Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure

Abstract

1. Introduction

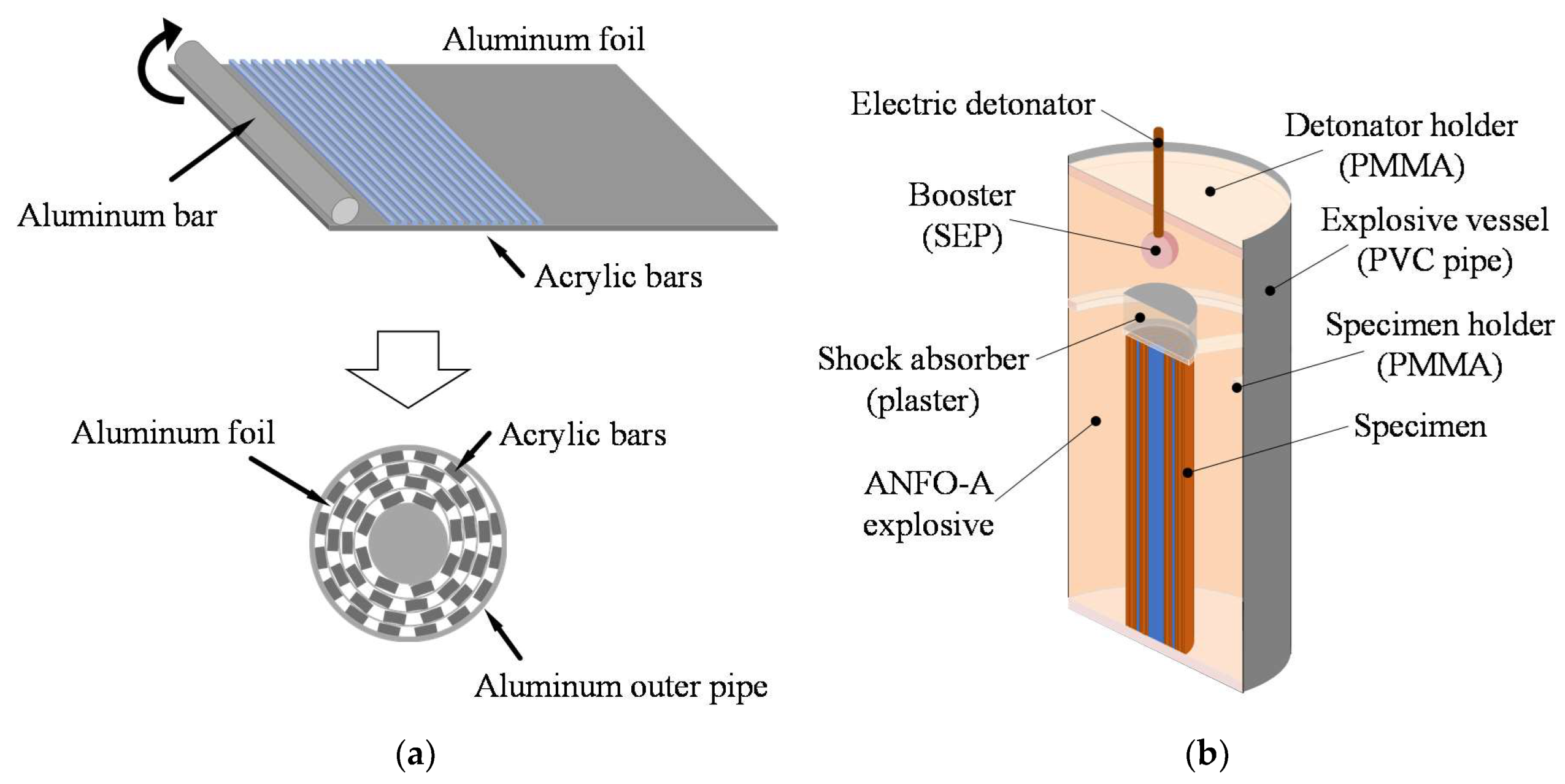

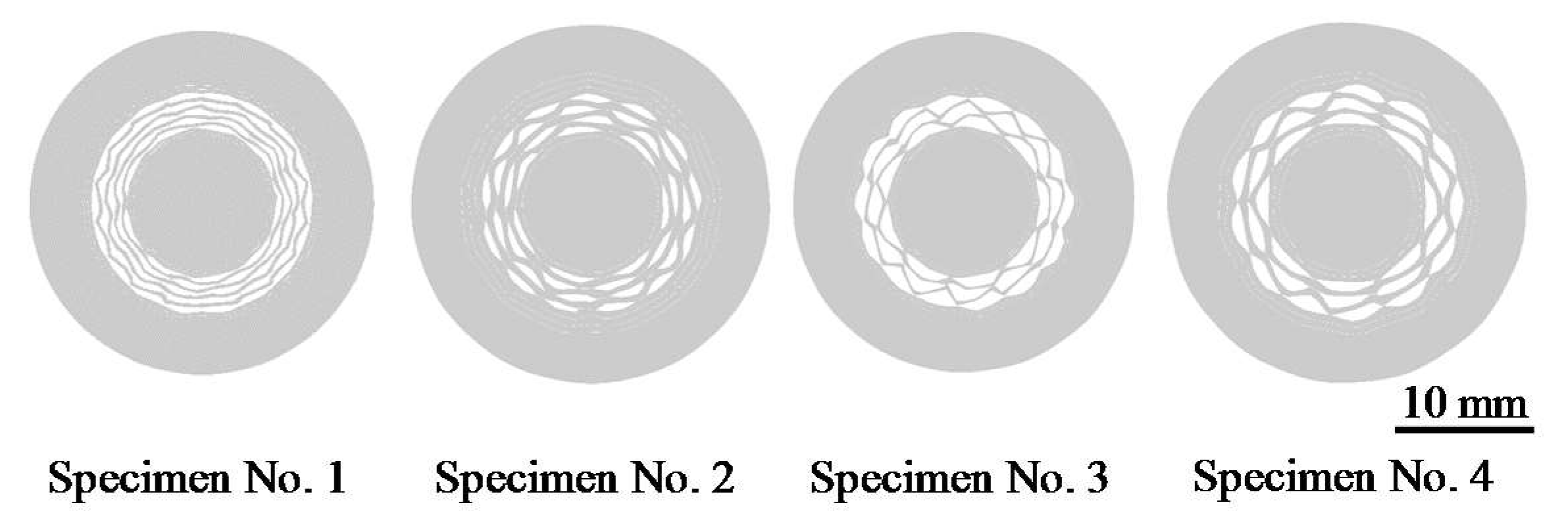

2. Fabrication Method and Specimens

3. Computational Analysis of the Fabrication Process

