Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

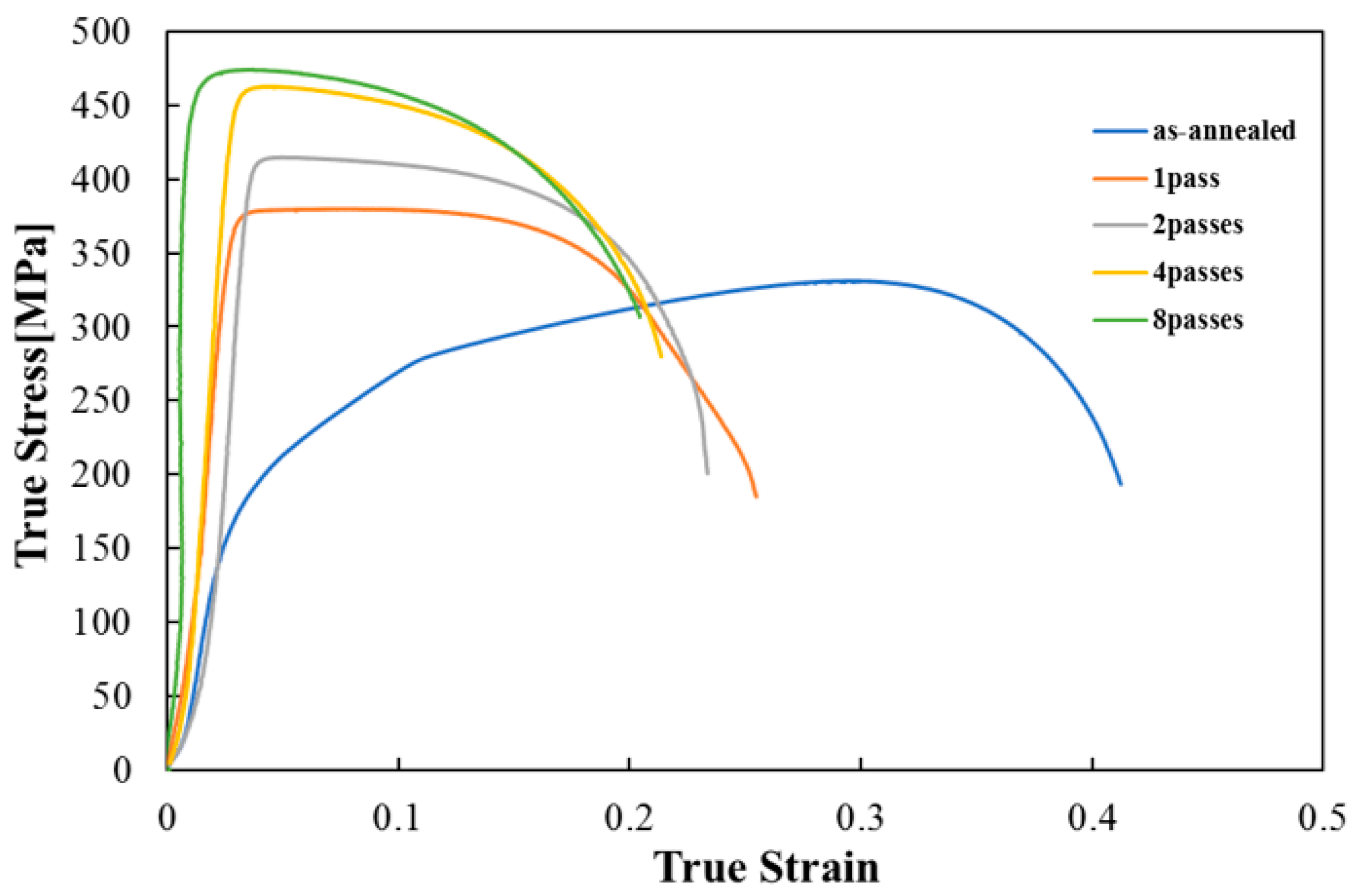

3.1. Microstructures and Tensile Properties of Ultrafine Grained Copper

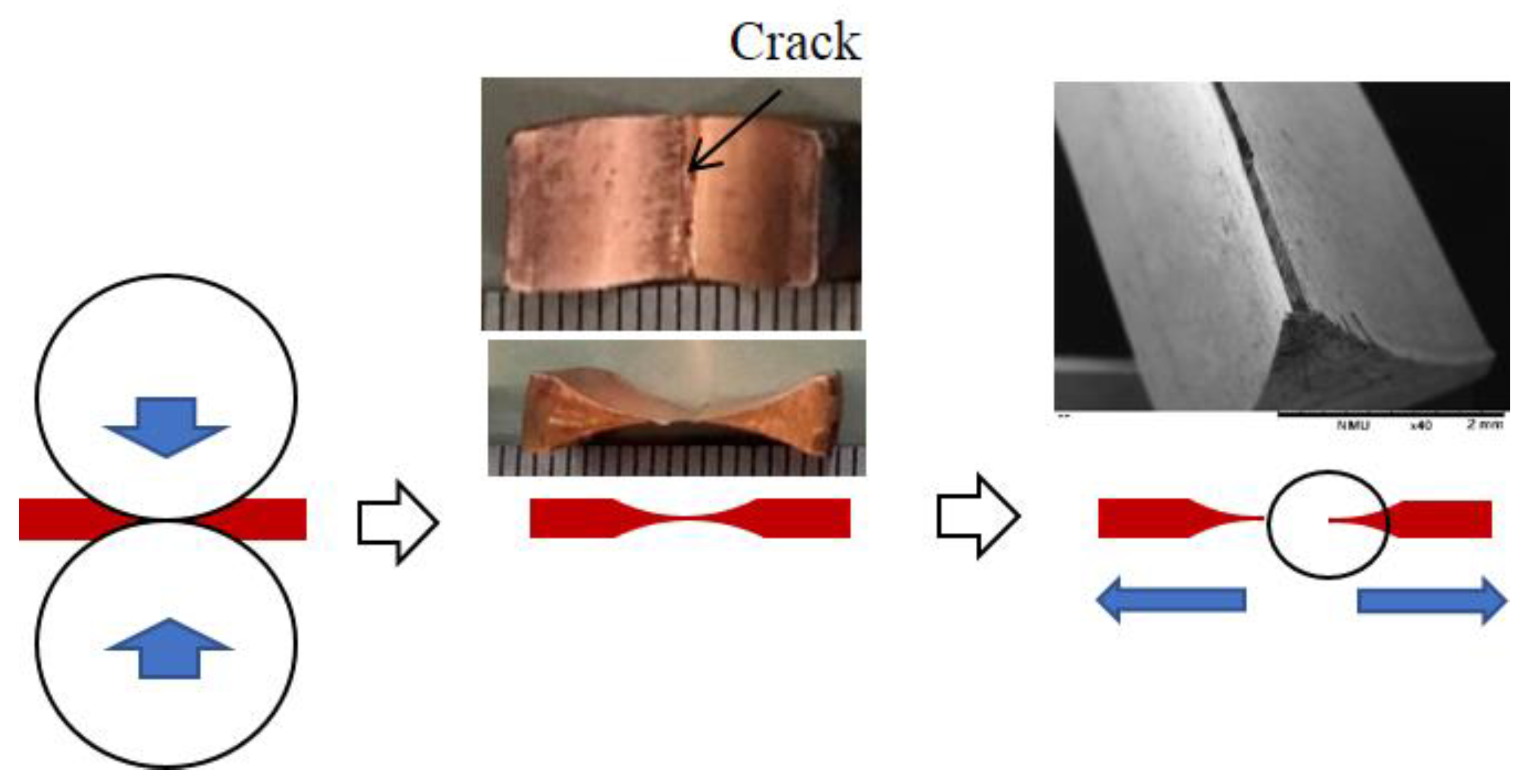

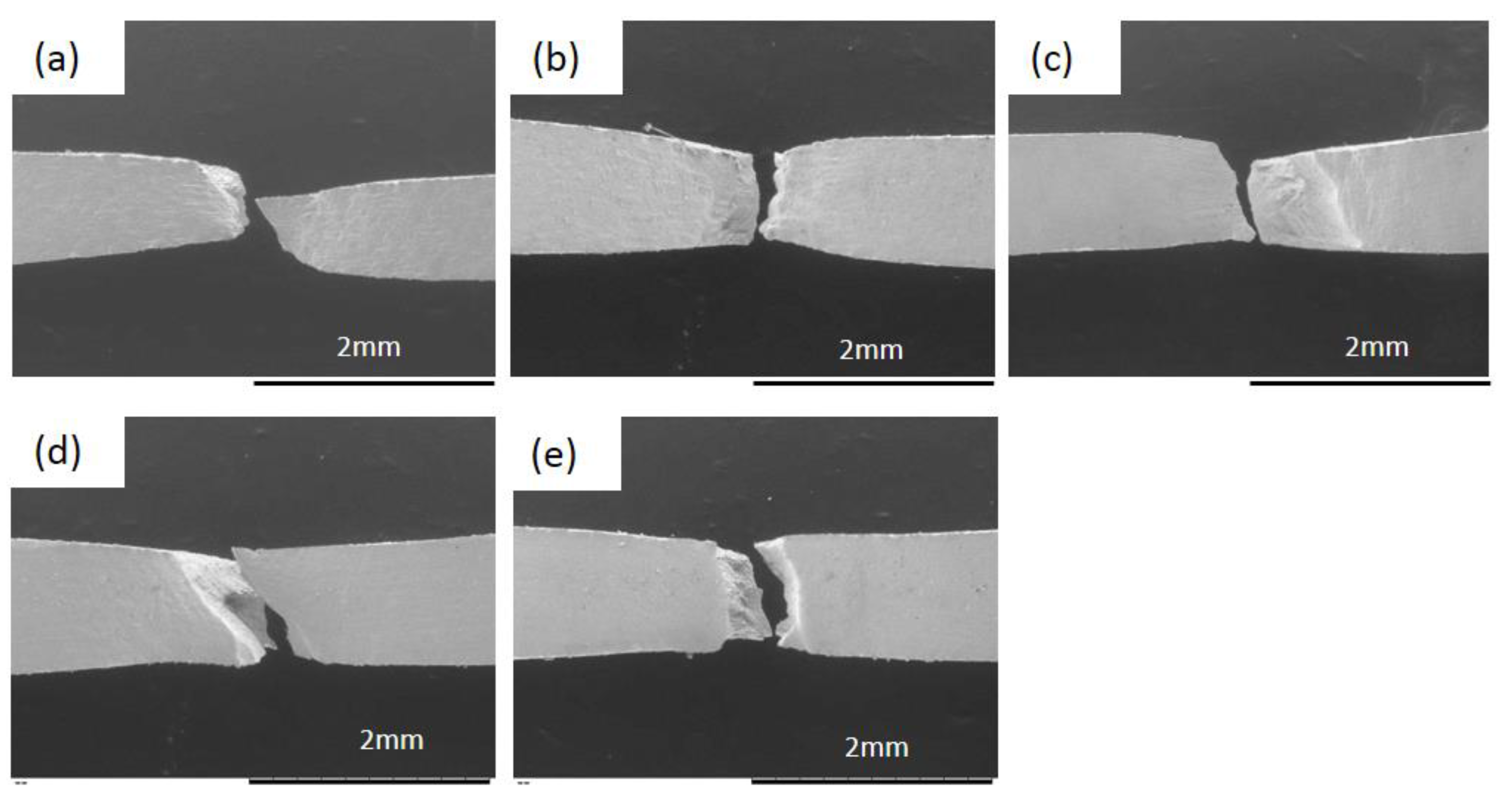

3.2. Compression Test and Parallel Round-Bar Compression Test

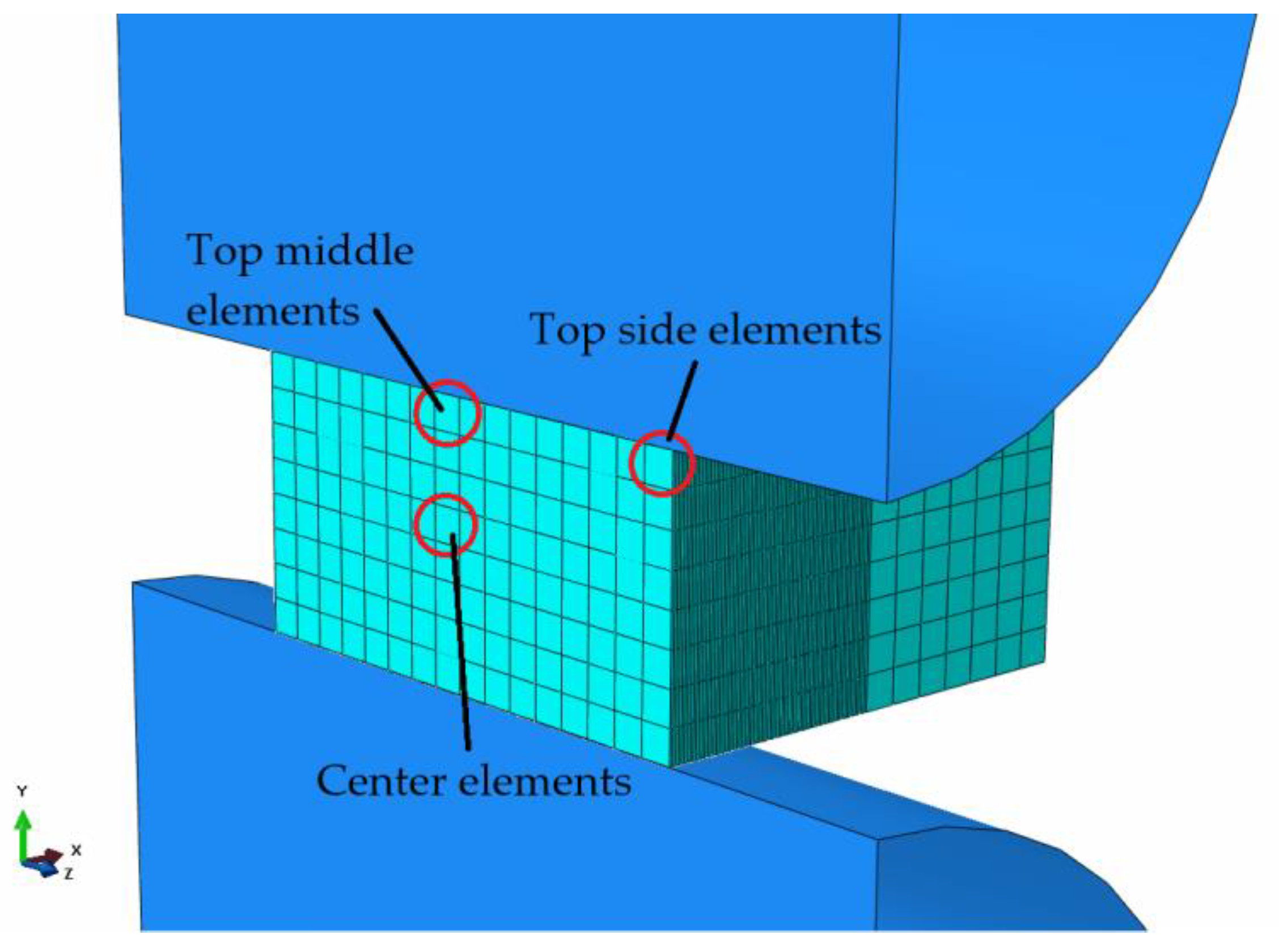

