Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

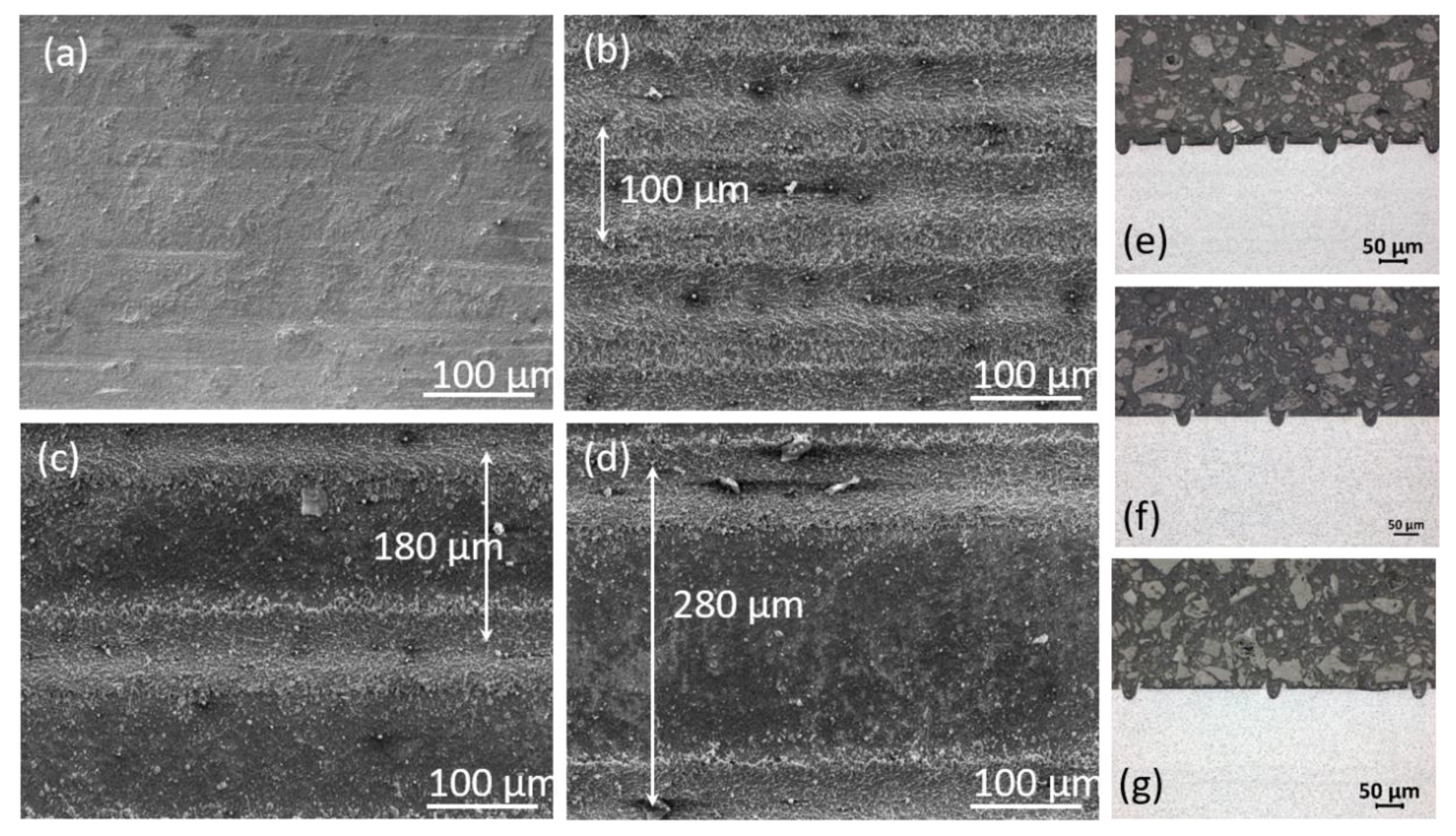

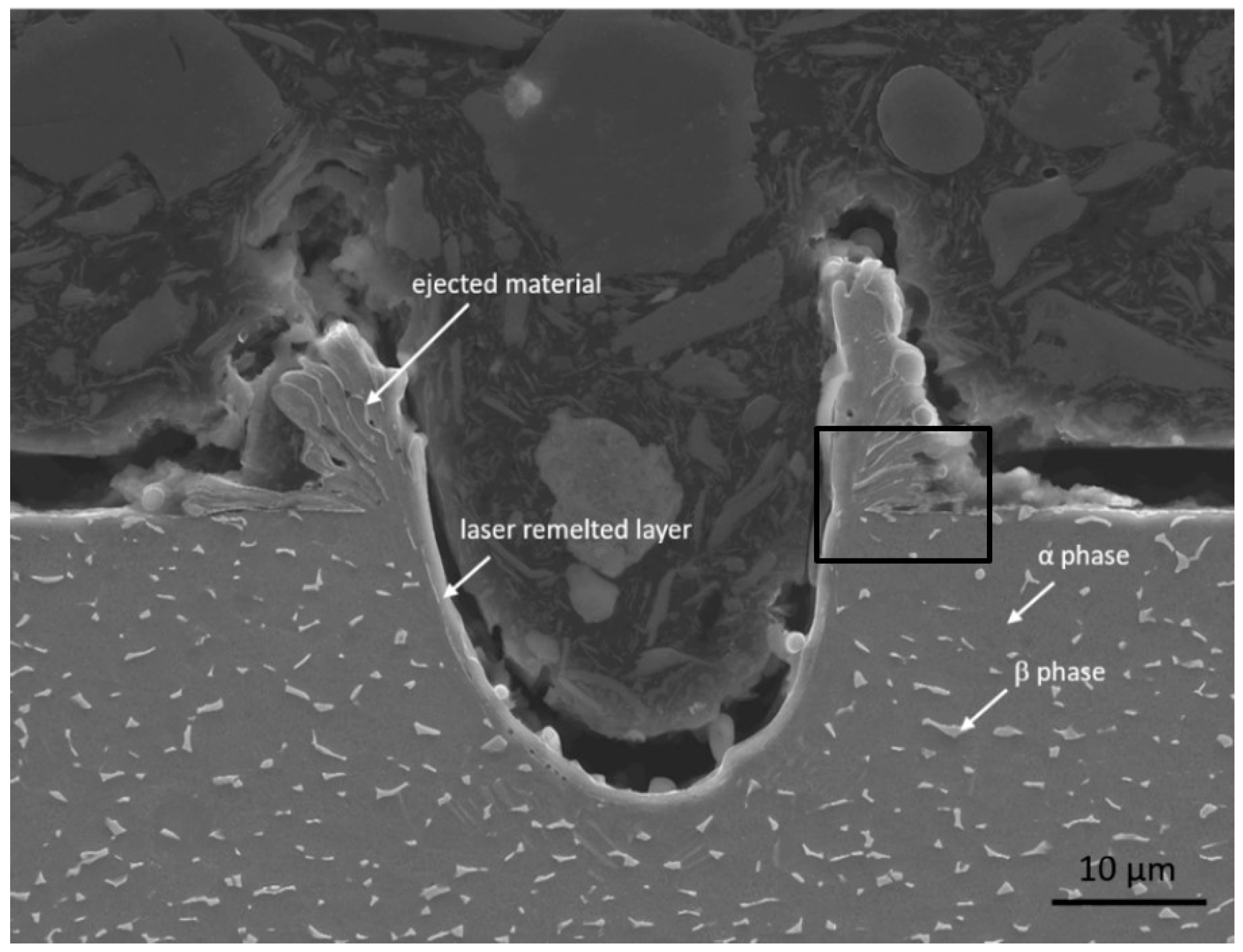

