1. Introduction

Recently, the joining of dissimilar metals has gained much attention in the automotive, aerospace, and electrical power industries, due to growing demands in efficiency and specific properties for metals. Steel, as the most widely used metal, cannot fulfil certain demands and is partly substituted by modern Al, Cu or Ti alloys. As a result, the necessity of joining dissimilar metals has gained much attention in the past decade and is growing rapidly.

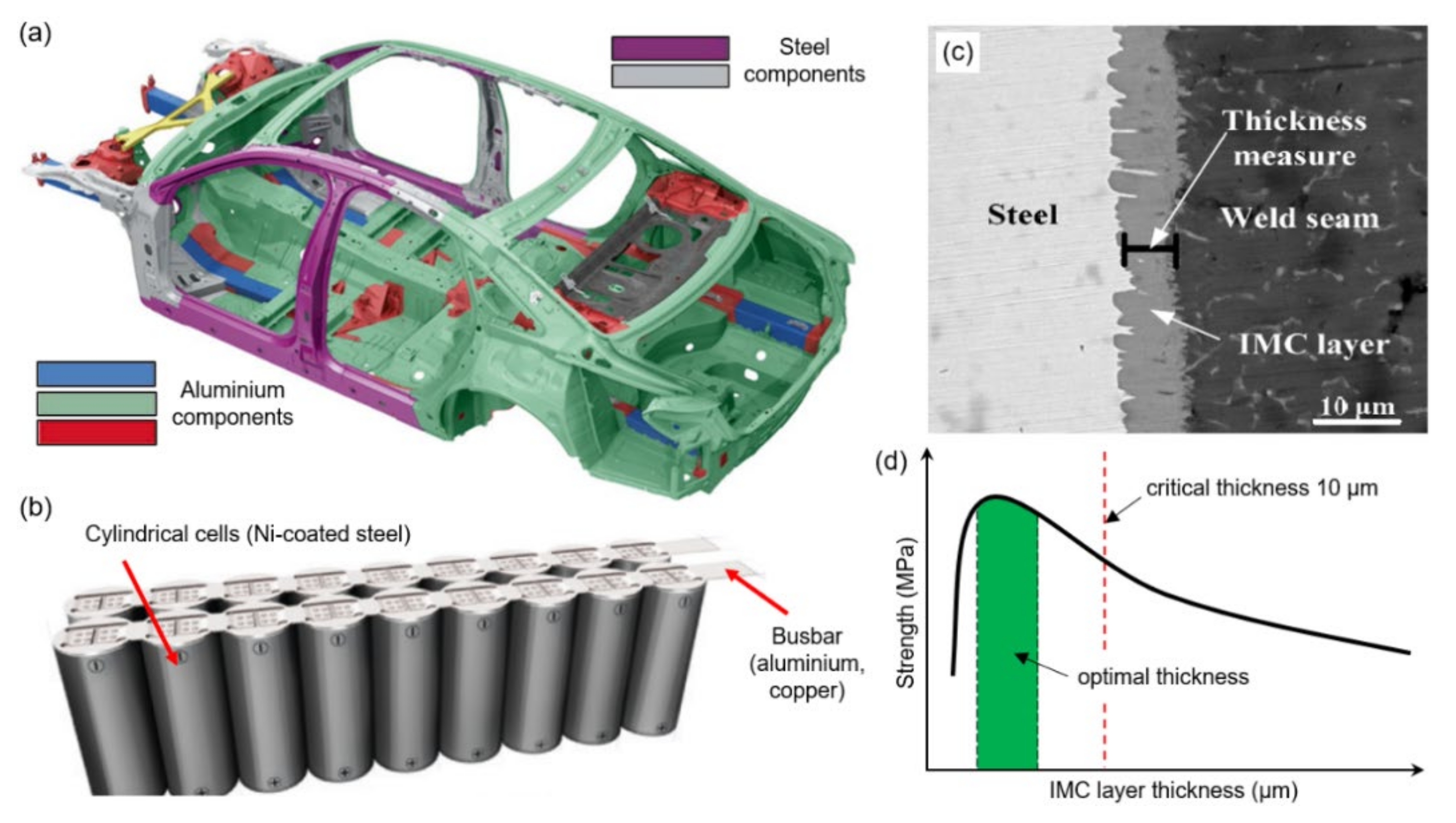

For car body production in the automotive industry, galvanised steel has been used for many years and is commonly welded by resistance spot welding. Aluminium is frequently applied for improved weight reduction and corrosion resistance. An example of different metal combinations in an automobile body structure is shown in

Figure 1a. In the aerospace industry, also the combination of aluminium with titanium is becoming frequent, due to weight reduction. Friction stir welding (FSW) has gained more popularity since it may provide high-quality joints, due to low heat input [

1]. However, the process has limited productivity and flexibility, compared to fusion welding processes. Batteries are an important part of society’s everyday needs, used in portable electronic devices, cordless power tools, energy storage, hybrid/electric vehicles, and many other applications. In the development of batteries, there are growing demands for weight reduction and an increase in corrosion resistance; therefore, parts made from steel in batteries are substituted with Al (weight reduction, higher electrical conductivity, corrosion resistance) and Cu (much higher electrical conductivity, corrosion resistance). Each individual battery cell (or cell unit) is connected, forming a pack of batteries (module), using a busbar (or terminal), which is now usually made from copper/aluminium, as exemplified in

Figure 1b. Lithium–ion cells are the most dominant type among batteries in the automotive vehicle industry, due to having the highest energy density available [

2], where the outer shells are often produced from nickel-plated steel. The pouch cell type is very popular and is produced in very large quantities, with more than 1 billion cells per year [

3]. Individual battery cells are joined (in series or parallel) to modules (consisting of cell units) by high electrical conductivity material, which is usually copper or aluminium. According to Das et al. [

