Structural, Fatigue Behavior, and Mechanical Properties of Zirconium Tungstate-Reinforced Casted A356 Aluminum Alloy

Abstract

1. Introduction

2. Material Properties and Experimental Procedure

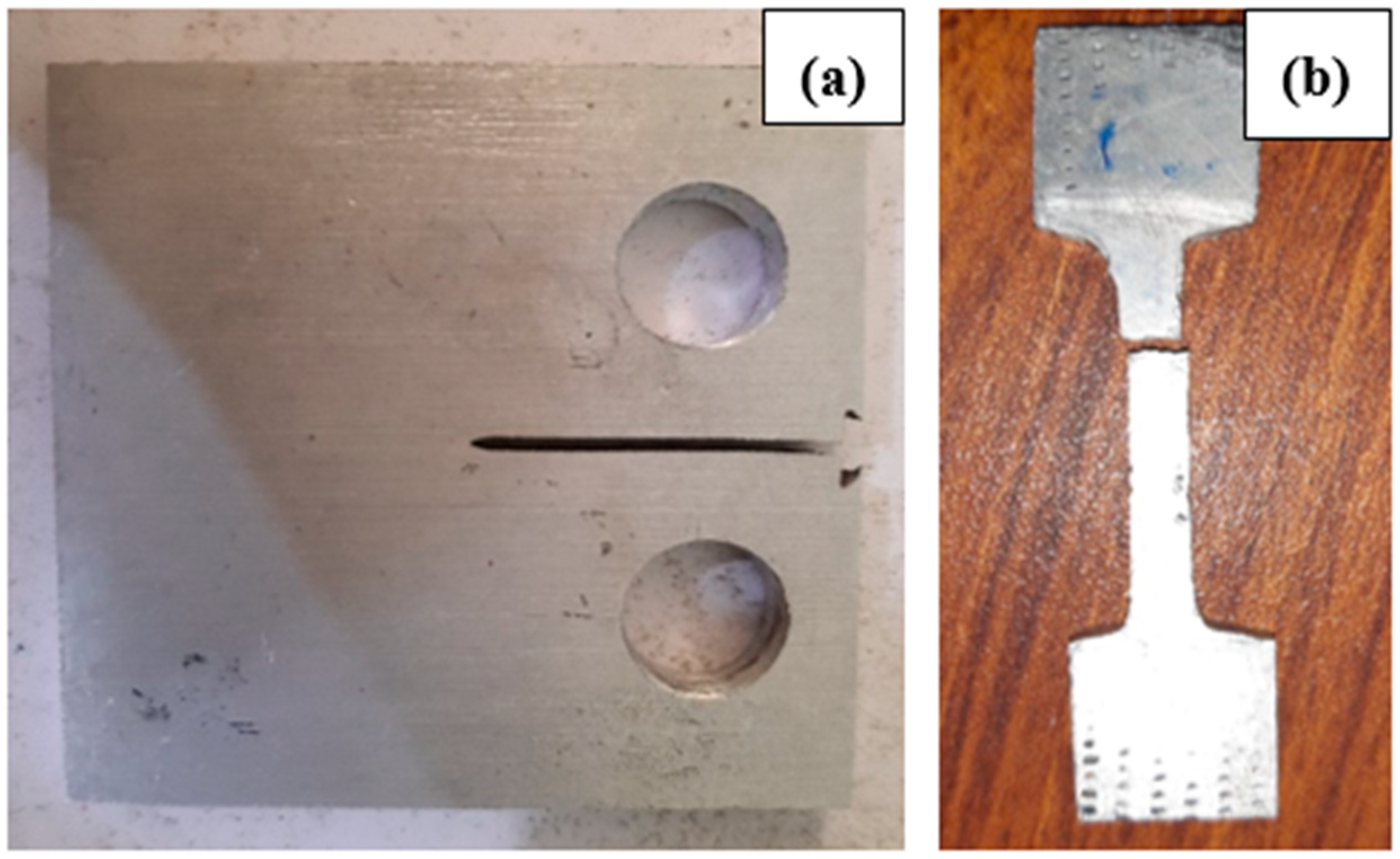

2.1. Sample Preparation

2.2. Experimental Techniques

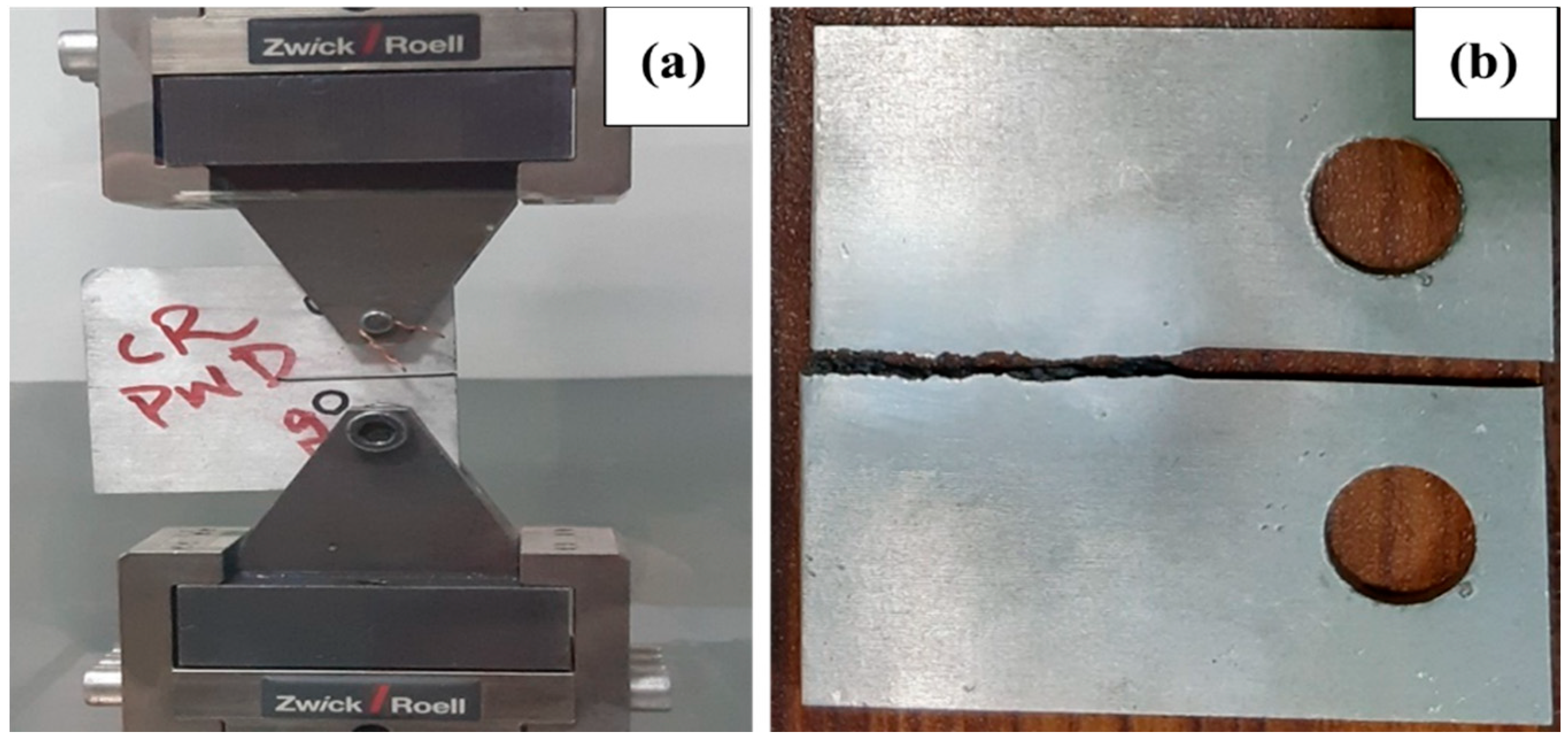

2.2.1. Tensile Testing

2.2.2. Hardness

2.2.3. Fatigue

2.2.4. Characterization

