Effect of Niobium on Inclusions in Fe-Mn-C-Al Twinning-Induced Plasticity Steel

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

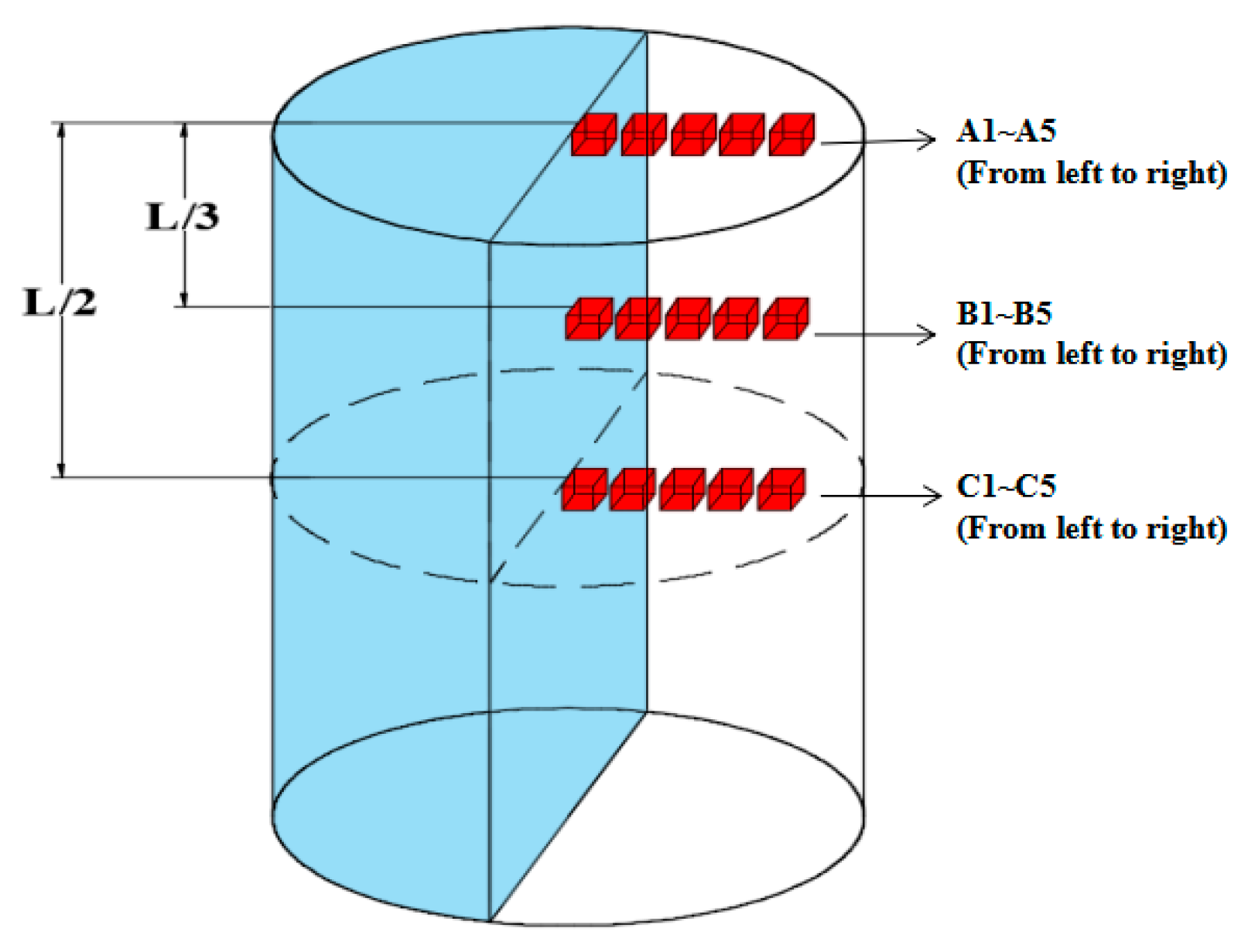

2.2. Sampling and Characterization of Inclusions

3. Experimental Results and Analysis

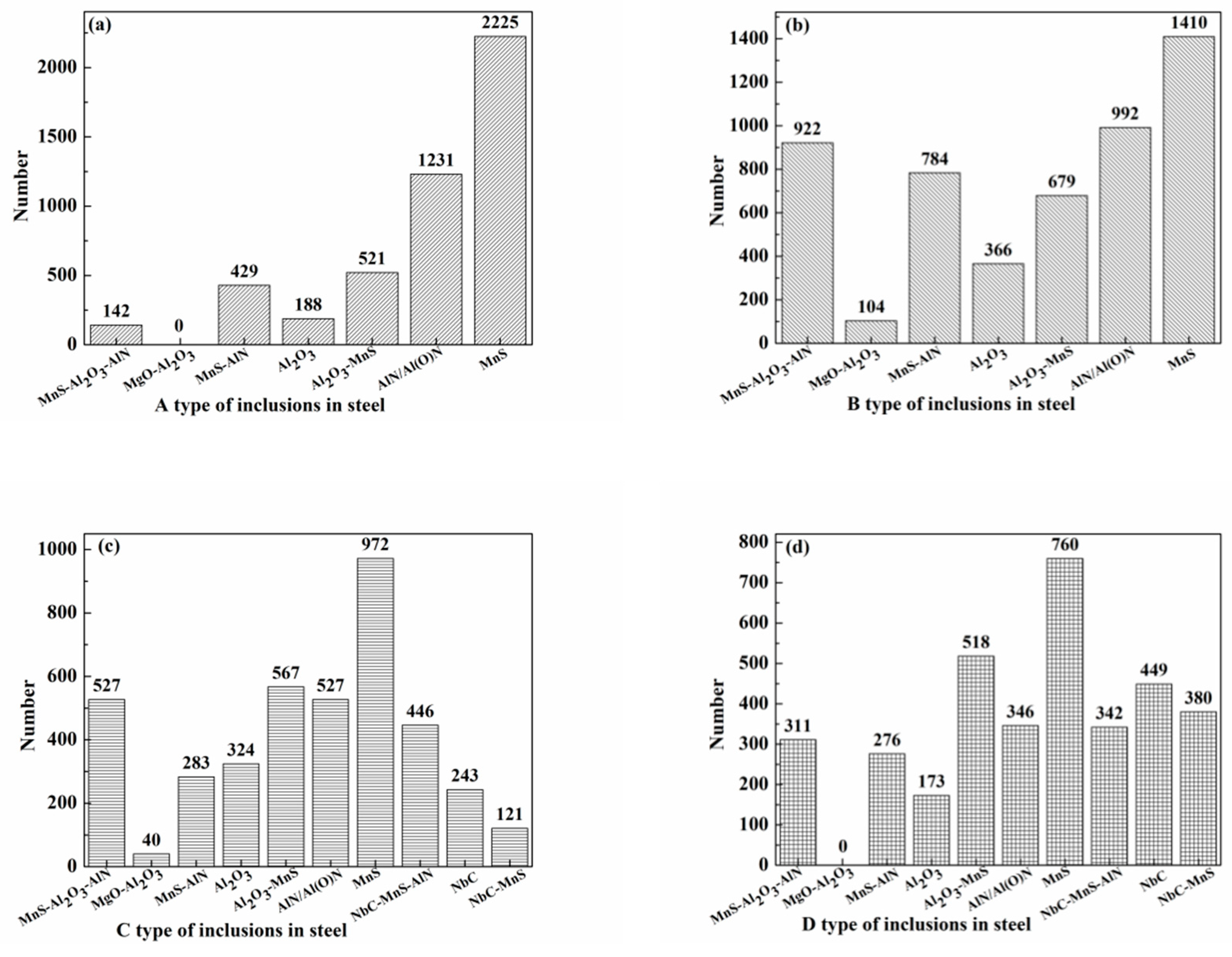

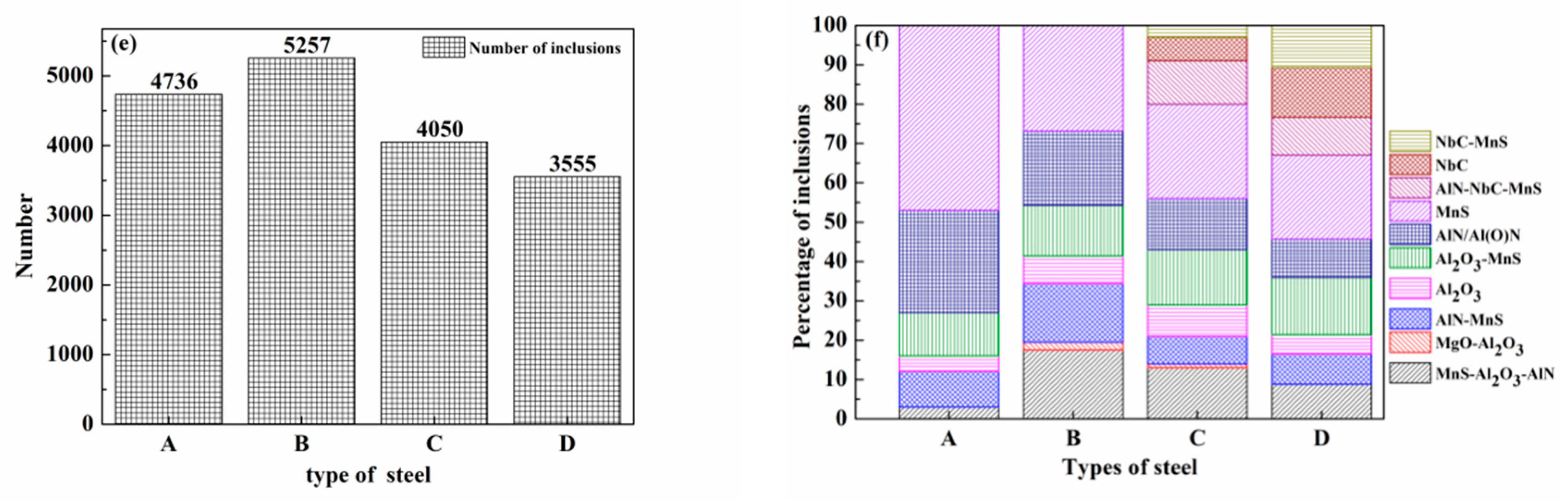

3.1. Characteristics of Inclusions in High Manganese Twinning Induced Plasticity Steel

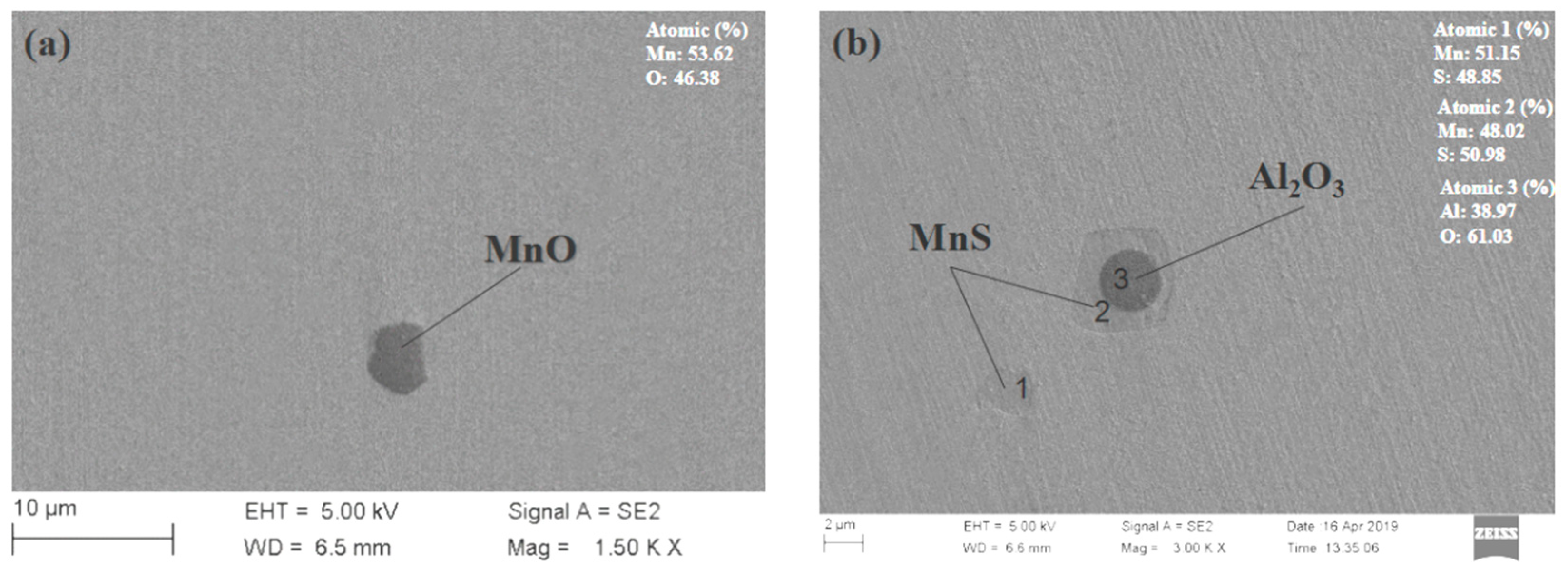