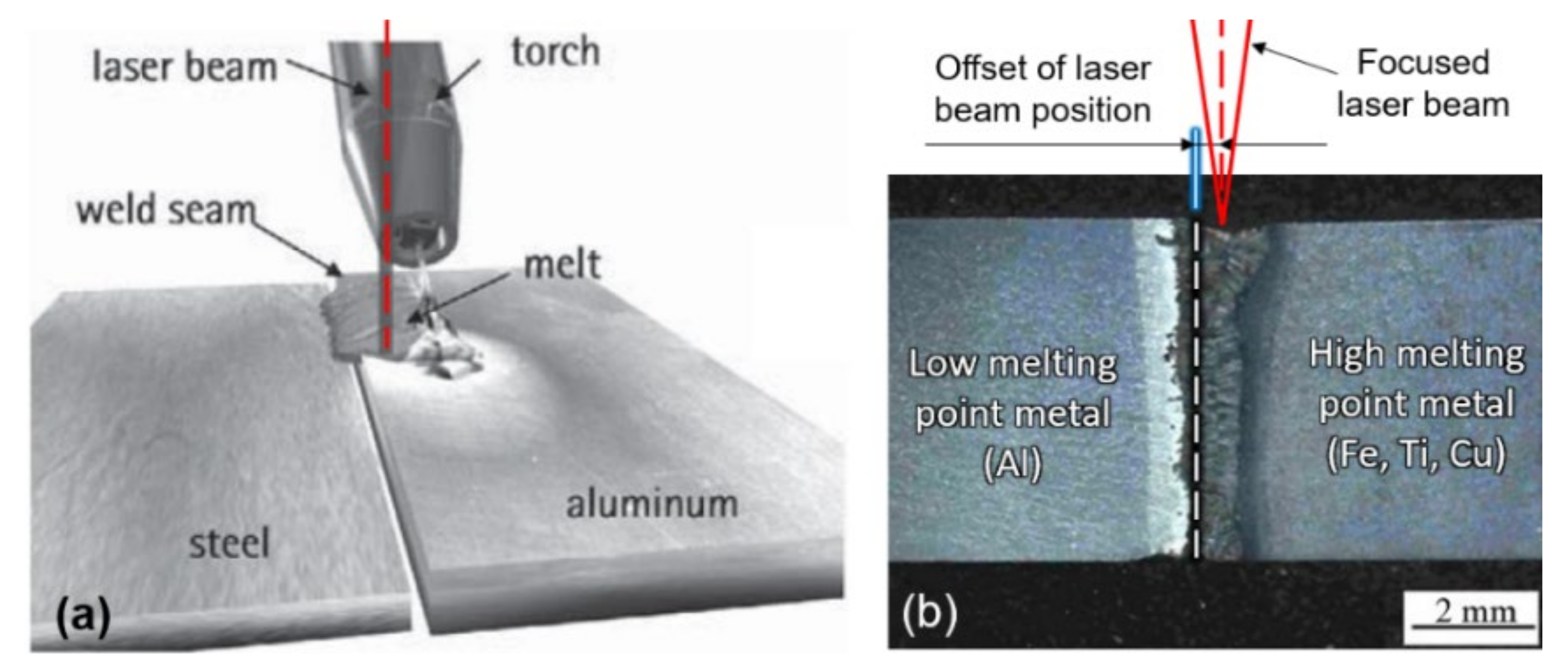

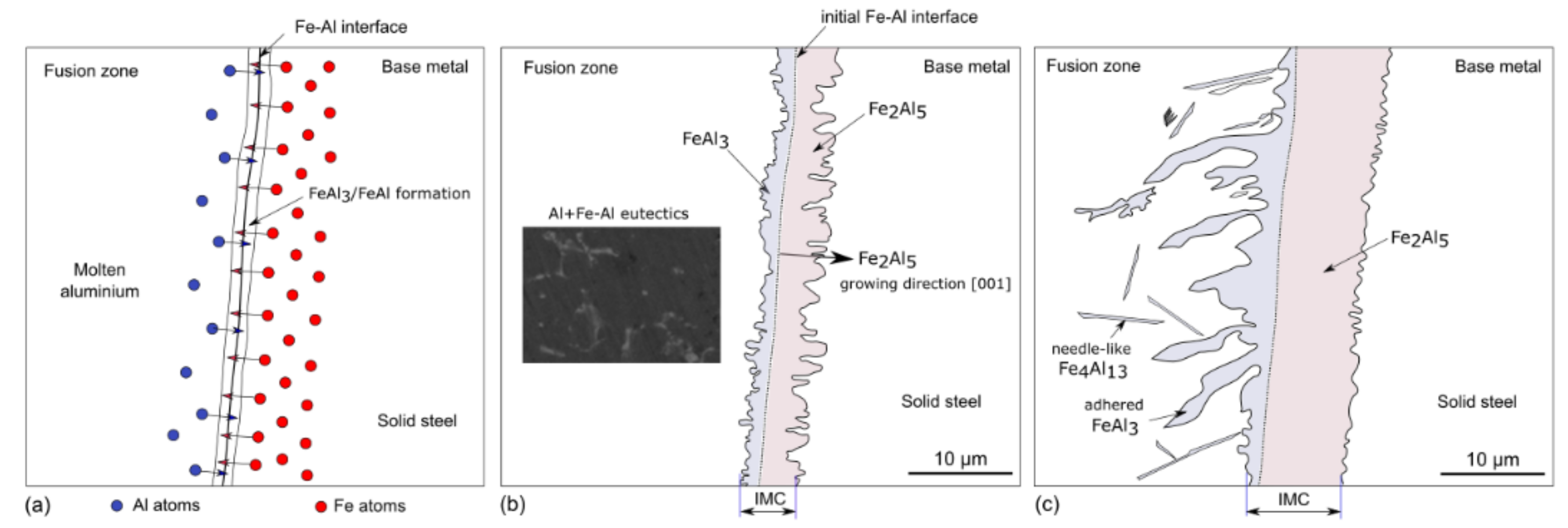

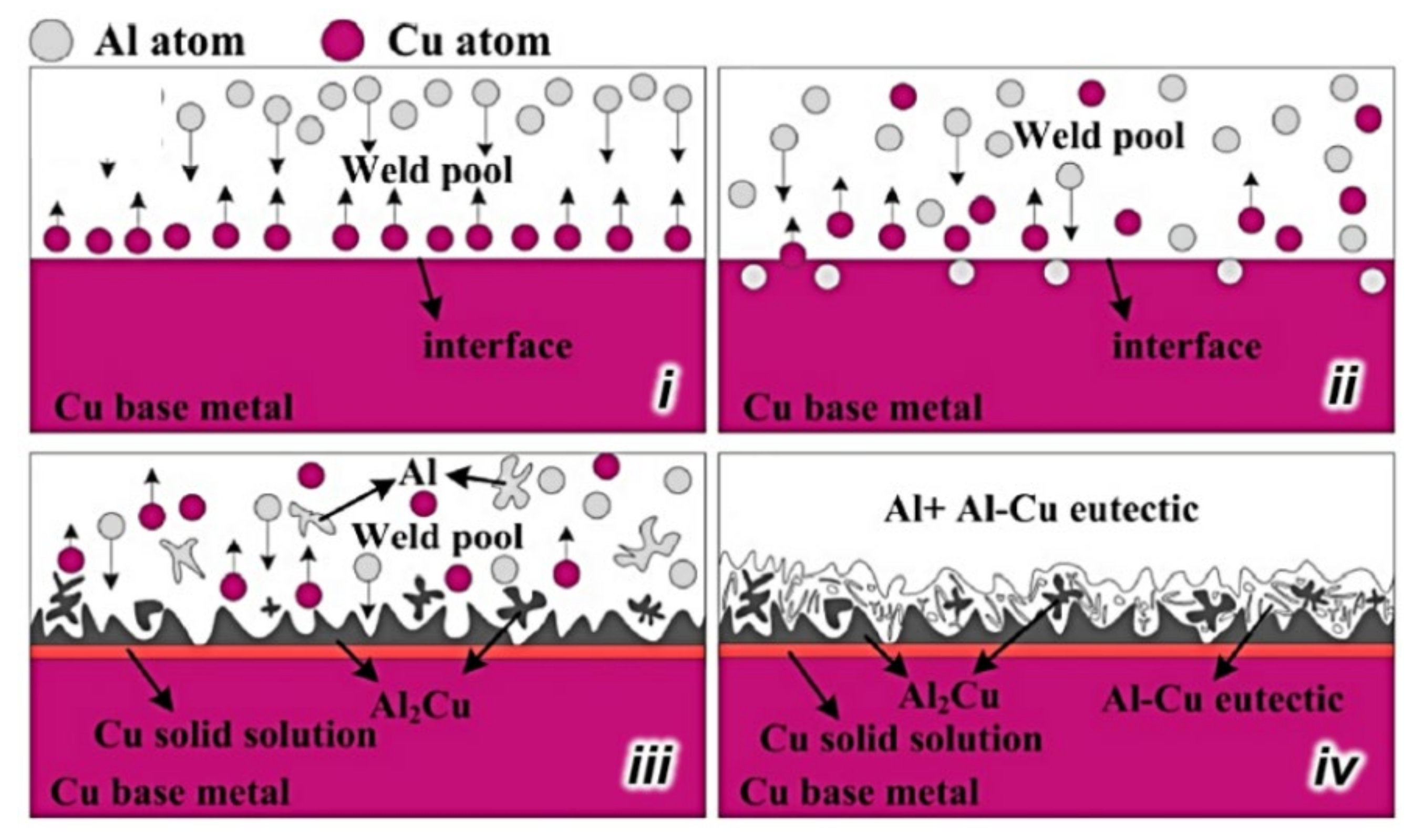

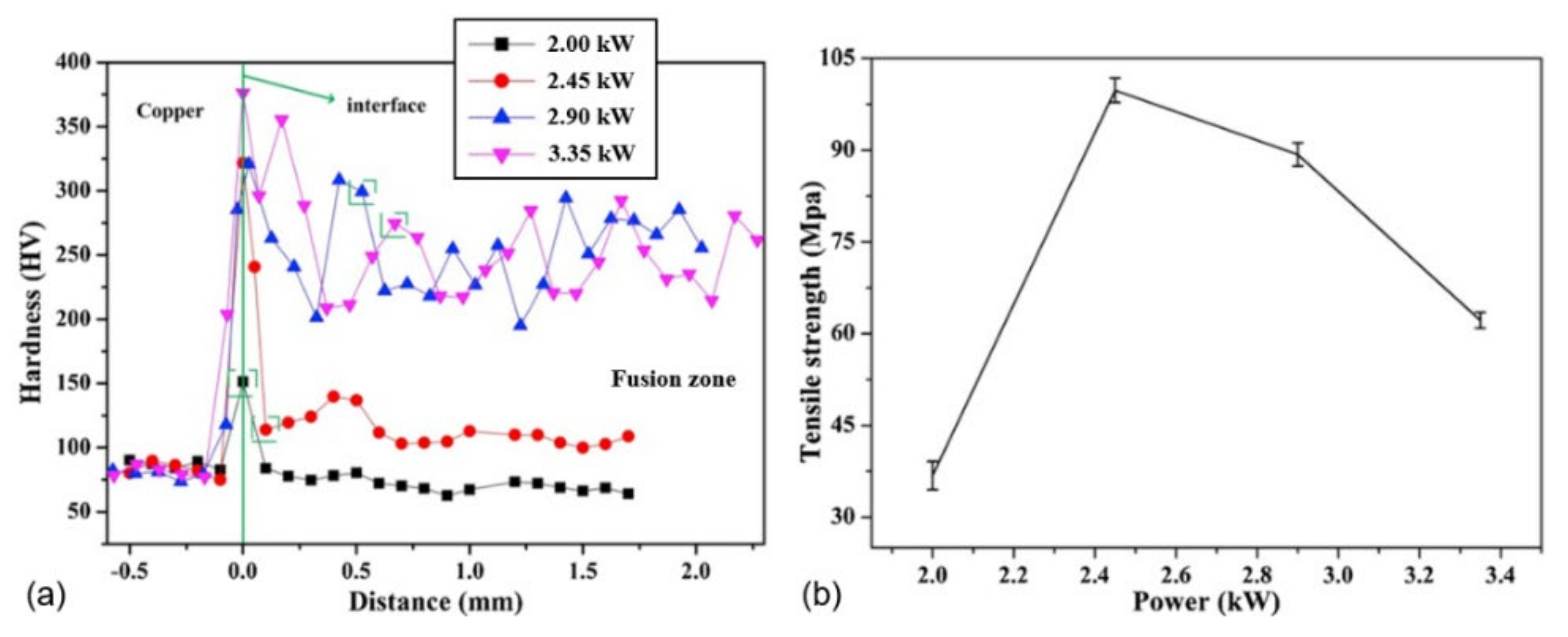

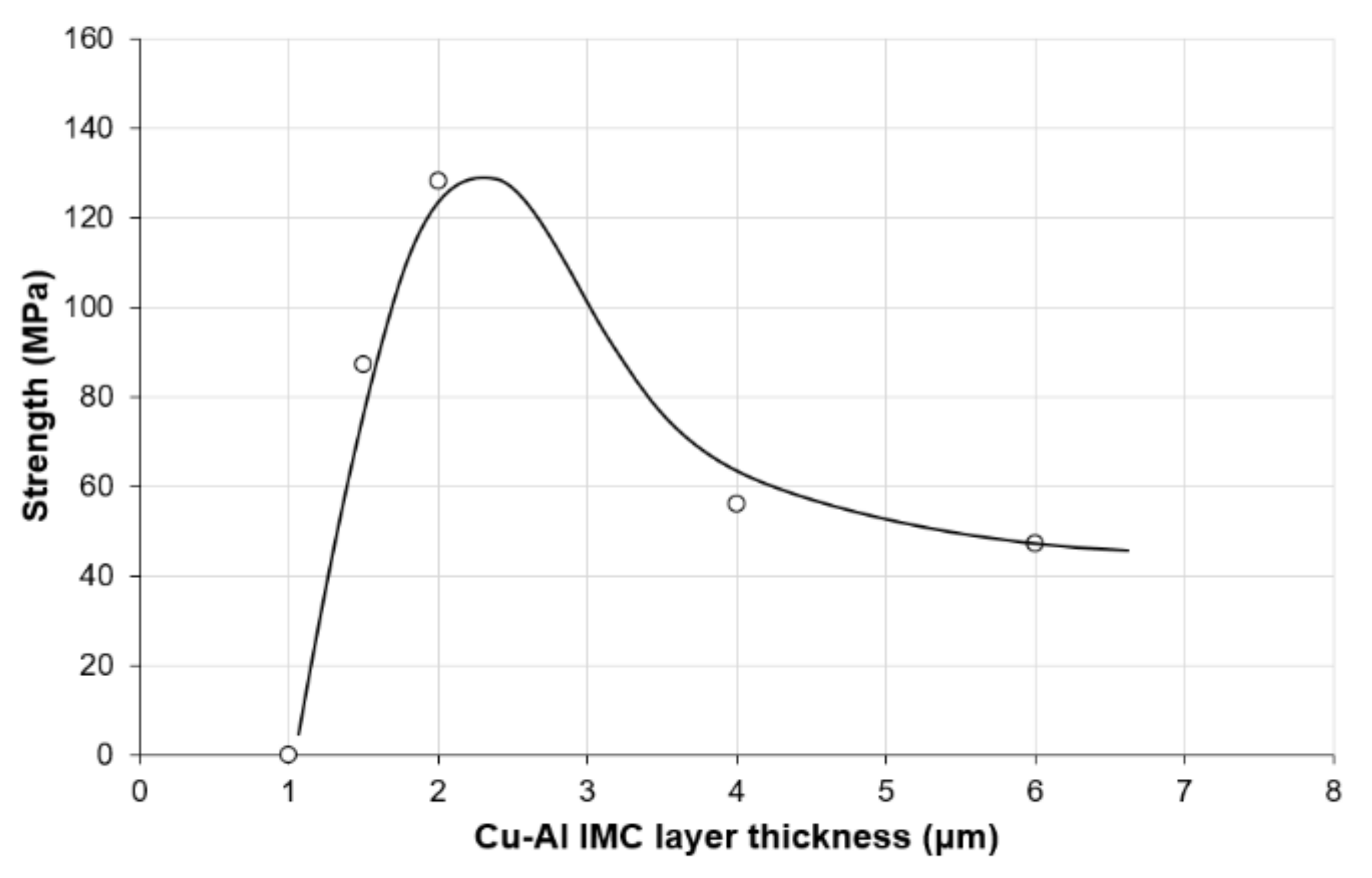

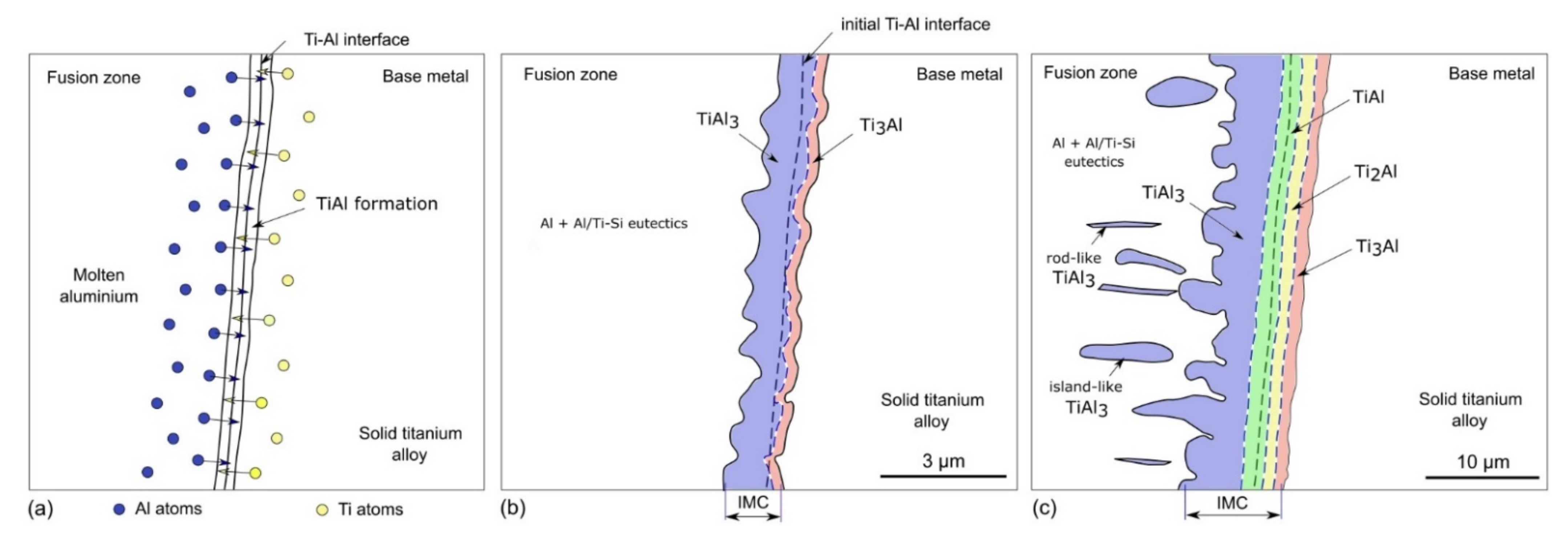

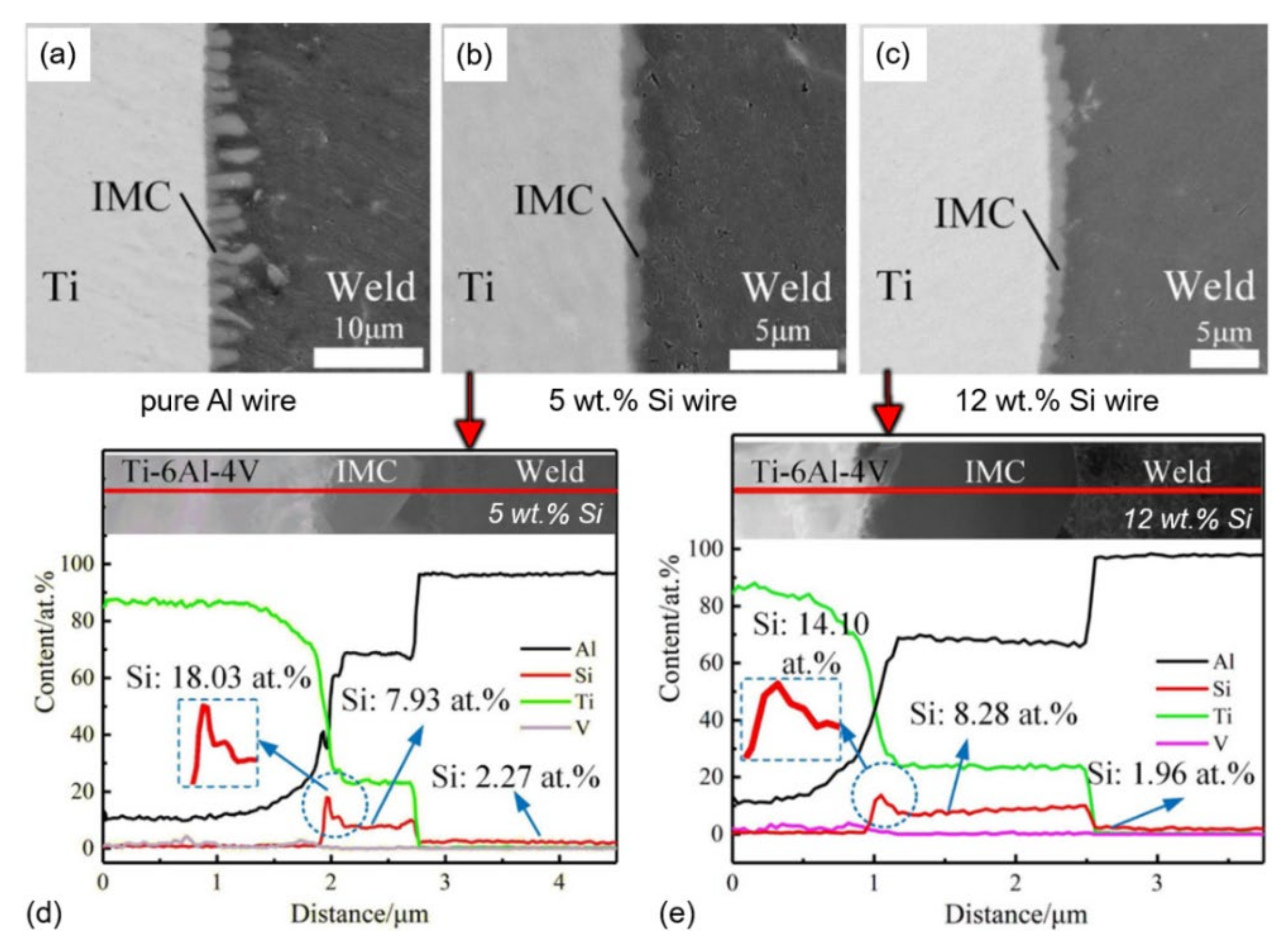

4], laser beam welding is a good alternative in the joining of electrical battery cells and pack level assembly since it may be used for different types of batteries. Aluminium-to-copper is particularly of high interest in the energy industry, due to the need for high electrical conductivity and weight reduction. Therefore, there is a growing demand for the joining of dissimilar metals, where aluminium is often one of metals, chosen for to its unique capability to significantly improve properties of the component/structure. However, there are many challenges and key factors in the joining of multi-material systems that need to be addressed. Aluminium and steel/Cu/Ti have a great difference in melting temperatures: 660 °C Al to 1520 °C/1083 °C/1660 °C for steel/Cu/Ti, respectively. In fusion welding, more aluminium is melted in the fusion zone and contraction forces are increased during solidification, causing hot tearing in the low melting point alloy (Al) at or nearby parent material (weld interface). Larger difference in thermal expansion coefficients strongly influence the residual stress distribution after welding, and hence, affect the component integrity. Aluminium has much greater heat conduction than steel and Ti, and thus, higher energy intensity is required for melting. Moreover, the temperature distribution may be highly asymmetric, with a complex residual stress pattern. Therefore, the location of melting and heat concentration is an important factor to consider. A critically important factor is the inevitable formation of the brittle intermetallic compound (IMC) layer (see example in