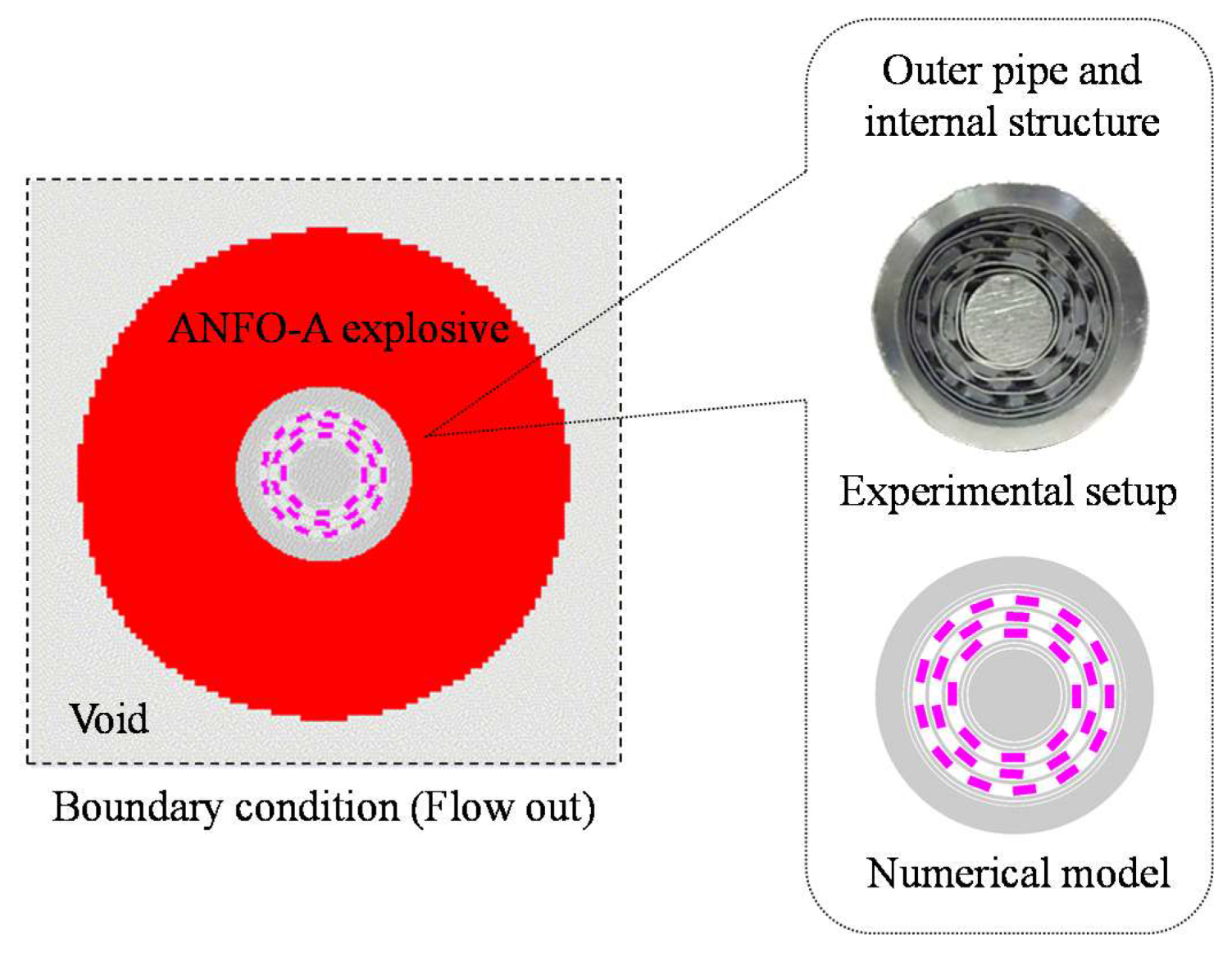

3.1. Computational Model

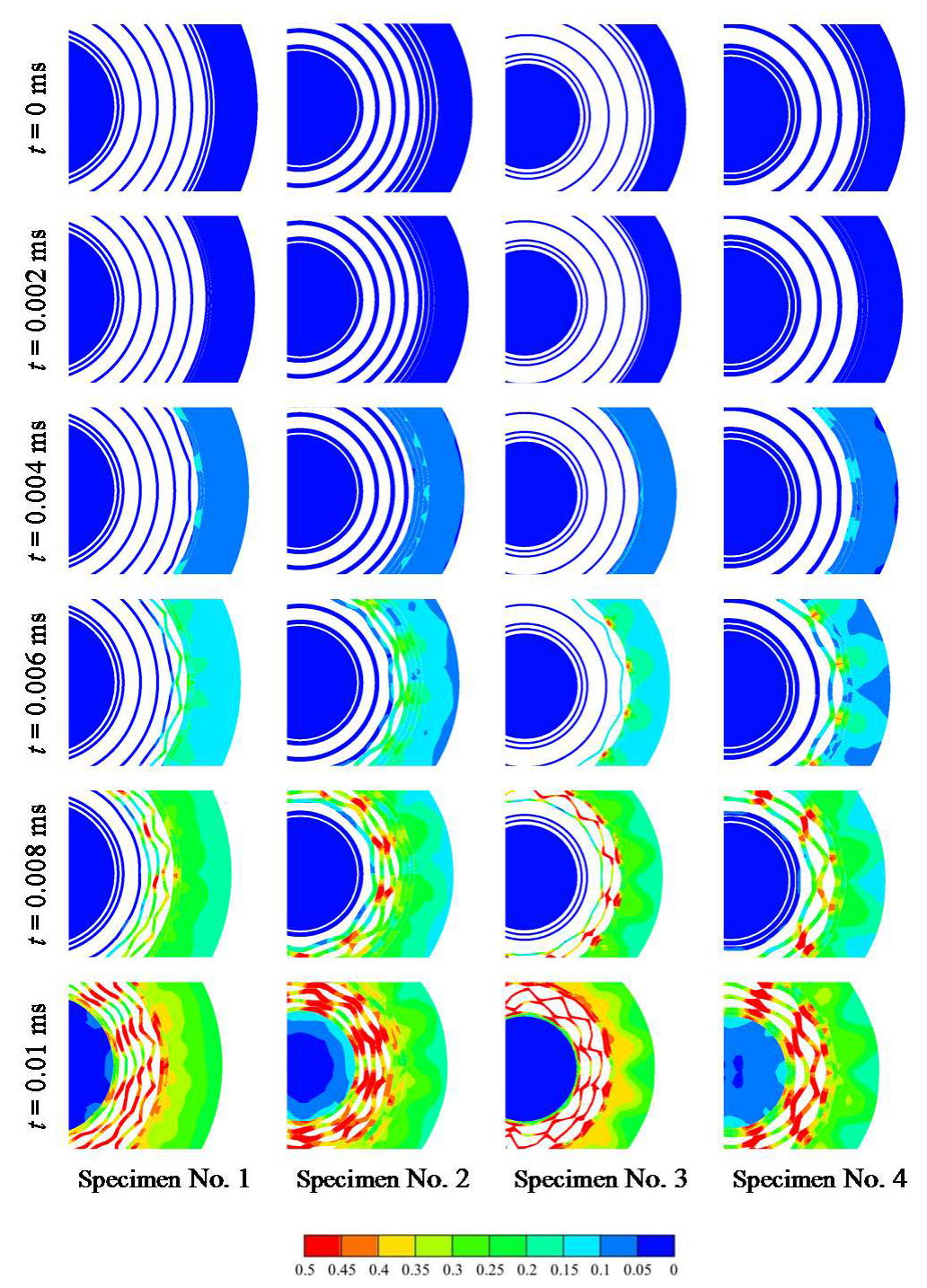

3.2. Computational Results

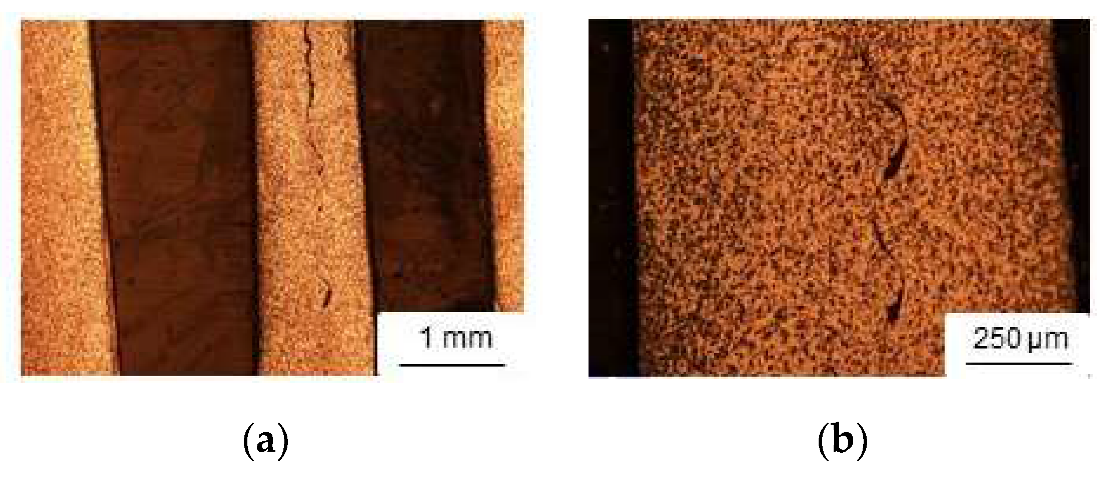

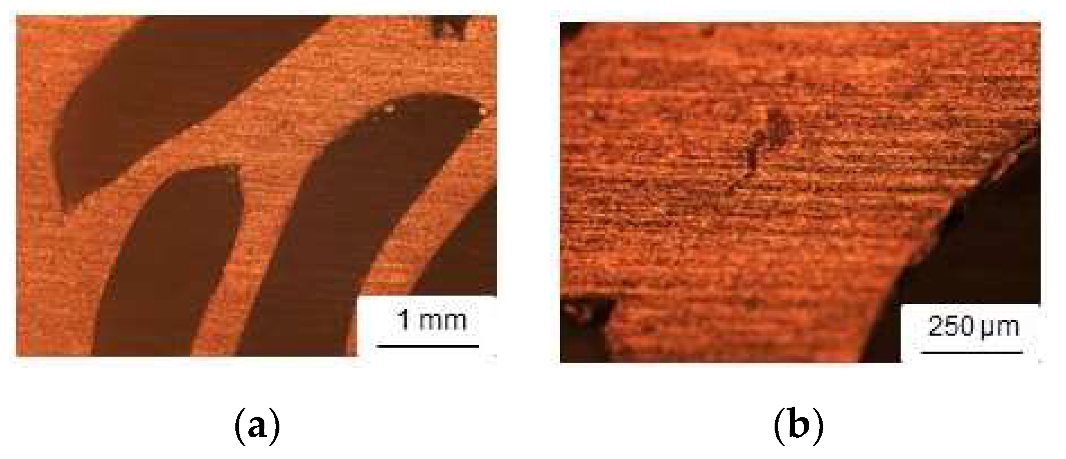

4. Metallographic Analysis

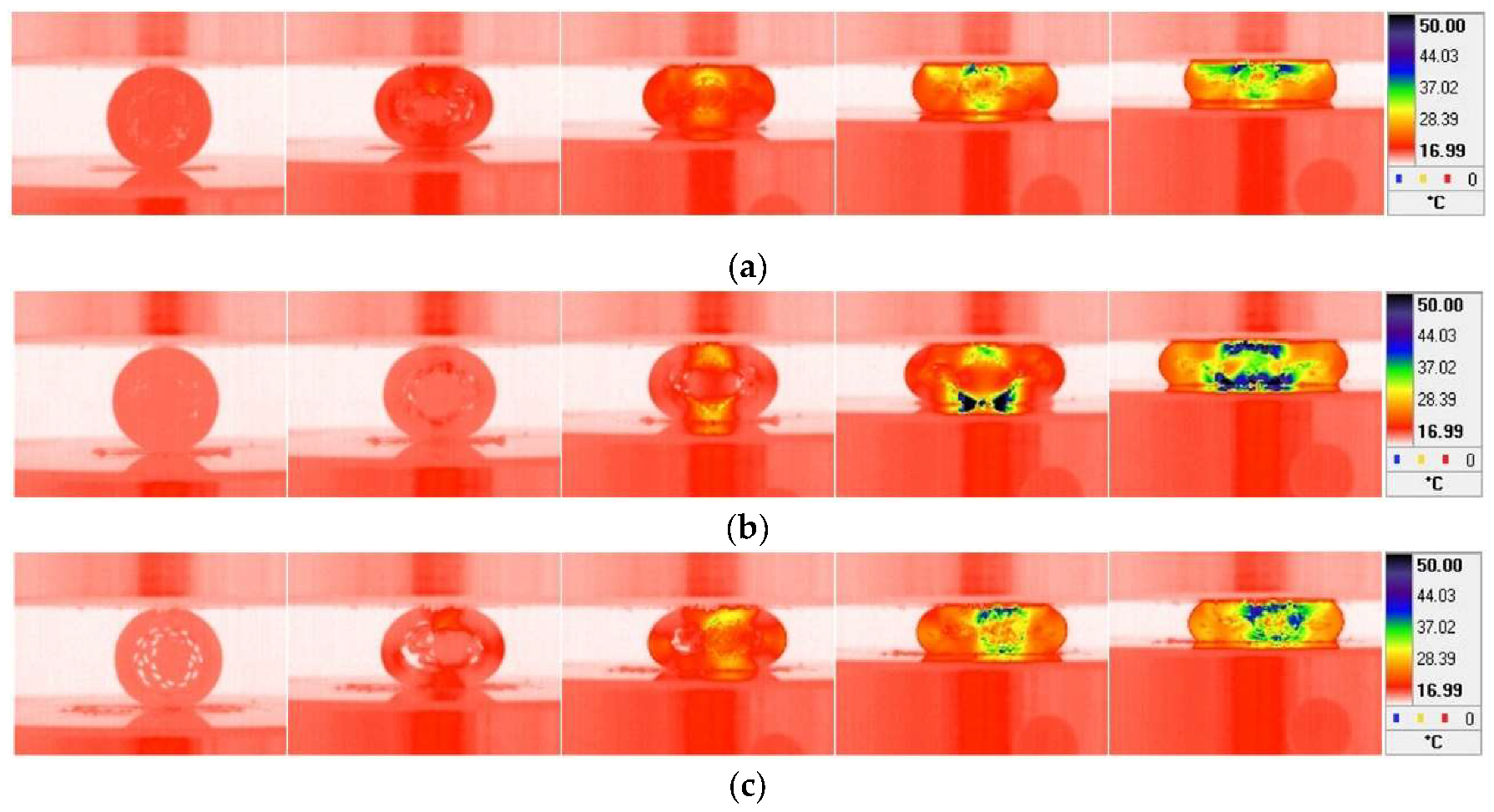