3.1.1. The TWIP Steel without Aluminum (the Actual Al Content Was 0.014%) Was Preset

3.1.2. TWIP Steel Containing 1.49% Al

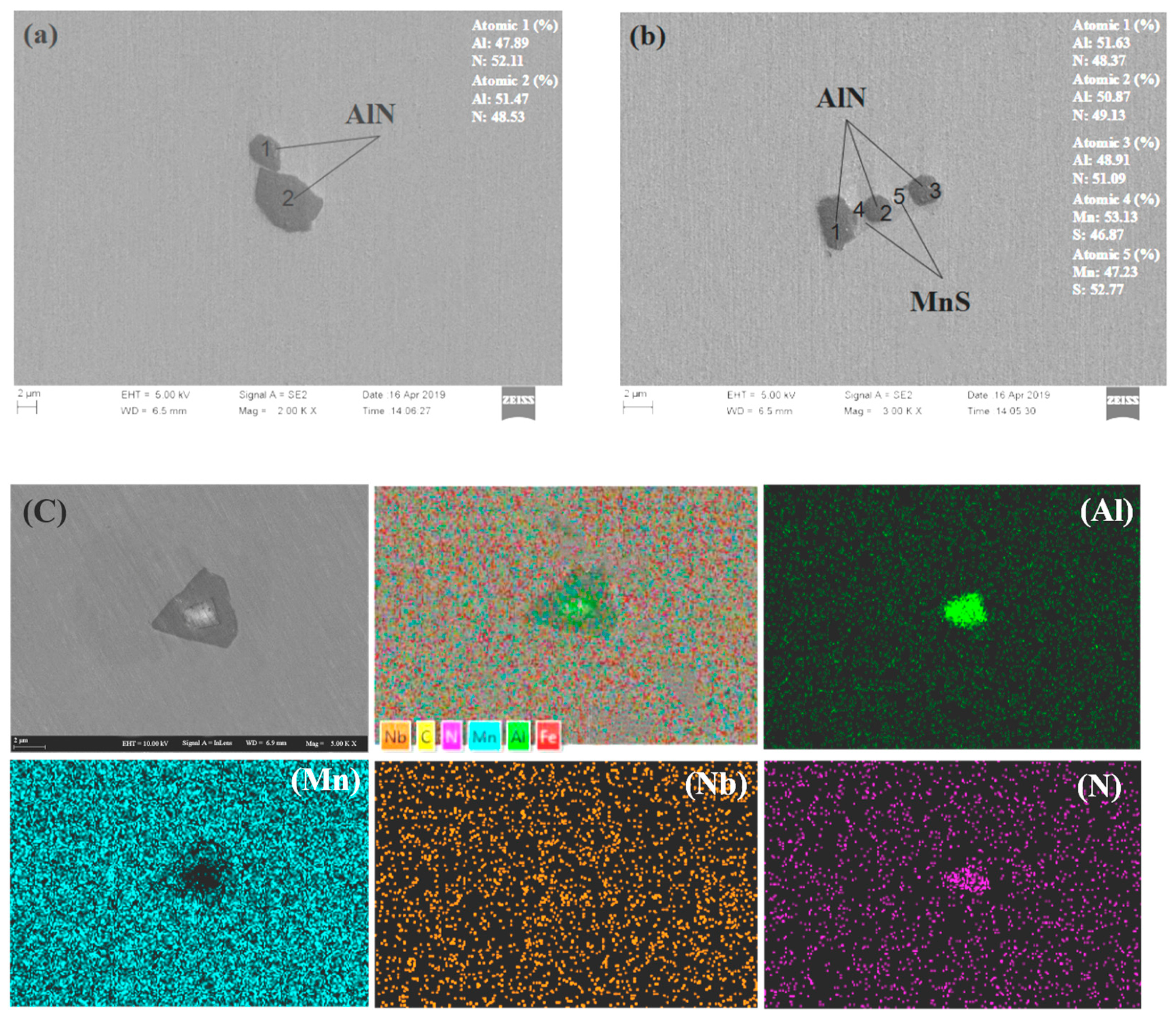

3.1.3. TWIP Steel Containing 1.5% Al and 0.04% Nb

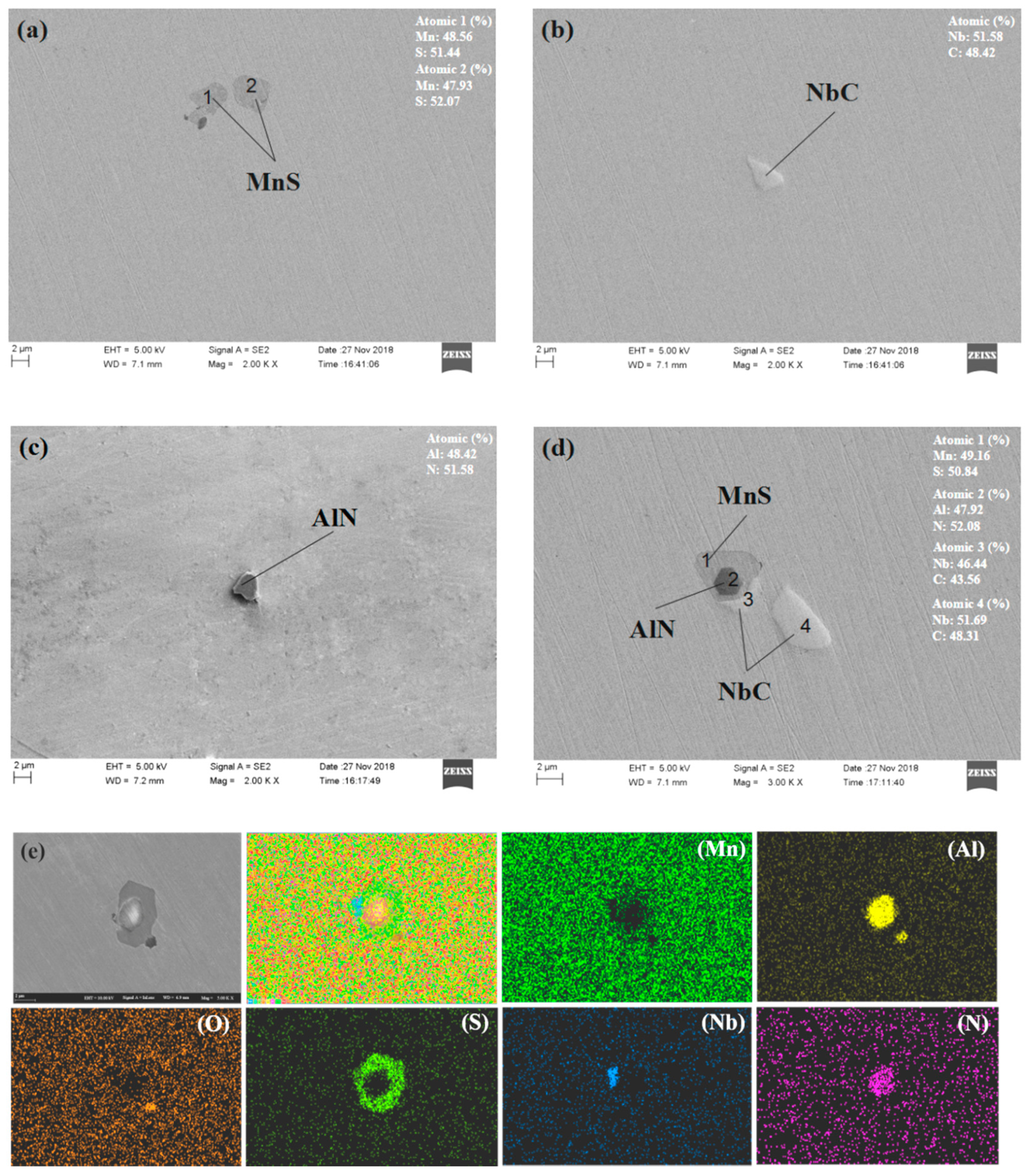

3.1.4. TWIP Steel Containing 1.5% Al and 0.08% Nb

3.2. Types and Evolution Rule of Inclusions in High Manganese Twinning-Induced Plasticity Steel

4. Analysis and Discussion

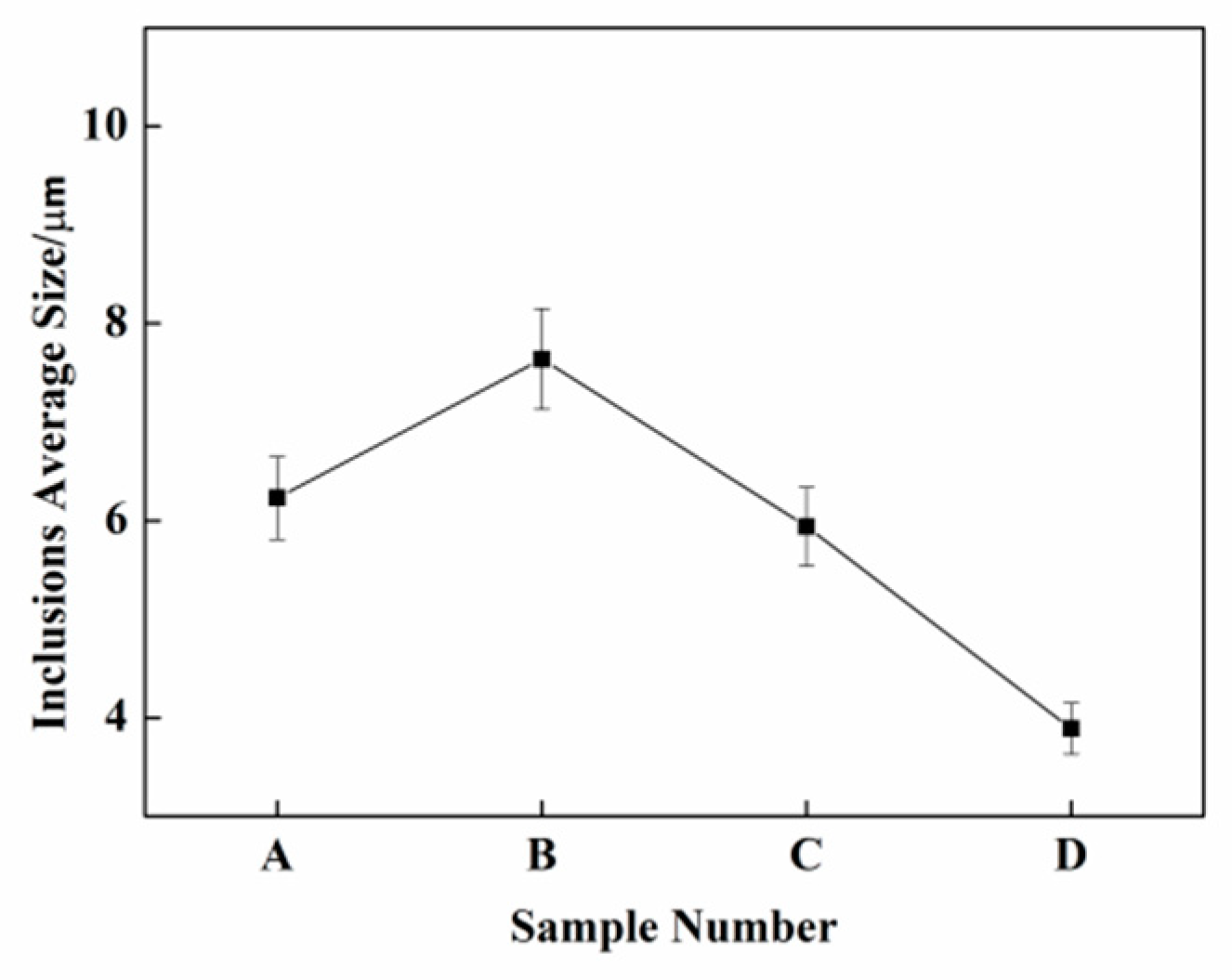

