Superficial Effects of Ball Burnishing on TRIP Steel AISI 301LN Sheets

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

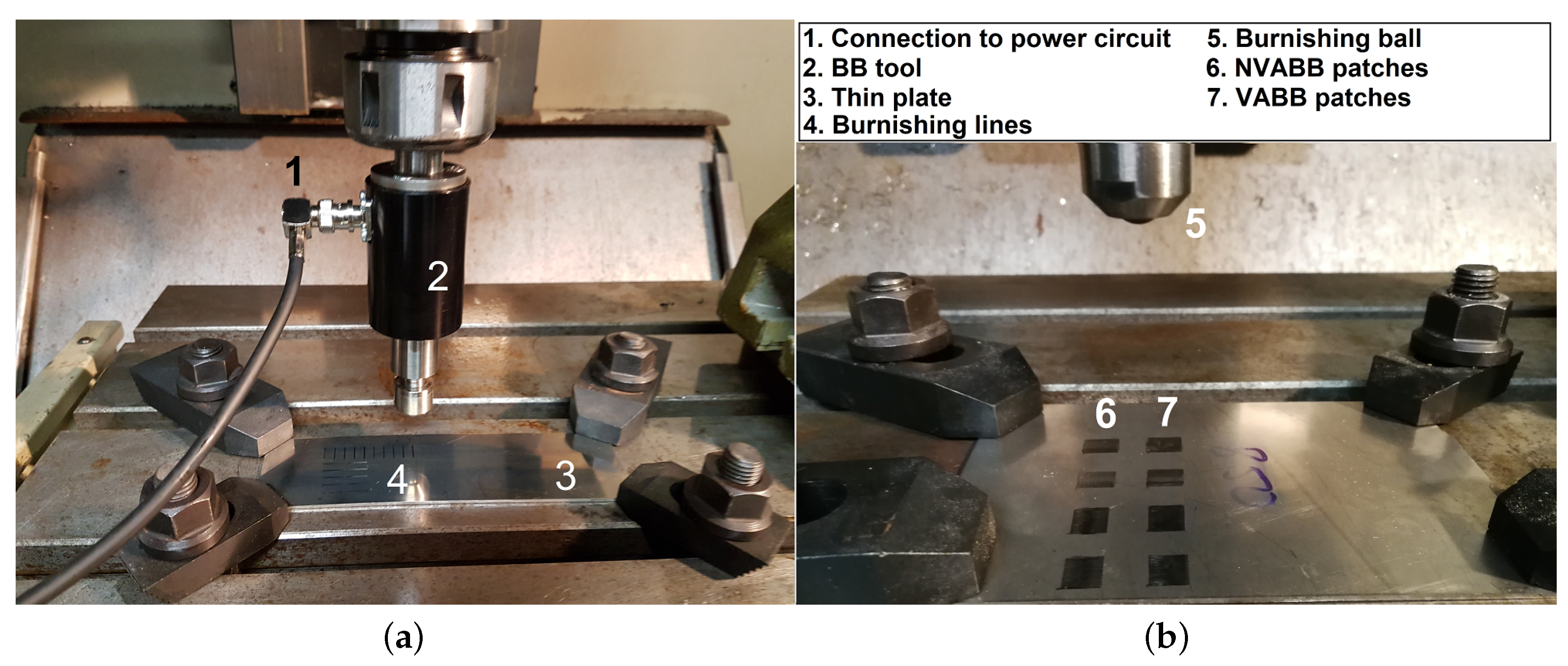

2.2. Experimental Campaign

2.2.1. First Phase: Simple BB Tests

2.2.2. Second Phase: Simple BB Tests

2.3. Characterization of BB Effects

2.3.1. Geometrical and Topological Features

2.3.2. Mechanical Characterization

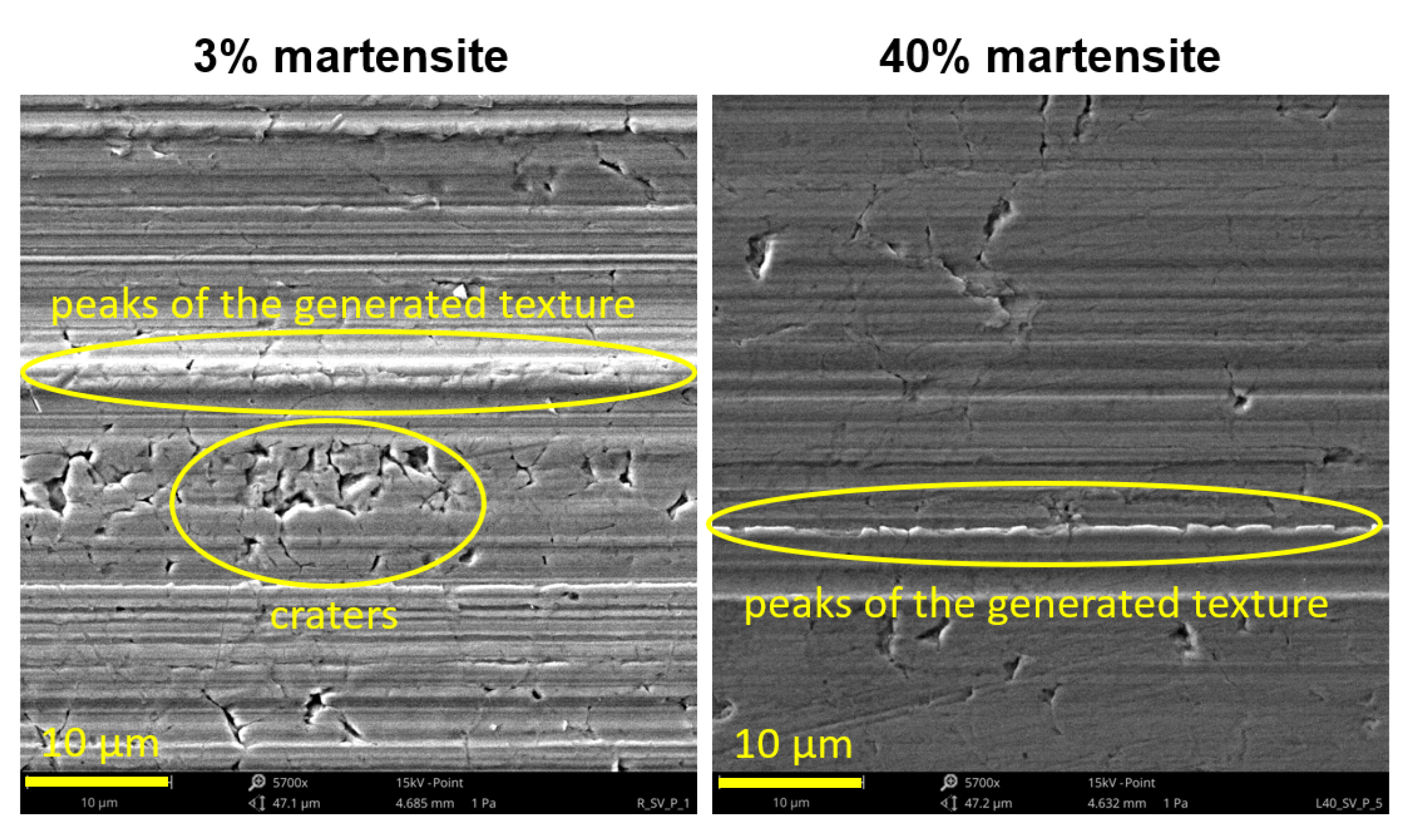

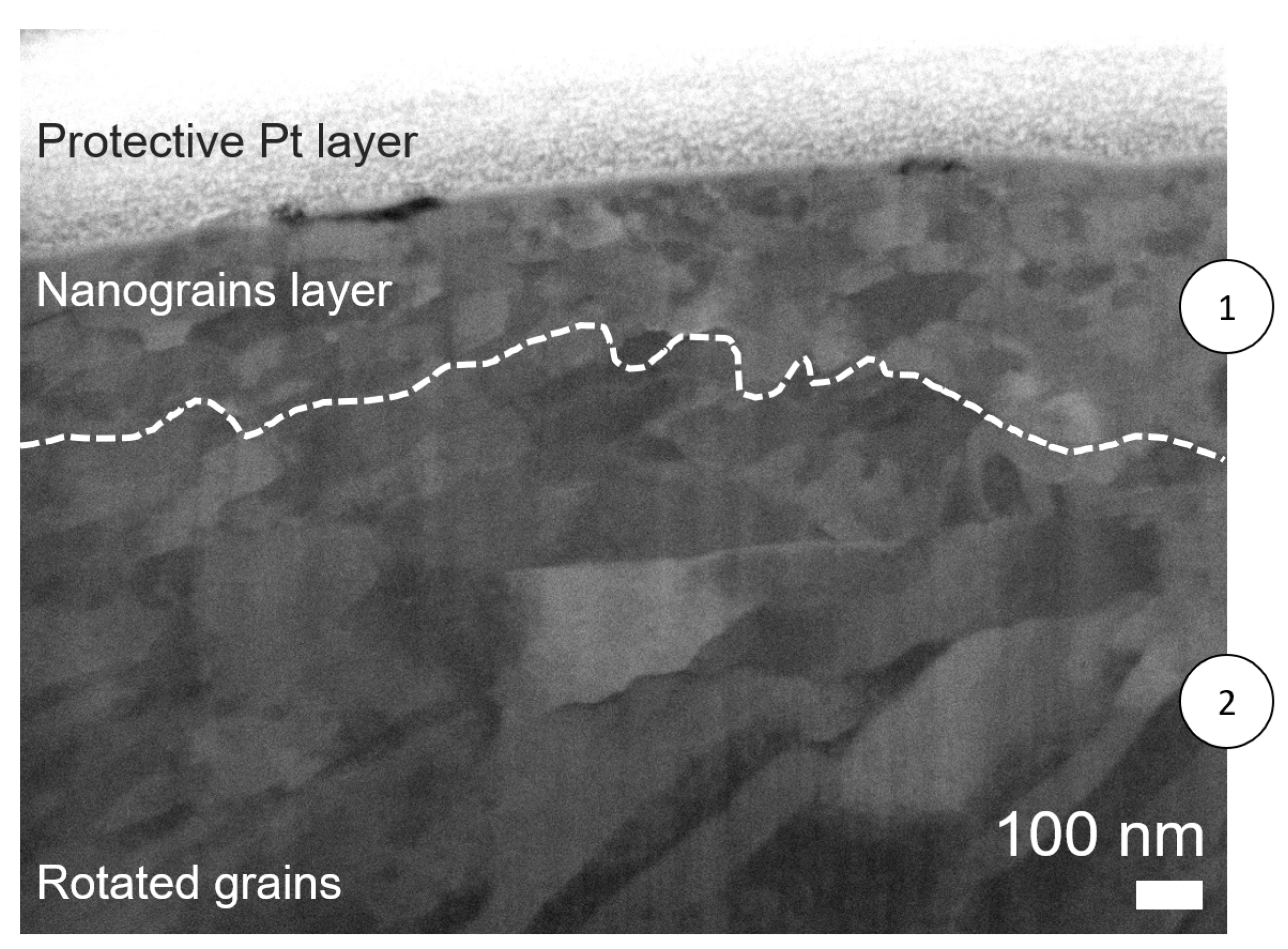

