Abstract

The influence of complex thermo-mechanical processing (TMP) on the mechanical properties of a Ti-Nb-Zr-Fe-O bio-alloy was investigated in this study. The proposed TMP program involves a schema featuring a series of severe plastic deformation (SPD) and solution treatment (STs). The purpose of this study was to find the proper parameter combination for the applied TMP and thus enhance the mechanical strength and diminish the Young’s modulus. The proposed chemical composition of the studied β-type Ti-alloy was conceived from already-appreciated Ti-Nb-Ta-Zr alloys with high β-stability by replacing the expensive Ta with more accessible Fe and O. These chemical additions are expected to better enhance β-stability and thus avoid the generation of ω, α’, and α” during complex TMP, as well as allow for the processing of a single bcc β-phase with significant grain diminution, increased mechanical strength, and a low elasticity value/Young’s modulus. The proposed TMP program considers two research directions of TMP experiments. For comparisons using structural and mechanical perspectives, the two categories of the experimental samples were analyzed using SEM microscopy and a series of tensile tests. The comparison also included some already published results for similar alloys. The analysis revealed the advantages and disadvantages for all compared categories, with the conclusions highlighting that the studied alloys are suitable for expanding the database of possible β-Ti bio-alloys that could be used depending on the specific requirements of different biomedical implant applications.

1. Introduction

Good biomedical materials for orthopedic implants with long-term service need a combination of a low Young’s modulus, close proximity to the human bone, and high strength to avoid the known “stress shielding effect” [1,2,3,4,5]. Among many investigated biocompatible materials, non-cytotoxic β-Ti alloys have been developed in recent decades [6,7,8,9,10,11,12,13], as these alloys have the most attractive combination of a low Young’s modulus, high mechanical strength, and high ductility. This property combination can also ensure good processability (i.e., plastic deformation, machinability, welding, etc.) and good tribological characteristics, all of which are necessary for the long-term dimensional stability of an implant [14]. Compared to other possible Ti-bio-alloys, such as the frequently used (α) or (α + β) types, the special advantage of β-type Ti-alloys is their lower Young’s modulus (45–65 GPa) [2,4,15,16,17]. Beta-Ti alloys are also reported to exhibit high fracture toughness [18] and a good response to heat treatment if the alloying is achieved using suitable β-stabilizing chemical elements [5,19,20,21], such as non-toxic Nb, Ta, Mo, and Zr [22,23,24]. Ti-Nb-Ta-Zr (TNTZ) alloys are highly regarded [25,26,27,28,29,30] because of their suitable combination of functional properties, both mechanical and biomedical. However, they exhibit some disadvantages, such as a much higher melting point of Ta compared to other related alloying elements (TtopTa = 2996 °C, TtopNb = 2468 °C, TtopZr = 1855 °C, TtopTi = 1660 °C), which decreases the casting alloy characteristics. Even though Nb also has a high melting point compared to Ti and Zr, it is still indispensable due to its strong β-stabilizing characteristics. In addition, Ta is an expensive chemical element [6]. Therefore, efforts have been made to replace Ta with more accessible Fe and O [31,32,33,34,35,36]. Fe is selected not only for economic considerations but also because it is a strong β stabilizer [37,38]. It was shown that the Young’s modulus (E) can be reduced to 91 GPa by adding Fe [38], which is slightly lower than the E value for commonly used α/β Ti-64 (~110 GPa [39]) but higher than the E of cortical bone (~30 GPa) [1]. Similar results were reported in [40,41,42,43,44]. Oxygen, despite not being a β stabilizing element [20,21], may hamper the formation of α″ [1,2]. Recent research found that by adding oxygen to β-Ti alloys, both strength and ductility can be improved simultaneously [43,44]. Moreover, Fe and interstitial oxygen are beneficial for improving mechanical properties through solid-solution strengthening [18,31,32,33]. Therefore, both Fe and O are attractive elements for the development of high-strength and low-Young’s-modulus β-Ti alloys.

Apart from the chemical composition being an important factor for enhancing the mechanical properties in β-Ti alloys, thermo-mechanical processing (TMP) is also a very important way to decrease the Young’s modulus and increase the mechanical strength of β-Ti alloys [14,45]. The applied TMP can involve a combination of severe plastic deformations (SPD) and solution treatments (STs) to achieve grain refinement featuring ultra-fine or even nano-meter grain dimensions. Through this, the mechanical strength can increase significantly, and the Young’s modulus can decrease. For example, Bertrand et al. [46] reported a very low Young’s modulus for a Ti-25Ta-25Nb alloy (55 GPa, one of the lowest values for a β-Ti alloy) developed via TMP; the objective of the applied treatment (cold rolling + solution treatment) was to restore a fully recrystallized β phase microstructure from the cold rolled state using a decreased β grain size and a low Young’s modulus.

Previous studies on TNTZ-Fe-O alloys [31,32,33,47,48] provided valuable information for developing novel alloys by tuning the composition and processing parameters to obtain the best mechanical and biomedical properties suitable for medical implants. These reports refer to alloys in a cold-rolling (CR) state or after a CR + ST combination, for which the Young’s modulus can vary between 60 and 107 GPa, and the ultimate tensile strength-UTS can vary between 903 and 1370 MPa. The intent of the present work is also to elaborate a complex TMP program applied to a particular chemical composition from the TNTZ-Fe-O family-alloy (but without Ta and with Fe and O) to find a better combination of TMP parameters coupled with a suitable chemical composition and ultimately obtain better mechanical properties than those reported previously. Thus, a chemical composition of the Ti-Nb-Zr-Fe-O alloy was proposed for investigation, with sufficient β-stabilizing elements to obtain a stable β-Ti alloy. On the other hand, the proposed TMP program contains two distinct directions: One is formed from a CR series with a gradual increase in the applied deformation degree, coupled with an ST series featuring variable parameters; the second one combines a series of severe plastic deformation (SPD) and ST, both in the effort to achieve evident grain refinement. Thus, both previously reported modalities for increasing the strength of β-Ti alloys will be applied [49,50,51], including the addition of Fe and O and a complex TMP program with variable processing parameters. The experimental results will be compared with those reported in [31,32,33,47,48] by highlighting the advantages and disadvantages of the results obtained for the proposed alloy and corresponding TMP parameters. At the same time, the proposed investigations seek to describe the relationship between the microstructure and mechanical properties of this alloy under different heat treatment conditions. Alongside this main objective, the intention is also to enlarge the database of possible β-Ti bio-alloys, depending on the specific requirements of different implant applications.

2. Materials and Methods

2.1. Synthesis of the Studied Alloy

The nominal new chemical composition for the studied alloy, Table 1, is as follows:

Table 1.

The chemical composition of the studied alloy (wt.%).

This alloy was obtained using a levitation induction melting furnace FIVE CELES-MP25 with a nominal power of 25 kW and a melting capacity of 30 cm3 in a high vacuum of 10−4–10−5 mbar. The alloy synthesis was conducted with an intense agitation of the melted alloy. The ingots were re-melted twice to achieve a high degree of chemical homogeneity.