4.1. Thermodynamic Calculation of Inclusions in TWIP Steel

4.2. Thermodynamic Analysis of Niobium Complex Inclusions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scott, C.; Remy, B.; Collet, J.L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Frommeyer, G.; Bruex, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Bouaziz, O.; Masse, J.P.; Petitgand, G.; Huang, M.X. A Novel Strong and Ductile TWIP/Martensite Steel Composite. Adv. Eng. Mater. 2016, 18, 56–59. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Kim, J.G.; Enikeev, N.A.; Seol, J.B.; Abramova, M.M.; Karavaeva, M.V.; Valiev, R.Z.; Park, C.G.; Kim, H.S. Superior Strength and Multiple Strengthening Mechanisms in Nanocrystalline TWIP Steel. Sci. Rep. 2018, 8, 11200. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Terner, M.; Lee, J.; Hong, H.-U.; Moon, J.; Park, S.; Jang, J.; Lee, C.; Lee, B.; Lee, Y. Partitioning of C into κ-carbides by Si addition and its effect on the initial deformation mechanism of Fe-Mn-Al-C lightweight steels. J. Alloys Compd. 2019, 775, 554–564. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Wu, B.; Shen, Y.; He, Y.; Ding, H.; Su, X. Effect of Mn and Al contents on hot ductility of high alloy Fe-xMn-C-yAl austenite TWIP steels. Mater. Sci. Eng. A 2017, 708, 360–374. [Google Scholar] [CrossRef]

- Kang, S.; Jung, J.-G.; Kang, M.; Woo, W.; Lee, Y.-K. The effects of grain size on yielding, strain hardening, and mechanical twinning in Fe–18Mn–0.6C–1.5Al twinning-induced plasticity steel. Mater. Sci. Eng. A 2016, 652, 212–220. [Google Scholar] [CrossRef]

- Yu, H.-Y.; Lee, S.-M.; Nam, J.-H.; Lee, S.-J.; Fabrègue, D.; Park, M.-H.; Tsuji, L.Z.N.P.Y.T.A.S.N.; Lee, Y.-K. Post-uniform elongation and tensile fracture mechanisms of Fe-18Mn-0.6C-xAl twinning-induced plasticity steels. Acta Mater. 2017, 131, 435–444. [Google Scholar] [CrossRef]