3. Results and Discussion

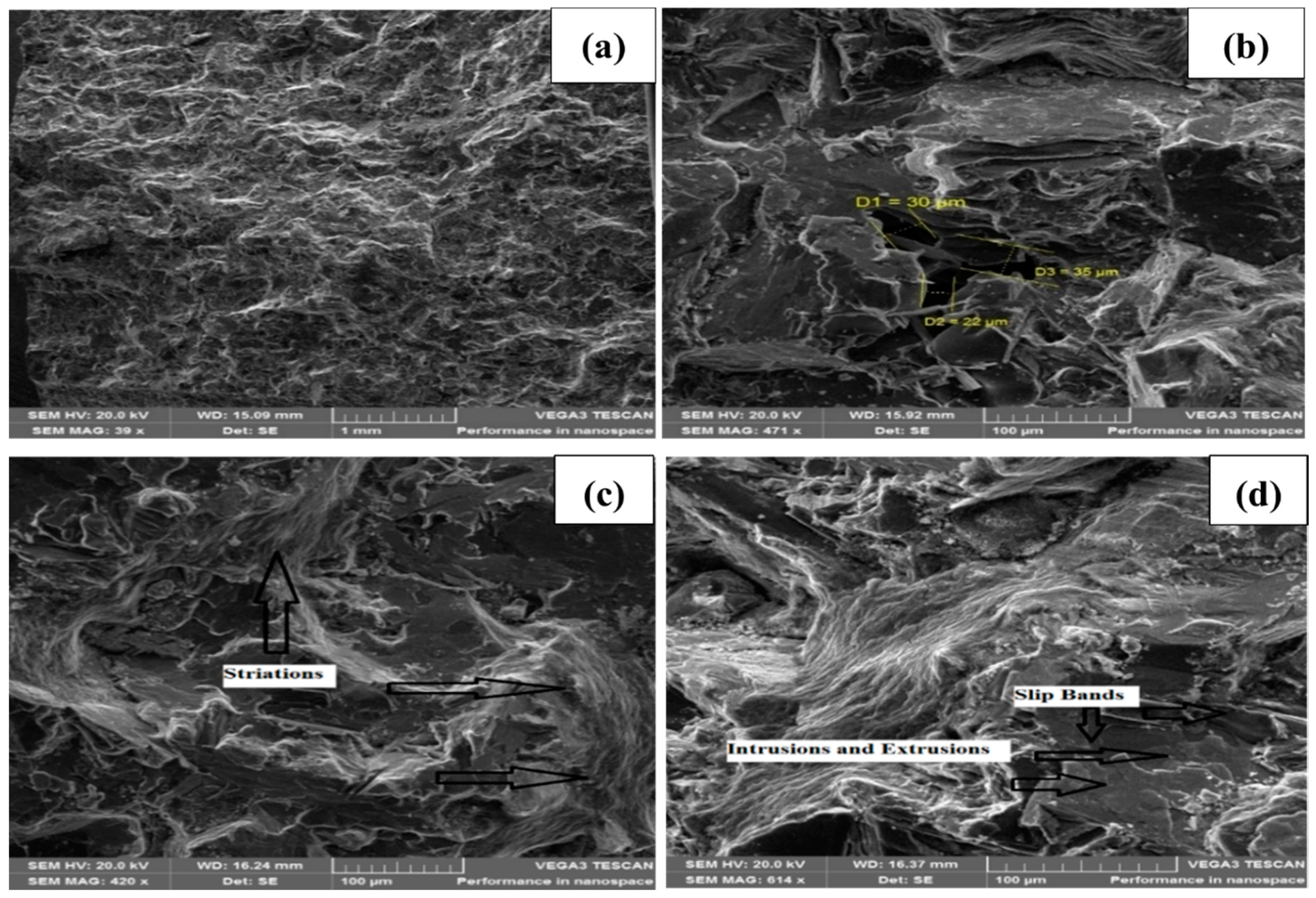

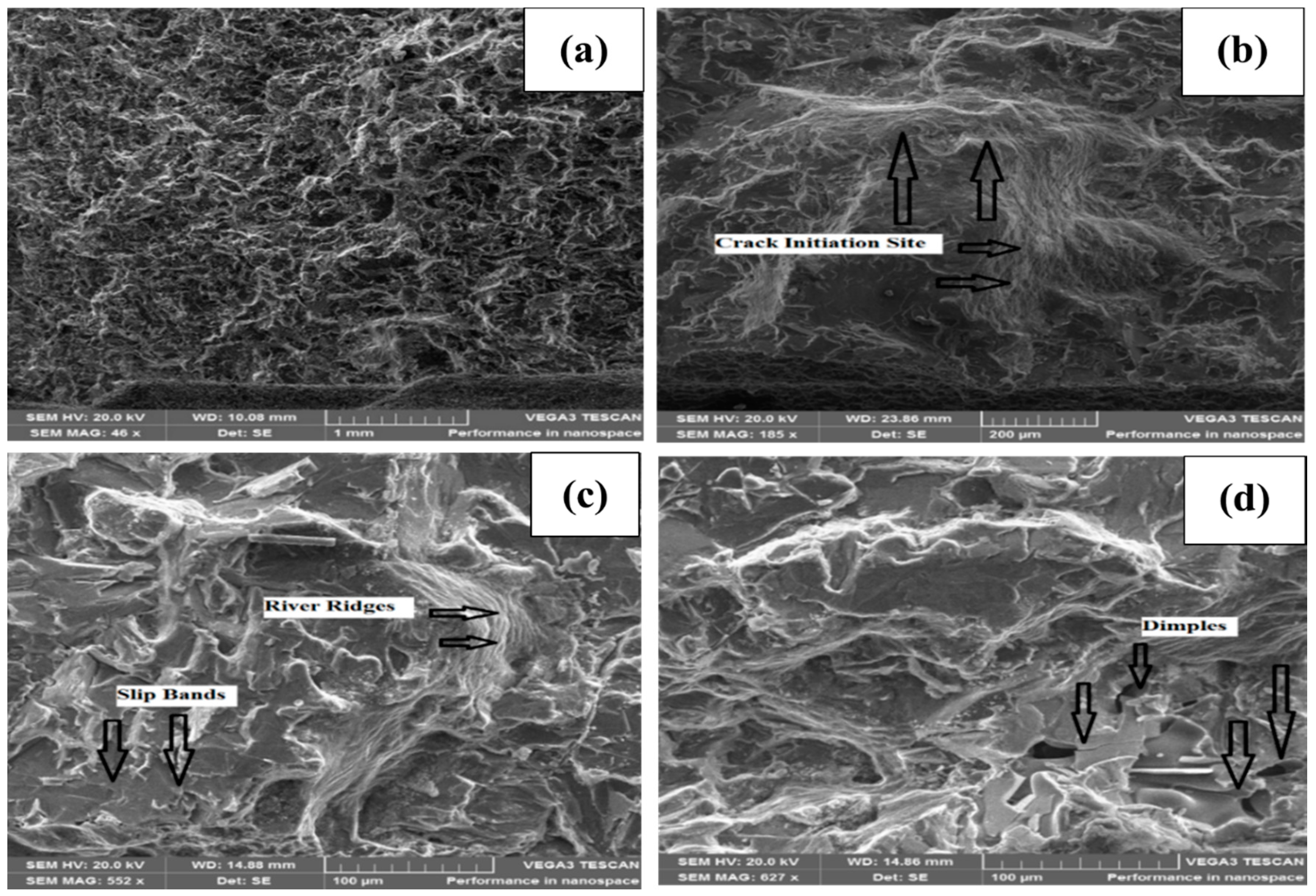

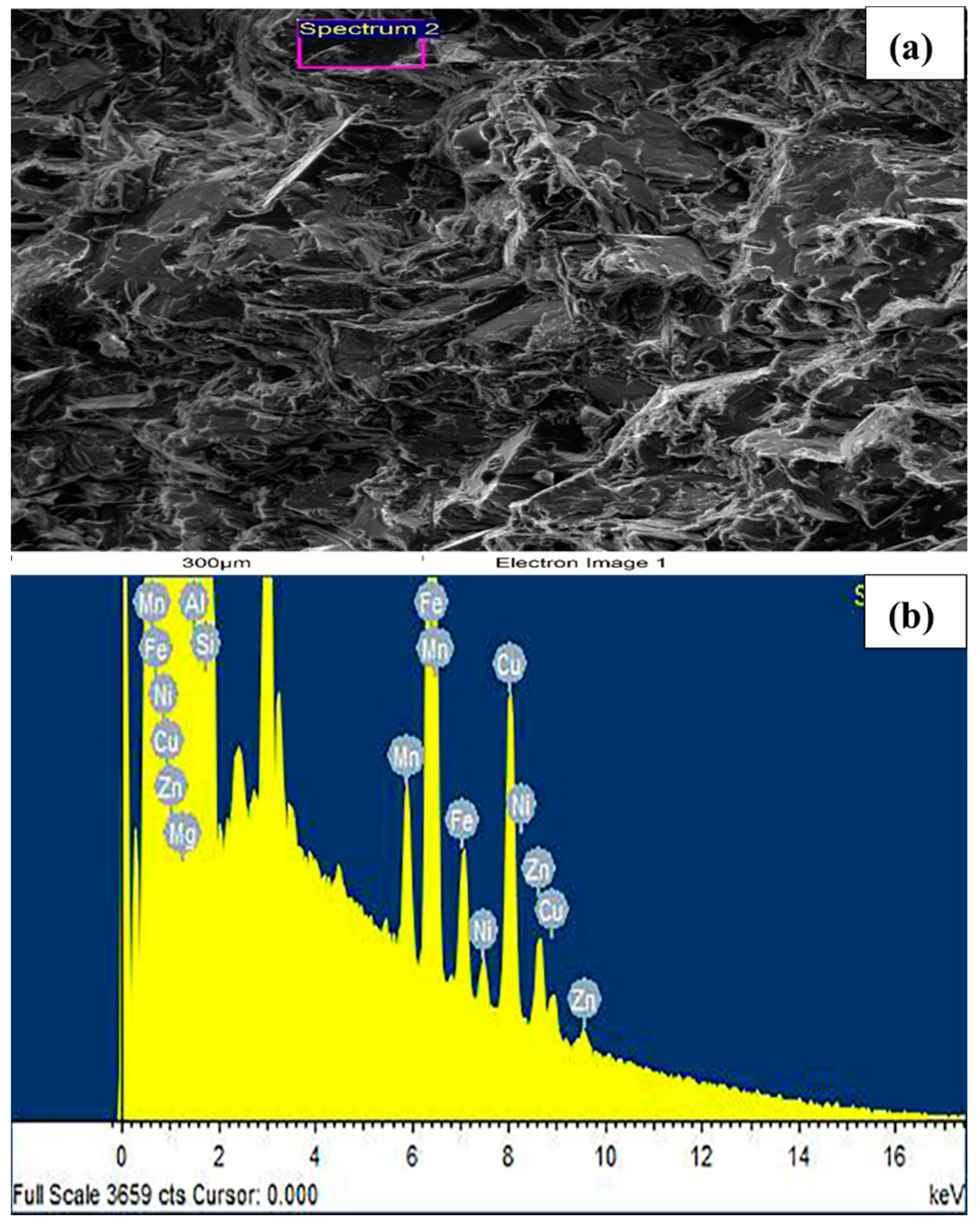

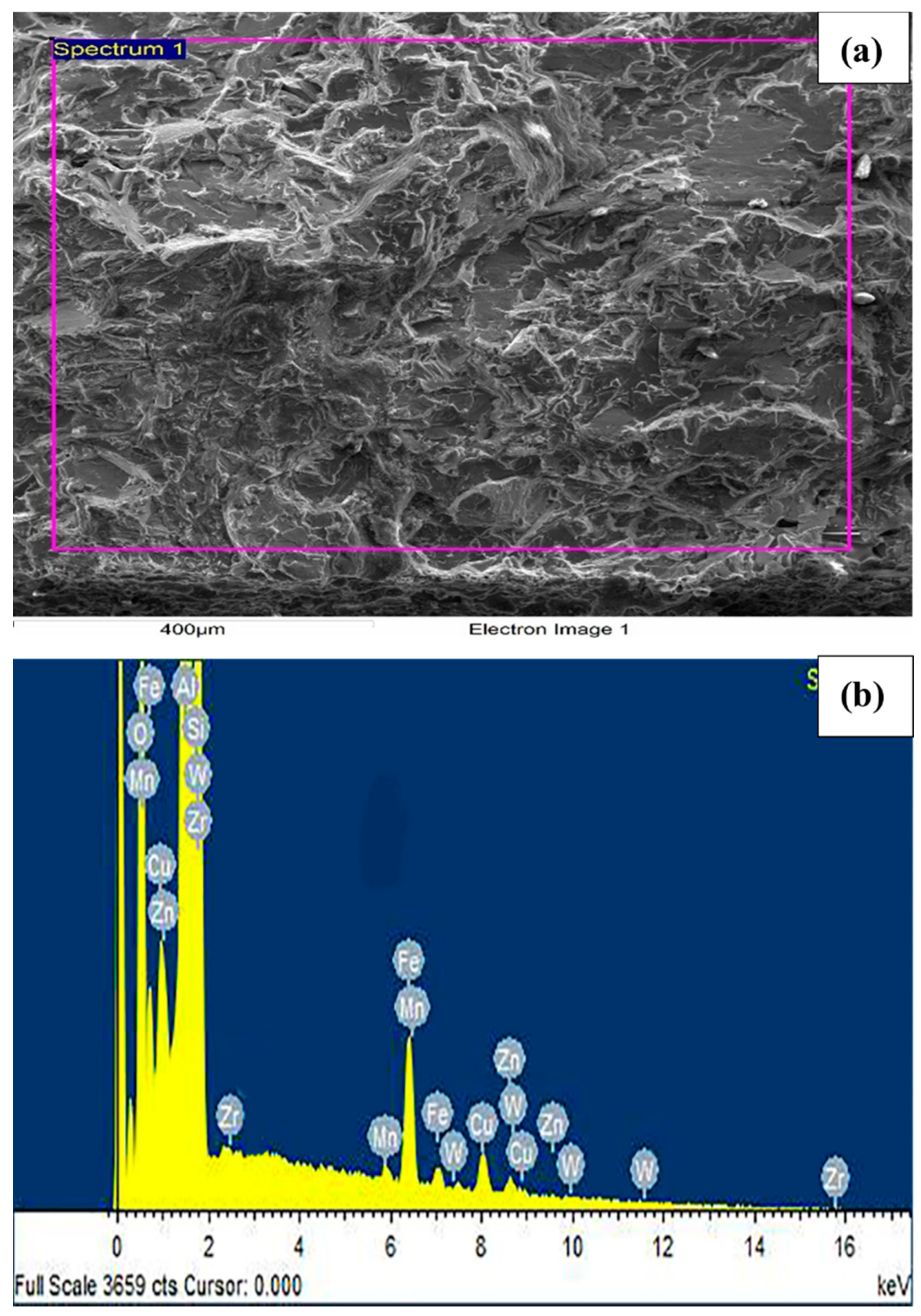