2.2. Thermomechanical Processing Program of the New β-Ti Alloy

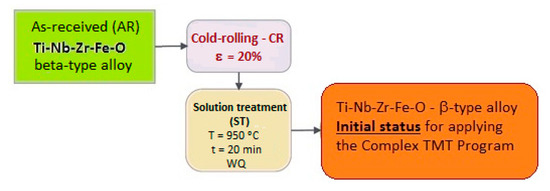

After the alloy synthesis and before the complex TMP program, the as-cast alloy was treated to obtain a quality-homogenised precursor (Figure 1). The applied treatment consisted of (a) Cold Rolling (CR) with a relative reduction of ε = 20% using a Mario di Maio LQR120AS rolling-mill (Mario di Maio Inc., Milano, Italy) with a 3 m/min rolling speed and no lubrication; before the CR process, the sample was cleaned using an ultrasonic bath at 60 °C in ethylic alcohol; (b) a Homogenization Treatment (HT) at 1223 K/950 °C (above the β-transus temperature) with a holding time of 20 min. and water quenching (w.q.) using a GERO SR 100 × 500 type oven (Carbolite-Gero Inc., Neuhausen, Germany) under a high vacuum. The final obtained homogenised alloy was named “the initial alloy” and was processed by a complex TMP program.

Figure 1.

Schema for processing the as-cast sample to obtain a quality homogenised precursor named the initial alloy.

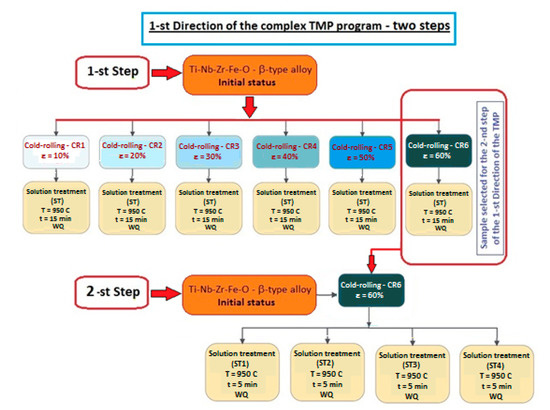

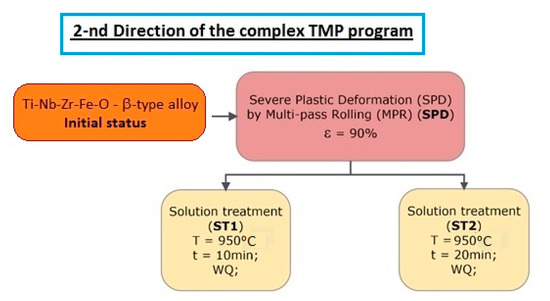

This program was structured and applied to two different research directions on a batch/group of samples obtained from the initial alloy (Figure 2 and Figure 3). These two categories of samples were processed with different thermo-mechanical parameters for the final analysis, comparison, and recommendations for potential selection/application.

Figure 2.

The 1st Direction of the complex TMP Program applied to the studied β-type Ti-Nb-Zr-Fe-O alloy.

Figure 3.

The 2nd Direction of the complex TMP Program applied to the studied β-type Ti-Nb-Zr-Fe-O alloy.

The first direction (Figure 2) included a two-step process: (1) The first step consisted of various CR cycles followed by identical STs for all CR samples—1223 K/15 min./w.q. CR was applied to six distinct samples with the initial state using six different total deformation degrees: εtot = 10%—1 pass; εtot = 20%—2 passes; εtot = 30%—3 passes; εtot = 40%—4 passes; εtot = 50%—5 passes; εtot = 60%—6 passes. (2) For the second step, from the six variants that were experimented on, the one with ((εtot = 60%) + ST) was selected, as it presented the smallest grain size. Four STs were applied to this selected sample after cold-rolling (εtot = 60%—6 passes) for different times of 5, 10, 15, and 20 min, while the other parameters remained unchanged.

The second direction (Figure 3) includes severe plastic deformation (SPD) using the multi-pass rolling (MPR) method, followed by two different STs. MPR processing was performed using 10 rolling passes with εtot = 90%. The two variants of the ST consisted of the same heating temperature (1223 K/950 °C) and cooling medium (water) but two distinct holding times (10 min. and 20 min.). All STs were performed using a GERO SR 100 × 500-type oven with a high vacuum—the same as that used for the initial treatment.

2.3. Micro-Structural and Mechanical Analysis of the Alloy Samples

A Metkon MICRACUT 200 type machine (Metkon Instruments Inc., Bursa, Turkey) with diamond cutting disks was used for cutting. The specimens were then fixed on a specific epoxy resin of a Buehler Sampl-Kwick type, abraded with 1200 grit SiC paper using a Metkon Digiprep ACCURA machine (Metkon Instruments Inc., Bursa, Turkey), and then mechanically polished using 6, 3, and 1 μm diamond paste and 0.03 μm colloidal silica on a Buehler VibroMet2 machine (Buehler Ltd., Lake Bluff, IL, USA).

The SEM images and analysis were realized using a scanning electron microscope—a TESCAN VEGA II—XMU (Tescan Orsay Holding, a.s., Brno, Czech Republic). The CR- and SPD-processed samples were examined mainly in the RD–ND cross-section (RD—rolling direction; ND—normal direction) to observe the grain deformation/texture degree evolution. To highlight the main microstructural characteristics, only the most representative images were selected.

The tensile tests, performed on the final states from both research directions, were achieved in the RD using a Gatan MicroTest-2000N-type machine (Gatan Inc., Pleasanton, CA, USA) with a strain rate of 1 × 10−4 s−1. Based on the obtained data, the following average values of the mechanical characteristics were determined: the ultimate tensile strength (σUTS); yield strength (σ0.2); the elongation to fracture (εf); and the elastic modulus (E). The standard deviation (SD) was also calculated.

3. Results

3.1. Micro-Structural Analysis of the As-Cast and Homogenized Sample, Named the Initial State

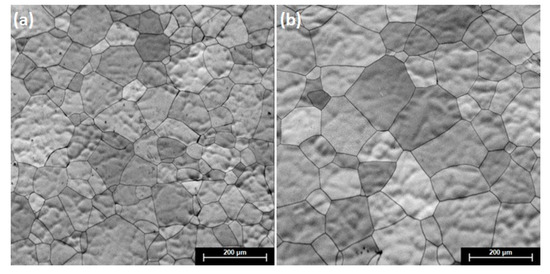

The structures corresponding to the cast sample and the homogenized sample (by applying CR + HT) are indicated in Figure 4. Due to consistent β-stabilizing alloying elements (~42% in total, excluding oxygen), the alloy’s structure was formed from only β-phase grains with an equiaxe shape. The measured average dimensions of the β grains were 121 μm for the as-cast sample and slightly larger for the homogenized sample (145 μm) due to grain growing during the applied heat treatment.

Figure 4.