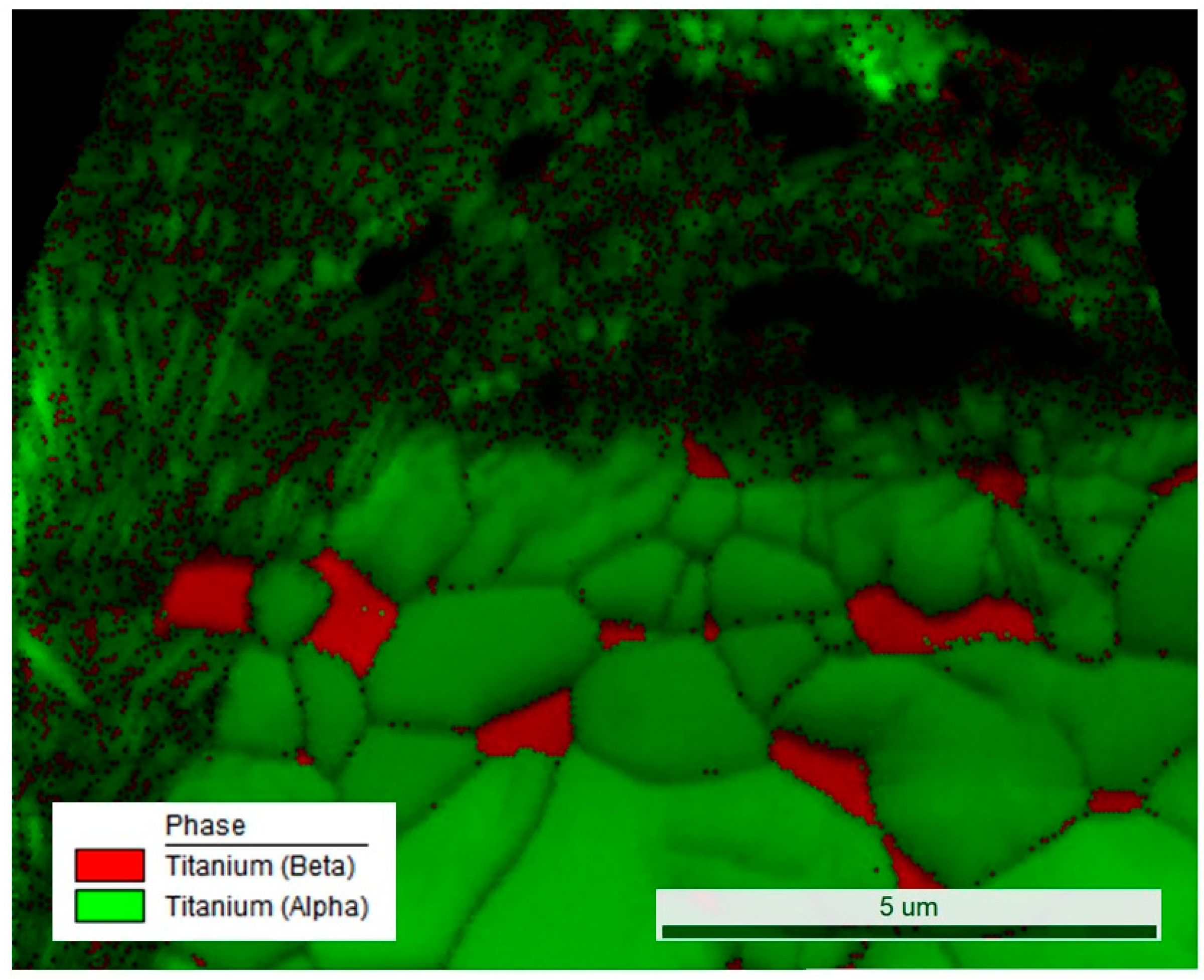

3.1. Surface Morphology

3.2. Vickers Hardness Test

