Melting Process

Abstract

:1. Introduction

2. Materials and Methods

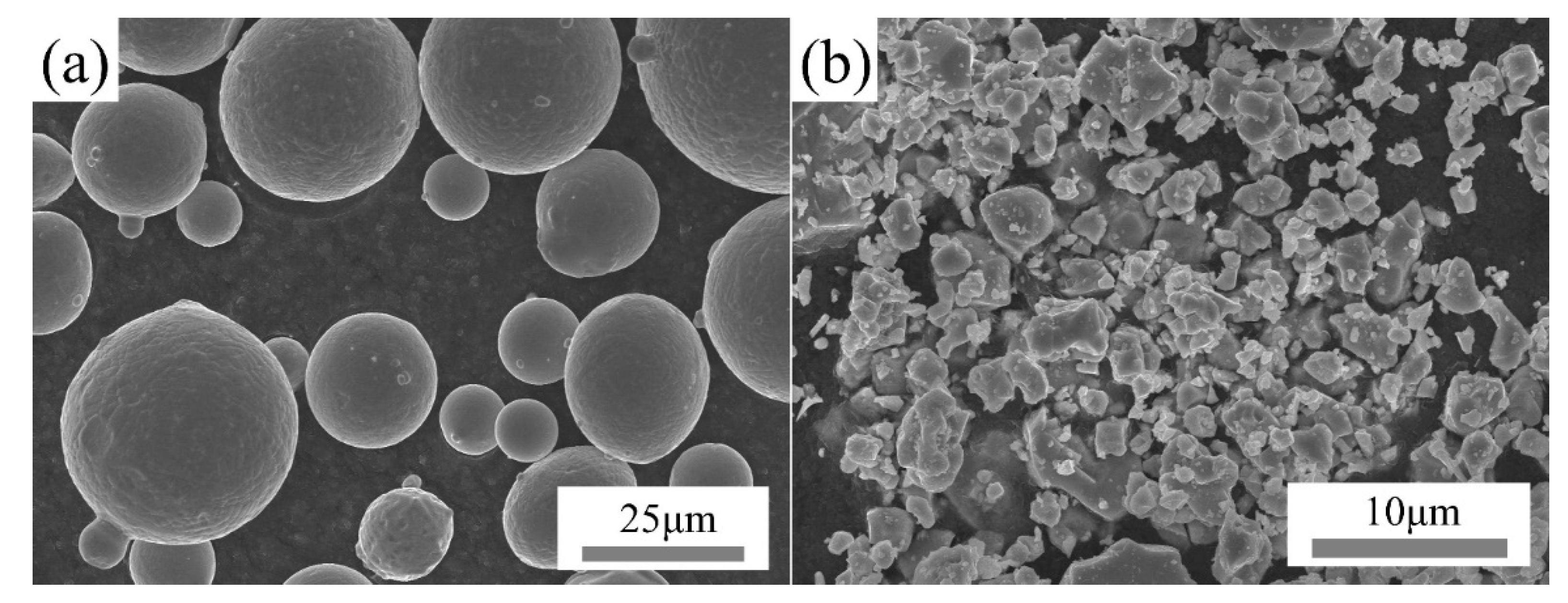

2.1. Powder Materials Preparation

2.2. Selective Laser Melting Process

2.3. Post-SLM Heat Treatment

2.4. Tensile Test

2.5. Microstructure Analysis

3. Results and Discussion