The SEM images of the Ti-Nb-Zr-Fe-O alloy microstructures in: (a) the as-cast state; (b) after the homogenisation treatment—named the initial state.

In metastable β-type Ti alloys, it is already known that the ω, α’, and α” phases can be produced in the β matrix as a result of cold plastic deformation [52,53,54,55]. These phases are detrimental to the formability of the material, making it difficult to process. Therefore, the interest lies in designing β-Ti-type alloys containing a sufficient quantity of alloying elements with β-stabilizing characteristics. For that purpose, the main β-stabilizing element—Nb—should be no less than 35–38% to ensure good stability of the β phase in binary Ti-Nb alloys (see Hu et al. [56]). For this study, besides high Nb content (34.1 wt.%), the addition of Fe and Zr was considered, as both elements are reported to be effective for solid solution strengthening, while also playing a very important role from the perspective of β-phase stability by suppressing the generation of α’ and ω and by shifting the martensite starting temperature (Ms) to a lower one [47]. Fe also is a strong β stabilizer [37], and Zr, despite being considered by some reports to be a neutral element from a β-stabilization perspective [57], has been demonstrated by others to be beneficial for β-Ti-alloys because it suppresses the nucleation of isothermal ω [6] and also decreases the Ms temperature [58]. Therefore, it can be presumed that the absence of the ω, α’, and α” phases may be a consequence of the combined stabilization of the β-phase under all the added alloying elements (~42%), a fact also reported in [4,59,60]. It can be also presumed that the design of the chemical composition of the studied alloy achieved the initially stated goal—obtaining a single β-phase for safe and easy mechanical processing. However, this assertion should be taken only as probably because, to prove the absence of the above secondary phases, a detailed XRD analysis should be performed, which represents a future objective for the following stages of this research work.

3.2. Micro-Structural and Mechanical Analysis of the Samples Processed by the First Direction of the TMP Program

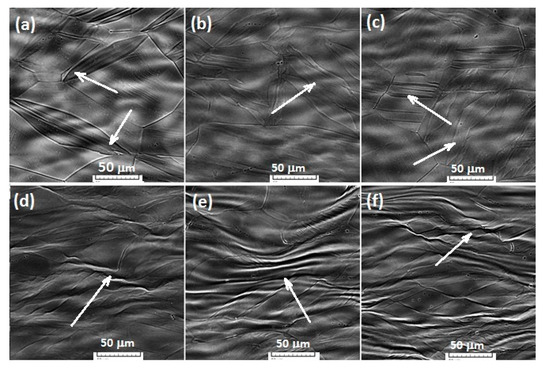

Following the first direction schema of the TMP Program, a series of samples was processed by CR with different deformation degrees from εtot = 10% to εtot = 60% (Figure 2). Figure 5 shows the obtained microstructures. It can be observed that the β grains lengthened in the rolling direction step-by-step from sample to sample due to the increase in the applied total deformation degree. It can also be observed that the deformation products became increasingly visible and pronounced with an increase of the deformation degree (Figure 5a–c). These deformation products seemed to be kink bands, twin bands, or even shear bands [4], depending on the opening/value of the misorientation angle, which were smaller or larger between the β matrix and these deformation products. For example, if the misorientation angles between the kink bands and the β matrix for the Ti-22.4Nb-0.73Ta-2Zr-1.34O alloy during its compression straining, as reported by Yang et al. [59], are between 10–30°, the visible deformation products of the band-types in Figure 5a (CR at 10%) with similar misorientation angles can also be considered kink bands. Further, in Figure 5b,c, the misorientation angle increases between 50–55°. Since the misorientation angle between the {332} <113> β-mechanical twins and the β matrix is 50.5° in the <110> β direction [61], it can be presumed that, for the present case, the deformation products are evolving gradually from kink to twin bands (white arrows on the images). Concerning increases in the misorientation angle with an increase in plastic deformation, similar research results were reported for other β-Ti alloys [52,53]. Generally, it is already known that the twining phenomenon facilitates subsequent grain fragmentation/refinement during plastic deformation process development [62,63,64,65]. For this study, Figure 5b,c show the gradual grain refinement as a function of an increase in the deformation degree. In addition to this grain fragmentation, the structure acquires a clear textured appearance (Figure 5d,f); these last three images show the formation of shear bands due to severe deformation degrees, which were also reported in [59,64] for other similar β-type Ti-alloys.

Figure 5.

The SEM images of the Cold Rolling (CR) processed samples from the 1st step of the 1st direction of the TMP Program: (a) CR—εtot = 10%; (b) CR—εtot = 20%; (c) CR—εtot = 30%; (d) CR—εtot = 40%; (e) CR—εtot = 50%; (f) CR—εtot = 60%.

From Figure 5, it can also be observed that the shear bands are not homogeneously distributed and have a wavy shape. This wavy shape of the slip bands is reported to be typical for bcc metals [38], as in our case. Shear bands are considered to be formed from rotated and severely distorted crystals due to the localization/accumulation of a mass of shear stress on a slip plane [59].

In this study, the process starting with kinking, passing through {332} <113> β-mechanical twinning, and arriving to shear band formations provides the most probable deformation products that will gradually facilitate alloy deformation and texture during CR as the degree of deformation increases. However, this assertion will also have to be proven by a future XRD/TEM analysis, as noted previously.

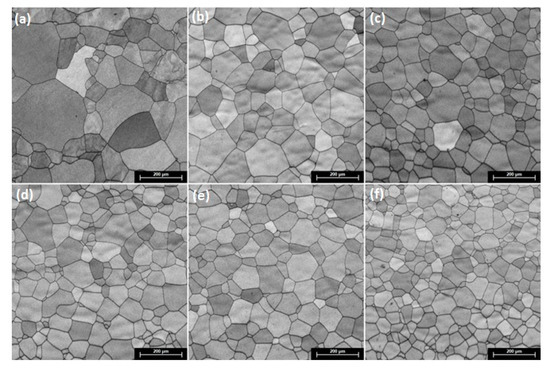

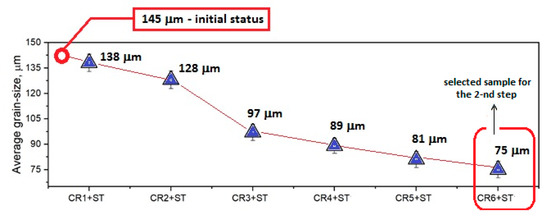

After applying the same ST for all six CRed samples (Figure 2), the β-grains again became equiaxe (Figure 6), but with the grain size decreasing steadily depending on the ascending degree of the deformation that was previously applied. This decreasing phenomenon of the grain size is proven once again in Figure 7, which shows the measured average values of the obtained β-grains from 138 μm corresponding to the sample (CR1 + ST) and those at 75 μm corresponding to the sample (CR6 + ST). In this way, the β-grain dimensions became almost two times smaller than the initial dimensions (138/75 = 1.84) by applying a deformation degree that was six times greater (from 10% to 60%).

Figure 6.

