Effect of Strain Rate on the Deformation Behaviour of A356-T7 Cast Aluminium Alloys at Elevated Temperatures

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Extraction for Testing

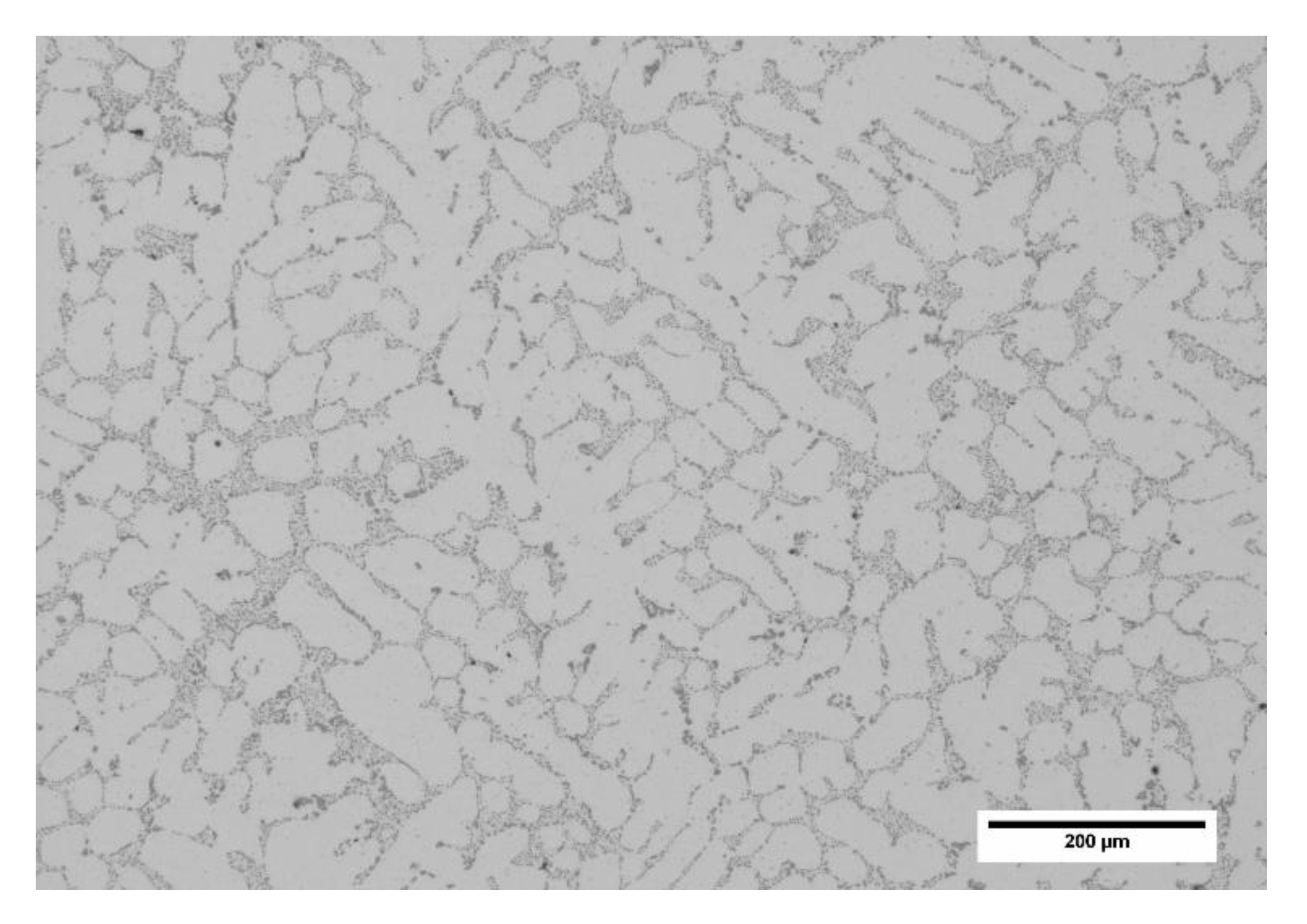

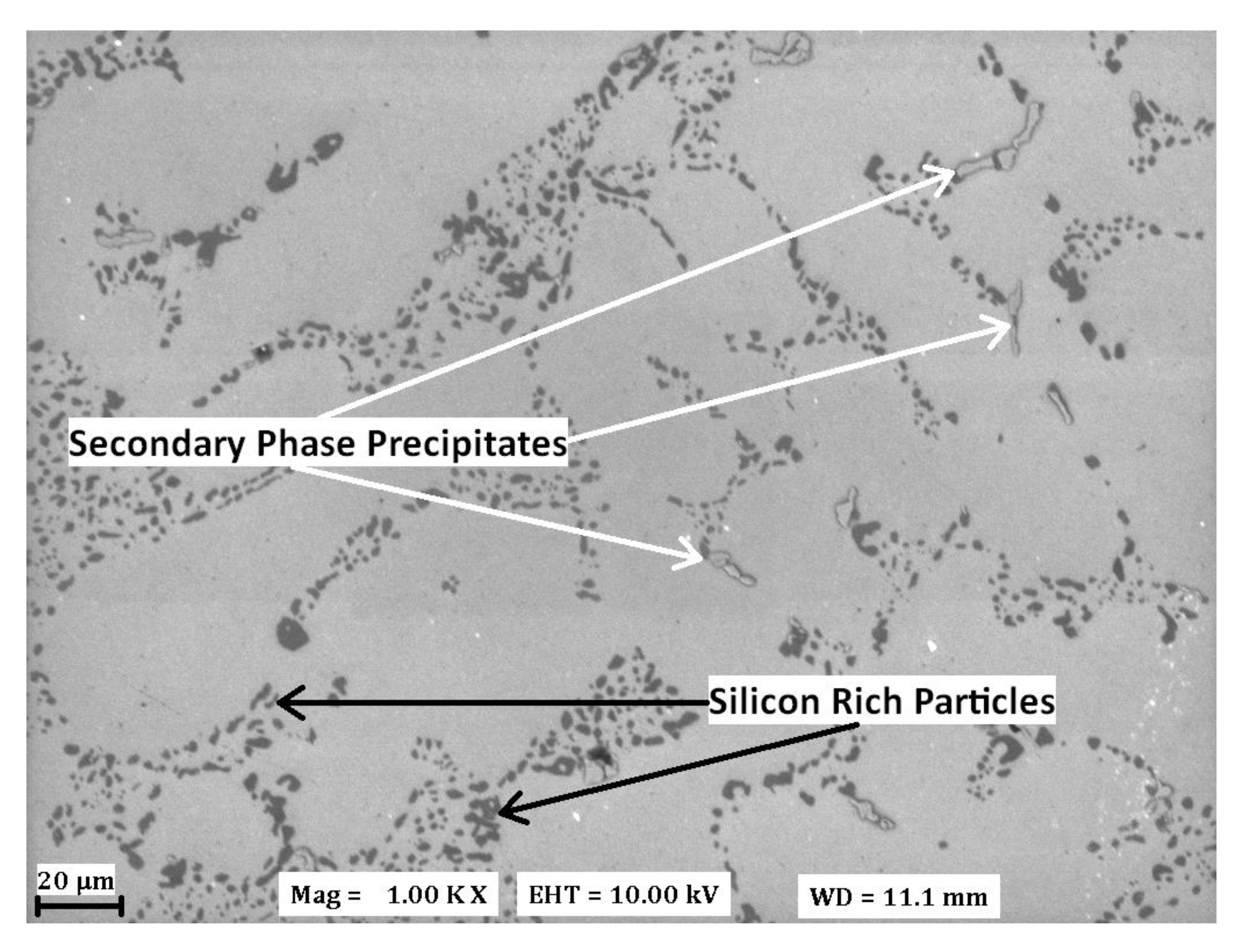

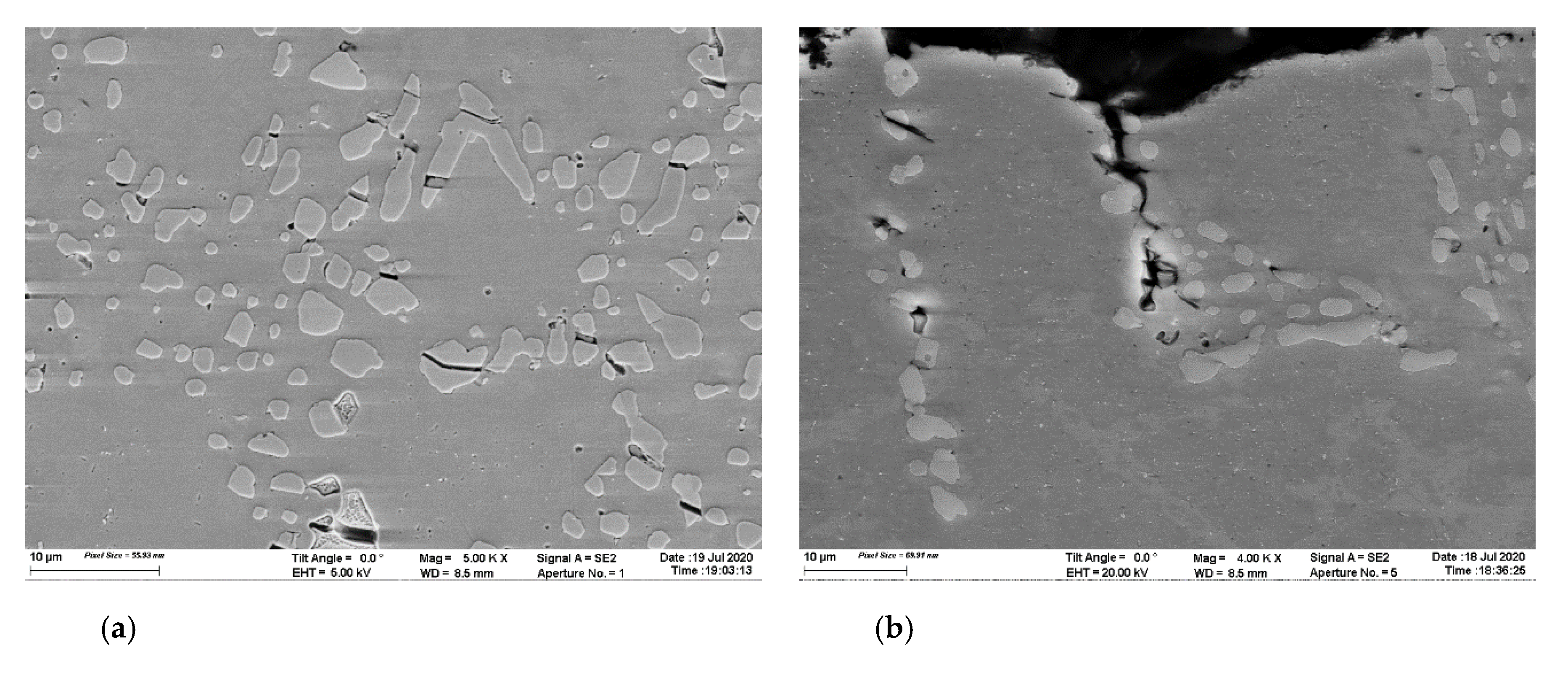

2.2. Material and Microstructure

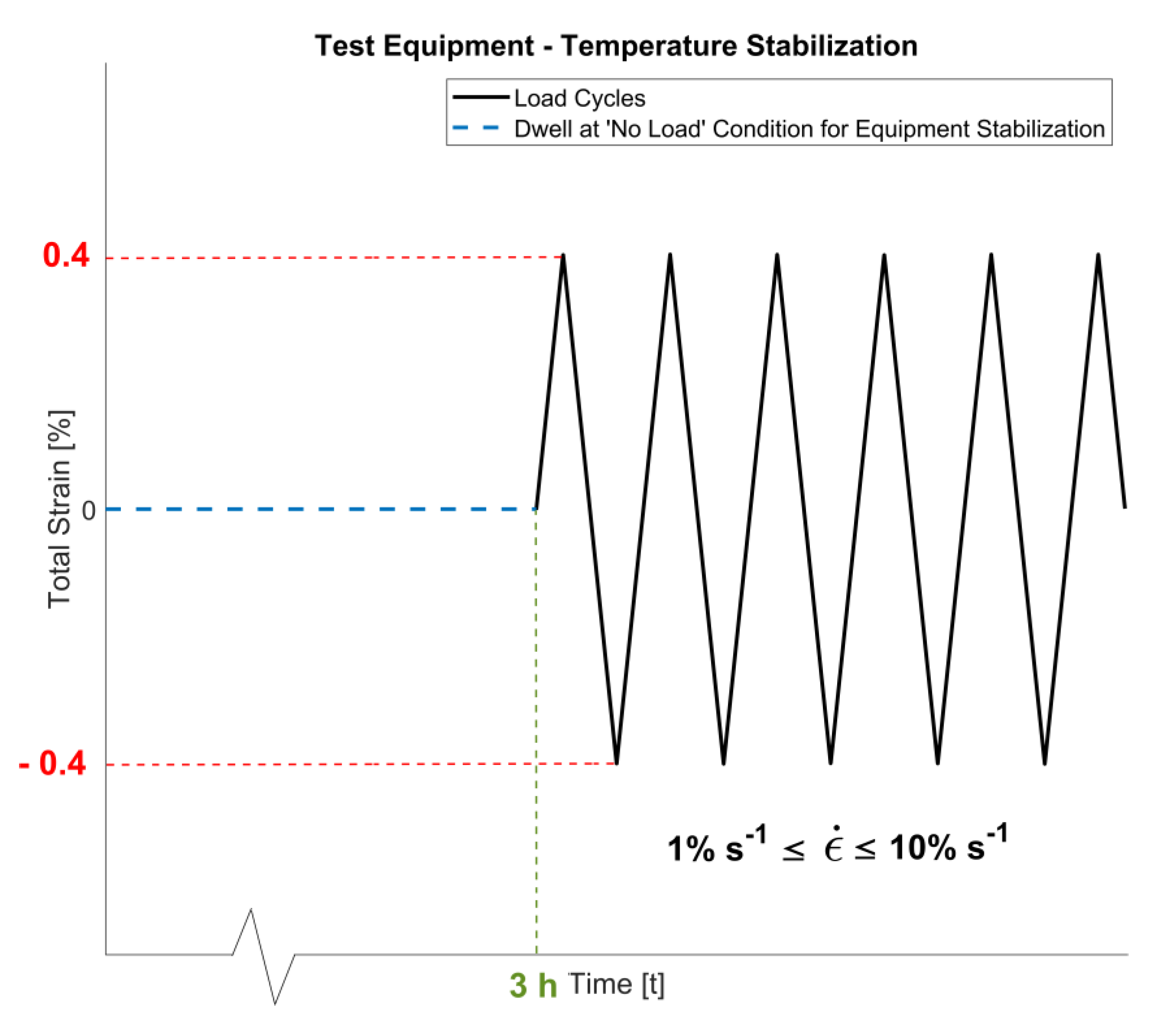

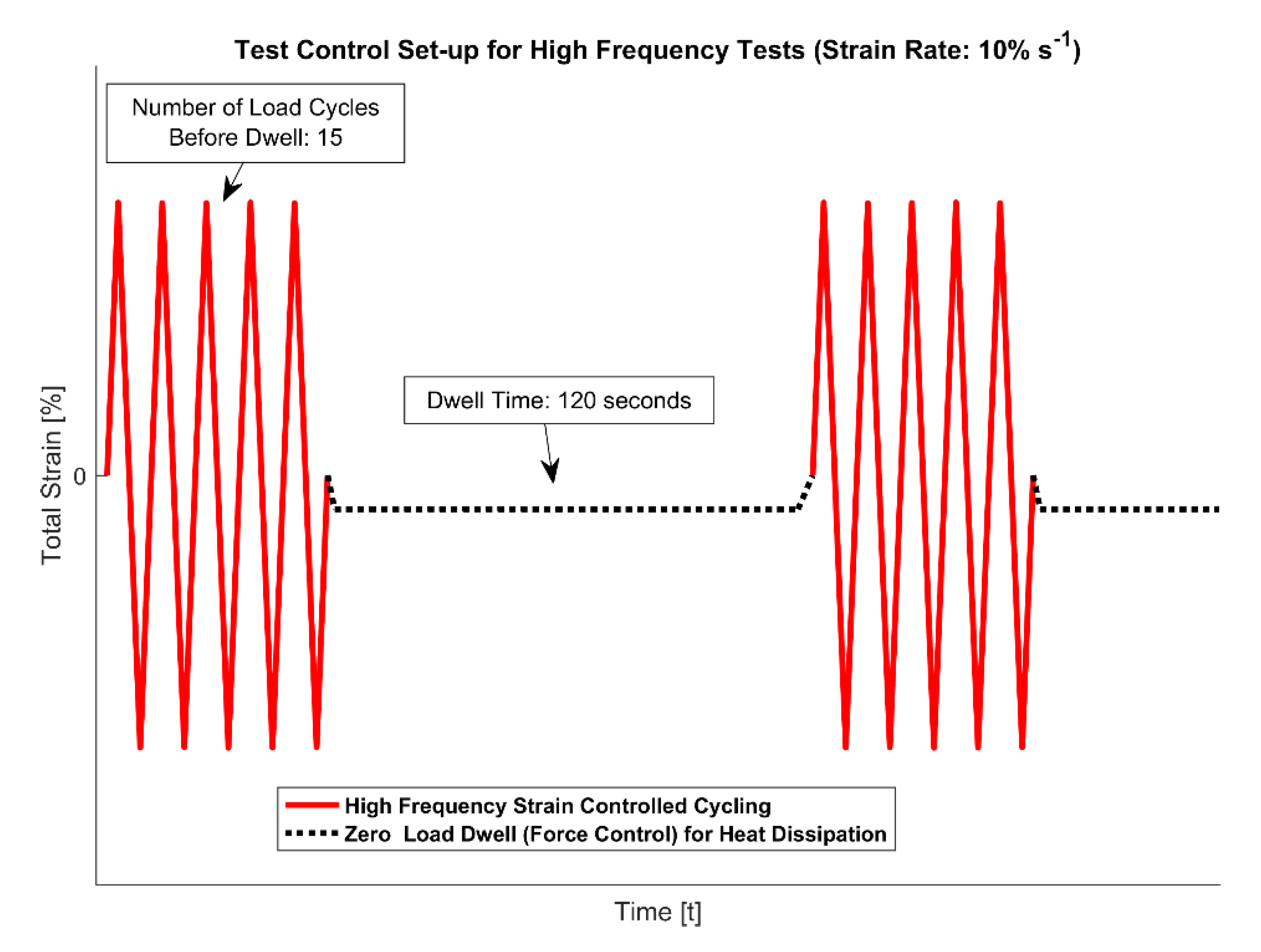

3. Test Methods

3.1. Sample Geometry and Test Setup

3.2. Test Plan

4. Results

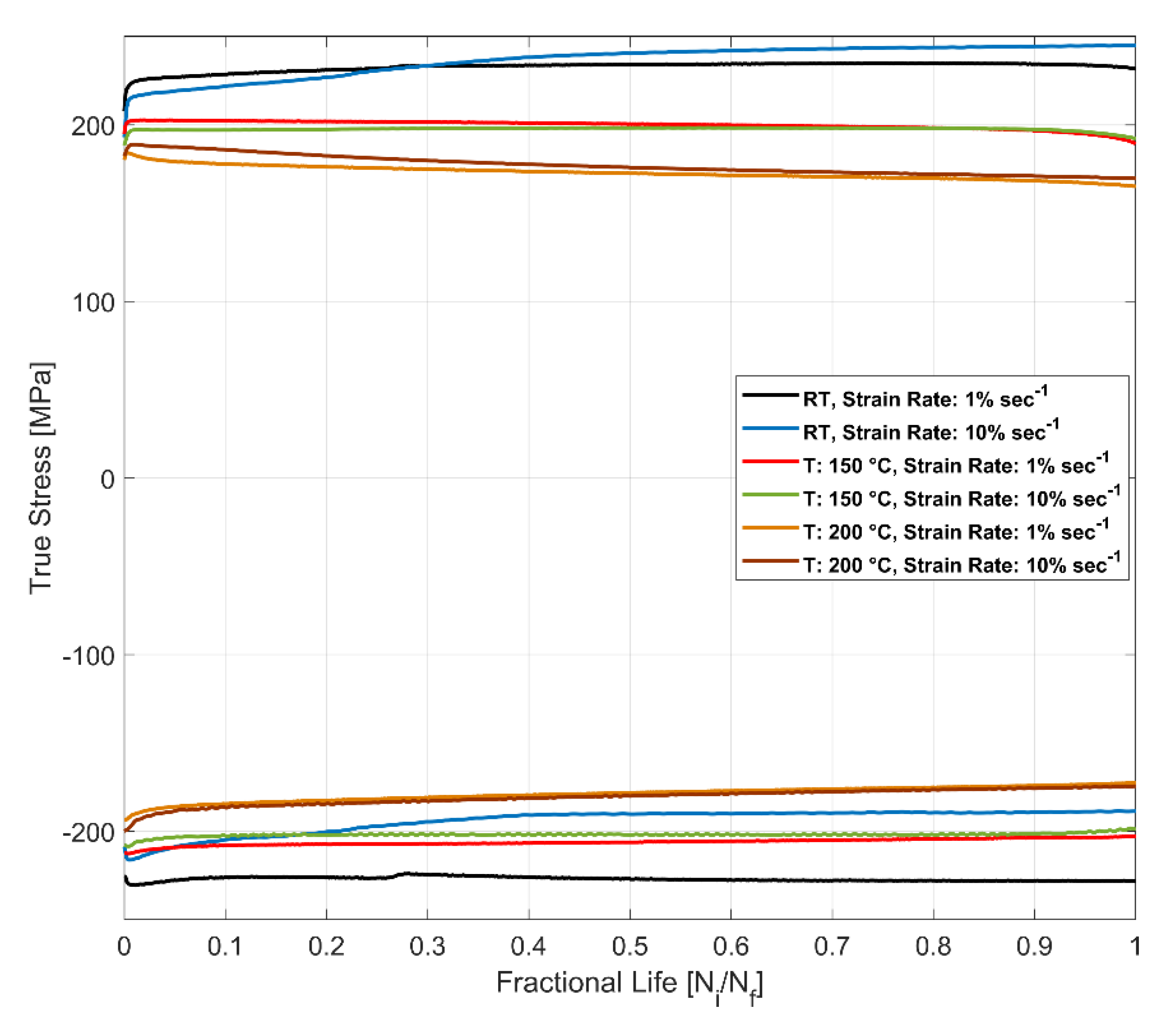

4.1. Peak and Trough Cyclic Stress Evolution

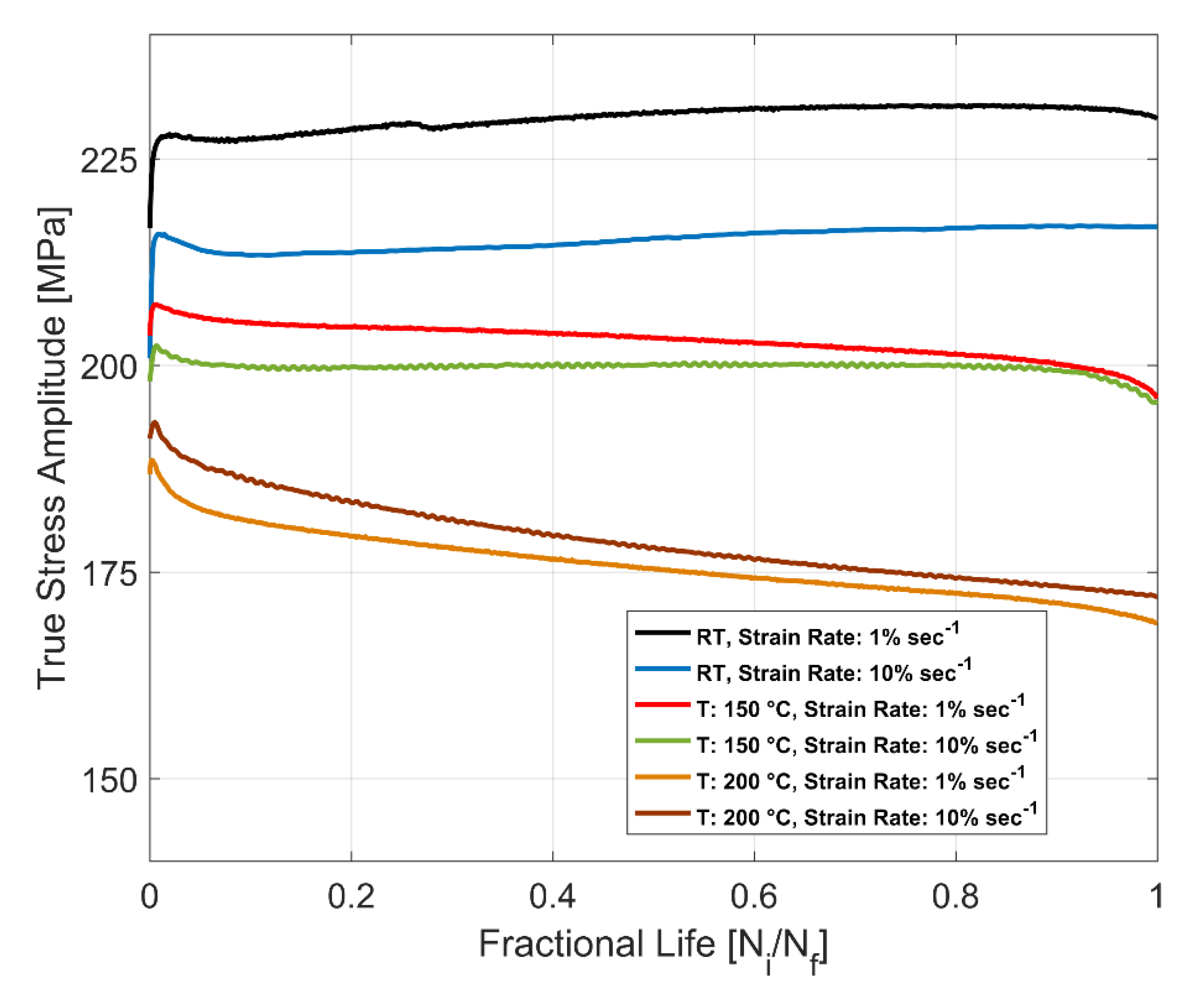

4.2. Cyclic Stress Amplitude Evolution

4.3. Mean Stress Evolution

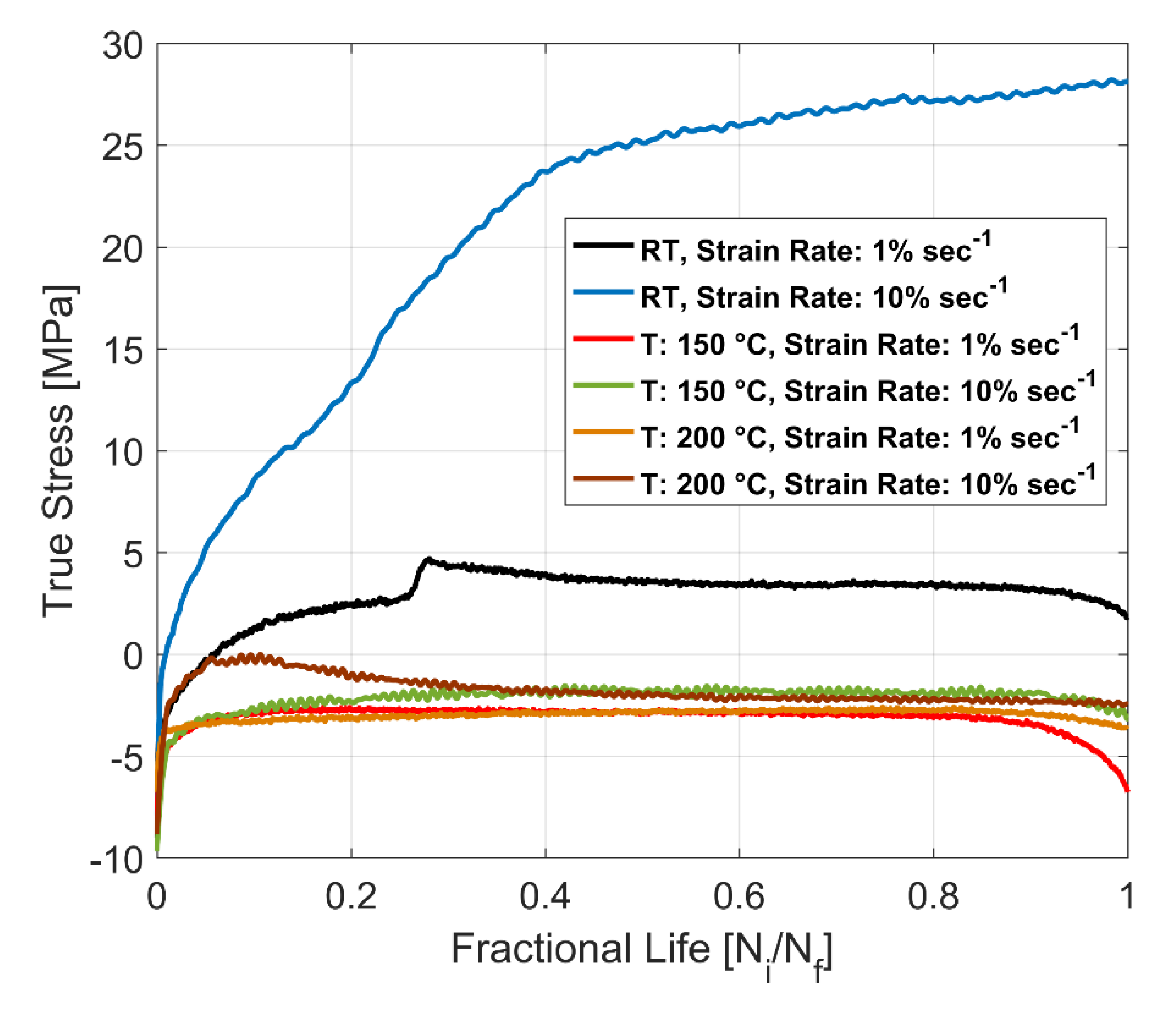

4.4. Cyclic Yield Strength Evolution

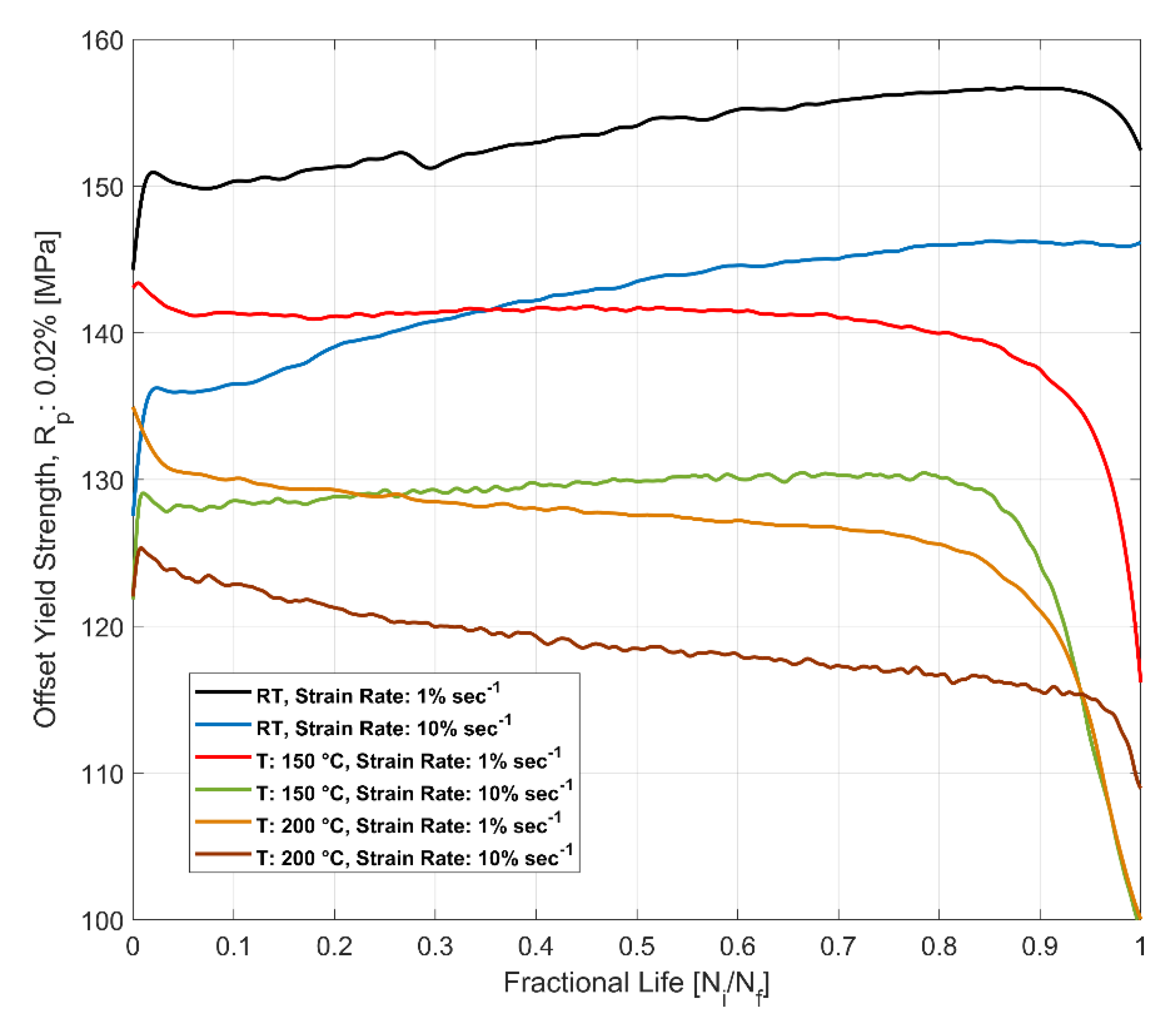

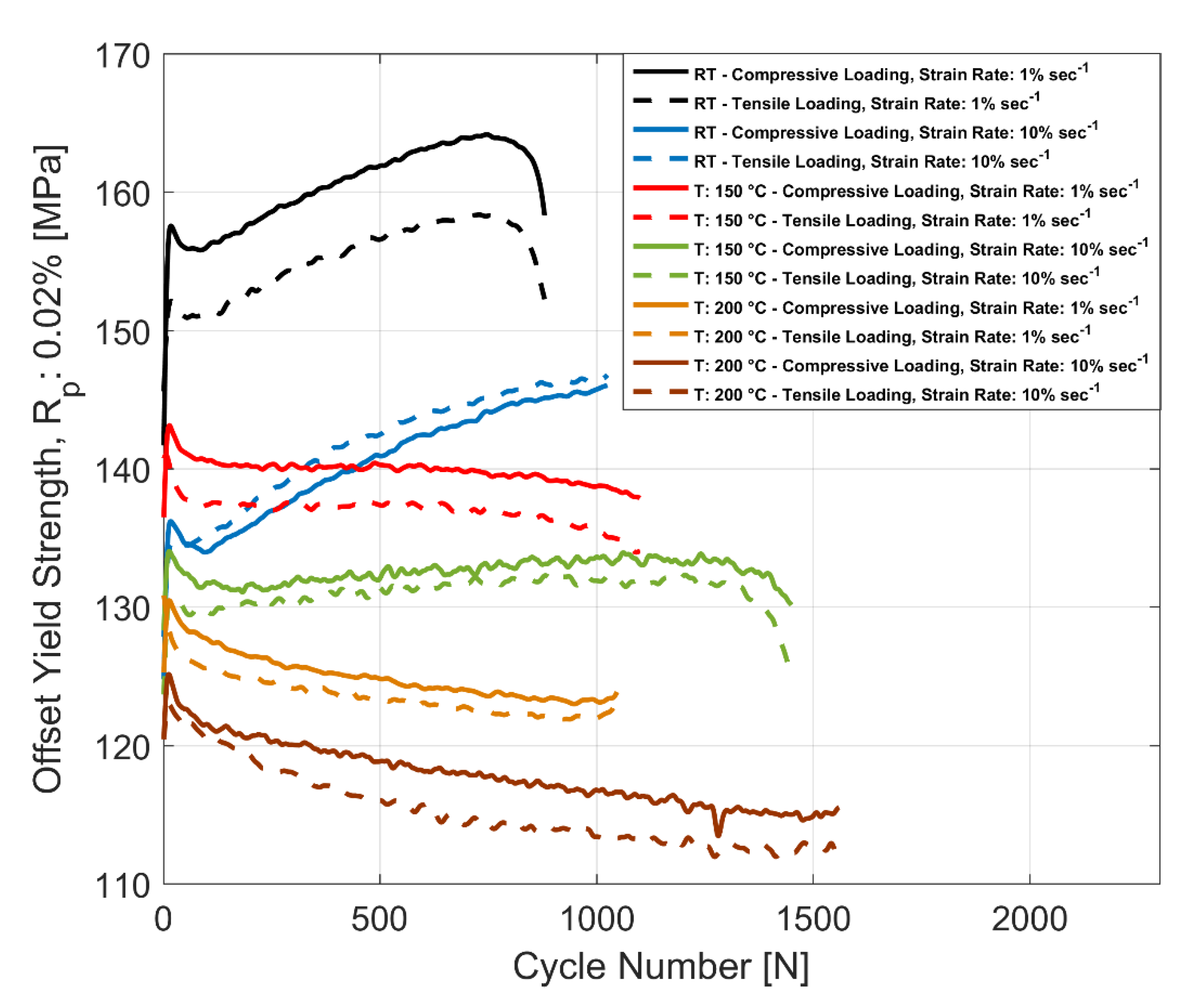