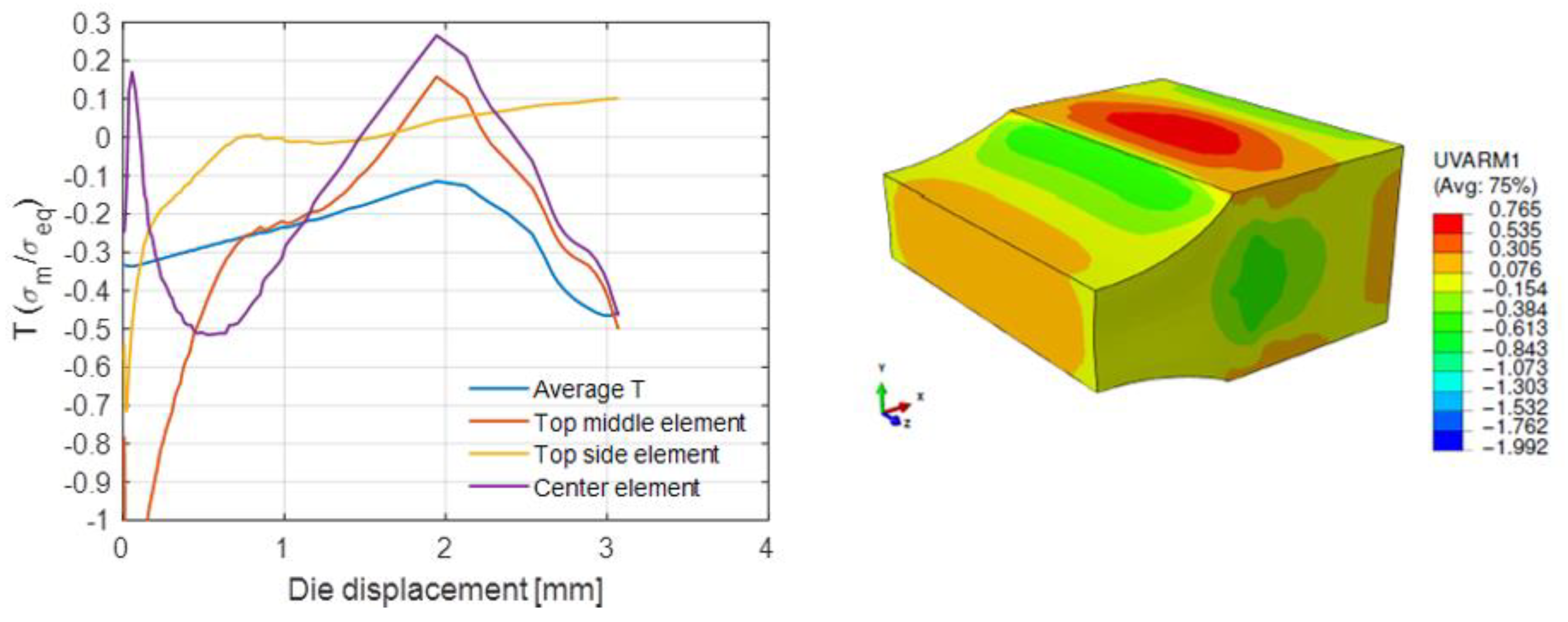

3.3. Finite Element Method Simulation

4. Conclusions

- Flow stress during tensile and compression tests increased with the increasing number of ECAP passes, up to eight passes. Strain-hardening capability was reduced with increasing ECAP passes. Elongation to failure was greatly reduced after one pass, but further reduction with additional passes was small until eight passes. Reduced uniform elongation due to reduced strain hardening with increasing number of passes was compensated by increasing post-necking local elongation.

- During compression tests, grain shape change was very small in UFG copper pressed using eight passes compared with as-annealed and other (one to four passes) samples. This confirms that the deformation mechanism is grain boundary-mediated plasticity accompanying grain boundary sliding and rotation, which has been suggested to operate in UFG materials. This may explain the limited strain hardening observed in the compression tests.

