A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry

Abstract

1. Introduction

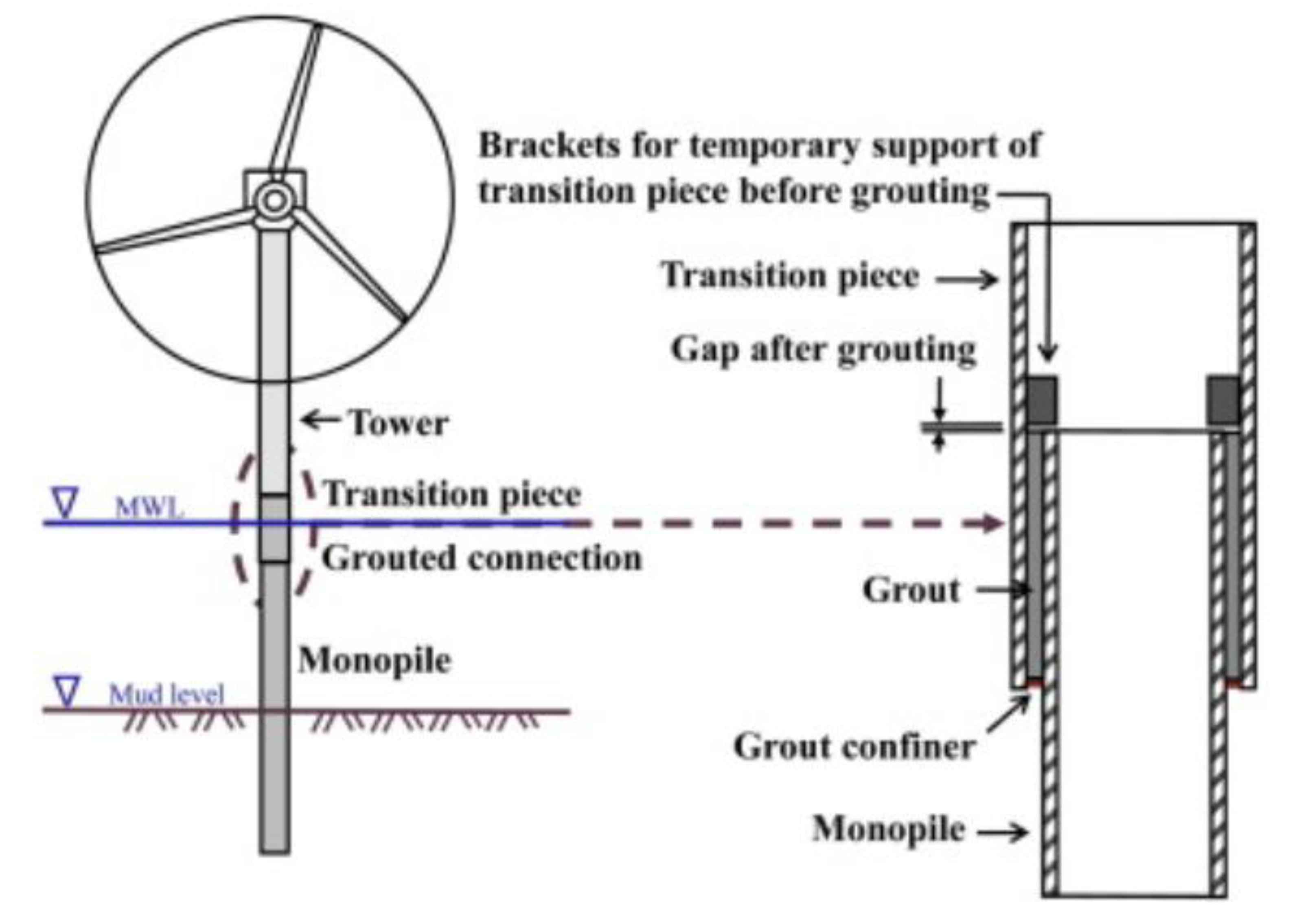

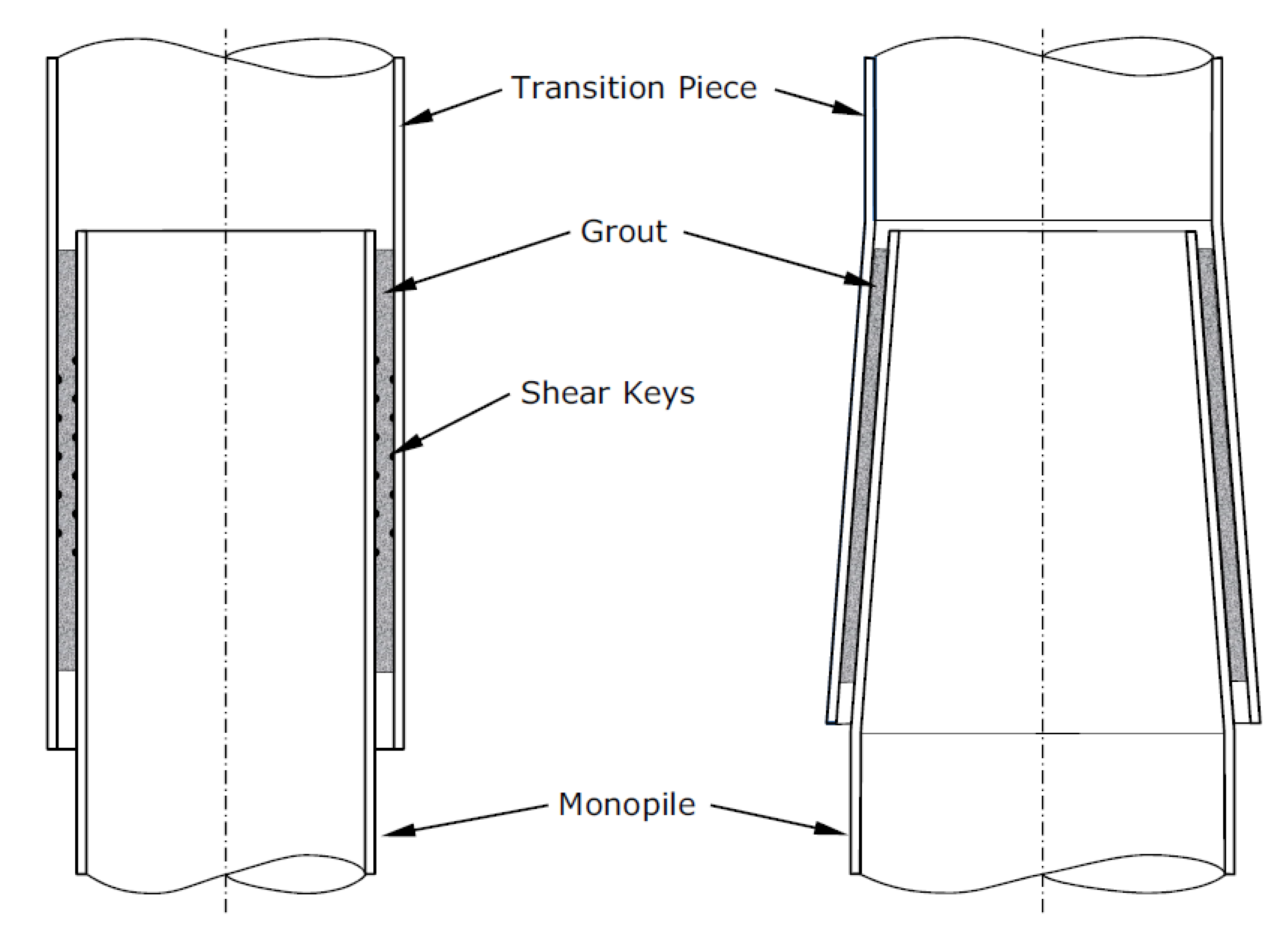

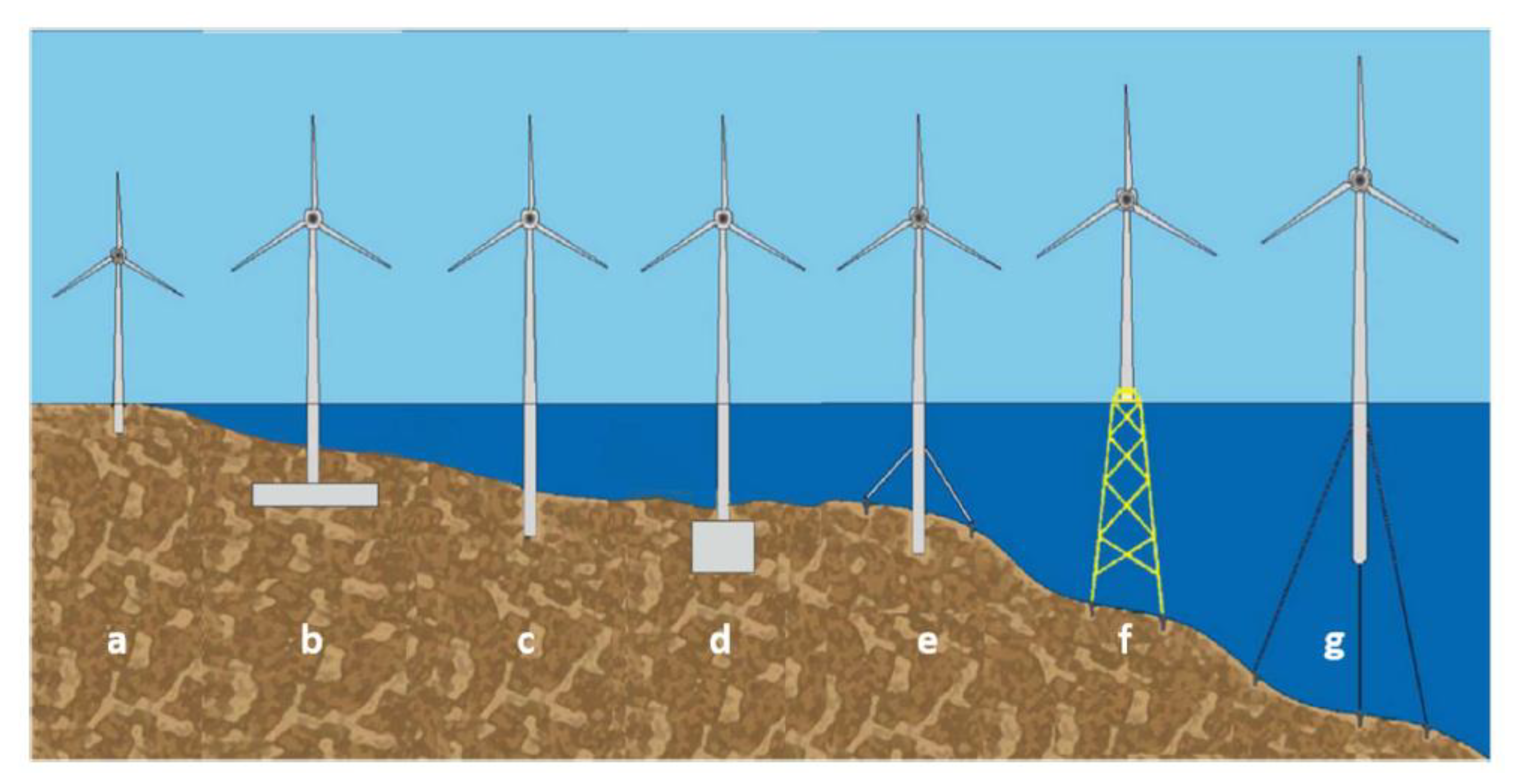

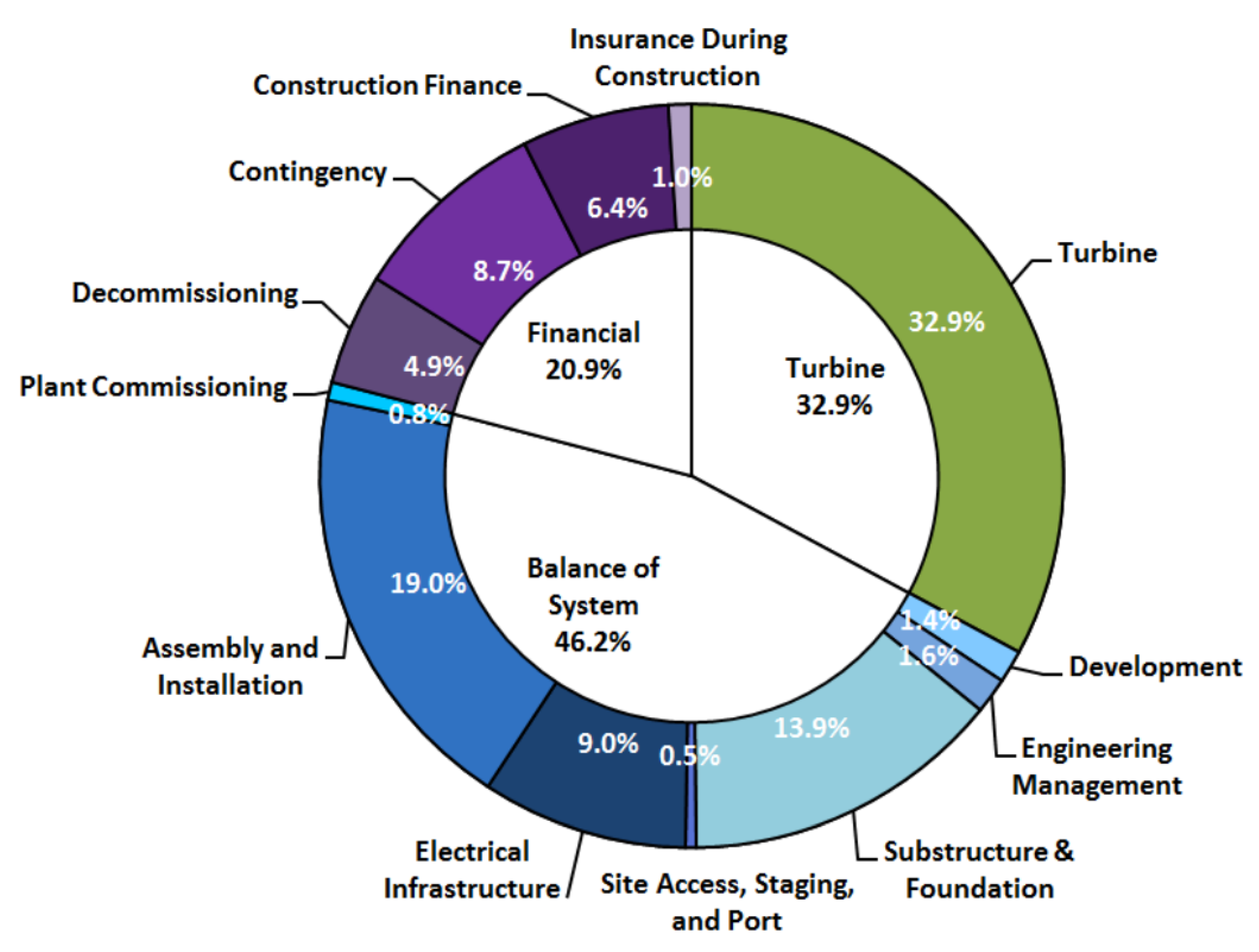

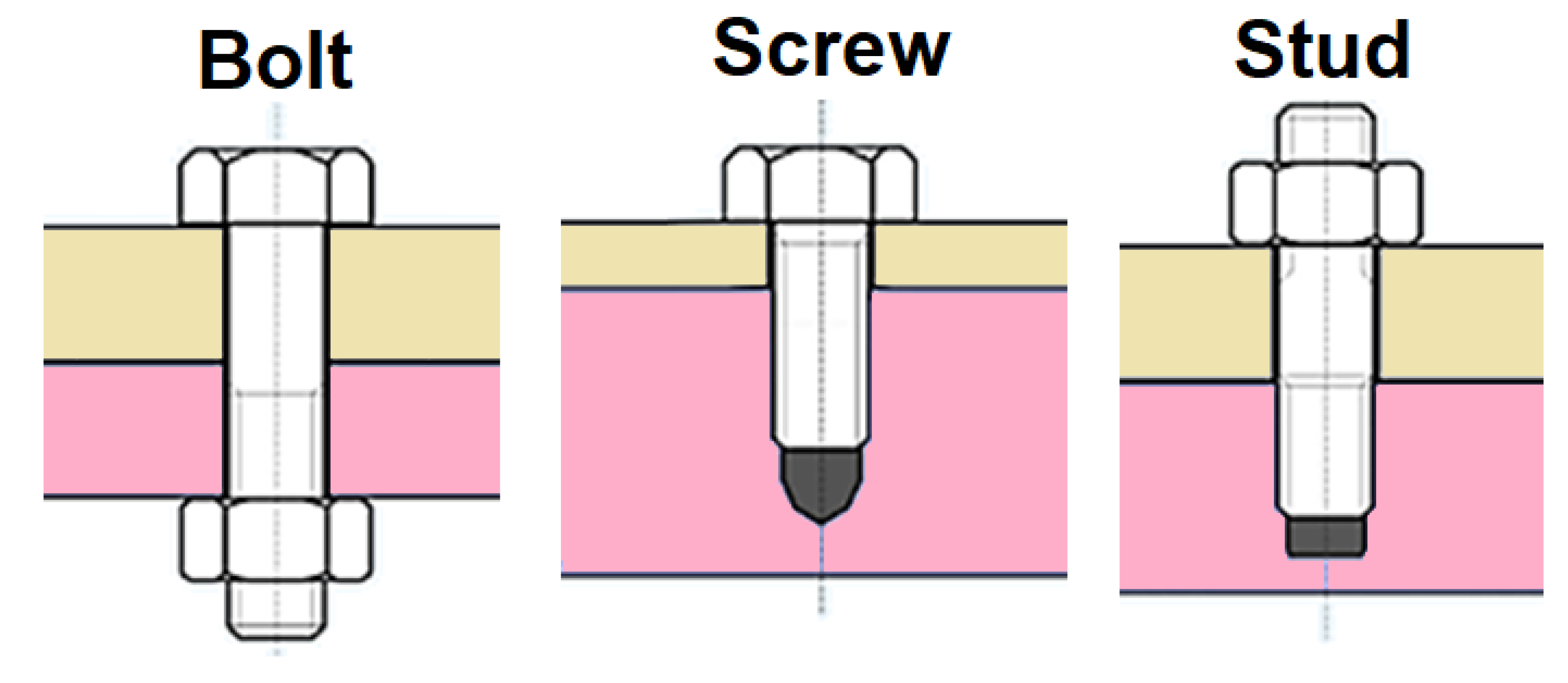

2. Offshore Wind Turbine Foundations

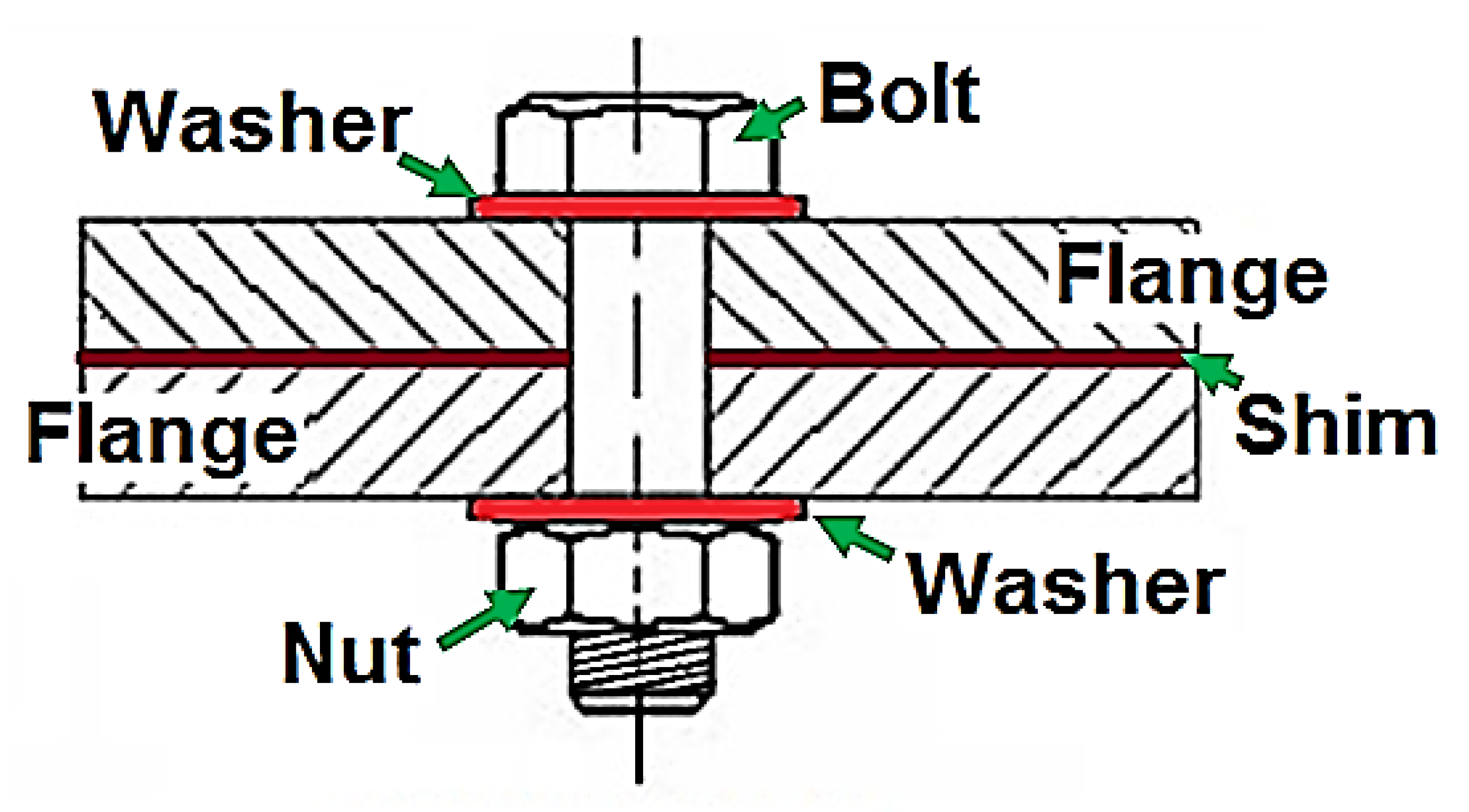

3. Bolted Flange Connections

4. Design Criteria for Bolted Joints

5. Challenges in Bolted Joints

5.1. Challenges in the Assembly Process

5.2. Challenges during the Operational Phase

6. Specific Issues Associated with Bolted Joints

6.1. Short-Term Relaxation of Individual Bolts

6.2. Bolt Material Selection

6.3. Strength of the Threads

7. Miscellaneous Setups Associated with Bolts and Failure Mechanisms

7.1. Washers