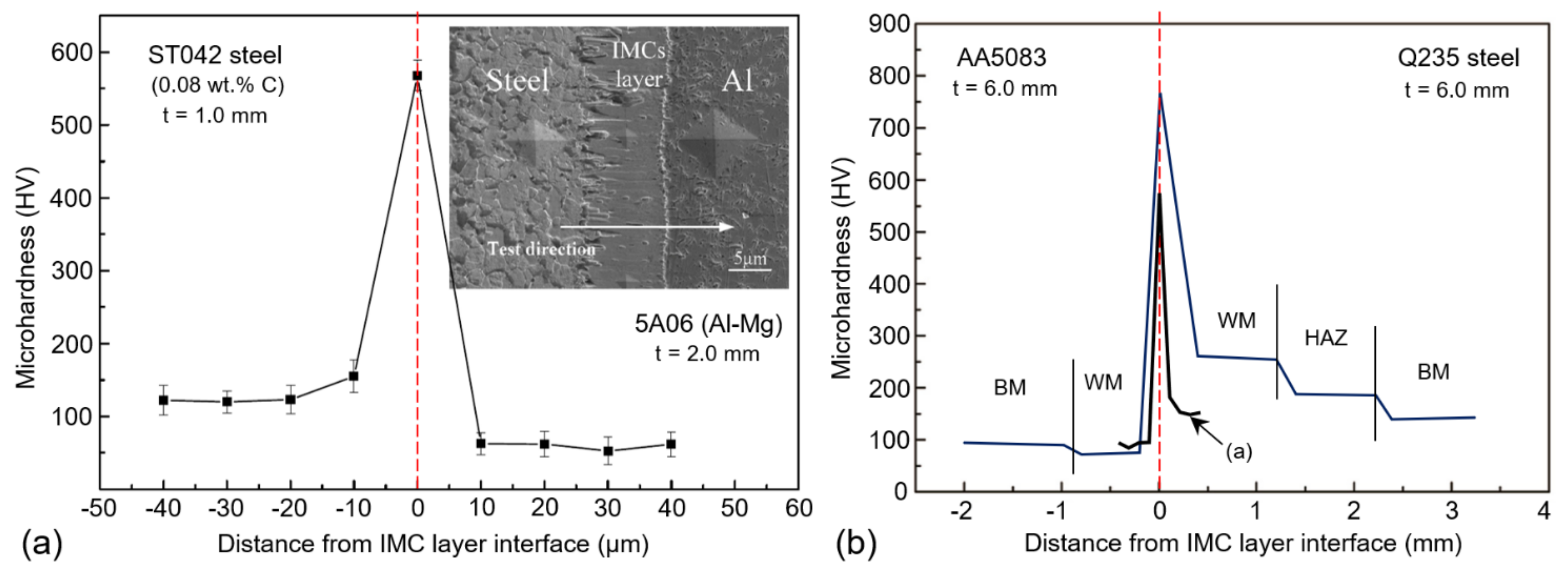

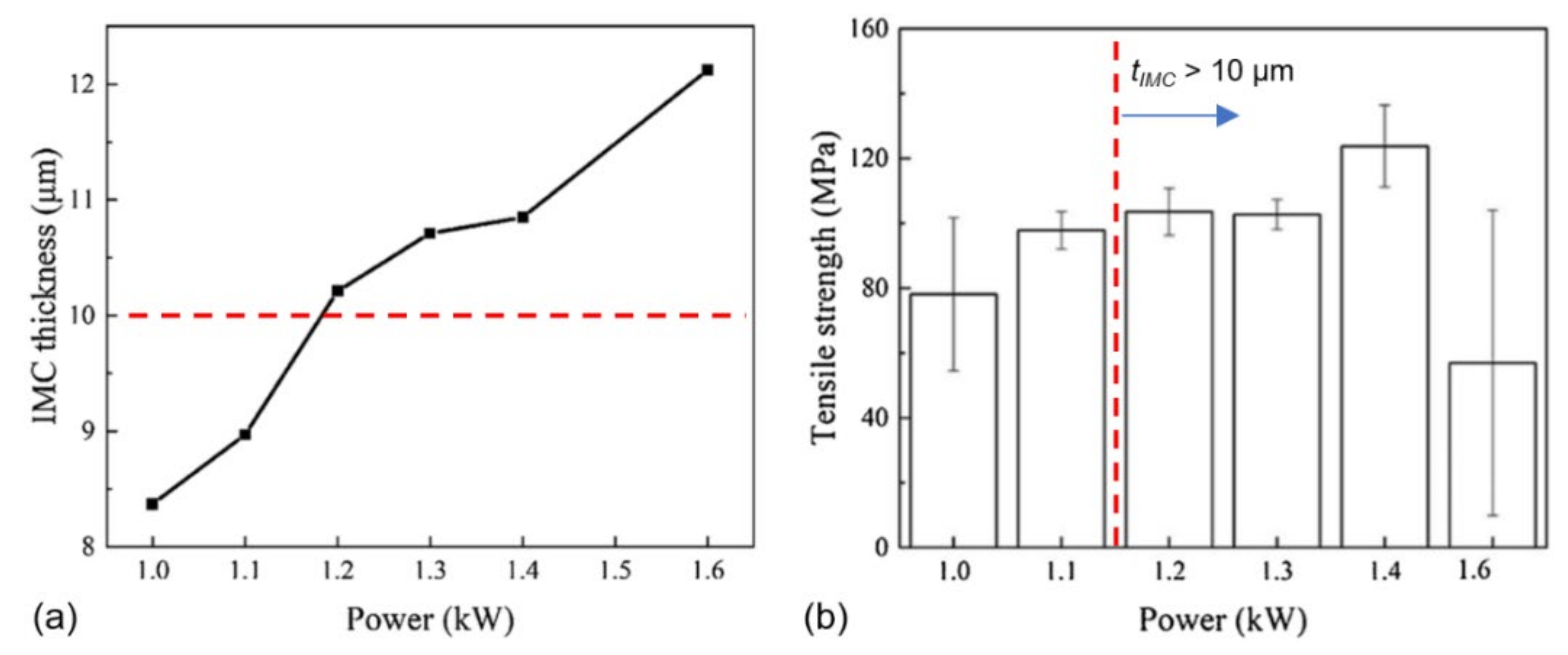

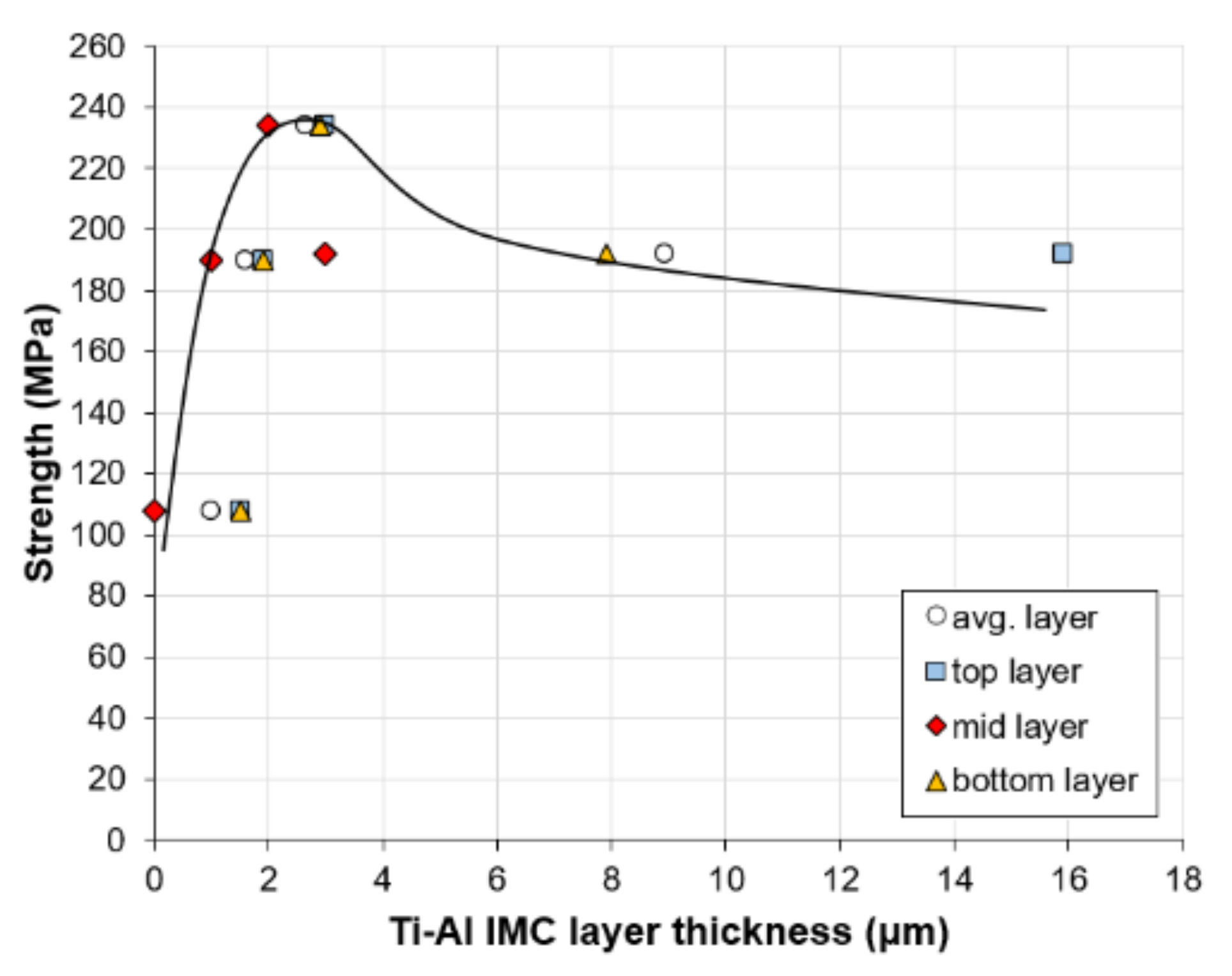

Figure 1c) between dissimilar metals, which is sometimes referred to as the reaction layer or the intermediate layer. The mechanical properties of the IMC layer are mainly dependent of the composition and thickness, which are highly dependent on heat input. It is known that >10 µm IMC thickness is harmful for mechanical properties in the case of steel to Al welding [

5]; being too thin may lead to poor bonding strength [

6,

7] (see

Figure 1d). Therefore, the heat input must be lower and strictly controlled; the choice of the welding process (arc, laser beam, and resistance) can significantly determine the quality of the joint. In addition, based on the selected welding process, geometrical weld pool parameters also contribute to the final quality of welded joint. Here, laser beam welding (LBW) is an excellent alternative to traditional resistance spot and arc welding. LBW offers much higher productivity, due to having more concentrated energy, easily melting highly conductive materials, and providing lower heat inputs, reducing the IMC layer thickness. Moreover, welds are narrower and may provide enhanced fatigue resistance. When filler wire is needed to enhance fusion zone properties with wider control of dilution, the laser-assisted arc welding process is another possibility.

During the thermal cycle, the kinetics of the IMC layer growth is mainly controlled by diffusion, and the diffusion coefficient (denoted as

D with dimension of m

2 s

−1) can be estimated, according to the Arrhenius equation based on Fick’s law of diffusion as follows [

5,

8,

9]:

where

D0 is the pre-exponential factor (m

2 s

−1),

Q is the activation energy for the growth of the interfacial IMC layer (J mol

−1),

T is absolute temperature (K), and

R is the gas constant (8.31446 J mol

−1 K

−1).

Figure 1.

(

a) Typical application of dissimilar materials in various industries, where Audi A8 is presented as an example and (

b) battery pack made of cylindrical cells; modified and based on [

10,

11]. (

c) Typical outlook and features of IMC layer by scanning electron microscope, from [

7]. (

d) Effect of IMC layer thickness on strength [

6,

7].

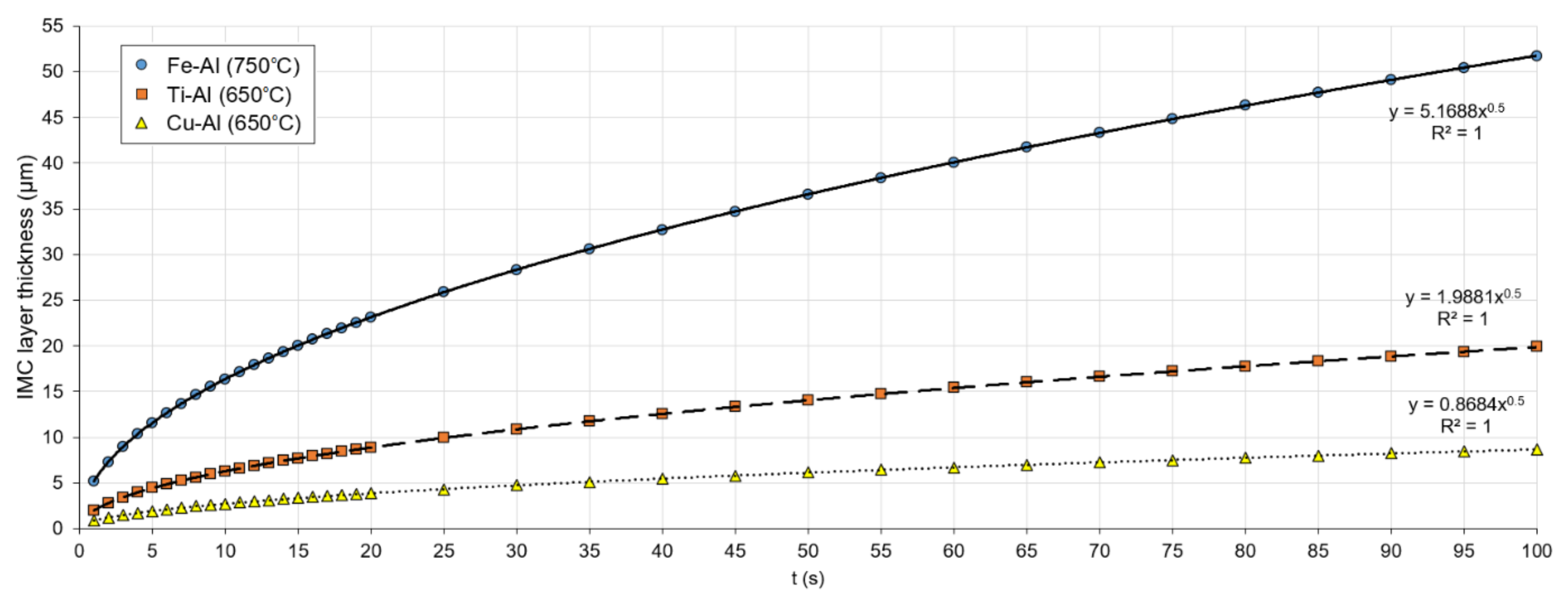

It was shown that the Fe–Al IMC layer growth has a linear relationship with the square root of diffusion time (

t), representing the parabolic rate law with the kinetic exponent (

n ≈ 0.5 for diffusion-controlled growth and

n = 0.9–1.0 for reaction-controlled growth). The thickness of the diffusion layer (denoted as

dIMC) can be estimated by the following equation [

5,

9]:

The presented Equation (1) is applicable for atom diffusion in solids (solid/solid), which is driven by several mechanisms. For the welding case, diffusion includes also the liquid state (solid/liquid), which is far more complex [

8]. However, the Arrhenius equation is still valid and was shown by Springer et al. [

9] for the Al–Fe case. In the case of overlap LBW joints, Fan et al. [

12] showed deviation in the calculated IMC layer thickness by using the Arrhenius equation when compared with measured values. The calculated values provided two to three times increased thicknesses. However, both obey parabolic law. The authors claimed that there may be the wrong selection of diffusion parameters (

D0 and

Q) since they are defined experimentally, and the exclusion of more complex phenomena, such as phase transformation and dissolution. This may also be linked to which element diffusion controls the reaction rate: either self-diffusion of Al to the interface towards the first intermetallic phase formed, or Fe diffusion into the phase formed.