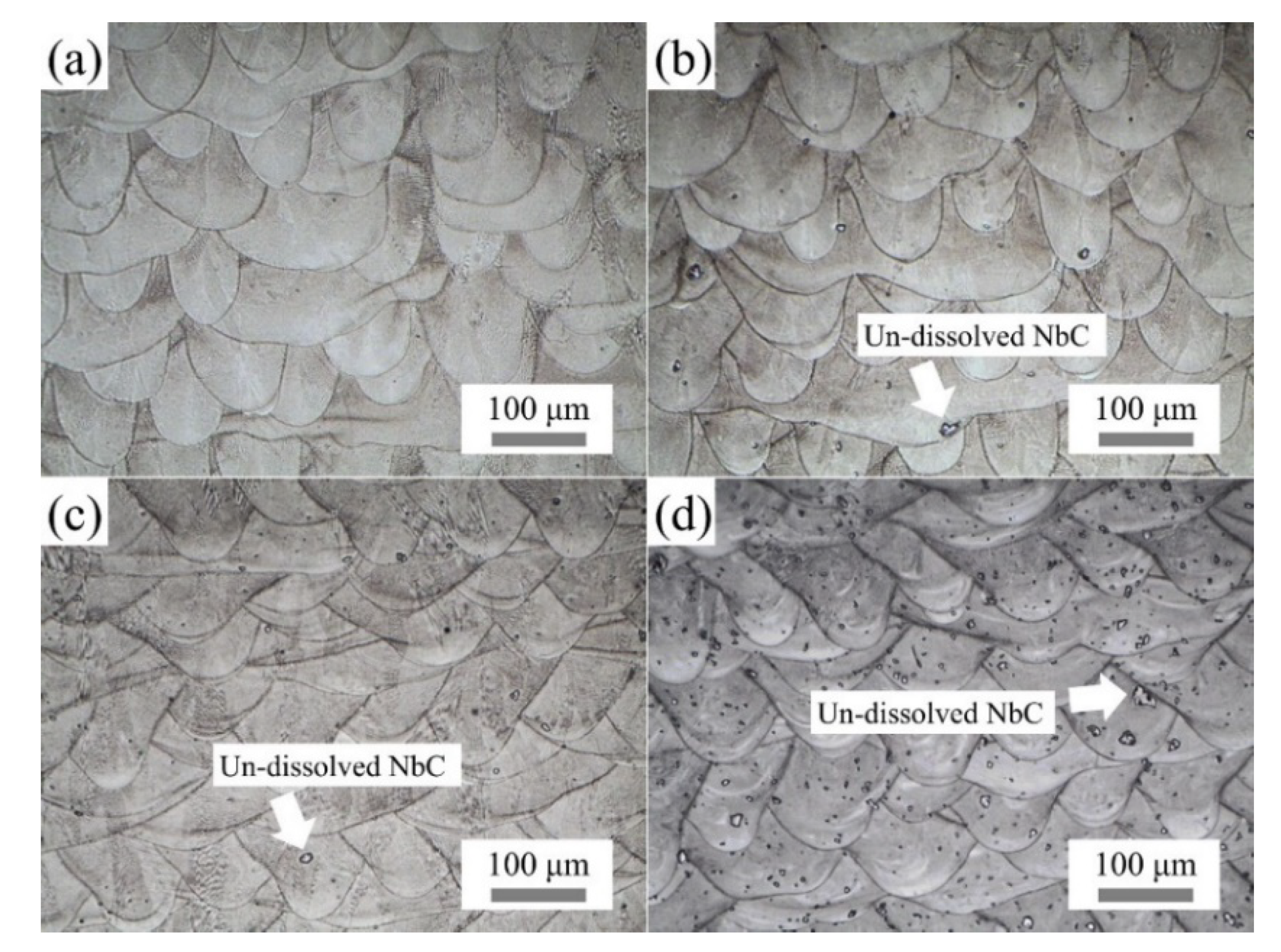

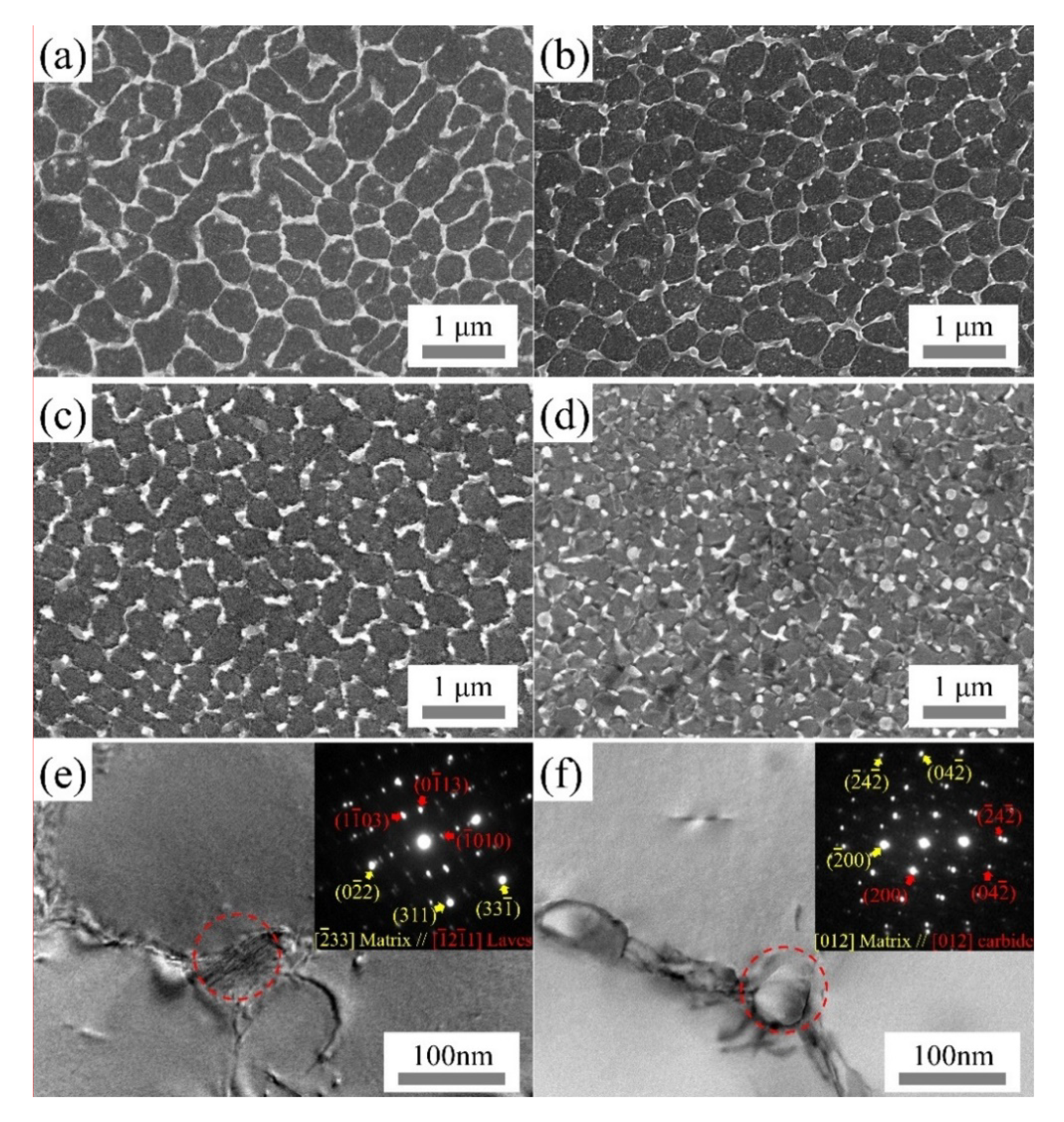

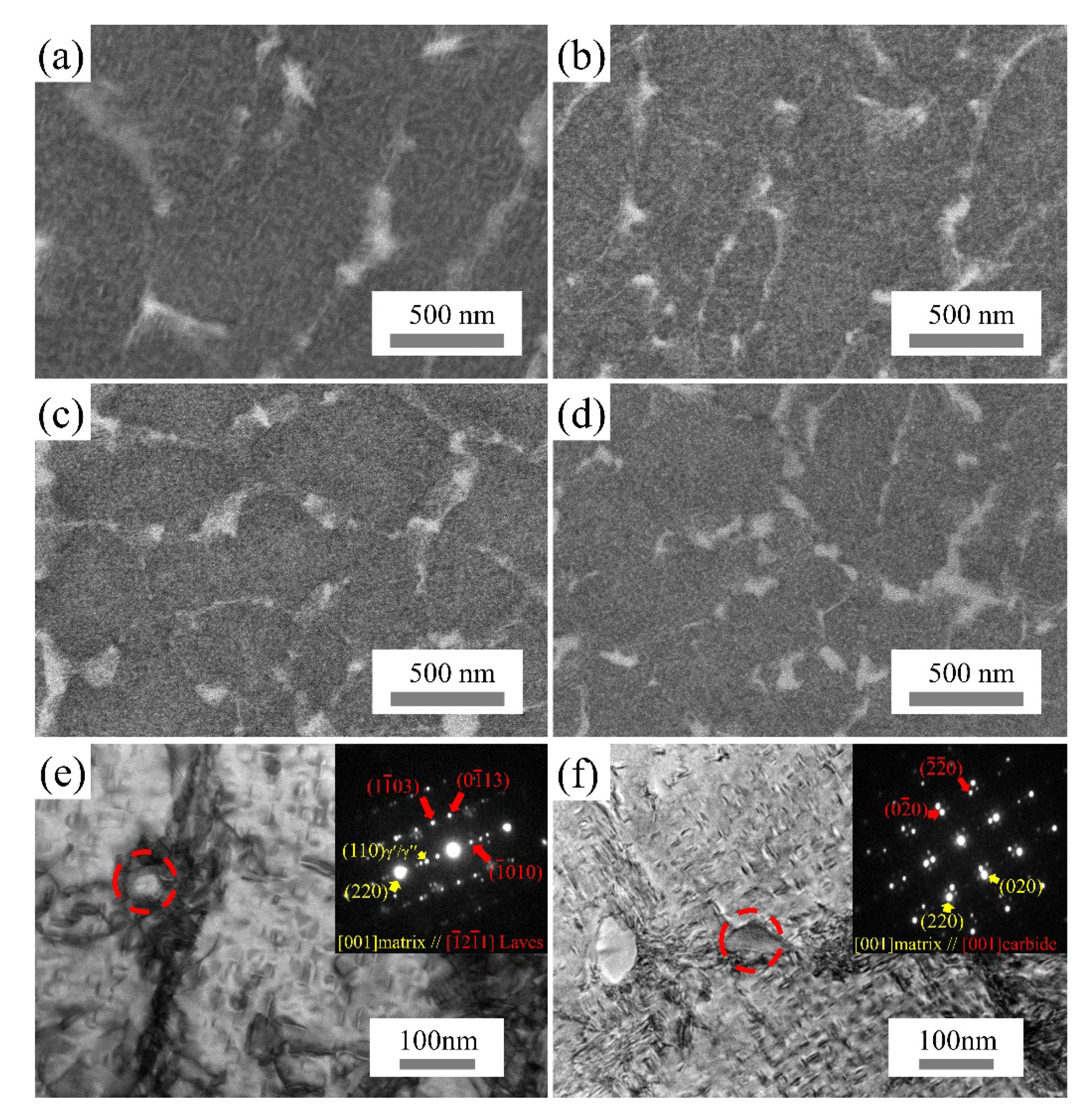

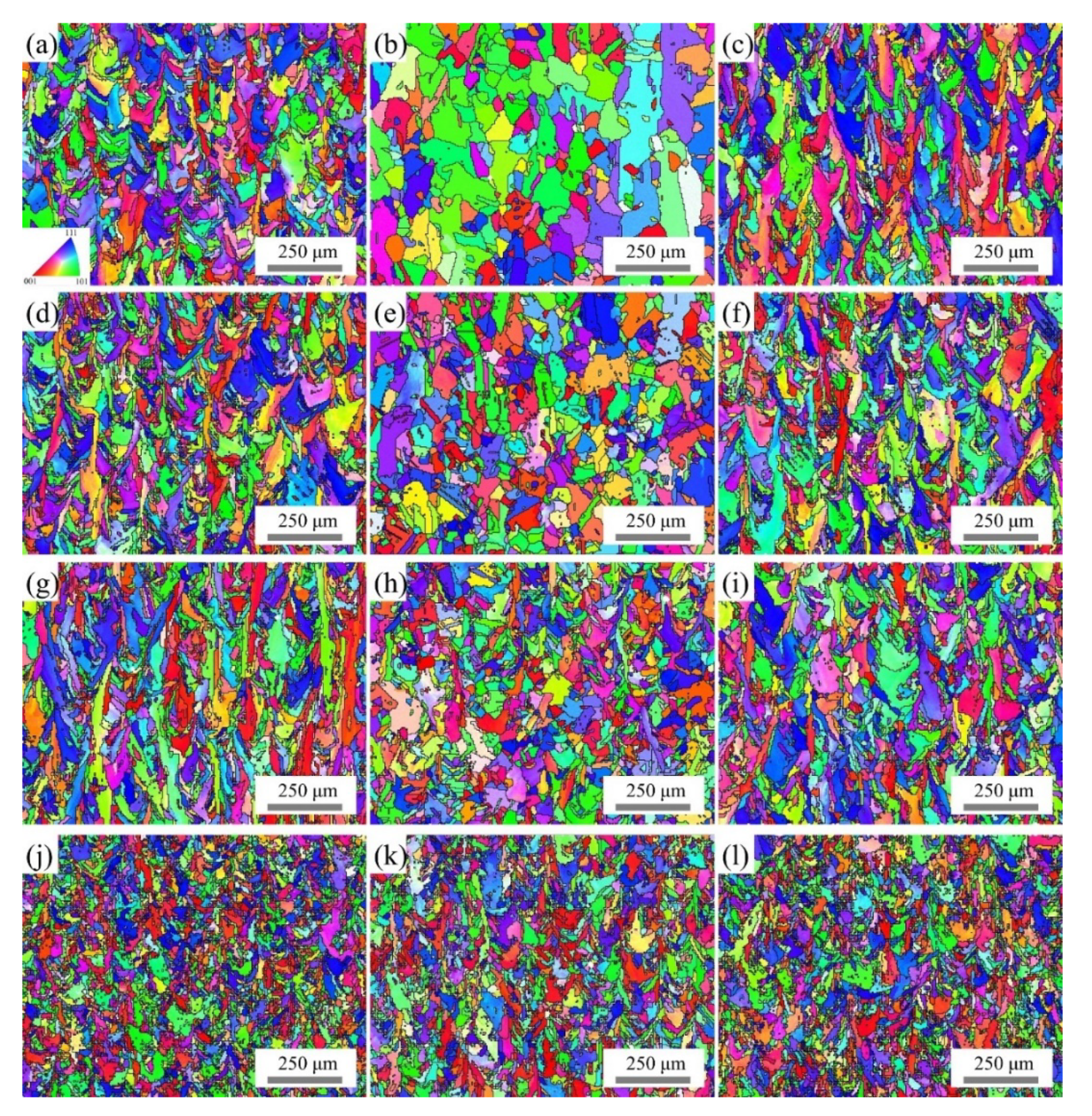

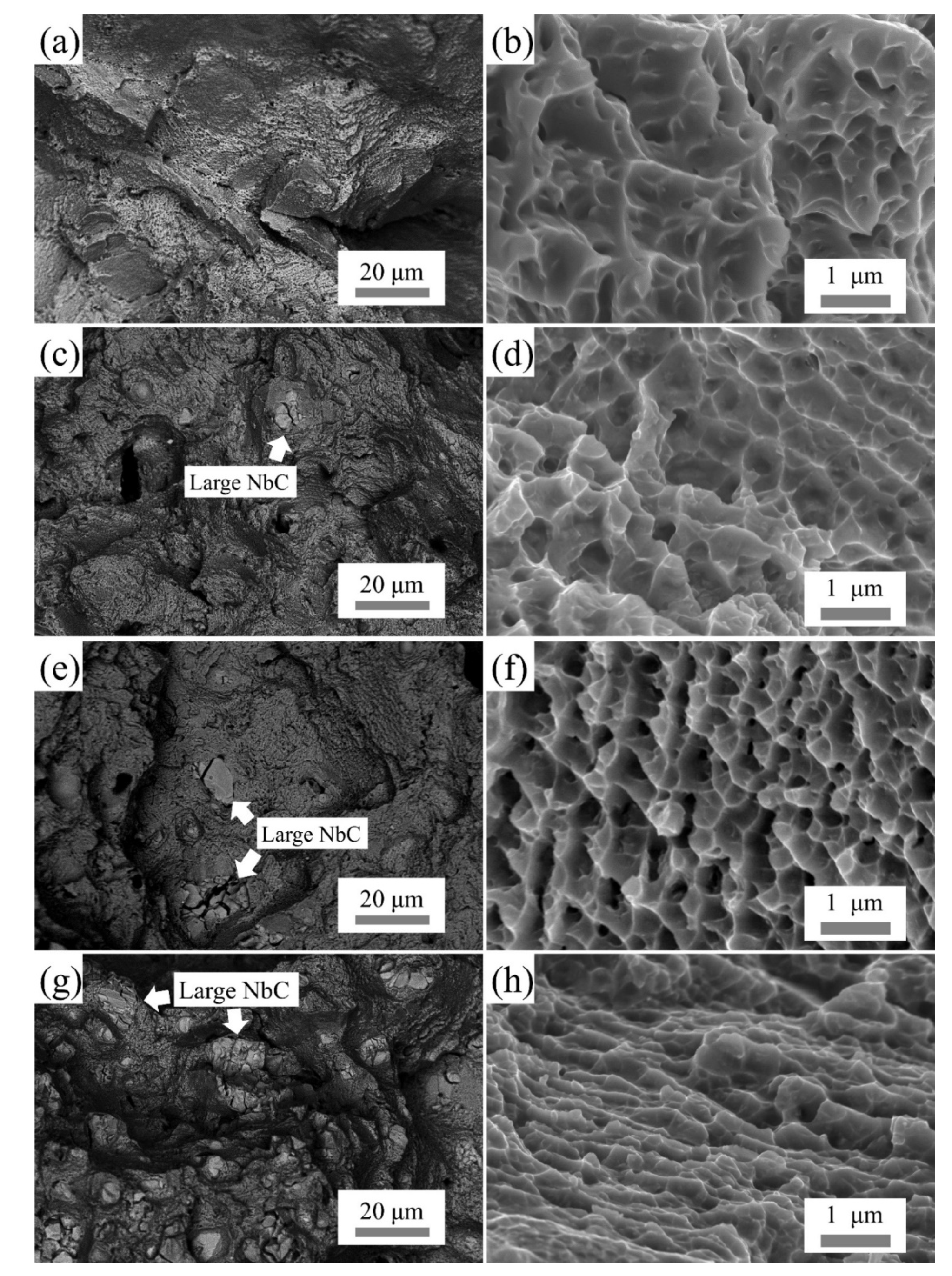

3.1. As-SLM Microstructures

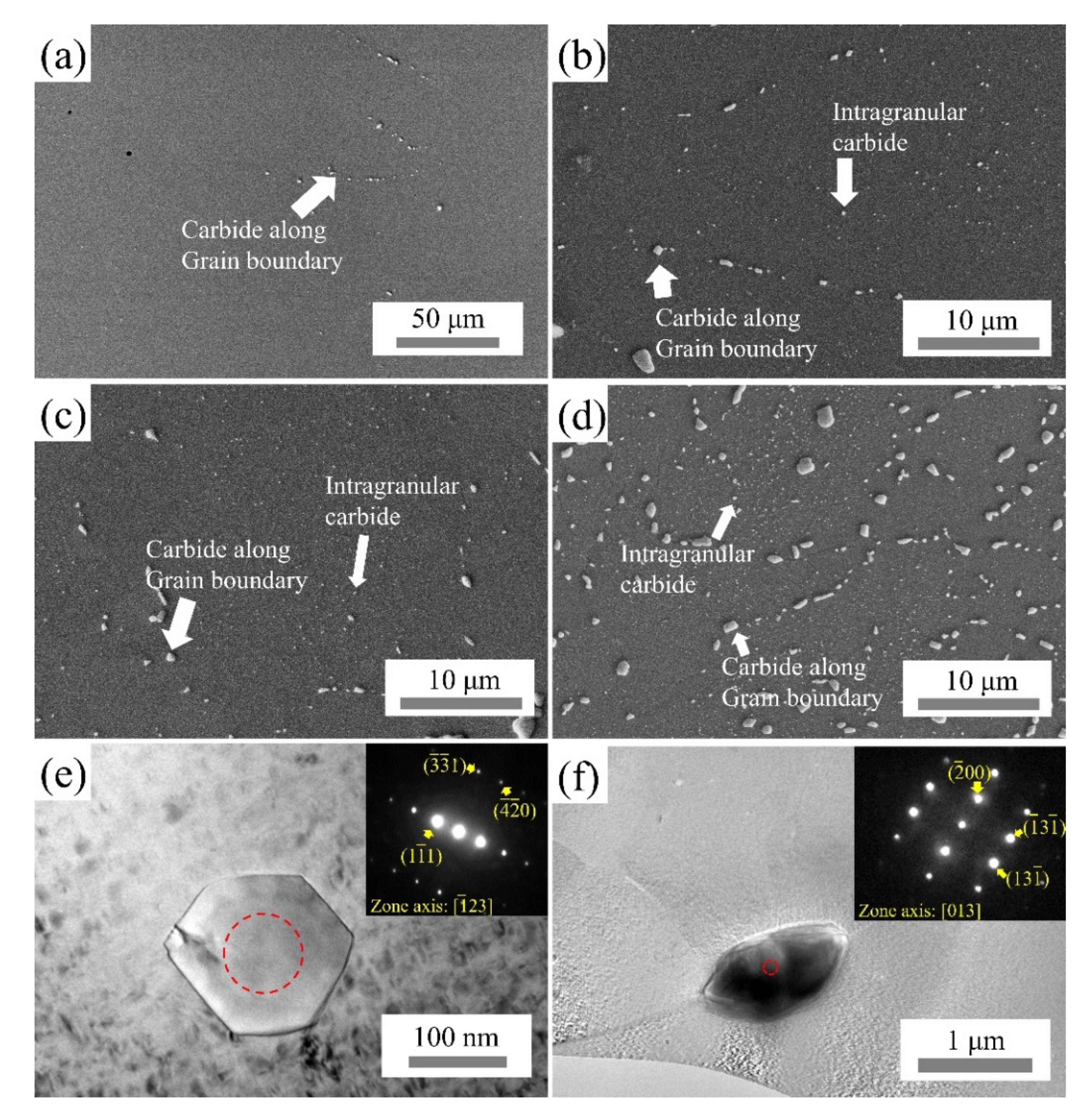

3.2. Microstructures after Post-SLM Heat Treatments

