Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave

Abstract

1. Introduction

2. Background

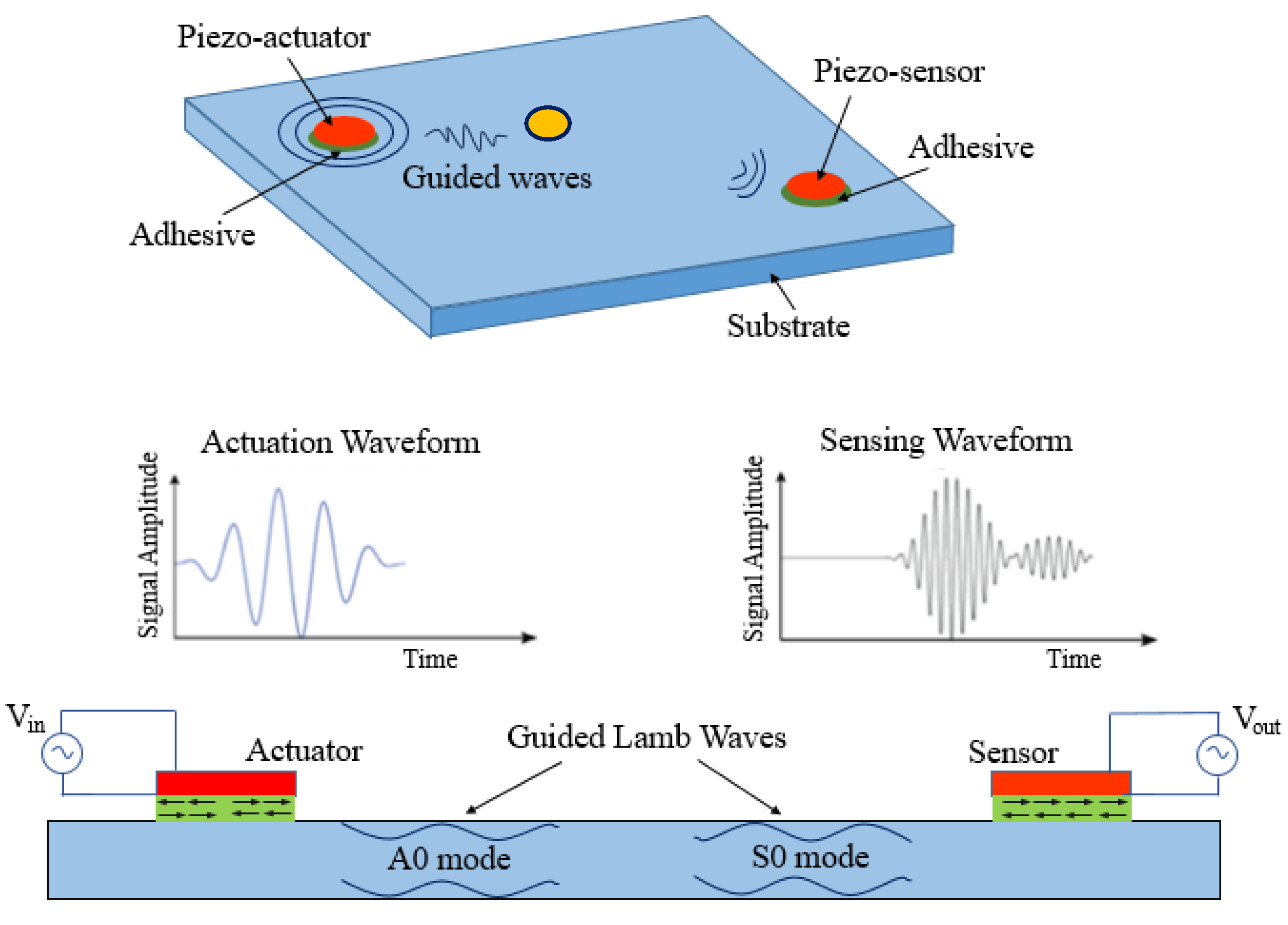

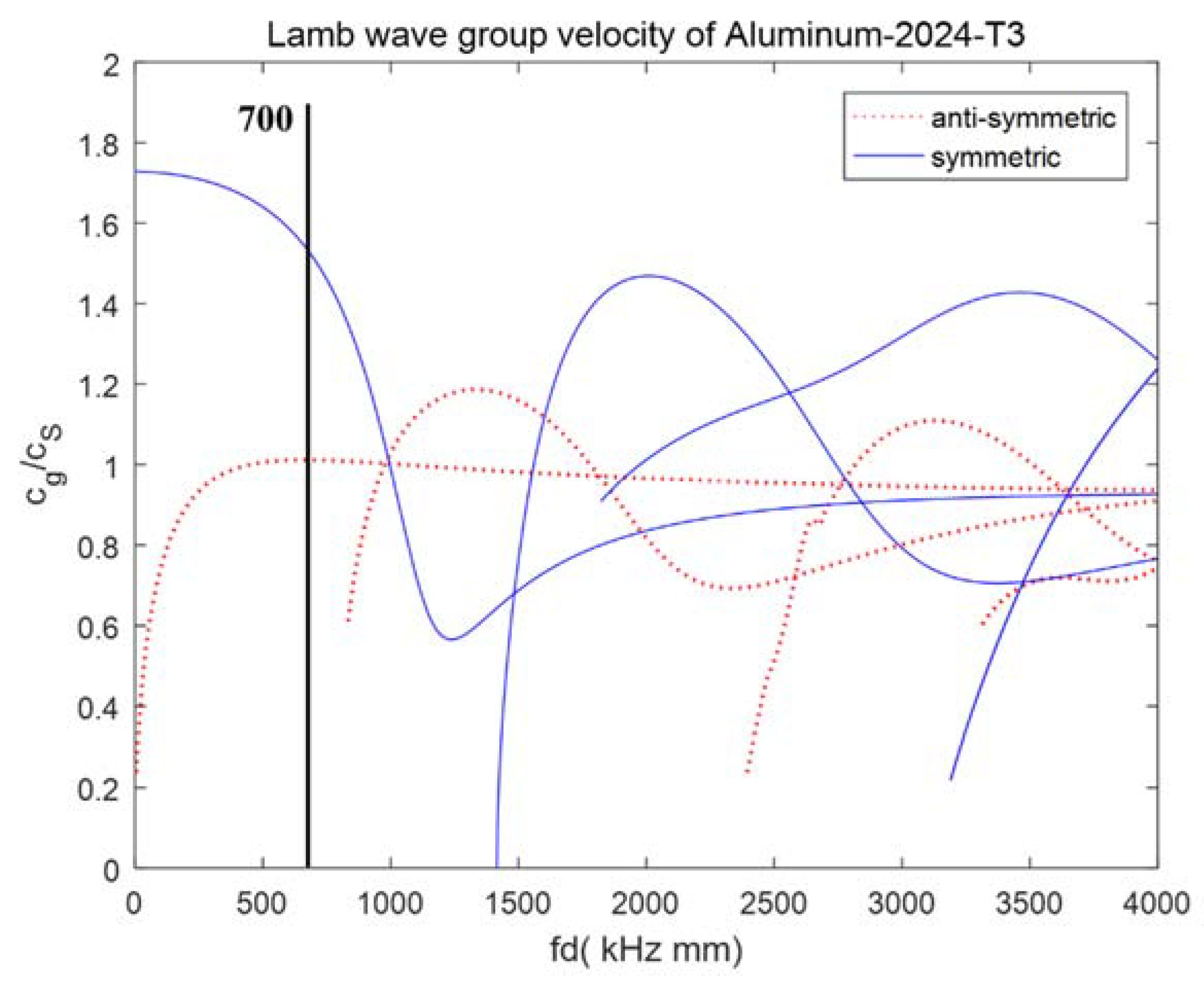

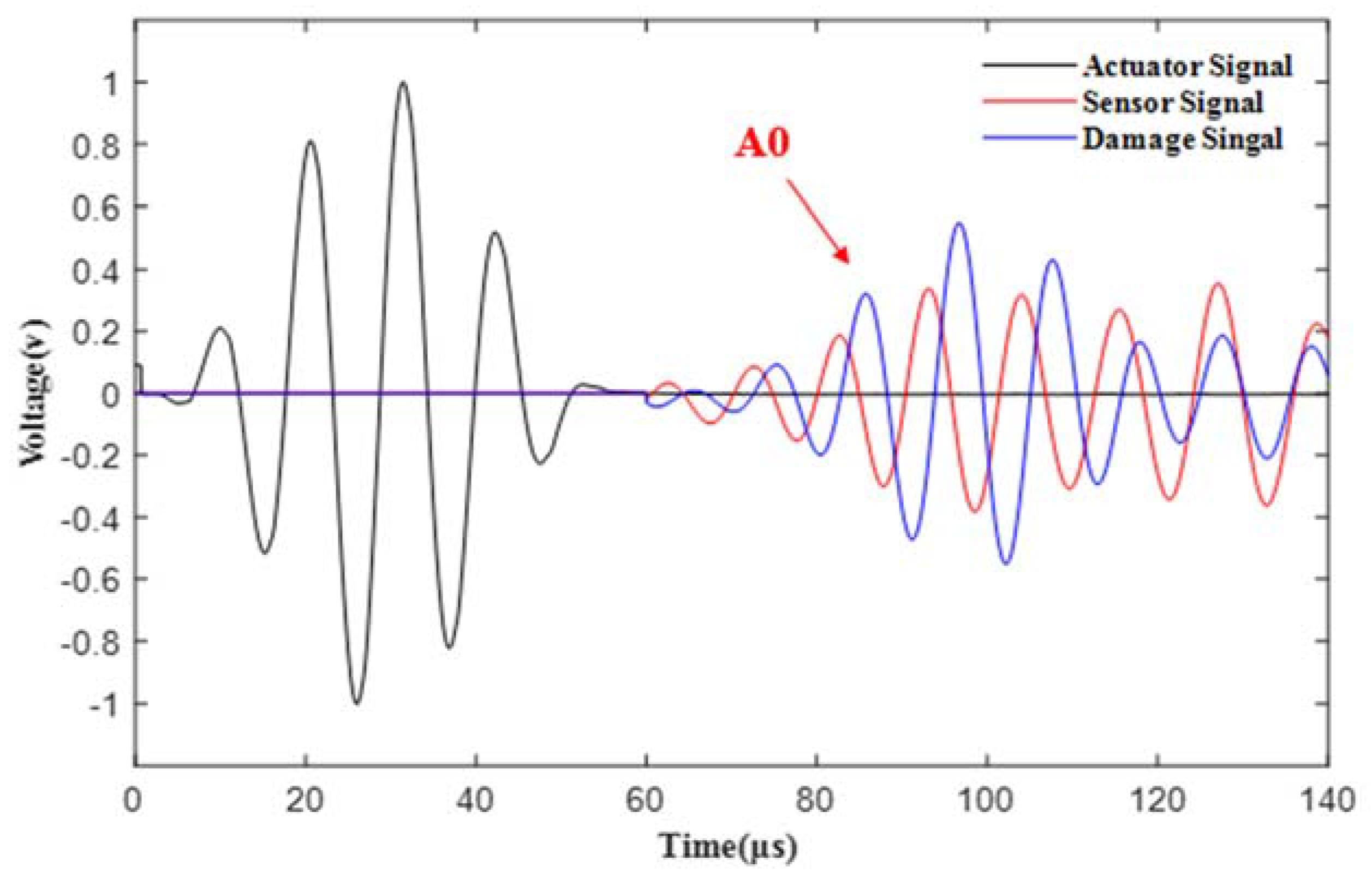

2.1. Guided Wave in Aluminum Alloy

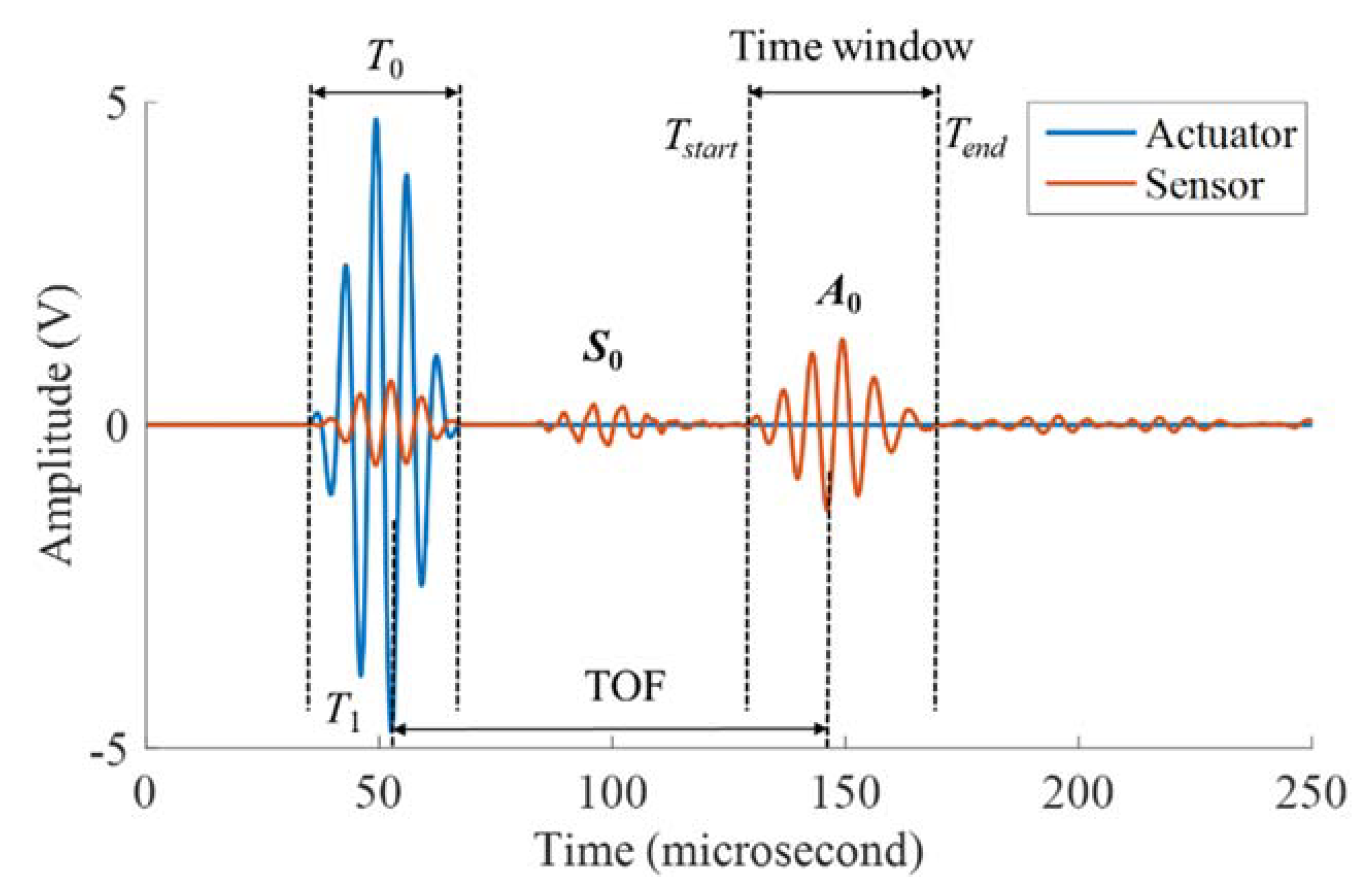

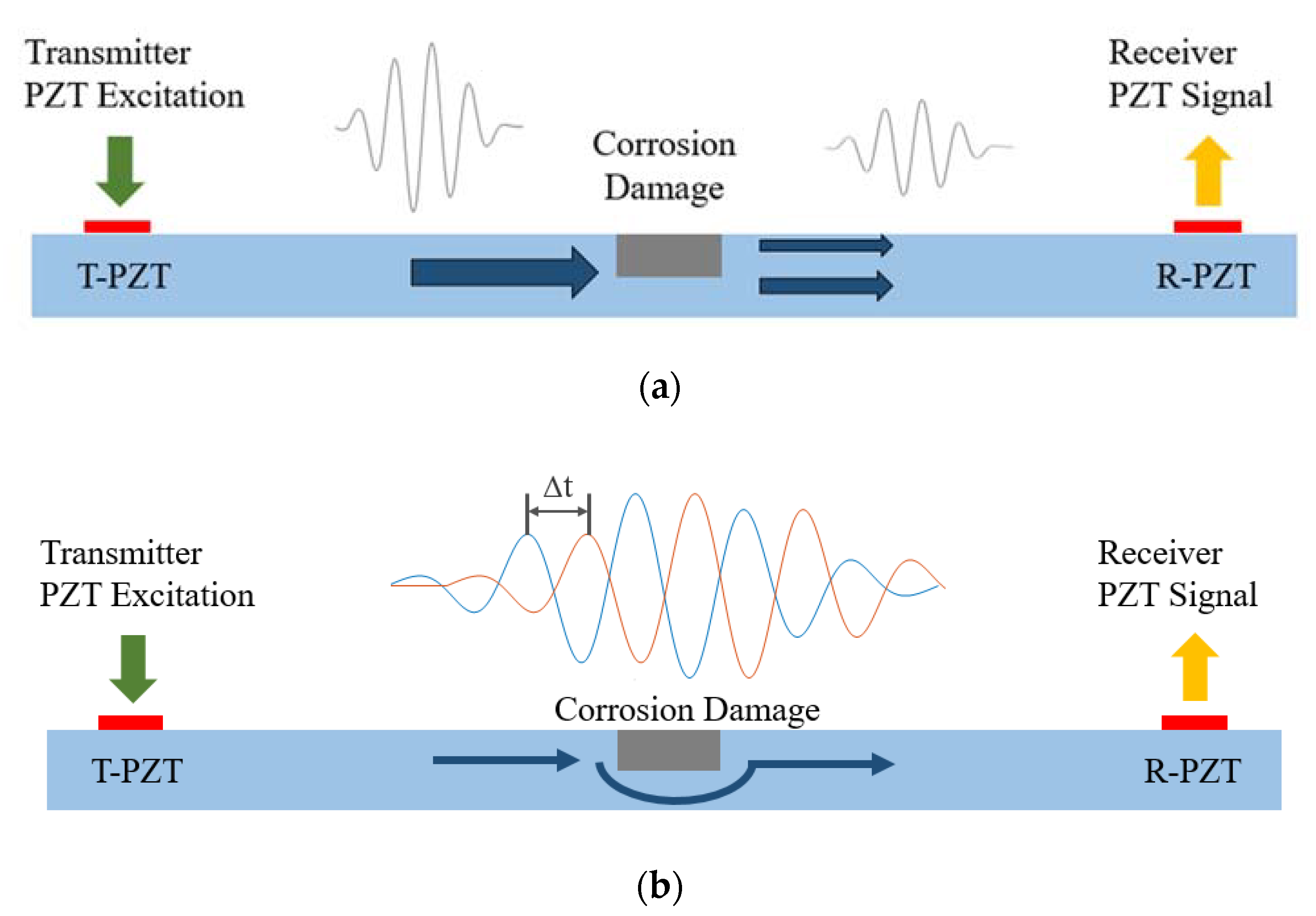

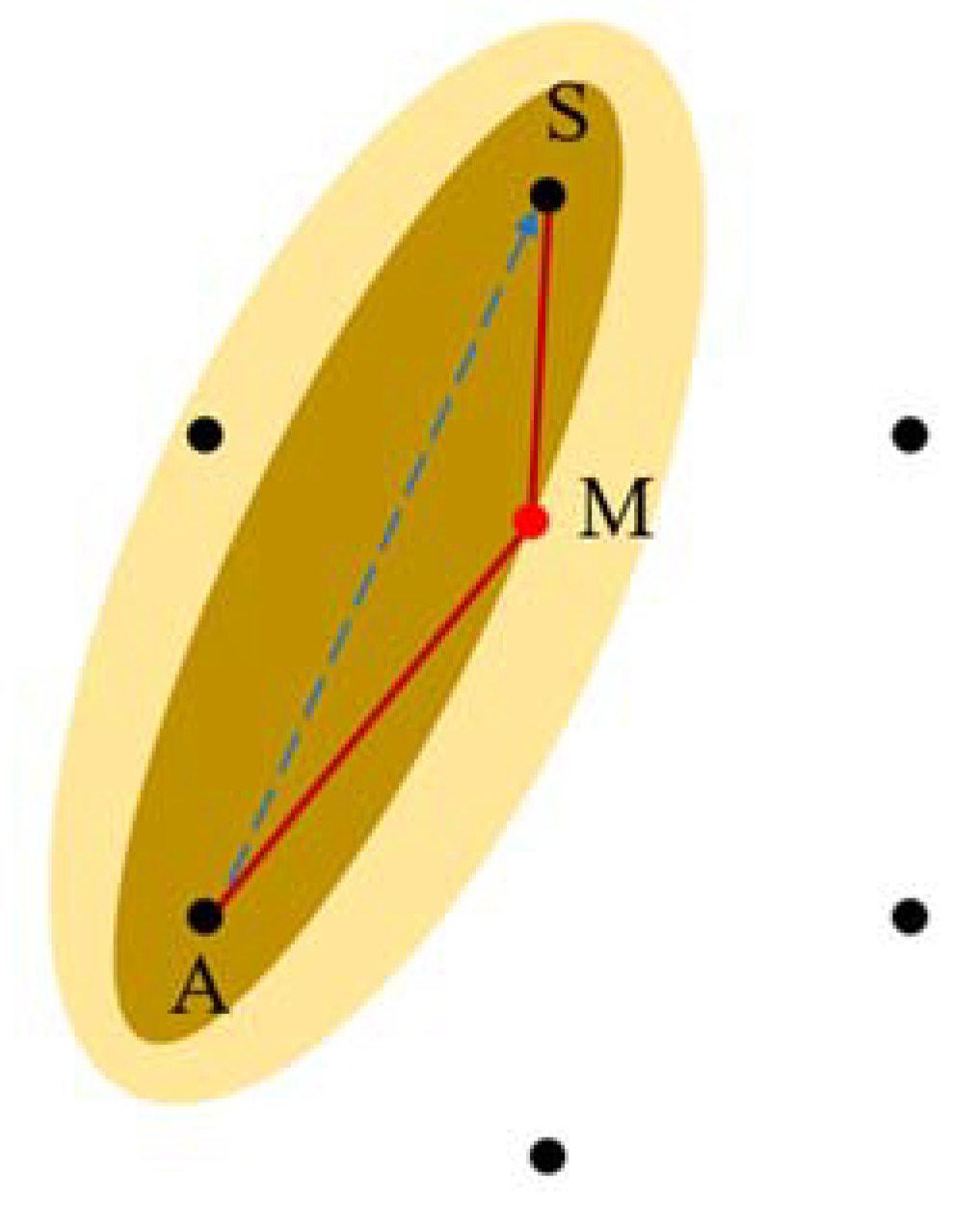

2.2. Corrosion Damage Parameters Selection

3. Experimental Procedure

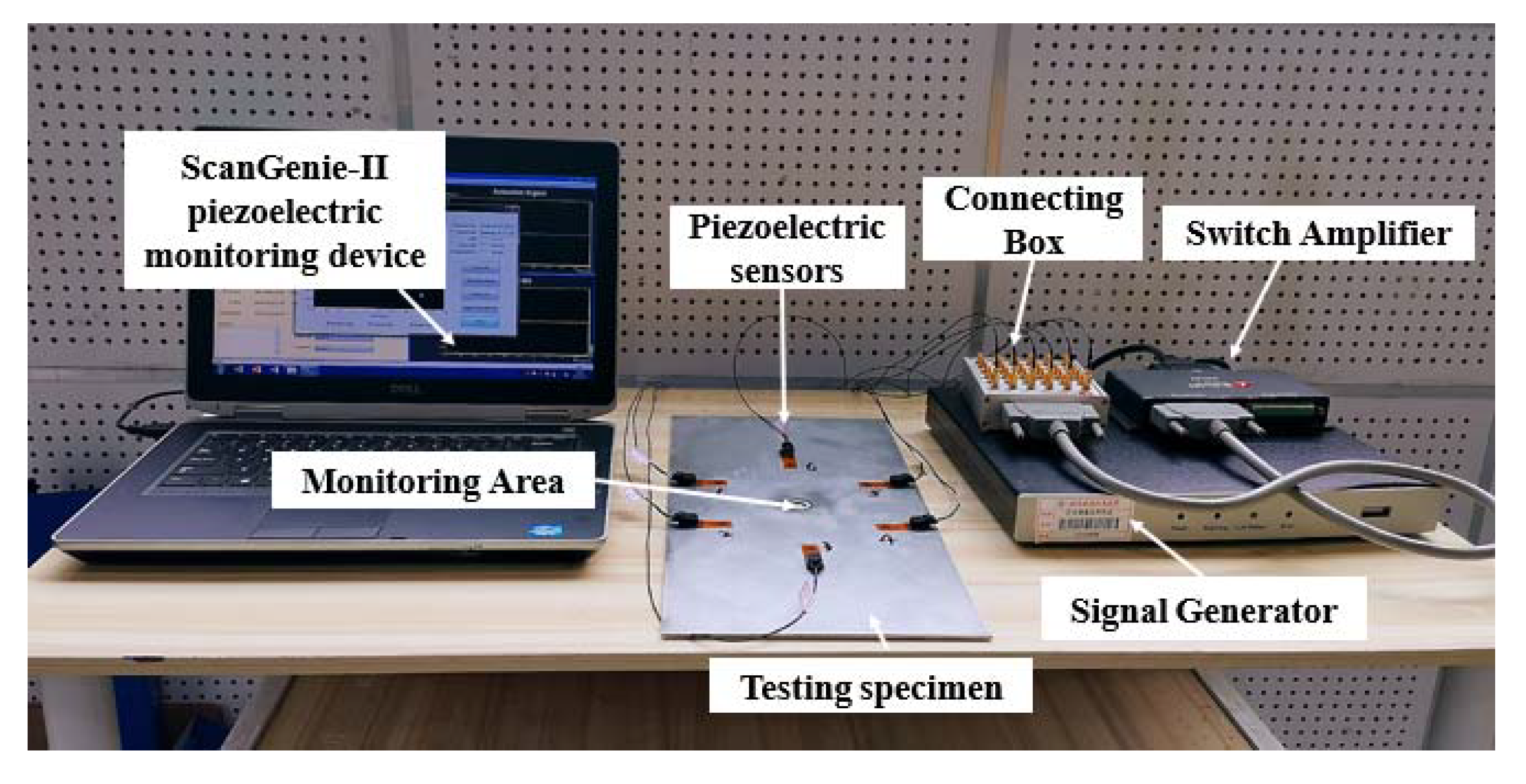

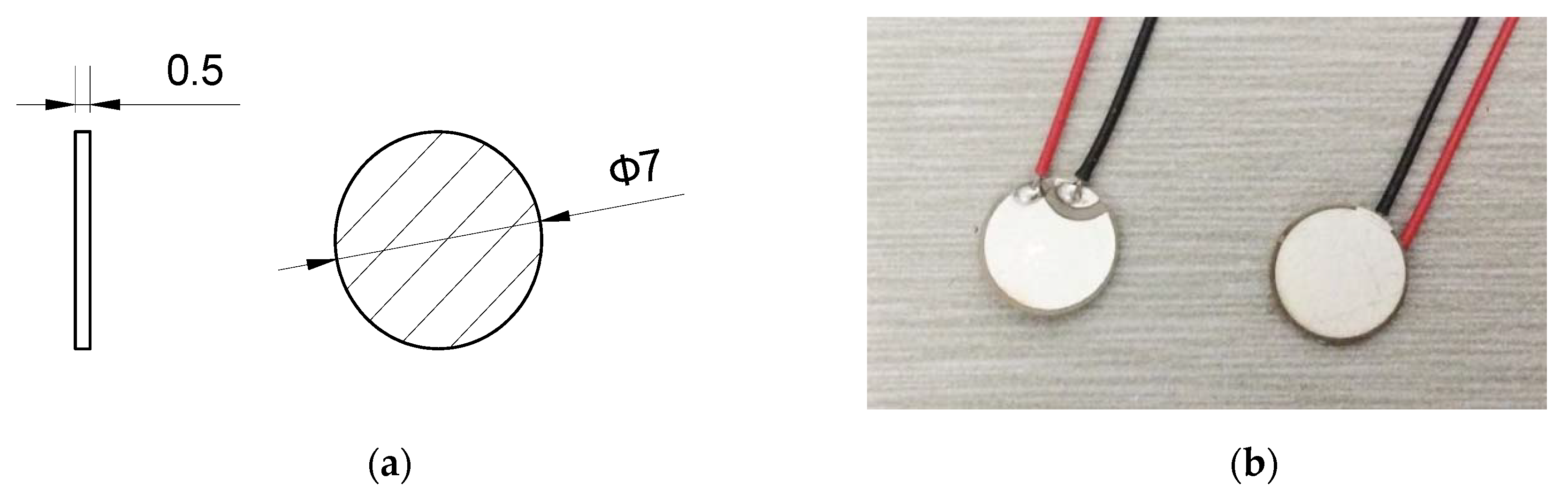

3.1. Experiment Equipment

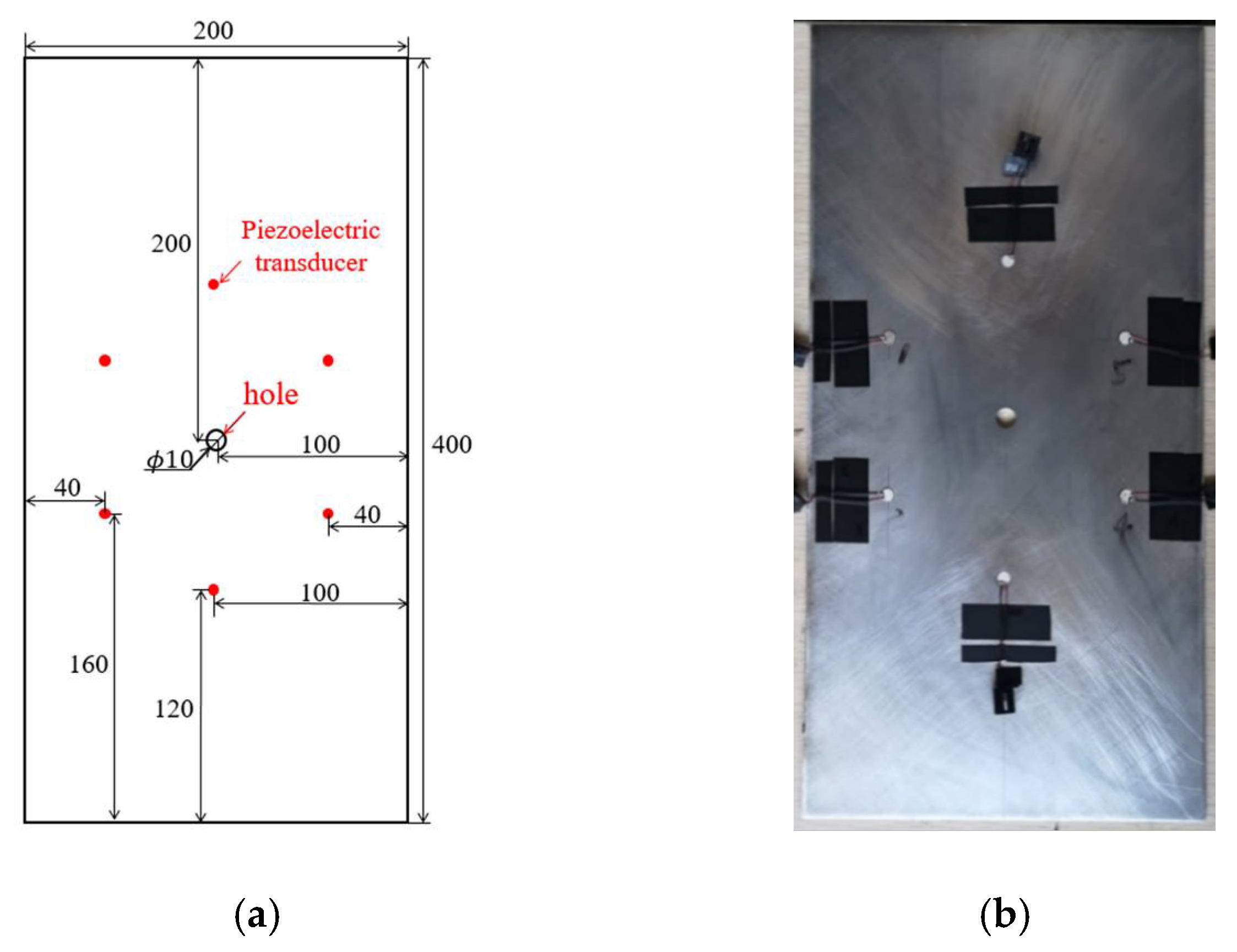

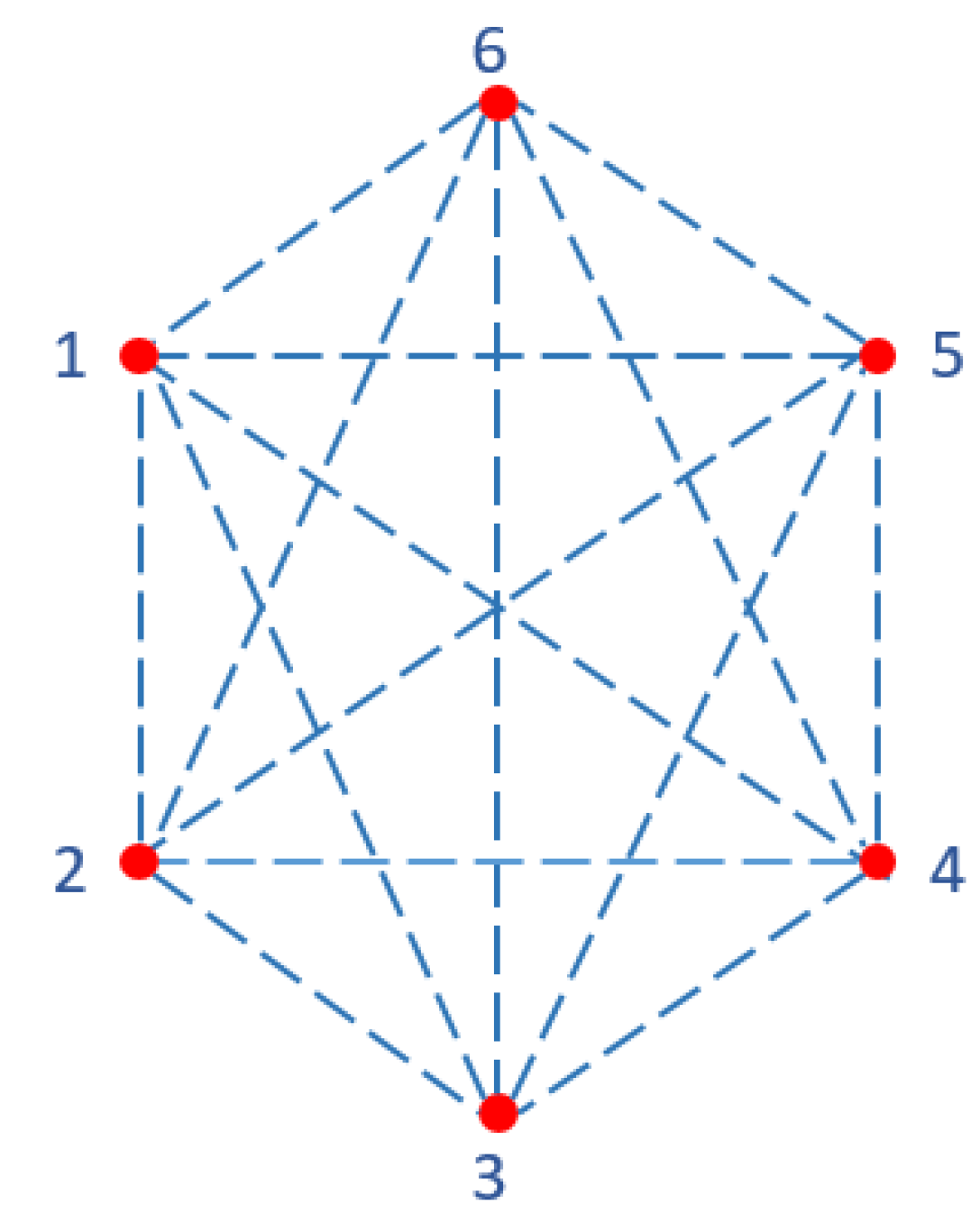

3.2. Test Design

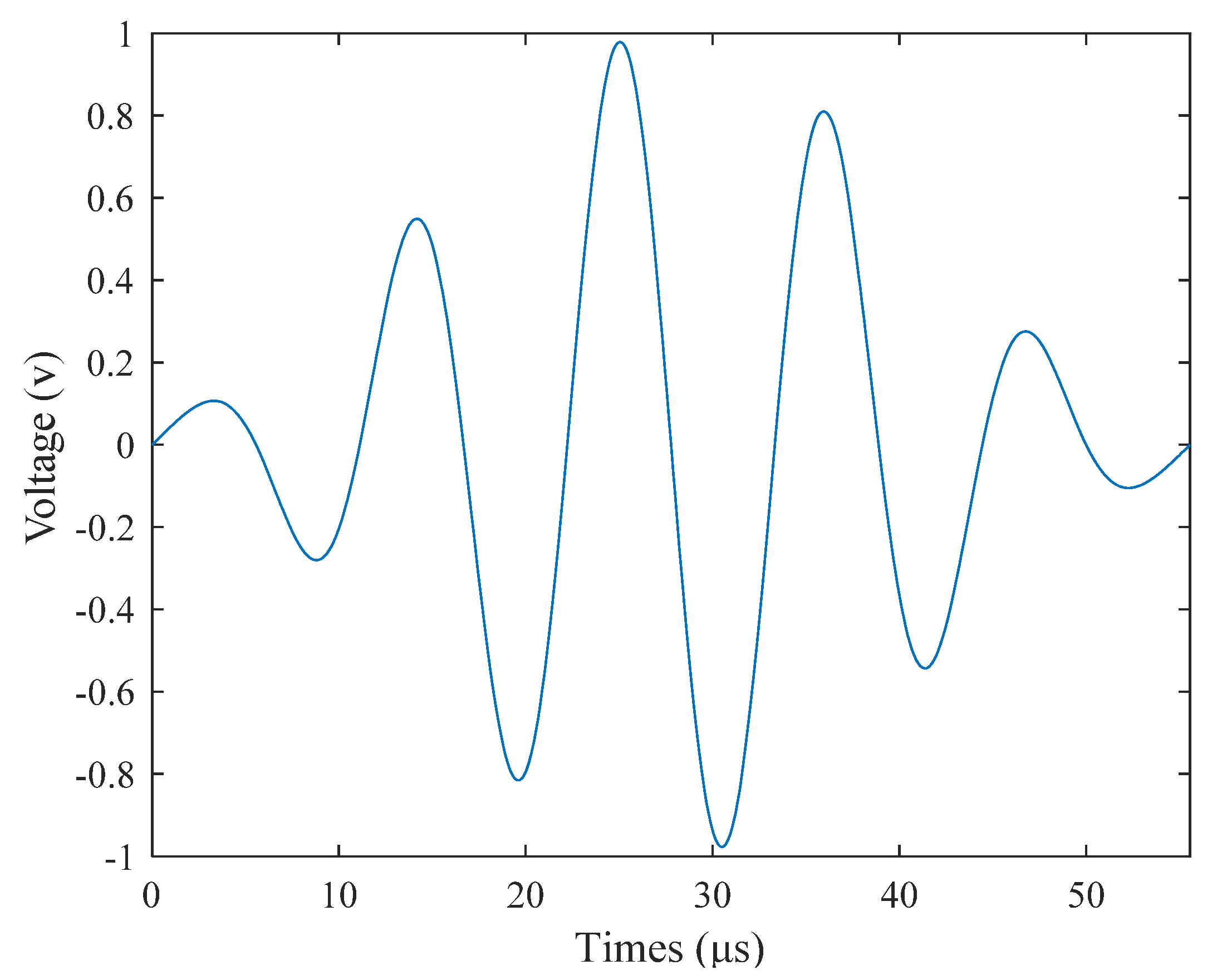

3.3. Excitation Signal

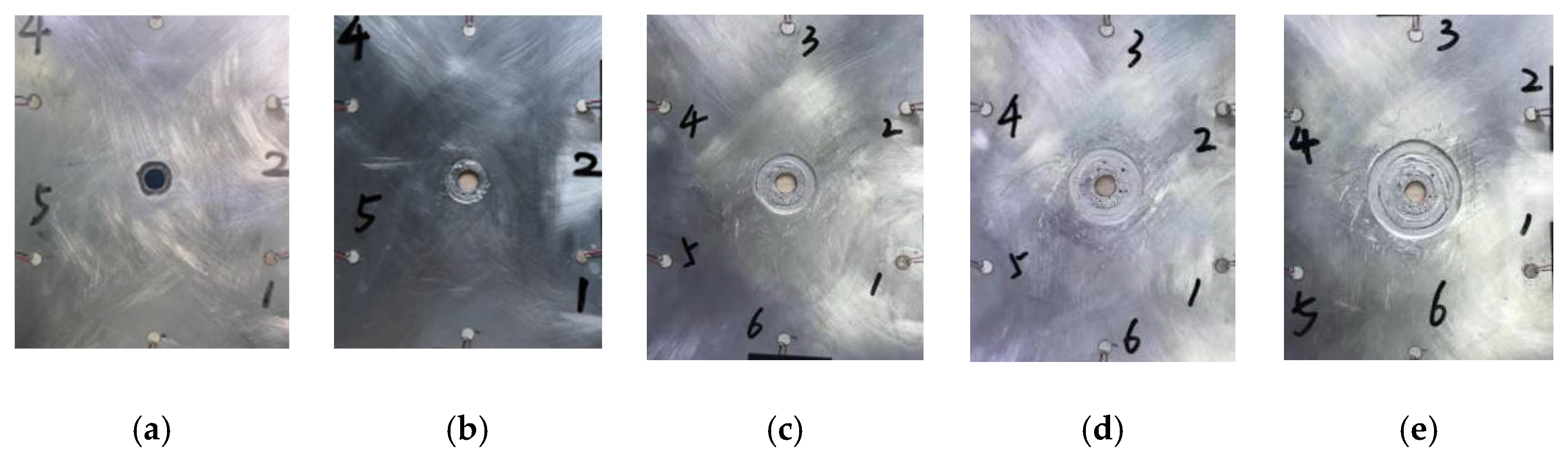

3.4. Corrosion Process

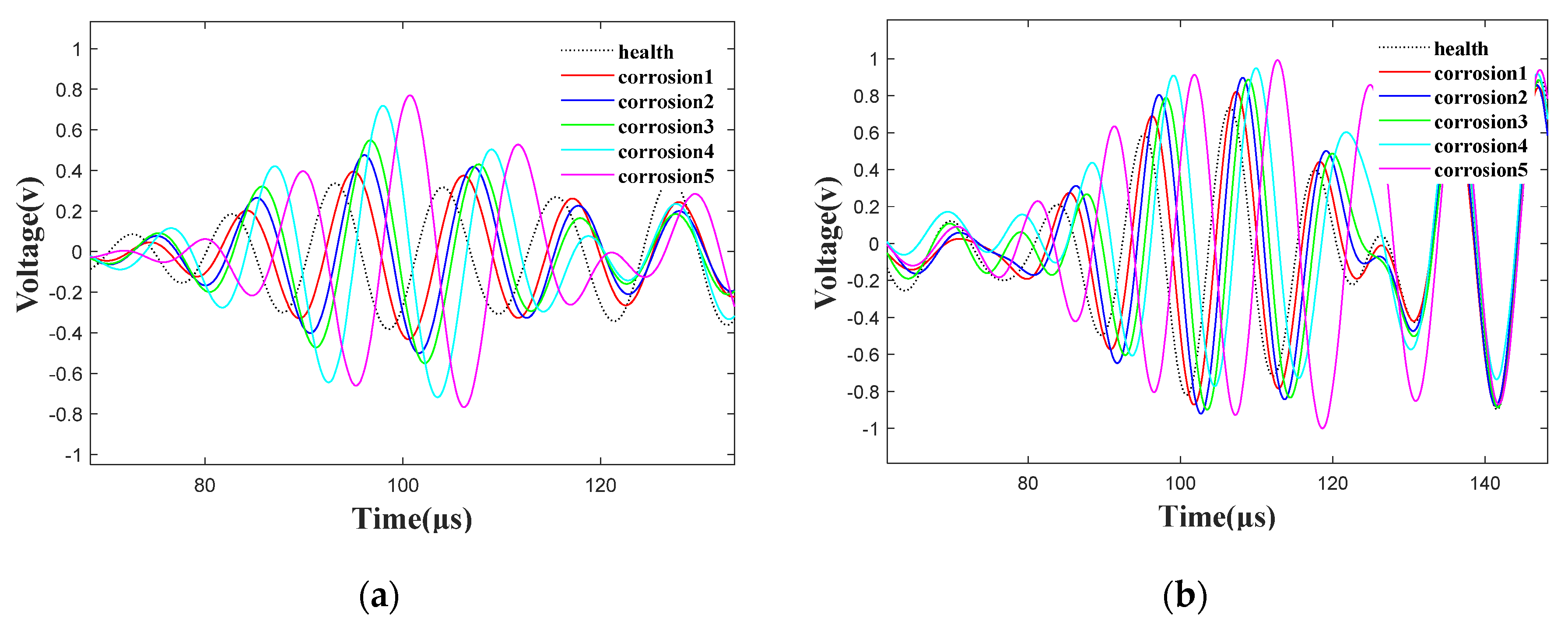

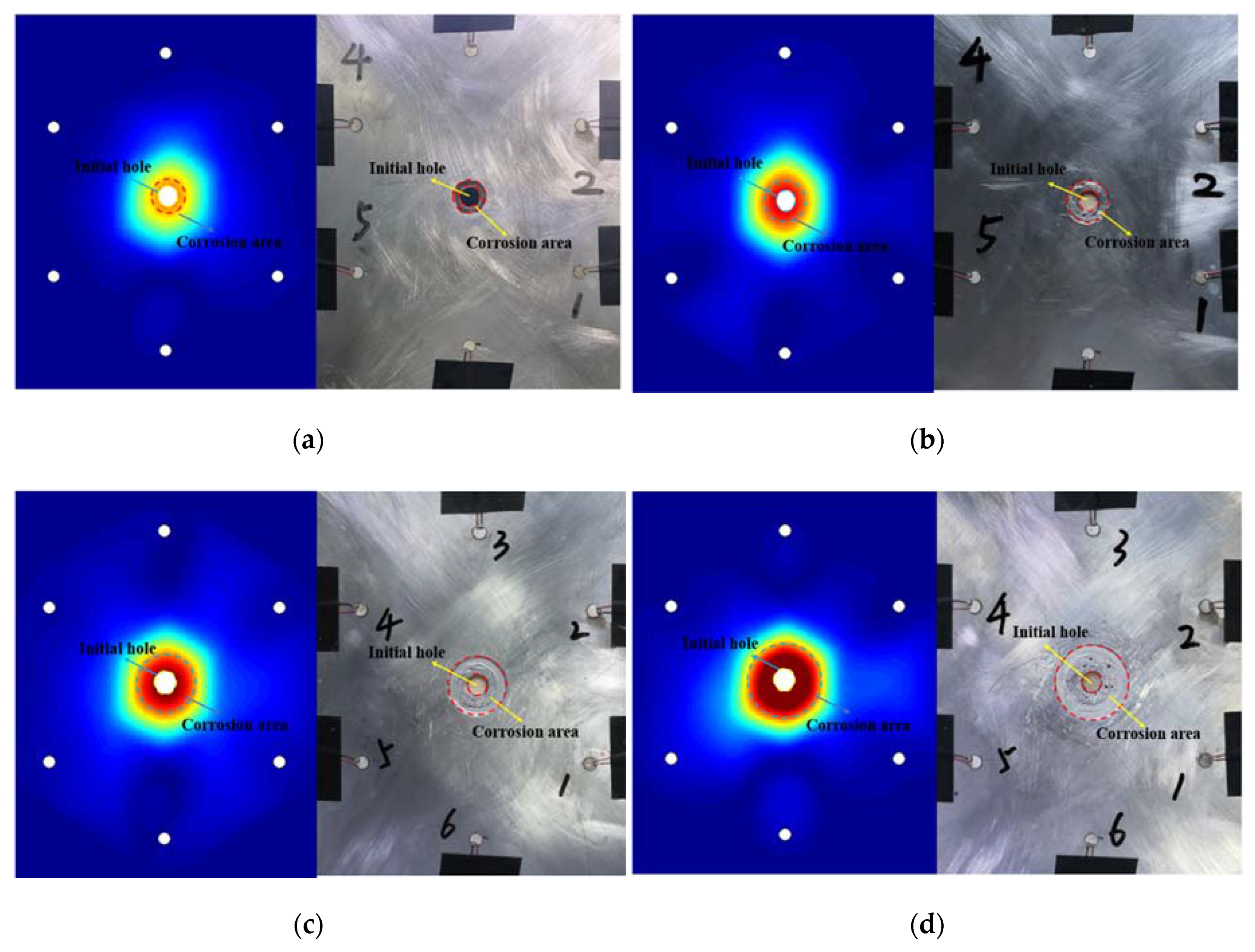

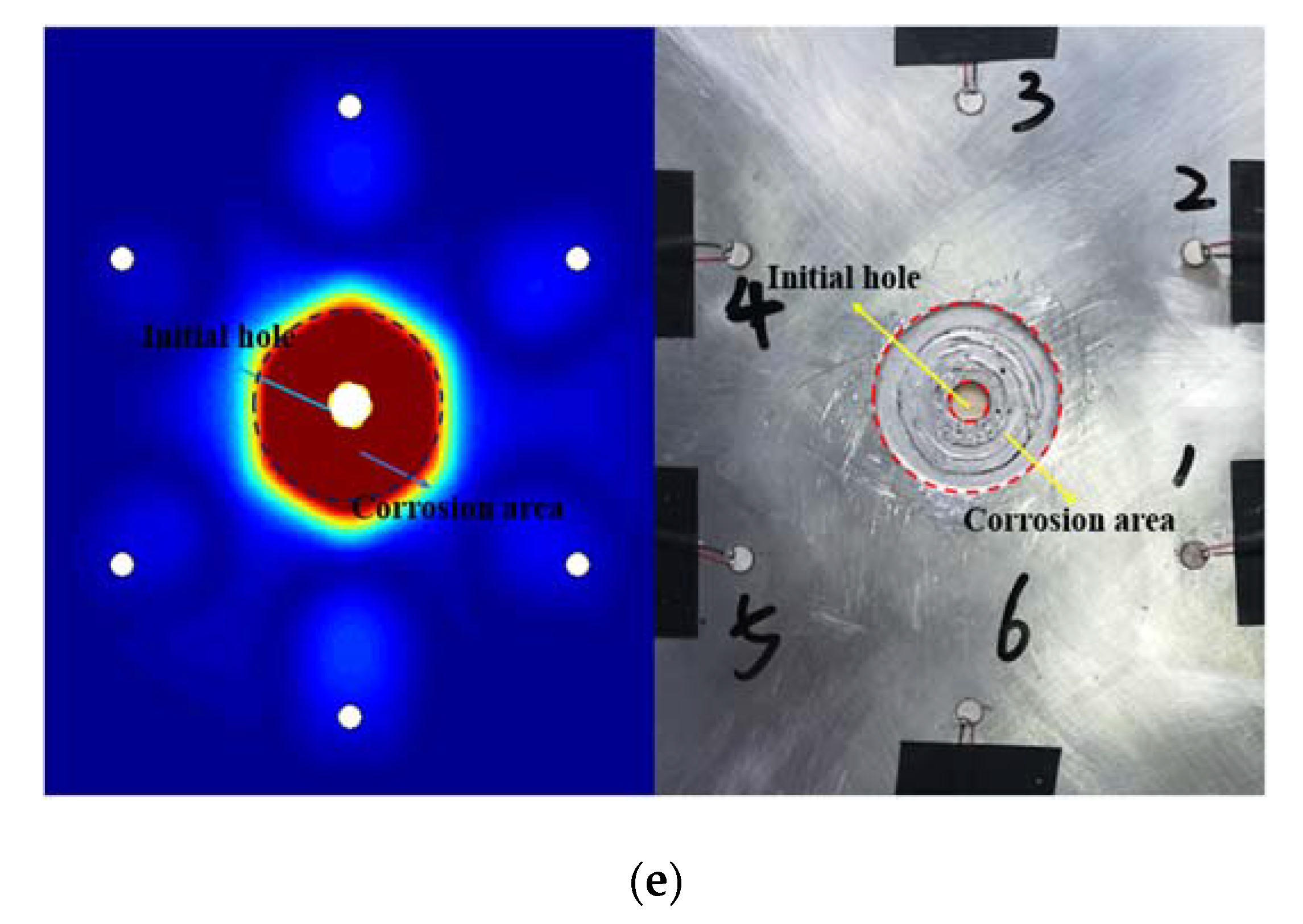

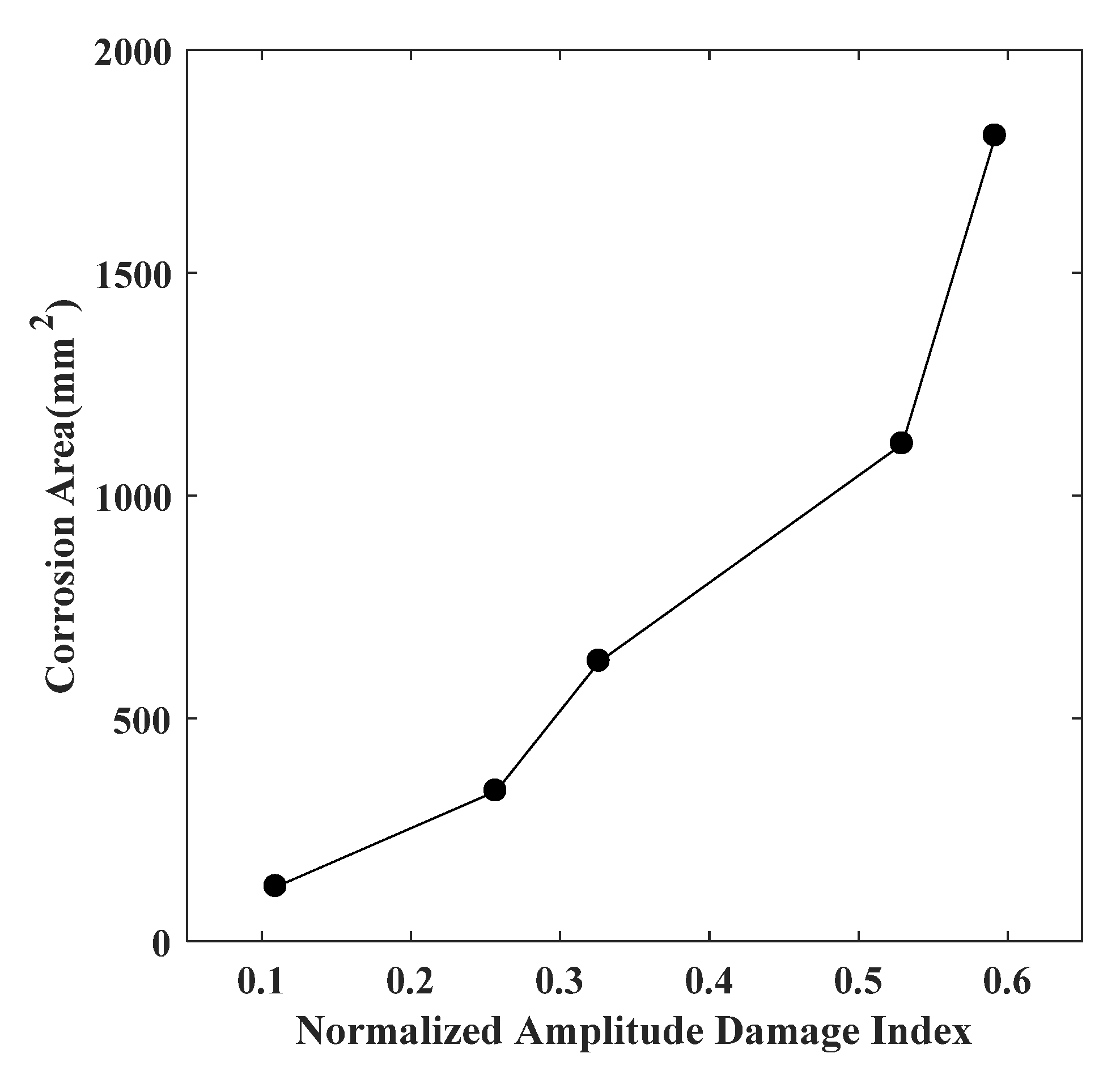