SEM images of the (CR + ST) processed samples corresponding to the 1st step of the 1st direction of the TMP Program, with various εtot values for CR and similar STs for all six samples: 1223 K/15 min./w.q.: (a) CR(εtot = 10%) + ST; (b) CR(εtot = 20%) + ST; (c) CR(εtot = 30%) + ST; (d) CR(εtot = 40%) + ST; (e) CR(εtot = 50%) + ST; (f) CR(εtot = 60%) + ST.

Figure 7.

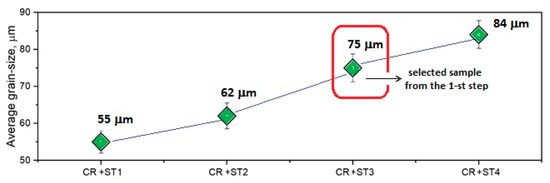

The evolution of the β grain average dimension as a function of the applied TMP variant corresponding to the 1st step of the 1st direction of the TMP Program.

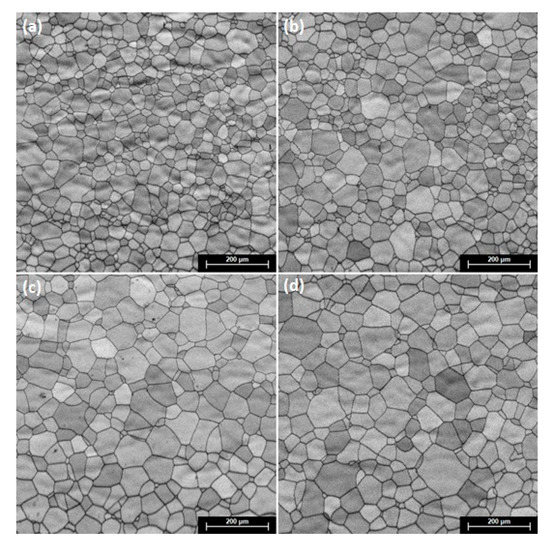

At this stage of the experiments, the sample (CR6 + ST) with the smallest β grains (75 μm) was selected to be further processed, following the 2nd step of the 1st direction of the TMP program. This second step (Figure 2) requires that for the sample selected (the one with the smallest β grains), after applying CR with the same εtot = 60%, the ST treatments will be varied/diversified by applying four different holding times of 5 min, 10 min, 15 min, and 20 min (same 1223 K/water quenching). The resulteding microstructures are shown in Figure 8, and the measured average values of the obtained β-grains are shown in Figure 9.

Figure 8.

The SEM images of the (CR + solution treatment (ST) processed samples corresponding to the 2nd step of the 1st direction of the TMP Program with the same εtot = 60% for the applied CR but with various STs: (a) CR + ST1 (1223 K/5 min./w.q.); (b) CR + ST2 (1223 K/10 min./w.q.); (c) CR + ST3 (1223 K/15 min./w.q.); (d) CR + ST4 (1223 K/20 min./w.q.).

Figure 9.

The evolution of the β grain average dimension as a function of the applied TMP variant, corresponding to the 2nd step of the 1st direction of the TMP Program.

The microstructures from Figure 8 also represent a series of β grains like those in Figure 6 but with visibly smaller grain dimensions. The grains are homogeneous and equiaxial without any traces of deformation products. Considering that the applied CR here was identical for all four samples (εtot = 60%), the variation of the β grain size was due to the use of a shorter or longer time for grain growing during the different holding times applied to the STs: The smallest grains correspond to the smallest holding time of 5 min., and vice versa. However, the resulting grains’ dimensions (Figure 9) are much smaller than those in the anterior 1st step of the TMP program. This time, the smallest grains of 55 μm were obtained for the sample with CR (εtot = 60%) and ST1 (1223 K/5 min./w.q.).

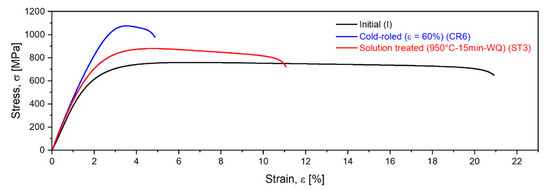

Furthermore, tensile tests were applied to all four resulting samples. Figure 10 shows the strain–stress curves for the following samples: (a) the sample in the initial state; (b) the sample after applying the CR (εtot = 60%); and (c) the sample CR (εtot = 60%) + ST3 (1223 K/15 min./w.q.). For reasons of space, the inclusion of curves was waived for the other three CR+ST samples. Nevertheless, the mechanical characteristics were determined for all four samples. Table 2 indicates the average values for the ultimate tensile strength (σUTS); yield strength (σ0.2); elongation to fracture (εf); and elastic modulus (E). Standard deviation is also included.

Figure 10.

The stress–strain curves of the samples corresponding to the 2nd step of the TMT program (sample selected from the 1st step).

Table 2.

Mechanical properties of the studied alloy at the end of the 1st direction of experiments from the TMP Program: Ultimate Tensile Strength (σUTS); Yield Strength (σ0.2); Elongation to Fracture (εf); Elastic Modulus (E); SD—Standard Deviation.

A general characteristic for strain–stress curves, observed for bcc β-Ti alloys with soluble substitution elements and interstitial oxygen, is a flat zone lacking classic double yielding [60,66,67]. This characteristic is also visible in Figure 10. The flat zone indicates that the yield strength is very close to the ultimate tensile strength. Moreover, the stress values remain constant by increasing the strain. The explanation of this phenomenon reported in [30,42,60,68,69] relates to the heterogeneity of the deformation process for β-Ti alloys: dislocation sliding, β-phase twining, or “stress-induced martensitic transformation” β→α” (SIM) depending on the alloy’s chemical composition, electronic parameters, deformation temperature, or even oxygen content. For the presently studied alloy, all these details regarding the deformation mechanisms are intended to be analysed in future research through TEM analyses specifically dedicated to this issue.

As shown in Table 2, it can be observed that the samples with CR + ST, compared to the initial state, feature increased values for UTS, between 6.5 and 26.7%, and YS provides values between 5.2 and 28.8%. The values of Young’s modulus are almost the same (a very small decrease), but the elongation to fracture decreased significantly to between 23.9 and 66.9%. Considering that the grain dimension decreased from 145 μm (the initial state) to 55 μm (by about 62%), a preliminary conclusion here is that a combination of the applied parameters increased the UTS and YS for this first direction of the experiments without losing the acceptable level of a low Young’s modulus (~48 GPa).

3.3. Micro-Structural and Mechanical Analysis of the Samples Processed by the 2nd Direction of the TMP Program

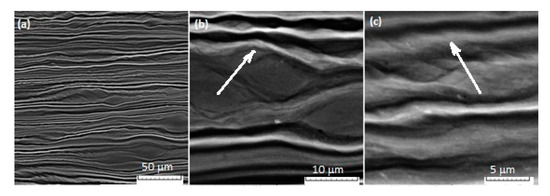

Following the 2nd Direction of the proposed experiments from the complex TMP Program, two samples of the initial state were processed by SPD-MPR with the same deformation degree of εtot = 60% (Figure 3). Figure 11 shows the obtained microstructures.