7.2. Lubricants

7.3. Coatings

7.4. Gaskets and Shimming

7.5. Self-Loosening

7.6. Fatigue Failure

7.7. Corrosion

7.8. Galling

7.9. Inspection and Maintenance of Bolted Connections

8. Discussion

9. Conclusions

- The advantages of bolted flange connections include the provision of direct load path through the primary steel alone, thereby avoiding slippage, reducing steel requirements compared with grouted connections, the absence of curing time, and easiness to inspect and monitor the MP–TP connection.

- The challenges associated with bolted flange connections include material selection issues, short-term relaxation of bolts, issues associated with load distribution in threads, and static failure of bolted flange.

- The main cause of short-term relaxation is the embedment that occurs mostly owing to surface irregularities as well as time-dependent creep deformation.

- The consequence of temperature differential can either increase or decrease the clamping force depending on the thermal expansion and contraction coefficient of the materials employed in bolted connections.

- The setups associated with bolted joint such as washers, lubricants, coatings, and gaskets play a pivotal role in creating and maintaining integrity in bolted joints.

- The failure modes observed in bolted joints include self-loosening, fatigue failure, corrosion, and galling.

- An expected trend in the bolted flange connection is the increased usage of tensioning tools compared with torqueing applications.

- Further studies in the offshore wind industry can enable the optimal use of bolted flange connections in design, manufacturing, installation, operation, maintenance, and decommissioning phases.