4.5. Effect of Strain Rate on Yield Strength Asymmetry

4.6. Effect of Strain Rate on Cyclic Plastic Strain Evolution

4.7. Effect of Strain Rate on the Number of Cycles to Failure

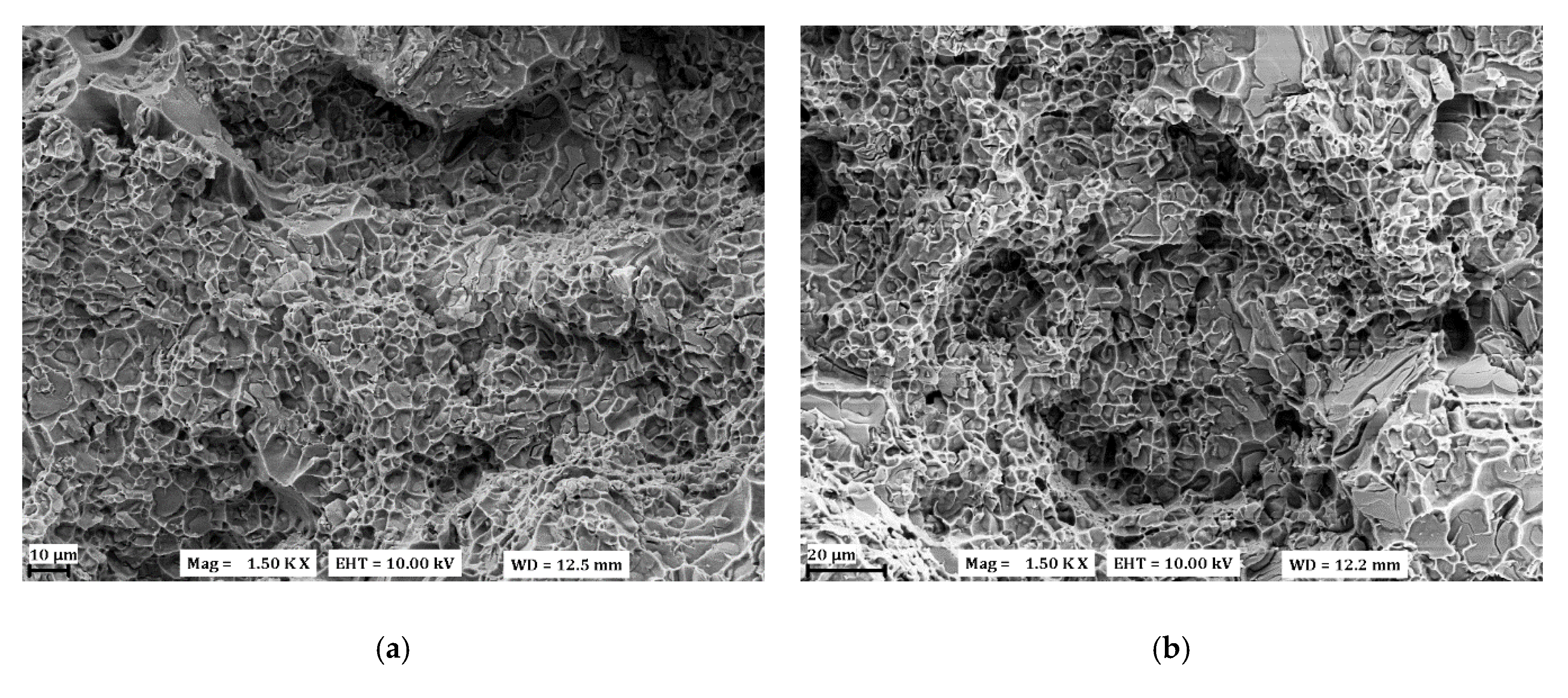

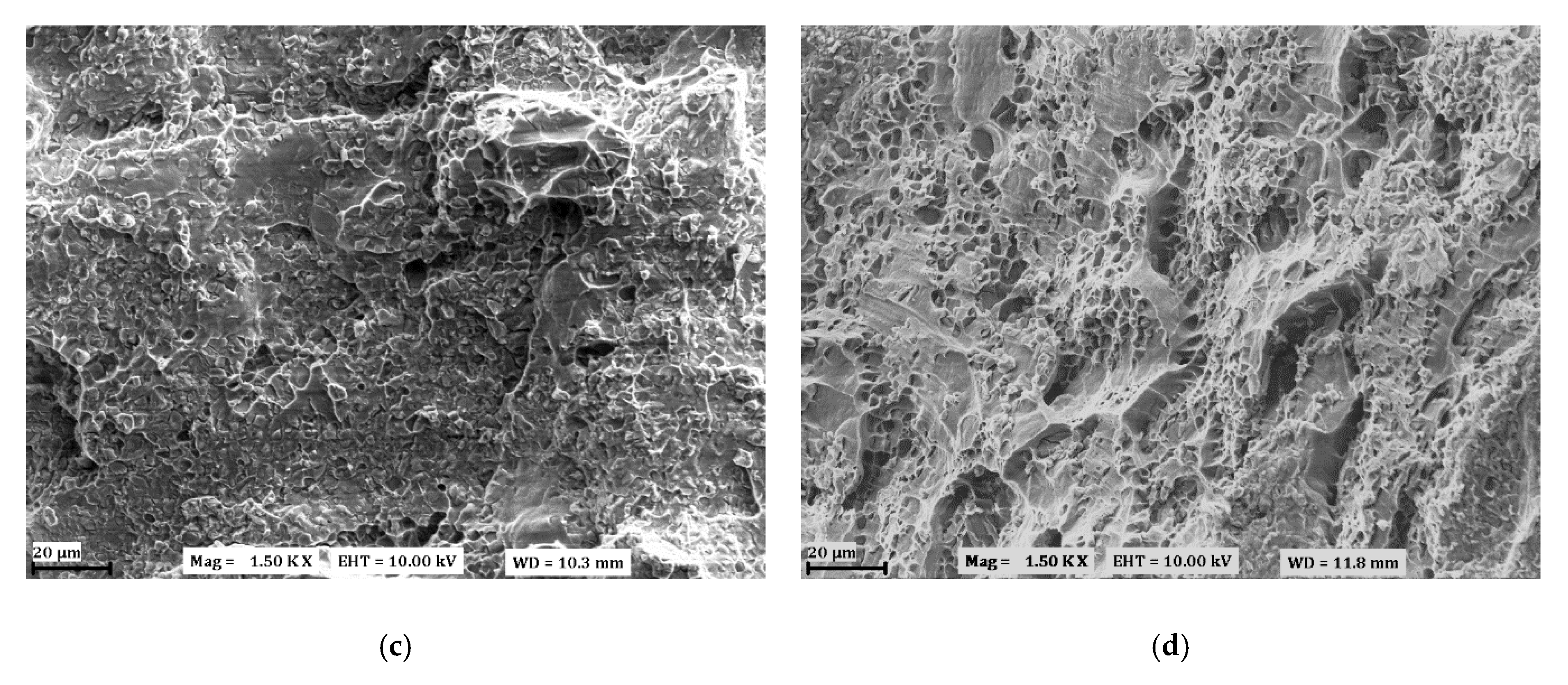

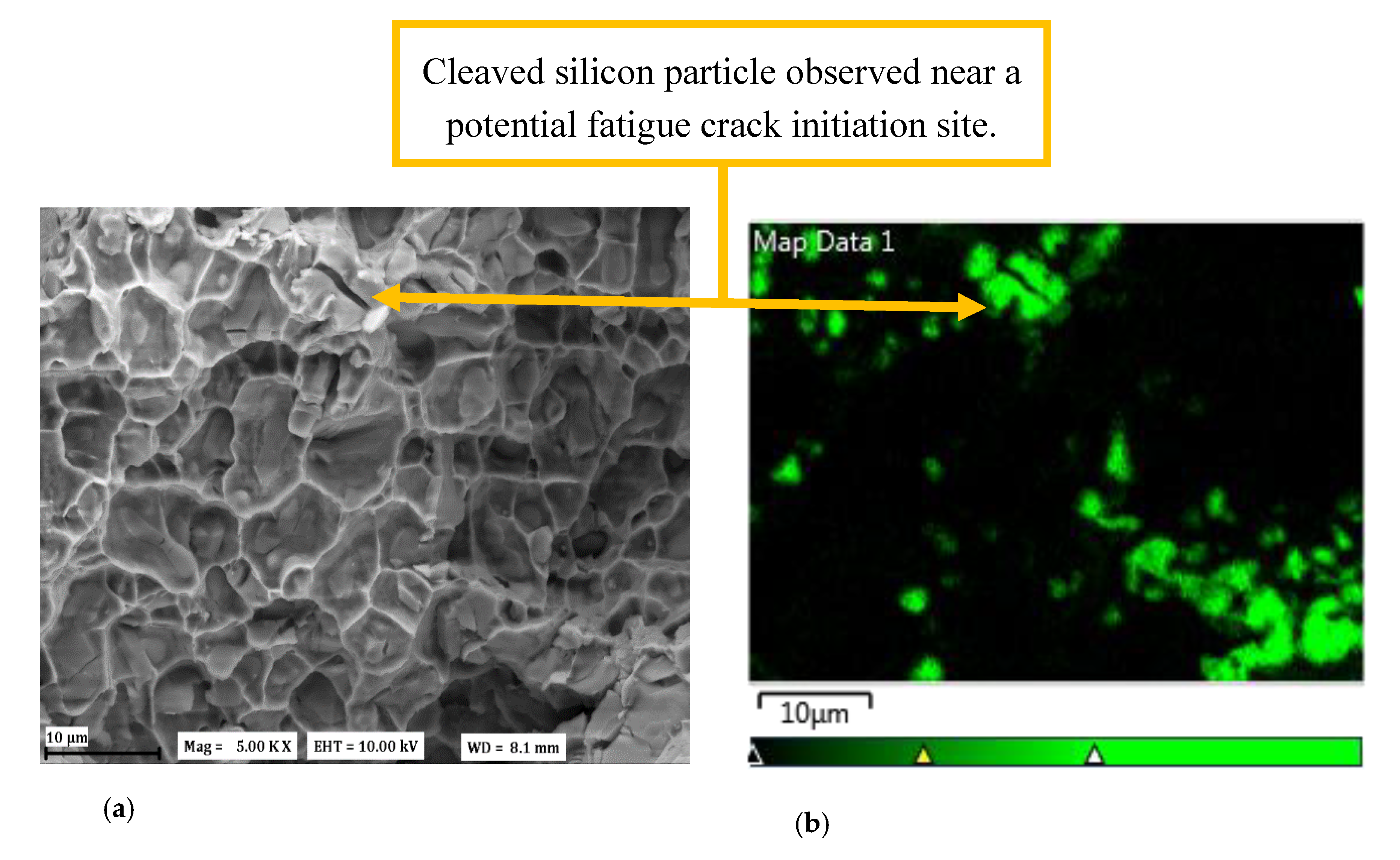

4.8. Fractography

5. Discussion

5.1. Effect on Number of Cycles to Failure

5.2. Fractography—Role of Shrinkage Porosity and Cleaved Silicon Particles in Fatigue Crack Initiation

6. Conclusions

- The influence of the strain rate on the cyclic peak stress development is minimal and exhibits no specific pattern at the tested temperatures and strain rates.

- The strain rate has a significant influence on the development of cyclic mean stress, especially at room temperature, with the mean stress changing by over 30 MPa, moving from compression initially to tension with subsequent cycling for the tests at 10% s−1.