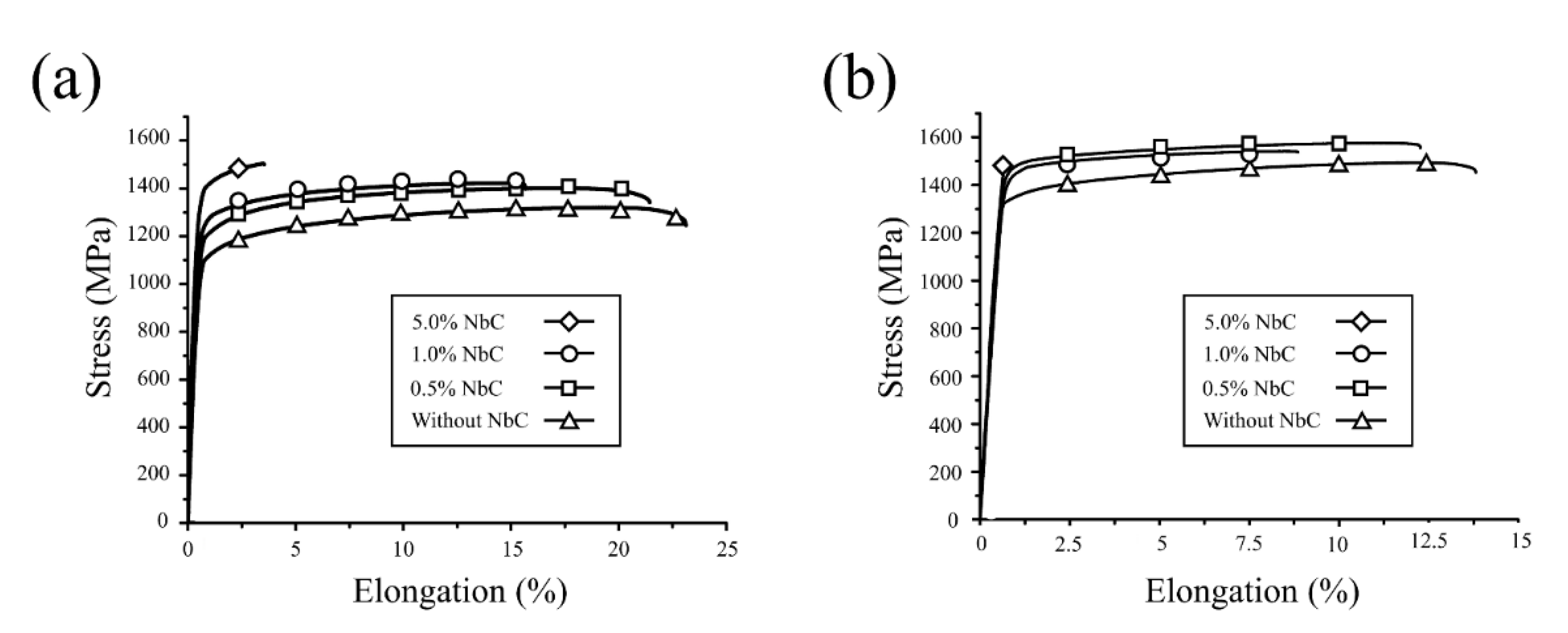

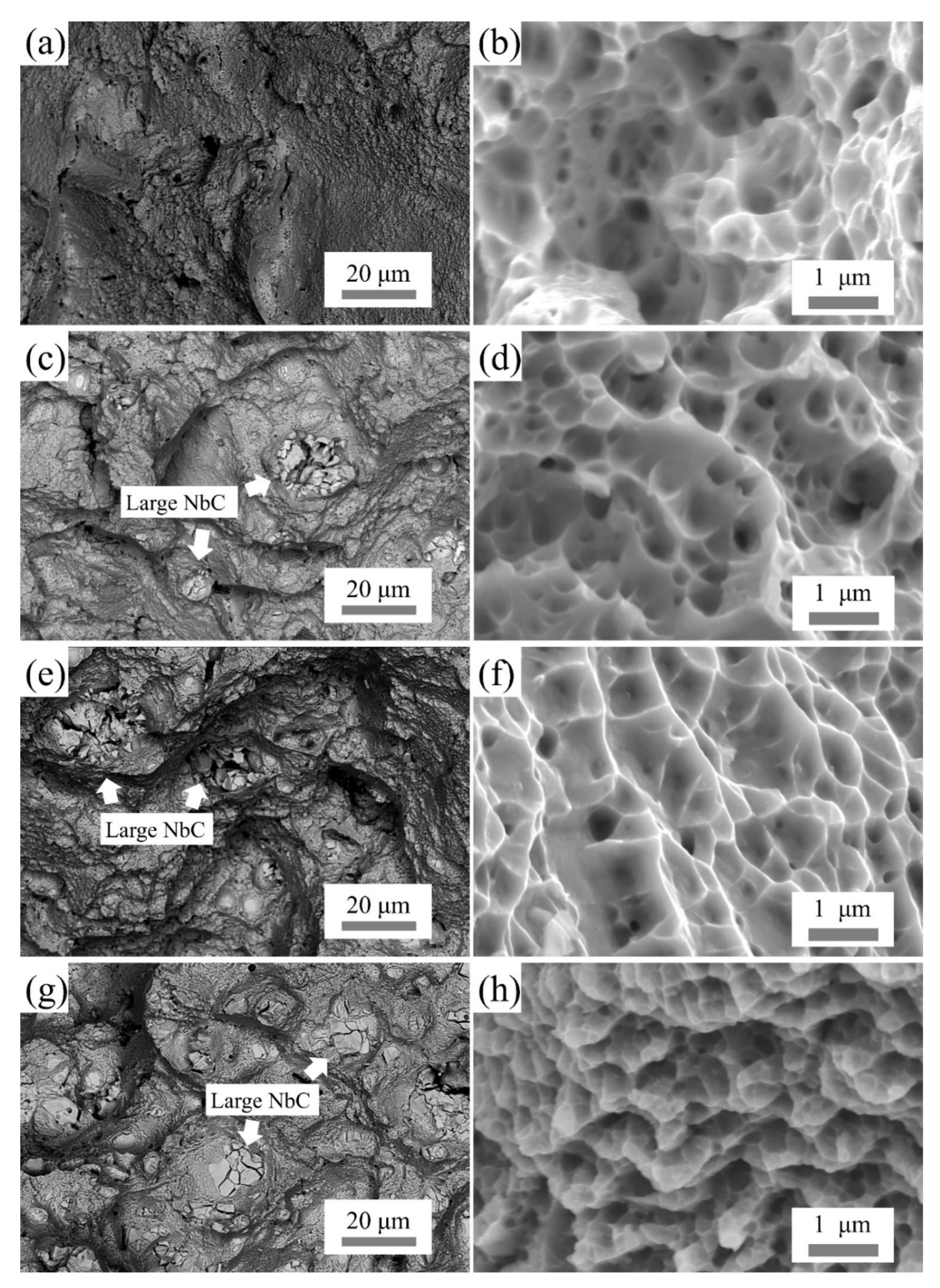

3.3. Tensile Properties

3.4. Comparison with Current State of the Art

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhavsar, R.B.; Collins, A.; Silverman, S. Use of Alloy 718 and 725 in Oil and Gas Industry. In Proceedings of the Fifth International Symposium on Superalloys 718, 625, 706, and Derivatives, Pittsburgh, PA, USA, 17–20 June 2001; pp. 47–55. [Google Scholar] [CrossRef]

- DeBarbadillo, J.J.; Mannan, S.K. Alloy 718 for Oilfield Applications. JOM 2012, 64, 265–270. [Google Scholar] [CrossRef]

- Radavich, J.F. The Physical Metallurgy of Cast and Wrought Alloy 718. In Proceedings of the Superalloys 2004: Tenth International Symposium on Superalloys 718, 625, 706, and Derivatives, Champion, PA, USA, 19–23 September 2004; pp. 229–240. [Google Scholar] [CrossRef]

- Private Communication with China Steel Corporation. 2014.