Author Contributions

Funding

Conflicts of Interest

References

- Ambrose, J. Offshore Wind to Power £17.5bn Investment Boom as Costs Halve. Available online: https://www.telegraph.co.uk/business/2017/09/11/offshore-wind-power-175bn-investment-boom-costs-halve (accessed on 1 August 2018).

- Hundleby, G.; Freeman, K. Unleashing Europe’s Offshore Wind Potential: A New Resource Assessment; BVG Associates: Brussels, Belgium, 2017; Volume 64. [Google Scholar]

- Kay, A. Cost Reduction Monitoring Framework 2016; Summary Report of the Offshore Wind Programme Board; ORE Catapult: Glasgow, UK, January 2017. [Google Scholar]

- Mehmanparast, A.; Brennan, F.; Tavares, I. Fatigue crack growth rates for offshore wind monopile weldments in air and seawater: SLIC inter-laboratory test results. Mater. Des. 2017, 114, 494–504. [Google Scholar] [CrossRef]

- Mehmanparast, A.; Taylor, J.; Brennan, F.; Tavares, I. Experimental investigation of mechanical and fracture properties of offshore wind monopile weldments: SLIC interlaboratory test results. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2485–2501. [Google Scholar] [CrossRef]

- Lotsberg, I.; Serednicki, A.; Lervik, A.; Bertnes, H. Design of grouted connections for monopile offshore structures. Stahlbau 2012, 81, 695–704. [Google Scholar] [CrossRef]

- Gollub, P.; Jensen, J.F.; Giese, D.; Güres, S. Flanged foundation connection of the offshore wind farm Amrumbank West—Concept, approval, design, tests and installation. Stahlbau 2014, 83, 522–528. [Google Scholar] [CrossRef]