3.1. Fractography

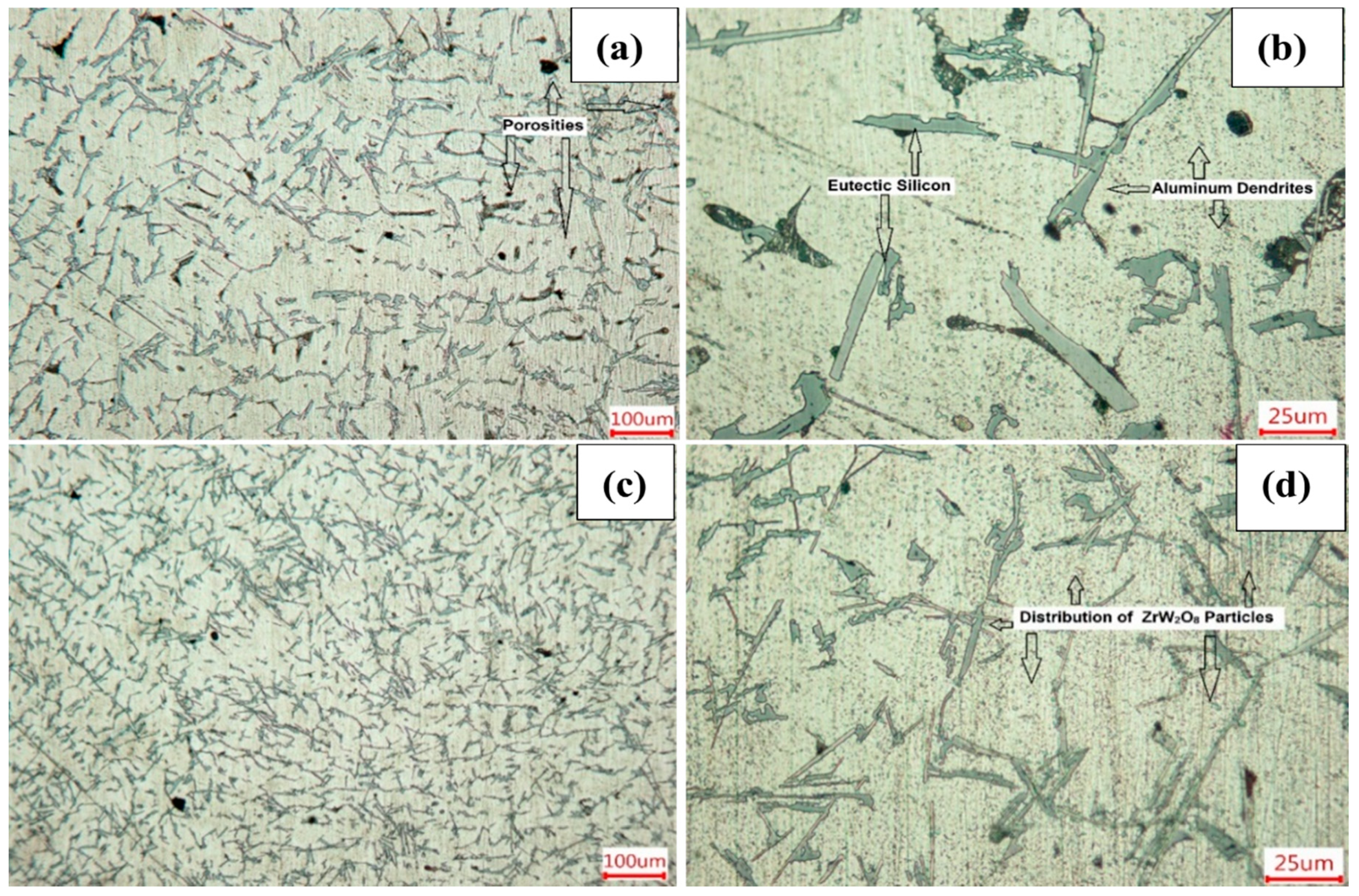

3.2. Microstructure Analysis

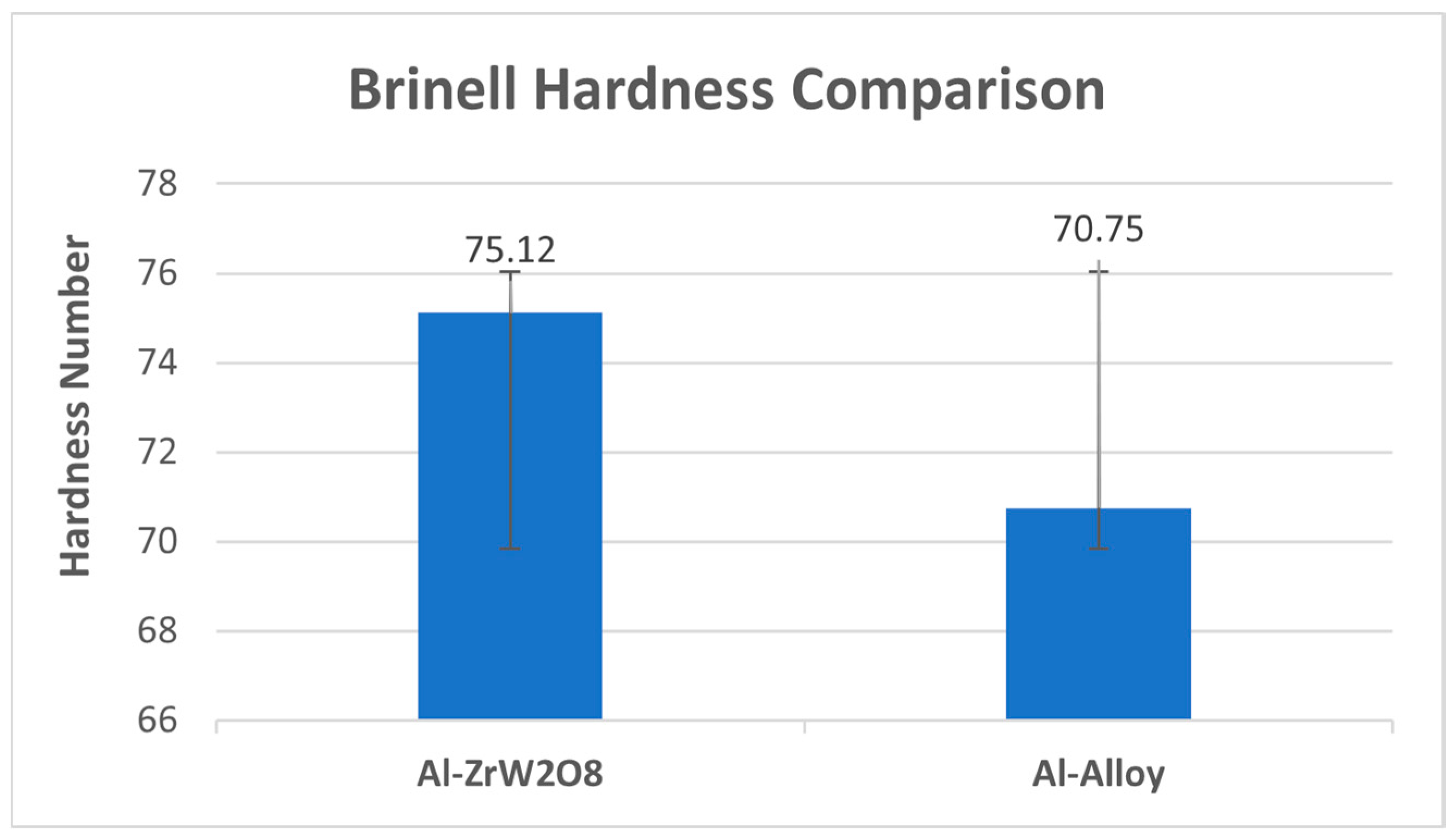

3.3. Hardness Effect

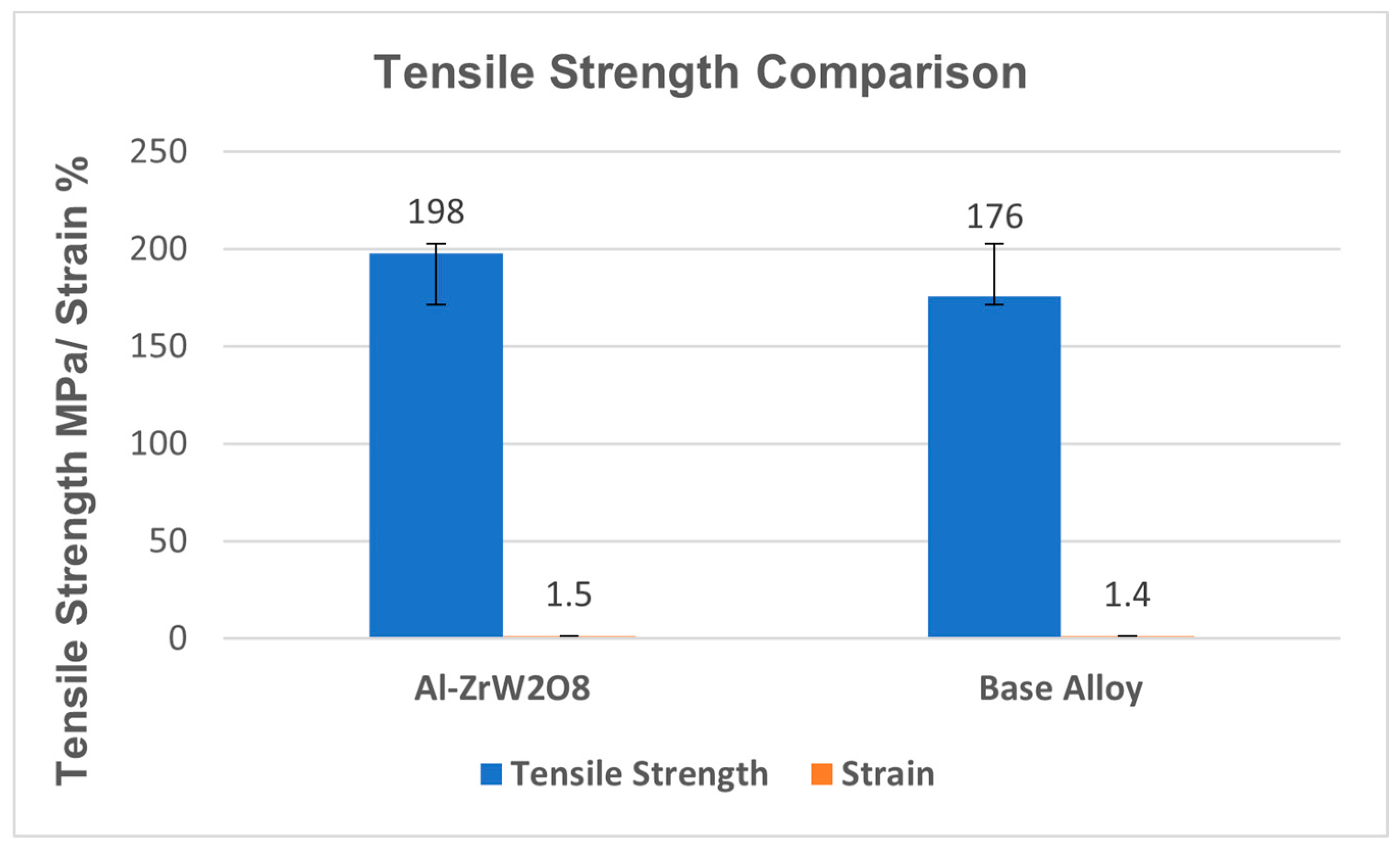