5. Compressive Experiments

5.1. Experimental Set-Up

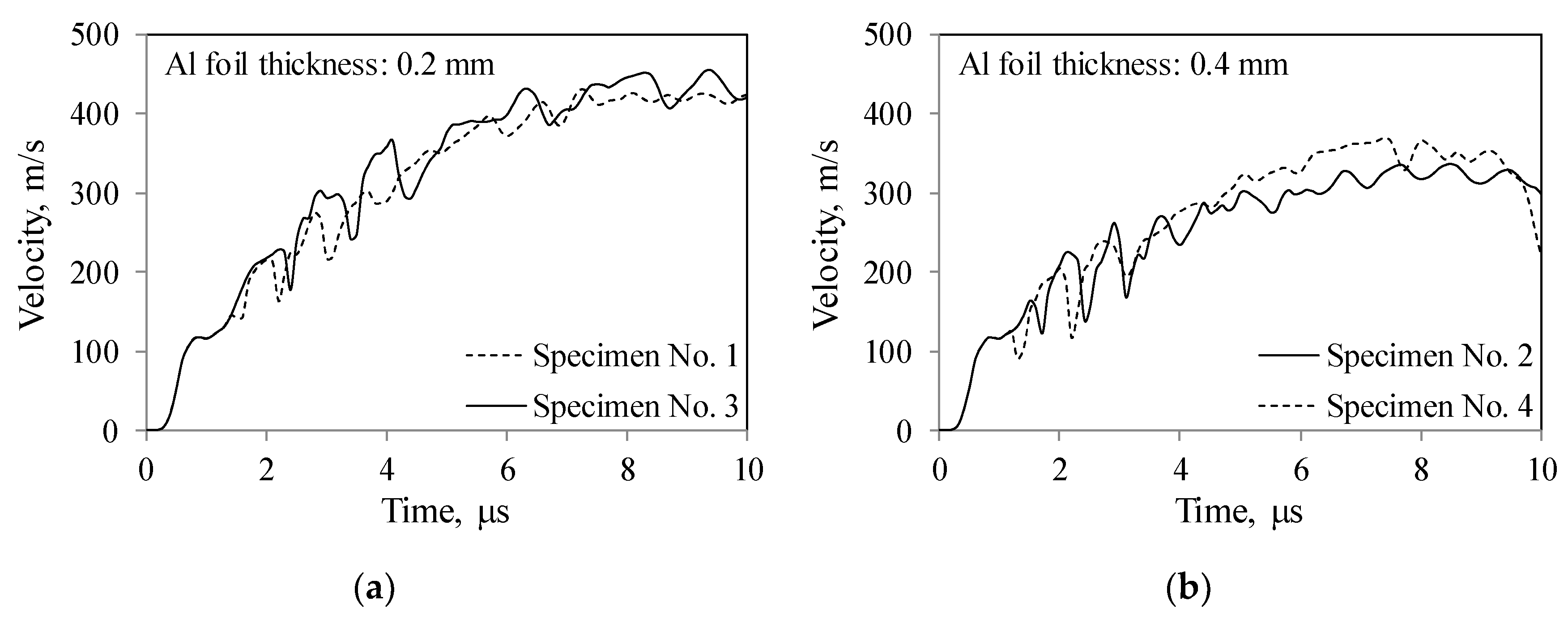

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lefebvre, L.P.; Banhart, J.; Dunand, D.C. Porous Metals and Metallic Foams: Current Status and Recent Developments. Adv. Eng. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams: A Design Guide; Elsevier Science: Burlington, MA, USA, 2000. [Google Scholar]

- Matsumoto, R.; Kanatani, S.; Utsunomiya, H. Filling of surface pores of aluminum foam with polyamide by selective laser melting for improvement in mechanical properties. J. Mater. Process. Technol. 2016, 237, 402–408. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Crush performance of multifunctional hybrid foams based on an aluminium alloy open-cell foam skeleton. Polym. Test. 2018, 67, 246–256. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Lehmhus, D.; Vesenjak, M.; de Schampheleire, S.; Fiedler, T.; Schampheleire, S.; Fiedler, T. From Stochastic Foam to Designed Structure: Balancing Cost and Performance of Cellular Metals. Materials 2017, 10, 922. [Google Scholar] [CrossRef]