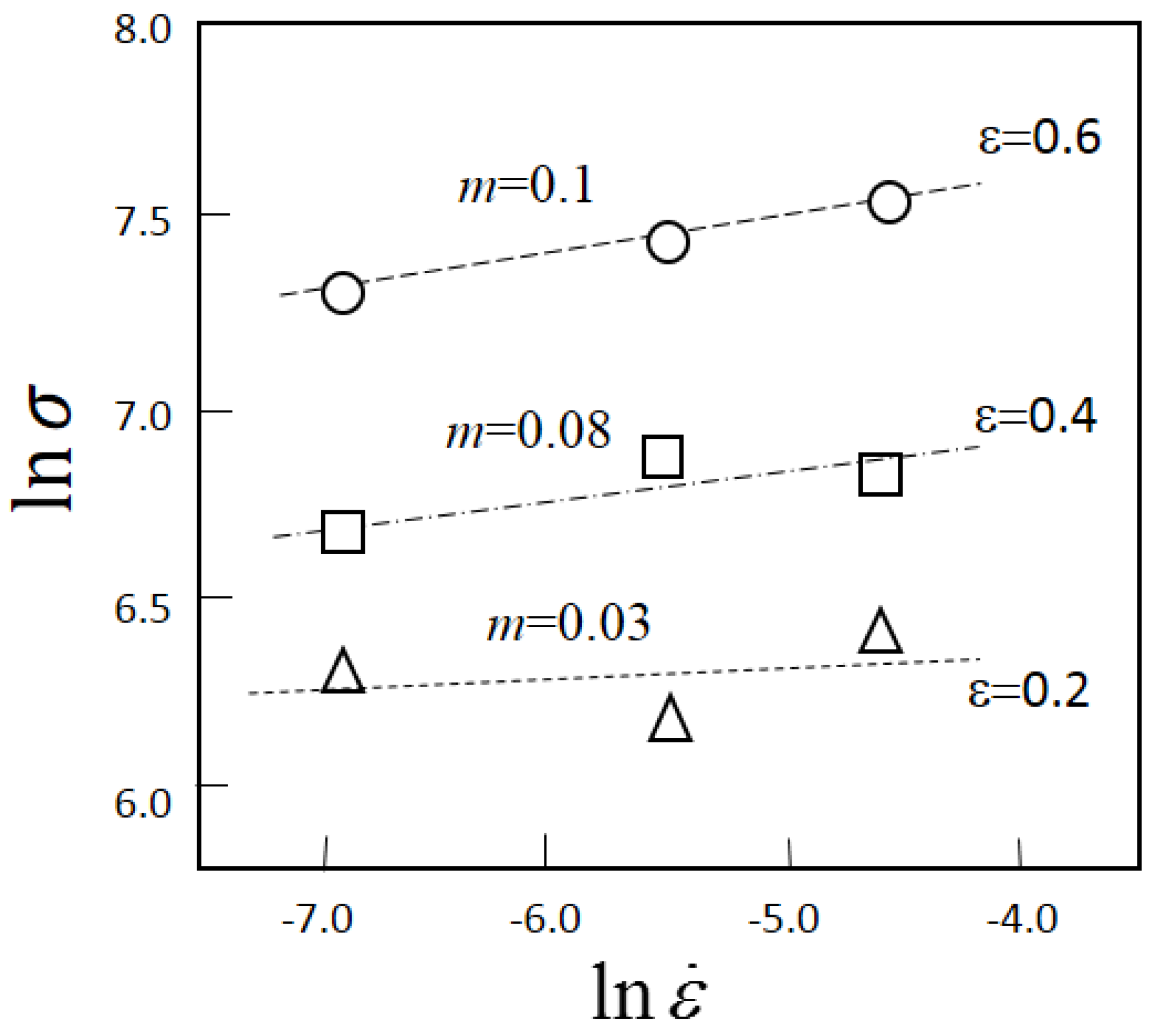

- Superior or comparable compressive ductility of UFG copper to as-annealed copper was revealed in the compression tests using the parallel round bars. UFG materials that are deformed by the grain boundary-mediated plasticity with no or limited strain hardening have high tolerance to damage accumulation and higher malleability under a preferable stress state for shear deformation. The viscous superplastic nature of a high m-value is not necessarily involved in the high compressive ductility.

Author Contributions

Funding

Conflicts of Interest

References

- Valiev, R.; Islamgaliev, R.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Miyamoto, H.; Erb, U.; Koyama, T.; Mimaki, T.; Vinogradov, A.; Hashimoto, S. Microstructure and texture development of copper single crystals deformed by equal-channel angular pressing. Philos. Mag. Lett. 2004, 84, 235–243. [Google Scholar] [CrossRef]

- Miyamoto, H.; Fushimi, J.; Mimaki, T.; Vinogradov, A.; Hashimoto, S. The Effect of the Initial Orientation on Microstructure Development of Copper Single Crystals Subjected to Equal-Channel Angular Pressing. Mater. Sci. Forum 2006, 503, 799–804. [Google Scholar] [CrossRef]