- DNVGL. DNV-OS-J101—Rules and Standards, Design of Offshore Wind Turbine Structures; Det Norske Veritas: Oslo, Norway, 2007. [Google Scholar]

- DNVGL. DNVGL-RP-0419, Analysis of Grouted Connections Using the Finite Element Method; DNVGL: Oslo, Norway, 2016. [Google Scholar]

- Oechsner, M.; Beyer, J.; Simonsen, F.; Schaumann, P.; Eichstädt, R. Experimental and analytical assessment of the fatigue strength of bolts with large dimensions under consideration of boundary layer effects. In Proceedings of the METEC & 2nd European Steel Technology and Application Days, Düsseldorf, Germany, 15–19 June 2015; pp. 1–6. [Google Scholar]

- Schaumann, P.; Seidel, M. Failure analysis of bolted steel flanges. In Proceedings of the Seventh International Symposium on Structural Failure and Plasticity (IMPLAST2000), Melbourne, Australia, 4–6 October 2000. [Google Scholar]

- Schaumann, P.; Eichstädt, R. Fatigue assessment of high-strength bolts with very large diameters in substructures for offshore wind turbines. In Proceedings of the Twenty-fifth International Ocean and Polar Engineering Conference. International Society of Offshore and Polar Engineers, Kona, HI, USA, 21–26 June 2015. [Google Scholar]

- Schaumann, P.; Marten, F. Fatigue resistance of high strength bolts with large diameters. In Proceedings of the International Symposium for Steel Structures ISSS, Seoul, Korea, 12–14 March 2009; Volume 12, pp. 1–8. [Google Scholar]

- Madsen, C.A.; Kragh-Poulsen, J.C.; Tage, K.J.; Andreassen, M.J. Analytical and numerical investigation of bolted steel ring flange connection for offshore wind monopile foundations. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 276, p. 012034. [Google Scholar]

- Leite, O.B. Review of Design Procedures for Monopile Offshore Wind Structures. Ph.D. Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, June 2015. [Google Scholar]

- Ng, C.; Ran, L. Offshore Wind Farms: Technologies, Design and Operation; Woodhead Publishing: Duxford, UK, 2016. [Google Scholar]

- Wang, X.; Zeng, X.; Li, J.; Yang, X.; Wang, H. A review on recent advancements of substructures for offshore wind turbines. Energy Convers. Manag. 2018, 158, 103–119. [Google Scholar] [CrossRef]

- Pineda, I.; Tardieu, P. The European offshore wind industry—Key trends and statistics 2016; European Wind Energy Association: Brussels, Belgium, 2016. [Google Scholar]

- Stehly, T.; Heimiller, D.; Scott, G. 2016 Cost of Wind Energy Review; Technical Report for National Renewable Energy Laboratory (NREL); NREL: Denver, CO, USA, 2017.

- Bickford, J.H. An Introduction to the Design and Behavior of Bolted Joints, 4th ed.; CRC Press: New York, NY, USA, 2008. [Google Scholar]

- Kulak, G.L.; Fisher, J.W.; Struik, J.H. Guide to Design Criteria for Bolted and Riveted Joints, 2nd ed.; AISC: Chicago, IL, USA, 2001. [Google Scholar]

- Bickford, J.H. Introduction to the Design and Behavior of Bolted Joints, Non-Gasketed Joints, 3rd ed.; CRC Press: New York, NY, USA, 1995. [Google Scholar]

- Braithwaite, J.; Mehmanparast, A. Analysis of Tightening Sequence Effects on Preload Behaviour of Offshore Wind Turbine M72 Bolted Connections. Energies 2019, 12, 4406. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. A review on defects in steel offshore structures and developed strengthening techniques. Structures 2019, 20, 635–657. [Google Scholar] [CrossRef]

- ASME. ASME BPVC Section III. Rules for Construction of Nuclear Facility Components; ASME: New York, NY, USA, 1963. [Google Scholar]

- Kadam, A.N.; Ingale, S.M. Experimental and numerical analysis of effect of washer size and preload on strength of double lap double bolted GFRP-to-steel joint. Int. J. Sci. Res. 2017, 6, 2397–2402. [Google Scholar]

- Shigley, J.E.; Mischke, C.R. Standard Handbook of Machine Design, 2nd ed.; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Zou, Q.; Sun, T.S.; Nassar, S.A.; Barber, G.C.; Gumul, A.K. Effect of lubrication on friction and torque-tension relationship in threaded fasteners. Tribol. Trans. 2007, 50, 127–136. [Google Scholar] [CrossRef]

- Hashimura, S.; Komatsu, K.; Otsu, T.; Sekido, Y. Influences of lubricants and bearing surface configuration under bolt head on self-loosening of bolted joints. J. Jpn. Soc. Tribol. 2017, 62, 205–216. [Google Scholar]

- Croccolo, D.; De Agostinis, M.; Vincenzi, N. Influence of tightening procedures and lubrication conditions on titanium screw joints for lightweight applications. Tribol. Int. 2012, 55, 68–76. [Google Scholar] [CrossRef]

- Gansheimer, J.; Wessely, J. Lubrication of threads. Wear 1980, 65, 201–206. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Ouyang, H.; Cai, Z.; Peng, J.; Zhu, M. Anti-loosening performance of coatings on fasteners subjected to dynamic shear load. Friction 2018, 6, 32–46. [Google Scholar] [CrossRef]