- Hohe, J.; Hardenacke, V.; Fascio, V.; Girard, Y.; Baumeister, J.; Stöbener, K.; Weise, J.; Lehmhus, D.; Pattofatto, S.; Zeng, H.; et al. Numerical and experimental design of graded cellular sandwich cores for multifunctional aerospace applications. Mater. Des. 2012, 39, 20–32. [Google Scholar] [CrossRef]

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Tan, J.; Meng, Z.D.; He, Z.Y.; Zhang, Y.Q.; Jiang, Y.H.; Zhou, R. Low elastic modulus Ti-Ag/Ti radial gradient porous composite with high strength and large plasticity prepared by spark plasma sintering. Mater. Sci. Eng. A 2017, 688, 330–337. [Google Scholar] [CrossRef]

- Harih, G.; Borovinsek, M.; Ren, Z.; Dolsak, B. Optimal Products’ Hand-Handle Interface Parameter Identification. Int. J. Simul. Model. 2015, 14, 404–415. [Google Scholar] [CrossRef]

- Duarte, I.; Banhart, J. A study of aluminium foam formation—kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar] [CrossRef]

- Öchsner, A.; Augustin, C. (Eds.) Multifunctional Metallic Hollow Sphere Structures; Springer: Berlin, Germany, 2009; ISBN 978-3-642-00490-2. [Google Scholar]

- Lee, Y.-H.; Lee, B.-K.; Jeon, I.; Kang, K.-J. Wire-woven bulk Kagome truss cores. Acta Mater. 2007, 55, 6084–6094. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Auxetic Cellular Materials-a Review. J. Mech. Eng. 2016, 62, 485–493. [Google Scholar] [CrossRef]

- Soro, N.; Attar, H.; Wu, X.; Dargusch, M.S. Investigation of the structure and mechanical properties of additively manufactured Ti-6Al-4V biomedical scaffolds designed with a Schwartz primitive unit-cell. Mater. Sci. Eng. A 2019, 745, 195–202. [Google Scholar] [CrossRef]

- Nakajima, H. Fabrication, properties and application of porous metals with directional pores. Prog. Mater. Sci. 2007, 52, 1091–1173. [Google Scholar] [CrossRef]

- Shapovalov, V.I. Porous metals. MRS Bull. 1994, 19, 24–29. [Google Scholar] [CrossRef]

- Hokamoto, K.; Vesenjak, M.; Ren, Z. Fabrication of cylindrical unidirectional porous metal with explosive compaction. Mater. Lett. 2014, 137, 323–327. [Google Scholar] [CrossRef]

- Movahedi, N.; Conway, S.; Belova, I.V.; Murch, G.E.; Fiedler, T. Influence of particle arrangement on the compression of functionally graded metal syntactic foams. Mater. Sci. Eng. A 2019, 764, 138242. [Google Scholar] [CrossRef]

- Katona, B.; Szlancsik, A.; Tábi, T.; Orbulov, I.N. Compressive characteristics and low frequency damping of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2019, 739, 140–148. [Google Scholar] [CrossRef]

- Hokamoto, K.; Torii, S.; Kimura, A.; Kai, S. Metal Pipe Joint Body and Manufacturing Method Thereof. Japanese Patent 5848016, 4 December 2015. [Google Scholar]

- Vesenjak, M.; Hokamoto, K.; Anžel, I.; Sato, A.; Tsunoda, R.; Krstulović-Opara, L.; Ren, Z. Influence of the explosive treatment on the mechanical properties and microstructure of copper. Mater. Des. 2015, 75, 85–94. [Google Scholar] [CrossRef]

- Nishi, M.; Oshita, M.; Ulbin, M.; Vesenjak, M.; Ren, Z.; Hokamoto, K. Computational Analysis of the Explosive Compaction Fabrication Process of Cylindrical Uni-directional Porous Copper. Met. Mater. Int. 2018, 24, 1143–1148. [Google Scholar] [CrossRef]

- Hokamoto, K.; Shimomiya, K.; Nishi, M.; Krstulović-opara, L.; Vesenjak, M.; Ren, Z. Fabrication of unidirectional porous-structured aluminum through explosive compaction using cylindrical geometry. J. Mater. Process. Technol. 2018, 251, 262–266. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Sakamoto, M.; Nishi, T.; Krstulović-Opara, L.; Ren, Z. Mechanical and microstructural analysis of unidirectional porous (UniPore) copper. Mater. Des. 2016, 90. [Google Scholar] [CrossRef]