- The higher strain rate has a similar influence on the yield strength asymmetry, with the yield in tension showing an increase over the yield in compression at room temperature. For all the other tested temperatures, the yield in compression is higher than the yield in tension for both the tested strain rates of 1% s−1 and 10% s−1.

- The material exhibits steeper isotropic hardening changes at higher strain rates, with the material hardening at room temperature and softening isotropically at 200 °C. The material exhibits insignificant changes to its yield surface at 150 °C for both the tested strain rates.

- The material exhibits an increased number of cycles to failure at higher strain rates, which could be explained partially by the adiabatic nature of the high strain rate tests and the associated higher heat accumulation in the material during deformation.

- Fractographic investigation of the fracture cross-section highlights the potential role of eutectic silicon particles and hard intermetallic phases on the crack initiation process besides the porosities, which tend to play a more dominant role in fatigue crack initiation in cast aluminium alloys [35]. The larger precipitates are preferentially cracked, highlighting the importance of refining the silicon particles and minimizing the shrinkage porosity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Statement

References

- European Aluminium. Aluminium Automotive Manual. Available online: https://www.european-aluminium.eu/resource-hub/aluminium-automotive-manual/ (accessed on 12 March 2020).

- Garat, M.; Laslaz, G. Improved aluminium alloys for common rail diesel cylinder heads. Trans. Am. Foundry Soc. 2007, 115, 1–8. [Google Scholar]

- Engler-Pinto, C.C.; Lasecki, J.V.; Boileau, J.M.; Allison, J.E. A comparative investigation on the high temperature fatigue of three cast aluminum alloys. In Proceedings of the SAE 2004 World Congress & Exhibition, Detroit, MI, USA, 8–11 March 2004. [Google Scholar]

- Fuchs, H.; Wappelhorst, M. Light metal materialsLeichtmetallwerkstoffe für hochbelastete Motorblöcke und Zylinderköpfe. MTZ Worldw. 2003, 64, 36–39. [Google Scholar] [CrossRef]

- Smith, T.J.; Maier, H.J.; Sehitoglu, H.; Fleury, E.; Allison, J. Modeling high-temperature stress-strain behavior of cast aluminum alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1999, 30, 133–146. [Google Scholar] [CrossRef]