2.3.3. Microstructure Characterization and Damage by Contact Loading

3. Results and Discussion

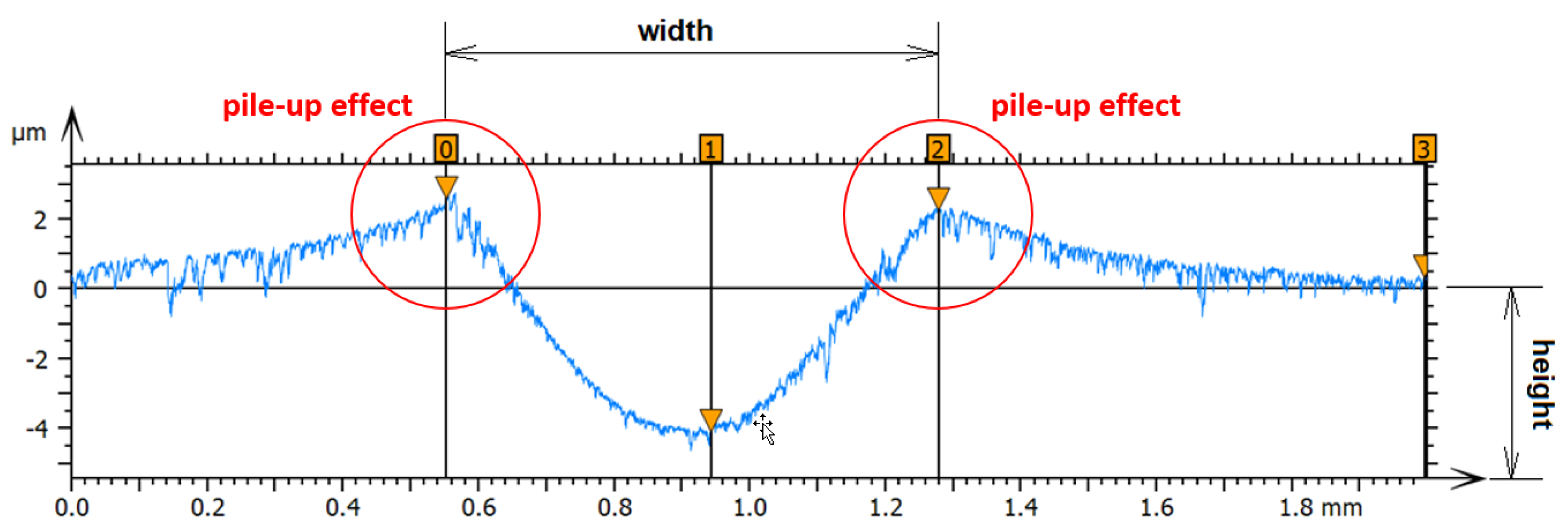

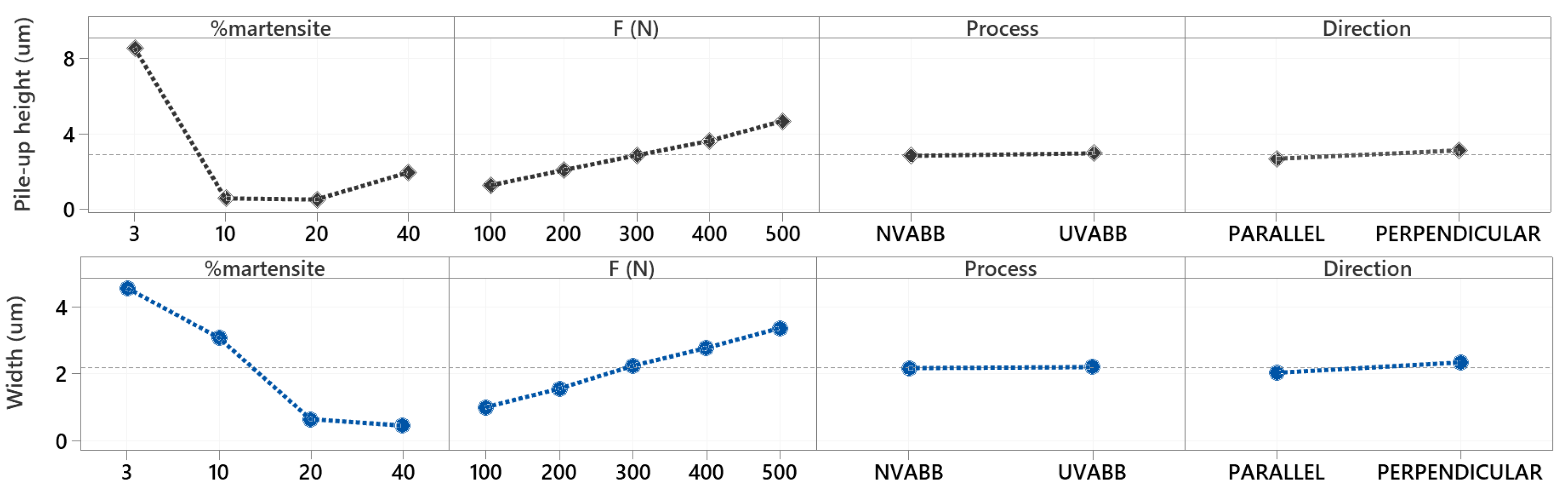

3.1. Geometrical Descriptors

3.1.1. Dimensions of BB Tracks (First Experimental Phase)

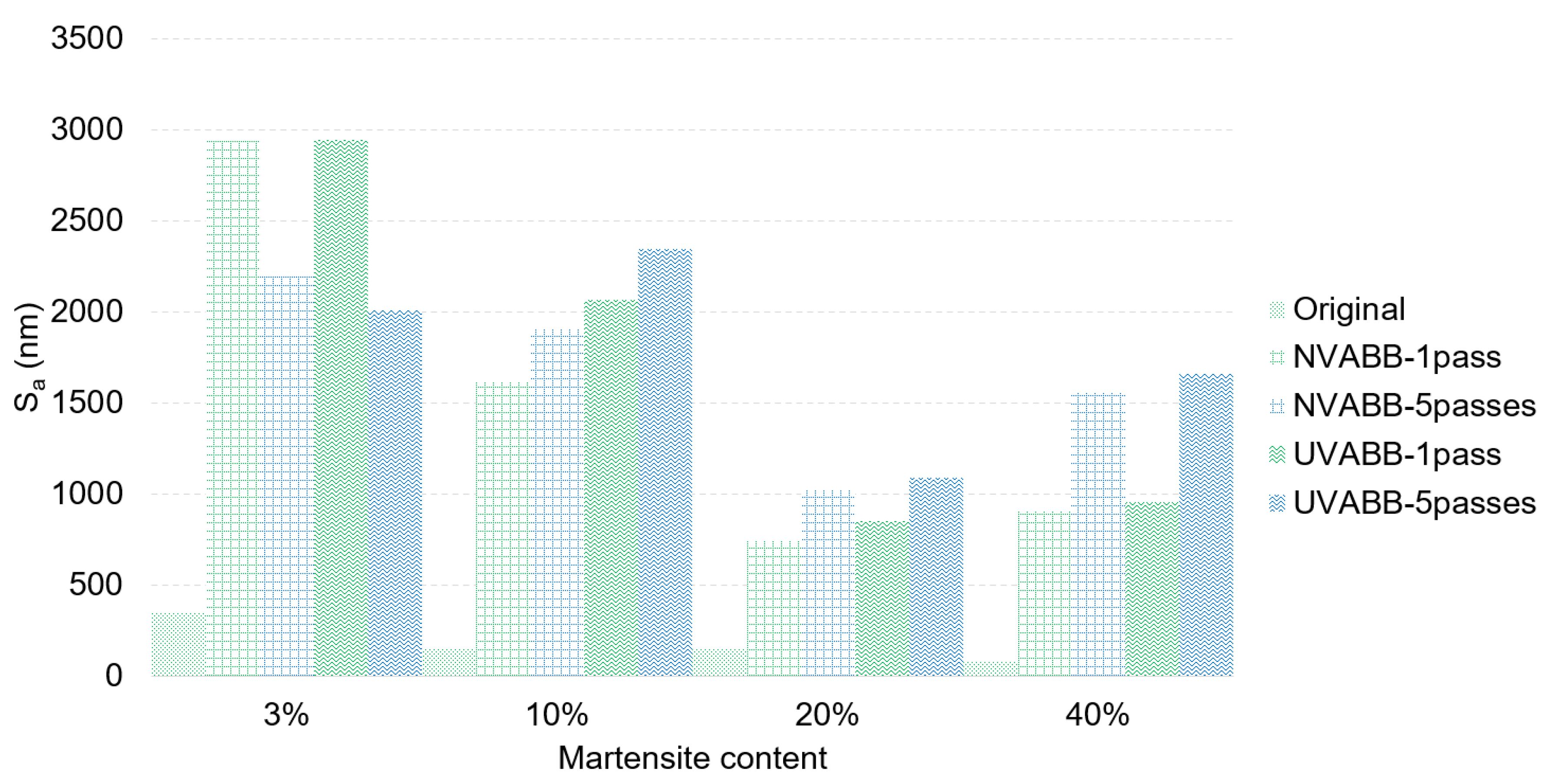

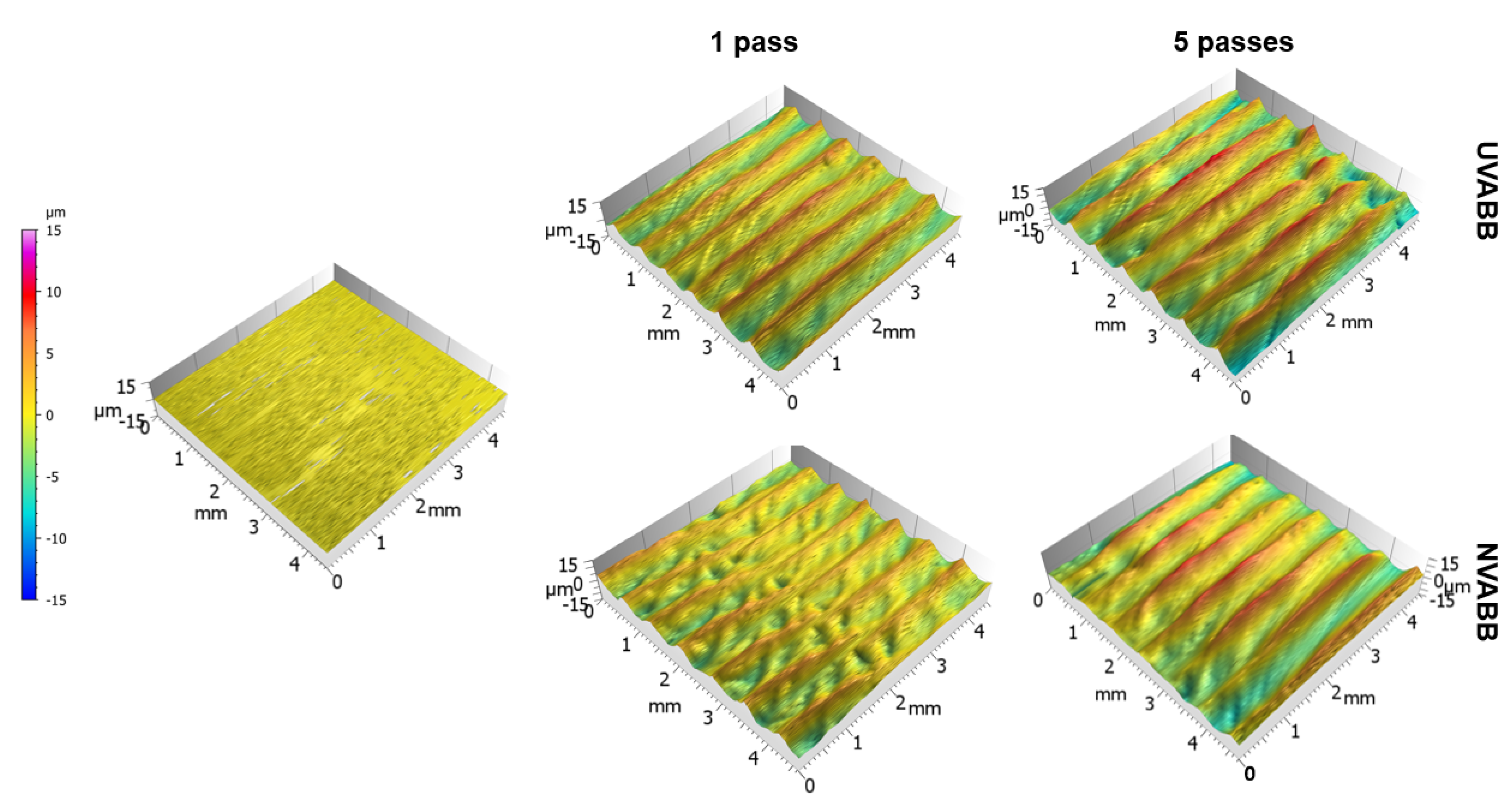

3.1.2. Topology of BB Patches (Second Experimental Phase)

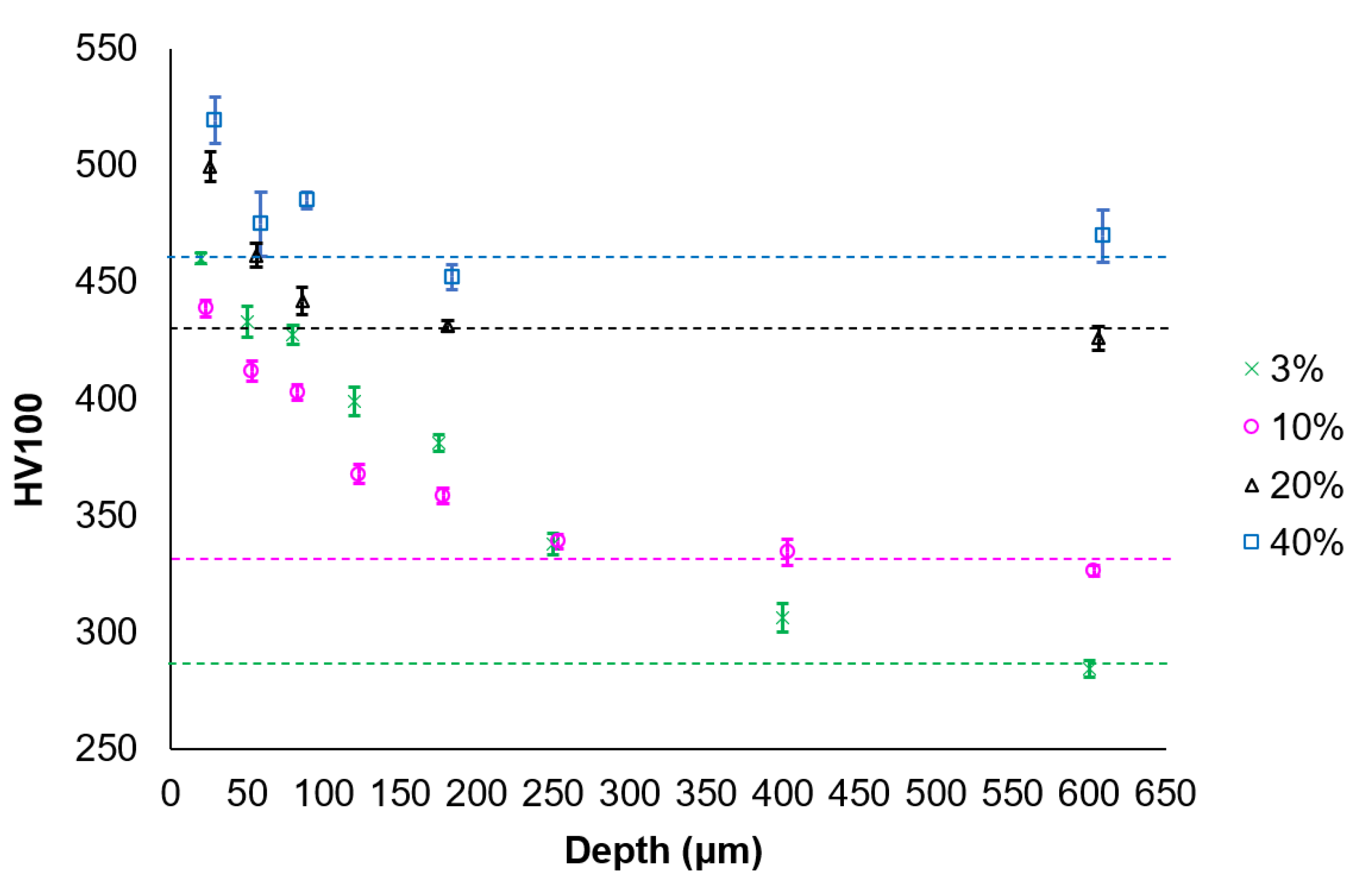