- Hou, R.; Zhu, C.; Li, G.; Zhou, B.; Jia, J. Effect of Niobium on Precipitates and Texture Evolution of Fe-3% Si Grain-oriented Electrical Steel Annealed Hot Band. ISIJ Int. 2017, 57, 2245–2254. [Google Scholar] [CrossRef]

- Xin, X.; Yang, J.; Wang, Y.; Wang, R.; Wang, W.; Zheng, H.; Hu, H. Effects of Al content on non-metallic inclusion evolution in Fe-16Mn-xAl-0.6C high Mn TWIP steel. Ironmak. Steelmak. 2016, 43, 234–242. [Google Scholar] [CrossRef]

- Gigacher, G.; Pierer, R.; Wiener, J.; Bernhard, C. Metallurgical Aspects of Casting High-Manganese Steel Grades. Adv. Eng. Mater. 2006, 8, 1096–1100. [Google Scholar] [CrossRef]

- Gigacher, G.; Krieger, W.; Scheller, P.R.; Thomser, C. Non-Metallic Inclusions in High-Manganese-Alloy Steels. Steel Res. Int. 2005, 76, 644–649. [Google Scholar] [CrossRef]

- Park, K.B.; Park, J.-Y.; Do Kim, Y.; Choi, J.; Kang, H.-S.; Kang, J.-W.; Park, K.; Park, H.-K. Effect of the microstructure refinement by powder metallurgy on the oxidation behavior of Nb-6Mo-20Si-3Cr silicide-based alloy. Mater. Charact. 2020, 170, 110708. [Google Scholar] [CrossRef]

- Takamiya, T.; Furukimi, O. Precipitation Behavior and Inhibition Effect of MnS, MnSe and AlN in 3% Si Steel. Tetsu-to-Hagane 2014, 100, 1413–1420. [Google Scholar] [CrossRef][Green Version]

- Bhattacharya, K.; Conti, S.; Zanzotto, G.; Zimmer, J. Crystal symmetry and the reversibility of martensitic transformations. Nature 2004, 428, 55–59. [Google Scholar] [CrossRef]

- Mapelli, C.; Vedani, M. State of the art in the inclusion control within Ca treated Al-killed steels. Metall. Ital. 2001, 93, 25–30. [Google Scholar]

- Kang, S.E.; Tuling, A.; Banerjee, J.; Gunawardana, W.; Mintz, B. Hot ductility of TWIP steels. Mater. Sci. Technol. 2011, 27, 95–100. [Google Scholar] [CrossRef]

- Wada, H.; Pehlke, R.D. Nitrogen solubility and nitride formation in austenitic Fe-Ti alloys. Metall. Trans. B 1985, 16, 815–822. [Google Scholar] [CrossRef]

- Paek, M.-K.; Jang, J.-M.; Do, K.-H.; Pak, J.-J. Nitrogen solubility in high manganese-aluminum alloyed liquid steels. Met. Mater. Int. 2013, 19, 1077–1081. [Google Scholar] [CrossRef]

- Paek, M.-K.; Jang, J.-M.; Kang, H.-J.; Pak, J.-J. Reassessment of AlN (s) = Al + N Equilibration in Liquid Iron. ISIJ Int. 2013, 53, 535–537. [Google Scholar] [CrossRef]

- Shin, J.H.; Lee, J.; Min, D.J.; Park, J.H. Solubility of Nitrogen in High Manganese Steel (HMnS) Melts: Interaction Parameter between Mn and N. Met. Mater. Trans. A 2011, 42, 1081–1085. [Google Scholar] [CrossRef]

- Kim, D.-H.; Jung, M.-S.; Nam, H.; Paek, M.-K.; Pak, J.-J. Thermodynamic Relation between Silicon and Aluminum in Liquid Iron. Met. Mater. Trans. A 2012, 43, 1106–1112. [Google Scholar] [CrossRef]

- Chen, J. Data Book of Steelmaking; Metallurgical Industry Press: Beijing, China, 2010; pp. 758–761. [Google Scholar]

- Jang, J.-M.; Seo, S.-H.; Jiang, M.; Paek, M.-K.; Wang, X.; Pak, J.-J. Nitrogen solubility in liquid Fe–C alloys. ISIJ Int. 2014, 54, 32–36. [Google Scholar] [CrossRef]

- Jang, J.-M.; Seo, S.-H.; Kim, Y.-D.; An, H.-J.; Pak, J.-J. Effect of Carbon on Nitrogen Solubility and AlN Formation in High Al Alloyed Liquid Steels. ISIJ Int. 2014, 54, 1578–1583. [Google Scholar] [CrossRef]

- Narita, K. Physical chemistry of the groups IVa (Ti, Zr), Va (V, Nb, Ta) and the rare earth elements in steel. Trans. Iron Steel Inst. Jpn. 1975, 15, 145–152. [Google Scholar] [CrossRef]