Figure 11.

(a–c) SEM images of the sample processed by SPD-MPR (εtot = 60%) corresponding to the 2nd direction of the TMP Program (a–c—same sample, with gradual increasing magnifications).

It can be observed that the β grains were strongly textured on the rolling direction. From the images with greater magnification, it can also be observed that the mechanism of deformation was similar to the mechanisms from the first category of the experimental samples, as discussed above. Here, due to the very high deformation degree being applied, the resulting deformation products are more like shear bands with very large misorientation angles, indicated by white arrows in Figure 11b. Moreover, the absence of any other phases can be observed—phases that, alongside β-grains, could have been formed during SPD (e.g., the ω, α’, and α” phases). This means that the amount of the alloying elements with β-stabilizing effects was sufficient to secure the stability of the β phase and suppress the formation of secondary phases.

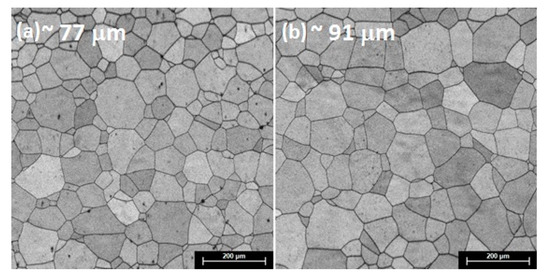

After SPD processing, both samples were subjected to ST using the same heating temperature and quenching medium (1223 K and water, respectively) as the first category of experiments but with two different holding times: 10 min and 20 min, respectively. The resulting microstructures are indicated in Figure 12, with the measured average β-grain dimensions indicated directly on the images. The first sample (SPD-60% + ST1(1223 K-10 min-w.q.)) had a similar β grain dimension (77 μm) to the sample (CR-60% + ST3(1223 K-15 min-w.q.)) from the first category of experiments (75 μm). The second sample (SPD-60% + ST2(1223 K-20 min-w.q.)) had a similar β-grain dimension (91 μm) to the sample (CR-40% + ST (1223 K/15 min/w.q.)) of 89 μm.

Figure 12.

The SEM images of the two samples corresponding to the 2nd direction of the TMP Program: (a) SPD-MPR (εtot = 60%) + ST1 (1223 K-10 min-w.q.); (b) SPD-MPR (εtot = 60%) + ST2 (1223 K-20 min-w.q.).

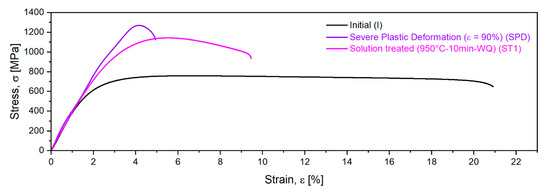

To assess the mechanical properties, tensile tests were applied to both the resulting SPD + ST samples. Similar to Figure 10, Figure 13 shows the strain–stress curves for initial, severely deformed, and solution-treated samples. Determination of the mechanical characteristics was also performed for both samples. Table 3 indicates the average values for the ultimate tensile strength (σUTS); yield strength (σ0.2); elongation to fracture (εf); and elastic modulus (E).

Figure 13.

The stress–strain curve of the samples processed by the 2nd direction of the TMP program: SPD-MPR (εtot = 60%) + ST1 (1223 K-10 min-WQ).

Table 3.

Mechanical properties of the studied alloy at the end of the 2nd direction of experiments: Ultimate Tensile Strength (σUTS); Yield Strength (σ0.2); Elongation to Fracture (εf); Elastic Modulus (E); SD (Standard Deviation).

In Table 3, it can be observed that the two samples with SPD + ST provide much greater UTS and YS values (almost 50%) compared to results from the first category of experiments (CR + ST) and the initial state. This time, the UTS increased by 36.3% and 50.6%, respectively, while the YS increased by 28.4% and 41.5%, respectively. At the same time, the values of Young’s modulus remained almost the same, and the elongation to fracture decreased significantly (by 54.5% and 66.9%, respectively). The obtained β-grain dimensions (77 μm and 91 μm, respectively) are situated in between the 1st step of the 1st experiments, at the bottom of the obtained values (138 → 128 → 97 → 89 → 81 → 75 μm—Figure 7), and those obtained from the 2nd steps of the 1st experiments, at the top of the obtained values (55 → 62 → 75 → 84 μm, Figure 9).

Comparing the mechanical properties obtained from the two research directions of the experimental program (Table 2 versus Table 3), the following observations can be underlined. The first direction of the experiments involved more processing steps than the second direction (two series of CR with two series of ST), but the result was a smaller β-grain dimension (55 μm versus 77 μm). The results for the Young’s modulus were similar for both experimental directions (about 48–49 GPa), indicating a very good achievement. The results for YS and UTS were slightly higher (about 150–200 MPa) for the samples processed by SPD-MPR compared to those processed two times by CR. Nevertheless, the εf values were better/higher for the samples processed by CR. Thus, both processing schemas can provide good results, depending on the final specific application requirements.

3.4. Comparison Between the Experimental Alloy and Other Published Results for Similar Alloys

To better appreciate the obtained experimental results, this analysis includes not only a presentation and discussion of the obtained results but also a comparison with other published data for similar alloys. These data are shown in Table 4.

Table 4.

Mechanical properties of the studied alloy and those of other similar alloys.

By highlighting the positive achievements and possible negative points, the following observations can be underlined. The first observation, common to all anterior reported alloys, relates to the presence of expensive Tantalum, which is absent in the alloy that was studied here. The reported alloys were in an ST condition (like the present alloy) in only two studies—Furuta et al. [47] and M.A.-H. Gepreel [48]. Compared to these two cases, the obtained results are similar, i.e., they have very good limits. It can be observed that the modulus is even lower for the reported results (~48 GPa compared to 50–55 GPa). Further, compared with Hussein et al. [31] and Strasky et al. [32], who reported similar alloys (but in CR or forged states with Ta), the studied alloy in an ST state (both experimental research directions) provides superior characteristics, i.e., the ST state achieved almost the same positive values as those of the reported CR or forged alloys. Usually, β-type alloys in an ST state are expected to have lower values for YS and UTS than alloys in a severely deformed state; here, the obtained values were very close to similar alloys in a severely deformed state, proving that the addition of Fe and O is beneficial for improving mechanical properties [18,31,32,33]. In addition, for the studied alloy, the Young’s modulus was much lower (~48 GPa) compared to the reported results (60, 80, or even 107 GPa).

As a conclusion, the mechanical parameters presented in Table 4 show that our experimental results are in good agreement with the values reported in the literature.

4. Conclusions

- A stable β-Ti alloy–Ti-34.1Nb-7.59Zr-0.9Fe-0.16O—Was subjected to two TMP processing directions with variable parameters to obtain mechanical properties suitable for orthopedic implants with long-term service.