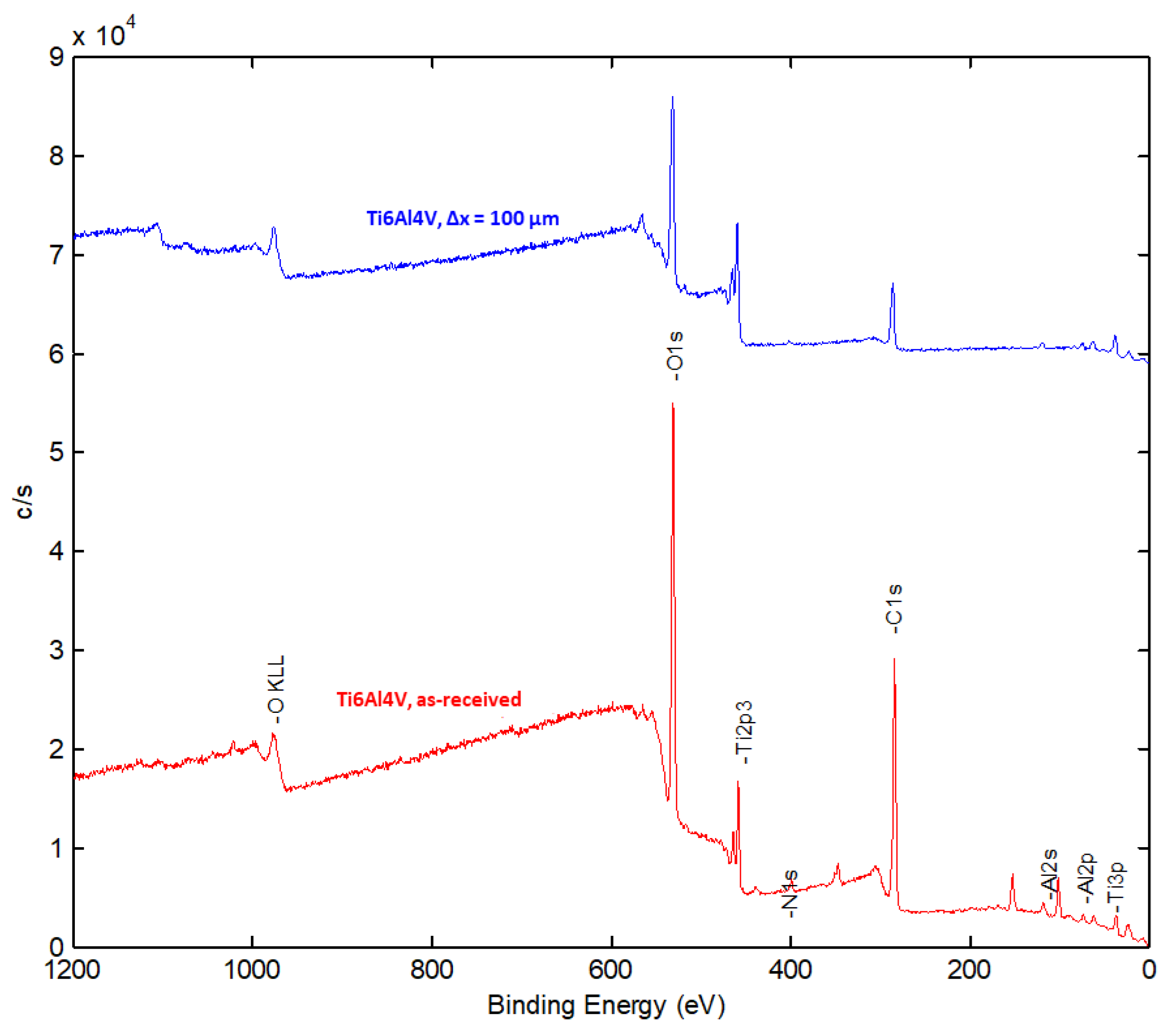

3.3. XPS Measurements

3.4. Surface Wettability

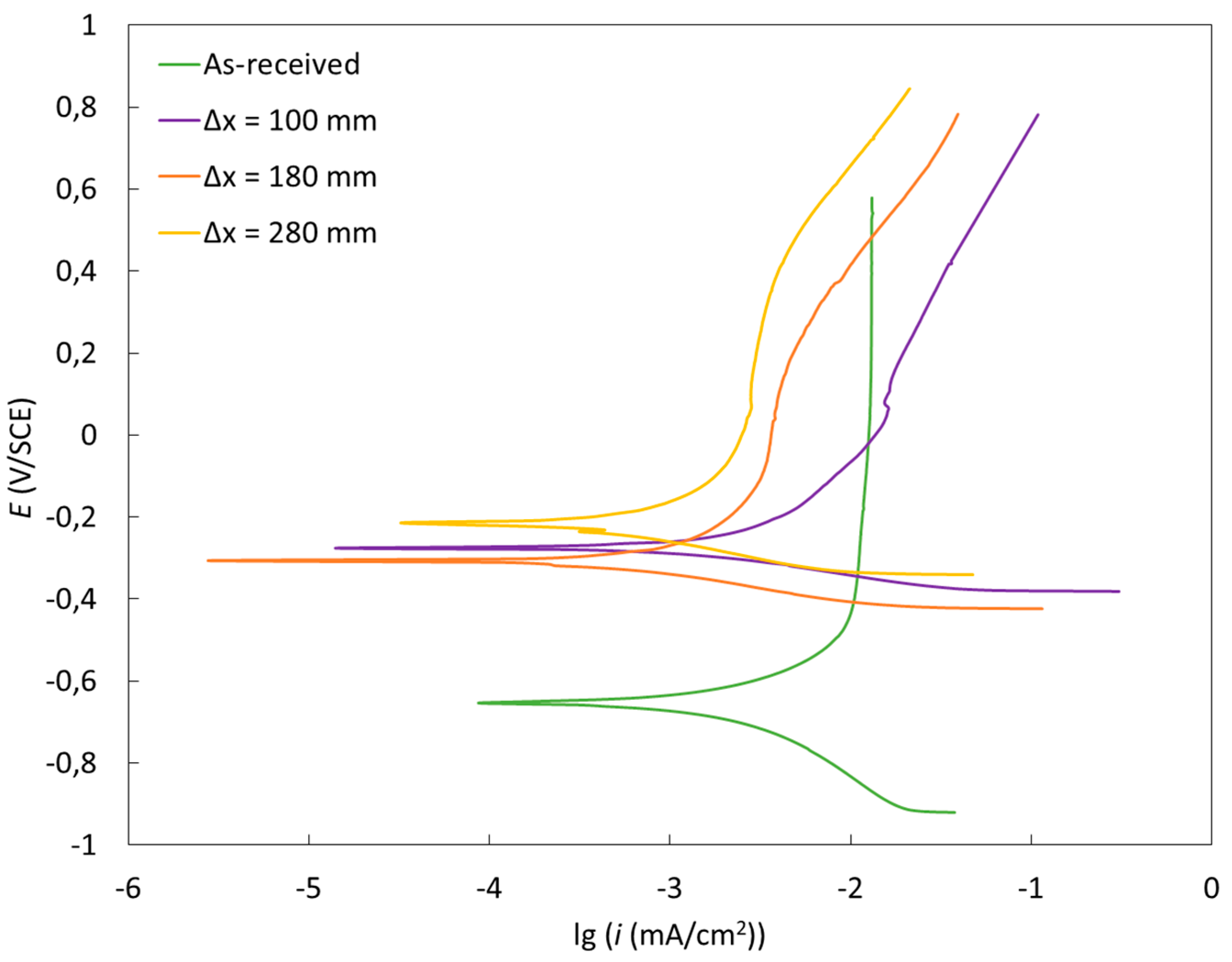

3.5. Electrochemical Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Galliano, F.; Landolt, D. Evaluation of corrosion protection properties of additives for waterborne epoxy coatings on steel. Prog. Org. Coat. 2002, 44, 217–225. [Google Scholar] [CrossRef]