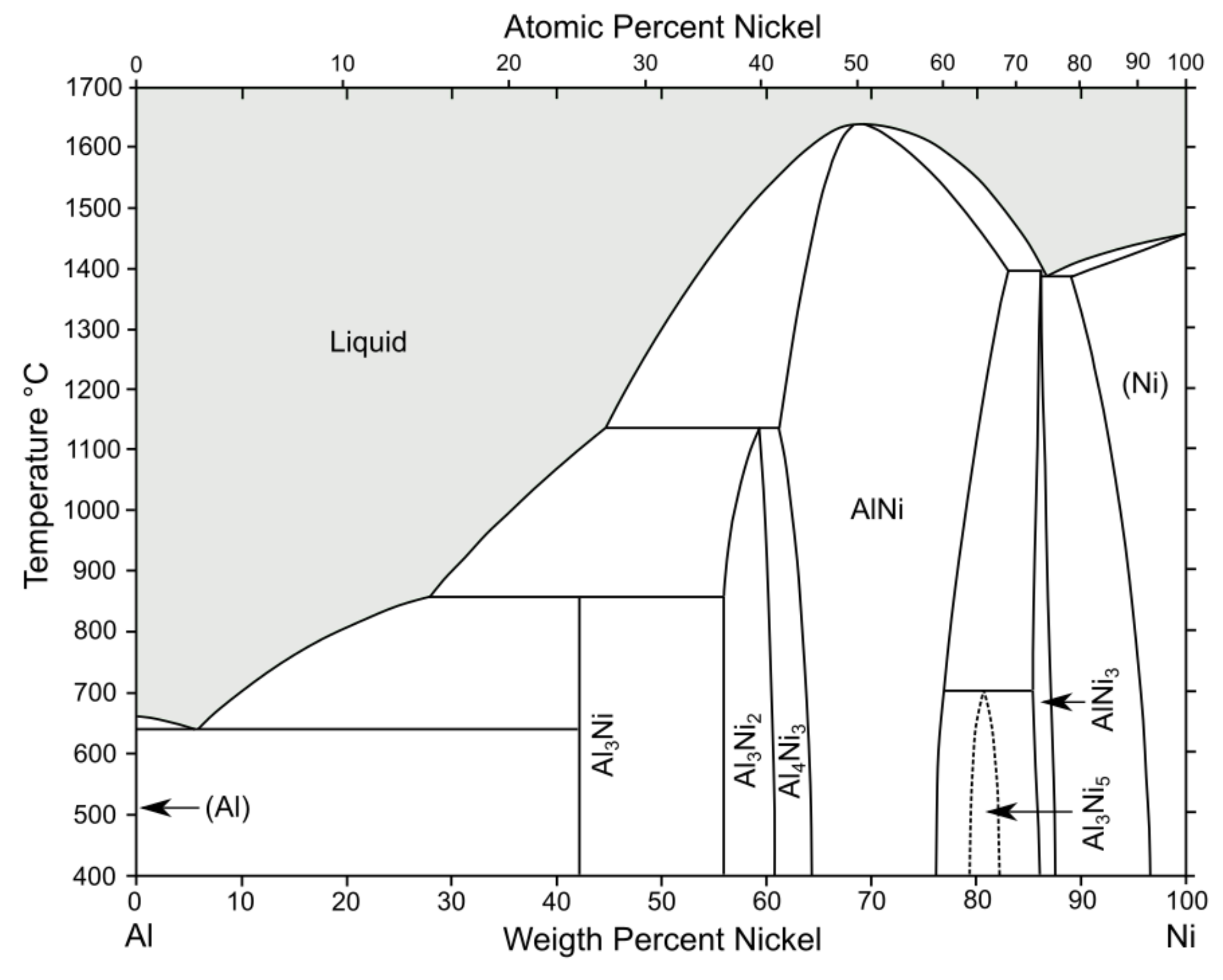

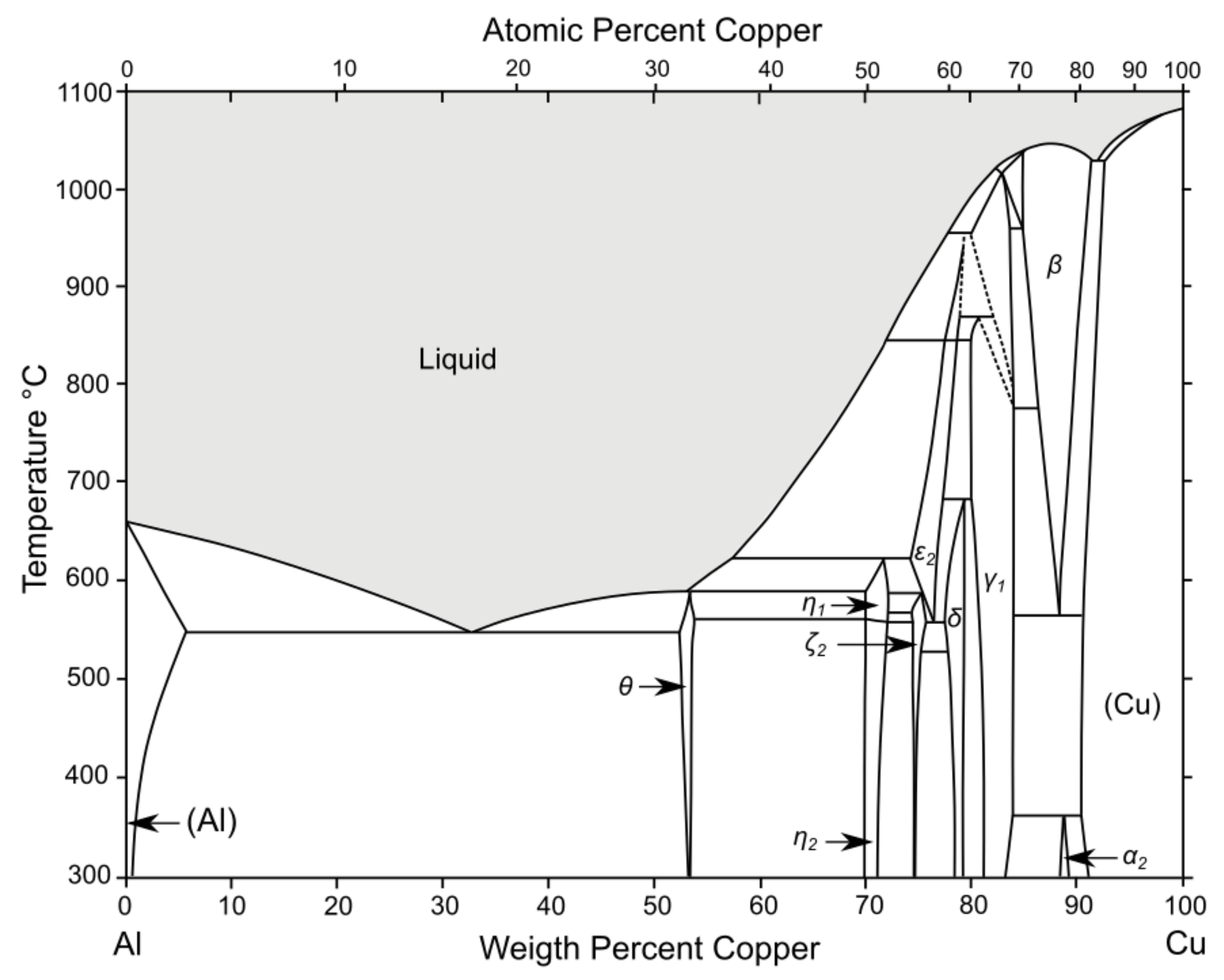

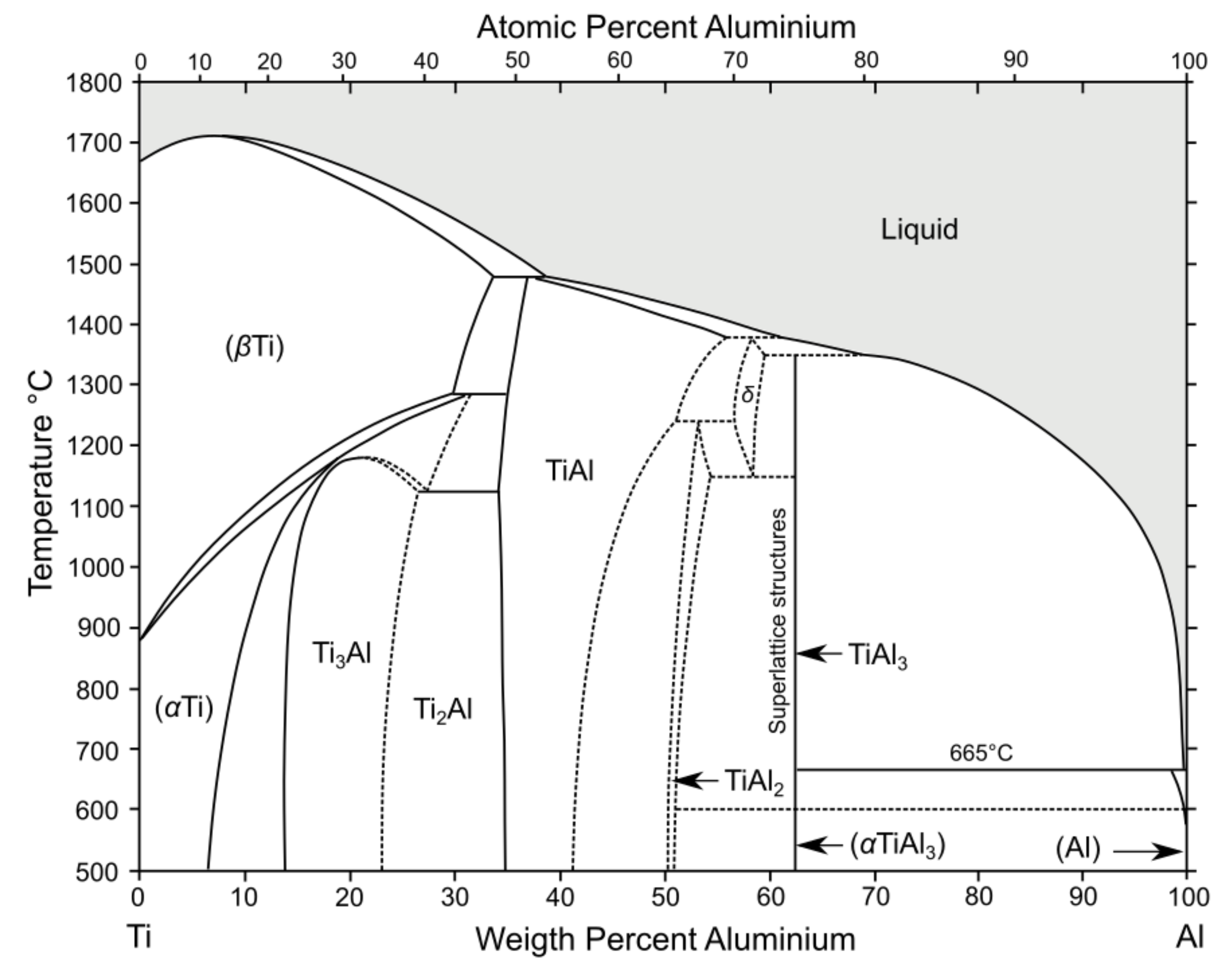

The application of Equation (2) for Fe–Al/Ti–Al/Cu–Al is shown in

Figure 2. For the Fe–Al case, the development of the Fe

2Al

5 phase is assumed since it is the predominant phase (see

Section 5.1). The phase growth parameters at 750 °C are taken for calculations as follows:

D0 = 53×10

−4 m

2 s

−1 [

5] (iron atom diffusion in Al) and

Q = 210 kJ mol

−1 [

13]. The IMC layer growth follows the parabolic law. At higher reaction temperatures and time, it may disobey the parabolic law and obey the linear increase. The applicability of Equation (2) showed also good agreement for the Ti–Al case [

14] (using

D0 = 21 × 10

−4 m

2 s

−1 and

Q = 296 kJ·mol

−1 at 650 °C) and for the Cu–Al case [

15,

16,

17] (using

D0 = 8.8 × 10

−4 m

2 s

−1 and

Q = 72 kJ·mol

−1 at 650 °C). Note that the linear relationship can also be shown by taking the natural logarithm (

ln) of both sides in Equations (1) and (2) and strongly depends on the temperature and the

D0 parameter.

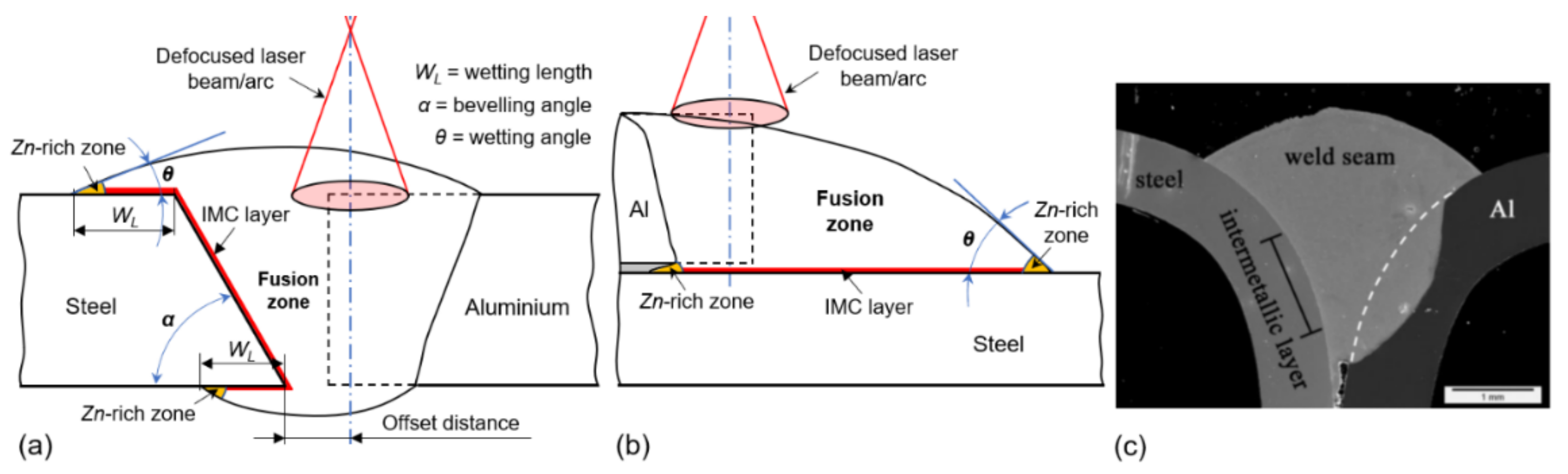

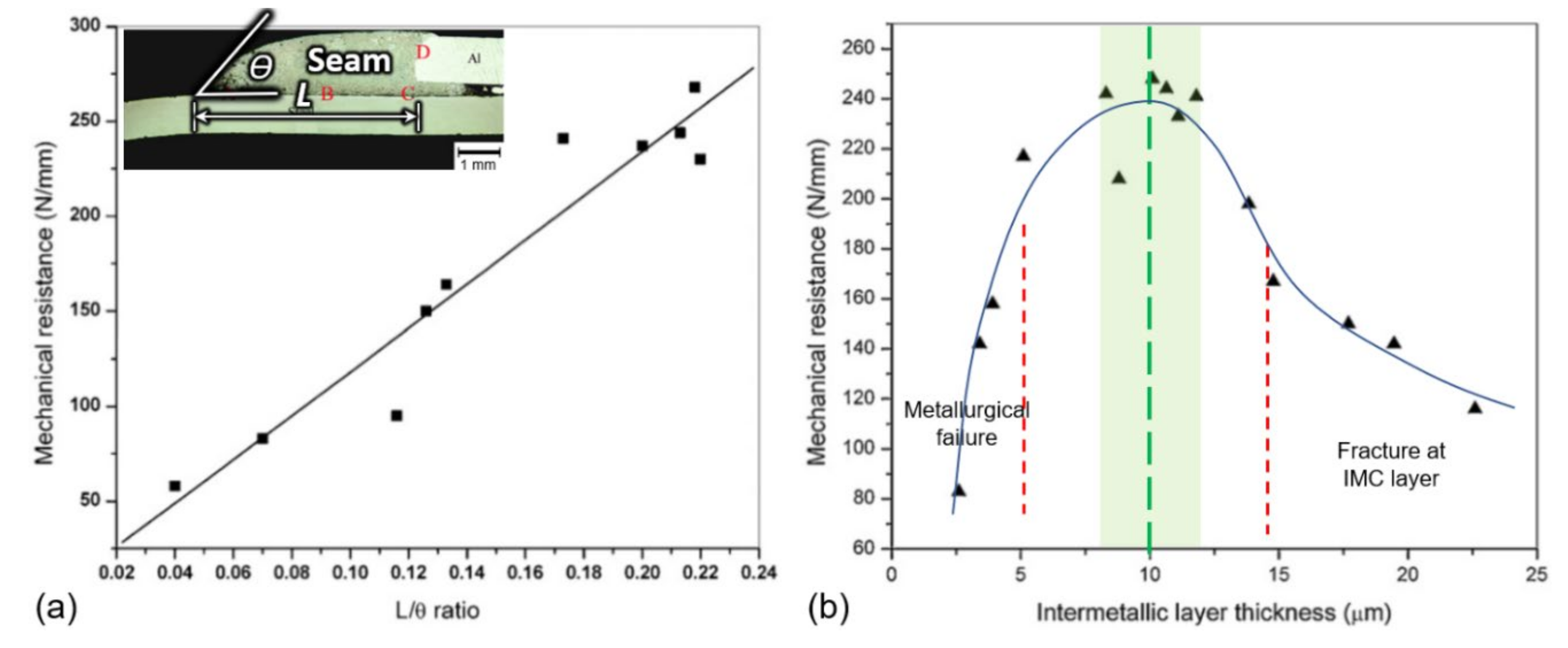

The wettability and wetting angle are important factors in dissimilar materials welding, especially in the case of lap or corner joint types. It depends on surface tension during solidification, and the energy balance can be calculated based on Young’s equation [

18,

19]:

where

θa is the contact angle between liquid and solid (wetting angle),

σsv is the interfacial free energy or surface tension of the solid–vapour;

σsl is the solid–liquid, and

σlv is the liquid–vapour interfaces, respectively. Note that

θa has a significant effect on joint strength and will be presented later in relevant sections.