- Thomas, J.J.; Verger, L.; Bignonnet, A.; Charkaluk, E. Thermomechanical design in the automotive industry. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 887–895. [Google Scholar] [CrossRef]

- Tabibian, S.; Charkaluk, E.; Constantinescu, A.; Szmytka, F.; Oudin, A. TMF-LCF life assessment of a lost foam casting A319 aluminum alloy. Int. J. Fatigue 2013, 53, 75–81. [Google Scholar] [CrossRef]

- Eichlseder, W.; Winter, G.; Köberl, H. Material and fatigue life models for thermomechanical loaded components. Mater. Werkst. 2008, 39, 777–782. [Google Scholar] [CrossRef]

- Dowling, N.E. Mechanical Behavior of Materials, 4th ed.; Pearson: London, UK, 2013; ISBN 978-0273764557. [Google Scholar]

- Charkaluk, E.; Bignonnet, A.; Constantinescu, A.; Dang Van, K. Fatigue design of structures under thermomechanical loadings. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 1199–1206. [Google Scholar] [CrossRef]

- Callister, W.D., Jr. Materials Science and Engineering: An Introduction, 7th ed.; Wiley Publishers: Hoboken, NJ, USA, 2006; ISBN 978-0006970118. [Google Scholar]

- Koch, F.; Maassen, F.; Deuster, U.; Loeprecht, M.; Marckwardt, H. Low cycle fatigue of aluminum cylinder heads—Calculation and measurement of strain under fired operation. J. Engines 1999. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Pekguleryuz, M. Enhanced mechanical properties of an Al–Si–Cu–Mg alloy at 300 °C: Effects of Mg and the Q-precipitate phase. Mater. Sci. Eng. A 2015, 621, 277–286. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Javidani, M.; Hoseini, M.; Larouche, D.; Pekguleryuz, M. Phase formation in as-solidified and heat-treated Al–Si–Cu–Mg–Ni alloys: Thermodynamic assessment and experimental investigation for alloy design. J. Alloys Compd. 2013, 551, 596–606. [Google Scholar] [CrossRef]