- Talo, A.; Forsén, O.; Yläsaari, S. Corrosion protective polyaniline epoxy blend coatings on mild steel. Synth. Met. 1999, 102, 1394–1395. [Google Scholar] [CrossRef]

- Diniz, F.B.; De Andrade, G.; Martins, C.; De Azevedo, W.M. A comparative study of epoxy and polyurethane based coatings containing polyaniline-DBSA pigments for corrosion protection on mild steel. Prog. Org. Coat. 2013, 76, 912–916. [Google Scholar] [CrossRef]

- Moloney, A.C.; Kausch, H.H.; Kaiser, T.; Beer, H.R. Parameters determining the strength and toughness of particulate filled epoxide-resins. J. Mater. Sci. 1987, 22, 381–393. [Google Scholar] [CrossRef]

- Hussain, M.; Oku, Y.; Nakahira, A.; Niihara, K. Effects of wet ball-milling on particle dispersion and mechanical properties of particulate epoxy composites. Mater. Lett. 1996, 26, 177–184. [Google Scholar] [CrossRef]

- Giannelis, E.P. Polymer-layered silicate nanocomposites: Synthesis, properties and applications. Appl. Organomet. Chem. 1998, 12, 675–680. [Google Scholar] [CrossRef]

- Zerda, A.S.; Lesser, A.J. Intercalated clay nanocomposites: Morphology, mechanics, and fracture behavior. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 1137–1146. [Google Scholar] [CrossRef]

- Singh, R.P.; Zhang, M.; Chan, D. Toughening of a brittle thermosetting polymer: Effects of reinforcement particle size and volume fraction. J. Mater. Sci. 2002, 37, 781–788. [Google Scholar] [CrossRef]

- Long, J.; Liu, W.; Zhang, H.; Fan, P. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air. J. Colloid Interface Sci. 2015, 441, 1–9. [Google Scholar] [CrossRef]

- Boinovich, L.; Emelyanenko, A.M.; Modestov, A.D.; Domantovsky, A.G.; Emelyanenko, K.A. Synergistic Effect of Superhydrophobicity and Oxidized Layers on Corrosion Resistance of Aluminum Alloy Surface Textured by Nanosecond Laser Treatment. ACS Appl. Mater. Interfaces 2015, 7, 19500–19508. [Google Scholar] [CrossRef]

- Ta, V.D.; Dunn, A.K.; Wasley, T.J.; Li, J.; Kay, R.W.; Stringer, J.; Smith, P.J.; Esenturk, E.; Connaughton, C.; Shephard, J.D. Laser textured superhydrophobic surfaces and their applications for homogeneous spot deposition. Appl. Surf. Sci. 2016, 365, 153–159. [Google Scholar] [CrossRef]

- Conradi, M.; Sever, T.; Gregorčič, P.; Kocijan, A. Short- and Long-Term Wettability Evolution and Corrosion Resistance of Uncoated and Polymer-Coated Laser-Textured Steel Surface. Coatings 2019, 9, 592. [Google Scholar] [CrossRef]

- Gregorčič, P.; Conradi, M.; Hribar, L.; Hočevar, M. Long-Term Influence of Laser-Processing Parameters on (Super)hydrophobicity Development and Stability of Stainless-Steel Surfaces. Materials 2018, 11, 2240. [Google Scholar] [CrossRef] [PubMed]

- Ta, D.V.; Dunn, A.K.; Wasley, T.J.; Kay, R.W.; Stringer, J.; Smith, P.J.; Connaughton, C.; Shephard, J.D. Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications. Appl. Surf. Sci. 2015, 357, 248–254. [Google Scholar] [CrossRef]

- Kietzig, A.-M.; Hatzikiriakos, S.G.; Englezos, P. Patterned Superhydrophobic Metallic Surfaces. Langmuir 2009, 25, 4821–4827. [Google Scholar] [CrossRef]