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qing, X.P.; Beard, S.; Shen, S.B.; Banerjee, S.; Bradley, I.; Salama, M.M.; Chang, F.K. Development of a real-time active pipeline integrity detection system. Smart Mater. Struct. 2009, 18, 115010. [Google Scholar] [CrossRef]

- He, J.; Guan, X.; Peng, T.; Liu, Y.; Saxena, A.; Celaya, J.; Goebel, K. A multi-feature integration method for fatigue crack detection and crack length estimation in riveted lap joints using Lamb waves. Smart Mater. Struct. 2013, 22, 105007. [Google Scholar] [CrossRef]

- Salehnasab, B.; Poursaeidi, E.; Mortazavi, S.A.; Farokhian, G.H. Hot corrosion failure in the first stage nozzle of a gas turbine engine. Eng. Fail. Anal. 2016, 60, 316–325. [Google Scholar] [CrossRef]

- Leonard, K.R.; Malyarenko, E.V.; Hinders, M.K. Ultrasonic Lamb wave tomography. Inverse Probl. 2002, 18, 1795–1808. [Google Scholar] [CrossRef]

- Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XIII; SPIE: Bellingham, WA, USA, 2019.

- Watanabe, T.; Trang, H.T.H.; Harada, K.; Hashimoto, C. Evaluation of corrosion-induced crack and rebar corrosion by ultrasonic testing. Constr. Build. Mater. 2014, 67, 197–201. [Google Scholar] [CrossRef]

- Jurek, M.; Radzieński, M.; Kudela, P.; Ostachowicz, W. Non-contact excitation and focusing of guided waves in CFRP composite plate by air-coupled transducers for application in damage detection. Procedia Struct. Integr. 2018, 13, 2089–2094. [Google Scholar] [CrossRef]

- Prado, G.D.O.; Tamba, A.K.; Dotta, F.; Vieira, C.; Rulli, R.P.; Silva, G.R.; Moreira, J. Further Results of lamb waves approach to assess corrosion damage in an aeronautical aluminum alloy. In Proceedings of the 8th European Workshop On Structural Health Monitoring (EWSHM 2016), Bilbao, Spain, 5–8 July 2016. [Google Scholar]

- Capineri, L.; Bulletti, A.; Calzolai, M.; Francesconi, D. Piezopolymer interdigital transducers for a structural health monitoring system. Lect. Notes Electr. Eng. 2014, 268, 9–12. [Google Scholar]