- Tronci, G.; Marshall, M.B. Understanding the behaviour of silver as a low friction coating in aerospace fasteners. Tribol. Int. 2016, 100, 162–170. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, M.; Lee, C.H. A study of early stage self-loosening of bolted joints. J. Mech. Des. 2003, 125, 518–526. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Y.; Lee, C.H. Finite element modelling of self-loosening of bolted joints. J. Mech. Des. 2007, 129, 218–226. [Google Scholar] [CrossRef]

- Stephen, J.; Marshall, J.M.; Lewis, R. Relaxation of contact pressure and self-loosening in dynamic bolted joints. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 3462–3475. [Google Scholar] [CrossRef]

- Gong, H.; Liu, J. Some factors affecting the loosening failure of bolted joints under vibration using finite element analysis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 3942–3953. [Google Scholar] [CrossRef]

- Liu, J.; Ouyang, H.; Feng, Z.; Cai, Z.; Liu, X.; Zhu, M. Study on self-loosening of bolted joints excited by dynamic axial load. Tribol. Int. 2017, 115, 432–451. [Google Scholar] [CrossRef]

- Dinger, G.; Friedrich, C. Avoiding self-loosening failure of bolted joints with numerical assessment of local contact state. Eng. Fail. Anal. 2011, 18, 2188–2200. [Google Scholar] [CrossRef]

- Yokoyama, T.; Olsson, M.; Izumi, S.; Sakai, S. Investigation into the self-loosening behavior of bolted joint subjected to rotational loading. Eng. Fail. Anal. 2012, 23, 35–43. [Google Scholar] [CrossRef]

- Pai, N.G.; Hess, D.P. Experimental study of loosening of threaded fasteners due to dynamic shear loads. J. Sound Vib. 2002, 253, 585–602. [Google Scholar] [CrossRef]

- Zadoks, R.I.; Yu, X. An investigation of the self-loosening behaviour of bolts under transverse vibration. J. Sound Vib. 1997, 208, 189–209. [Google Scholar] [CrossRef]

- Marshall, M.B.; Lewis, R.; Howard, T.; Brunskill, H. Ultrasonic measurement of self-loosening in bolted joints. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 1869–1884. [Google Scholar] [CrossRef]

- Chakherlou, T.N.; Oskouei, R.H.; Vogwell, J. Experimental and numerical investigation of the effect of clamping force on the fatigue behaviour of bolted plates. Eng. Fail. Anal. 2008, 15, 563–574. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Farrahi, G.H.; Habibi, N. Experimental evaluation of the effect of thread pitch on fatigue life of bolts. Int. J. Fatigue 2005, 27, 189–196. [Google Scholar] [CrossRef]

- Korin, J.; Perez, I. Experimental evaluation of fatigue life and fatigue crack growth in a tension bolt–nut threaded connection. Int. J. Fatigue 2011, 33, 166–175. [Google Scholar] [CrossRef]

- Mínguez, J.M.; Vogwell, J. Effect of torque tightening on the fatigue strength of bolted joints. Eng. Fail. Anal. 2006, 13, 1410–1421. [Google Scholar] [CrossRef]

- Wei, J.; Jiao, G.; Jia, P.; Huang, T. The effect of interference fit size on the fatigue life of bolted joints in composite laminates. Compos. Part B Eng. 2013, 53, 62–68. [Google Scholar] [CrossRef]

- Leander, J.; Wadi, A.; Pettersson, L. Fatigue testing of a bolted connection for buried flexible steel culverts. Arch. Inst. Civil Eng. 2017, 23, 153–162. [Google Scholar] [CrossRef]

- Jiménez-Peña, C.; Talemi, R.H.; Rossi, B.; Debruyne, D. Investigations on the fretting fatigue failure mechanism of bolted joints in high strength steel subjected to different levels of pre-tension. Tribol. Int. 2017, 108, 128–140. [Google Scholar] [CrossRef]

- Grabon, W.A.; Osetek, M.; Mathia, T.G. Friction of threaded fasteners. Tribol. Int. 2018, 118, 408–420. [Google Scholar] [CrossRef]

- Lochan, S.; Mehmanparast, A.; Wintle, J. A review of fatigue performance of bolted connections in offshore wind turbines. Procedia Struct. Integr. 2019, 17, 276–283. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A.; Kolios, A. Current trend in offshore wind energy sector and material requirements for fatigue resistance improvement in large wind turbine support structures—A review. Renew. Sustain. Energy Rev. 2019, 101, 181–196. [Google Scholar] [CrossRef]

- Ahn, J.H.; You, J.M.; Huh, J.; Kim, I.T.; Jeong, Y.S. Residual clamping force of bolt connections caused by sectional damage of nuts. J. Constr. Steel Res. 2017, 136, 204–214. [Google Scholar] [CrossRef]

- Brown, W.; Long, S. Acceptable levels of corrosion for pressure boundary bolted joints. In Proceedings of the ASME Pressure Vessels and Piping Conference, Waikoloa, HA, USA, 16–20 July 2017; p. 57946. [Google Scholar]

- Narayanaswamy, R. The process of materials selection for pipeline systems optimisation for life cycles. In Proceedings of the ASME India Oil and Gas Pipeline Conference, Mumbai, India, 20–22 April 2017; p. 50763. [Google Scholar]