- Fiedler, T.; Borovinšek, M.; Hokamoto, K.; Vesenjak, M. High-performance thermal capacitors made by explosion forming. Int. J. Heat Mass Transf. 2015, 83, 366–371. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Matsumoto, S.; Marumo, Y.; Ren, Z. Unidirectional porous metal fabricated by rolling of copper sheet and explosive compaction. Mater. Lett. 2016, 170, 39–43. [Google Scholar] [CrossRef]

- Meyers, M.A.; Murr, L.E. Shock Waves and High-Strain-Rate Phenomena Effects in Metals; Springer: New York, NY, USA, 1981. [Google Scholar]

- Mayers, M.A. Dynamic Behavior of Materials; Wiley Interscience: New York, NY, USA, 1994. [Google Scholar]

- Marsh, S.P. Los Alamos Scientific Laboratory Report; LA-4167-MS; University of California Press: Oakland, CA, USA, 1969. [Google Scholar]

- Marsh, M.A. LASL Shock Hugoniot Data; University of California Press: Berkeley, CA, USA, 1980. [Google Scholar]

- Fujita, M.; Chiba, A.; Fukuda, I.; Osaka, H.; Baba, F.; Manabe, T. An analysis of multilayered explosive bonding process. Kyogyo-kayaku 1987, 48, 176–182. (In Japanese) [Google Scholar]

- Crossland, B. Explosive Welding of Metals and Its Application; Oxford University Press: Oxford, UK, 1982; Volume 8, p. 233. [Google Scholar]

- Krstulović-Opara, L.; Surjak, M.; Vesenjak, M.; Tonković, Z.; Kodvanj, J.; Domazet, Ž. Comparison of infrared and 3D digital image correlation techniques applied for mechanical testing of materials. Infrared Phys. Technol. 2015, 73, 166–174. [Google Scholar] [CrossRef]

| Specimen Type | Outer Pipe Diameter (mm) | Length (mm) | Internal Structure | Estimated Porosity (%) | |||

|---|---|---|---|---|---|---|---|

| Al Core Diameter (mm) | Al Foil Thickness (mm) | Acrylic Bar | |||||

| Thickness (mm) | Quantity (-) | ||||||

| No. 1 | 30/24 | 210 | 10 | 0.2 | 0.5 | 67 | 16.5 |

| No. 2 | 0.4 | 0.5 | 40 | 9.4 | |||

| No. 3 | 0.2 | 1.0 | 35 | 18.1 | |||

| No. 4 | 0.4 | 1.0 | 31 | 15.0 | |||

| Specimen Type | Number of Recovered Specimens (-) | Average Diameter (mm) | Average Height (mm) | Average Mass (g) | Achieved Average Porosity (%) |

|---|---|---|---|---|---|

| No. 1 | 4 | 26.2 | 11.0 | 12.8 | 15.5 |

| No. 2 | 4 | 26.2 | 11.9 | 14.9 | 9.3 |

| No. 3 | 1 | 26.3 | 10.4 | 12.7 | 17.5 |

| No. 4 | 4 | 26.0 | 10.4 | 12.3 | 15.0 |

| Material | Reference Density (kg/m3) | Gruneisen Coefficient (-) | Speed of Sound (m/s) | Material Constant (-) |

|---|---|---|---|---|

| A1100-O | 2707 | 1.9 | 5386 | 1.339 |

| Acrylic resin | 1186 | 0.97 | 2598 | 1.516 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vesenjak, M.; Nishi, M.; Nishi, T.; Marumo, Y.; Krstulović-Opara, L.; Ren, Z.; Hokamoto, K. Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure. Metals 2020, 10, 770. https://doi.org/10.3390/met10060770

Vesenjak M, Nishi M, Nishi T, Marumo Y, Krstulović-Opara L, Ren Z, Hokamoto K. Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure. Metals. 2020; 10(6):770. https://doi.org/10.3390/met10060770

Chicago/Turabian StyleVesenjak, Matej, Masatoshi Nishi, Toshiya Nishi, Yasuo Marumo, Lovre Krstulović-Opara, Zoran Ren, and Kazuyuki Hokamoto. 2020. "Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure" Metals 10, no. 6: 770. https://doi.org/10.3390/met10060770

APA StyleVesenjak, M., Nishi, M., Nishi, T., Marumo, Y., Krstulović-Opara, L., Ren, Z., & Hokamoto, K. (2020). Fabrication and Mechanical Properties of Rolled Aluminium Unidirectional Cellular Structure. Metals, 10(6), 770. https://doi.org/10.3390/met10060770