- Hua, J.; Cao, X.; Yi, Y.; Lin, J. Time-frequency damage index of Broadband Lamb wave for corrosion inspection. J. Sound Vib. 2020, 464, 114985. [Google Scholar] [CrossRef]

- Canle, D.V.; Salmi, A.; Hggstrom, E. Non-contact damage detection on a rotating blade by Lamb wave analysis. NDT E Int. 2017, 92, 159–166. [Google Scholar] [CrossRef]

- Jenot, F.; Ouaftouh, M.; Duquennoy, M.; Ourak, M. Corrosion thickness gauging in plates using Lamb wave group velocity measurements. Meas. Sci. Technol. 2001, 12, 1287–1293. [Google Scholar] [CrossRef]

- Rao, J.; Ratassepp, M.; Fan, Z. Guided wave tomography based on full waveform inversion manuscript. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 5, 737–745. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Pollock, P. A multi-mode sensing system for corrosion detection using piezoelectric wafer active sensors. Proc. SPIE Int. Soc. Opt. Eng. 2008, 6932, 69321–69322. [Google Scholar]

- Thomas, D.T.; Welter, J.T.; Giurgiutiu, V. Corrosion damage detection with piezoelectric wafer active sensors. In Health Monitoring and Smart Nondestructive Evaluation of Structural and Biological Systems III; SPIE: San Diego, CA, USA, 2004; Volume 5394, p. 11. [Google Scholar]

- Rathod, V.T.; Mahapatra, D.R. Ultrasonic Lamb wave based monitoring of corrosion type of damage in plate using a circular array of piezoelectric transducers. NDT E Int. 2011, 44, 628–636. [Google Scholar] [CrossRef]

- Giridhara, G.; Rathod, V.T.; Naik, S.; Mahapatra, D.R.; Gopalakrishnan, S. Rapid localization of damage using a circular sensor array and Lamb wave based triangulation. Mech. Syst. Signal Process. 2010, 24, 2929–2946. [Google Scholar] [CrossRef]

- Bao, Q.; Yuan, S.; Guo, F.; Qiu, L. Transmitter beamforming and weighted image fusion–based multiple signal classification algorithm for corrosion monitoring. Struct. Health Monit. 2018, 18, 621–634. [Google Scholar] [CrossRef]