3.2. Deep Hardness Profiles

3.3. Microstructural Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BB | Multidisciplinary Digital Publishing Institute |

| FESEM | Field Emission Scanning Electron Microscopy |

| NVABB | Directory of open access journals |

| SEM | Scanning Electron Microscopy |

| VABB | Three letter acronym |

References

- Ghassemieh, E. Materials in automotive application, state of the art and prospects. In New Trends and Developments in Automotive Industry; InTech: New York, NY, USA, 2011; pp. 365–394. [Google Scholar]

- Krupp, U.; West, C.; Christ, H.J. Deformation-induced martensite formation during cyclic deformation of metastable austenitic steel: Influence of temperature and carbon content. Mater. Sci. Eng. A 2008, 481, 713–717. [Google Scholar] [CrossRef]

- Mangonon, P.L.; Thomas, G. The martensite phases in 304 stainless steel. Metall. Trans. 1970, 1, 1577–1586. [Google Scholar] [CrossRef]

- Robles, A.S.; De la Peña, J.Á.D.; García, A.d.J.B.; Gómez, E.A.; MORA, H.P.; Robles, N.S. El proceso de bruñido con bola: Estado del arte de una tecnología en desarrollo. DYNA 2017, 92, 28–33. [Google Scholar] [CrossRef]

- Sachin, B.; Narendranath, S.; Chakradhar, D. Selection of optimal process parameters in sustainable diamond burnishing of 17-4 PH stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 219. [Google Scholar] [CrossRef]

- Rotella, G.; Rinaldi, S.; Filice, L. Roller burnishing of Ti6Al4V under different cooling/lubrication conditions and tool design: Effects on surface integrity. Int. J. Adv. Manuf. Technol. 2020, 106, 431–440. [Google Scholar] [CrossRef]

- Ding, Z.; Zhao, J.; Liu, H.; Dong, Y. Effects of ball burnishing on surface properties of SKD11 mold steel. Eng. Res. Express 2020, 2, 025004. [Google Scholar] [CrossRef]