- Krstic, B.; Rebhi, L.; Ilic, N.; Dodic, M.; Dinulovic, M.; Andric, P.; Trifkovic, D. Failure of mounting bolt of helicopter main gearbox support strut. Eng. Fail. Anal. 2016, 70, 351–363. [Google Scholar] [CrossRef]

- Uchneat, S.; Stevenson, M.; McDougall, J. Case study: Analysis of corrosion patterns to evaluate the preaccident configuration of an ATV tie rod end connection. J. Fail. Anal. Prev. 2016, 16, 537–542. [Google Scholar] [CrossRef]

- Larché, N.; Thierry, D.; Boillot, P.; Cassagne, T.; Blanc, J.; Dézerville, P. Crevice corrosion performance of high grade stainless steels and Ni-based alloys in natural and treated seawater. In Proceedings of the Corrosion 2016, NACE International, Vancouver, BC, Canada, 6–10 March 2016. [Google Scholar]

- Kikuchi, T.; Omiya, Y.; Sawa, T. Effects of nut thinning due to corrosion on the strength characteristics and the sealing performance of bolted flange joints under internal pressure. In Proceedings of the ASME Pressure Vessels and Piping Division, Baltimore, MD, USA, 17–21 July 2011; pp. 35–41. [Google Scholar]

- Kikuchi, T.; Sawa, T. Effects of nut thinning on the bolt load reduction in bolted flange joints under internal pressure and bending moments. In Proceedings of the ASME Pressure Vessels and Piping Division, Paris, France, 17–21 July 2013; pp. 41–53. [Google Scholar]

- Charlton, R.S. Threaded fasteners: Part 1—Failure modes and design criteria of connections. In Proceedings of the CORROSION 2011, Houston, TX, USA, 13–17 March 2011; NACE International: Houston, TX, USA, 2011. [Google Scholar]

- Igwemezie, V.; Mehmanparast, A. Waveform and frequency effects on corrosion-fatigue crack growth behaviour in modern marine steels. Int. J. Fatigue 2020, 134, 105484. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A.; Kolios, A. Materials selection for XL wind turbine support structures: A corrosion-fatigue perspective. Mar. Struct. 2018, 61, 381–397. [Google Scholar] [CrossRef]

- Jacob, A.; Mehmanparast, A.; D’Urzo, R.; Kelleher, J. Experimental and numerical investigation of residual stress effects on fatigue crack growth behaviour of S355 steel weldments. Int. J. Fatigue 2019, 128, 105196. [Google Scholar] [CrossRef]

- Jacob, A.; Oliveira, J.; Mehmanparast, A.; Hosseinzadeh, F.; Kelleher, J.; Berto, F. Residual stress measurements in offshore wind monopile weldments using neutron diffraction technique and contour method. Theor. Appl. Fract. Mech. 2018, 96, 418–427. [Google Scholar] [CrossRef]

- Price, S.J.; Figueira, R.B. Corrosion protection systems and fatigue corrosion in offshore wind structures: Current status and future perspectives. Coatings 2017, 7, 25. [Google Scholar] [CrossRef]

- Charlton, R.S. Threaded fasteners: Part 2—Fundamentals of threaded fasteners, friction and lubrication effects, installation methods, guidelines and corrosion upgrading. In Proceedings of the CORROSION 2012, Salt Lake City, UT, USA, 11–15 March 2012; NACE International: Houston, TX, USA, 2012. [Google Scholar]

- Fukuoka, T.; Nomura, M.; Kawabayashi, H. A new experimental approach for measuring friction coefficients of threaded fasteners focusing on the repetition of tightening operation and surface roughness. In Proceedings of the ASME PVP Conference, Paris, France, 14–18 June 2013. [Google Scholar]

- Yamamoto, E.K.; Wada, K.; Fukuzuka, T.; Shimogori, K.; Fujiwara, K. Lubricating films to prevent galling of stainless steel threaded parts. Lubr. Eng. 1984, 40, 588–597. [Google Scholar]

- Scott, R.L.; Harley, P.H. Failures of threaded fittings and fasteners at nuclear facilities. Nucl. Saf. 1972, 13, 47–53. [Google Scholar]

| Type of Foundation | Characteristics |

|---|---|

| Gravity foundation (Figure 3b) |

|

| Monopile foundation (Figure 3c) |

|

| Suction bucket foundation (Figure 3d) |

|

| Tripod foundation (Figure 3e) |

|

| Jacket foundation (Figure 3f) |

|

| Floating foundation (Figure 3g) |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehmanparast, A.; Lotfian, S.; Vipin, S.P. A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry. Metals 2020, 10, 732. https://doi.org/10.3390/met10060732

Mehmanparast A, Lotfian S, Vipin SP. A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry. Metals. 2020; 10(6):732. https://doi.org/10.3390/met10060732

Chicago/Turabian StyleMehmanparast, Ali, Saeid Lotfian, and Sukumara Pillai Vipin. 2020. "A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry" Metals 10, no. 6: 732. https://doi.org/10.3390/met10060732

APA StyleMehmanparast, A., Lotfian, S., & Vipin, S. P. (2020). A Review of Challenges and Opportunities Associated with Bolted Flange Connections in the Offshore Wind Industry. Metals, 10(6), 732. https://doi.org/10.3390/met10060732