- Zhao, Y.-H.; Bingert, J.F.; Liao, X.-Z.; Cui, B.-Z.; Han, K.; Sergueeva, A.V.; Mukherjee, A.K.; Valiev, R.Z.; Langdon, T.G.; Zhu, Y.T. Simultaneously Increasing the Ductility and Strength of Ultra-Fine-Grained Pure Copper. Adv. Mater. 2006, 18, 2949–2953. [Google Scholar] [CrossRef]

- Miyamoto, H.; Harada, K.; Mimaki, T.; Vinogradov, A.; Hashimoto, S. Corrosion of ultra-fine grained copper fabricated by equal-channel angular pressing. Corros. Sci. 2008, 50, 1215–1220. [Google Scholar] [CrossRef]

- Miyamoto, H. Corrosion of Ultrafine Grained Materials by Severe Plastic Deformation, an Overview. Mater. Trans. 2016, 57, 559–572. [Google Scholar] [CrossRef]

- Yalçinkaya, T.; Şimşek, Ü.; Miyamoto, H.; Yuasa, M. Numerical Analysis of a New Nonlinear Twist Extrusion Process. Metals 2019, 9, 513. [Google Scholar] [CrossRef]

- Bagherpour, E.; Qods, F.; Ebrahimi, R.; Miyamoto, H. Nanostructured pure copper fabricated by simple shear extrusion (SSE): A correlation between microstructure and tensile properties. Mater. Sci. Eng. A 2017, 679, 465–475. [Google Scholar] [CrossRef]

- Łyszkowski, R.; Łazińska, M.; Zasada, D. The Influence of a Cross-Channel Extrusion Process on the Microstructure and Properties of Copper. Materials 2019, 12, 3995. [Google Scholar] [CrossRef]