- Hamadache, H.; Bourebia, M.; Taamallah, O.; Laouar, L. Surface hardening of 36 NiCrMo 6 steel by ball burnishing process. Mater. Res. Express 2019, 6, 106538. [Google Scholar] [CrossRef]

- Travieso-Rodríguez, J.A.; Jerez-Mesa, R.; Gómez-Gras, G.; Llumà-Fuentes, J.; Casadesús-Farràs, O.; Madueño-Guerrero, M. Hardening effect and fatigue behavior enhancement through ball burnishing on AISI 1038. J. Mater. Res. Technol. 2019, 8, 5639–5646. [Google Scholar] [CrossRef]

- Kuznetsov, V.; Smolin, I.Y.; Dmitriev, A.; Tarasov, S.Y.; Gorgots, V. Toward control of subsurface strain accumulation in nanostructuring burnishing on thermostrengthened steel. Surf. Coat. Technol. 2016, 285, 171–178. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Yao, M.; Wang, R. Compressive residual stress introduced by shot peening. J. Mater. Process. Technol. 1998, 73, 64–73. [Google Scholar] [CrossRef]

- Terres, M.A.; Laalai, N.; Sidhom, H. Effect of nitriding and shot-peening on the fatigue behavior of 42CrMo4 steel: Experimental analysis and predictive approach. Mater. Des. 2012, 35, 741–748. [Google Scholar] [CrossRef]

- Nikitin, I.; Altenberger, I. Comparison of the fatigue behavior and residual stress stability of laser-shock peened and deep rolled austenitic stainless steel AISI 304 in the temperature range 25–600 C. Mater. Sci. Eng. A 2007, 465, 176–182. [Google Scholar] [CrossRef]

- Torres, M.; Voorwald, H. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 2002, 24, 877–886. [Google Scholar] [CrossRef]

- Palacios, M.; Bagherifard, S.; Guagliano, M.; Fernández Pariente, I. Influence of severe shot peening on wear behaviour of an aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 821–829. [Google Scholar] [CrossRef]

- Fargas, G.; Roa, J.; Mateo, A. Effect of shot peening on metastable austenitic stainless steels. Mater. Sci. Eng. A 2015, 641, 290–296. [Google Scholar] [CrossRef]

- De Los Rios, E.; Trull, M.; Levers, A. Modelling fatigue crack growth in shot-peened components of Al 2024-T351. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 709–716. [Google Scholar] [CrossRef]

- Guagliano, M.; Vergani, L. An approach for prediction of fatigue strength of shot peened components. Eng. Fract. Mech. 2004, 71, 501–512. [Google Scholar] [CrossRef]

- Estevez-Urra, A.; Llumà, J.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A. Monitoring of Processing Conditions of an Ultrasonic Vibration-Assisted Ball-Burnishing Process. Sensors 2020, 20, 2562. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Landon, Y.; Travieso-Rodriguez, J.A.; Dessein, G.; Lluma-Fuentes, J.; Wagner, V. Topological surface integrity modification of AISI 1038 alloy after vibration-assisted ball burnishing. Surf. Coat. Technol. 2018, 349, 364–377. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodríguez, J.A.; Landon, Y.; Dessein, G.; Lluma-Fuentes, J.; Wagner, V. Comprehensive analysis of surface integrity modification of ball-end milled Ti-6Al-4V surfaces through vibration-assisted ball burnishing. J. Mater. Process. Technol. 2019, 267, 230–240. [Google Scholar] [CrossRef]

- Siu, K.; Ngan, A.; Jones, I. New insight on acoustoplasticity–ultrasonic irradiation enhances subgrain formation during deformation. Int. J. Plast. 2011, 27, 788–800. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Pan, Y.; Li, X. Effects of the different frequencies and loads of ultrasonic surface rolling on surface mechanical properties and fretting wear resistance of HIP Ti–6Al–4V alloy. Appl. Surf. Sci. 2016, 389, 324–334. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Xie, M.; Li, X. Effect of ultrasonic surface rolling at low temperatures on surface layer microstructure and properties of HIP Ti-6Al-4V alloy. Surf. Coat. Technol. 2017, 316, 75–84. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, Z.; Su, W.; Zhou, H.; Liu, C.; Yang, Y.; Qi, X. Microstructure and surface properties of 17-4PH stainless steel by ultrasonic surface rolling technology. Surf. Coat. Technol. 2017, 321, 64–73. [Google Scholar] [CrossRef]

- Liu, D.; Liu, D.; Zhang, X.; Ma, A.; Liu, C. Microstructural evolution mechanisms in rolled 17-4PH steel processed by ultrasonic surface rolling process. Mater. Sci. Eng. A 2020, 773, 138720. [Google Scholar] [CrossRef]

- Salmi, M.; Huuki, J.; Ituarte, I.F. The ultrasonic burnishing of cobalt-chrome and stainless steel surface made by additive manufacturing. Prog. Addit. Manuf. 2017, 2, 31–41. [Google Scholar] [CrossRef]