- Zhang, D.; Feng, Z.; Wang, C.; Wang, W.; Liu, Z.; Niu, W. Comparison of microstructures and mechanical properties of Inconel 718 alloy processed by selective laser melting and casting. Mater. Sci. Eng. A 2018, 724, 357–367. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Mukhtarov, S.K. Effect of Grain Size on the Superplastic Behavior of a Nanostructured Nickel-Based Superalloy. Mater. Sci. Forum 2009, 633–634, 569–575. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Yeh, A.-C.; Li, M.-Y.; Kuo, S.-M. Effects of processing routes on room temperature tensile strength and elongation for Inconel 718. Mater. Des. 2017, 119, 235–243. [Google Scholar] [CrossRef]

- Praveen, K.V.U.; Sastry, G.V.S.; Singh, V. Work-Hardening Behavior of the Ni-Fe Based Superalloy IN718. Metall. Mater. Trans. A 2008, 39, 65–78. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Kamigaichi, A.; Kakehi, K. Characterization of Ni-Based Superalloy Built by Selective Laser Melting and Electron Beam Melting. Metall. Mater. Trans. A 2018, 49, 3831–3837. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Ho, I.-T.; Chen, Y.-T.; Yeh, A.-C.; Chen, C.-P.; Jen, K.-K. Microstructure evolution induced by inoculants during the selective laser melting of IN718. Addit. Manuf. 2018, 21, 465–471. [Google Scholar] [CrossRef]

- Kakehi, K.; Banoth, S.; Kuo, Y.-L.; Hayashi, S. Effect of yttrium addition on creep properties of a Ni-base superalloy built up by selective laser melting. Scr. Mater. 2020, 183, 71–74. [Google Scholar] [CrossRef]

- Poyraz, Ö.; Kuşhan, M.C. Residual Stress-induced Distortions in Laser Powder Bed Additive Manufacturing of Nickel-based Superalloys. Stroj. Vestn. J. Mech. Eng. 2019, 65, 343–350. [Google Scholar] [CrossRef]

- Diepold, B.; Vorlaufer, N.; Neumeier, S.; Gartner, T.; Göken, M. Optimization of the heat treatment of additively manufactured Ni-base superalloy IN718. Int. J. Miner. Metall. Mater. 2020, 27, 640–648. [Google Scholar] [CrossRef]

- Ho, I.-T.; Hsu, T.-H.; Chang, Y.-J.; Li, C.-W.; Chang, K.-C.; Tin, S.; Kakehi, K.; Yeh, A.-C. Effects of CoAl2O4 inoculants on microstructure and mechanical properties of IN718 processed by selective laser melting. Addit. Manuf. 2020, 35, 101328. [Google Scholar] [CrossRef]

- Hsu, T.-H.; Chang, K.-C.; Chang, Y.-J.; Ho, I.-T.; Tin, S.; Li, C.-W.; Kakehi, K.; Chen, C.-P.; Jen, K.-K.; Hsieh, H.-Y.; et al. Effect of Carbide Inoculants Additions in IN718 Fabricated by Selective Laser Melting Process. In Superalloy 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 982–989. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Horikawa, S.; Kakehi, K. The effect of interdendritic δ phase on the mechanical properties of Alloy 718 built up by additive manufacturing. Mater. Des. 2017, 116, 411–418. [Google Scholar] [CrossRef]

- Gallmeyer, T.G.; Moorthy, S.; Kappes, B.B.; Mills, M.J.; Amin-Ahmadi, B.; Stebner, A.P. Knowledge of process-structure-property relationships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718. Addit. Manuf. 2020, 31, 100977. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Texture control during laser deposition of nickel-based superalloy. Scr. Mater. 2012, 67, 503–506. [Google Scholar] [CrossRef]

- Baufeld, B. Mechanical Properties of INCONEL 718 Parts Manufactured by Shaped Metal Deposition (SMD). J. Mater. Eng. Perform. 2012, 21, 1416–1421. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of Standard Heat Treatment Effects on Microstructure and Mechanical Properties of Laser Net Shape Manufactured INCONEL 718. Metall. Mater. Trans. A 2009, 40, 2410–2422. [Google Scholar] [CrossRef]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar] [CrossRef]

- Sames, W. Additive Manufacturing of Inconel 718 Using Electron Beam Melting: Processing, Post-Processing, & Mechanical Properties. Ph.D. Thesis, Texas Agricultural and Mechanical University, College Station, TX, USA, 2015. [Google Scholar]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Barroqueiro, B.; Andrade-Campos, A.; Valente, R.A.F.; Neto, V. Metal additive manufacturing cycle in aerospace industry: A comprehensive review. J. Manuf. Mater. Process. 2019, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wooldridge, M.; Wangenheim, C.; Herberg, W.; Wettmarshausen, T. Applications of Metal Additive Manufacturing in the Oil and Gas Industry. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Choe, J.; Lee, K.-A. Selective laser melted equiatomic CoCrFeMnNi high-entropy alloy: Microstructure, anisotropic mechanical response, and multiple strengthening mechanism. J. Alloys Compd. 2019, 805, 680–691. [Google Scholar] [CrossRef]

- Lin, W.-C.; Chang, Y.-J.; Hsu, T.-H.; Gorsse, S.; Sun, F.; Furuhara, T.; Yeh, A.-C. Microstructure and tensile property of a precipitation strengthened high entropy alloy processed by selective laser melting and post heat treatment. Addit. Manuf. 2020, 36, 101601. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.-K.; Grzesiak, D.; Lee, K.-A. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, T.; Manvatkar, V.; De, A.; DebRoy, T. Mitigation of thermal distortion during additive manufacturing. Scr. Mater. 2017, 127, 79–83. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Setchi, R.; Lacan, F.; Johnston, R.; Evans, S.L.; Yang, S. Additive manufacturing of high-strength crack-free Ni-based Hastelloy X superalloy. Addit. Manuf. 2019, 30, 100919. [Google Scholar] [CrossRef]

- Beaubois, V.; Huez, J.; Coste, S.; Brucelle, O.; Lacaze, J. Short term precipitation kinetics of delta phase in strain free Inconel* 718 alloy. Mater. Sci. Technol. 2004, 20, 1019–1026. [Google Scholar] [CrossRef]

- ASTM E8/E8M-21 Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Konijnenberg, P.J.; Zaefferer, S.; Raabe, D. Assessment of geometrically necessary dislocation levels derived by 3D EBSD. Acta Mater. 2015, 99, 402–414. [Google Scholar] [CrossRef]

- Muránsky, O.; Balogh, L.; Tran, M.; Hamelin, C.J.; Park, J.S.; Daymond, M.R. On the measurement of dislocations and dislocation substructures using EBSD and HRSD techniques. Acta Mater. 2019, 175, 297–313. [Google Scholar] [CrossRef]