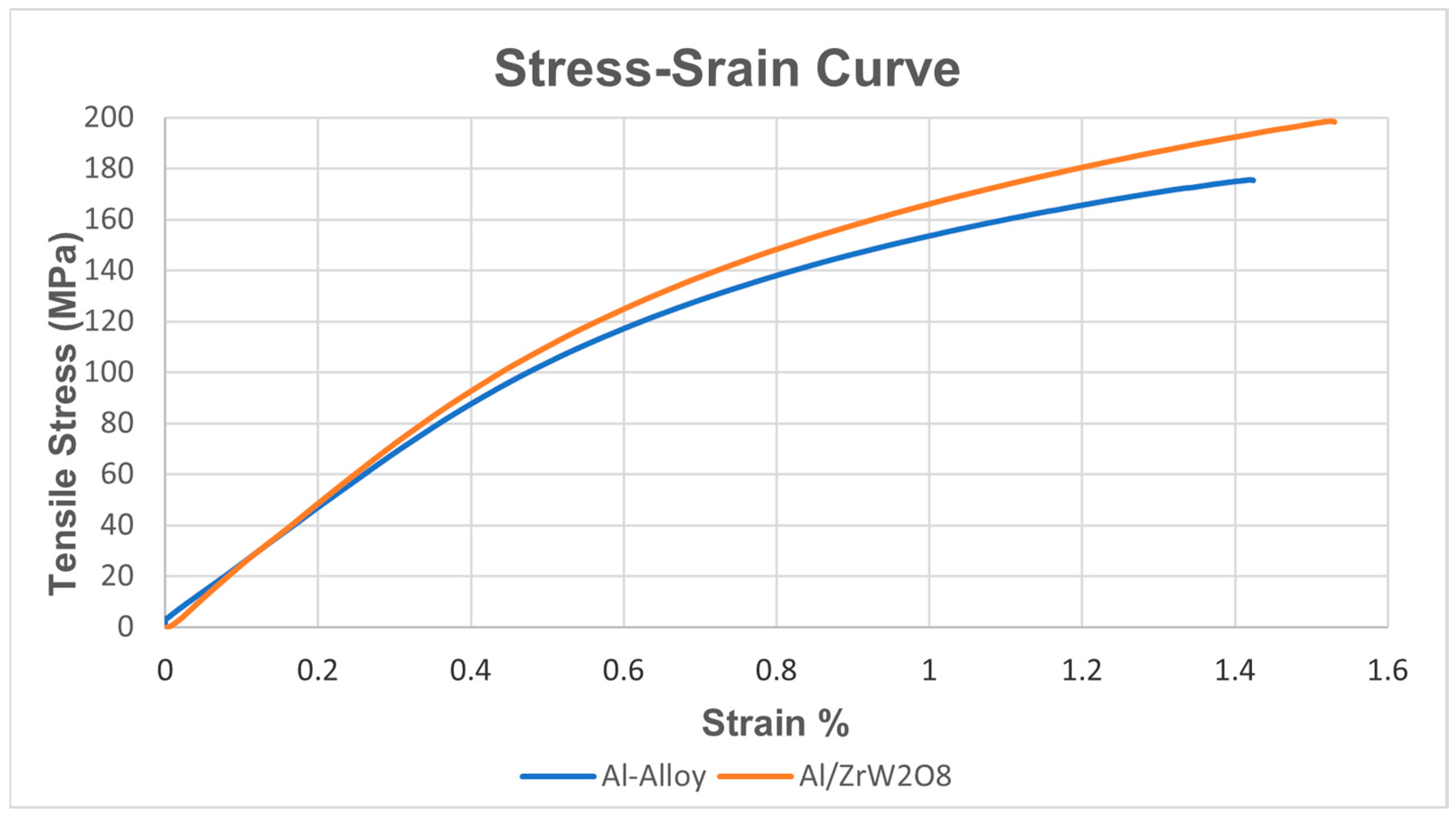

3.4. Tensile Properties

3.5. Fatigue Performance

4. Conclusions

- In this study, the effect of a 4% zirconium tungstate-reinforced A356 alloy on the microstructure, fatigue, and mechanical properties were investigated. The ceramic inclusion had shown noticeable improvements in fatigue behavior, and mechanical properties (i.e., hardness and tensile strength).