- Lesyk, D.; Soyama, H.; Mordyuk, B.; Dzhemelinskyi, V.; Martinez, S.; Khripta, N.; Lamikiz, A. Mechanical surface treatments of AISI 304 stainless steel: Effects on surface microrelief, residual stress, and microstructure. J. Mater. Eng. Perform. 2019, 28, 5307–5322. [Google Scholar] [CrossRef]

- Wang, H.; Song, G.; Tang, G. Effect of electropulsing on surface mechanical properties and microstructure of AISI 304 stainless steel during ultrasonic surface rolling process. Mater. Sci. Eng. A 2016, 662, 456–467. [Google Scholar] [CrossRef]

- Wang, H.b.; Yang, X.h.; Li, H.; Song, G.l.; Tang, G.y. Enhanced fatigue performance and surface mechanical properties of AISI 304 stainless steel induced by electropulsing-assisted ultrasonic surface rolling process. J. Mater. Res. 2018, 33, 3827–3840. [Google Scholar] [CrossRef]

- Li, L.; Kim, M.; Lee, S.; Bae, M.; Lee, D. Influence of multiple ultrasonic impact treatments on surface roughness and wear performance of SUS301 steel. Surf. Coat. Technol. 2016, 307, 517–524. [Google Scholar] [CrossRef]

- Fargas, G.; Zapata, A.; Roa, J.J.; Sapezanskaia, I.; Mateo, A. Correlation between microstructure and mechanical properties before and after reversion of metastable austenitic stainless steels. Metall. Mater. Trans. A 2015, 46, 5697–5707. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Gomez-Gras, G.; Lluma-Fuentes, J. Development, characterization and test of an ultrasonic vibration-assisted ball burnishing tool. J. Mater. Process. Technol. 2018, 257, 203–212. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Lluma-Fuentes, J.; de la Calle, B.G. Experimental study of lateral pass width in conventional and vibrations-assisted ball burnishing. Int. J. Adv. Manuf. Technol. 2016, 87, 363–371. [Google Scholar] [CrossRef]

- Dong, W.; Sullivan, P.; Stout, K. Comprehensive study of parameters for characterising three-dimensional surface topography: III: Parameters for characterising amplitude and some functional properties. Wear 1994, 178, 29–43. [Google Scholar] [CrossRef]

- Minguela, J.; Slawik, S.; Mücklich, F.; Ginebra, M.; Llanes, L.; Mas-Moruno, C.; Roa, J. Evolution of microstructure and residual stresses in gradually ground/polished 3Y-TZP. J. Eur. Ceram. Soc. 2020, 40, 1582–1591. [Google Scholar] [CrossRef]

| State | % Martensite | Grain | Yield | Tensile | Deformation | HV100 |

|---|---|---|---|---|---|---|

| Mass Fraction | Size (μm) | Strength (MPa) | Strength (MPa) | at Break (%) | ||

| Annealed | <3% | 11.70 ± 4.35 | 360 ± 6 | 902 ± 11 | 42 ± 2 | 240 ± 4 |

| Cold worked | 10% | 8.55 ± 3.74 | 650 ± 7 | 967 ± 9 | 38 ± 6 | 300 ± 5 |

| 20% | 9.05 ± 4.21 | 926 ± 12 | 1113 ± 18 | 30 ± 5 | 400 ± 5 | |

| 40% | 9.24 ± 4.19 | 1148 ± 17 | 1173 ± 20 | 21 ± 3 | 436± 7 |

| Factor | Levels/Description |

|---|---|

| Burnishing pre-load force (N) | 100–200–300–400–500 |

| Vibration assistance | VABB–NVABB |

| Burnishing direction with regards to lamination direction | perpendicular–parallel |

| Factor | Levels/Description |

|---|---|

| Vibration assistance | VABB–NVABB |

| Burnishing direction with regards to lamination direction | perpendicular–parallel |

| Number of passes | 1–5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jerez-Mesa, R.; Fargas, G.; Roa, J.J.; Llumà, J.; Travieso-Rodriguez, J.A. Superficial Effects of Ball Burnishing on TRIP Steel AISI 301LN Sheets. Metals 2021, 11, 82. https://doi.org/10.3390/met11010082

Jerez-Mesa R, Fargas G, Roa JJ, Llumà J, Travieso-Rodriguez JA. Superficial Effects of Ball Burnishing on TRIP Steel AISI 301LN Sheets. Metals. 2021; 11(1):82. https://doi.org/10.3390/met11010082

Chicago/Turabian StyleJerez-Mesa, Ramón, Gemma Fargas, Joan Josep Roa, Jordi Llumà, and J. Antonio Travieso-Rodriguez. 2021. "Superficial Effects of Ball Burnishing on TRIP Steel AISI 301LN Sheets" Metals 11, no. 1: 82. https://doi.org/10.3390/met11010082

APA StyleJerez-Mesa, R., Fargas, G., Roa, J. J., Llumà, J., & Travieso-Rodriguez, J. A. (2021). Superficial Effects of Ball Burnishing on TRIP Steel AISI 301LN Sheets. Metals, 11(1), 82. https://doi.org/10.3390/met11010082