- Kamaya, M. Assessment of local deformation using EBSD: Quantification of accuracy of measurement and definition of local gradient. Ultramicroscopy 2011, 111, 1189–1199. [Google Scholar] [CrossRef] [PubMed]

- Abbaschian, R.; Abbaschian, L.; Reed-Hill, R.E. Physical Metallurgy Principles, 4th ed.; SI vesrion; CENGAGE Learning: Boston, MA, USA, 2010; ISBN 978-0495438519. [Google Scholar]

- Gu, D.; Ma, C.; Xia, M.; Dai, D.; Shi, Q. A Multiscale Understanding of the Thermodynamic and Kinetic Mechanisms of Laser Additive Manufacturing. Engineering 2017, 3, 675–684. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Borkar, T.; Yang, J.-M. Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting. Mater. Des. 2018, 138, 119–128. [Google Scholar] [CrossRef]

- Kou, S. Basic Solidification Concepts. In Welding Metallurgy; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 143–169. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; San Marchi, C.; Schoenung, J.M. Strengthening mechanisms in directed energy deposited austenitic stainless steel. Acta Mater. 2019, 164, 728–740. [Google Scholar] [CrossRef]

- Wang, G.; Ouyang, H.; Fan, C.; Guo, Q.; Li, Z.; Yan, W.; Li, Z. The origin of high-density dislocations in additively manufactured metals. Mater. Res. Lett. 2020, 8, 283–290. [Google Scholar] [CrossRef]

- Birnbaum, A.J.; Steuben, J.C.; Barrick, E.J.; Iliopoulos, A.P.; Michopoulos, J.G. Intrinsic strain aging, Σ3 boundaries, and origins of cellular substructure in additively manufactured 316L. Addit. Manuf. 2019, 29, 100784. [Google Scholar] [CrossRef]

- Ci, S.; Liang, J.; Li, J.; Wang, H.; Zhou, Y.; Sun, X.; Zhang, H.; Ding, Y.; Zhou, X. Prediction of Primary Dendrite Arm Spacing in Pulsed Laser Surface Melted Single Crystal Superalloy. Acta Metall. Sin. (Engl. Lett.) 2020, 34, 485–494. [Google Scholar] [CrossRef]

- Manikandan, S.G.K.; Sivakumar, D.; Rao, K.P.; Kamaraj, M. Laves phase in alloy 718 fusion zone—Microscopic and calorimetric studies. Mater. Charact. 2015, 100, 192–206. [Google Scholar] [CrossRef]

- Cuppari, M.; Santos, S. Physical Properties of the NbC Carbide. Metals 2016, 6, 250. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Deb, P.; Chaturvedi, M.C. Coarsening behaviour of γ″- and γ′-particles in Inconel alloy 718. Met. Sci. 1982, 16, 555–562. [Google Scholar] [CrossRef]

- Kleemola, H.J.; Nieminen, M.A. On the strain-hardening parameters of metals. Metall. Trans. 1974, 5, 1863–1866. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Kozar, R.W.; Suzuki, A.; Milligan, W.W.; Schirra, J.J.; Savage, M.F.; Pollock, T.M. Strengthening Mechanisms in Polycrystalline Multimodal Nickel-Base Superalloys. Metall. Mater. Trans. A 2009, 40, 1588–1603. [Google Scholar] [CrossRef]

- Mughrabi, H. A two-parameter description of heterogeneous dislocation distributions in deformed metal crystals. Mater. Sci. Eng. 1987, 85, 15–31. [Google Scholar] [CrossRef]

- Hong, Y.; Zhou, C.; Zheng, Y.; Zhang, L.; Zheng, J. The cellular boundary with high density of dislocations governed the strengthening mechanism in selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2021, 799, 140279. [Google Scholar] [CrossRef]

- Cheng, Y.; Xiao, Z.; Zhu, H.; Zeng, X.; Wang, G. Influence of substrate characteristics on residual stress of SLMed Inconel 718. Rapid Prototyp. J. 2019, 25, 792–799. [Google Scholar] [CrossRef]

- Reed, R.C. The physical metallurgy of nickel and its alloys. In The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 33–120. [Google Scholar] [CrossRef]

- Chaturvedi, M.C.; Han, Y. Strengthening mechanisms in Inconel 718 superalloy. Met. Sci. 1983, 17, 145–149. [Google Scholar] [CrossRef]

- AMS F Corrosion Heat Resistant Alloys Committee. Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings 52.5Ni-19Cr-3.0Mo-5.1Cb (Nb)-0.90Ti-0.50Al-18Fe Consumable Electrode or Vacuum Induction Melted 1775 °F (968 °C) Solution and Precipitation Heat Treated (SAE AMS 5663); SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Fe | Nb | Mo | Al | Ti | C |

|---|---|---|---|---|---|---|---|---|

| at% | 51.00 | 19.63 | 21.51 | 3.39 | 1.85 | 1.23 | 1.26 | 0.1334 |

| Condition | Position | Ni | Cr | Fe | Nb | Mo | Al | Ti |

|---|---|---|---|---|---|---|---|---|

| Without NbC | Cellular core | 51.53 ± 0.91 | 21.60 ± 1.29 | 19.05 ± 0.26 | 2.81 ± 0.25 | 2.15 ± 0.24 | 1.45 ± 1.03 | 1.18 ± 0.1 |

| Cellular wall | 45.42 ± 0.62 | 18.96 ± 1.92 | 15.73 ± 1.97 | 13.43 ± 2.07 | 2.97 ± 1.73 | 1.40 ± 0.40 | 2.10 ± 0.70 | |

| Laves | 40.40 ± 2.01 | 16.40 ± 0.91 | 17.83 ± 1.85 | 15.95 ± 2.60 | 6.40 ± 1.74 | 1.45 ± 0.24 | 1.33 ± 0.43 | |

| With NbC (0.5%) | Cellular core | 50.33 ± 0.57 | 22.53 ± 1.40 | 19.37 ± 0.90 | 3.43 ± 0.47 | 1.70 ± 0.30 | 1.60 ± 0.10 | 1.03 ± 0.27 |

| Cellular wall | 46.25 ± 0.35 | 19.05 ± 1.35 | 15.40 ± 0.31 | 12.85 ± 3.05 | 3.15 ± 0.35 | 1.63 ± 0.43 | 1.68 ± 0.42 | |

| Carbide | 17.57 ± 6.22 | 12.50 ± 0.83 | 5.87 ± 2.00 | 47.22 ± 5.11 | 7.20 ± 2.30 | 1.00 ± 0.08 | 8.63 ± 4.20 |

| Treatment | Condition | Ni | Cr | Fe | Nb | Mo | Al | Ti |

|---|---|---|---|---|---|---|---|---|

| STA | Without NbC | 5.45 ± 0.44 | 3.25 ± 0.15 | 2.67 ± 0.21 | 67.26 ± 1.55 | - | 0.75 ± 0.45 | 20.71 ± 1.41 |