- Boinovich, L.; Gnedenkov, S.; Alpysbaeva, D.; Egorkin, V.; Emelyanenko, A.; Sinebryukhov, S.; Zaretskaya, A. Corrosion resistance of composite coatings on low-carbon steel containing hydrophobic and superhydrophobic layers in combination with oxide sublayers. Corros. Sci. 2012, 55, 238–245. [Google Scholar] [CrossRef]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review. Materials 2018, 11, 487. [Google Scholar] [CrossRef]

- Malinov, S.; Guo, Z.; Sha, W.; Wilson, A. Differential scanning calorimetry study and computer modeling of beta double right arrow alpha phase transformation in a Ti-6Al-4V alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001, 32, 879–887. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- ASTM International. ASTM G102-89(2015)e1, Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Kumari, R.; Scharnweber, T.; Pfleging, W.; Besser, H.; Majumdar, J.D. Laser surface textured titanium alloy (Ti-6Al-4V)—Part II—Studies on bio-compatibility. Appl. Surf. Sci. 2015, 357, 750–758. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Zhang, G.; Wang, G.; Zeng, Z.; Wang, C.; Wang, C.; Zhao, S.; Zhang, Y.; Ren, T. Electrochemical corrosion and anisotropic tribological properties of bioinspired hierarchical morphologies on Ti-6Al-4V fabricated by laser texturing. Tribol. Int. 2019, 134, 352–364. [Google Scholar] [CrossRef]

- Kosec, T.; Legat, A.; Kovač, J.; Klobčar, D. Influence of Laser Colour Marking on the Corrosion Properties of Low Alloyed Ti. Coatings 2019, 9, 375. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Li, S.; Huo, Q. Research progress on laser surface modification of titanium alloys. Appl. Surf. Sci. 2005, 242, 177–184. [Google Scholar] [CrossRef]

| Surface | Sa [μm] |

|---|---|

| As-received | 0.89 ± 0.15 |

| ∆x = 100 μm | 2.98 ± 0.10 |

| ∆x = 180 μm | 1.86 ± 0.12 |

| ∆x = 280 μm | 1.47 ± 0.12 |

| Surface | HV20 |

|---|---|

| As-received | 325 ± 5 |

| ∆x = 100 μm | 350 ± 5 |

| ∆x = 180 μm | 344 ± 5 |

| ∆x = 280 μm | 338 ± 5 |

| Surface | Contact Angle [o] |

|---|---|

| As-received | 91.6 ± 1.4 |

| ∆x = 100 μm | 21.1 ± 2.2 |

| ∆x = 180 μm | 64.5 ± 2.1 |

| ∆x = 280 μm | 113.4 ± 1.9 |

| Ecorr (mV) | Icorr (uA) | vcorr (um/year) | |

|---|---|---|---|

| As-received | −647 ± 5 | 2.1 ± 0.5 | 18.7 ± 0.7 |

| ∆x = 100 µm | −283 ± 2 | 1.2 ± 0.4 | 10.8 ± 0.6 |

| ∆x = 180 µm | −325 ± 3 | 0.6 ± 0.2 | 5.8 ± 0.4 |

| ∆x = 280 µm | −238 ± 2 | 0.5 ± 0.2 | 4.6 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conradi, M.; Kocijan, A.; Klobčar, D.; Godec, M. Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals 2020, 10, 1504. https://doi.org/10.3390/met10111504

Conradi M, Kocijan A, Klobčar D, Godec M. Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals. 2020; 10(11):1504. https://doi.org/10.3390/met10111504

Chicago/Turabian StyleConradi, Marjetka, Aleksandra Kocijan, Damjan Klobčar, and Matjaž Godec. 2020. "Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V" Metals 10, no. 11: 1504. https://doi.org/10.3390/met10111504

APA StyleConradi, M., Kocijan, A., Klobčar, D., & Godec, M. (2020). Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals, 10(11), 1504. https://doi.org/10.3390/met10111504