- Andrade, H.; Akben, M.; Jonas, J. Effect of molybdenum, niobium, and vanadium on static recovery and recrystallization and on solute strengthening in microalloyed steels. Metall. Trans. A 1983, 14, 1967–1977. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Kirkaldy, J. Thermodynamics of Fe-Ti-C and Fe-Nb-C Austenites and Nonstoichiometric Titanium and Niobium Carbides. Adv. Phase Transit. 1988, 51, 37–51. [Google Scholar] [CrossRef]

- Mori, T.; Tokizane, M.; Yamaguchi, K.; Sunami, E.; Nakazima, Y. Thermodynamic Properties of Niobium Carbides and Nitrides in Steels. Tetsu-to-Hagane 1968, 54, 763–776. [Google Scholar] [CrossRef]

- Palmiere, E.; Garcia, C.; De Ardo, A. Compositional and microstructural changes which attend reheating and grain coarsening in steels containing niobium. Metall. Mater. Trans. A 1994, 25, 277–286. [Google Scholar] [CrossRef]

- Yong, Q. Precipitates in Iron and Steel; Metallurgical Industry Press: Beijing, China, 2006; Volume 15, pp. 141–171. [Google Scholar]

| Serial Number | C | Mn | Al | Nb | N | O | S | Fe |

|---|---|---|---|---|---|---|---|---|

| A | 0.71 | 15.83 | 0.014 | 0 | 0.0019 | 0.0018 | 0.0071 | Bal. |

| B | 0.65 | 17.65 | 1.49 | 0 | 0.0023 | 0.002 | 0.0076 | Bal. |

| C | 0.69 | 17.16 | 1.5 | 0.04 | 0.0018 | 0.0017 | 0.008 | Bal. |

| D | 0.61 | 16.02 | 1.51 | 0.08 | 0.0017 | 0.0016 | 0.0073 | Bal. |

| , , | |||||||||

| C | Si | Mn | P | S | Al | O | N | ||

| Al | 0.091 | 0.0056 | 0.012 | 0.05 | 0.03 | 0.045 | −6.6 | −0.058 | |

| N | 0.13 | 0.047 | −0.02 | 0.045 | 0.007 | −0.028 | 0.05 | 0 | |

| Primary and Secondary Interaction Coefficient | Interaction Coefficient | Numerical Value(1873K) | Scope of Application | Reference |

|---|---|---|---|---|

| −0.0209 | [%Mn] < 25 | [23] | ||

| 0.017 | [%Al] < 2.5 | [24] | ||

| 0.08 | [%C] < 5.2 | [26] | ||

| 0.043 | [%Al] < 4.5 | [22] | ||

| 0 | [%Mn] < 22 | [22] | ||

| 0.033 | [%Al] < 4.5 | [22] | ||

| 0.03 | [%Al] < 2.45 | [27] | ||

| 0 | [%Mn] < 26 | [21] | ||

| 0 | [%Al] < 2.5 | [22] | ||

| 0.014 | [%C] < 5.2 | [26] | ||

| 0 | [%Al] < 4.5 | [22] | ||

| 0 | [%Mn] < 22 | [22] | ||

| 0 | [%Al] < 4.5 | [27] | ||

| 0 | [%C] < 3.9 | [27] |

| C | Mn | P | S | Al | N | |

|---|---|---|---|---|---|---|

| Mn | −0.07 | - | −0.0035 | −0.048 | - | −0.091 |

| S | 0.11 | −0.026 | 0.029 | −0.028 | 0.035 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, F.; Du, W.; Zhuang, C.; Li, C. Effect of Niobium on Inclusions in Fe-Mn-C-Al Twinning-Induced Plasticity Steel. Metals 2021, 11, 83. https://doi.org/10.3390/met11010083

Lan F, Du W, Zhuang C, Li C. Effect of Niobium on Inclusions in Fe-Mn-C-Al Twinning-Induced Plasticity Steel. Metals. 2021; 11(1):83. https://doi.org/10.3390/met11010083

Chicago/Turabian StyleLan, Fangjie, Wenhui Du, Changling Zhuang, and Changrong Li. 2021. "Effect of Niobium on Inclusions in Fe-Mn-C-Al Twinning-Induced Plasticity Steel" Metals 11, no. 1: 83. https://doi.org/10.3390/met11010083

APA StyleLan, F., Du, W., Zhuang, C., & Li, C. (2021). Effect of Niobium on Inclusions in Fe-Mn-C-Al Twinning-Induced Plasticity Steel. Metals, 11(1), 83. https://doi.org/10.3390/met11010083