- The amount of the β-stabilizing alloying elements was sufficient to obtain a single β-phase, without any subsequent generation of the secondary phases that are possible to be formed during complex TMP and can decrease the processability of the alloy.

- The deformability of the studied alloy in the monophasic bcc β-status allowed the application of high deformation degrees for the CR process, as well as for SPD.

- The ST parameters in both TMP variants led to the restoration of a fully recrystallized β phase microstructure from the cold rolled state, with a small β grain size and a reduced Young’s modulus.

- The structural deformation mechanisms during cold-rolling were predicted by SEM analysis, but these mechanisms must be proven by future detailed analyses.

- The selected chemical composition and TMP parameters can obtain promising mechanical properties with high levels of YS (about 600–770 MPa) and UTS (about 900–1140 MPa), and low values for the Young’s modulus (around 48 GPa, very close to the 30 GPa of the cortical bone), comparable to or even better than other data reported for similar alloys.

- Both TMP methods applied to the studied alloy provided good final results, including a low β-grain size, low modulus, and high mechanical strength, all for a single β-phase, which can ensure adequate subsequent processability for the final implant shape.

- In these obtained experimental results, the database for the mechanical properties of Ti-Nb-Zr-Fe-O family alloys was extended to a beneficial application as biomaterials for human implants with long-term service.

Author Contributions

Conceptualization, V.D.C.; methodology, A.N.; software, A.D.; validation, D.R. and A.N.; formal analysis, B.M.G.; investigation, C.T.-R.; writing—original draft preparation, A.N. and D.R.; writing—review and editing, A.N.; visualization, R.I.; supervision, V.D.C.; project administration, D.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Romanian National Authority for Scientific Research CCCDI–UEFISCDI, grant no. 143/2020, within the Program PNCDI-III-EraNet-MANUNET-III.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Niinomi, M.; Yi, L.; Nakai, M.; Liu, H.; Hua, L. Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regener. Biomater. 2016, 3, 173–185. [Google Scholar] [CrossRef] [PubMed]

- Gepreel, M.A.-H.; Niinomi, M. Biocompatibility of Ti-alloys for long-term implantation. J. Mech. Behav. Biomed. Mater. 2013, 20, 407–415. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Wang, J.; Xiao, W.; Zhao, X.; Ma, C. Microstructure evolution and mechanical properties of Ti–8Nb–2Fe-0.2O alloy with high elastic admissible strain for orthopedic implant applications. Prog. Nat. Sci.-Mater. Int. 2020, 30, 100–105. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Zhang, Y.; Li, Y.; Wen, C. Cold rolling deformation and annealing behavior of a β-type Ti–34Nb–25Zr titanium alloy for biomedical applications. J. Mater. Res. Technol. 2020, 92, 2308–2318. [Google Scholar] [CrossRef]

- Raducanu, D.; Cojocaru, V.D.; Nocivin, A.; Cinca, I.; Serban, N.; Cojocaru, E.M. Surface Modifications of a Biomedical Gum-Metal Type Alloy by Nano Surface-Severe Plastic Deformation. JOM 2019, 71, 4114–4124. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Chen, W.; Li, C.; Feng, K.; Lin, Y.; Zhang, X.; Chen, C.; Zhou, K. Strengthening of a Near β-Ti Alloy through β Grain Refinement and Stress-Induced α Precipitation. Materials 2020, 13, 4255. [Google Scholar] [CrossRef] [PubMed]

- Du, Z.; Ma, Y.; Liu, F.; Xu, N.; Chen, Y.; Wang, X.; Chen, Y.; Gong, T.; Xu, D. The Influences of Process Annealing Temperature on Microstructure and Mechanical Properties of near β High Strength Titanium Alloy Sheet. Materials 2019, 12, 1478. [Google Scholar] [CrossRef]

- Wang, W.; Xu, X.; Ma, R.; Xu, G.; Liu, W.; Xing, F. The Influence of Heat Treatment Temperature on Microstructures and Mechanical Properties of Titanium Alloy Fabricated by Laser Melting Deposition. Materials 2020, 13, 4087. [Google Scholar] [CrossRef]

- Lan, C.; Wu, Y.; Guo, L.; Chen, H.; Chen, F. Microstructure, texture evolution and mechanical properties of cold rolled Ti-32.5Nb-6.8Zr-2.7Sn biomedical β-Ti alloy. J. Mater. Sci. Technol. 2018, 34, 788–792. [Google Scholar] [CrossRef]

- Dong, R.; Li, J.; Kou, H.; Fan, J.; Tang, B. Dependence of mechanical properties on the microstructure characteristics of a near β-Ti alloy Ti-7333. J. Mater. Sci. Technol. 2019, 35, 48–54. [Google Scholar] [CrossRef]

- Lei, X.; Dong, L.; Zhang, Z.; Liu, Y.; Hao, Y.; Yang, R.; Zhang, L.-C. Microstructure, Texture Evolution and Mechanical Properties of VT3-1 Titanium Alloy Processed by Multi-Pass Drawing and Subsequent Isothermal Annealing. Metals 2017, 7, 131. [Google Scholar] [CrossRef]

- Ma, Y.; Du, Z.; Cui, X.; Cheng, J.; Liu, G.; Gong, T.; Liu, H.; Wang, X.; Chen, Y. Effect of cold rolling process on microstructure and mechanical properties of high strength β titanium alloy thin sheets. Prog. Nat. Sci. Mater. Int. 2018, 28, 711–717. [Google Scholar] [CrossRef]

- Mohammed, M.T.; Khan, Z.A.; Siddiquee, A.N. Beta Titanium Alloys: The Lowest Elastic Modulus for Biomedical Applications: A Review; World Academy of Science Engineering and Technology. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2014, 8, 822–827. [Google Scholar]

- Gupta, A.; Khatirkar, R.K.; Kumar, A.; Parihar, M.S. Investigations on the effect of heating temperature and cooling rate on evolution of microstructure in an α + β titanium alloy. Mater. Res. Soc. 2018, 33, 946–957. [Google Scholar] [CrossRef]

- Padmalatha, T.S.R.V.; Chakkingal, U. The effect of heat treatment and the volume fraction of the alpha phase on the workability of Ti-5Al-5Mo-5V-3Cr alloy. J. Mater. Eng. Perform. 2019, 28, 5352–5360. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, L.; Han, M.; Wei, Z.; Liang, Y. Flash-butt welded Ti6242 joints preserved base-material strength and ductility. Mater. Sci. Eng. A 2020, 774, 138915. [Google Scholar] [CrossRef]

- Terlinde, G.; Fischer, G. Beta titanium alloys. In Titanium and Titanium Alloys—Fundamentals and Applications; Leyens, C., Peters, M., Eds.; Wiley-VCH: Weinheim, Germany, 2003; pp. 37–59. [Google Scholar]

- Cordeiro, J.M.; Beline, T.; Ribeiro, A.L.R.; Rangel, E.C.; da Cruz, N.C.; Landers, R.; Faverani, L.P.; Vaz, L.G.; Fais, L.M.; Vicente, F.B.; et al. Development of binary and ternary titanium alloys for dental implants. Dent. Mater. 2017, 33, 1244–1257. [Google Scholar] [CrossRef]