- Seifeddine, S.; Sjölander, E.; Bogdanoff, T. On the role of copper and cooling rates on the microstructure, defect formations and mechanical properties of Al-Si-Mg alloys. Mater. Sci. Appl. 2013, 4, 171–178. [Google Scholar] [CrossRef]

- Azadi, M. Effects of strain rate and mean strain on cyclic behavior of aluminum alloys under isothermal and thermo-mechanical fatigue loadings. Int. J. Fatigue 2013, 47, 148–153. [Google Scholar] [CrossRef]

- Fan, K.L.; Liu, X.S.; He, G.Q.; Cheng, H.; Zhang, Z. Influences of strain rate on the low cycle fatigue behavior of gravity casting Al alloys. Mater. Charact. 2015. [Google Scholar] [CrossRef]

- Dighe, M.D.; Gokhale, A.M.; Horstemeyer, M.F.; Mosher, D.A. Effect of strain rate on damage evolution in a cast Al-Si-Mg base alloy. Metall. Mater. Trans. A 2000, 31, 1725–1731. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014. [Google Scholar] [CrossRef]

- Korbel, A.; Swiatkowski, K. The role of strain rate in the formation of dislocation structure and its influence on the mechanical properties of aluminium. Met. Sci. J. 1972. [Google Scholar] [CrossRef]

- Chen, Y.; Clausen, A.H.; Hopperstad, O.S.; Langseth, M. Stress-strain behaviour of aluminium alloys at a wide range of strain rates. Int. J. Solids Struct. 2009. [Google Scholar] [CrossRef]

- Reyes, A.; Hopperstad, O.S.; Lademo, O.G.; Langseth, M. Modeling of textured aluminum alloys used in a bumper system: Material tests and characterization. Comput. Mater. Sci. 2006. [Google Scholar] [CrossRef]

- Djapic Oosterkamp, L.; Ivankovic, A.; Venizelos, G. High strain rate properties of selected aluminium alloys. Mater. Sci. Eng. A 2000. [Google Scholar] [CrossRef]

- Megel, M.C.; Bailey, G.E. Material and Process Selection-Cylinder Blocks and Heads. In Encyclopedia of Automotive Engineering; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 1–10. [Google Scholar]

- Oberreiter, M.; Pomberger, S.; Leitner, M.; Stoschka, M. Validation Study on the Statistical Size Effect in Cast Aluminium. Metals (Basel) 2020, 10, 710. [Google Scholar] [CrossRef]

- Koutiri, I.; Bellett, D.; Morel, F.; Augustins, L.; Adrien, J. High cycle fatigue damage mechanisms in cast aluminium subject to complex loads. Int. J. Fatigue 2013, 47, 44–57. [Google Scholar] [CrossRef]

- Grieb, M.B.; Christ, H.J.; Plege, B. Thermomechanical fatigue of cast aluminium alloys for cylinder head applications experimental characterization and life prediction. In Proceedings of the Procedia Engineering, Prague, Czech Republic, 6–11 June 2010; Volume 2, pp. 1767–1776. [Google Scholar]

- ASTM E1251-17a. Standard Test Method for Analysis of Aluminum and Aluminum Alloys by Spark Atomic Emission Spectrometry; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. ASTM E606/E606M—12: Standard Test Method for Strain-Controlled Fatigue Testing. In ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2019; ISBN 5935522004. [Google Scholar]

- Natesan, E.; Eriksson, S.; Ahlström, J.; Persson, C. Effect of temperature on deformation and fatigue behaviour of A356–T7 cast aluminium alloys used in high specific power IC engine cylinder heads. Materials (Basel) 2020, 13, 1202. [Google Scholar] [CrossRef] [PubMed]

- Natesan, E.; Meyer, K.A.; Eriksson, S.; Ahlström, J.; Persson, C. Effects of dwell time on the deformation and fatigue behaviour of A356-T7 cast aluminium alloys used in high specific power IC engine cylinder heads. Materials (Basel) 2020, 13, 2727. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008; ISBN 9780511810947. [Google Scholar]

- Begum, S.; Chen, D.L.; Xu, S.; Luo, A.A. Effect of strain ratio and strain rate on low cycle fatigue behavior of AZ31 wrought magnesium alloy. Mater. Sci. Eng. A 2009, 517, 334–343. [Google Scholar] [CrossRef]

- Tucker, M.T.; Horstemeyer, M.F.; Whittington, W.R.; Solanki, K.N.; Gullett, P.M. The effect of varying strain rates and stress states on the plasticity, damage, and fracture of aluminum alloys. Mech. Mater. 2010. [Google Scholar] [CrossRef]

- Natesan, E.; Eriksson, S.; Ahlström, J.; Persson, C. Deformation and fatigue behaviour of A356-T7 cast aluminium alloys used in high specific power IC engines. Materials (Basel) 2019, 12, 3033. [Google Scholar] [CrossRef]

- Yeh, J.W.; Liu, W.P. The cracking mechanism of silicon particles in an A357 aluminum alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1996. [Google Scholar] [CrossRef]

- Dighe, M.D.; Gokhale, A.M. Relationship between microstructural extremum and fracture path in a cast Al-Si-Mg alloy. Scr. Mater. 1997. [Google Scholar] [CrossRef]

- Lee, F.T.; Major, J.F.; Samuel, F.H. Effect of silicon particles on the fatigue crack growth characteristics of Al-12 Wt Pct Si-0.35 Wt Pct Mg-(0 to 0.02) Wt Pct Sr casting alloys. Metall. Mater. Trans. A 1995, 26, 1553–1570. [Google Scholar] [CrossRef]

- Samuel, A.M.; Samuel, F.H. A metallographic study of porosity and fracture behavior in relation to the tensile properties in 319.2 end chill castings. Metall. Mater. Trans. A 1995, 26, 2359–2372. [Google Scholar] [CrossRef]

| Si | Cu | Mg | Ti | Fe | Mn | B | Others | Al |

|---|---|---|---|---|---|---|---|---|

| 6.8 | 0.53 | 0.35 | 0.12 | 0.10 | 0.07 | 0.0012 | <0.05 | Bal |

| Test Series | Test Temperatures | Load Levels | Replicas |

|---|---|---|---|

| Strain rate: 1% s−1 | RT, 150 and 200 °C | εTotAmp: 0.4% Rε = −1 | 2 |

| Strain Rate: 10% s−1 | RT, 150 and 200 °C | εTotAmp: 0.4% Rε = −1 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natesan, E.; Ahlström, J.; Manchili, S.K.; Eriksson, S.; Persson, C. Effect of Strain Rate on the Deformation Behaviour of A356-T7 Cast Aluminium Alloys at Elevated Temperatures. Metals 2020, 10, 1239. https://doi.org/10.3390/met10091239

Natesan E, Ahlström J, Manchili SK, Eriksson S, Persson C. Effect of Strain Rate on the Deformation Behaviour of A356-T7 Cast Aluminium Alloys at Elevated Temperatures. Metals. 2020; 10(9):1239. https://doi.org/10.3390/met10091239

Chicago/Turabian StyleNatesan, Elanghovan, Johan Ahlström, Swathi K. Manchili, Stefan Eriksson, and Christer Persson. 2020. "Effect of Strain Rate on the Deformation Behaviour of A356-T7 Cast Aluminium Alloys at Elevated Temperatures" Metals 10, no. 9: 1239. https://doi.org/10.3390/met10091239

APA StyleNatesan, E., Ahlström, J., Manchili, S. K., Eriksson, S., & Persson, C. (2020). Effect of Strain Rate on the Deformation Behaviour of A356-T7 Cast Aluminium Alloys at Elevated Temperatures. Metals, 10(9), 1239. https://doi.org/10.3390/met10091239