- Orlowska, M.; Olejnik, L.; Lewandowska, M. The influence of an ECAP-based deformation process on the microstructure and properties of electrolytic tough pitch copper. J. Mater. Sci. 2017, 53, 3862–3875. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Alexandrov, I.V.; Zhu, Y.T.; Lowe, T.C. Paradox of strength and ductility in metals processed by severe plastic deformation. J. Mater. Res. 2002, 17, 5–8. [Google Scholar] [CrossRef]

- Ma, E. Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM J. Miner. Met. Mater. Soc. 2006, 58, 49–53. [Google Scholar] [CrossRef]

- Koch, C. Optimization of strength and ductility in nanocrystalline and ultrafine grained metals. Scr. Mater. 2003, 49, 657–662. [Google Scholar] [CrossRef]

- Koch, C.; Morris, D.; Lu, K.; Inoue, A. Ductility of Nanostructured Materials. MRS Bull. 1999, 24, 54–58. [Google Scholar] [CrossRef]

- Kumar, P.; Kawasaki, M.; Langdon, T.G. Review: Overcoming the paradox of strength and ductility in ultrafine-grained materials at low temperatures. J. Mater. Sci. 2016, 51, 7–18. [Google Scholar] [CrossRef]

- Considere, A. Memoire sur l’emploi du fer et de l’acier dans les constructions. Ann. Ponts Chaussees 1885, 9, 574–575. [Google Scholar]

- Wang, Y.M.; Ma, E.; Chen, M.W. Enhanced tensile ductility and toughness in nanostructured Cu. Appl. Phys. Lett. 2002, 80, 2395–2397. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Hoseini, S.H.; Khalilpourazary, S.; Zadshakoyan, M. Fracture Behavior of Annealed and Equal Channel Angular Pressed Copper: An Experimental Study. J. Mater. Eng. Perform. 2020, 29, 975–986. [Google Scholar] [CrossRef]

- Lu, L.; Sui, M.L.; Lu, K. Superplastic Extensibility of Nanocrystalline Copper at Room Temperature. Science 2000, 287, 1463–1466. [Google Scholar] [CrossRef]

- Talebanpour, B.; Ebrahimi, R.; Janghorban, K. Microstructural and mechanical properties of commercially pure aluminum subjected to Dual Equal Channel Lateral Extrusion. Mater. Sci. Eng. A 2009, 527, 141–145. [Google Scholar] [CrossRef]

- Sabirov, I.; Barnett, M.; Estrin, Y.; Hodgson, P. The effect of strain rate on the deformation mechanisms and the strain rate sensitivity of an ultra-fine-grained Al alloy. Scr. Mater. 2009, 61, 181–184. [Google Scholar] [CrossRef]

- El-Danaf, E.; Soliman, M.; Almajid, A.; El-Rayes, M. Enhancement of mechanical properties and grain size refinement of commercial purity aluminum 1050 processed by ECAP. Mater. Sci. Eng. A 2007, 458, 226–234. [Google Scholar] [CrossRef]

- Blum, W.; Li, Y.; Zhang, Y.; Wang, J. Deformation resistance in the transition from coarse-grained to ultrafine-grained Cu by severe plastic deformation up to 24 passes of ECAP. Mater. Sci. Eng. A 2011, 528, 8621–8627. [Google Scholar] [CrossRef]

- El-Danaf, E.A. Mechanical properties and microstructure evolution of 1050 aluminum severely deformed by ECAP to 16 passes. Mater. Sci. Eng. A 2008, 487, 189–200. [Google Scholar] [CrossRef]

- Hockauf, M.; Meyer, L.W. Work-hardening stages of AA1070 and AA6060 after severe plastic deformation. J. Mater. Sci. 2010, 45, 4778–4789. [Google Scholar] [CrossRef]

- May, J.; Hoppel, H.W.; Goken, M. Strain rate sensitivity of ultrafine-grained aluminum processed by severe plastic deformation. Scr. Mater. 2005, 53, 189–194. [Google Scholar] [CrossRef]

- Valiev, R.; Kozlov, E.; Ivanov, Y.; Lian, J.; Nazarov, A.; Baudelet, B. Deformation behaviour of ultra-fine-grained copper. Acta Met. Mater. 1994, 42, 2467–2475. [Google Scholar] [CrossRef]

- Han, B.Q.; Mohamed, F.A.; Lavernia, E.J. Mechanical properties of iron processed by severe plastic deformation. Met. Mater. Trans. A 2003, 34, 71–83. [Google Scholar] [CrossRef]