- Mohammed, M.T. Development of a new metastable beta titanium alloy for biomedical applications. Karbala Int. J. Mod. Sci. 2017, 3, 224–230. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef]

- Mantri, S.A.; Banerjee, R. Microstructure and micro-texture evolution of additively manufactured β-Ti alloys. Addit. Manuf. 2018, 23, 86–98. [Google Scholar] [CrossRef]

- Hafeez, N.; Liu, J.; Wang, L.; Wei, D.; Tang, Y.; Lu, W.; Zhang, L.C. Superelastic response of low-modulus porous beta-type Ti-35Nb-2Ta-3Zr alloy fabricated by laser powder bed fusion. Addit. Manuf. 2020, 34, 101264. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Li, Y.; Wen, C. New Ti-Ta-Zr-Nb alloys with ultrahigh strength for potential orthopedic implant applications. J. Mech. Behav. Biomed. Mater. 2017, 75, 119–127. [Google Scholar] [CrossRef]

- Liu, H.; Niinomi, M.; Nakai, M.; Cho, K. β-Type titanium alloys for spinal fixation surgery with high Young’s modulus variability and good mechanical properties. Acta Biomater. 2015, 24, 361–369. [Google Scholar] [CrossRef]

- Zheng, Y.; Williams RE, A.; Nag, S.; Banerjee, R.; Fraser, H.L.; Banerjee, D. The effect of alloy composition on instabilities in the β phase of titanium alloys. Scr. Mater. 2016, 116, 49–52. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709. [Google Scholar] [CrossRef]

- Kalaie, M.A.; Zarei-Hanzaki, A.; Ghambari, M.; Dastur, P.; Málek, J.; Farghadany, E. The effects of second phases on super elastic behavior of TNTZ bio alloy. Mater. Sci. Eng. A 2017, 703, 513–520. [Google Scholar] [CrossRef]

- Wu, C.; Zhan, M. Microstructural evolution, mechanical properties and fracture toughness of near β titanium alloy during different solution plus aging heat treatments. J. Alloys Compd. 2019, 805, 1144–1160. [Google Scholar] [CrossRef]

- Nakai, M.; Niinomi, M.; Akahori, T.; Tsutsumi, H.; Ogawa, M. Effect of Oxygen Content on Microstructure and Mechanical Properties of Biomedical Ti-29Nb-13Ta-4.6Zr Alloy under Solutionized and Aged Conditions. Mater. Trans. 2009, 50, 2716–2720. [Google Scholar] [CrossRef]

- Hussein, A.H.; Gepreel, M.A.-H.; Gouda, M.K.; Hefnawy, A.M.; Kandil, S.H. Biocompatibility of new Ti–Nb–Ta base alloys. Mater. Sci. Eng. C 2016, 61, 574–578. [Google Scholar] [CrossRef]

- Strasky, J.; Harcuba, P.; Vaclavova, K.; Horvath, K.; Landa, M.; Srba, O.; Janecek, M. Increasing strength of a biomedical Ti-Nb-Ta-Zr alloy by alloying with Fe, Si and O. J. Mech. Behav. Biomed. Mater. 2017, 71, 329–336. [Google Scholar] [CrossRef]

- Nocivin, A.; Cojocaru, V.D.; Raducanu, D.; Cinca, I.; Angelescu, M.L.; Dan, I.; Serban, N.; Cojocaru, M. Finding an Optimal Thermo-Mechanical Processing Scheme for a Gum-type Ti-Nb-Zr-Fe-O Alloy. J. Mater. Eng. Perform. 2017, 26, 4373–4380. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Lin, J.; Li, Y.; Ping, D.; Yamabe-Mitarai, Y.; Wen, C. Investigations into Ti-(Nb,Ta)-Fe Alloys for Biomedical Applications. Acta Biomater. 2016, 32, 336–347. [Google Scholar] [CrossRef]

- Kopova, J.; Strasky, P.; Harcuba, M.; Landa, M.; Janecek, M.; Bacakova, L. Newly developed Ti-Nb-Zr-Ta-Si-Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater. Sci. Eng. C 2016, 60, 230–238. [Google Scholar] [CrossRef]

- Zhang, D.C.; Mao, Y.F.; Li, Y.L.; Li, J.J.; Yuan, M.; Lin, J.G. Effect of ternary alloying elements on microstructure and superelasticity of Ti–Nb alloys. Mater. Sci. Eng. A 2013, 559, 706–710. [Google Scholar] [CrossRef]

- Li, Q.; Miao, P.; Li, J.; He, M.; Nakai, M.; Niinomi, M.; Chiba, A.; Nakano, T.; Liu, X.; Zhou, K.; et al. Effect of Nb Content on Microstructures and Mechanical Properties of Ti-xNb-2Fe Alloys. J. Mater. Eng. Perform. 2019, 28, 5501–5508. [Google Scholar] [CrossRef]

- Ehtemam, H.S.; Attar, H.; Okulov, I.V.; Dargusch, M.S.; Kent, D. Microstructural evolution and mechanical properties of bulk and porous low-cost Ti–Mo–Fe alloys produced by powder metallurgy. J. Alloys Compd. 2020, 853, 156768. [Google Scholar] [CrossRef]

- Park, C.H.; Park, J.W.; Yeom, J.T.; Chun, Y.S.; Lee, C.S. Enhanced mechanical compatibility of submicrocrystalline Ti-13Nb-13Zr alloy. Mater. Sci. Eng. A 2010, 527, 4914–4919. [Google Scholar] [CrossRef]

- Hsu, H.C.; Hsu, S.K.; Wu, S.C.; Lee, C.J.; Ho, W.F. Structure and mechanical properties of as-cast Ti–5Nb–xFe alloys. Mater. Charact. 2010, 61, 851–858. [Google Scholar] [CrossRef]

- Cui, W.F.; Guo, A.H. Microstructure and properties of biomedical TiNbZrFe β-titanium alloy under aging conditions. Mater. Sci. Eng. A 2009, 527, 258–262. [Google Scholar] [CrossRef]

- Gordin, D.M.; Ion, R.; Vasilescu, C.; Drob, S.I.; Cimpean, A.; Gloriant, T. Potentiality of the “Gum Metal” titanium-based alloy for biomedical applications. Mater. Sci. Eng. C 2014, 44, 362–370. [Google Scholar] [CrossRef] [PubMed]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Liu, H.; Niinomi, M.; Nakai, M.; Cong, X.; Cho, K.; Boehlert, C.J.; Khademi, V. Abnormal Deformation Behavior of Oxygen-Modified β-Type Ti-29Nb-13Ta-4.6Zr Alloys for Biomedical Applications. Metall. Mater. Trans. A 2016, 48, 139–149. [Google Scholar] [CrossRef]