- The existence of ZrW2O8 particles refined the microstructure of the aluminum matrix.

- The hardness value of composite increases by 7% compared to the casted aluminum.

- Tensile strength of the composite increases up to 13% compared to the base alloy.

- The addition of ZrW2O8 causes improvement in the fatigue life of the aluminum alloy; the addition of 4% ceramic powder increased the fatigue life more than 50% of the base alloy. Fatigue life would be further increased if defects were minimized during casting and if aging of the sample was done.

Author Contributions

Funding

Conflicts of Interest

References

- Harlow, D.G.; Nardiello, J.; Payne, J. The effect of constituent particles in aluminum alloys on fatigue damage evolution: Statistical observations. Int. J. Fatigue 2010, 32, 505–511. [Google Scholar] [CrossRef]

- Tajiri, A.; Nozaki, T.; Uematsu, Y.; Kakiuchi, T.; Nakajima, M.; Nakamura, Y.; Tanaka, H. Fatigue Limit Prediction of Large Scale Cast Aluminum Alloy A356. Procedia Mater. Sci. 2014, 3, 924–929. [Google Scholar] [CrossRef]

- Chandra, B.; Kumar, J.; Singh, H. Fabrication and characterisation of Al2O3/aluminium alloy 6061 composites fabricated by Stir casting. Mater. Today Proc. 2017, 4, 2783–2792. [Google Scholar]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92–93, 1–7. [Google Scholar] [CrossRef]

- Thomas, A.T.; Parameshwaran, R.; Muthukrishnan, A.; Kumaran, M.A. Development of Feeding & Stirring Mechanisms for Stir Casting of Aluminium Matrix Composites. Procedia Mater. Sci. 2014, 5, 1182–1191. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Chen, L.; Qi, Y.; Fei, Y.; Du, Z. Enhanced Mechanical Properties and Thermal Conductivity for GNPs/Al2024 Composites with In Situ SiC Nanorods. Met. Mater. Int. 2020, 26, 1–8. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Particle distribution in cast metal matrix composites—Part I. J. Mater. Process. Technol. 2002, 123, 251–257. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ashraf Imam, M.; Srivatsan, T.S. Fatigue of Materials III—Advances and Emergences in Understanding; Springer: Cham, Switzerland, 2016; pp. 3–30. [Google Scholar]

- Elhadari, H.A.; Patel, H.A.; Chen, D.L.; Kasprzak, W. Tensile and fatigue properties of a cast aluminum alloy with Ti, Zr and V additions. Mater. Sci. Eng. A 2011, 528, 8128–8138. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Characterization of cast A356 alloy reinforced with nano SiC composites. Trans. Nonferrous Met. Soc. China 2012, 22, 275–280. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Al-Hajri, M. The fatigue and final fracture behavior of SiC particle reinforced 7034 aluminum matrix composites. Compos. Part B Eng. 2002, 33, 391–404. [Google Scholar] [CrossRef]

- Winter, L.; Hockauf, K.; Lampke, T. Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy. Metals 2018, 8, 43. [Google Scholar] [CrossRef]

- Bekheet, N.E.; Gadelrab, R.M.; Salah, M.F.; El-azim, A.N.A. The effects of aging on the hardness and fatigue behavior of 2024 Al alloy /SiC composites. Mater. Des. 2002, 23, 153–159. [Google Scholar] [CrossRef]

- Afkham, Y.; Khosroshahi, R.A.; Rahimpour, S.; Aavani, C.; Brabazon, D.; Mousavian, R.T. Enhanced mechanical properties of in situ aluminium matrix composites reinforced by alumina nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 215–226. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Parizi, M.T. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Zhu, S.J.; Iizuka, T. Fatigue behavior of Al18B4O33 whisker-framework reinforced Al matrix composites at high temperatures. Compos. Sci. Technol. 2003, 63, 265–271. [Google Scholar] [CrossRef]

- Jeykrishnan, J.; Nathan, S.J.; Karthik, M.R. Fabrication and Characterization of Aluminum Titanium Di-Boride Metal Matrix Composites using Stir Casting Technique. Int. J. Mech. Eng. Technol. 2017, 8, 13–18. [Google Scholar]

- Fu, H.; Liang, Y. Study of the Surface Integrity and High Cycle Fatigue Performance of AISI 4340 Steel after Composite Surface Modification. Metals 2019, 9, 856. [Google Scholar] [CrossRef]

- Kumar, K.R.; Pridhar, T.; Balaji, V.S.S. Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash (CSA) reinforced aluminium (Al 6082) matrix hybrid composite. J. Alloys Compd. 2018, 765, 171–179. [Google Scholar] [CrossRef]

- Mummoorthi, D.; Rajkumar, M.; Kumar, S.G. Advancement and characterization of Al-Mg-Si alloy using reinforcing materials of Fe2O3 and B4C composite produced by stir casting method. J. Mech. Sci. Technol. 2019, 33, 3213–3222. [Google Scholar] [CrossRef]

- Pandiyarajan, R.; Maran, P.; Marimuthu, S.; Ganesh, K.C. Mechanical and tribological behavior of the metal matrix composite AA6061/ZrO2/C. J. Mech. Sci. Technol. 2017, 31, 4711–4717. [Google Scholar] [CrossRef]

- Madhusudan, S.; Sarcar, M.M.M.; Rao, N.B.R.M. Mechanical properties of Aluminum-Copper(p) composite metallic materials. J. Appl. Res. Technol. 2016, 14, 293–299. [Google Scholar] [CrossRef]

- Grima, J.N.; Zammit, V.; Gatt, R. Negative thermal expansion. J. Phys. Condens. Matter 2005, 17, 16–29. [Google Scholar]

- Takenaka, K. Negative thermal expansion materials: Technological key for control of thermal expansion. Sci. Technol. Adv. Mater. 2012, 13, 013001. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties, 1st ed.; Butterworths-Heinemann: Oxford, UK, 1976; pp. 86–87. [Google Scholar]

- Kaufman, J.G.; Rooy, E.L. Aluminum Casting Alloys: Properties, Processes, and Applications, 1st ed.; ASM International: Cleveland, OH, USA, 2004; pp. 13–33. [Google Scholar]

- González, R.; Martínez, D.I.; González, J.A.; Talamantes, J.; Valtierra, S.; Colás, R. Experimental investigation for fatigue strength of a cast aluminum alloy. Int. J. Fatigue 2011, 33, 273–278. [Google Scholar] [CrossRef]

- Standards For Aluminum Sand and Permanent Mold Castings; Engineering Series(E); 2005; pp. 1–3. Available online: https://www.aluminum.org/sites/default/files/Sand%20and%20Permanent%20Mold%20Casting%20Errata%20watermark.pdf (accessed on 4 November 2020).

- Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials 1; ASTM International: West Conshohocken, PA, USA, 1997; pp. 1–31.

- Graff, W.R.; Sargent, D.C. A new grain-boundary etchant for aluminum alloys. Metallography 1981, 14, 69–72. [Google Scholar] [CrossRef]

- Kim, K.S.; Sung, S.-Y.; Han, B.-S.; Jung, C.-Y.; Lee, K.-A. High temperature high cycle fatigue behavior of new aluminum alloy strengthened by (Co, Ni)3Al4 particles. Met. Mater. Int. 2014, 20, 243–248. [Google Scholar] [CrossRef]

- Wang, Q.G. Microstructural Effects on the Tensile and Fracture Behavior of Aluminum Casting Alloys A356/357. Metall. Mater. Trans. A 2003, 34, 2887–2899. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Anand, S.; Sriram, S.; Vasudevan, V.K. The high-cycle fatigue and fracture behavior of aluminum alloy 7055. Mater. Sci. Eng. A 2000, 281, 292–304. [Google Scholar] [CrossRef]

- Gholipour, V.; Shamanian, M.; Ashrafi, A.; Maleki, A. Development of Aluminium-Nanoclay Composite by Using Powder Metallurgy and Hot Extrusion Process. Met. Mater. Int. 2020, 1–14. [Google Scholar] [CrossRef]

- Qian, H.; Zhu, D.; Hu, C.; Jiang, X. Effects of Zr Additive on Microstructure, Mechanical Properties, and Fractography of Al-Si Alloy. Metals 2018, 8, 124. [Google Scholar] [CrossRef]

- Zhukov, I.A.; Kozulin, A.A.; Khrustalyov, A.P.; Kahidze, N.I.; Khmeleva, M.G.; Moskvichev, E.N.; Lychagin, D.V.; Vorozhtsov, A.B. Pure Aluminum Structure and Mechanical Properties Modified by Al 2O3 Nanoparticles and Ultrasonic Treatment. Metals 2019, 9, 1199. [Google Scholar] [CrossRef]

- Almotairy, S.M.; Boostani, A.F.; Hassani, M.; Wei, D.; Jiang, Z.Y. Mechanical Properties of Aluminium Metal Matrix Nanocomposites Manufactured by Assisted-Flake Powder Thixoforming Process. Met. Mater. Int. 2019. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Song, X. Fatigue behavior and damage mechanism of aluminum foam sandwich with carbon-fiber face-sheets. J. Mech. Sci. Technol. 2020, 34, 1119–1127. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, R.; Li, X.; Zhang, Y.; Li, R. Effect of Nanoparticle Content on the Microstructural and Mechanical Properties of Forged and Heat-Treated TiC/2219 Nanocomposites. Metals 2019, 9, 982. [Google Scholar] [CrossRef]

- Wang, Q.; Apelian, D.; Lados, D.A. Fatigue behavior of A356-T6 aluminum cast alloys. Part I. Effect of casting defects. J. Light Met. 2001, 1, 73–84. [Google Scholar] [CrossRef]

- Srivatsan, T.S. The low-cycle fatigue behaviour of composite. Int. J. Fatigue 1992, 3, 173–182. [Google Scholar] [CrossRef]

| Si % | Cu% | Mg% | Mn% | Ni% | Zn% | Fe% | Ti% | Al% |

|---|---|---|---|---|---|---|---|---|

| 7.5 | 0.25 | 0.20 | 0.35 | 0.2 | 0.35 | 0.8 | 0.25 | Bal. |

| ZrW2O8 | Impurities (%Max) | Density | Particle Size | Appearance | |||

|---|---|---|---|---|---|---|---|

| (%Min) | Fe2O3 | SiO2 | Mo | TiO2 | g/cm3 | (D50, μm) | Powder |

| 99.6 | 0.001 | 0.0071 | 0.002 | 0.0062 | 5.07 | 1.86 | Light Yellowish |

| Materials | Brinell Hardness | Yield Strength (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|

| A356 | 70.75 | 154.52 | 175.60 | 21.7 | 1.5 |

| A356-ZrW2O8 | 75.12 | 174.65 | 198.47 | 23.8 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raza, M.; Alrobei, H.; Malik, R.A.; Hussain, A.; Alzaid, M.; Saleem, M.; Imran, M. Structural, Fatigue Behavior, and Mechanical Properties of Zirconium Tungstate-Reinforced Casted A356 Aluminum Alloy. Metals 2020, 10, 1492. https://doi.org/10.3390/met10111492

Raza M, Alrobei H, Malik RA, Hussain A, Alzaid M, Saleem M, Imran M. Structural, Fatigue Behavior, and Mechanical Properties of Zirconium Tungstate-Reinforced Casted A356 Aluminum Alloy. Metals. 2020; 10(11):1492. https://doi.org/10.3390/met10111492

Chicago/Turabian StyleRaza, Muhammad, Hussein Alrobei, Rizwan Ahmed Malik, Azhar Hussain, Meshal Alzaid, Mohsin Saleem, and Mian Imran. 2020. "Structural, Fatigue Behavior, and Mechanical Properties of Zirconium Tungstate-Reinforced Casted A356 Aluminum Alloy" Metals 10, no. 11: 1492. https://doi.org/10.3390/met10111492

APA StyleRaza, M., Alrobei, H., Malik, R. A., Hussain, A., Alzaid, M., Saleem, M., & Imran, M. (2020). Structural, Fatigue Behavior, and Mechanical Properties of Zirconium Tungstate-Reinforced Casted A356 Aluminum Alloy. Metals, 10(11), 1492. https://doi.org/10.3390/met10111492