- Cao, X.; Zeng, L.; Lin, J.; Hua, J.; Lin, J. A correlation-based approach to corrosion detection with lamb wave mode cutoff. J. Nondestruct. Eval. 2019, 38, 87. [Google Scholar] [CrossRef]

- Stawiarski, A.; Barski, M.; Paj, P. Fatigue crack detection and identification by the elastic wave propagation method. Mech. Syst. Signal Process. 2017, 89, 119–130. [Google Scholar] [CrossRef]

- Method, W.P. On transducers localization in damage detection by wave propagation method. Sensors 2019, 19, 1937. [Google Scholar] [CrossRef]

- Barski, M.; Stawiarski, A. The crack detection and evaluation by elastic wave propagation in open hole structures for aerospace application. Aerosp. Sci. Technol. 2018, 81, 141–156. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Wang, J.; Shin, Y.J. Corrosion detection with piezoelectric wafer active sensors using pitch-catch waves and cross-time-frequency analysis. Struct. Health Monit. 2012, 11, 83–93. [Google Scholar] [CrossRef]

- Dai, W.; Wang, X.; Zhang, M.; Zhang, W.; Wang, R. Corrosion monitoring method of porous aluminum alloy plate hole edges based on piezoelectric sensors. Sensors 2019, 19, 1106. [Google Scholar] [CrossRef]

- Chang, F.-K.; Yu, P.; Beard, S.; Kumar, A.; Qing, P.; Zhang, D.C. A new SMART sensing system for aerospace structures. Unmanned Syst. Technol. IX 2007, 6561, 656107. [Google Scholar]

- Zhu, W.; Rose, J.L.; Barshinger, J.N.; Agarwala, V.S. Ultrasonic guided wave NDT for hidden corrosion detection. Res. Nondestruct. Eval. 1998, 10, 205–225. [Google Scholar] [CrossRef]

- Tibaduiza, D.; Torres-arredondo, M.; Mujica, L.E.; Rodellar, J. A study of two unsupervised data driven statistical methodologies for detecting and classifying damages in structural health monitoring. Mech. Syst. Signal Process. 2013, 41, 1–18. [Google Scholar] [CrossRef]