In order to obtain the liquid metal spreading, the following requirement, Equation (4), and condition, Equation (5), must be satisfied [

19]:

In this work, a comprehensive review is focused on the laser beam and laser-assisted welding of Al–Fe, Al–Cu and Al–Ti, due to the high relevance to industrial applications. The scope of the review includes understanding thermophysical properties and laser beam absorption principles, fundamentals of laser beam and laser-assisted arc welding physics, metallurgical studies of steel to aluminium, galvanised steel to aluminium, copper to aluminium, and titanium to aluminium welding-brazing fundamentals. The latest development in the welding of these alloys is presented, including an in-depth metallurgical analysis.

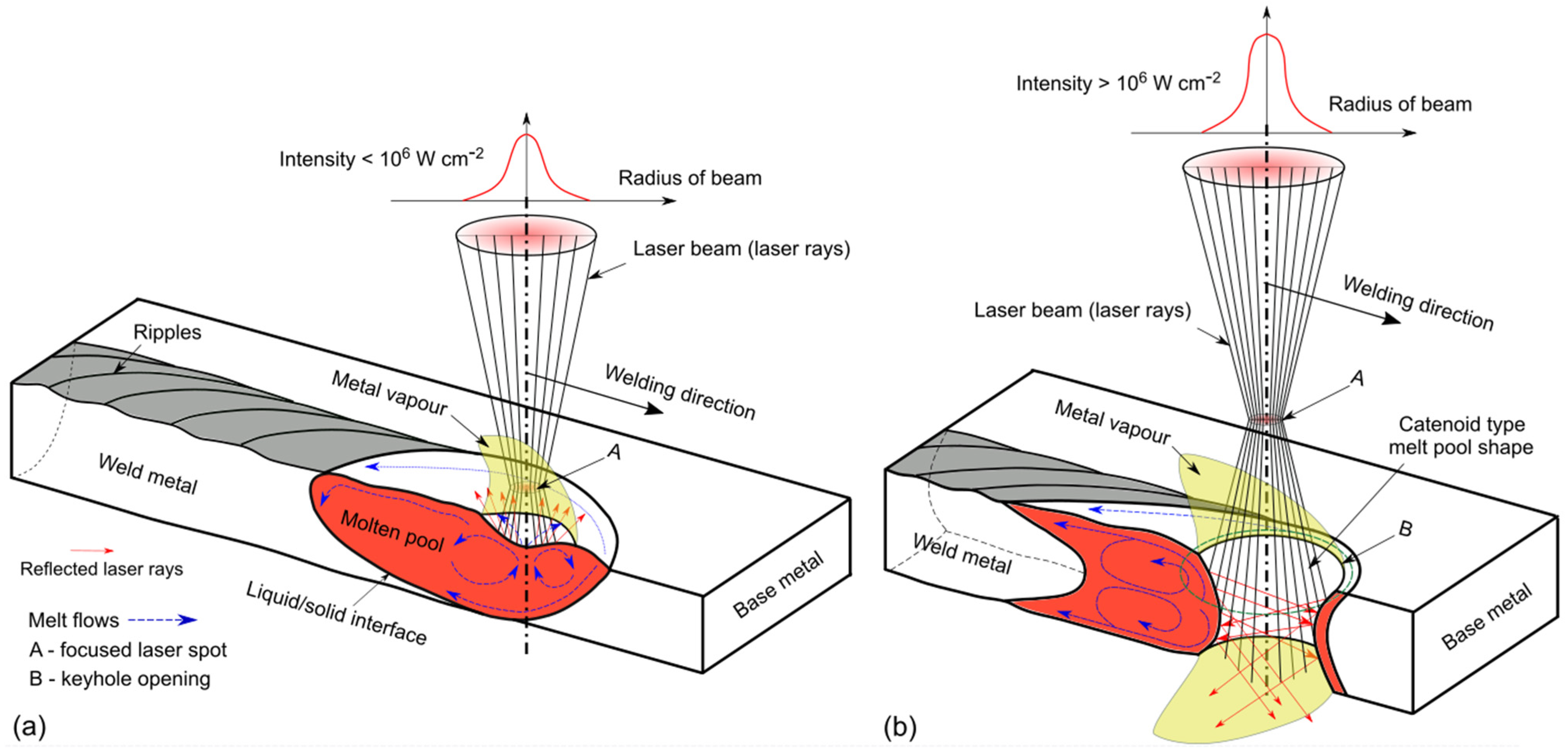

2. Fundamentals of Laser Beam Welding

Laser beam welding has high potential in joining dissimilar metals. LBW may be suitable for highly conductive materials, due to high concentrated energy for melting. A laser beam is a non-contact flexible tool, and the power intensity distribution can be changed for specific purposes with enhanced productivity [

2]. Low heat input provides a narrower heat-affected zone (HAZ), and thus, the strength may be enhanced. Laser beams may operate under two essential temporal modes, continuous wave (CW) and pulsed wave (PW) [

20]. Modern laser beams have highly customisable pulsing capabilities with a pulse duration in the order of µs, very high peak powers in the order of megawatts, and complex pulse shapes with frequencies that greatly surpass that of pulsed arc welding. LBW is normally carried out without filler wire, especially for thinner sheets, and is mainly used in the automotive and aerospace industry. Addition of the filler wire can be complicated and requires tedious optimisation, especially for thin sheets [

21,

22]. Heat conduction laser welding usually operates under <10

6 W/cm

2 energy density (see

Figure 3a) and is more often used for thin plates (<1 mm), where the energy should not be sufficient to generate a keyhole but high enough to melt the material locally. Here, the melt flows are very dependent on the active surface elements and are similar to the tungsten inert gas (TIG) process weld pool [

23]. Higher energy density (>10

6 W/cm

2) forms a keyhole, providing much higher penetration depths, due to multiple reflections (see

Figure 3b) and increased absorption. The threshold for transition from the heat conduction mode and keyhole varies and mainly depends on the wavelength and surface conditions. Based on Behler et al. [

24], Nd:YAG requires two times lower power density to generate a keyhole, and its drilling time is several times faster, compared to the CO

2 laser. Similar is expected for the fiber/disk laser. There is also the transition mode between heat conduction and keyhole. Notably, the stability in the heat conduction mode is much higher than in the keyhole mode, due to a more stable weld pool with low porosity and spattering. The keyhole mode often has a spiking effect, as the keyhole collapses, causing porosity. Therefore, more optimisation of parameters is needed, but it is more attractive for thicker plates [

25,

26].

Due to the fast solidification speed, LBW may cause cracking, porosity, and poor metallurgical affinity in the fusion zone due to brittle phases. Microstructure in the fusion zone can be improved by using specific interlayers by coating components [

27]. Disadvantages of LBW are high-cost investments, safety issues, high requirements of joint preparations of components to be joined, more complex process and variables to be adjusted, and lower wall plug (electrical) efficiency, compared to other processes.

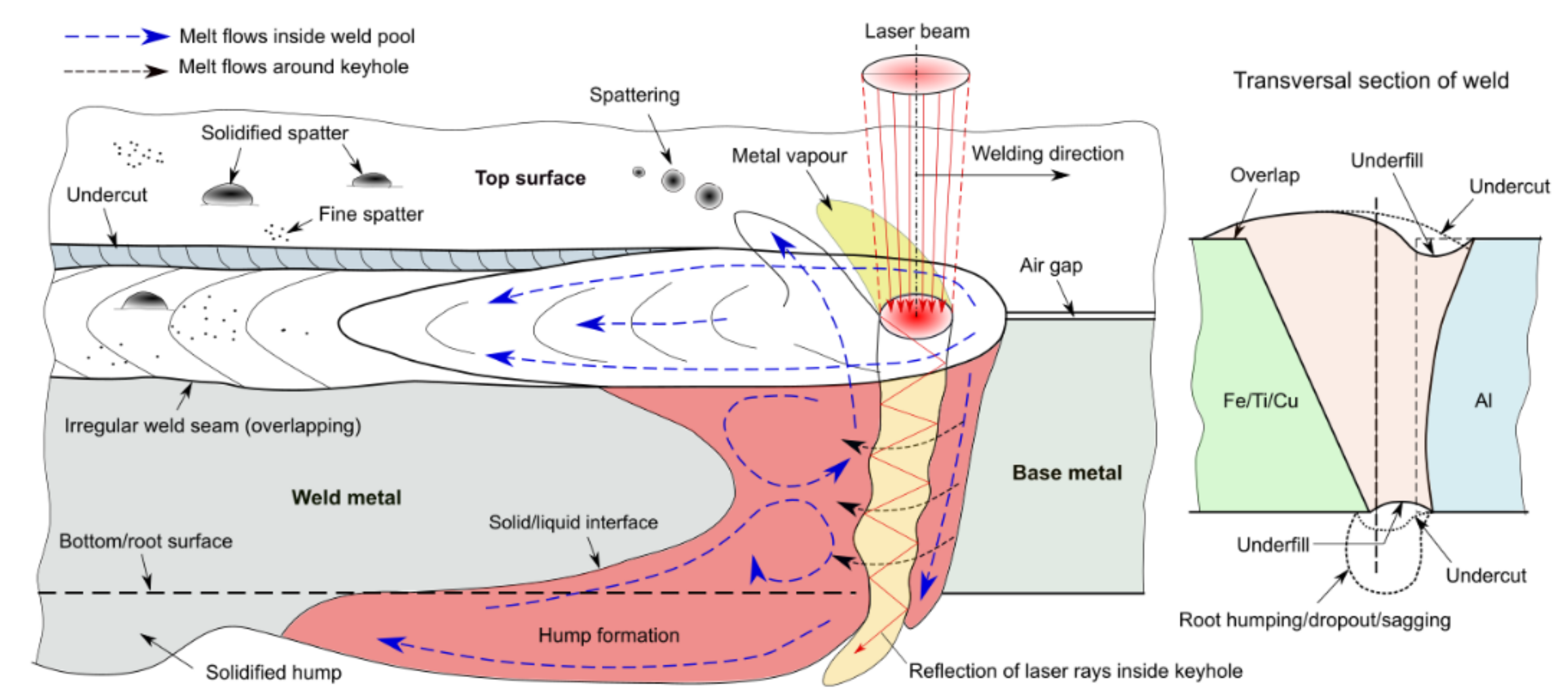

Poor appearance of weld bead and surface defects are frequent challenges in LBW, due to unstable melt pool formation, especially in the keyhole mode (see

Figure 4). External weld seam defects are undercut and underfill (top and root), spattering, upper and root humping. The formation of undercuts, spattering and root humping are attributed to many factors, including process parameters, welding conditions, shielding gas composition, surface tension and viscosity of the used metals. International standards ISO 13919-1 [

28] (for steel) and ISO 13919-2 [

29] (for Al) specify the limits for different quality levels. Detailed information concerning various external weld pool defects and mechanisms can be found in [

30].

Figure 3.

(

a) Schematic illustration of laser beam physics (beam focused near surface) during heat conduction mode with melt flows based on [

31,

32]. (

b) Schematic drawing of laser beam physics (defocused beam) during keyhole mode welding [

21,

22,

33].