- Reihanian, M.; Ebrahimi, R.; Tsuji, N.; Moshksar, M. Analysis of the mechanical properties and deformation behavior of nanostructured commercially pure Al processed by equal channel angular pressing (ECAP). Mater. Sci. Eng. A 2008, 473, 189–194. [Google Scholar] [CrossRef]

- Long, F.-W.; Jiang, Q.-W.; Xiao, L.; Li, X.-W. Compressive Deformation Behaviors of Coarse- and Ultrafine-Grained Pure Titanium at Different Temperatures: A Comparative Study. Mater. Trans. 2011, 52, 1617–1622. [Google Scholar] [CrossRef]

- Meyers, M.A. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Fleck, N.A.; Hutchinson, J.W.; Bilby, B.A. Void growth in shear. Proc. R. Soc. Lond. A Math. Phys. Sci. 1986, 407, 435–458. [Google Scholar]

- Xu, C.; Furukawa, M.; Horita, Z.; Langdon, T.G. The evolution of homogeneity and grain refinement during equal-channel angular pressing: A model for grain refinement in ECAP. Mater. Sci. Eng. A 2005, 398, 66–76. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. Factors influencing the equilibrium grain size in equal-channel angular pressing: Role of Mg additions to aluminum. Met. Mater. Trans. A 1998, 29, 2503–2510. [Google Scholar] [CrossRef]

- Horita, Z.; Fujinami, T.; Nemoto, M.; Langdon, T.G. Equal-channel angular pressing of commercial aluminum alloys: Grain refinement, thermal stability and tensile properties. Met. Mater. Trans. A 2000, 31, 691–701. [Google Scholar] [CrossRef]

- Huang, C.-X.; Hu, W.; Yang, G.; Zhang, Z.; Wu, S.; Wang, Q.; Gottstein, G. The effect of stacking fault energy on equilibrium grain size and tensile properties of nanostructured copper and copper–aluminum alloys processed by equal channel angular pressing. Mater. Sci. Eng. A 2012, 556, 638–647. [Google Scholar] [CrossRef]

- Torre, F.D.; Lapovok, R.; Sandlin, J.; Thomson, P.; Davies, C.; Pereloma, E. Microstructures and properties of copper processed by equal channel angular extrusion for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Szommer, P.; Horita, Z.; Langdon, T.G. Experimental Evidence for Grain-Boundary Sliding in Ultrafine-Grained Aluminum Processed by Severe Plastic Deformation. Adv. Mater. 2006, 18, 34–39. [Google Scholar] [CrossRef]

- Torre, F.D.; Pereloma, E.; Davies, C. Strain hardening behaviour and deformation kinetics of Cu deformed by equal channel angular extrusion from 1 to 16 passes. Acta Mater. 2006, 54, 1135–1146. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press (CUP): Cambridge, UK, 1997; pp. 1–125. [Google Scholar]

- Łyszkowski, R.; Bystrzycki, J. Hot deformation and processing maps of a Fe–Al intermetallic alloy. Mater. Charact. 2014, 96, 196–205. [Google Scholar] [CrossRef]

| Pass Number | to (mm) | tf (mm) | εf |

|---|---|---|---|

| 0 | 4.0 | 0.25 | 2.80 |

| 1 | 4.0 | 0.025 | 5.07 |

| 2 | 4.0 | 0.03 | 4.89 |

| 4 | 4.0 | 0.035 | 4.74 |

| 8 | 4.0 | 0.030 | 4.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asano, M.; Yuasa, M.; Miyamoto, H.; Tanaka, T.; Erdogan, C.; Yalçinkaya, T. Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation. Metals 2020, 10, 1503. https://doi.org/10.3390/met10111503

Asano M, Yuasa M, Miyamoto H, Tanaka T, Erdogan C, Yalçinkaya T. Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation. Metals. 2020; 10(11):1503. https://doi.org/10.3390/met10111503

Chicago/Turabian StyleAsano, Mayu, Motohiro Yuasa, Hiroyuki Miyamoto, Tatsuya Tanaka, Can Erdogan, and Tuncay Yalçinkaya. 2020. "Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation" Metals 10, no. 11: 1503. https://doi.org/10.3390/met10111503

APA StyleAsano, M., Yuasa, M., Miyamoto, H., Tanaka, T., Erdogan, C., & Yalçinkaya, T. (2020). Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation. Metals, 10(11), 1503. https://doi.org/10.3390/met10111503