- Zafari, A.; Ding, Y.; Cui, J.; Xia, K. Achieving fine beta grain structure in a metastable beta titanium alloy through multiple forging-annealing cycles. Metal. Mater. Trans. A 2016, 47, 3633–3648. [Google Scholar] [CrossRef]

- Bertrand, E.; Gloriant, T.; Gordin, D.M.; Vasilescu, E.; Drob, P.; Vasilescu, C.; Drob, S.I. Synthesis and characterisation of a new superelastic Ti–25Ta–25Nb biomedical alloy. J. Mech. Behav. Biomed. Mater. 2010, 3, 559–564. [Google Scholar] [CrossRef]

- Furuta, T.; Kuramoto, S.; Hwang, J.; Nishino, K.; Saito, T.; Niinomi, M. Mechanical Properties and Phase Stability of Ti-Nb-Ta-Zr-O Alloys. Mater. Trans. 2007, 48, 1124–1130. [Google Scholar] [CrossRef]

- Gepreel, M.A.-H. Improved elasticity of new Ti-Alloys for Biomedical Applications. Mater. Today Proceed. 2015, 2, S979–S982. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Li, Y.; Ipek, R.; Wen, C. Development of Ti–Nb–Zr alloys with high elastic admissible strain for temporary orthopedic devices. Acta Biomater. 2015, 20, 176–187. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Lin, J.X.; Munir, K.; Ozan, S.; Li, Y.C.; Wen, C.E. An investigation of the mechanical and microstructural evolution of a TiNbZr alloy with varied ageing time. Sci. Rep. 2018, 8, 5737. [Google Scholar] [CrossRef] [PubMed]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy Ti-5Al-5V-5Mo-3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Li, Y.; Zhang, Y.; Munir, K.; Jiang, H.; Wen, C. Deformation mechanism and mechanical properties of a thermo-mechanically processed β Ti–28Nb–35.4Zr alloy. J. Mech. Behav. Biomed. Mater. 2018, 78, 224–234. [Google Scholar] [CrossRef]

- Ozan, S.; Li, Y.C.; Lin, J.X.; Zhang, Y.W.; Jiang, H.W.; Wen, C.E. Microstructural evolution and its influence on the mechanical properties of a thermos-mechanically processed beta Ti-32Zr-30Nb alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process 2018, 719, 112–123. [Google Scholar] [CrossRef]

- Tang, B.; Chu, Y.; Zhang, M.; Meng, C.; Fan, J.; Kou, H.; Li, J. The ω phase transformation during the low temperature aging and low rate heating process of metastable β titanium alloys. Mater. Chem. Phys. 2020, 239, 122–125. [Google Scholar] [CrossRef]

- Ali, T.; Wang, L.; Cheng, X.; Liu, A.; Xu, X. Omega phase formation and deformation mechanism in heat treated Ti-5553 alloy under high strain rate compression. Mater. Lett. 2019, 236, 163–166. [Google Scholar] [CrossRef]

- Hu, Q.-M.; Li, S.-J.; Hao, Y.-L.; Yang, R.; Johansson, B.; Vitos, L. Phase stability and elastic modulus of Ti alloys containing Nb, Zr, and/or Sn from first-principles calculations. Appl. Phys. Lett. 2008, 93, 121902. [Google Scholar] [CrossRef]

- Correa, D.R.N.; Vicente, F.B.; Donato, T.A.G.; Arana-Chavez, V.E.; Buzalaf, M.A.R.; Grandini, C.R. The effect of the solute on the structure, selected mechanical properties, and biocompatibility of Ti–Zr system alloys for dental applications. Mater. Sci. Eng. C 2014, 34, 354–359. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, S.Q.; Li, G.P.; Li, Y.L.; Lu, Y.F.; Yang, K.; Ge, P. Evolution of deformation mechanisms of Ti-22.4Nb-0.73Ta-2Zr-1.34Oalloy during straining. Acta Mater. 2010, 58, 2778–2787. [Google Scholar] [CrossRef]

- Besse, M.; Castany, P.; Gloriant, T. Mechanisms of deformation in gum metal TNTZ-O and TNTZ titanium alloys: A comparative study on the oxygen influence. Acta Mater. 2011, 59, 5982–5988. [Google Scholar] [CrossRef]

- Furuta, T.; Kuramoto, S.; Hwang, J.; Nishino, K.; Saito, T. Elastic deformation behavior of multi-functional Ti-Nb-Ta-Zr-O alloys. Mater. Trans. 2005, 46, 3001–3007. [Google Scholar] [CrossRef]

- Tan, M.H.C.; Baghi, A.D.; Ghomashchi, R.; Xiao, W.; Oskouei, R.H. Effect of niobium content on the microstructure and Young’s modulus of Ti-xNb-7Zr alloys for medical implants. J. Mech. Behav. Biomed. Mater. 2019, 99, 78–85. [Google Scholar] [CrossRef]

- Ozan, S.; Lin, J.; Weng, W.; Zhang, Y.; Li, Y.; Wen, C. Effect of thermomechanical treatment on the mechanical and microstructural evolution of a β-type Ti-40.7Zr-24.8Nb alloy. Bioact. Mater. 2019, 4, 303–311. [Google Scholar] [CrossRef]

- Wang, L.; Lu, W.; Qin, J.; Zhang, F.; Zhang, D. Microstructure and mechanical properties of cold-rolled TiNbTaZr biomedical β-titanium alloy. Mater. Sci. Eng. A 2008, 490, 421–426. [Google Scholar] [CrossRef]

- Okulov, I.V.; Wendrock, H.; Volegov, A.S.; Attar, H.; Kühn, U.; Skrotzki, W.; Eckert, J. High strength beta titanium alloys: New design approach. Mater. Sci. Eng. A 2015, 628, 297–302. [Google Scholar] [CrossRef]

- Xie, K.Y.; Wang, Y.; Zhao, Y.; Chang, L.; Wang, G.; Chen, Z.; Cao, Y.; Liao, X.; Lavernia, E.J.; Valiev, R.B.; et al. Nanocrystalline β-Ti alloy with high hardness, low Young’s modulus and excellent in vitro biocompatibility for biomedical applications. Mater. Sci. Eng. C 2013, 33, 3530–3536. [Google Scholar] [CrossRef]

- Tahara, M.; Kim, H.Y.; Inamura, T.; Hosoda, H.; Miyazaki, S. Role of interstitial atoms in the microstructure and non-linear elastic deformation behavior of Ti–Nb alloy. J. Alloys Compd. 2013, 577, S404–S407. [Google Scholar] [CrossRef]

- Wei, L.S.; Kim, H.Y.; Miyazaki, S. Effects of oxygen concentration and phase stability on nano-domain structure and thermal expansion behavior of Ti–Nb–Zr–Ta–O alloys. Acta Mater. 2015, 100, 313–322. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, L.; Fu, Y.; Qin, J.; Lu, W.; Zhang, D. Influence of oxygen content on microstructure and mechanical properties of Ti–Nb–Ta–Zr alloy. Mater. Des. 2011, 32, 2934–2939. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).