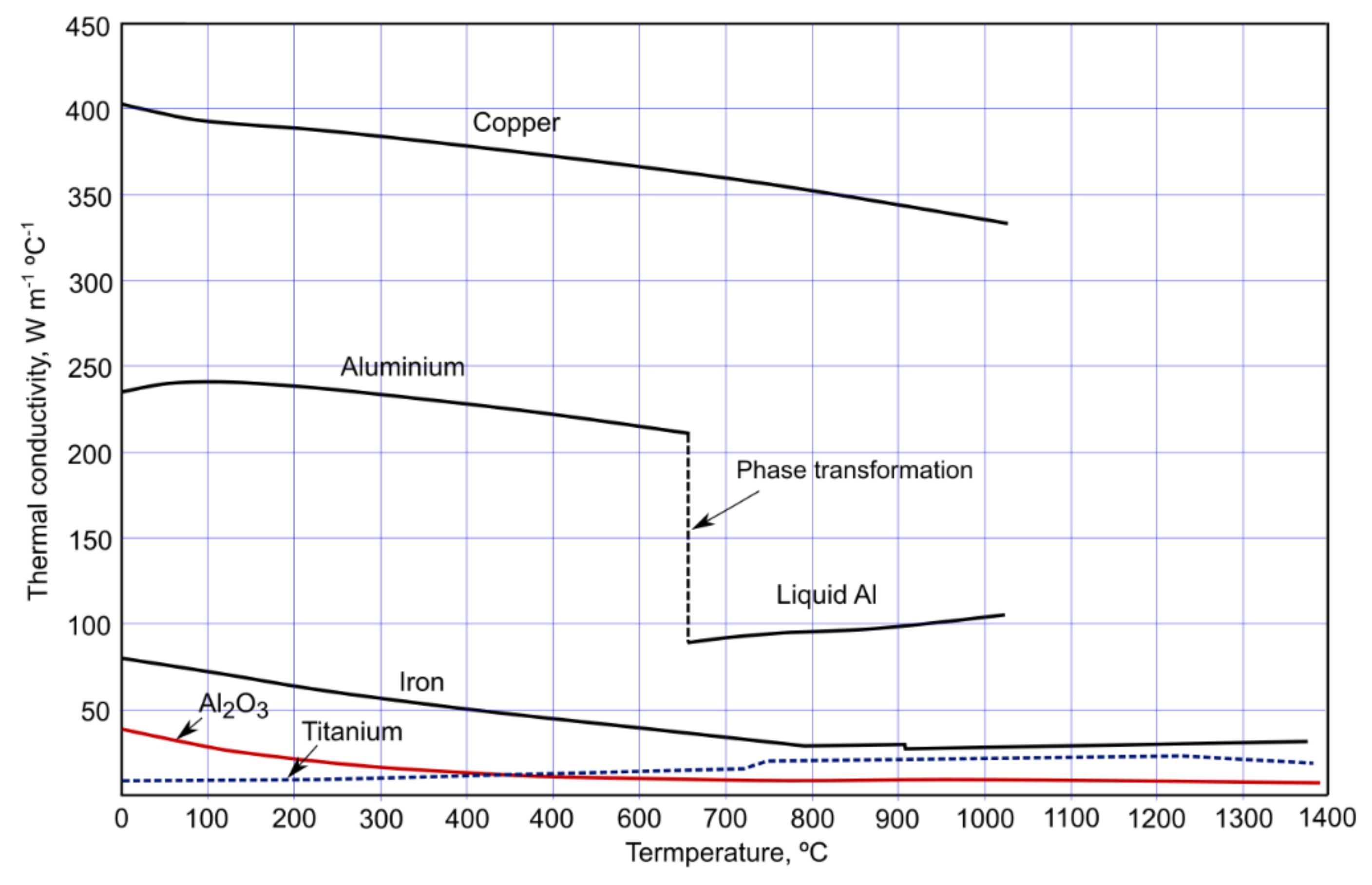

3. Thermophysical Properties of Different Metals and Laser Beam Absorption

Aluminium alloys are widely used, due to their low weight and corrosion resistance. Al alloys possess high thermal conductivity requiring higher energy for melting, similar to Cu. A comparison of aluminium to other metals in terms of thermal conductivity versus temperature is shown in

Figure 5. For aluminium, the thermal conductivity decreases with increasing temperature in solid and drops significantly at phase transformation stage. Oxide film (Al

2O

3), which naturally occurs at the surface, has much lower conductivity with a constant decrease with the temperature. Al has low melting point (660 °C), compared with many metals and its alloying elements, except Zn and Mg as shown in

Table 1. However, on the surface, the Al

2O

3 film is inevitable formed and has a much higher melting point (~2050 °C); thus, additional removal of the oxides is required (e.g., mechanical or chemical cleaning). This oxide layer can be removed by applying fluxes or mechanically by a stainless-steel brush prior to welding. The TIG process with DCEN (direct current electrode negative) provides the cathodic cleaning effect by removing surface oxides through ions with high kinetic energy [

54]. A rapid change in the thermophysical properties (except surface tension) of pure Al occurs at 660 °C, due to the transition from solid to liquid. Another important issue is the high difference in thermal expansion between Al/Cu alloys and carbon steels/Ti, 2.0−2.4 × 10

−5 m·m

−1℃

−1 and 0.8−1.2 × 10

−5 m·m

−1 °C

−1, respectively, which may lead to high distortions and residual stresses [

55]. The solubility of alloying elements in Al/Fe as an important metallurgical factor is indicated in

Table 1. Metals may have high solubility in each other, forming a homogenous substitutional solid solution when the atomic size is within 15% of Al, with a similar crystal structure, the same valency, and similar electronegativity, according to the Hume–Rothery rules [

56].

Table 1.

Thermophysical properties of different metals [

57,

58,

59]. Solubility values are maximum possible values usually achieved at high temperatures (e.g., >700 °C). Face-centred cubic denoted as

f.c.c., body-centred cubic as

b.c.c, and hexagonal close-packed as

h.c.p. crystal structures. Note, Si has complex face-centred diamond cubic crystal structure (*). Indicated valency (+) values are most common.

χ is electronegativity by Pauling scale.

| Element | Melting Point, °C | Boiling Point, °C | Solubility in Al, wt.% | Solubility in Fe, wt.% | Crystal Structure | Atomic Radius, pm | Valency | χ | Density, g/cm3 |

|---|

| Al | 660 | 2467 | − | negligible | f.c.c. | 118 | 3 | 1.61 | 2.7 |

| Mg | 649 | 1090 | 17.4 | negligible | h.c.p. | 145 | 2 | 1.31 | 1.7 |

| Mn | 1244 | 1962 | 1.82 | negligible | b.c.c. | 161 | 2, 4, 7 | 1.55 | 7.3 |

| Cu | 1083 | 2567 | 5.65 | negligible | f.c.c. | 145 | 1, 2 | 1.90 | 8.9 |

| Si | 1410 | 2355 | 1.65 | negligible | f.c.c. * | 111 | 4 | 1.90 | 2.7 |

| Zn | 420 | 907 | 66.4 | negligible | h.c.p. | 142 | 2 | 1.65 | 7.1 |

| Fe | 1535 | 2750 | 0.04 | − | b.c.c. | 156 | 2, 3 | 1.83 | 7.9 |

| Cr | 1857 | 2672 | 0.77 | <4.0 | b.c.c. | 166 | 2, 3, 6 | 1.66 | 7.1 |

| Ni | 1453 | 2732 | 0.04 | <3.0 | f.c.c. | 149 | 2 | 1.91 | 8.9 |

| Ti | 1660 | 3287 | 1.32 | negligible | h.c.p. | 176 | 2, 3, 4 | 1.54 | 4.5 |

Figure 5.

Thermal conductivity changes with temperature of different metals. Redrawn from [

60].

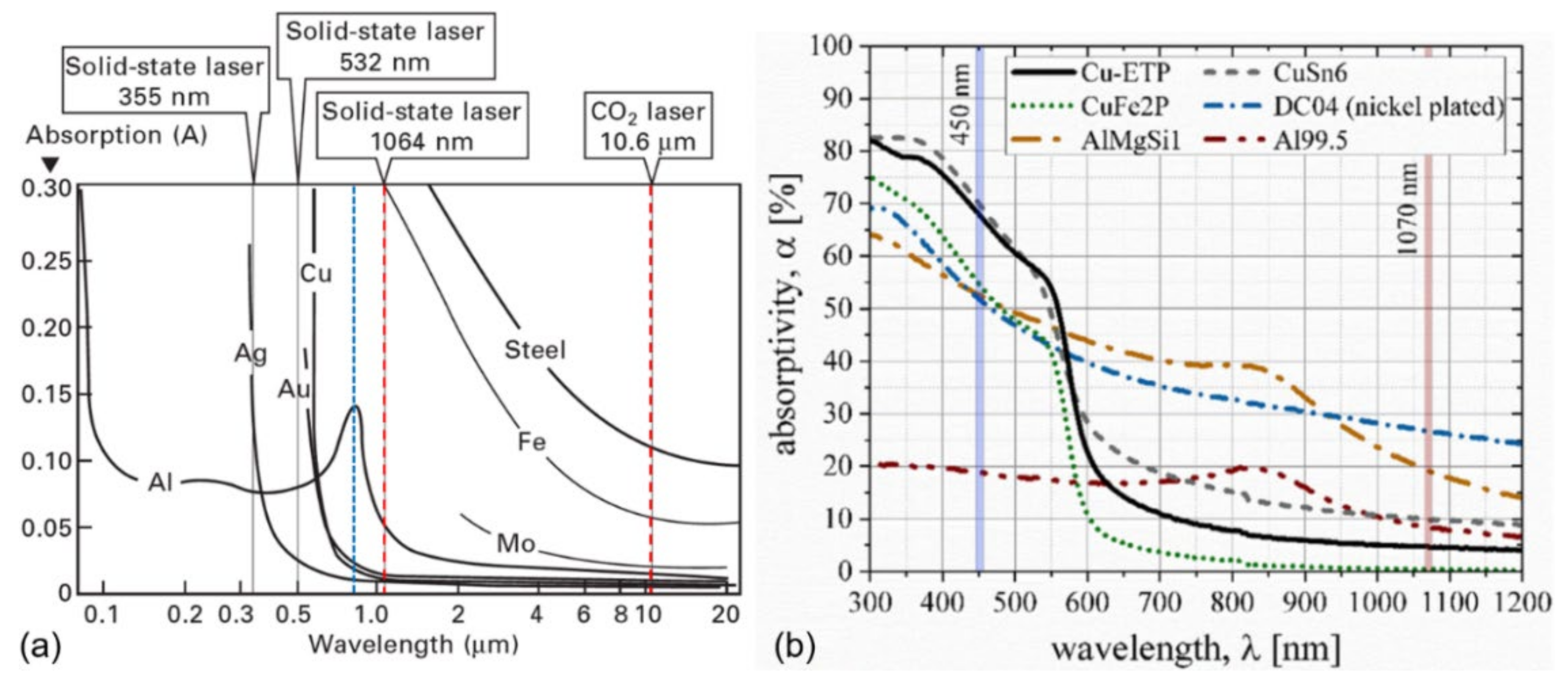

Reflectivity and the associated absorption of the electromagnetic wave, the laser ray, during laser–matter interaction is an important phenomenon. A general overview of the absorption coefficient of different metals in a wide spectrum [

61] is shown in

Figure 6a. Note that this graph does not consider the incident laser power level and its angle, surface condition, welding speed and other process parameters. Therefore, this graph is often under update and mostly applicable for general understanding. Moreover, each alloy has a specific chemical composition and provides slightly different temperature-dependent absorption coefficients. Generally, Al alloys (and Cu alloys) have much higher reflectivity, compared to steel, especially for long wavelength lasers, such as CO

2 laser; thus, lower absorption is expected. The most widely used is the ytterbium fibre/disc laser, due to its high-power scalability and short wavelength of 1030–1070 nm. Infrared diode lasers (λ ≈ 820 nm) provide higher absorption and can be increased at a shorter wavelength [

62]. Emission of 450 nm wavelength (a blue laser) is preferable for highly reflective metals and proven on the industrial scale [

63,

64] (see

Figure 6b). These lasers can be produced up to 2.0 kW, which is enough to weld more than 1 mm thick Cu. However, they have high beam parameter product (BPP), meaning lower quality of the beam, but it is enough to perform heat conduction mode laser welding.

The actual absorption measurement is complicated and few research works have been conducted. At the stationary condition, 70% of absorption (at 3.2 kW) was obtained during Nd:YAG laser (1064 nm) keyhole welding of AA1xxx [

65]. The absorption of Yb:fiber laser power from 2 to 10 kW increased from 56 to 84%, respectively, during LBW of AA5052 [

66]. Moreover, the absorption was reduced (to 72%) by increasing the welding speeds. Miyagi et al. [

67] reported the absorption of 50–55% during Yb:fiber laser welding in a wide range of different Al alloys. Absorption may be significant improved by using power modulation as well instead of the CW mode [

68]. In the case of the heat conduction mode and high Mg content, improved absorption can be achieved [

69], especially with longer pulse durations in PW mode. Absorption may be also improved by modifying the surface conditions, e.g., a chemically etched or anodised surface provides high absorption [

31]. Due to constant reflection by the surface, the absorption during heat conduction mode of LBW is reduced, e.g., only 23% was obtained in the case of AA5182 [

31]. Titanium alloys have reflectivity similar to steel, which also strongly depends on the laser wavelength. Lisiecki [

70] measured absorption of 52% for a polished Ti surface and up to 72% for as-received (with oxide layer), using a high-power diode laser (λ = 808 nm) at 0.8–1.8 kW power range and 0.2–0.8 m/min scanning speed, similar to welding.