| With NbC (0.5%) | 6.60 ± 0.50 | 3.43 ± 0.26 | 2.67 ± 0.21 | 68.83 ± 0.17 | 1.17 ± 0.17 | 0.3 ± 0.08 | 17.00 ± 0.96 | |

| DA | Without NbC | 29.76 ± 0.78 | 19.93 ± 1.50 | 18.83 ± 0.66 | 15.00 ± 3.14 | 15.57 ± 2.09 | - | 0.87 ± 0.12 |

| With NbC (1.0%) | 8.53 ± 0.50 | 11.97 ± 1.96 | 3.47 ± 0.09 | 58.9 ± 2.81 | 5.03 ± 0.29 | 1 ± 0.08 | 8.63 ± 4.20 |

| Condition | Treatment | Site | Volume Fraction | Average Diameter |

|---|---|---|---|---|

| Without NbC | STA | Intragranular carbide | 0.11% | 47.4 nm |

| Grain boundary carbide | 0.09% | 544.3 nm | ||

| DA | Cellular wall Laves | 1.28% | 35.3 nm | |

| 0.5% NbC | STA | Intragranular carbide | 0.53% | 46.0 nm |

| Grain boundary carbide | 0.71% | 458.8 nm | ||

| DA | Cellular wall carbide | 2.54% | 32.6 nm | |

| 1.0% NbC | STA | Intragranular carbide | 0.80% | 57.0 nm |

| Grain boundary carbide | 0.93% | 519.3 nm | ||

| DA | Cellular wall carbide | 3.61% | 32.3 nm | |

| 5.0% NbC | STA | Intragranular carbide | 3.23% | 51.1 nm |

| Grain boundary carbide | 4.36% | 628 nm | ||

| DA | Cellular wall carbide | 7.60% | 42.5 nm |

| Condition | As-Built | STA | DA |

|---|---|---|---|

| Without NbC | 18.94 μm | 44.53 μm | 19.90 μm |

| 0.5% NbC | 17.97 μm | 30.85 μm | 18.57 μm |

| 1.0% NbC | 17.11 μm | 21.53 μm | 18.26 μm |

| 5.0% NbC | 10.51 μm | 13.45 μm | 11.11 μm |

| Condition | As-Built | STA | DA |

|---|---|---|---|

| Without NbC | 4.18 × 1013 /m2 | 1.31 × 1012 /m2 | 4.32 × 1013 /m2 |

| 0.5% NbC | 4.06 × 1013 /m2 | 2.84 × 1012 /m2 | 4.05 × 1013 /m2 |

| 1.0% NbC | 4.54 × 1013 /m2 | 1.74 × 1013 /m2 | 4.35 × 1013 /m2 |

| 5.0% NbC | 4.04 × 1013 /m2 | 3.62 × 1013 /m2 | 3.87 × 1013 /m2 |

| Condition | Treatment | YS (MPa) | UTS (MPa) | E (GPa) | Elongation% | Strain Hardening Exponent n |

|---|---|---|---|---|---|---|

| Without NbC | As-built | 771.6 ± 3.2 | 1031.5 ± 5.2 | 200.04 ± 13.7 | 25.94 ± 0.14 | 0.1230 ± 0.0048 |

| SHT | 379.5 ± 6.4 | 876.2 ± 9.7 | 205.3 ± 7.7 | 61.02 ± 0.67 | 0.2162± 0.0091 | |

| STA | 1134.8 ± 4.8 | 1312.5 ± 3.3 | 200.0 ± 7.0 | 23.86 ± 1.19 | 0.1001 ± 0.0032 | |

| DA | 1357.5 ± 2.5 | 1490.4 ± 3.4 | 223.0 ± 3.0 | 14.59 ± 4.45 | 0.0796 ± 0.0041 | |

| 0.5% NbC | As-built | 841.4 ± 0.35 | 1105.9 ± 1.1 | 212.8 ± 3.2 | 20.62 ± 0.77 | 0.1199 ± 0.0035 |

| STA | 1175.7 ± 20.4 | 1395.3 ± 3.3 | 205.2 ± 17.9 | 20.40 ± 0.50 | 0.0968 ± 0.0004 | |

| DA | 1461.0 ± 2.5 | 1575.2 ± 0.2 | 219.2 ± 10.0 | 10.45 ± 0.19 | 0.0679 ± 0.0011 | |

| 1.0% NbC | STA | 1221.6 ± 5.4 | 1423.8 ± 2.2 | 214.2 ± 20.8 | 9.95 ± 1.45 | 0.0850 ± 0.0006 |

| DA | 1439.5 ± 16.5 | 1545.3 ± 4.4 | 212.5 ± 1.3 | 6.80 ± 1.43 | 0.0541 ± 0.0027 | |

| 5.0% NbC | STA | 1325.5 ± 35.5 | 1498.4 ± 5.4 | 235.0 ± 1.0 | 3.33 ± 0.03 | 0.0654 ± 0.0002 |

| DA | Broke before YS | 1412.8 ± 85.2 | 213.8 ± 1.3 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, K.-C.; Lee, M.-Y.; Hsu, T.-H.; Chang, Y.-J.; Lo, K.-C.; Kim, H.S.; Jen, K.-K.; Yeh, A.-C. An Effective Strengthening Strategy of Nano Carbide Precipitation and Cellular Microstructure Refinement in a Superalloy Fabricated by Selective Laser Melting Process. Metals 2021, 11, 1691. https://doi.org/10.3390/met11111691

Chang K-C, Lee M-Y, Hsu T-H, Chang Y-J, Lo K-C, Kim HS, Jen K-K, Yeh A-C. An Effective Strengthening Strategy of Nano Carbide Precipitation and Cellular Microstructure Refinement in a Superalloy Fabricated by Selective Laser Melting Process. Metals. 2021; 11(11):1691. https://doi.org/10.3390/met11111691

Chicago/Turabian StyleChang, Kai-Chun, Meng-Yun Lee, Tzu-Hou Hsu, Yao-Jen Chang, Kai-Chi Lo, Hyoung Seop Kim, Kuo-Kuang Jen, and An-Chou Yeh. 2021. "An Effective Strengthening Strategy of Nano Carbide Precipitation and Cellular Microstructure Refinement in a Superalloy Fabricated by Selective Laser Melting Process" Metals 11, no. 11: 1691. https://doi.org/10.3390/met11111691

APA StyleChang, K.-C., Lee, M.-Y., Hsu, T.-H., Chang, Y.-J., Lo, K.-C., Kim, H. S., Jen, K.-K., & Yeh, A.-C. (2021). An Effective Strengthening Strategy of Nano Carbide Precipitation and Cellular Microstructure Refinement in a Superalloy Fabricated by Selective Laser Melting Process. Metals, 11(11), 1691. https://doi.org/10.3390/met11111691