- Pau, A.; Achillopoulou, D.V. Interaction of shear and Rayleigh-Lamb waves with notches and voids in plate waveguides. Materials 2017, 10, 841. [Google Scholar] [CrossRef]

- Wang, Q.; Hong, M.; Su, Z. An In-Situ Structural Health Diagnosis Technique and Its Realization via a Modularized System. IEEE Trans. Instrum. Meas. 2015, 64, 873–887. [Google Scholar] [CrossRef]

- Wilson, C.L.; Chang, F.K. Monitoring fatigue-induced transverse matrix cracks in laminated composites using built-in acousto-ultrasonic techniques. Struct. Health Monit. 2016, 15, 335–350. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Piezoelectric Wafer Active Sensors for Structural Health Monitoring of Composite Structures Using Tuned Guided Waves. J. Eng. Mater. Technol. 2013, 133, 1–6. [Google Scholar] [CrossRef]

- Chen, J.; Su, Z.; Cheng, L. Identification of corrosion damage in submerged structures using fundamental anti-symmetric Lamb waves. Smart Mater. Struct. 2010, 19, 015004. [Google Scholar] [CrossRef]

- Hillger, W.; Pfeiffer, U. Structural health monitoring using lamb waves. In Proceedings of the 9th European NDT Conference (ECNDT), Berlin, Germany, 25–29 September 2006; pp. 1–7. [Google Scholar]

- Rao, J.; Ratassepp, M.; Lisevych, D.; Caffoor, M.H.; Fan, Z. On-line corrosion monitoring of plate structures based on guided wave tomography using piezoelectric sensors. Sensors 2017, 17, 2882. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Tuned Lamb wave excitation and detection with piezoelectric wafer active sensors for structural health monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Masserey, B.; Fromme, P. Analysis of high frequency guided wave scattering at a fastener hole with a view to fatigue crack detection. Ultrasonics 2017, 76, 78–86. [Google Scholar] [CrossRef]

| Device Number | ScanGenie-II |

|---|---|

| Frequency | 10–700 kHz |

| Conversion Rates | 1.5, 6, 12, 24, 48 MHz |

| Integrated Power Amplifier | ±60 V |

| Memory | 16,000 Samples |

| Sampling Rates | 6, 12, 24, 48 MS/s |

| Resolution | 12-bit |

| ADC Range | ±1 V |

| Product Number | SMD07T05R412WL |

|---|---|

| Material | SM412 |

| Geometry | diameter: 7 mm |

| thickness: 0.5 mm | |

| Resonance frequency | 4.25 MHz ± 5% |

| Electrostatic capacitance | 2.5 nF ± 30% |

| Specimen Material Grade | Aluminum 2024-T3 |

|---|---|

| Poisson’s Ratio | 0.33 |

| Density | 2.78 g/cc |

| Young’s Modulus | 73.1 GPa |

| Fatigue Strength | 130 MPa |

| Molecular Formula | HF | |

|---|---|---|

| Content of HF | ≥40% | |

| Impurity content (%) | Fe | ≤0.0001 |

| Cl | ≤0.001 | |

| PO4 | ≤0.0002 | |

| Heavy metal (Pb) | ≤0.0005 | |

| Fluorosilicate (SiF6) | ≤0.04 | |

| Others | ≤0.004 | |

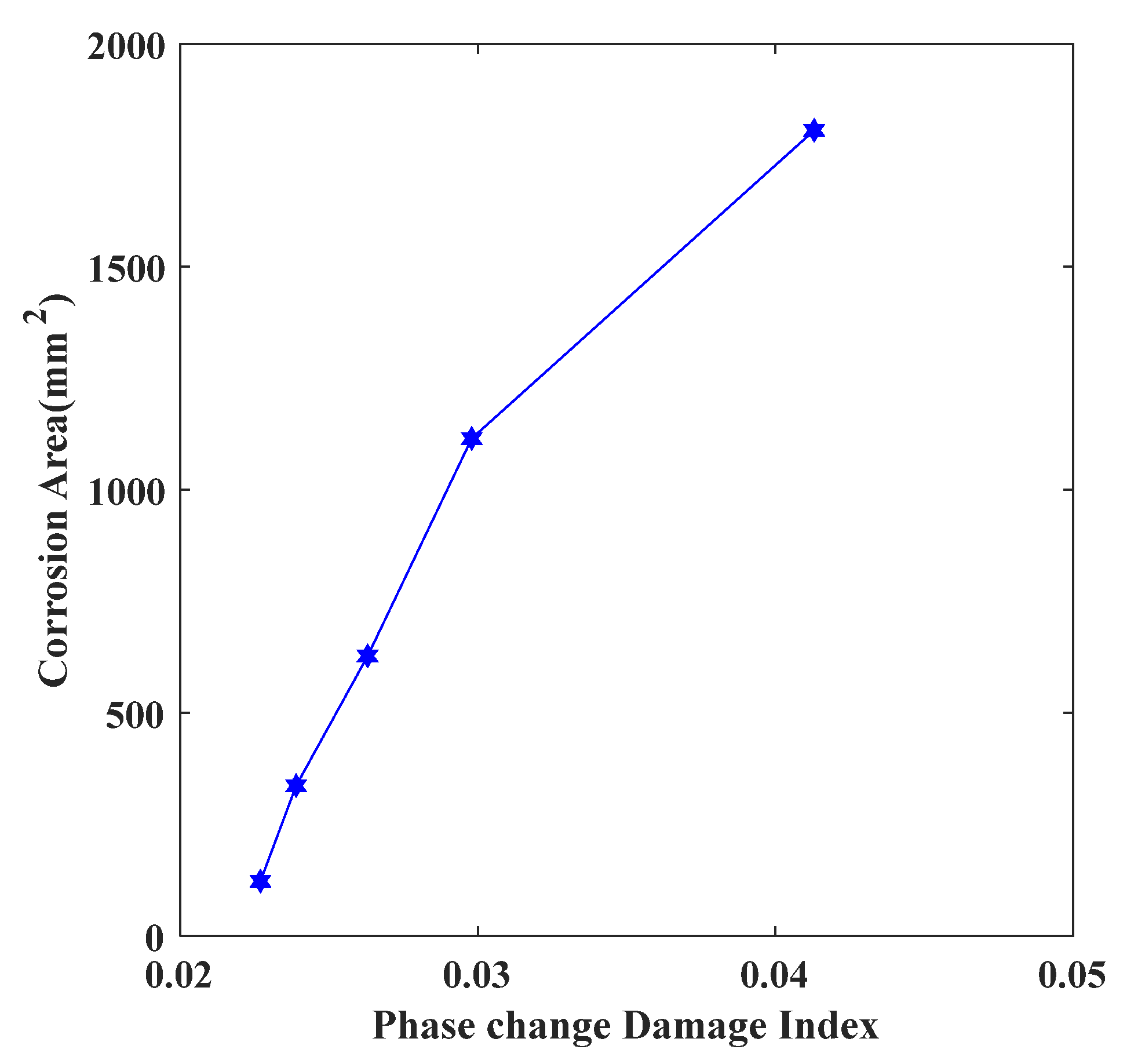

| Corrosion State | Amount of Hydrofluoric Acid Added (mL) | Corrosion Diameter (mm) | Corrosion Area (mm2) | Corrosion Time (h) |

|---|---|---|---|---|

| No Corrosion | 0 | 0 10 (hole) | 0 78.5 (hole) | 0 |

| 1st Corrosion | 8 | 16 | 122.5 | 8 |

| 2nd Corrosion | 10 | 23 | 336.8 | 15 |

| 3rd Corrosion | 12 | 30 | 628 | 22.5 |

| 4th Corrosion | 14 | 39 | 1115.5 | 27 |

| 5th Corrosion | 16 | 49 | 1806.3 | 32 |

| Corrosion State | Actual Corrosion Area (mm2) | Predicted Corrosion Area (mm2) | Percentage Error |

|---|---|---|---|

| No Corrosion | 0 (hole 78.5) | - | - |

| 1st Corrosion | 122.5 | 145.7 | 18.9% |

| 2nd Corrosion | 336.8 | 388.9 | 15.5% |

| 3rd Corrosion | 628 | 715.3 | 12.3% |

| 4th Corrosion | 1115.5 | 1202.7 | 7.8% |

| 5th Corrosion | 1806.3 | 1963.3 | 8.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Dai, W.; Xu, D.; Zhang, W.; Ran, Y.; Wang, R. Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave. Metals 2020, 10, 1469. https://doi.org/10.3390/met10111469

Wang X, Dai W, Xu D, Zhang W, Ran Y, Wang R. Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave. Metals. 2020; 10(11):1469. https://doi.org/10.3390/met10111469

Chicago/Turabian StyleWang, Xiangyu, Wei Dai, Duo Xu, Weifang Zhang, Yunmeng Ran, and Rongqiao Wang. 2020. "Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave" Metals 10, no. 11: 1469. https://doi.org/10.3390/met10111469

APA StyleWang, X., Dai, W., Xu, D., Zhang, W., Ran, Y., & Wang, R. (2020). Hole-Edge Corrosion Expansion Monitoring Based on Lamb Wave. Metals, 10(11), 1469. https://doi.org/10.3390/met10111469