8. Challenges and Future Trends

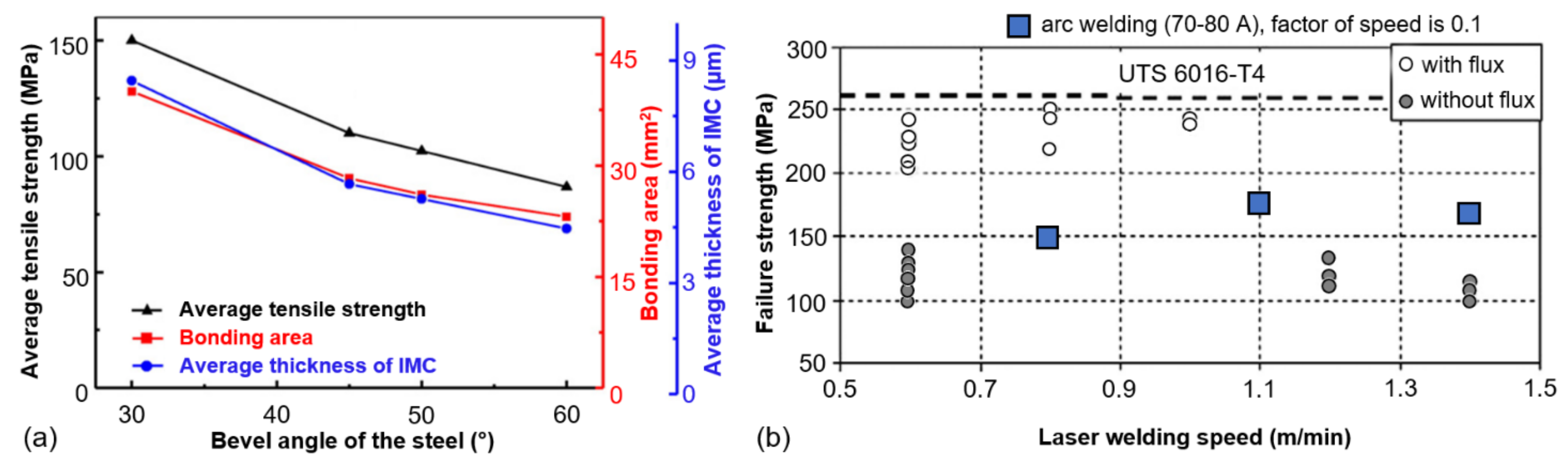

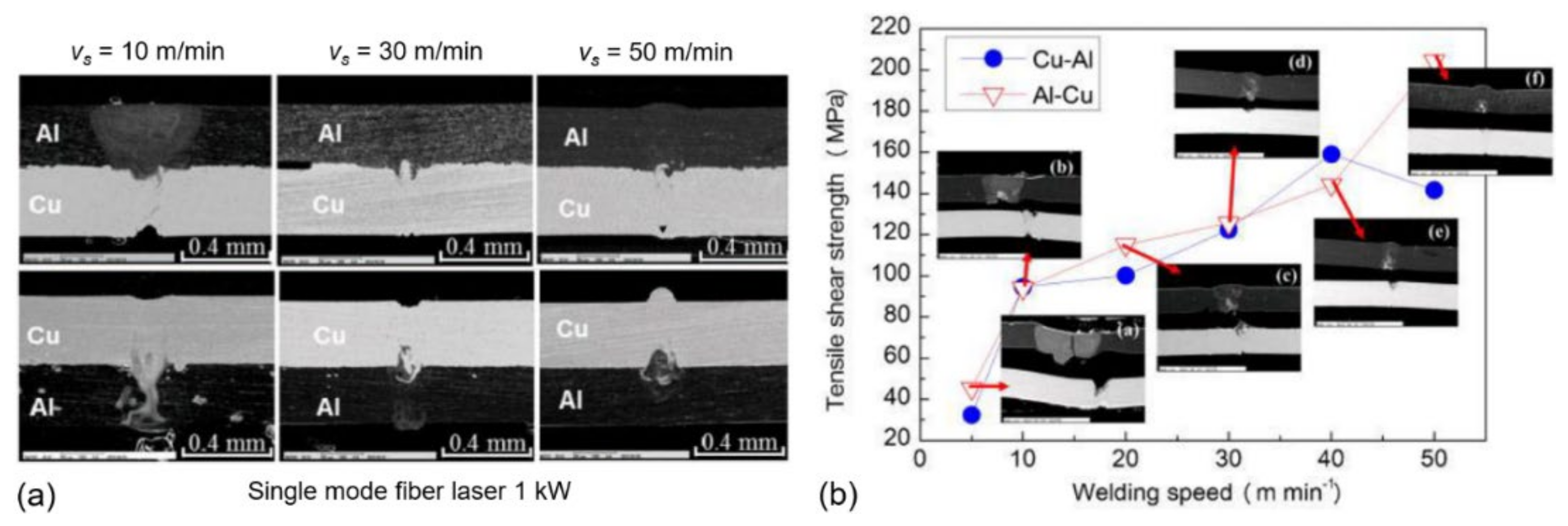

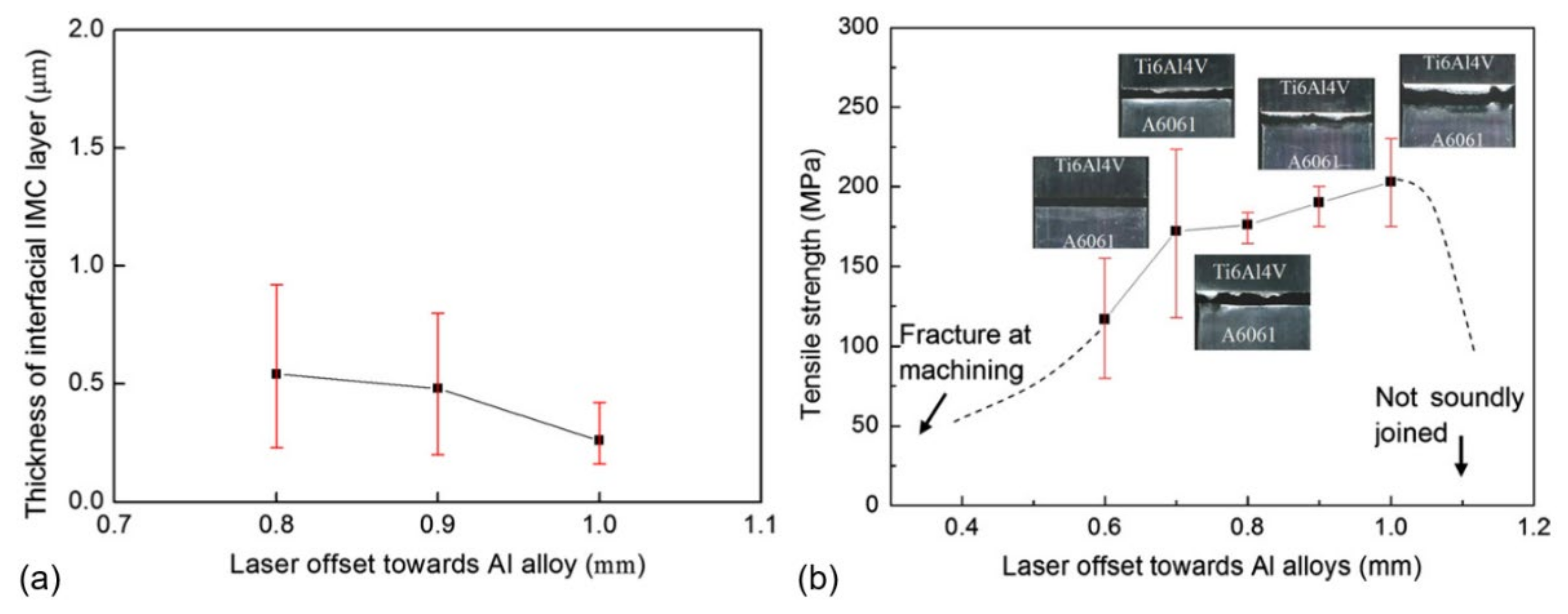

The welding of aluminium alloys to other metals is challenging, due to the formation of the hard and brittle intermetallic compound layer. The thickness of the IMC layer has a direct effect on strength in all studied multi-metal systems (Fe–Al, Cu–Al, and Ti–Al). The thickness is mainly controlled by the heat input, which mainly depends on the heat source power output and welding speed. In fusion welding, the heat inputs are higher than in FSW or ultrasound welding, and thus, the IMC thickness is usually larger than 2 µm. However, a too-thin IMC layer (<2–3 µm) may provide poor metallurgical bonding. The layer thickness of >10–12 µm provides reduced mechanical properties, due to excessive hardness and brittleness. Therefore, the optimal thickness is 5–10 µm. Another important factor is the morphology of the IMC layer. With continuous, non-disruptive morphology of the layer, improved strength is achieved, due to lower stress raising. A too-high heat input provides an unfavourable morphology in the form of sharp edges and islands, along with large IMC layer thickness, which is harmful for mechanical properties. The heat input may influence the chemical composition or formed phases. An important note is that a true heat input from laser beam, especially in the keyhole mode with full penetration, is very challenging since the laser beam partially escapes through the keyhole exit. Moreover, the absorption must be considered as well. The spreading distance, both on top and root side, and wetting angle have large influence on strength. The process parameters must be adjusted to provide larger spreading distance with good metallurgical bonding along with smaller wetting angles, regardless of the type of the joint. In this case, the optimisation of arc welding parameters is more important, due to the wider effect on melting material; the CMT arc process is advantageous, with lower heat inputs to mitigate layer growth.

The IMC layer thickness can be effectively suppressed by filler wire with 5 wt.% Si by changing the chemical composition. As an alternative, interlayer coatings are effective. Further development of filler wires is required. So far, the most widely studied are Si-alloyed and Zn-based filler wires. More advanced filler wires may provide an enhanced microstructure, improved spreading distances and bonding strength.

An important factor is the type of joint and stress/strain distribution at the IMC layer interface. Thus, the bevelling angle is an important factor to consider. The effect of residual stresses and stress/strain fields on mechanical properties is not widely studied. However, dissimilar materials exert much of the strain field, due to the high difference in the thermophysical properties and contraction upon cooling. The optimisation of process parameters is more complex in satisfying the adapted stress field, thermal cycle affecting microstructure and welding defects (cracking and pores).

There is a necessity to use newer techniques, e.g., preheating with pulsed laser, laser ablation of oxide Al alloy prior welding, external factors (ultrasound/mechanical vibrations), as they may further improve the weldability and strength of joints. The use of fluxes was proven to increase the quality of the joints by removing oxides from surfaces effectively. However, there is very low development towards more effective and less aggressive types of fluxes. A multi-beam system may provide a solution to the challenges. However, they are more complex than single beam solutions. Laser beam oscillations may help to improve spearing distances along higher tolerances to air gaps. Moreover, the morphology of IMC layer can be manipulated. However, the penetration depth may be reduced, and heat inputs may be increased. The application of acoustic vibrations during welding may provide a more uniform IMC layer morphology, grain refinement, lower porosity (as described in [

185,

186,

187]) and is very rarely published. Surface texturing and surface roughness optimisation can significantly improve strength by increasing the bonding area. It is scarcely studied, and there is a large room for newer discoveries. However, surface modification may add substantial additional costs for production and should be carefully accessed.

Numerical simulation of the IMC later formation and growth in multi-materials system is scarcely studied, due to its complexity. In welding, more complex physical phenomena are involved; the IMC layer growth may deviate from parabolic law and its thickness prediction with mechanical properties is challenging. This is mainly related to high thermal gradients and stronger heat convection by fast melt flows.

Hydrogen trapping and precipitation, due to its high solubility in Al alloys within a multi-material system, has been scarcely addressed. Hydrogen may significantly degrade the mechanical properties of joints. Thus, more studies are expected in this area.

In the case of Cu–Al joining, electrical conductivity plays a vital role, and thus, parameters and IMC layer characteristics should provide low electrical resistance. In general, Cu–Al joining may be more challenging since Cu is a highly conductive and reflective material. Therefore, more advanced laser systems are required with shorter wavelengths (<500 nm). However, these lasers have power limitation (<2 kW) with low beam quality that is unable to be focused to smaller spots for advanced manufacturing, having wider windows for heat inputs. There is a trend to substitute Cu with mode advanced Al alloys, due to weight and costs. However, the electrical conductivity of Al alloys must be enhanced for energy sector needs. Moreover, the weldability of these alloys should also be considered. In addition, due to Cu, more advanced techniques for phase recognition are required.

As a result, high mechanical properties and integrity of welded joints can be achieved by the optimisation of many process parameters and factors with implementation of the innovative techniques, which represent a significant challenge.

The future research direction for the filling knowledge gaps may include better understanding of formation and growth of the IMCs during welding and their properties after welding, more advanced filler materials and cost-effective interlayers allowing higher heat inputs to use for enhanced productivity, and advanced filler materials for improved corrosion resistance in harsh environments. In laser-based welding–brazing, more in-depth research of the process parameters and heat source interaction would be beneficial for a more stable process, providing improved quality welds.